Patents

Literature

104results about How to "High magnetic induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

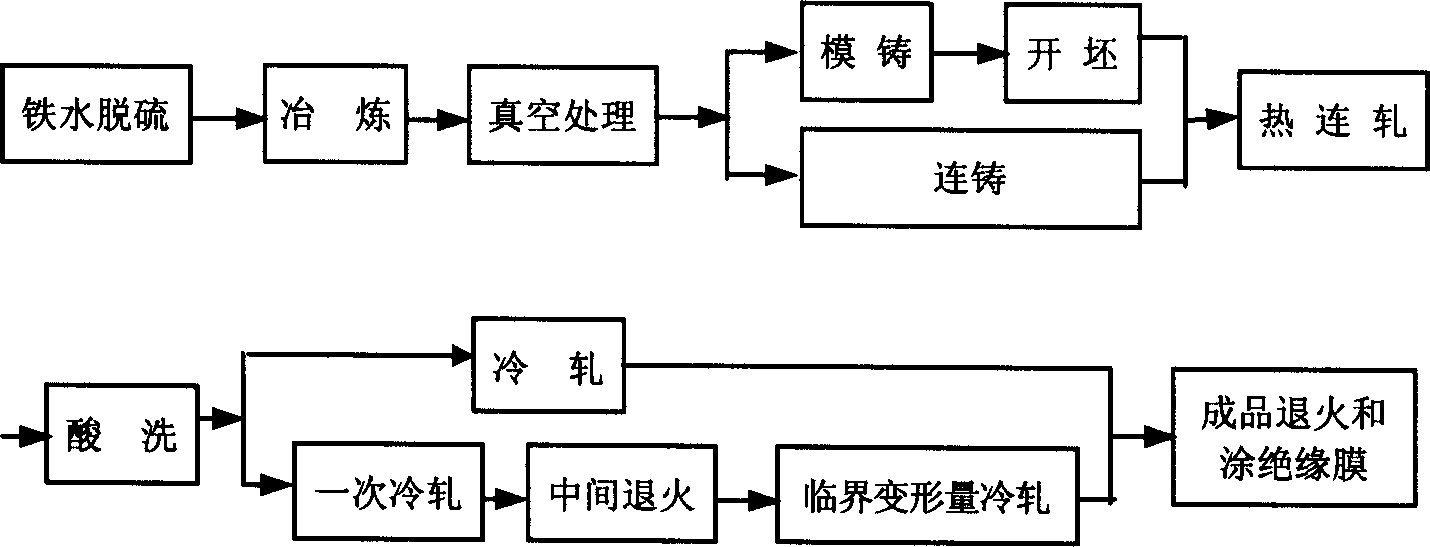

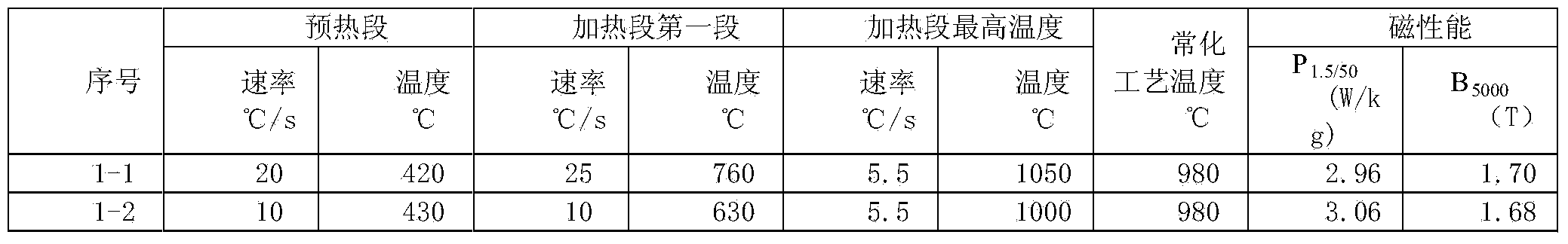

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

High magnetic induction and high grad non-orientation electrical steel and its making process

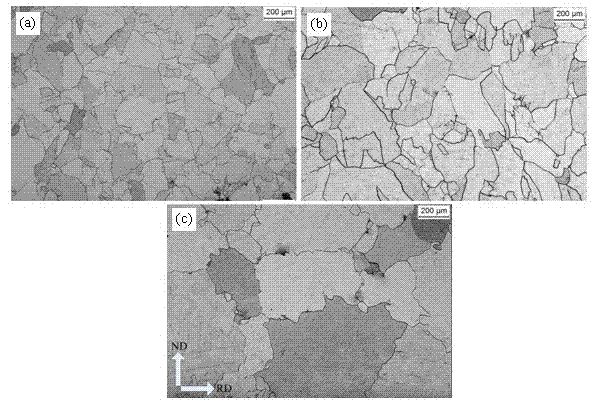

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing non-oriented silicon steel with high magnetic induction

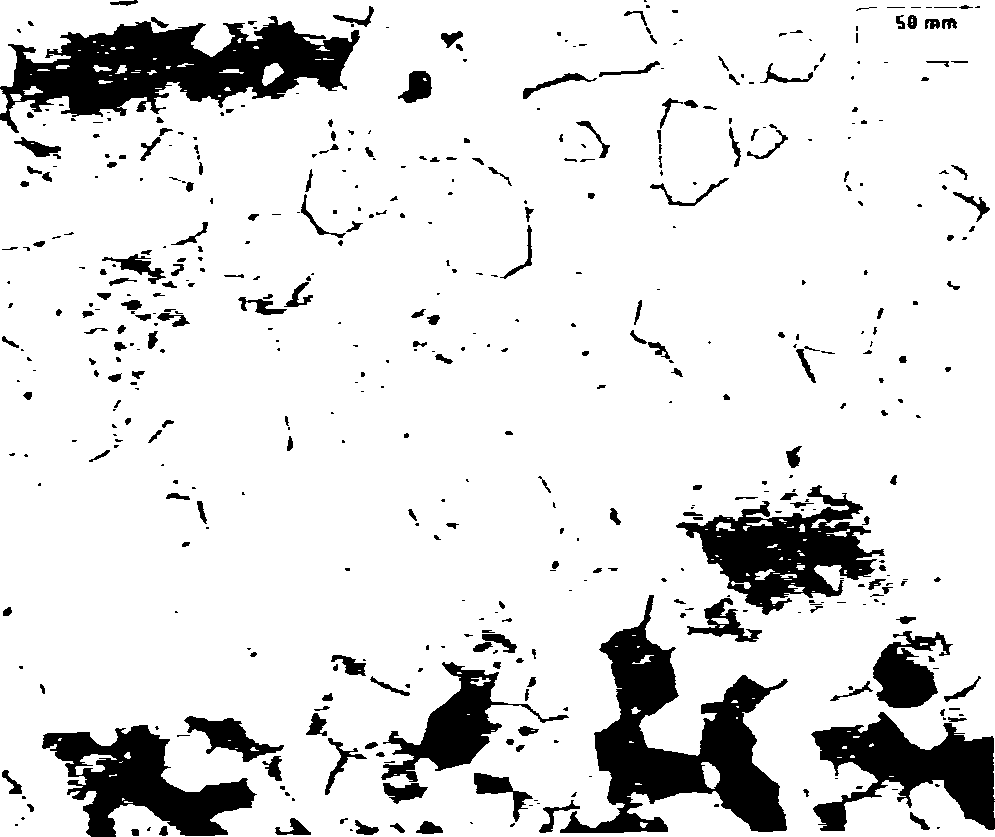

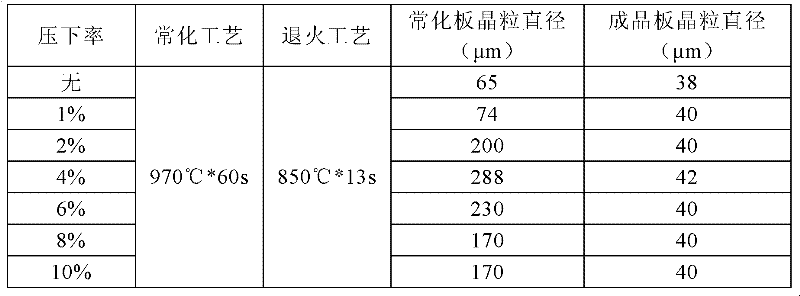

ActiveCN102453837AHigh magnetic inductionGuaranteed iron lossInorganic material magnetismMetal rolling arrangementsReduction ratioSlow cooling

Owner:BAOSHAN IRON & STEEL CO LTD

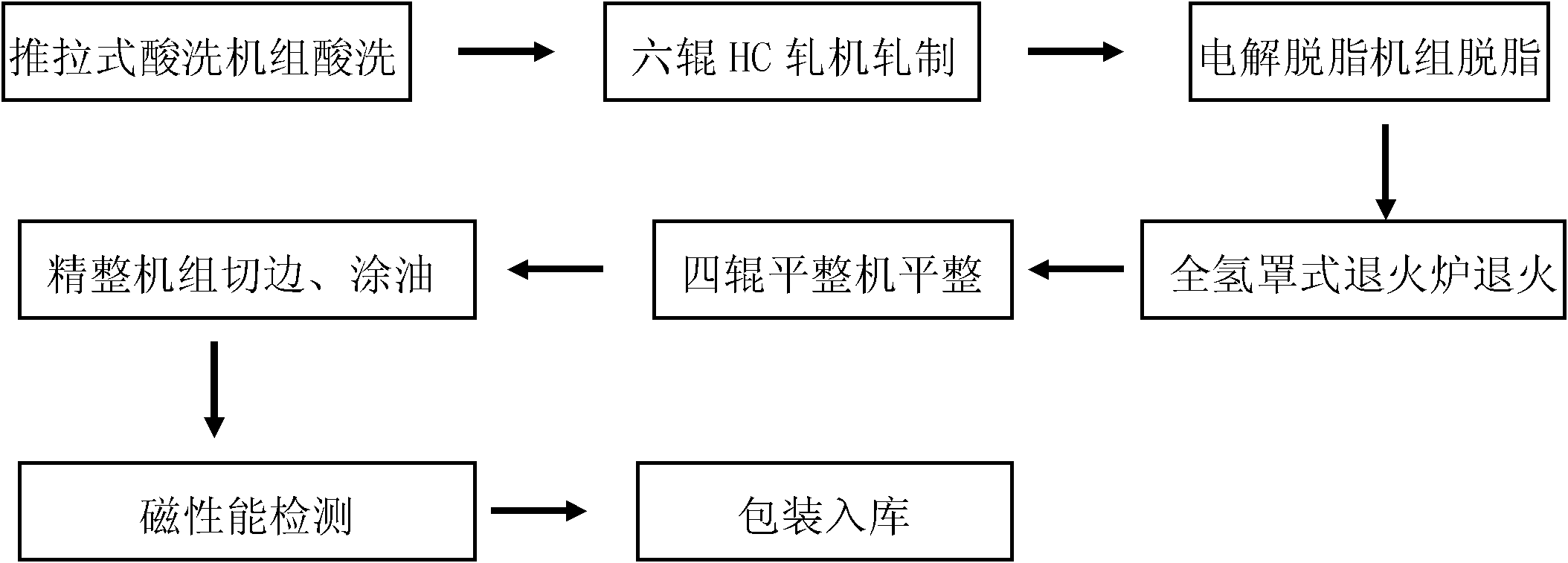

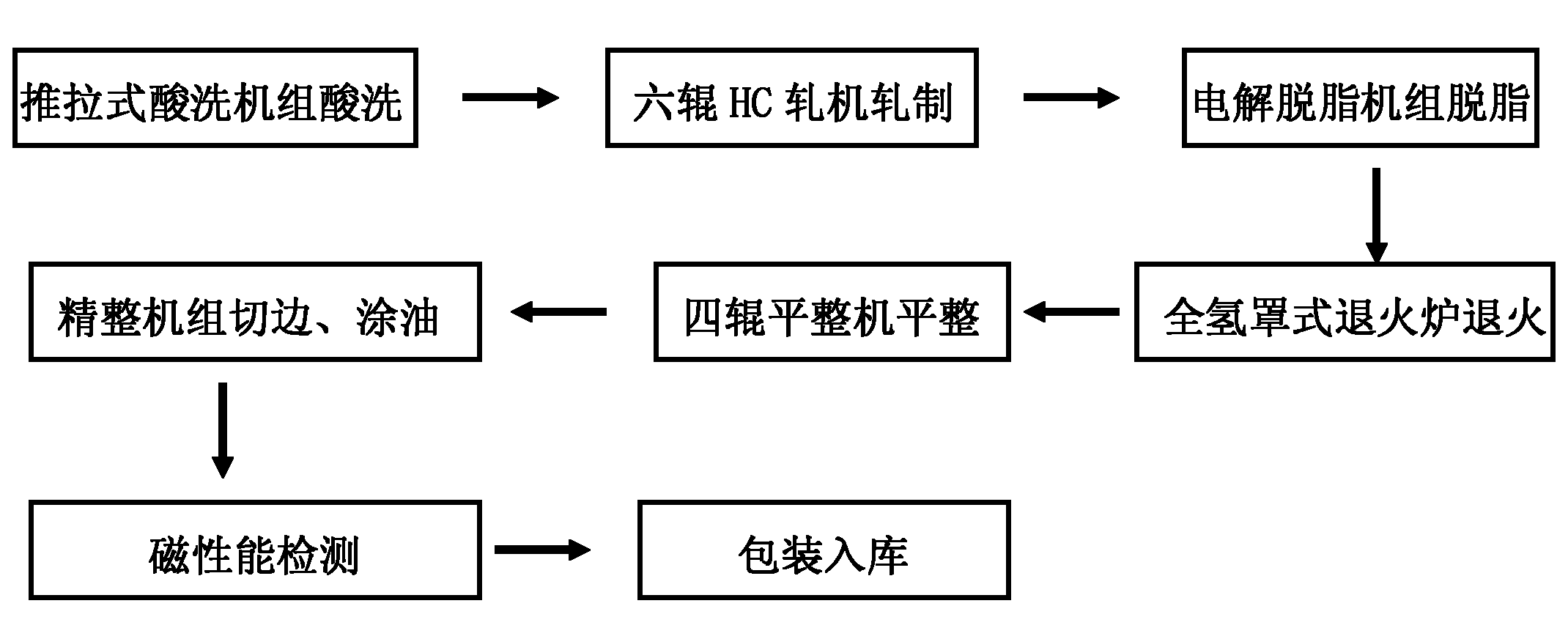

Production method of low iron loss high magnetic sensing cold milling orientation less electrical steel plate

InactiveCN100999050AImprove plasticityEasy to grow grainsOther manufacturing equipments/toolsCrystalliteSheet steel

The present invention relates to a method for producing low-iron-loss high-magnetic-induction cold-rolled non-oriented electrical steel strip by using cap cover furnace annealing treatment. Said method includes the following steps: (a), raw material preparation: including (by wt%) C, its content is loss than or equal to 0.010%; Si, its content is 0.1-3.50%; Al, its content is less than or equal to 1.5%; Man, its content is 0.10%-1.50%; P, is content is less than or equal to 0.20%; S, its content is less than or equal to 0.008%; N, its content is less than or equal to 0.0030%, and the rest is iron and inevitable impurity; (b), smelting, continuous casting and hot-rolling; (c), normalizing treatment, making hot-rolled sheet undergo the process of normalizing treatment, under the condition of cap cover furnace making full hydrogen annealing, annealing temperature is 700 deg.C-900deg.C; (d), cold-rolling to obtain cold-rolled sheet; and (e), annealing treatment, making cold-rolled sheet undergo the process of annealing treatment so as to obtain the invented product.

Owner:BAOSHAN IRON & STEEL CO LTD

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

Manufacturing method of cold rolling electric steel special for compressor

InactiveCN1948517AHigh magnetic inductionIncrease stretch straighteningRoll mill control devicesHeat treatment process controlTemperature controlElectrical steel

The invention discloses a method to produce electrical steel by steel cold-rolling which is specially used for compressors. The method integrates the craft flows of hot rolling with traditional continuous metal cast process and hot rolling with continuous metal cast process of thin stock. It is characterized in that: The chemical constitution (percentage of weight) as follows is adopted: C<=0.03%,Si<=4.0%,Mn:0.1-1.0%,P<=0.16%, S<=0.01%,Al:0.1-0.8%, the rest is Fe and a little impurity. The craft feature is to control the batching temperature of hot rolling at 680-730deg.C. Cold rolling adopts endless rolling by laser welding, and its speed is 600-1000M / min. Crafts including cover annealing with full H2, flash heat and slow cool are introduced. Soaking time is 8 to 15 hours and the temperature is controlled at 670+-30deg.C. The annealing temperature is lower than recrystallization temperature. Crafts of leveling, tension and straightening under high pressure are adopted. The non-oriented electrical steel in this invention has high magnetic strength and low iron loss, which can produce various electrical steel with requirements of other breeds.

Owner:ANGANG STEEL CO LTD

Method for production of non-oriented electrical steel

InactiveCN1463811AImprove surface qualityReduce defectsMetal rolling arrangementsElectrical steelMolten steel

The present invention is the double-roller thin belt continuous casting process of producing non-oriented electrical steel. Molten steel containing silicon in 0-3.5 % is made to pass through two crystallizing rollers to form coagulated shell and led out the crystallizing rollers to form cast belt; and the belt is hot rolled in a hot milling roll at 800-1000 deg.c to produce a hot rolling deformation of 5-25 % and wound. The simple technological process can produce high performance non-oriented electrical steel effectively.

