Manufacture Process Of Non-Oriented Silicon Steel With High Magnetic Induction

a manufacturing process and non-oriented technology, applied in the direction of metal rolling arrangement, inorganic material magnetism, etc., can solve the problems of increasing electric loss in end use, weakening the magnetic induction of the sheet, and affecting the magnetic properties of non-oriented silicon steel, so as to improve the magnetic induction, improve the grain structure and texture, and improve the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0032](1) Hot-rolled non-oriented silicon steel plate with 2.6 mm thickness, its compositions and their contents are: Si 0.799%, Al 0.4282%, C 0.0016%, Mn 0.26%, P≦0.022%, S≦0.0033%, N≦0.0007%, Nb 0.0004%, V 0.0016%, Ti 0.0009%, the rest is Fe and unavoidable inclusions.

[0033](2) The hot-rolled plate is cold-rolled at a compression ratio of 1˜10%.

[0034](3) The cold-rolled plate is normalized at normalization soakage temperature of 970° C. and maintained at the temperature for 60s, thereafter the normalized plate is pickled, and then, cold-rolled into a Steel of 0.5 mm thickness.

[0035](4) the cold-rolled sheet is annealed at a high heating rate in an electric annealing furnace in a laboratory, with temperature rise rate of 250° C. / s, soakage temperature of 850° C. and soakage time of 13s.

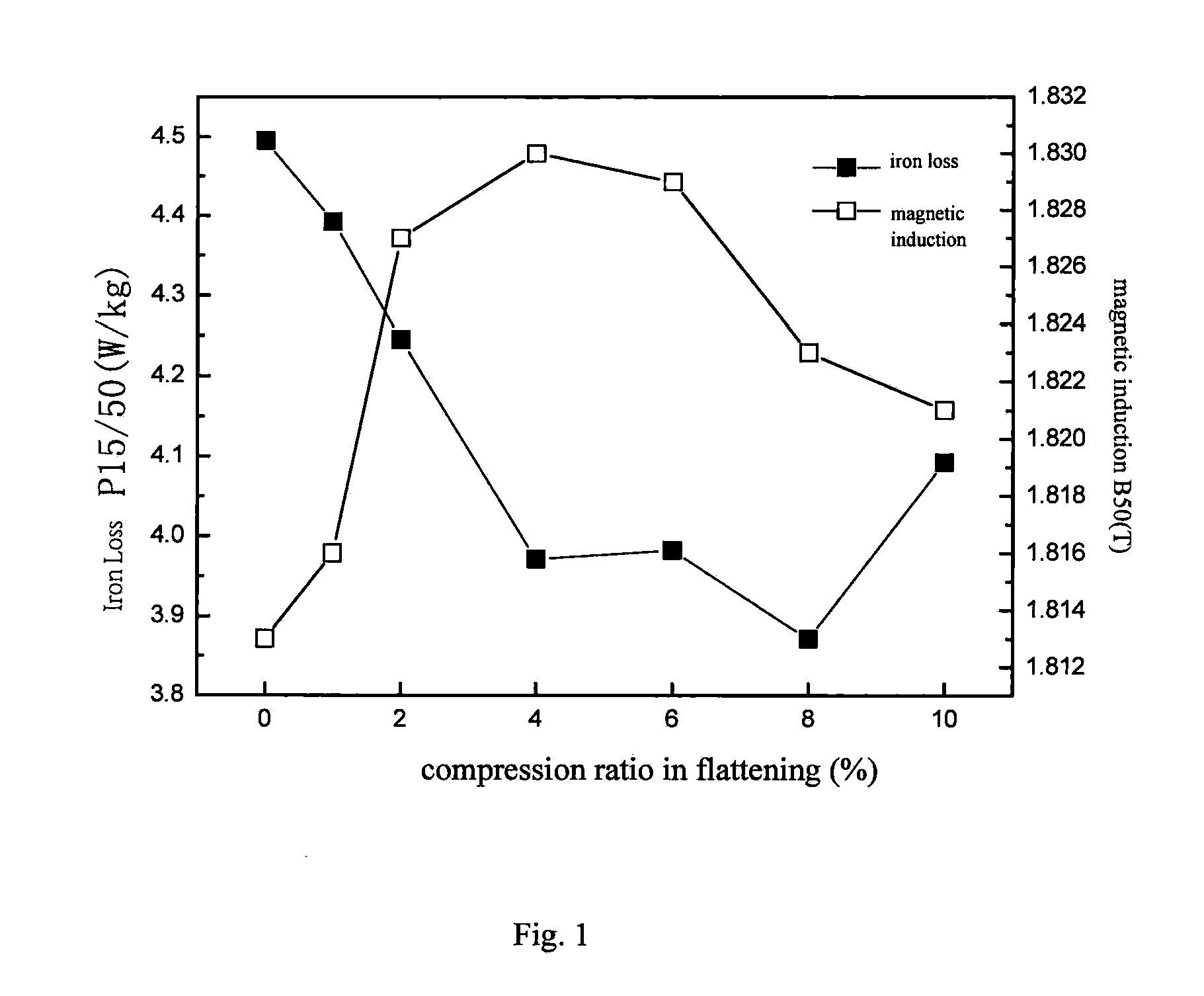

[0036]It is found that in the case of the hot-rolled plate being cold-rolled at a compression ratio of 1˜10%, the re-crystallized grains of the normalized sheet after being normalized become clearly ...

embodiment 2

[0038](1) Hot-rolled non-oriented silicon steel plate with 2.6 mm thickness, its compositions and their contents are: Si 1%, Al 0.2989%, C 0.0015%, Mn 0.297%, P 0.0572%, S 0.0027%, N 0.0009%, Nb 0.0005%, V 0.0015%, Ti 0.0011%, the rest is Fe and unavoidable inclusions.

[0039](2) The hot-rolled plate is cold-rolled at rolling compression ratio of 4%.

[0040](3) The cold-rolled plate is normalized at normalization soakage temperature of 950° C. and maintained at the temperature for 60s, thereafter, the normalized plate is pickled, and then cold-rolled into a Steel of 0.5mm thickness.

[0041](4) the cold-rolled sheet is annealed at a high heating rate in an electric annealing furnace in a laboratory, with different temperature rise rates of 20° C. Is, 150° C. / s and 250° C. Is, respectively, soakage temperature of 960° C. and soakage time of 13s.

[0042]The magnetic property of the finish-annealed sheet is shown in Table 3.

TABLE 3magnetic property of the finish-annealed non-oriented silicon St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com