Non-oriented silicon steel for efficient inverter compressor and manufacturing method thereof

A frequency conversion compressor, oriented silicon steel technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of motor energy saving, high iron loss, etc., to meet low iron loss, meet blanking requirements, yield strength and resistance Appropriate effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

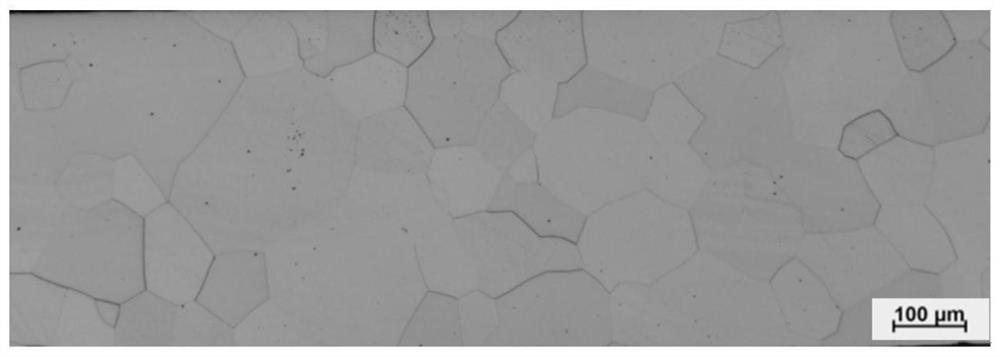

Image

Examples

Embodiment 1

[0041] A non-oriented silicon steel for high-efficiency frequency conversion compressors in this embodiment, its chemical composition percentage by weight: C: 0.003%, Si: 2.15%, Mn: 0.2%, Als: 0.3%, Sn: 0.08%, S: 0.005%, P: 0.03%, N: 0.002%, Ti: 0.002%, and the rest are Fe and unavoidable impurities.

[0042] A method for manufacturing non-oriented silicon steel for high-efficiency inverter compressors in this embodiment, the above-mentioned molten steel components are prepared according to the following preparation process: smelting-continuous casting-heating-hot rolling-normalized pickling-cold rolling-annealing- Coating, in the normalization pickling process, the normalization temperature is 880°C-940°C, and the normalization time is 2min-5min. After normalization, it undergoes shot blasting treatment to remove the oxide scale on the surface of the strip, and then pickles with hydrochloric acid. , pickling temperature 75 ℃ ~ 90 ℃, to ensure that the strip surface clean. In...

Embodiment 2

[0050] A non-oriented silicon steel for high-efficiency frequency conversion compressors in this embodiment, its chemical composition percentage by weight: C: 0.003%, Si: 2.25%, Mn: 0.3%, Als: 0.35%, Sn: 0.09%, S: 0.004%, P: 0.02%, N: 0.003%, Ti: 0.003%, and the rest is Fe and unavoidable impurities.

[0051] A method for manufacturing non-oriented silicon steel for high-efficiency inverter compressors in this embodiment is basically the same as in Embodiment 1, the difference is that in this embodiment, the molten steel refined in the RH furnace is continuously cast into a plate with a thickness of 220 mm Then the slab is directly loaded into the heating furnace for heating, wherein the temperature of the heating furnace is controlled at 1100°C, and the heating and holding time is 220min.

[0052] In this example, the above-mentioned slab is roughly rolled to an intermediate slab with a thickness of 35mm, and the rough rolling temperature is 930°C, and the hot-rolled plate is...

Embodiment 3

[0058] A non-oriented silicon steel for high-efficiency inverter compressors in this embodiment has a chemical composition in percentages by weight: C: 0.0028%, Si: 2.45%, Mn: 0.45%, Als: 0.51%, Sn: 0.11%, S: 0.003%, P: 0.03%, N: 0.002%, Ti: 0.002%, and the rest are Fe and unavoidable impurities.

[0059] A method for manufacturing non-oriented silicon steel for high-efficiency variable frequency compressors in this embodiment is basically the same as in Embodiment 1, the difference is that in this embodiment, the molten steel refined in the RH furnace is continuously cast into a plate with a thickness of 210mm Then the slab is directly loaded into the heating furnace for heating, wherein the temperature of the heating furnace is controlled at 1150°C, and the heating and holding time is 210min.

[0060] In this example, the above-mentioned slab is rough rolled to a 30mm thick intermediate slab, the rough rolling temperature is 930°C, and the hot rolled plate is finished 7 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com