Owner:BAOSHAN IRON & STEEL CO LTD +1

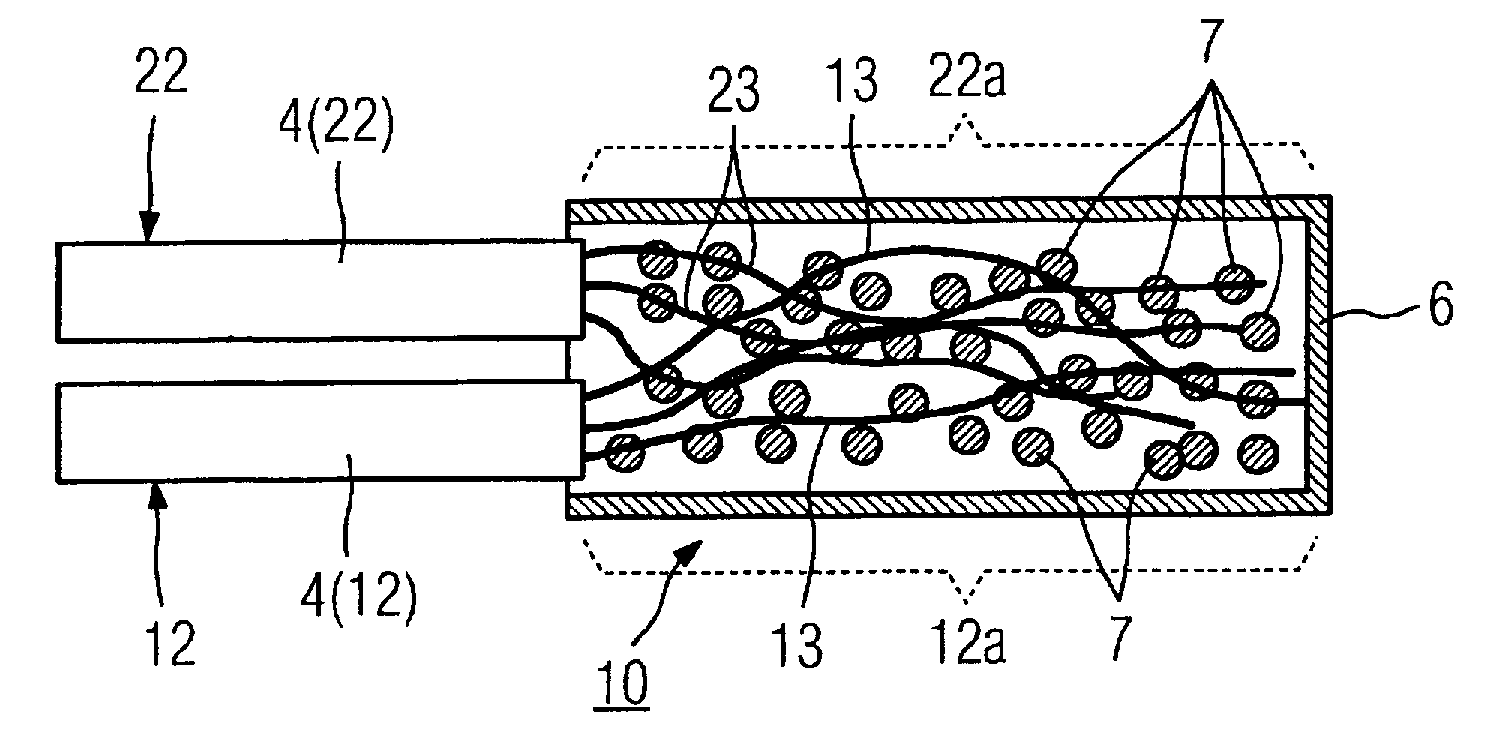

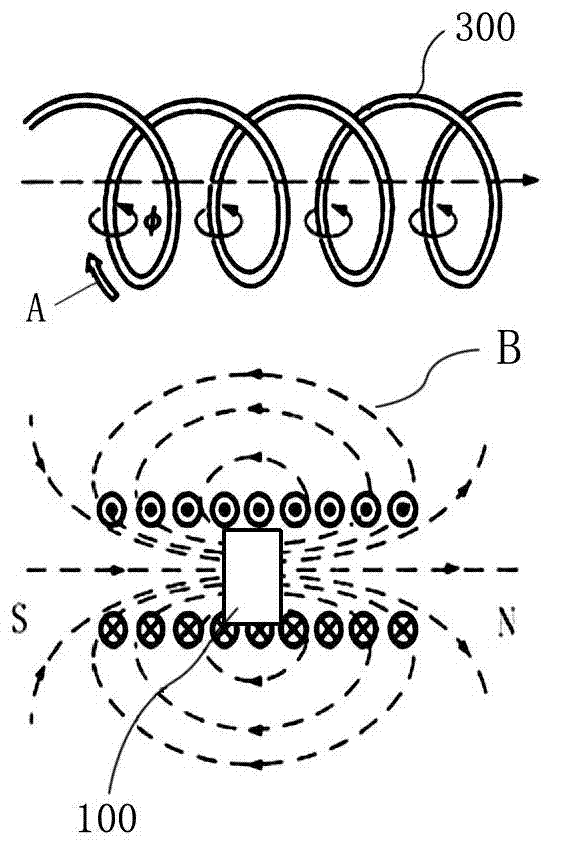

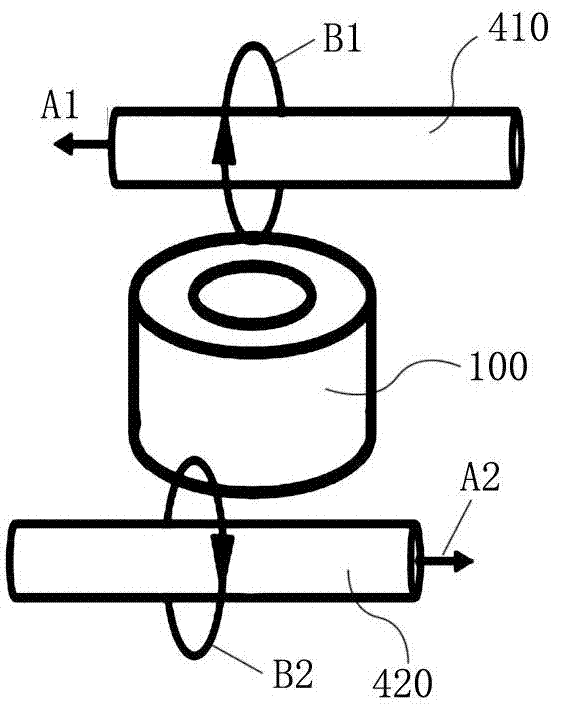

Superconductive connection of the end pieces of two superconductors and method for manufacturing this connection

InactiveUS20090105079A1High magnetic inductionSimple wayLine/current collector detailsSuperconductors/hyperconductorsConductive materialsEngineering

In a superconductive connection for two end pieces of superconductors that each have a matrix of normally-conductive material and at least one superconductor lead, of superconductive material, in the matrix, and in a method for making such a superconductive connection, the respective end pieces of the conductor leads are stripped of the matrix material and are inserted into a sheath or bushing. MgB2, as superconductive contacting material, is additionally inserted into the sheath or bushing, so as to at least partially fill regions in the sheath or bushing between the conductor leads. The cross-section of the sheath or bushing is then reduced.

Owner:SIEMENS AG

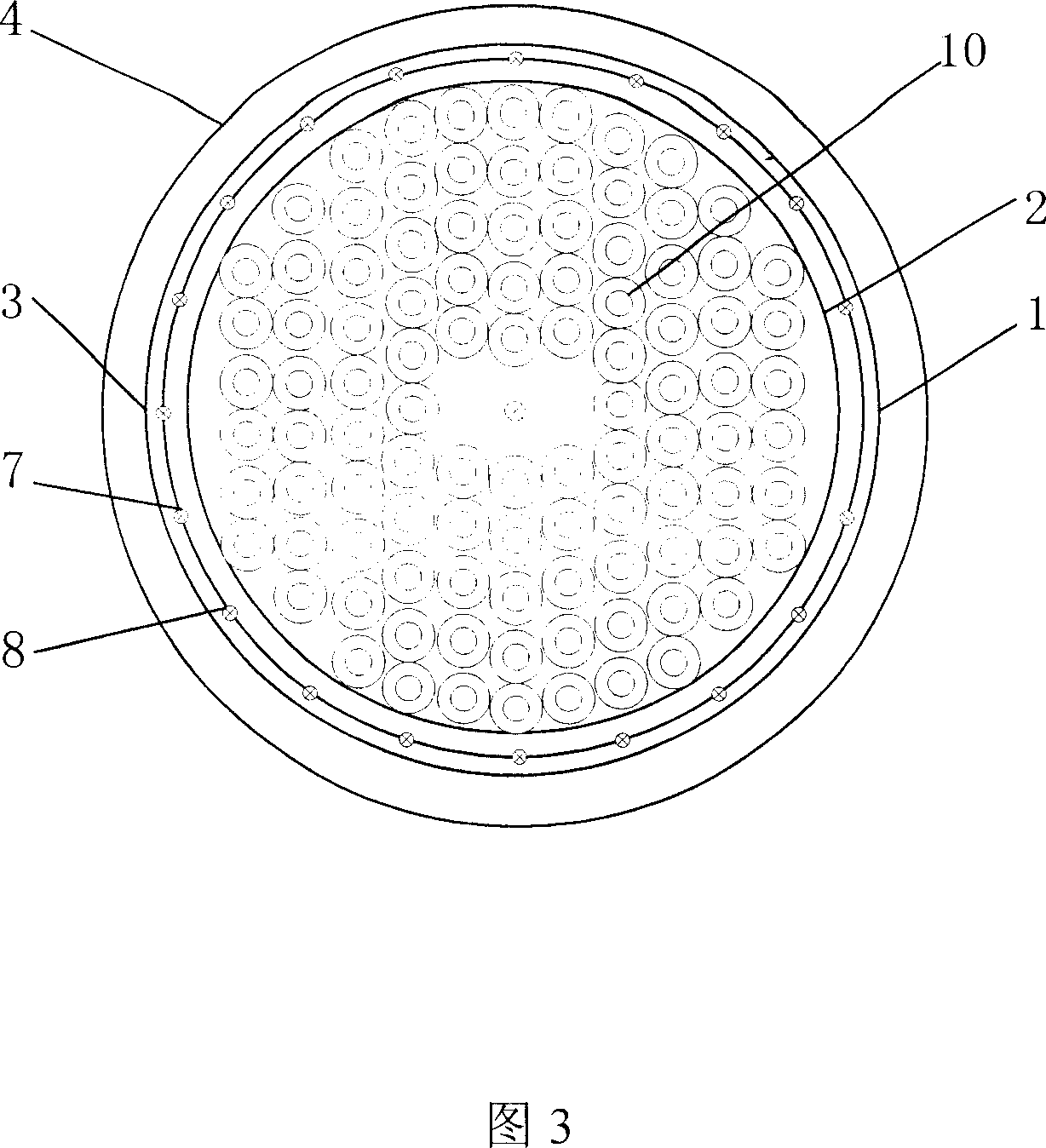

Coated semi-processed non-oriented electrical steel sheet and manufacturing method thereof

InactiveCN101654757AFulfil requirementsReduce iron lossFurnace typesHeat treatment furnacesChemical compositionSheet steel

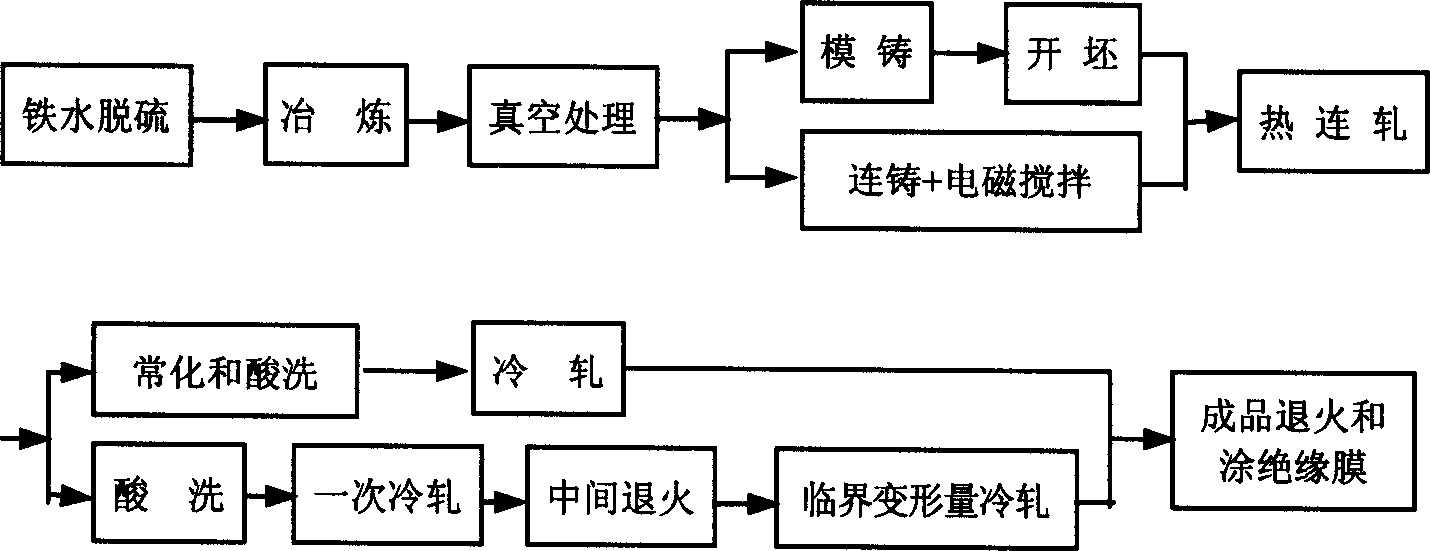

The invention provides a coated semi-processed non-oriented electrical steel sheet and a manufacturing method thereof. The steel sheet comprises the following chemical compositions in percentage by mass: less than or equal to 0.003 percent of C, 1.00 to 2.30 percent of Si, 0.20 to 1.00 percent of Mn, 0.01 to 0.10 percent of P, 0.20 to 0.80 percent of Al, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method does not need electromagnetic stirring in slab continuous casting; when the content of Si is between 1.65 to 2.30 percent, a normalizing treatment procedure is added before the step of pickling; and an annealing condition is that: a temperature is between 650 and 800 DEG C, the annealing time is between 1 and 4 minutes and the annealing is carried out in a dry atmosphere of whole nitrogen. The coated semi-processed non-oriented electrical steel sheet has low iron loss, high magnetic induction, good mechanical property, simple procedure and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

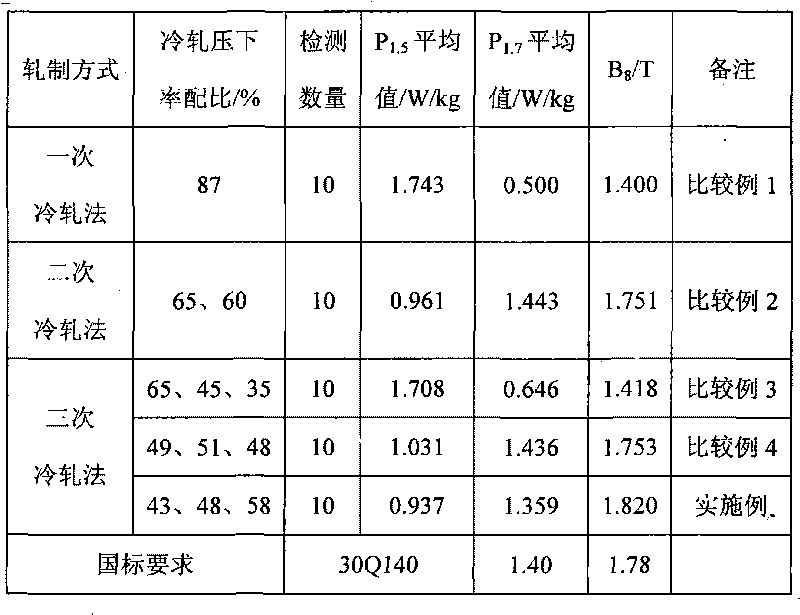

Method for manufacturing directional silicon steel

ActiveCN101748257AUniform internal organizationReduced high temperature annealing timeSiliconCoating

The invention discloses a method for manufacturing directional silicon steel. The method is characterized in that a rolling and treating process adopts a manufacture process of triple cold rolling, twice intermediate annealing, and once MgO coating, and finally carrying out high temperature annealing. One-pass roll separating force in the triple rolling is reduced, the internal tissue of the steel is uniform, so the time for high temperature annealing is reduced by 20 to 30 percent, and a product with strong (110)[001] structure is finally obtained. The method not only can obviously improve the electromagnetic performance (iron loss reduces but magnetic induction increases), ensures that the iron loss P1.7 is reduced by about 0.08W / kg, ensures the magnetic induction B8 is improved by about 0.07T, not only ensures that the product is improved from half to one grade, but also ensures that the total production time is obviously reduced, the total production time is remarkably shortened, thereby improving the manufacture efficiency of the directional silicon steel.

Owner:ANGANG STEEL CO LTD

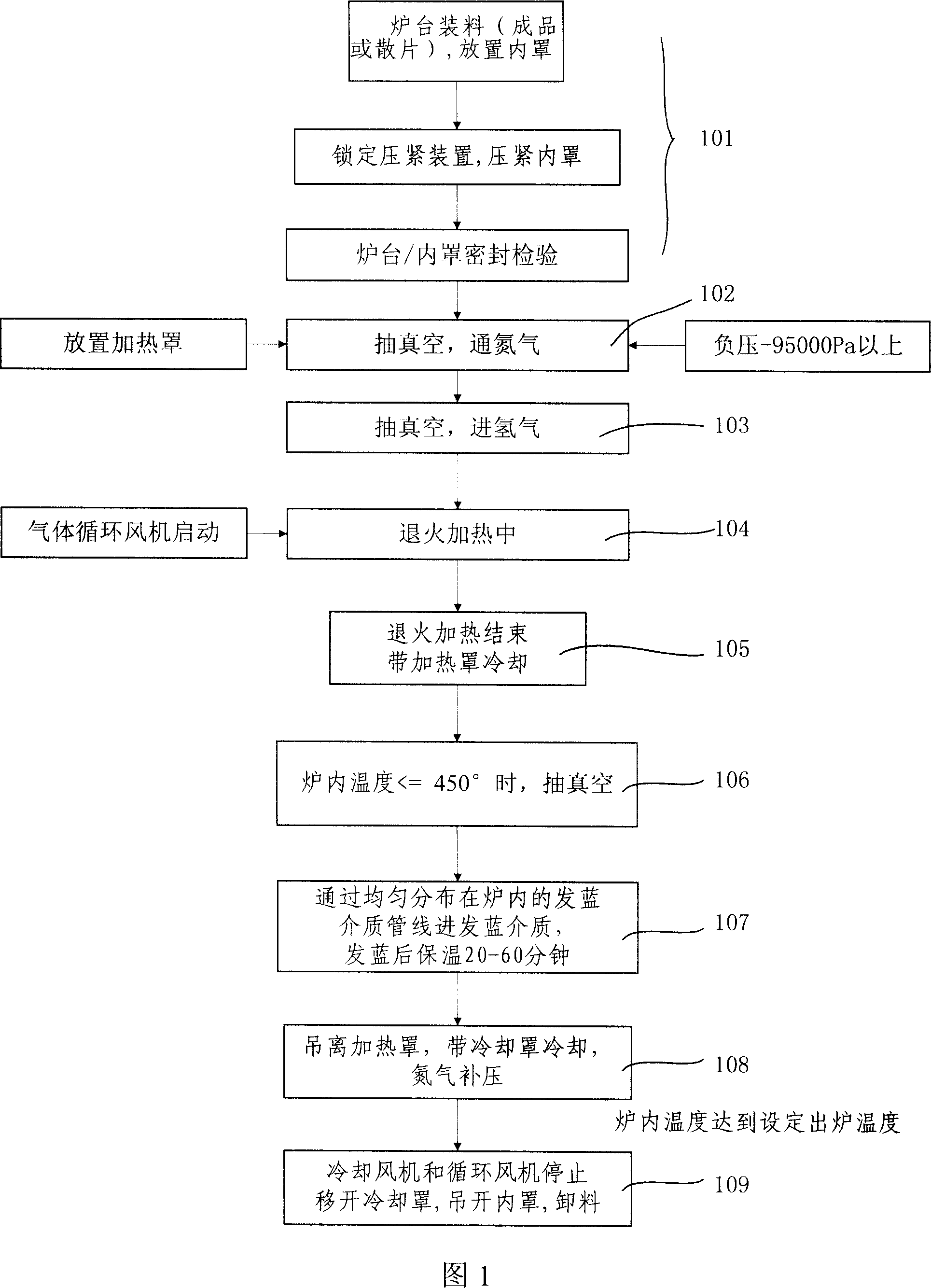

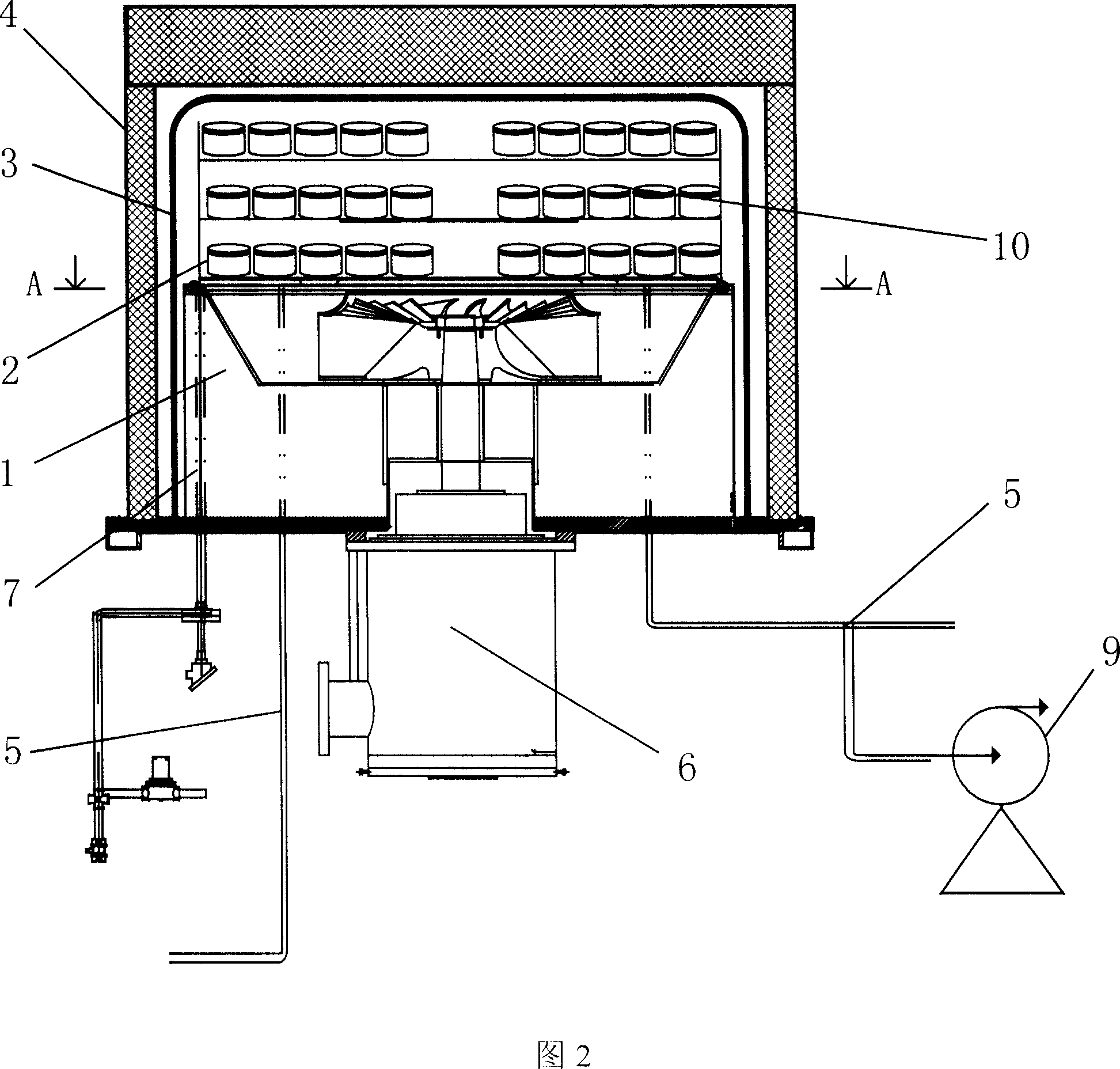

Process and device for coating-free electrical steel annealing and bluing

ActiveCN101082075AHigh magnetic inductionImprove efficiencyMetallic material coating processesHeat treatment process controlElectrical steelStress relieving

The no-coating electric steel sheet annealing and blueing process includes the following steps: 1. annealing laminated no-coating silicon steel sheets inside a bell type furnace under hydrogen atmosphere; 2. vacuumizing the bell type furnace to vacuum degree lower than 95000 Pa after the silicon steel sheets are cooled slowly to 300-450 deg.c, and leading blueing water solution to the furnace before maintaining the temperature for 20-60 min; and 3. vacuumizing for the second time, filling nitrogen for cooling and discharging in the temperature lower than 150 deg.c. The process has high annealing quality, homogeneous blueing effect, and capacity of raising the magnetic induction coefficient of silicon steel sheets and lowering their iron loss.

