Producing method of hot rolled round steel used for high-rise building structure

A high-rise building and production method technology, applied in the field of metallurgy, can solve the problems that there are no reports of high-rise building structures using round steel, achieve good yield ratio, improve production efficiency, and do not increase investment and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

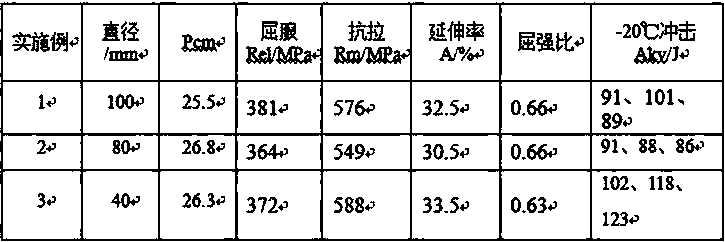

Examples

Embodiment 1

[0027] A method for producing hot-rolled round steel for high-rise building structures. The composition weight percentage of steel is: C=0.16, Si=0.37, Mn=1.52, P=0.015, S=0.002, Al=0.029, CEV=0.43, and the rest For Fe and unavoidable impurities. Key process steps include:

[0028] Converter smelting: end point C: 0.08%, P: 0.013%; blowing times after high-strength supplementary blowing is 1 time; alloy is added to the ladle when tapping 1 / 4;

[0029] LF furnace: the molten steel is energized in the LF furnace for 28 minutes, and the total argon blowing time is 52 minutes; the molten steel is fed with Ca wire for 180 meters before leaving the station.

[0030] VD furnace: the total argon blowing time in the VD furnace is 50 minutes; the vacuum time is 15 minutes, and the soft argon blowing time after breaking the air is 18 minutes; set [H] 1.2ppm;

[0031] Continuous casting: superheat 20℃~21℃, casting speed 0.65m / min, billet size: 300*340*mm*6m;

[0032] Heating: the bille...

Embodiment 2

[0037] A production method of hot-rolled round steel for high-rise building structures, the composition weight percentage of steel is C=0.17, Si=0.37, Mn=1.55, P=0.021, S=0.002, Al=0.029, CEV=0.44, and the rest are Fe and unavoidable impurities; key process steps include:

[0038] Converter smelting: end point C: 0.10%, P: 0.017%; blowing times after high-draw blowing is 1 time, and alloy is added to the ladle when 1 / 4 of the steel is tapped;

[0039] LF furnace: The molten steel is energized in the LF furnace for 28 minutes, and the total argon blowing time is 68 minutes; the molten steel is fed with Ca wire for 200 meters before leaving the station.

[0040] Continuous casting: superheat 30℃~33℃, casting speed 0.70~080m / min, billet size: 240*240*mm*6m;

[0041] Heating: the billet heating temperature is between 1180 and 1200 ℃, and the time in the furnace is 150 minutes;

[0042] Rolling: Two-stage rolling is adopted, the first stage is billet rolling, and the second stage...

example 3

[0046]A production method of hot-rolled round steel for high-rise building structures, the composition weight percentage of steel is C=0.17, Si=0.40, Mn=1.49, P=0.019, S=0.004, Al=0.032, CEV=0.43, and the rest are Fe and unavoidable impurities; key process steps include:

[0047] Converter smelting: end point C: 0.09%, P: 0.017%; blowing times after high-strength supplementary blowing is 1 time, and alloy is added to the ladle when tapping 1 / 4;

[0048] LF furnace: The molten steel is energized in the LF furnace for 22 minutes, and the total argon blowing time is 47 minutes; the molten steel is fed with Ca wire for 200 meters before leaving the station.

[0049] Continuous casting: superheat 27℃~31℃, casting speed 1.60~1.70m / min, billet size: 150*150*mm*12m;

[0050] Heating: the billet heating temperature is between 1020 and 1100°C, and the time in the furnace is 120min;

[0051] Rolling: Start rolling at 1010°C, after roughing, intermediate rolling and continuous rolling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com