Cr-contained non-oriented electrical steel and production method thereof

A technology of grain-oriented electrical steel and process, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problem of no key research, and achieve the effect of excellent punching process performance, good isotropy and good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A detailed description is given below:

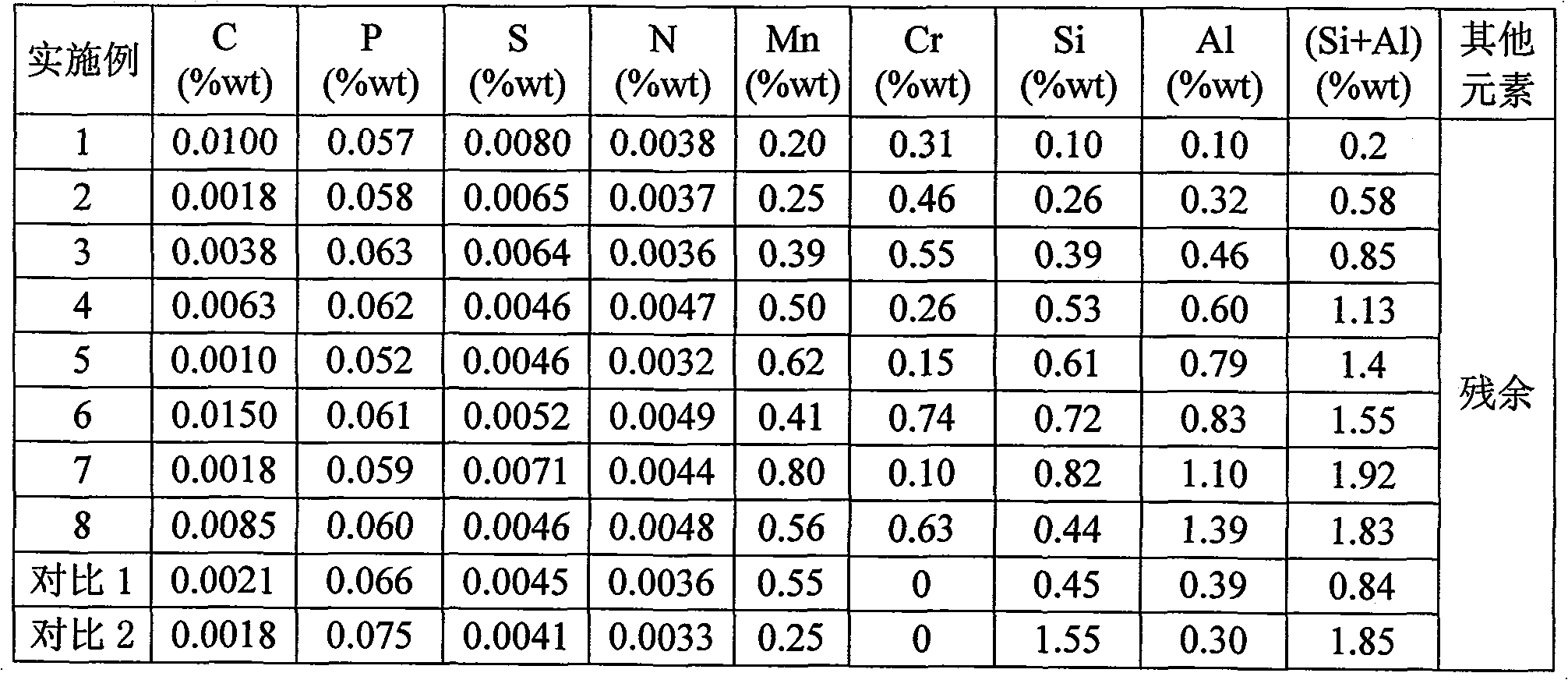

[0039] The smelting composition of each embodiment is shown in Table 1:

[0040] Table 1

[0041]