Owner:BAOSHAN IRON & STEEL CO LTD

Iron-based soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN104078182AThickness controllable and adjustableGuaranteed uniformityInorganic material magnetismAlcoholHeat stability

The invention relates to an iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The invention adopts the technical scheme as follows: sequentially adding iron-based alloy powder, absolute ethyl alcohol, a silane coupling agent and distilled water into a reaction vessel according to the mass ratio of 1:(6-10):(0.04-0.10):(0.2-0.4), and stirring; adding tetraethyl orthosilicate or methyl silicate, then adding ammonia water, stirring continuously, washing, filtering and drying; placing the obtained composite powder with a core-shell heterostructure into an annealing furnace, performing heat preservation for 1-3 h under the condition of 600-800 DEG C, performing furnace cooling and performing compression moulding; sintering for 1-10 h under the condition of 900-1350 DEG C, so that the iron-based soft magnetic composite magnetic powder core is obtained after furnace cooling. The prepared iron-based soft magnetic composite magnetic powder core has the characteristics that the insulating property is good, the iron loss is low, high magnetic strength is achieved, the heat stability is good and the service life is prolonged when the iron-based soft magnetic composite magnetic powder core is used at a higher environment temperature.

Owner:WUHAN UNIV OF SCI & TECH

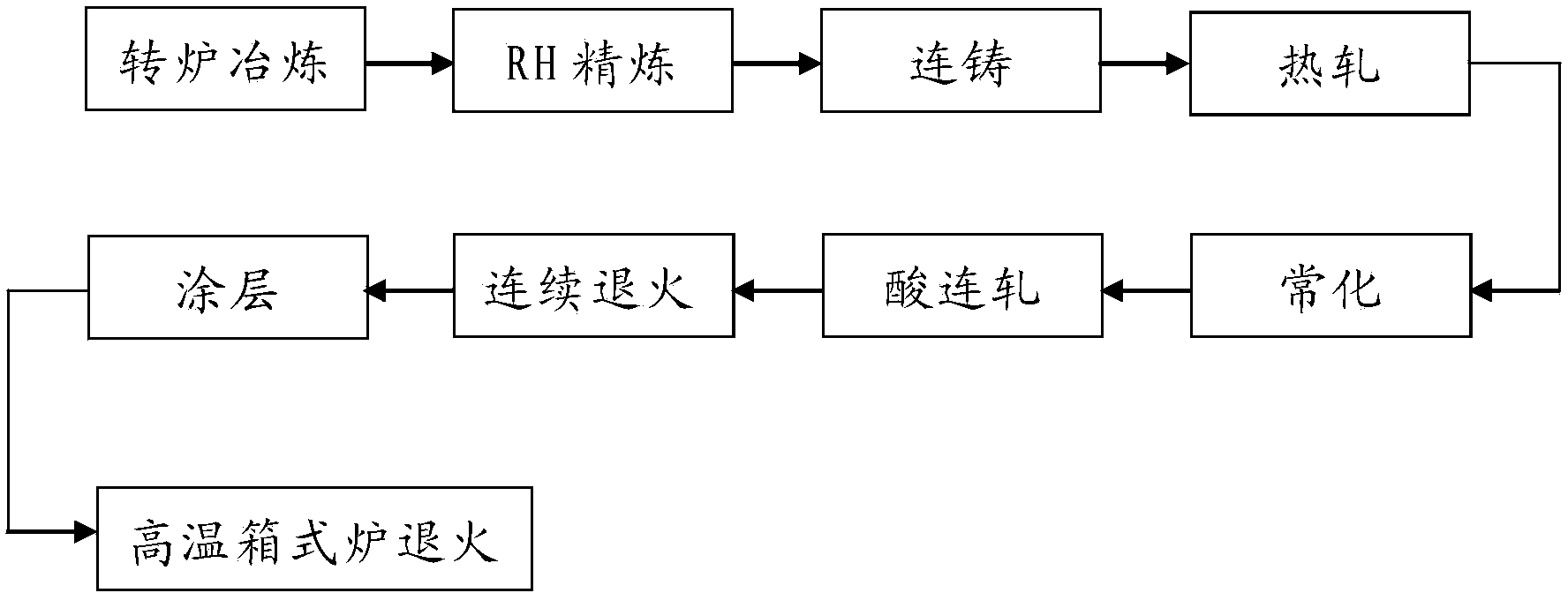

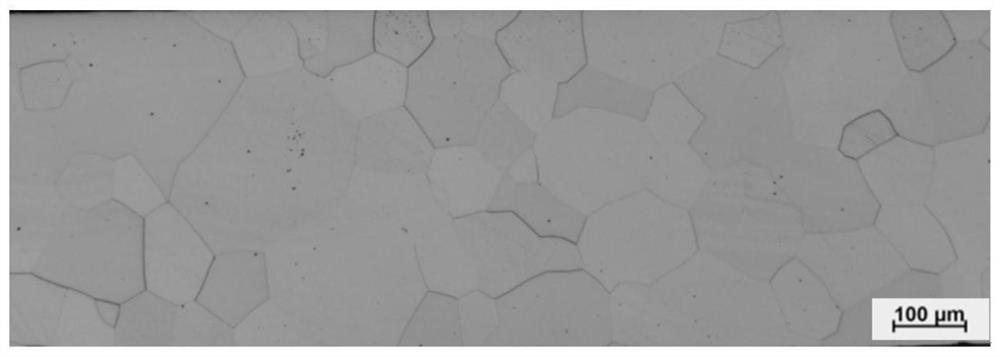

Non-oriented electrical steel used for stereoscopic transformer with rolled iron core and production method thereof

The invention provides non-oriented electrical steel used for a stereoscopic transformer with a rolled iron core. The non-oriented electrical steel comprises, by weight, 0.001-0.003% of carbon, 0.6-1.5% of silicon, 0.3-1.0% of aluminum, 0.2-0.8% of manganese, less than or equal to 0.1% of phosphorus, less than or equal to 0.003% of sulfur, less than or equal to 0.003% of nitrogen, less than or equal to 0.003% of titanium, less than or equal to 0.003% of niobium, less than or equal to 0.003% of vanadium, and balance iron and unavoidable impurities. The invention further provides a production method of the non-oriented electrical steel used for the stereoscopic transformer with the rolled iron core. The production method includes the production steps of converter smelting, RH refining, continuous casting, hot rolling, normalizing, acid tandem rolling, continuous annealing, coating, high-temperature batch-type furnace annealing and the like. The non-oriented electrical steel used for the stereoscopic transformer with the rolled iron core has the advantages of being high in magnetic induction and low in iron loss.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

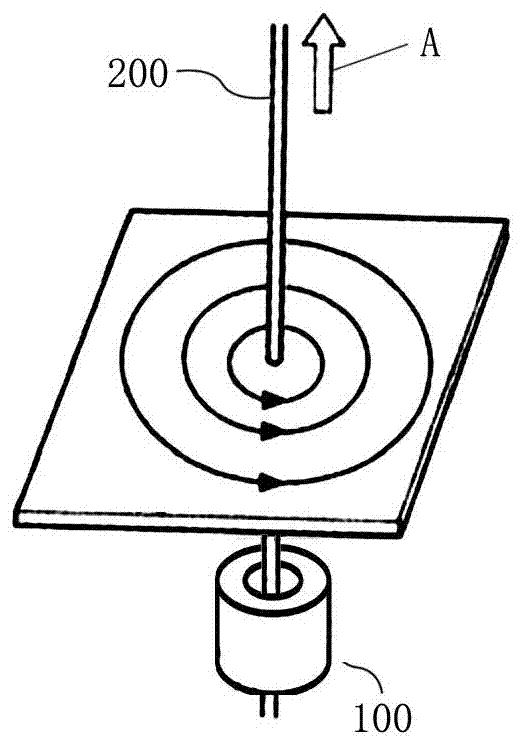

Amorphous soft magnet core and manufacturing method thereof

ActiveCN103050210AEasy to operate and controlHigh magnetic inductionInductances/transformers/magnets manufactureMagnetic materialsDriving currentSoft magnet

The invention discloses an amorphous soft magnet core and a manufacturing method thereof. The manufacturing method of the amorphous soft magnet core includes: manufacturing an amorphous soft magnet alloy tape; coiling the alloy tape into a circular core in the preset size; subjecting the circular core to magnetostatic field annealing to obtain exchange biasing; and subjecting the circular core subjected to magnetostatic field annealing to functional controllable operation of loop biasing. Maximum induction of the amorphous soft magnet core manufactured by the manufacturing method can be obtained by drive current as small as possible, and optimal operation is achieved.

Owner:CENT IRON & STEEL RES INST

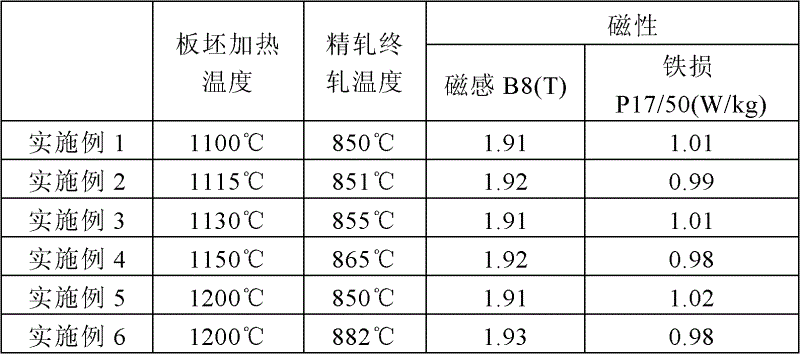

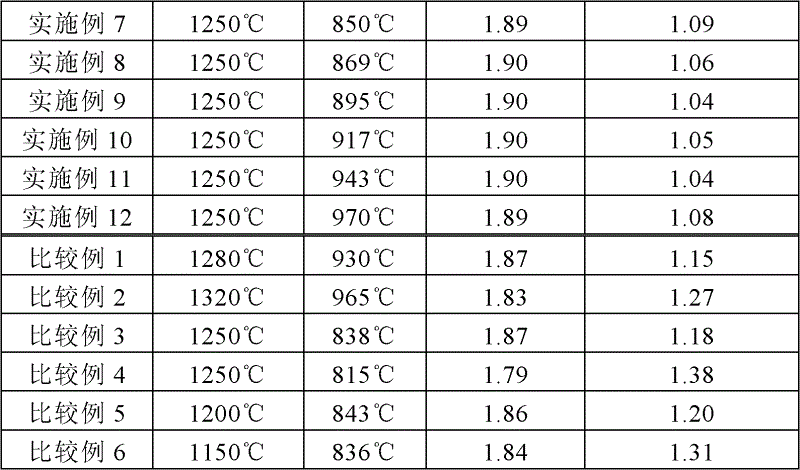

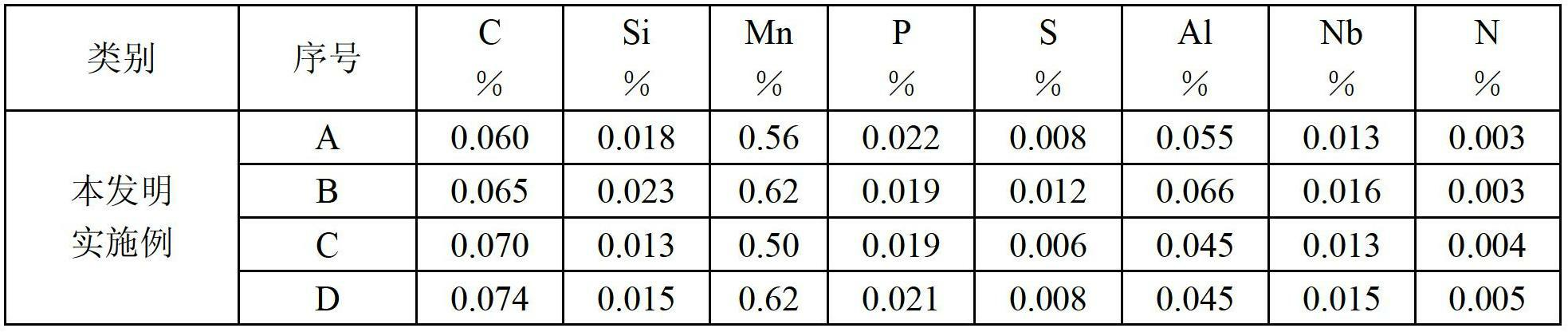

Production method of high magnetic induction oriented silicon steel

The invention discloses a production method of high magnetic induction oriented silicon steel, comprising the following steps: a) carrying out steel-making and continuous casting to produce slabs, wherein the slabs comprise 0.05-0.10 wt% of C, 2.5-4.0 wt% of Si, 0.008-0.028 wt% of S, 0.008-0.040 wt% of Als, 0.004-0.012 wt% of N, 0.08-0.20 wt% of Mn, 0.08-0.30 wt% of Cu, and the balance of Fe; b) preserving heat at no higher than 1250 DEG C and then carrying out hot rolling, wherein the finishing temperature is higher than 850 DEG C; c) carrying out annealing, pickling, once cold rolling or twice cold rolling containing intermediate annealing to get finished product thickness; d) decarburizing annealing, and preserving heat in wet nitrogen-hydrogen protective atmosphere; e) coating an annealing isolation agent and then carrying out high temperature annealing; f) carrying out nitriding treatment; and g) coating an insulating coating, and carrying out stretching, flattening and annealing. According to the invention, the types and distribution of the inhibitor is adjusted, the stable and high inhibition capability is guaranteed, by cooperating with hot rolling and twice recrystallization, the high magnetic induction oriented silicon steel with stable properties is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

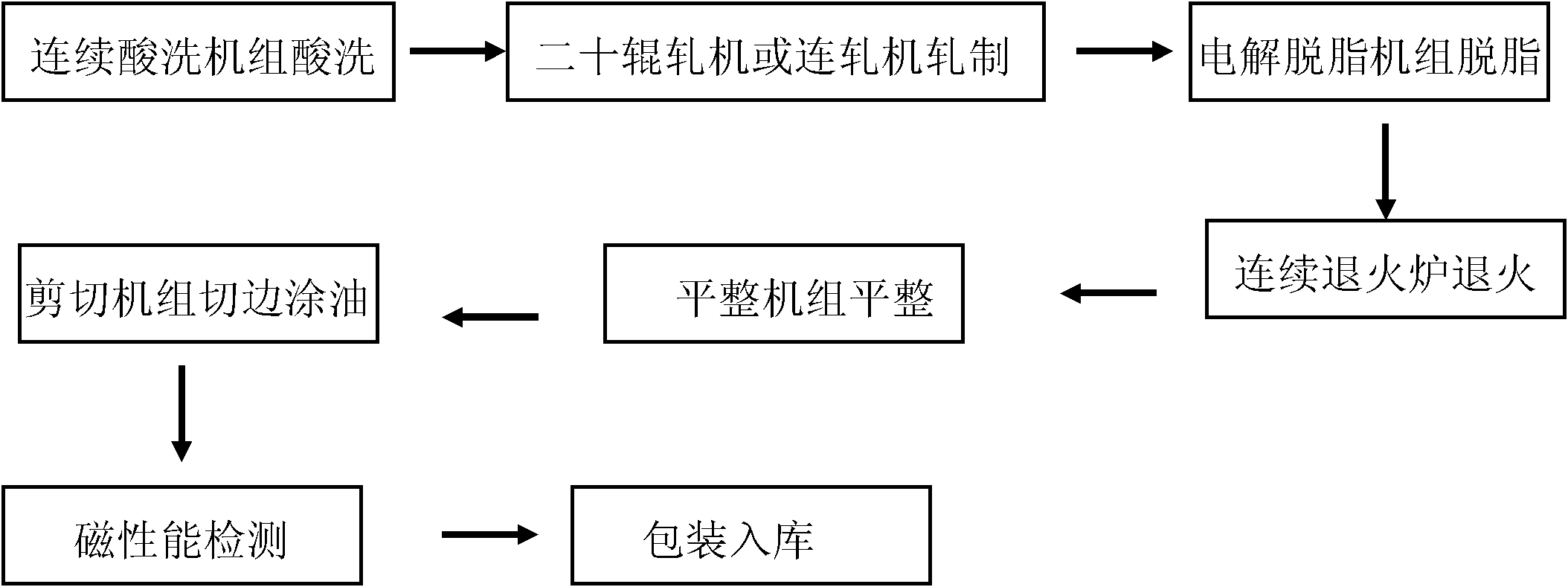

Method for producing semi-processed cold-rolled non-oriented electrical steel

InactiveCN102220466AReduce manufacturing costGood magnetic properties and process performanceMetal rolling arrangementsElongation control deviceElectrical steelTechnical performance

The invention relates to a method for producing semi-processed cold-rolled non-oriented electrical steel, which comprises the steps of pickling, rolling, electrolytically degreasing, annealing and leveling of non-oriented hot-rolled silicon steel, wherein annealing is performed in a full-hydrogen bell-type annealing furnace by first heating to 730 to 820 DEG C within 10 hours, then recrystallizing and annealing for more than 12 hours at 730 to 820 DEG C, next slowly cooling to 600 to 500 DEG C, later on cooling in a cooling cover to 80 to 60 DEG C and finally discharging. In the semi-processed non-oriented cold-rolled electrical steel with a mark of 50WB800 produced by the invention, the product magnetism is characterized in that: the P1.5 / 50 is 7.181W / kg; and the B5000 is 1.708T. Compared with the requirements of corresponding standards of the common semi-processed cold-rolled non-oriented electrical steel, the iron loss value is reduced by 0.819W / kg, and the magnetic induction is improved by 0.008T. As a material for iron cores of motors and generators working in rotary magnetic fields, the semi-processed cold-rolled non-oriented electrical steel produced by the method has high magnetic performance and technical performance.

