Pickling cold-formed steel and manufacturing method thereof

A manufacturing method and pickling technology, applied in the field of steelmaking, can solve the problems of increased production cost, increased production cost, unfavorable surface quality of finished pickling coils, etc., and achieves good elongation performance, good yield ratio, high roughness and The effect of surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

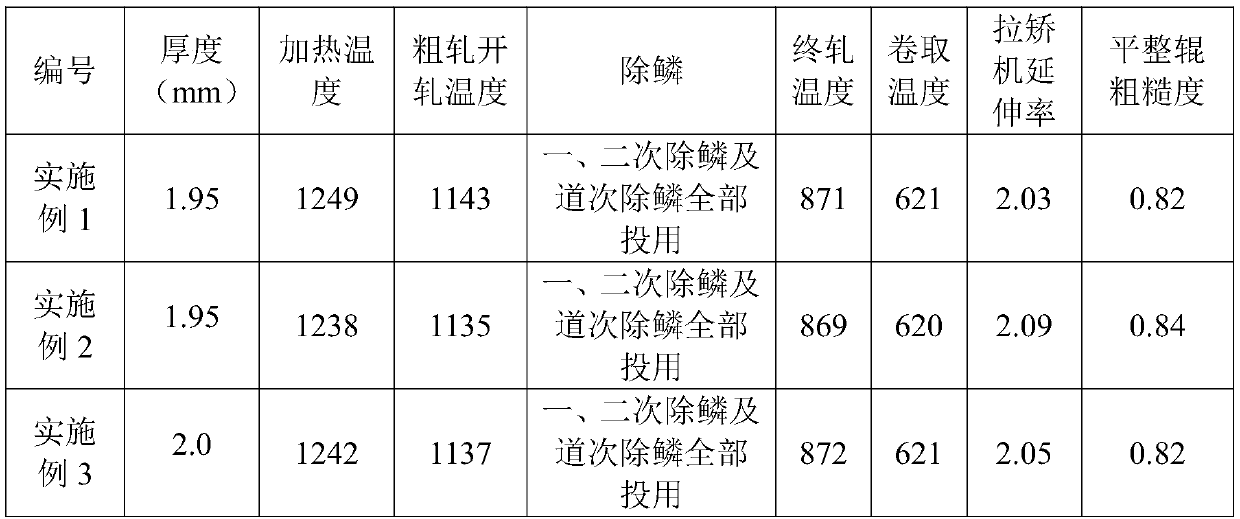

Examples

Embodiment 1

[0028] from Figure 1-2 It can be seen that the chemical components of the pickled cold-formed steel in this embodiment are: C≤0.07%, Si≤0.05%, Mn≤0.45%, P≤0.020%, S≤0.010%, Als ≤0.060%, N≤0.0100%, the rest is Fe and inevitable inclusions.

Embodiment 2

[0030] A pickling cold-formed steel according to this embodiment, its chemical composition weight percent content is: C: 0.04-0.07%, Si≤0.035%, Mn≤0.25-0.45%, P≤0.020%, S≤0.010%, Als ≤0.025~0.045%, N≤0.0060%, the rest is Fe and unavoidable inclusions.

Embodiment 3

[0032] A pickling cold-formed steel according to this embodiment, its chemical composition weight percent content is: C ≤ 0.050%, Si ≤ 0.030%, Mn ≤ 0.35%, P ≤ 0.015%, S ≤ 0.008%, Als ≤ 0.035%, N≤0.0050%, the rest is Fe and inevitable inclusions.

[0033] The present invention adopts the C-Mn composition system in composition design, and strictly controls the content of impurity elements such as P, S and N. C and Mn, as basic elements in steel, play a very important role in improving the strength of steel. In order to obtain For good plasticity and elongation, the C content must be kept below 0.07%. If the C content is too high, it will be difficult to obtain the required amount of ferrite during the cooling process after hot rolling, resulting in poor plasticity of the steel; The strengthening elements can improve the strength and hardenability of steel. The Mn content should be controlled above 0.5%, but the Mn content should not be too high. With the increase of Mn content, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com