Patents

Literature

85results about How to "Reduce lattice distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

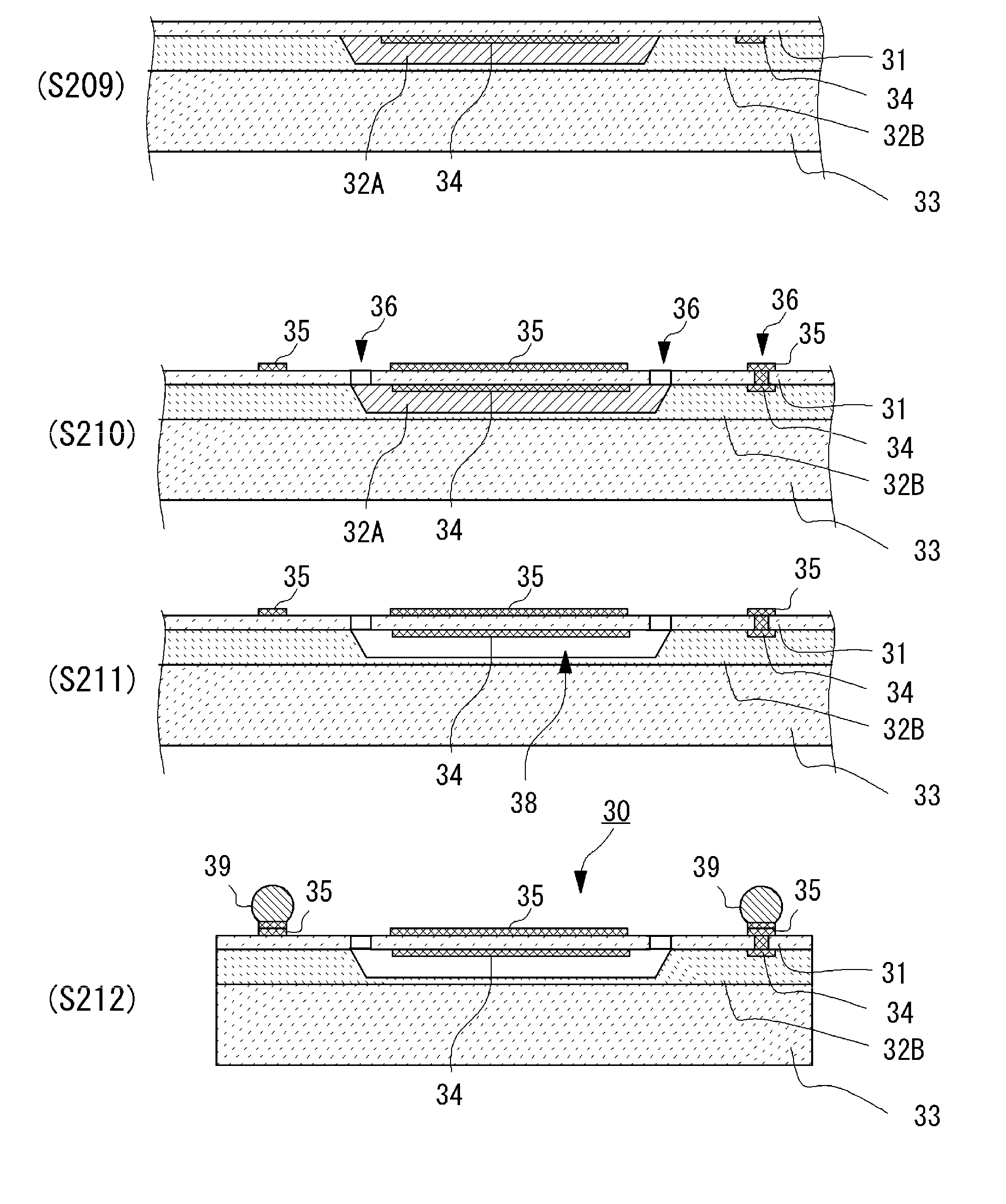

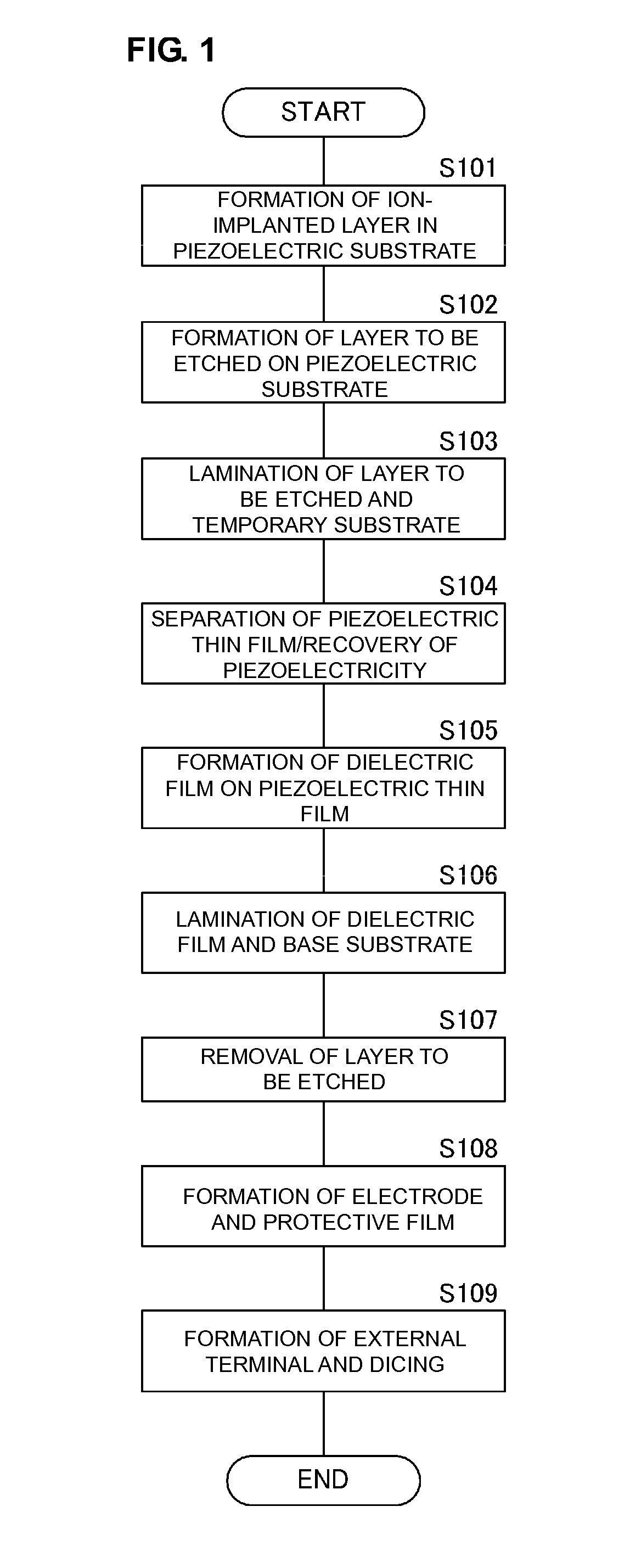

