High-magnetic-induction low-iron-loss no-oriented silicon steel sheet and manufacturing method thereof

A technology of oriented silicon steel and manufacturing method, which is applied in the direction of manufacturing tools, inorganic material magnetism, furnace type, etc., can solve the problems of production site technology, quality management troubles, prolong material manufacturing and delivery cycle, increase manufacturing costs, etc., and achieve electromagnetic Excellent performance, easy operation, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

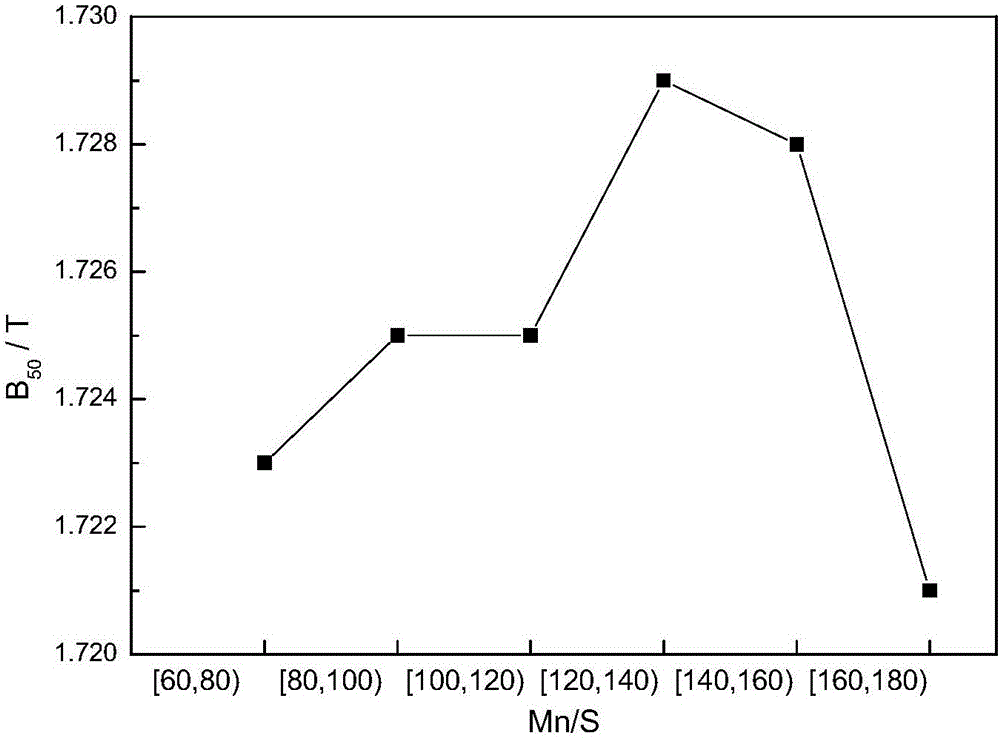

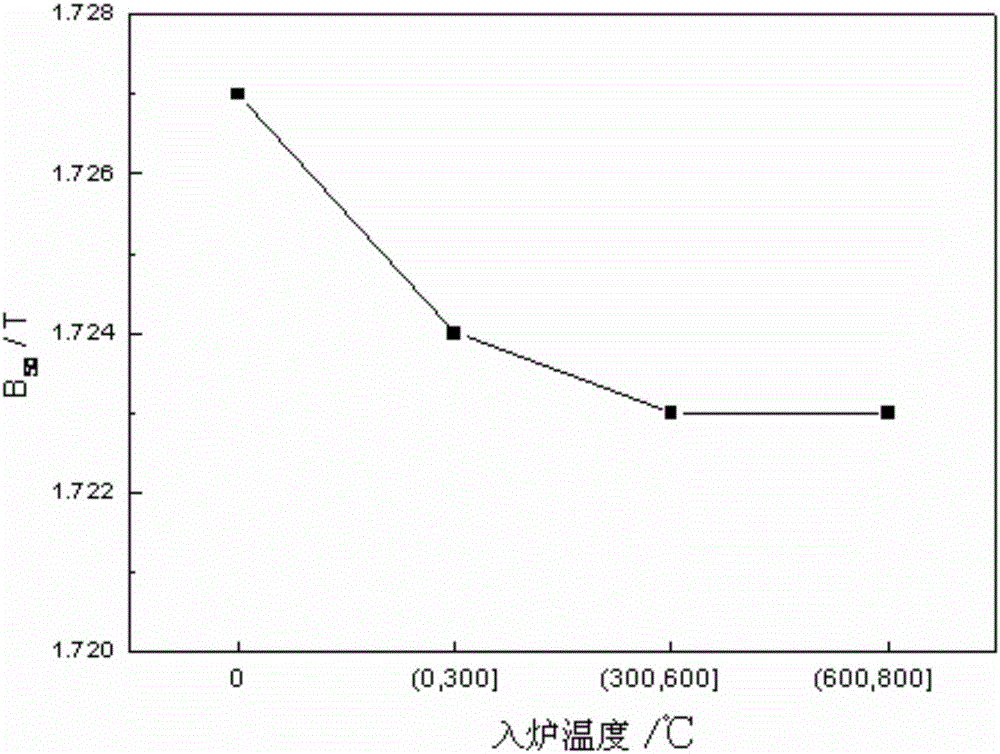

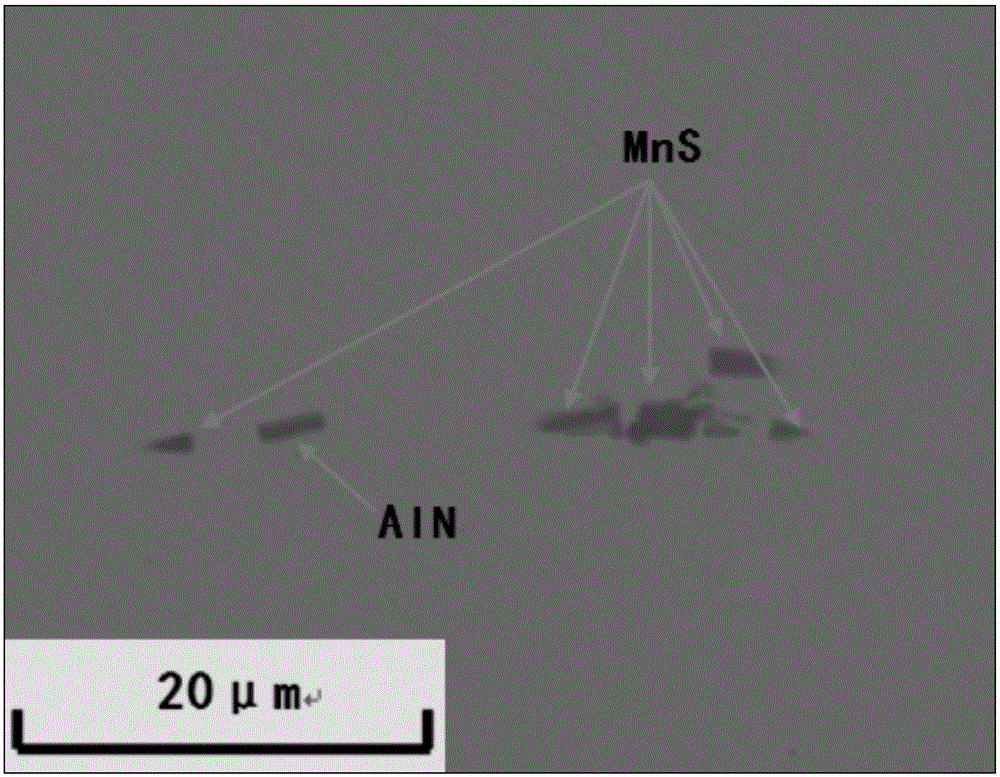

[0057] The molten iron and steel scrap are matched according to the chemical composition ratio in Table 1. After being smelted in a 300-ton converter, decarburization, deoxidation, and alloying are carried out by RH refining; the Mn content is dynamically adjusted according to the S content in the steel to obtain the optimal ratio of [Mn ] / [S], control the content of C, N, Nb, V, Ti, Al to meet the design requirements; after continuous casting of molten steel, a slab with a thickness of 170mm-250mm and a width of 800mm-1400mm is obtained; The cooling rate during the cooling process of billet surface temperature from 1100°C to 700°C is controlled at 2.5 to 20°C / min; then, the temperature of billet entering the furnace is adjusted to ≤600°C, preferably ≤300°C by means of temperature control; then, The slab is hot-rolled, pickled, cold-rolled, annealed, and coated in sequence to obtain the final product. The process parameters and electromagnetic properties are shown in Table 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com