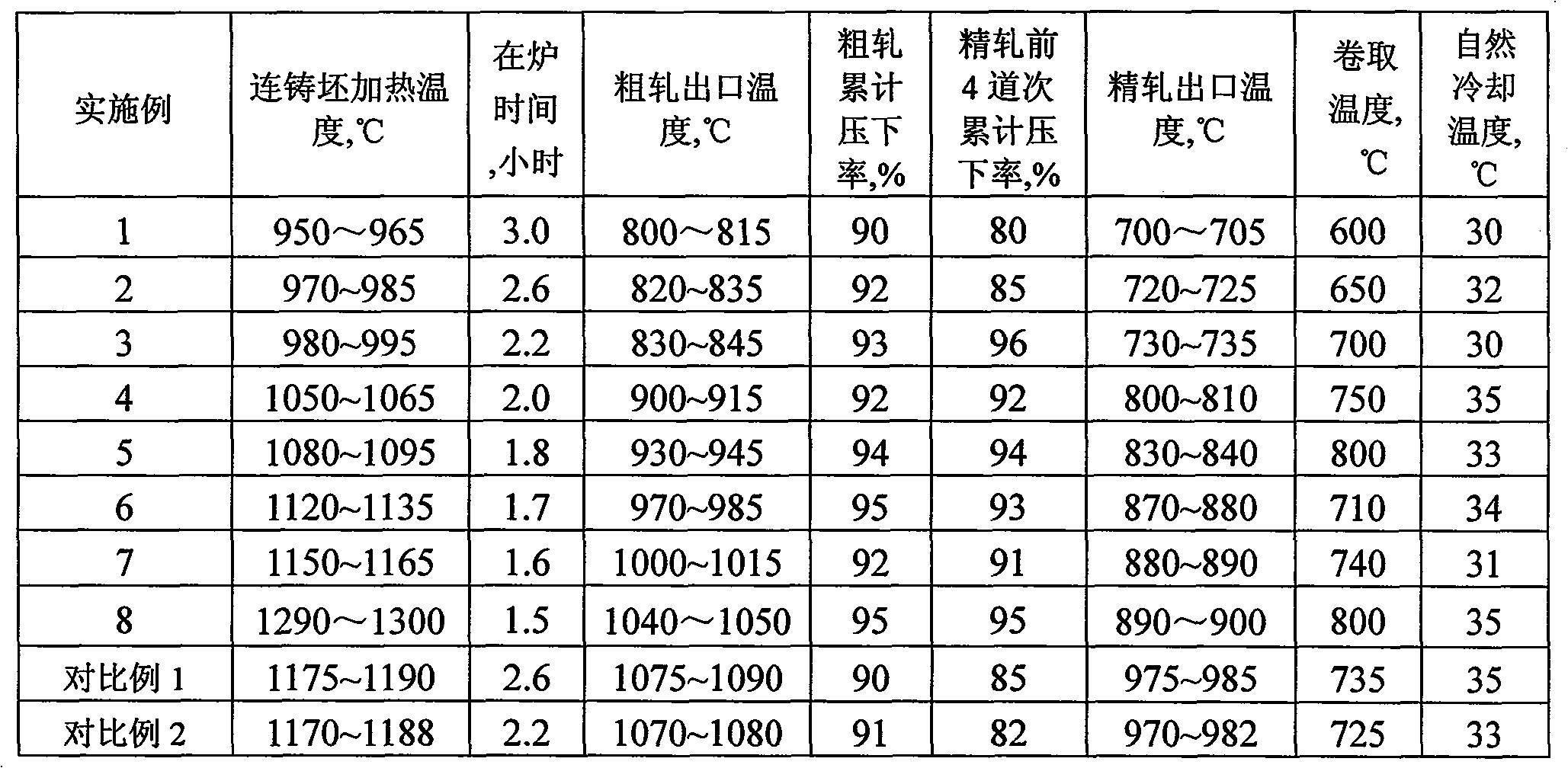

[0042] 3. According to the composition design in Table 1, carry out smelting and rolling, according to the process steps:

[0043] 1) The smelting process of clean steel is used for smelting and continuous casting into billets;

[0044] 2) Heat the continuous casting billet to 950-1300°C, and control its time in the furnace: 1.5-3 hours;

[0045] 3) Rough rolling is carried out, the outlet temperature is controlled to be 800-1050°C, and the cumulative reduction rate is controlled to be 90-95%;

[0046] 4) Carry out finish rolling, control the cumulative reduction ratio of the first 4 passes to 80-95%, and control the cold-rolling temperature at 700-900°C;

[0047] 5) Carry out coiling, and its coiling temperature is controlled at 600~800 ℃;

[0048] 6) naturally cool to room temperature;

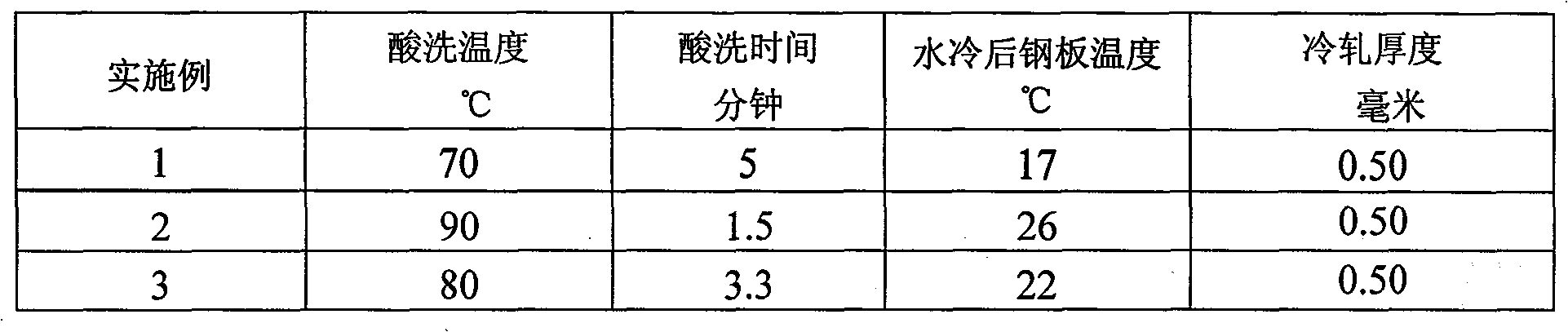

[0049] 7) Pickling, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com