Owner:山东泰山轧钢有限公司

Method for preparing non-oriented silicon steel with excellent magnetic property and high efficiency

ActiveCN102453844AReduce dosageReduce manufacturing costTemperature control deviceInorganic material magnetismChemical compositionElectrical steel

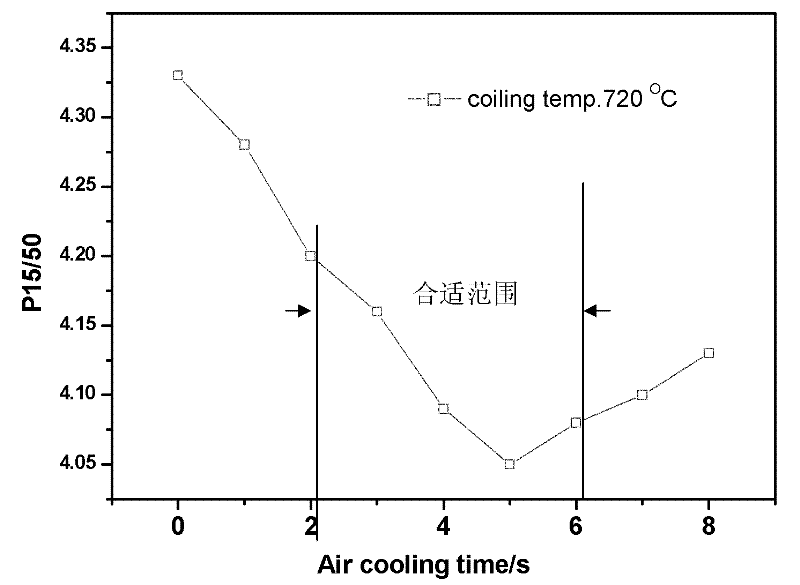

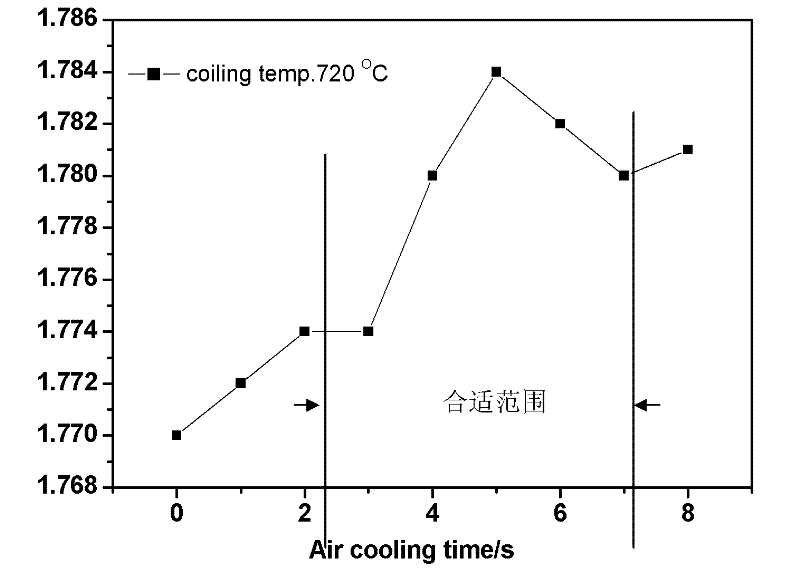

The invention relates to a method for preparing a non-oriented silicon steel with excellent magnetic property and high efficiency, which comprises the following steps: 1) smelting and casting: wherein the non-oriented silicon steel comprises the following chemical components by weight percentage: less than or equal to 0.0040% of C, 0.1-0.8% of Si, 0.002-1.0% of Al, 0.10%-1.50% of Mn, less than orequal to 0.2% of P, 0.04%-0.08% of Sb, less than or equal to 0.0030% of S, less than or equal to 0.0020% of N, less than or equal to 0.0020% of Ti, balance of iron and inevitable impurity; smelting the above components and casting to casting blank; 2) hot rolling, wherein the slab heating temperature is 1100 DEG C-1150 DEG C, the finishing temperature is 860 DEG C-920 DEG C; rolling and air cooling, wherein the air cooling time (t) is greater than or equal to (2+30*Sb%)s and less than or equal to 7s; reeling at the temperature of 720 DEG C; 3) pickling, cold rolling and rolling with reductionratio of 70-78%; 4) annealing, heating to the temperature of 800-1000 DEG C with speed of greater than or equal to 15 DEG C, insulating for 10s-25s. Under the prerequisite that the magnetic property is ensured, by adding favorable texture elements during the steel-making process, controlling the harmful elements, controlling the air cooling time during the hot rolling process and cooperating by high temperature reeling, the electrical steel production with low cost and high efficiency can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

High-magnetic-induction low-iron-loss no-oriented silicon steel sheet and manufacturing method thereof

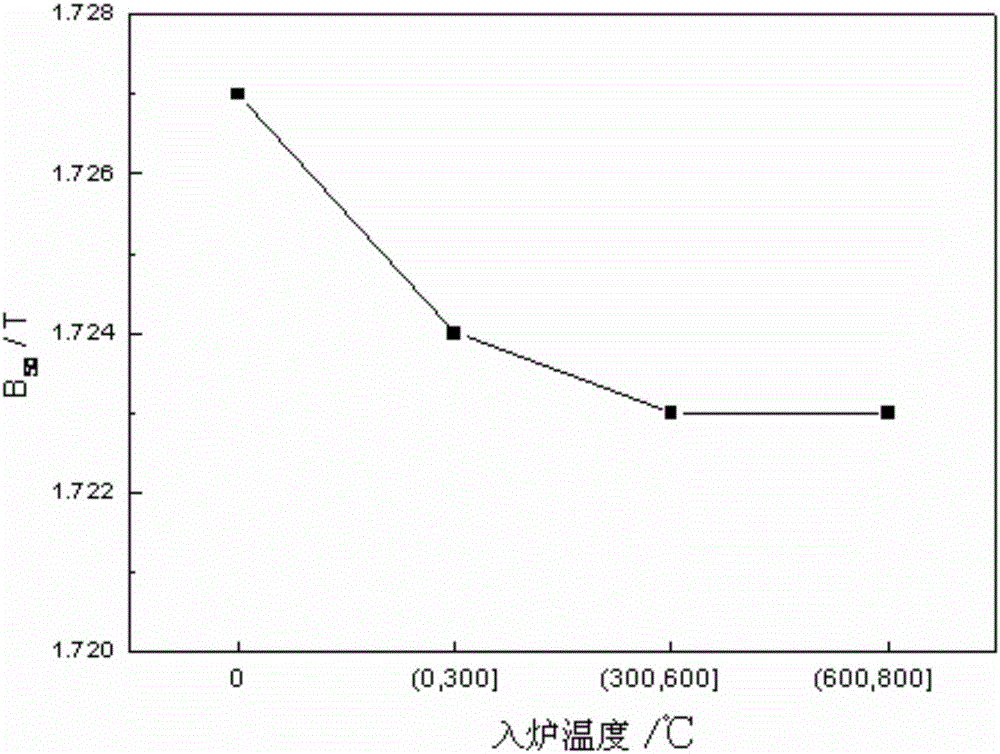

ActiveCN105925884AHigh magnetic inductionReduce iron lossInorganic material magnetismFurnace typesTemperature control modeMolten steel

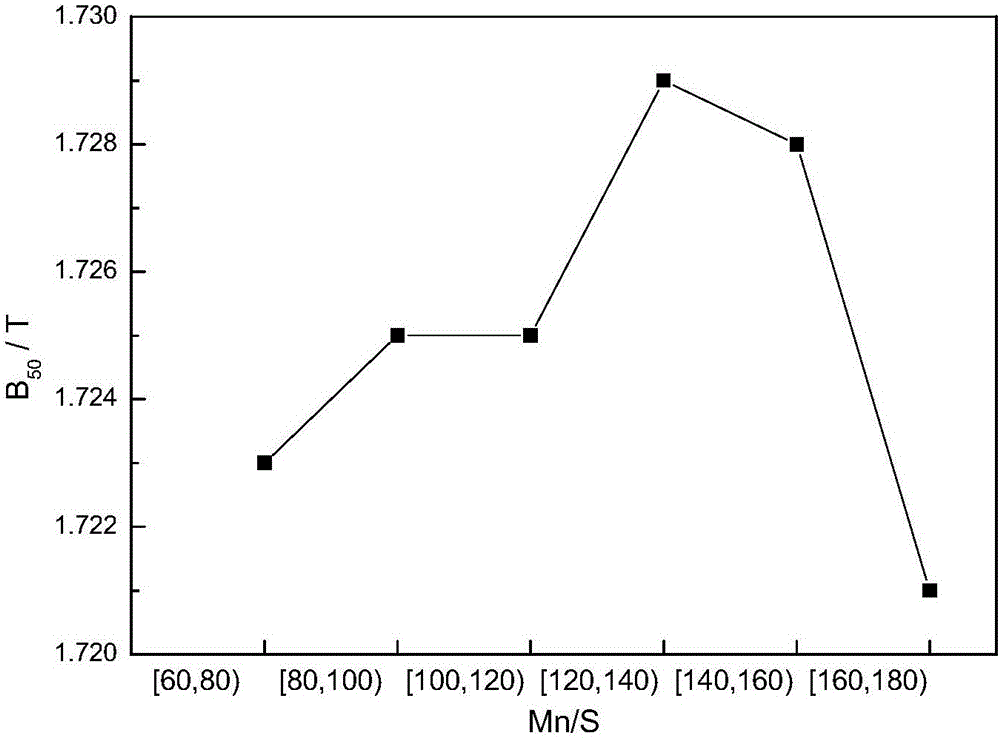

The invention discloses a high-magnetic-induction low-iron-loss no-oriented silicon steel sheet and a manufacturing method thereof. The no-oriented silicon steel sheet is composed of, by mass, less than or equal to 0.005% of C, 0.1%-1.6% of Si, 0.1%-0.5% of Mn, less than or equal to 0.2% of P, less than or equal to 0.004% of S, less than or equal to 0.003% of Al, less than or equal to 0.005% of N, less than or equal to 0.004% of Nb, less than or equal to 0.004% of V, less than or equal to 0.003% of Ti, and the balance Fe and inevitable impurities, wherein 120<=Mn / S<=160, and Nb / 93+V / 51+Ti / 48+Al / 27<=C / 12+N / 14. After completion of molten steel casting, the cast blank furnace inlet temperature is adjusted through a temperature control mode, stable production of the high-magnetic-induction low-iron-loss no-oriented silicon steel sheet is effectively achieved, the manufacturing cost is relatively low, and normalizing treatment or bell-type furnace intermediate annealing is not needed.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

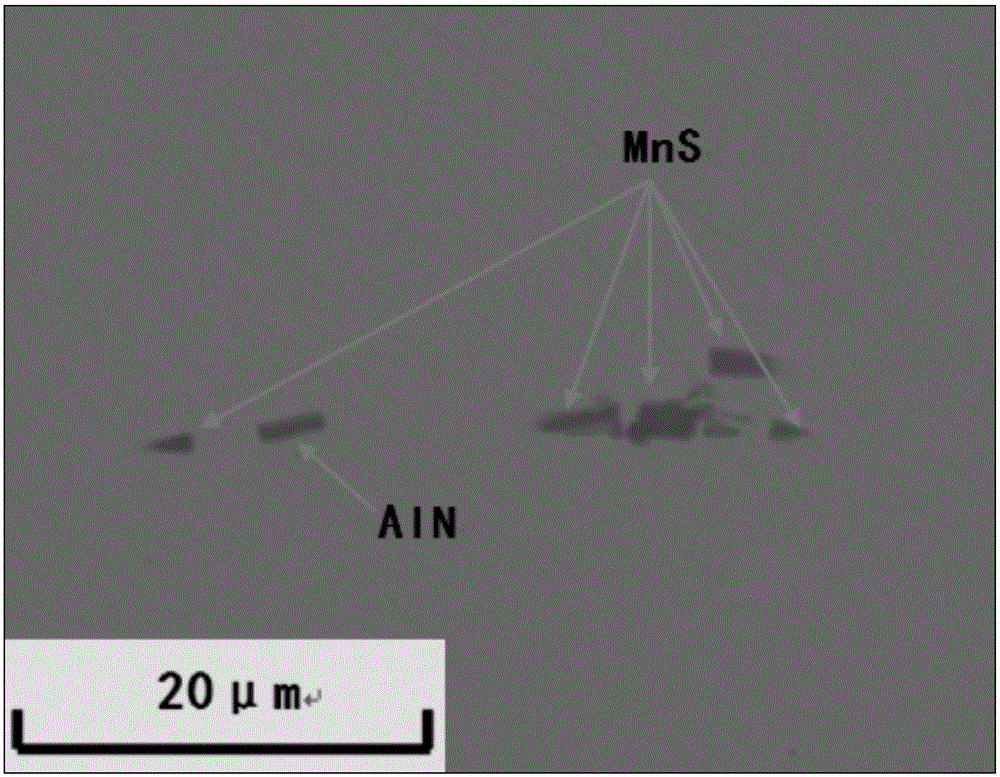

Method for preparing high-magnetic-strength non-oriented silicon steel thin products on basis of thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a method for preparing high-magnetic-strength non-oriented silicon steel thin products on the basis of thin-strip casting. The method comprises the following steps: (1) smelting molten steel according to set ingredients, wherein the molten steel comprises the following ingredients in percentages by mass: less than or equal to 0.003% of C, 2.0-3.5% of Si, less than or equal to 0.01% of Mn, less than or equal to 0.003% of Al, 0.02-0.06% of P, less than or equal to 0.003% of S, and the balance of Fe and inevitable impurities; (2) carrying out thin-strip casting to obtain a cast strip; (3) carrying out hot rolling under the condition of an inert atmosphere; (4) reeling the cast strip after the cast strip is cooled to the temperature of 650 DEG C, removing iron oxide scale and then carrying out single-stage multi-pass cold rolling; and (5) carrying out continuous annealing on the cold rolled strip, coating the cold rolled strip with an insulating layer and then drying the insulating layer to obtain the high-performance non-oriented silicon steel thin products. The method is based on a thin-strip casting technology, the process is simplified, the production cost is reduced, and the magnetic performance of the non-oriented silicon steel thin finished products is improved.

Owner:NORTHEASTERN UNIV

Non-oriented electrical steel plate and production method thereof

InactiveCN103572158AImprove thermal conductivityReduce carbon increaseMetal rolling arrangementsProduction lineElectrical steel

The invention relates to a non-oriented electrical steel plate Which comprises the following components in percentage by mass: less than or equal to 0.0060 percent of C, 0.60 to 0.80 percent of Si, 0.20 to 0.40 percent of Mn, less than or equal to 0.10 percent of P, less than or equal to 0.0080 percent of S, 0.015 to 0.025 percent of Als, 0.001 to 0.002 percent of B, and the balance of Fe and unavoidable impurity elements. The production method comprises the following steps of smelting in a converter, argon blowing to steel ladle, RH vacuum treatment, refining of an LF furnace, continuous casting of a sheet billet, heat equalizing through a tunnel, fine rolling, cooling, coiling, acid pickling, cold rolling and continuous annealing. Compared with the prior art, the method is high in magnetic induction and low in iron loss. A manufacturing process for producing the non-oriented electrical steel plate by continuously casting and continuously rolling the sheet billet is provided for the first time, and the technical support is provided for production of a novel non-oriented electrical steel hot-rolling raw material with excellent environmental-protection performance by utilizing a sheet billet continuous-casting and continuous rolling production line.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

