Hot-rolled steel plate for submarine conveying pipe and preparation method thereof

A technology for hot-rolled steel plates and pipes is applied in the field of hot-rolled steel plates for submarine conveying pipes and their preparation, and can solve problems such as deformation, buckling and plastic deformation of steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A hot-rolled steel plate for seabed transportation pipes. In terms of mass percentage, the chemical composition of the hot-rolled steel plate includes: C: 0.031%, Si: 0.21%, Mn: 1.45%, Al: 0.03%, Nb: 0.035%, Ti: 0.015%, Ni: 0.43%, Cr: 0.20%, Mo: 0.15%, P: 0.007%, S: 0.001%, and the balance is Fe and unavoidable impurity elements.

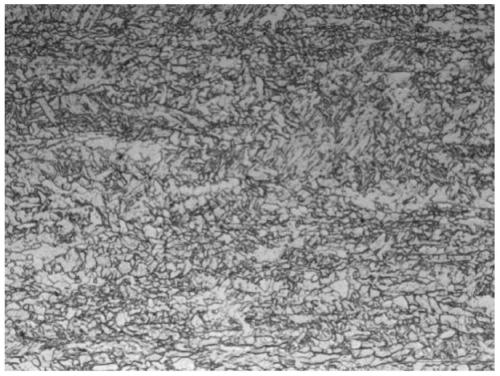

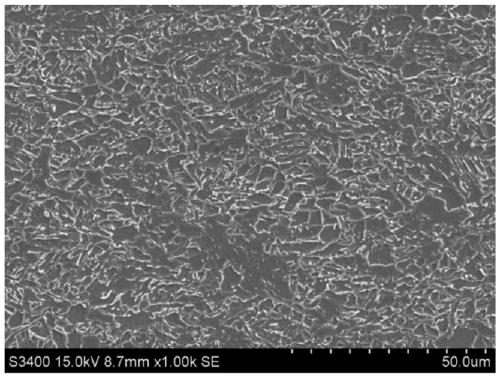

[0038] The above-mentioned hot-rolled steel sheet is composed of fine-grained ferrite and acicular ferrite, wherein the proportion of fine-grained ferrite is 22.6%.

[0039] The preparation method of the hot-rolled steel plate for the above-mentioned seabed delivery pipe is as follows:

[0040] S1: cast molten steel that has been smelted and melted into steel billets by continuous casting machine, and the steel billets are sent into the heating furnace. The heating furnace is heated at a rate of 20°C / min, heated to 1080°C, and kept at this temperature for heat preservation 30min;

[0041] S2: rolling the heated billet 10 times on the roughin...

Embodiment 2

[0045] A hot-rolled steel plate for seabed transportation pipes. In terms of mass percentage, the chemical composition of the hot-rolled steel plate includes: C: 0.035%, Si: 0.20%, Mn: 1.46%, Al: 0.03%, Nb: 0.036%, Ti: 0.012%, Ni: 0.43%, Cr: 0.20%, Mo: 0.12%, P: 0.007%, S: 0.001%, and the balance is Fe and unavoidable impurity elements.

[0046] The above-mentioned hot-rolled steel sheet is composed of fine-grained ferrite and acicular ferrite, wherein the proportion of fine-grained ferrite is 35.8%.

[0047] The preparation method of the hot-rolled steel plate for the above-mentioned seabed delivery pipe is as follows:

[0048] S1: cast molten steel that has been smelted and melted into steel billets by continuous casting machine, and the steel billets are sent into the heating furnace. The heating furnace is heated at a rate of 20°C / min, heated to 1100°C, and kept at this temperature for heat preservation 28min;

[0049] S2: rolling the heated billet 10 times on the roughi...

Embodiment 3

[0053] A hot-rolled steel plate for seabed transportation pipes. In terms of mass percentage, the chemical composition of the hot-rolled steel plate includes: C: 0.035%, Si: 0.21%, Mn: 1.49%, Al: 0.03%, Nb: 0.037%, Ti: 0.015%, Ni: 0.44%, Cr: 0.23%, Mo: 0.13%, P: 0.007%, S: 0.001%, and the balance is Fe and unavoidable impurity elements.

[0054] The above-mentioned hot-rolled steel sheet is composed of fine-grained ferrite and acicular ferrite, wherein the proportion of fine-grained ferrite is 40%.

[0055] The preparation method of the hot-rolled steel plate for the above-mentioned seabed delivery pipe is as follows:

[0056] S1: cast molten steel that has been smelted and melted into steel billets by continuous casting machine, and the steel billets are sent into the heating furnace. The heating furnace is heated at a rate of 24°C / min, heated to 1100°C, and kept at this temperature for heat preservation 25min;

[0057] S2: rolling the heated billet 10 times on the roughing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com