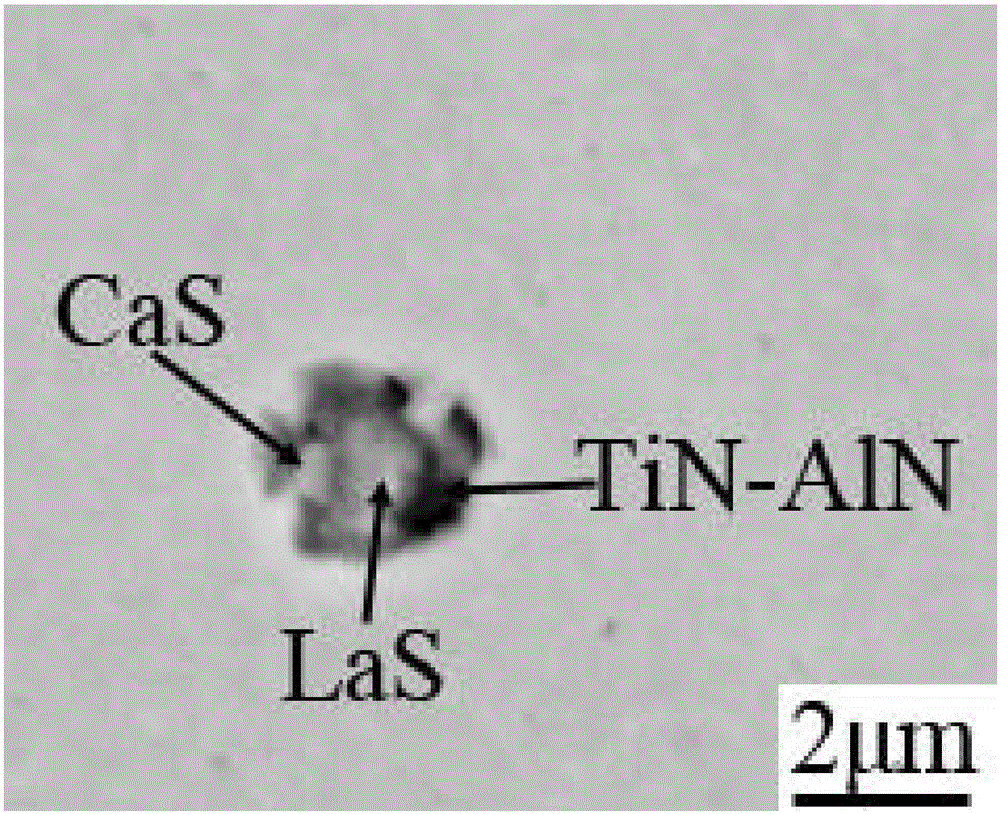

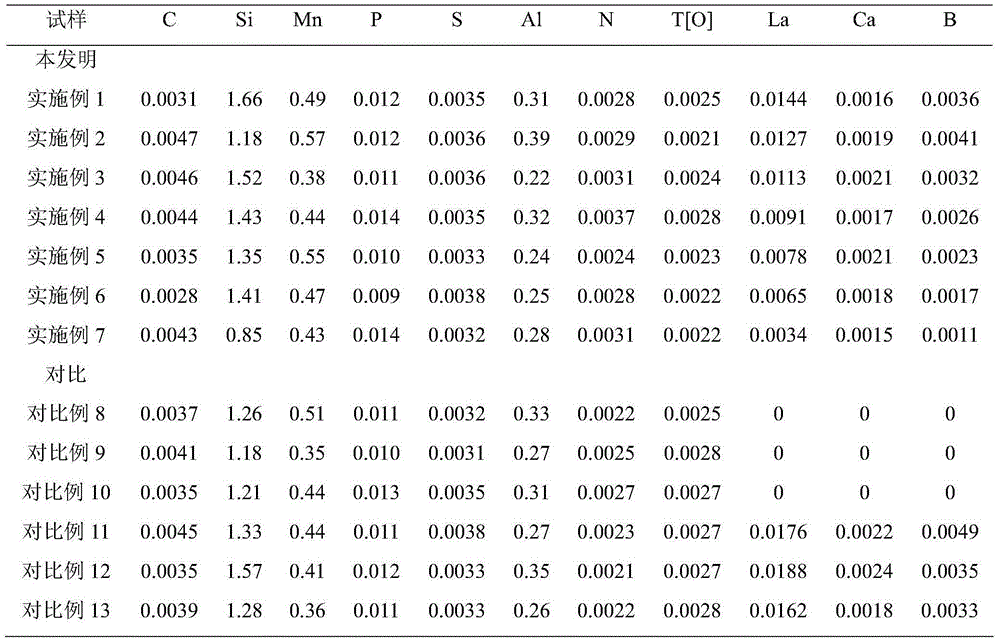

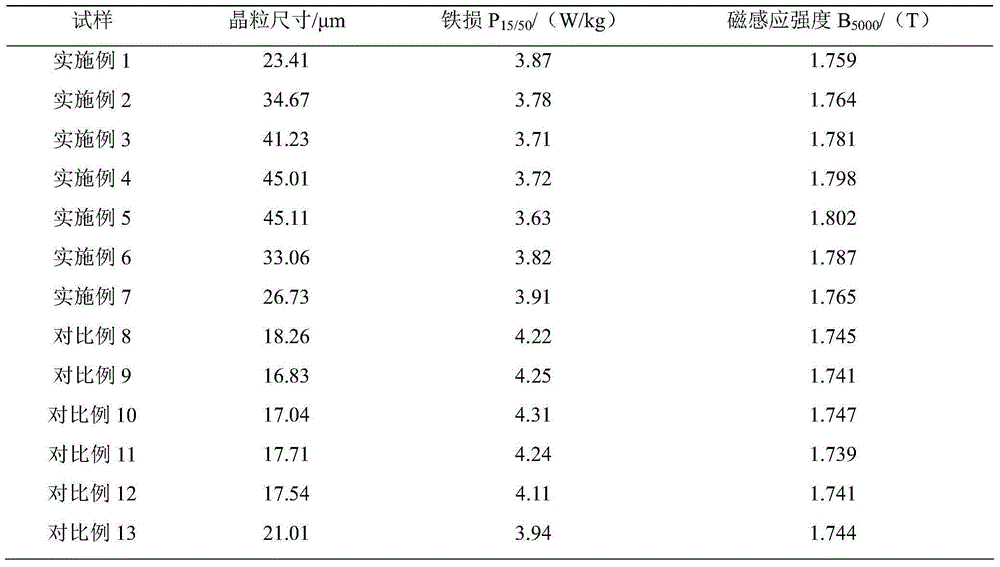

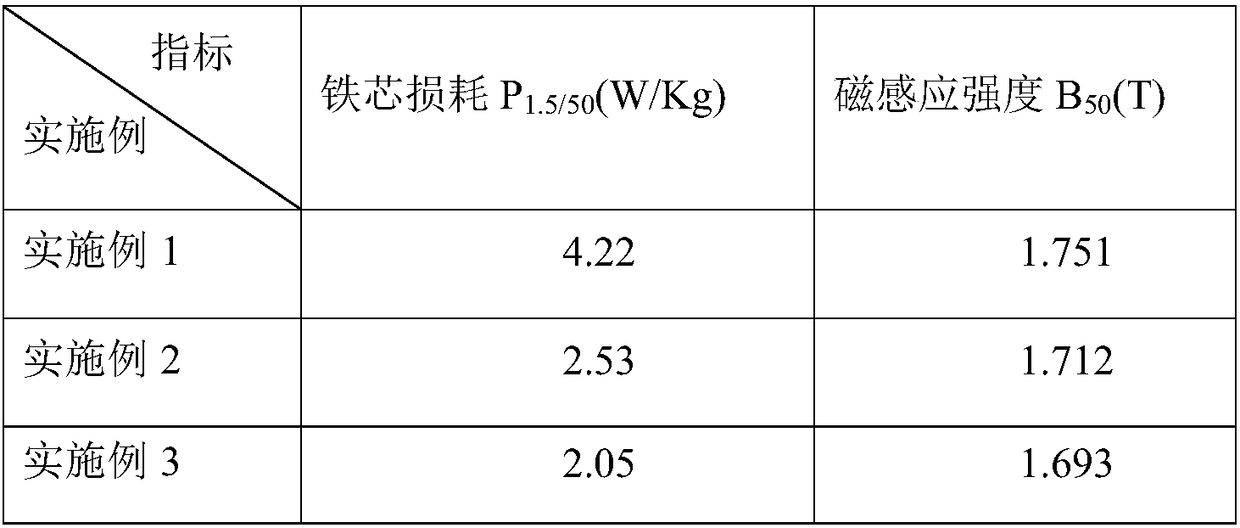

Method for preparing compound element processed non-oriented silicon steel for high-efficiency motor

The invention discloses a method for preparing compound element processed non-oriented silicon steel for a high-efficiency motor and belongs to the technical field of electrical steel. A non-oriented electrical steel casting blank into which a certain amount of Ca, a certain amount of La and a certain amount of B are added serves as the raw material, smelting, forging, hot rolling, normalizing, acid pickling, primary cold rolling, intermediate annealing, secondary cold rolling and finished product annealing are conducted in sequence, the temperature and time of finished product annealing are controlled to be 900-940 DEG C and 3-5 min respectively, and the non-oriented silicon steel product, which is low in iron loss and high in magnetic strength, for the high-efficiency motor is obtained finally. The final magnetic performance of the product is that when a steel plate is 0.5 mm thick, P15 / 50=3.6-3.9 W / kg, and B5000=1.76-1.80 T. The steel belt finished product can be widely applied to large and medium motor manufacturing as well as variable-frequency air conditioner compressor manufacturing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

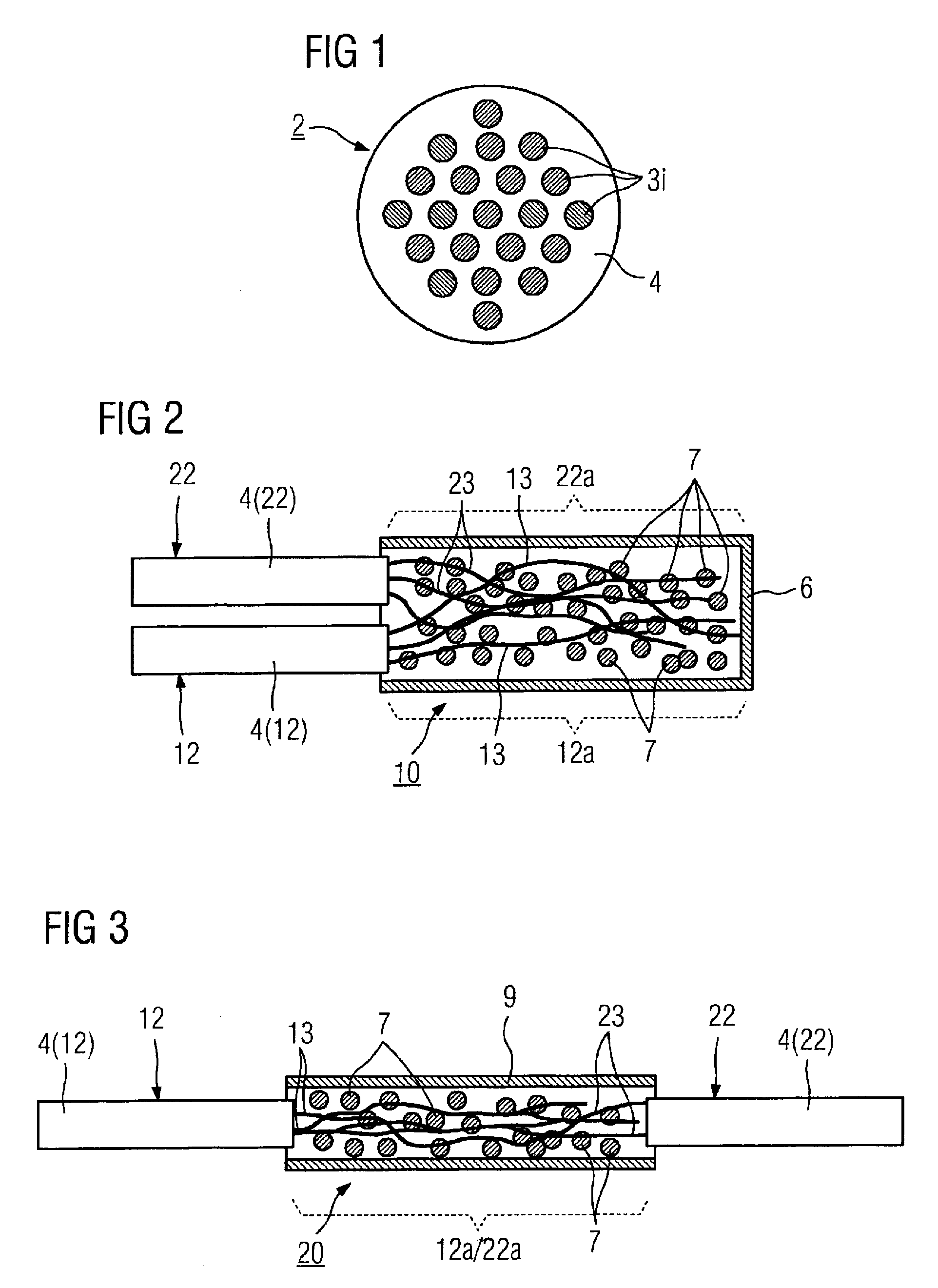

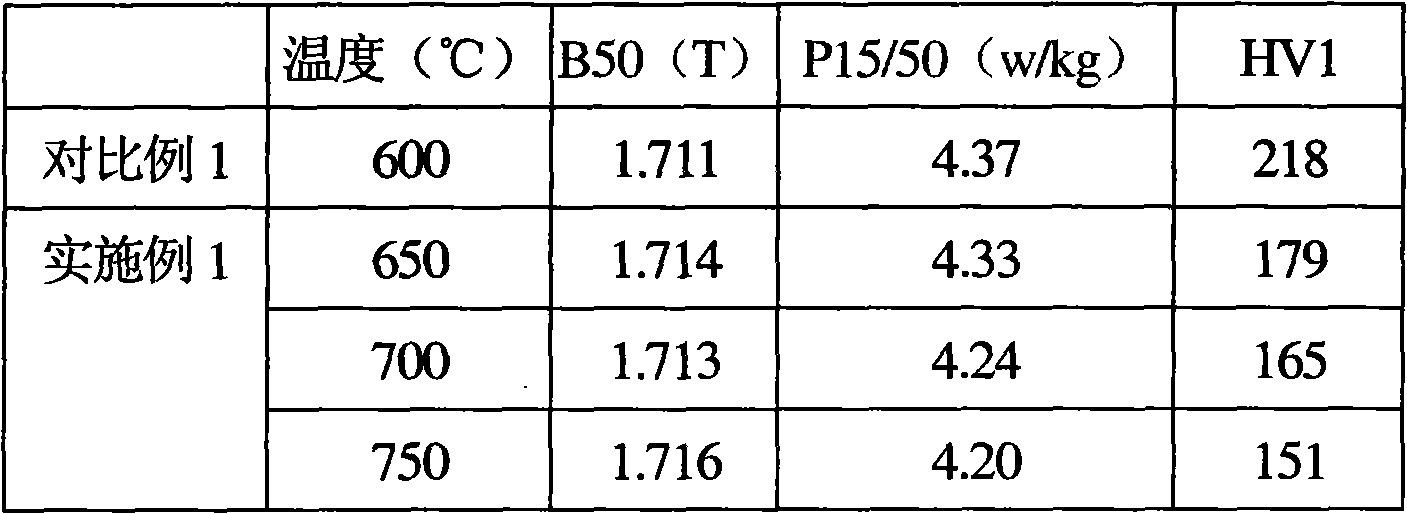

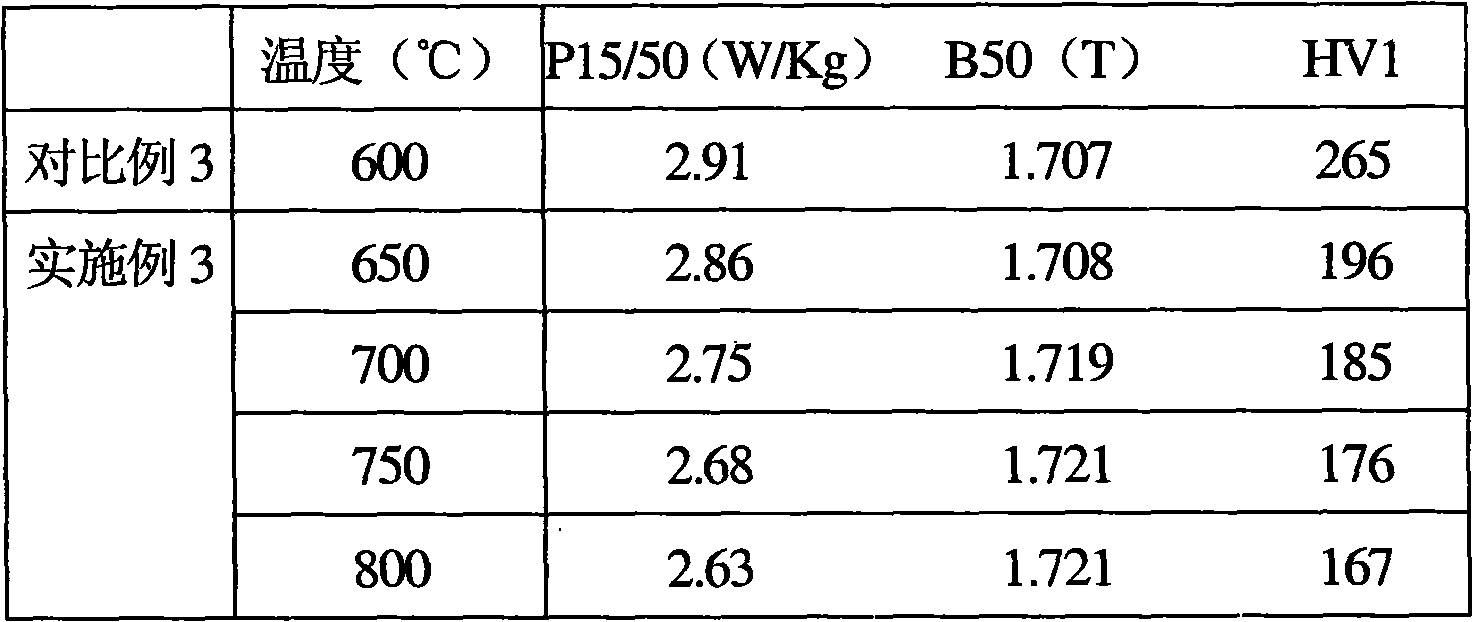

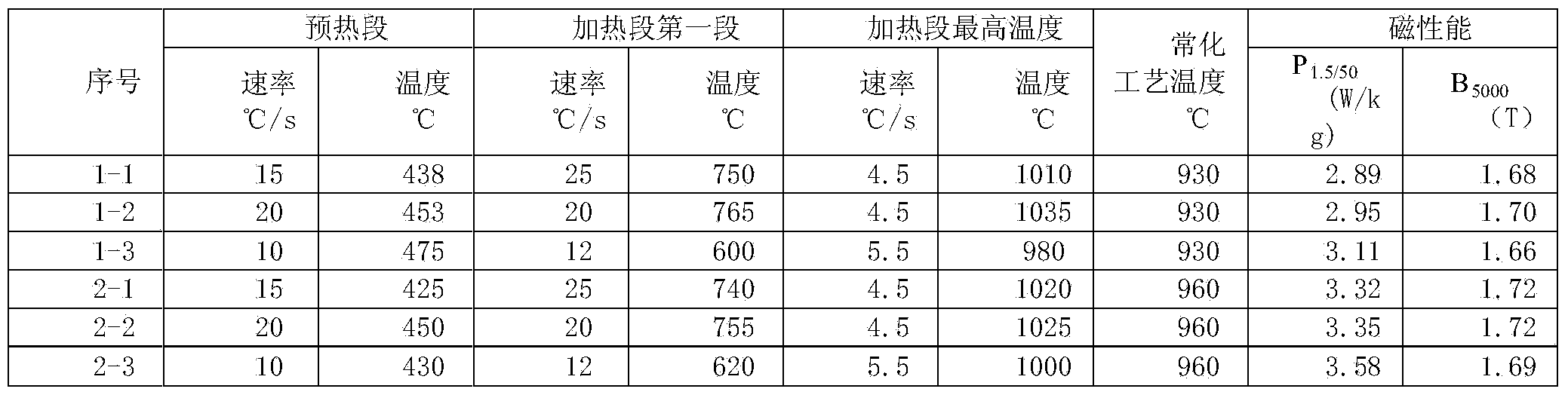

Non-oriented electrical steel with high magnetic induction and manufacturing method thereof

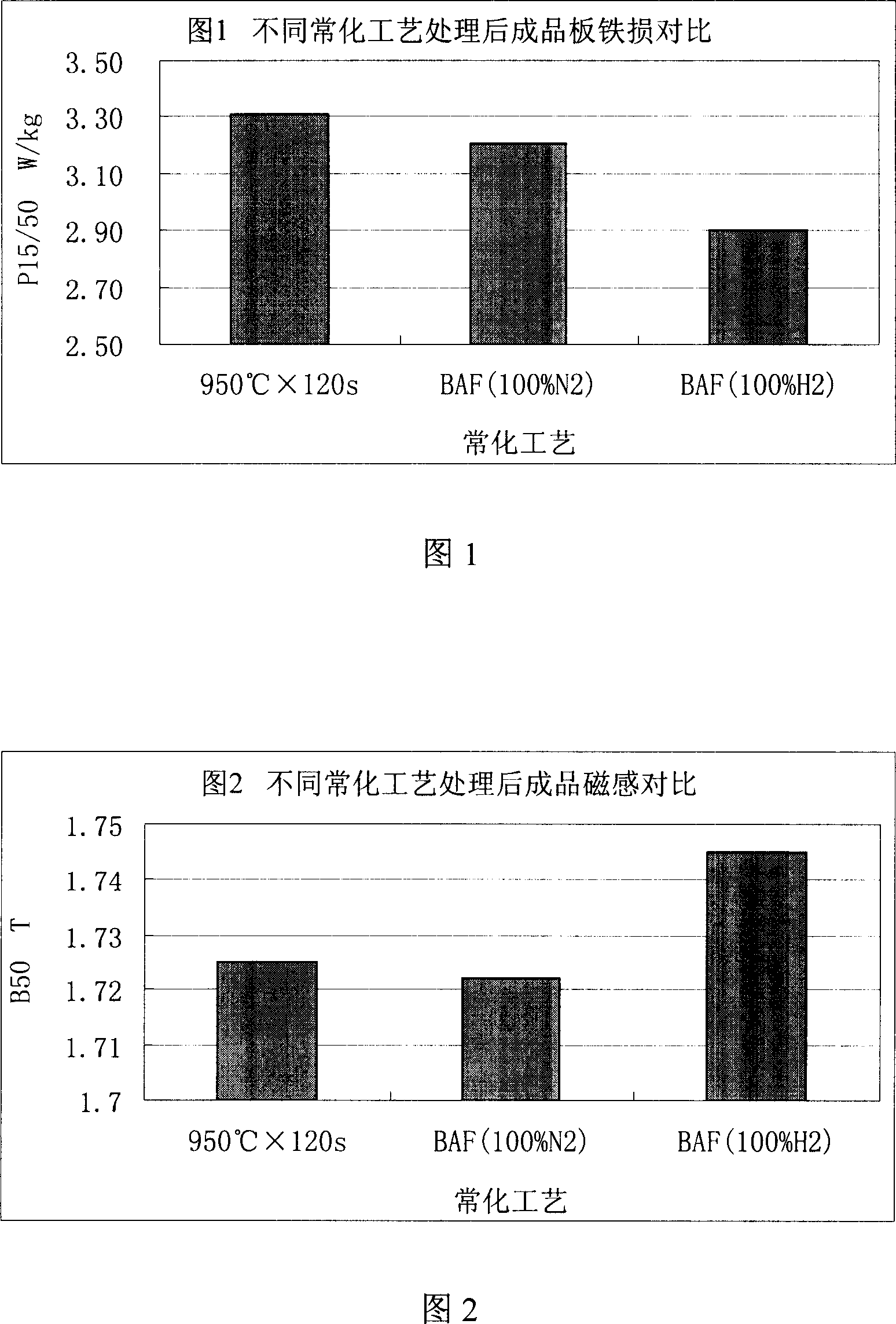

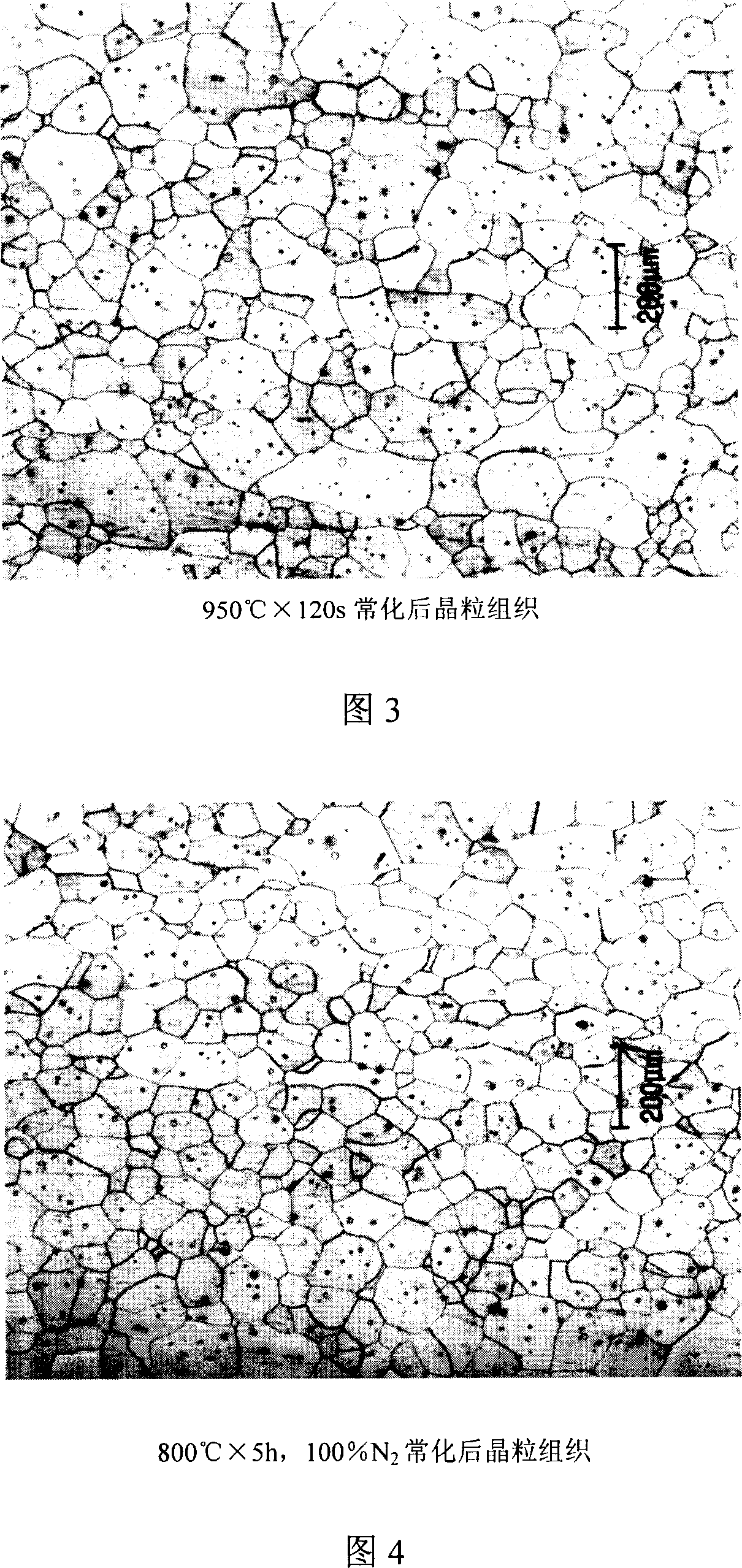

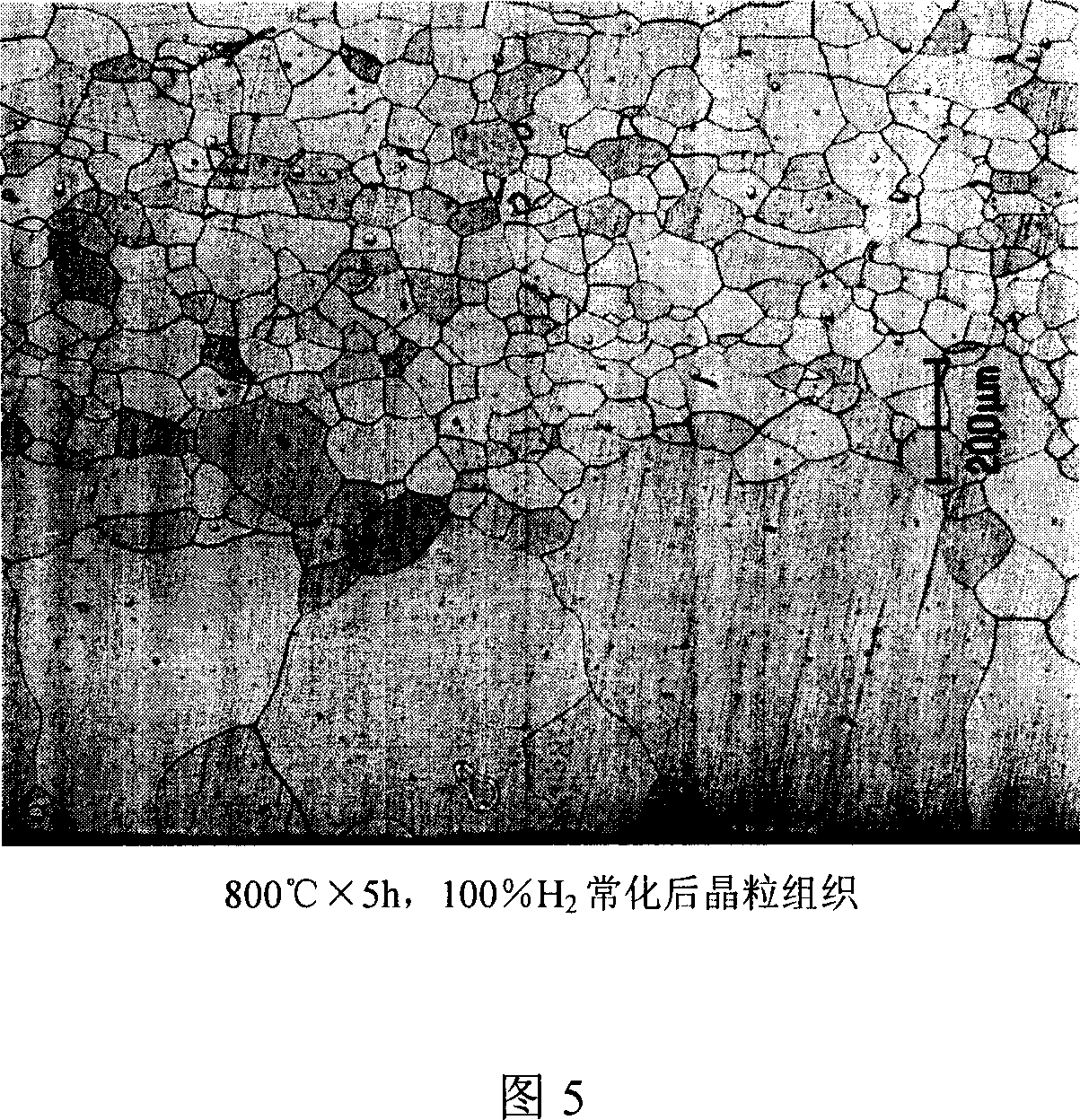

The invention relates to non-oriented electrical steel with high magnetic induction and a manufacturing method of the steel. According to the manufacturing method of the steel, high-quality board raw materials are provided for the subsequent processes by controlling heating speed of a normalizing and heating stage, controlling a speed of a normalizing and cooling stage and using cooperation of proper blasting and pickling processes. The magnetic induction B50 of the manufactured non-oriented electrical steel is increased by 200-500 gausses, and the quality level of the iron loss material object is increased by 3-5% under the conditions that additional alloy elements are not added and the annealing process of the finished product is not changed; and the magnetic property of the manufactured non-oriented electrical steel is further improved by optimizing the annealing process, so that the magnetic induction is further improved. The manufactured non-oriented electrical steel can meet the requirements of normal motors and also can meet the requirement of high magnetic induction of electrical steel applied to iron cores of efficient motors and frequency-variable motors; the efficiency of the motors can be improved; and the energy consumption and the noise of the manufactured non-oriented electrical steel can be reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

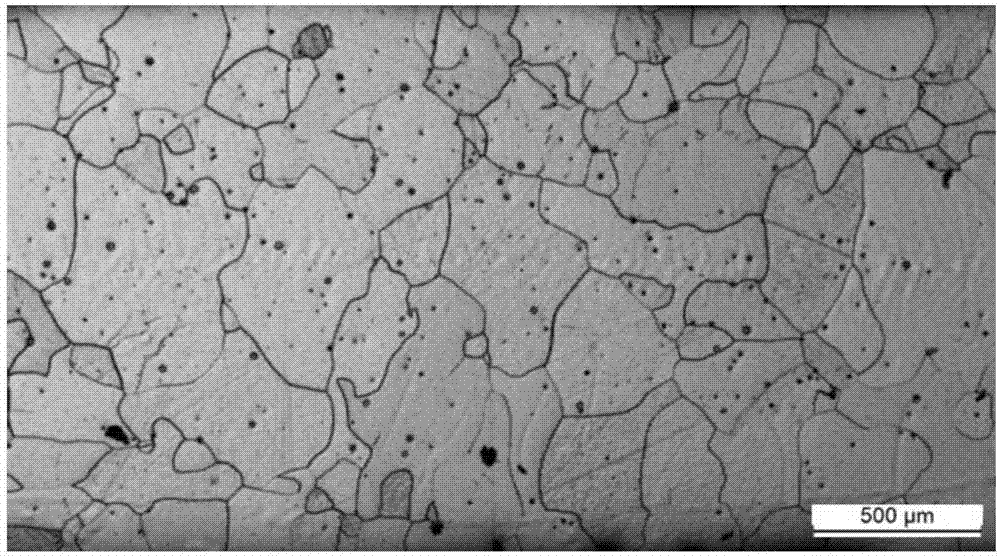

Preparation method of high-magnetic-strength thin-gauge non-oriented silicon steel

InactiveCN104294022ASignificantly improved magnetic senseSoft magnetic liftIngot castingMetallic materials

The invention belongs to the field of metal material processing and relates to high-magnetic-strength thin-gauge non-oriented silicon steel and a preparation method thereof. The preparation method of the high-magnetic-strength thin-gauge non-oriented silicon steel comprises the following steps: selecting a silicon steel ingot casting as a raw material, wherein the silicone steel ingot casting contains the following components (in percent by mass): 2.8-3.2% of Si, 0.025-0.045% of C, 0.05-0.35% of Mn, less than or equal to 0.008% of P, less than ore equal to 0.005% of N, less then or equal to 0.02% of S and balance of Fe and inevitable impurities, and volume percent of columnar crystals in the ingot casting is 50-100%; heating the silicon steel ingot casting to 1200-1350 DEG C, carrying out hot rolling, normalizing at the temperature of 1110-1150 DEG C, rolling until thickness is 0.12-0.2mm by adopting a two-stage cold-rolling method including intermediate annealing, then carrying out decarburizing annealing, and finally carrying out final annealing for 10-20 minutes at the temperature of 900-950 DEG C. The preparation method of the high-magnetic-strength thin-gauge non-oriented silicon steel has the advantages that a processing technology easier to implement is adopted and a thin-gauge non-oriented silicon steel product with magnetic strength B50 more than 1.73T is obtained.

Owner:UNIV OF SCI & TECH BEIJING

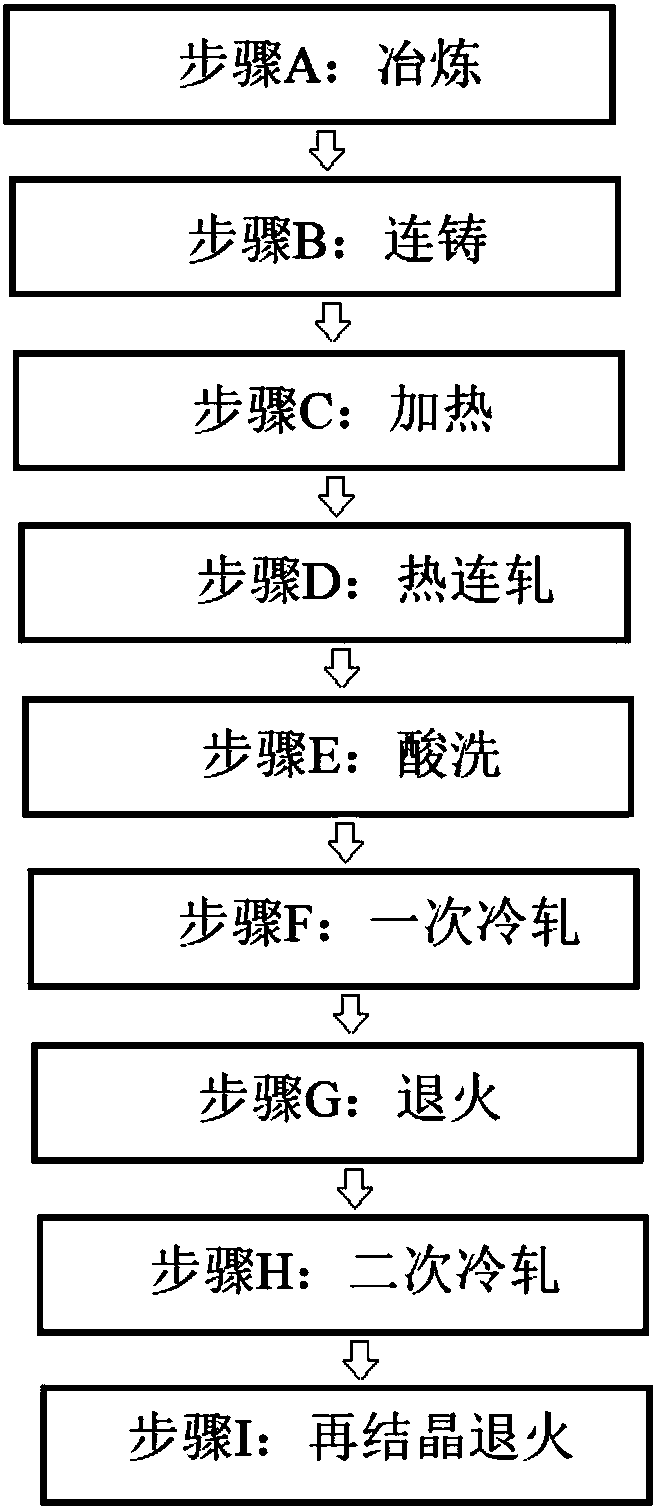

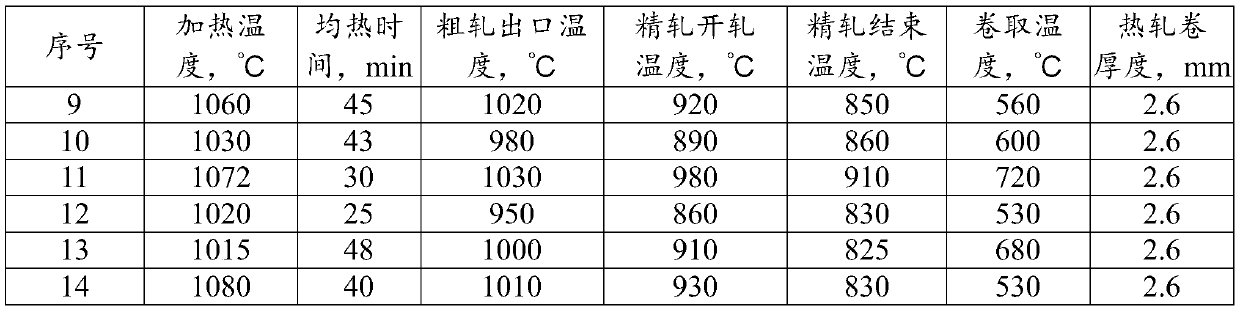

Method for producing non-oriented electrical steel with high magnetic induction and low iron loss by CSP process

The invention discloses a method for producing non-oriented electrical steel with high magnetic induction and low iron loss by a CSP process, and relates to a production method of non-oriented electrical steel. The method comprises the following steps that step A, smelting is carried out; step B, continuous casting is carried out; step C, heating is carried out; step D, hot continuous rolling is carried out; step E, pickling is carried out; step F, one-time cold rolling is carried out; step G, annealing is carried out; step H, secondary cold rolling is carried out; and step I, recrystallization and annealing are carried out. The purpose of the method is to overcome the defect of unqualified magnetic properties caused by too large cold rolling reduction rate in the process of producing non-oriented electrical steel by an existing CSP process, and the produced non-oriented electrical steel has excellent magnetic properties of high magnetic induction and low iron loss under the premise that the total pressure reduction rate of cold rolling is far greater than 85%.

Owner:INNER MONGOLIA UNIV OF TECH

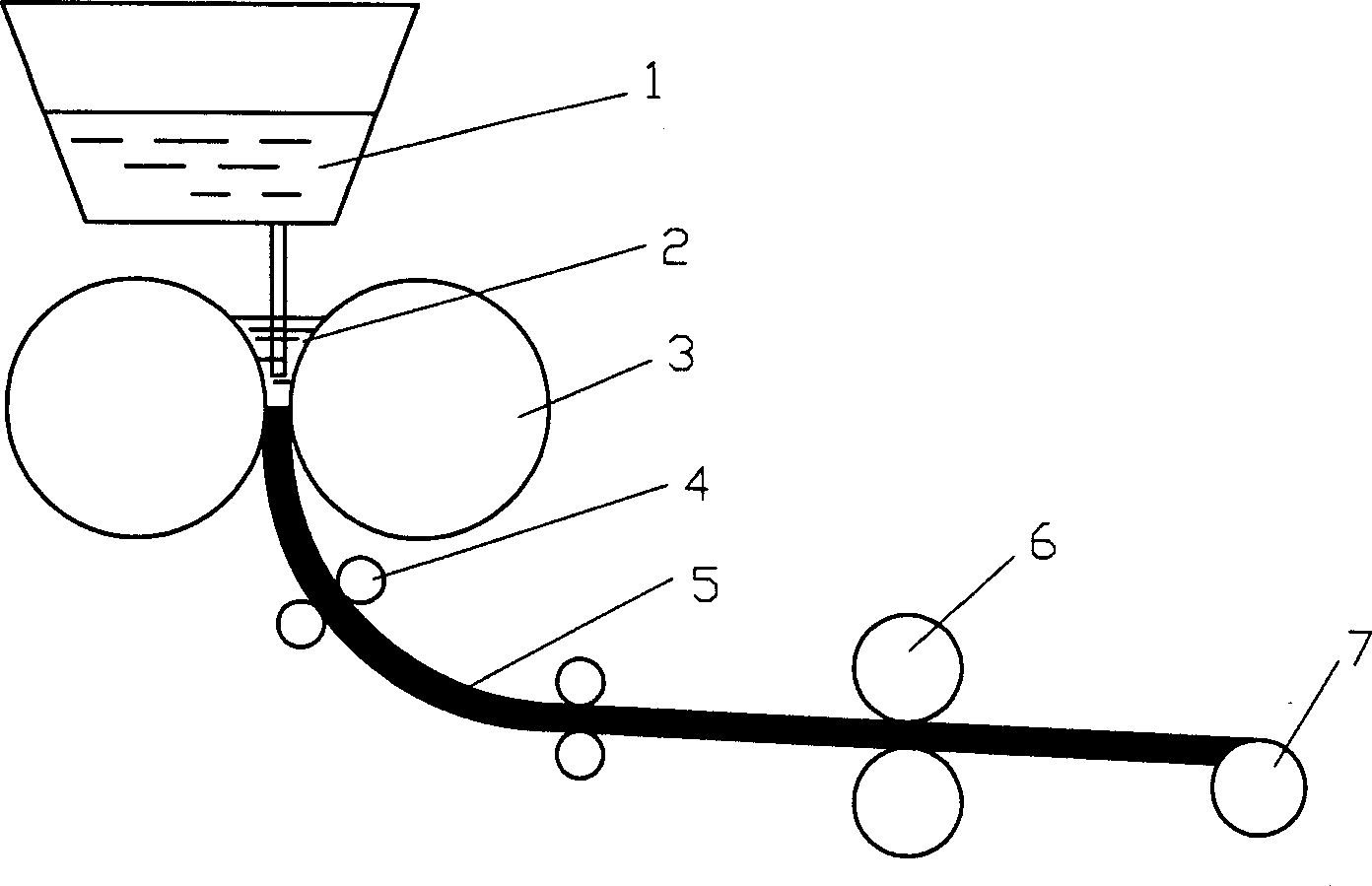

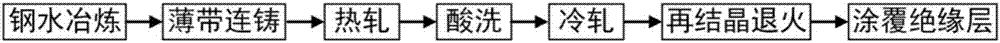

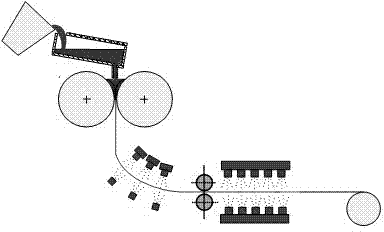

Method for preparing non-oriented electrical steel for high-efficient motor via twin roll strip casting

The invention belongs to the technical field of metallurgy, and in particular relates to a method for preparing non-oriented electrical steel for a high-efficient motor via twin roll strip casting. The method comprises the following steps: firstly, smelting molten steel according to components; then controlling a pouring temperature within 1600 DEG C to 1540 DEG C; pouring the molten steel into a rotating steel roller through a tundish; rapidly solidifying and molding so as to obtain a casting strip; cooling the casting strip; rolling the casting strip at 500 DEG C to 700 DEG C; performing acid pickling on the casting strip; and then performing cold rolling and annealing on the casting strip, thereby obtaining the non-oriented electrical steel for the high-efficient motor. The crystallite grain dimensions and the structural components of the casting strip are controlled by virtue of the special advantages of a casting-rolling process, so that the crystallite grain dimensions and the favorable structural components of an annealing plate are fully improved. As a result, the magnetic property of the non-oriented electrical steel is improved.

Owner:NORTHEASTERN UNIV

Non-Oriented Electrical Steel Having High Magnetic Induction And High Intensity And Manufacturing Method Thereof

InactiveUS20120298267A1Prominent deterioration in magnetic propertyHigh magnetic inductionElectrical steelHigh intensity

A non-oriented electrical steel has relative high magnetic induction and high intensity without increasing manufacturing difficulty. The weight percentage of the compositions of the electrical steel are as follows: C≦0.0040%, Si is 2.50% to 4.00%, Al is 0.20% to 0.80%, Cr is 1.0 to 8.0%, Ni is 0.5 to 5.0%, Mn≦0.50%, P≦0.30%, S≦0.0020%, N≦0.0030%, Ti≦0.0030%, Nb≦0.010%, V≦0.010%, C+S+N+Ti≦0.010%, and a balance substantially being Fe and inevitable impurities.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-oriented silicon steel for efficient inverter compressor and manufacturing method thereof

InactiveCN112210716AMeet low iron lossFulfil requirementsFurnace typesHeat treatment furnacesStrip steelIron oxide

The invention discloses non-oriented silicon steel for an efficient inverter compressor and a manufacturing method thereof, and belongs to the technical field of non-oriented silicon steel. The non-oriented silicon steel comprises the following chemical components in percentage by weight: less than or equal to 0.003% of C, 2.0%-2.7% of Si, 0.2%-0.5% of Mn, 0.2%-0.7% of Als, 0.06%-0.11% of Sn, lessthan or equal to 0.005% of S, less than or equal to 0.03% of P, less than or equal to 0.003% of N, less than or equal to 0.003% of Ti and the balance of Fe and inevitable impurities. The preparationprocess includes smelting, continuous casting, heating, hot rolling, normalizing pickling, cold rolling, annealing and coating. In the normalizing pickling process, the normalizing temperature is 880-940 DEG C, the normalizing time is 2-5 minutes, shot blasting treatment is carried out after normalizing to remove oxide scales on the surface of the strip steel, then hydrochloric acid is adopted forpickling, the pickling temperature is 75-90 DEG C, and it is ensured that the surface of the strip steel is cleaned up. The invention aims to overcome the defect of high iron loss of non-oriented silicon steel with high magnetic induction and magnetic property in the prior art, and can meet the requirements of low iron loss and high magnetic induction and magnetic property for the high-efficiencyinverter compressor.

Owner:MAANSHAN IRON & STEEL CO LTD

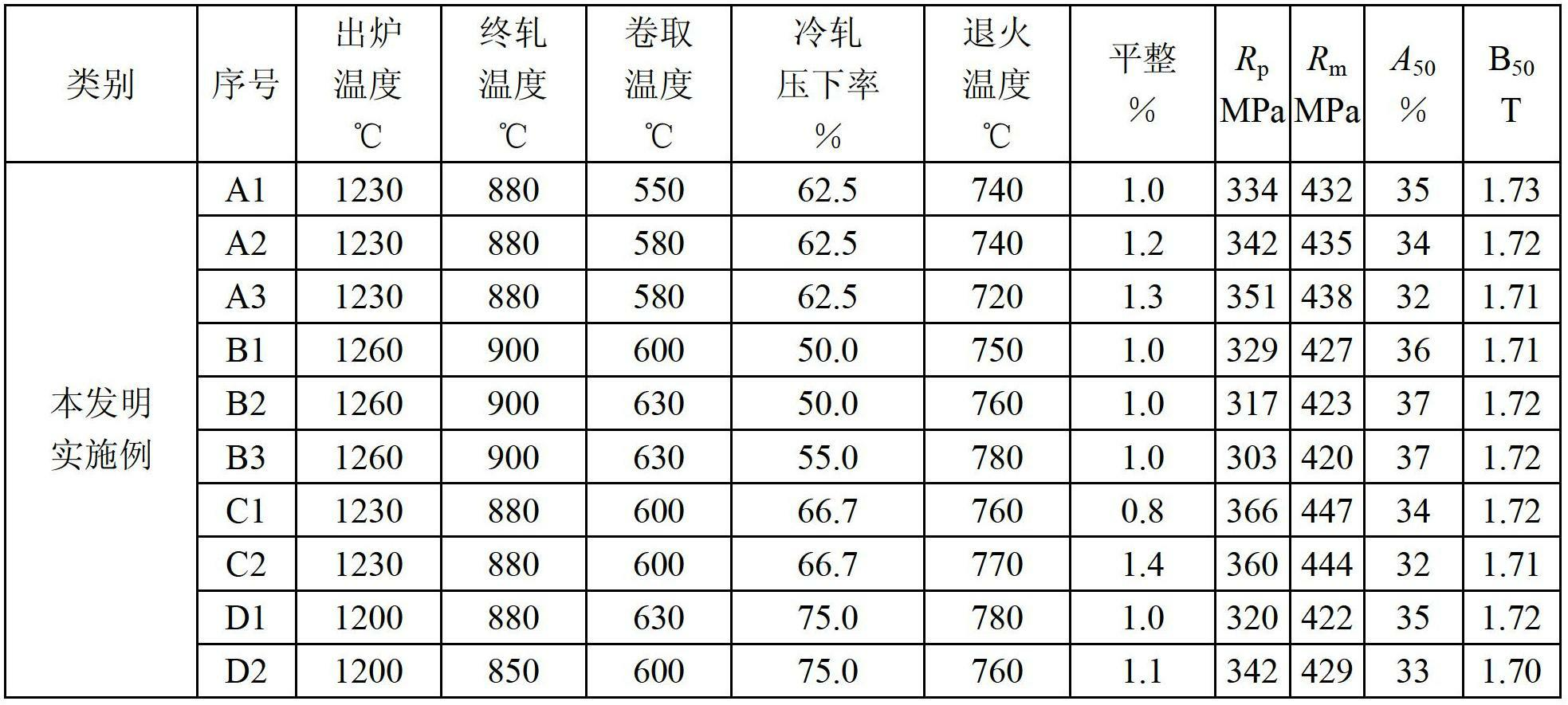

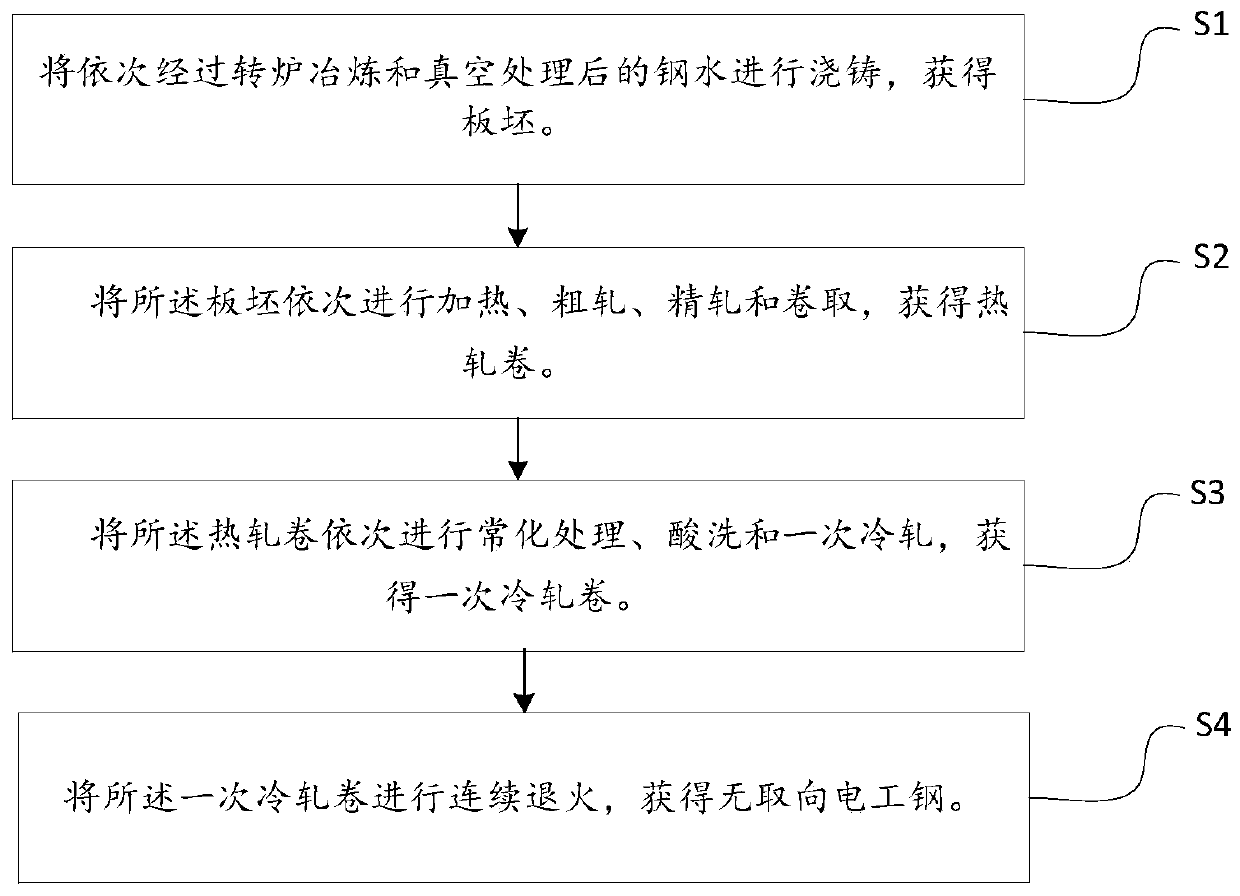

Manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel

ActiveCN102650016AFully exert the strengthening effectImprove shape qualityRoll mill control devicesMetal rolling arrangementsReduction rateHeating time

The invention discloses a manufacturing method for high-magnetic induction low-cost 250 MPa cold-rolled magnetic pole steel. The manufacturing method comprises the steps as follows: heating a plate blank to be 1200-1260 DEG C and insulating; hotly rolling, wherein the final rolling temperature is 850-900 DEG C, the coiling temperature is 550-630 DEG C and a jet water cooling way is adopted as a cooling way; cooling to be 60-80 DEG C for acid washing, wherein an air cooling way is adopted as the cooling way; coldly rolling, wherein the cold rolling reduction rate is 50-75%; continuously annealing, wherein the temperature of an uniform heating section is 720-780 DEG C and the uniform heating time is 60-200 s; and flattening by a flattening elongation rate of 0.8-1.4% to prepare the 250 MPa cold-rolled magnetic pole steel. The produced magnetic pole steel has lower yield strength ReL of more than 250 MPa and magnetic induction strength B50 of more than 1.70 T, and is suitable for manufacturing a magnetic pole iron core of a rotor body of a large water-wheel generator.

Owner:BAOSHAN IRON & STEEL CO LTD

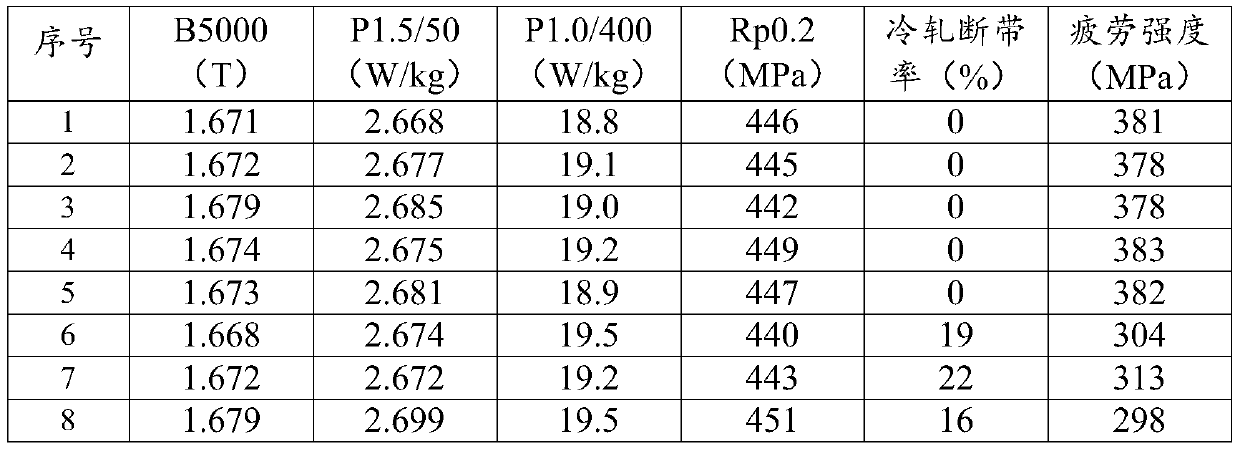

Non-oriented electrical steel and preparing method and application thereof

ActiveCN111057821AImprove cleanlinessHigh magnetic inductionFurnace typesMagnetic circuit characterised by magnetic materialsElectrical steelElectric machine

The invention discloses non-oriented electrical steel and a preparing method and application thereof. The non-oriented electrical steel comprises chemical components including, by mass percent, not larger than 0.004% of C, 1.8 to 4.00% of Si, 0.30 to 1.20% of Al, 0.40 to 1.0% of Mn, 0.50 to 2.0% of Ni, 0.50 to 2.0% of Cr, 0.010 to 0.10% of Sn, not larger than 0.0020% of S, not larger than 0.002% of N, not larger than 0.005% of V, not larger than 0.005% of Ti, not larger than 0.002% of P, not larger than 0.7% of the sum of mass percents of Ga and Hf, and the balance Fe and inevitable impurities. Component design is adopted, a preparing process is matched, the obtained non-oriented electrical steel is excellent in comprehensive properties of iron loss, magnetic induction and mechanical properties, in the production process, no strip breaking exists, and reliability and high efficiency of a motor core can be improved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

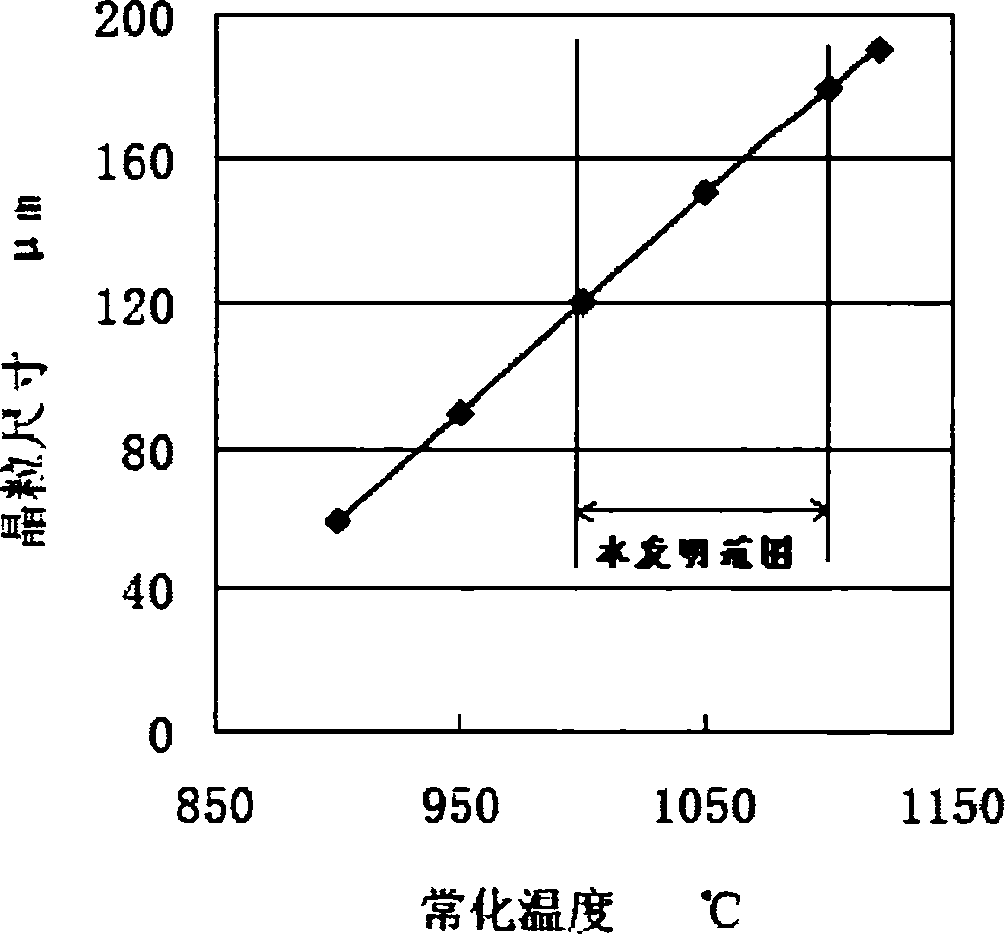

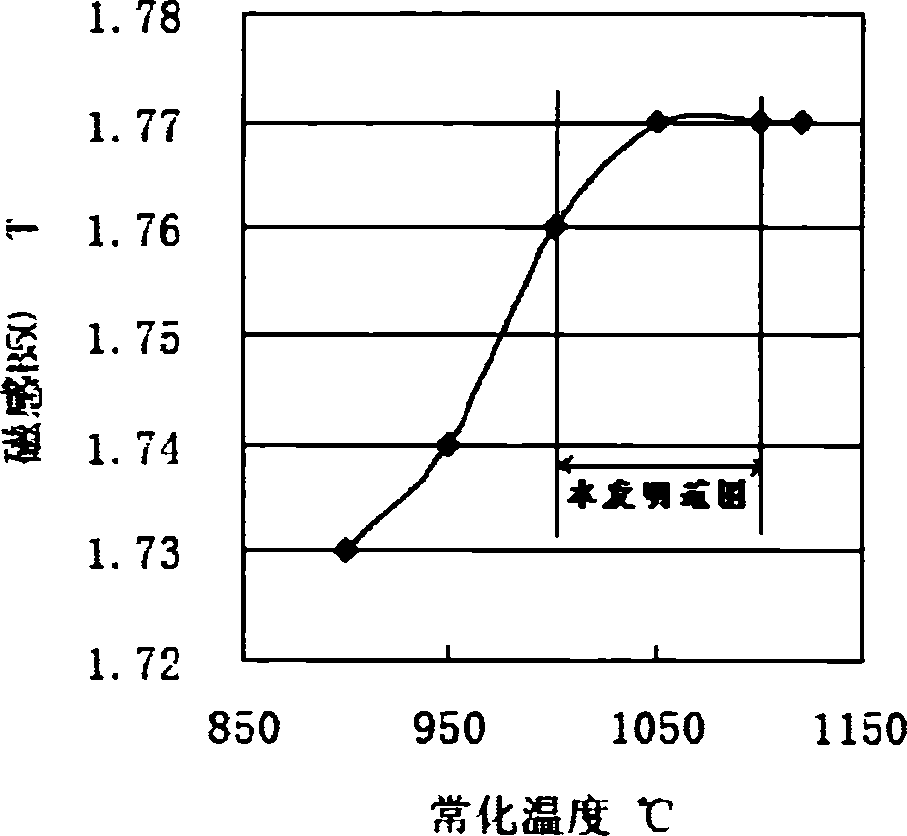

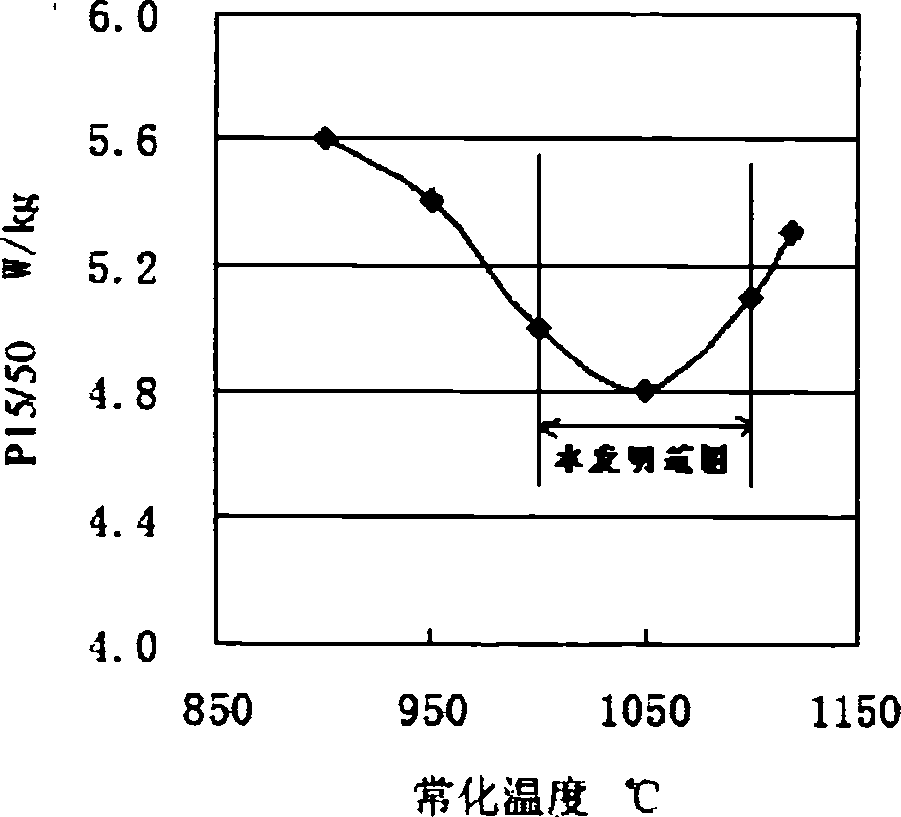

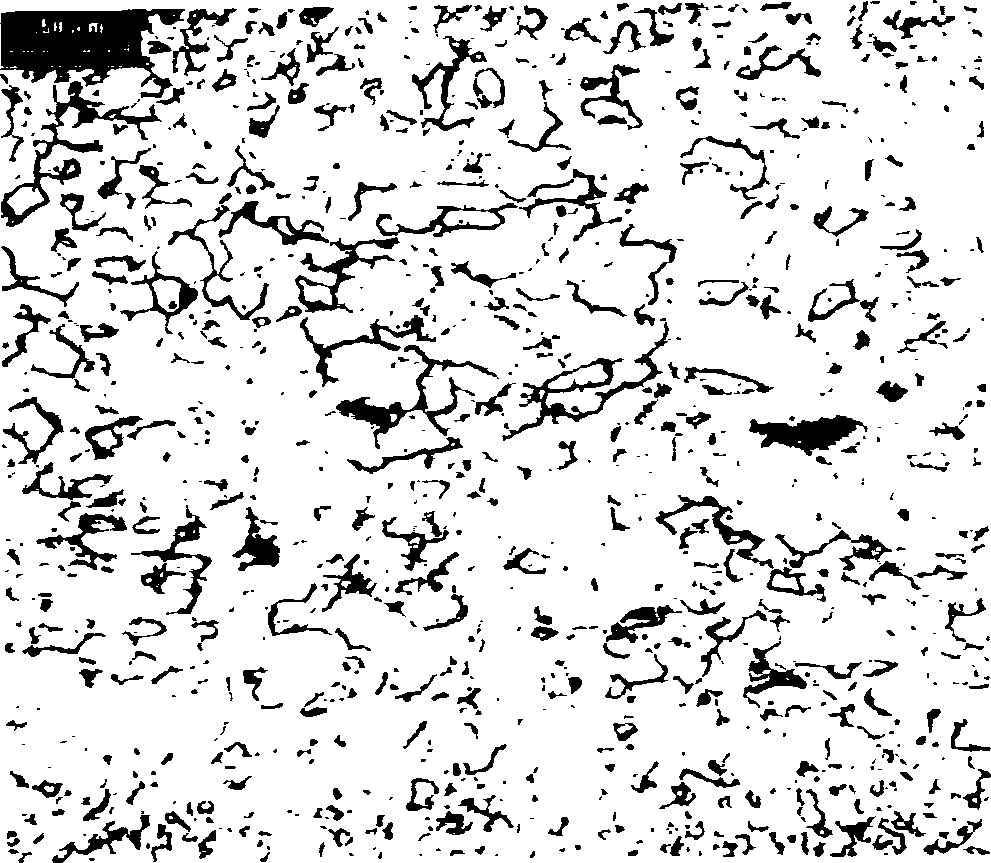

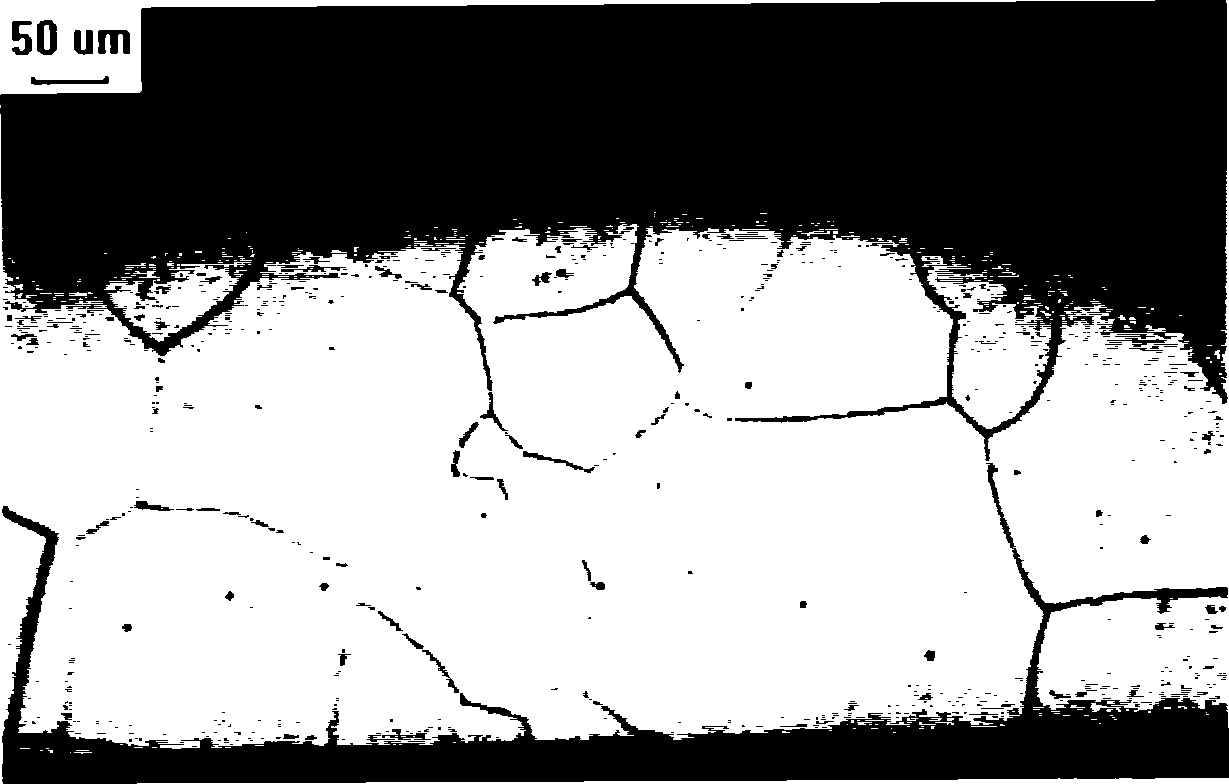

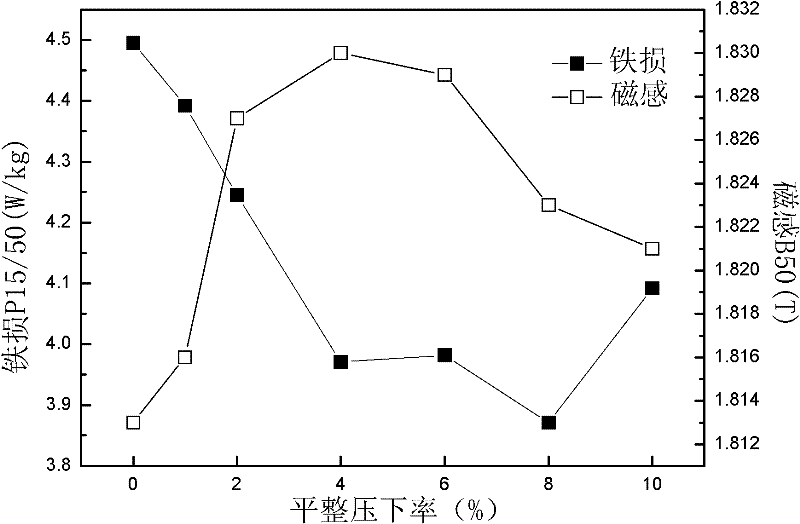

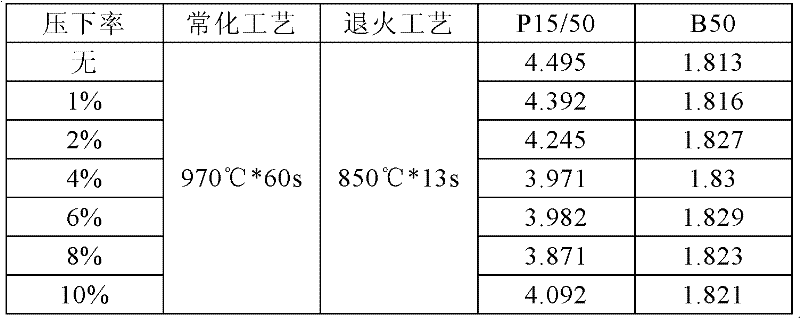

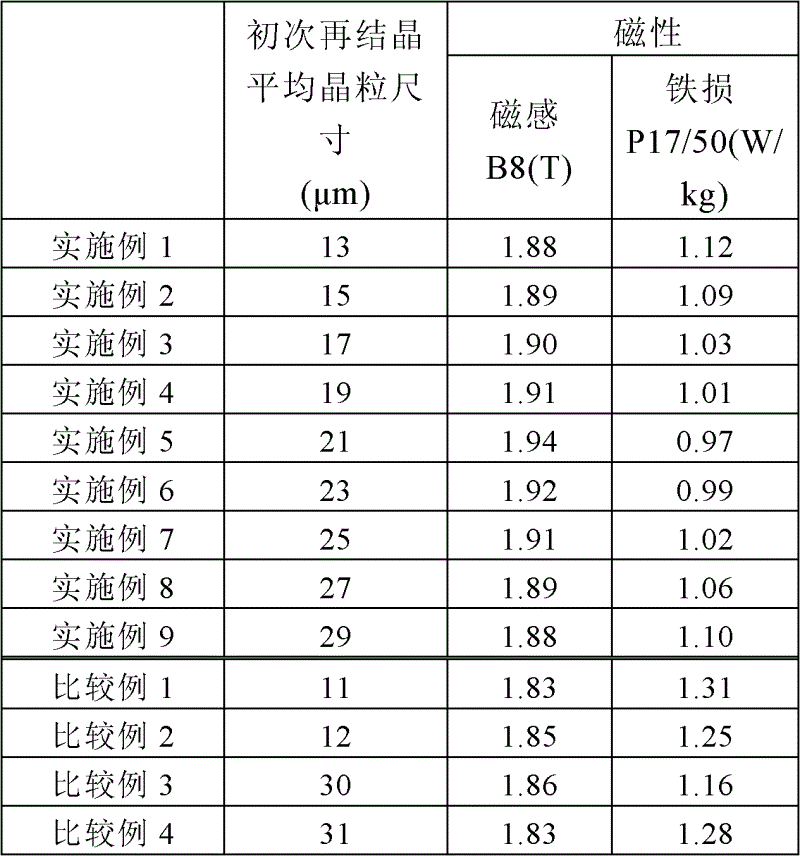

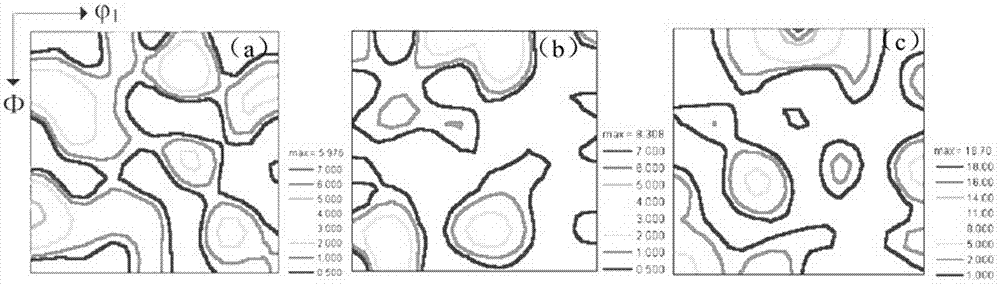

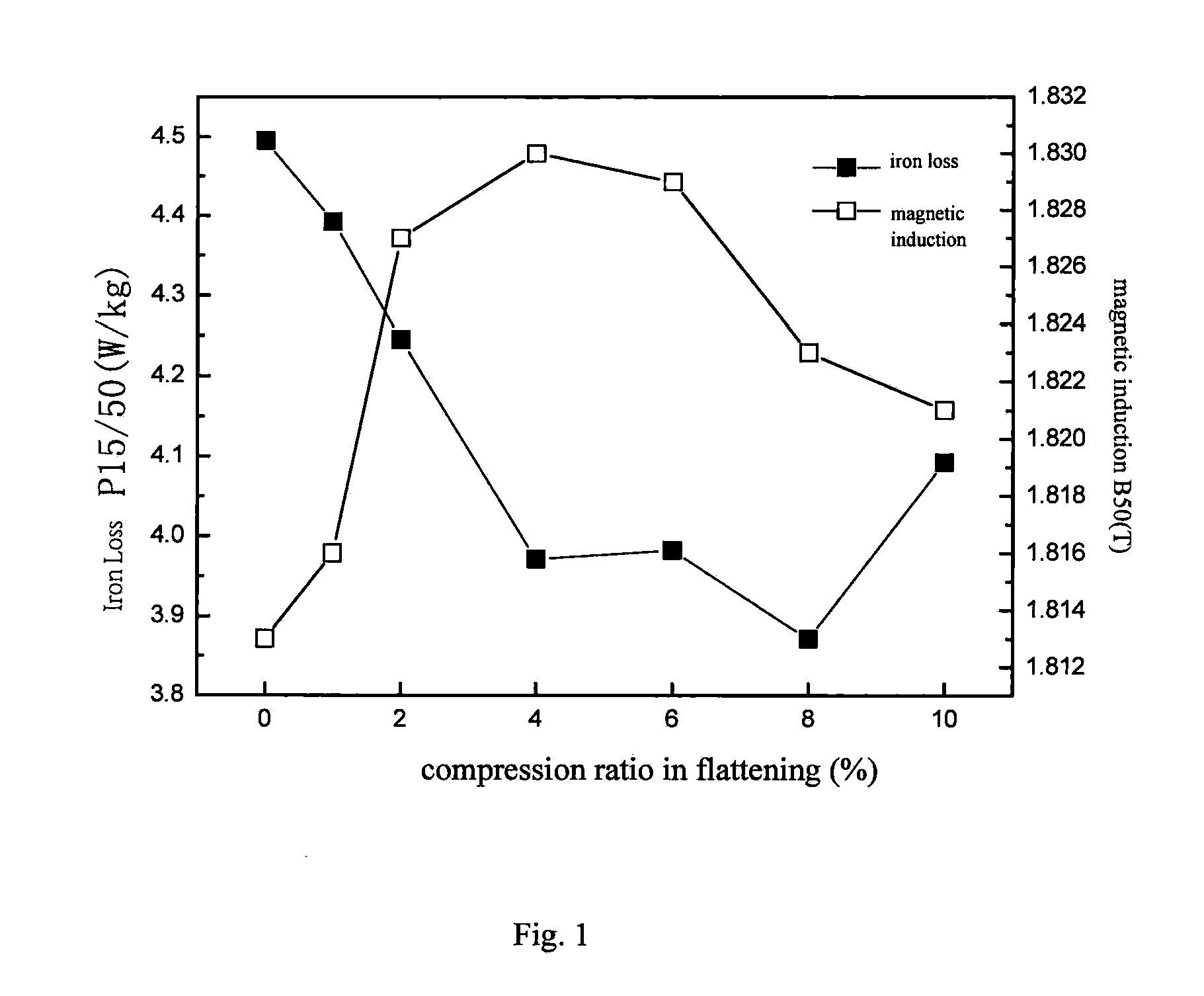

Manufacture Process Of Non-Oriented Silicon Steel With High Magnetic Induction

InactiveUS20120285584A1Increase the granular structureImprove textureInorganic material magnetismMetal rolling arrangementsChemical compositionSilicon

A manufacture process of non-oriented silicon steel with high magnetic induction includes smelting and casting steel having a chemical composition by weight percent: Si 0.1˜1%, Al 0.005˜1.0%, C≦0.004%, Mn=0.10˜1.50%, P≦0.2%, S≦0.005%, N≦0.002, Nb+V+Ti≦0.006%, and the rest is Fe. The steel is cast into a billet, which is heated and hot-rolled to 1150˜1200° C. into a plate at a finish-rolling temperature 830˜900° C. The plate is cooled to a temperature ≧570° C. and cold-roll flattened at compression ratio 2˜5%. The flattened plate is normalized at temperature not below 950° C. for 30˜180s, and then pickled and cold-rolled into a sheet with thickness of the finished product. The sheet is finish-annealed quickly heating the sheet to 800˜1000° C. at temperature rise rate ≧100° C. / s, soaking the heated sheet for 5˜60s at the temperature, and then slowly cooling the sheet to 600˜750° C.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com