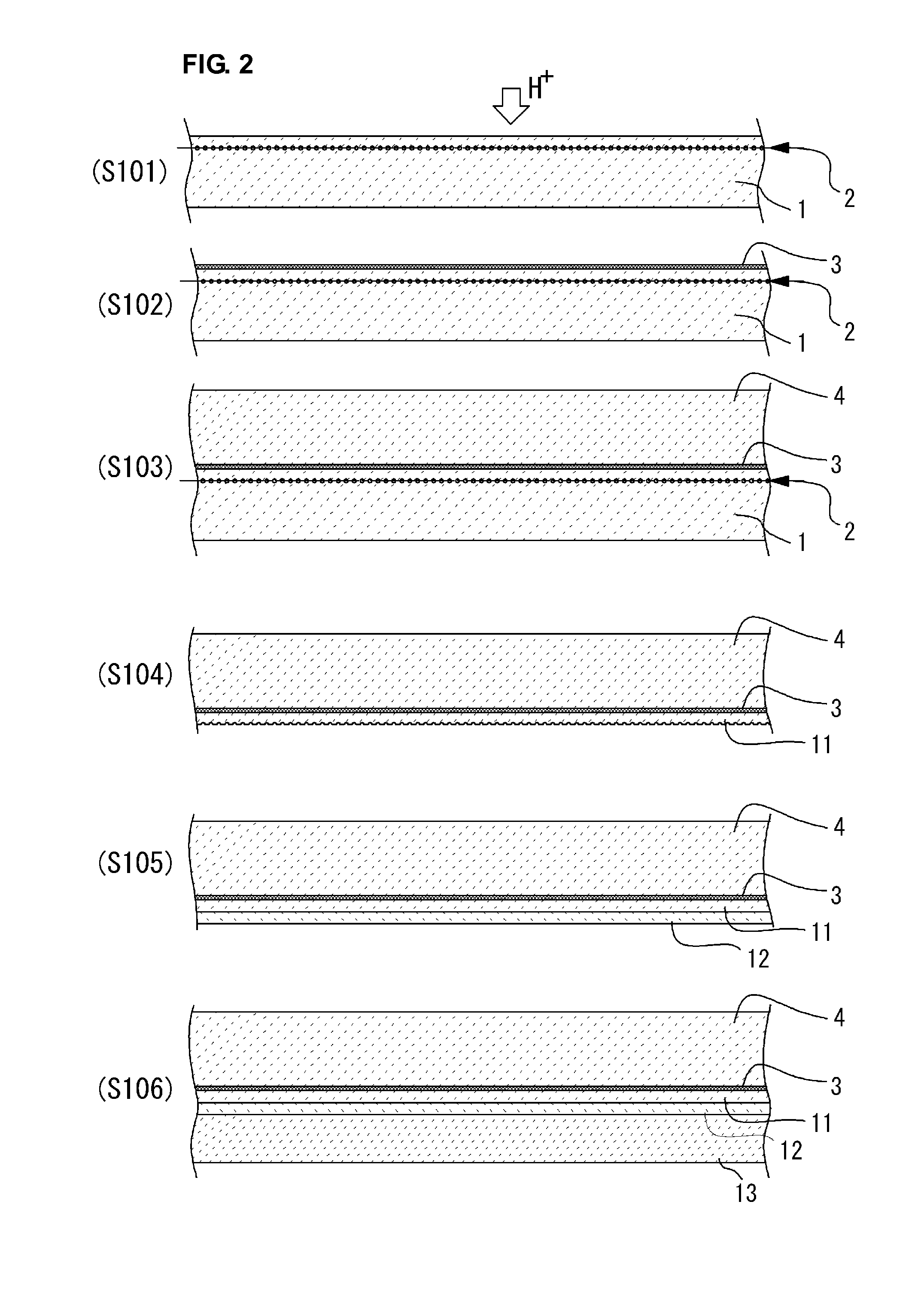

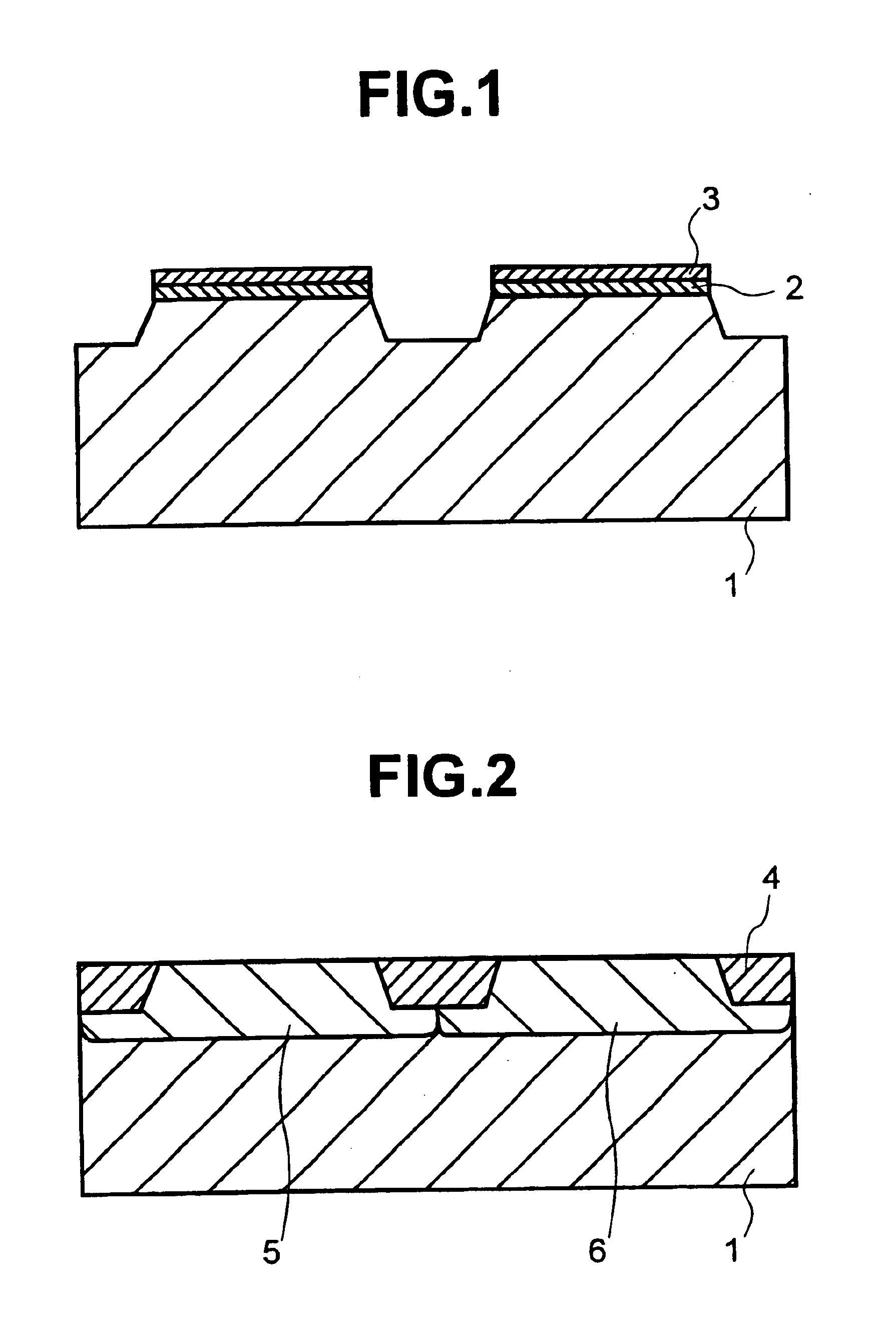

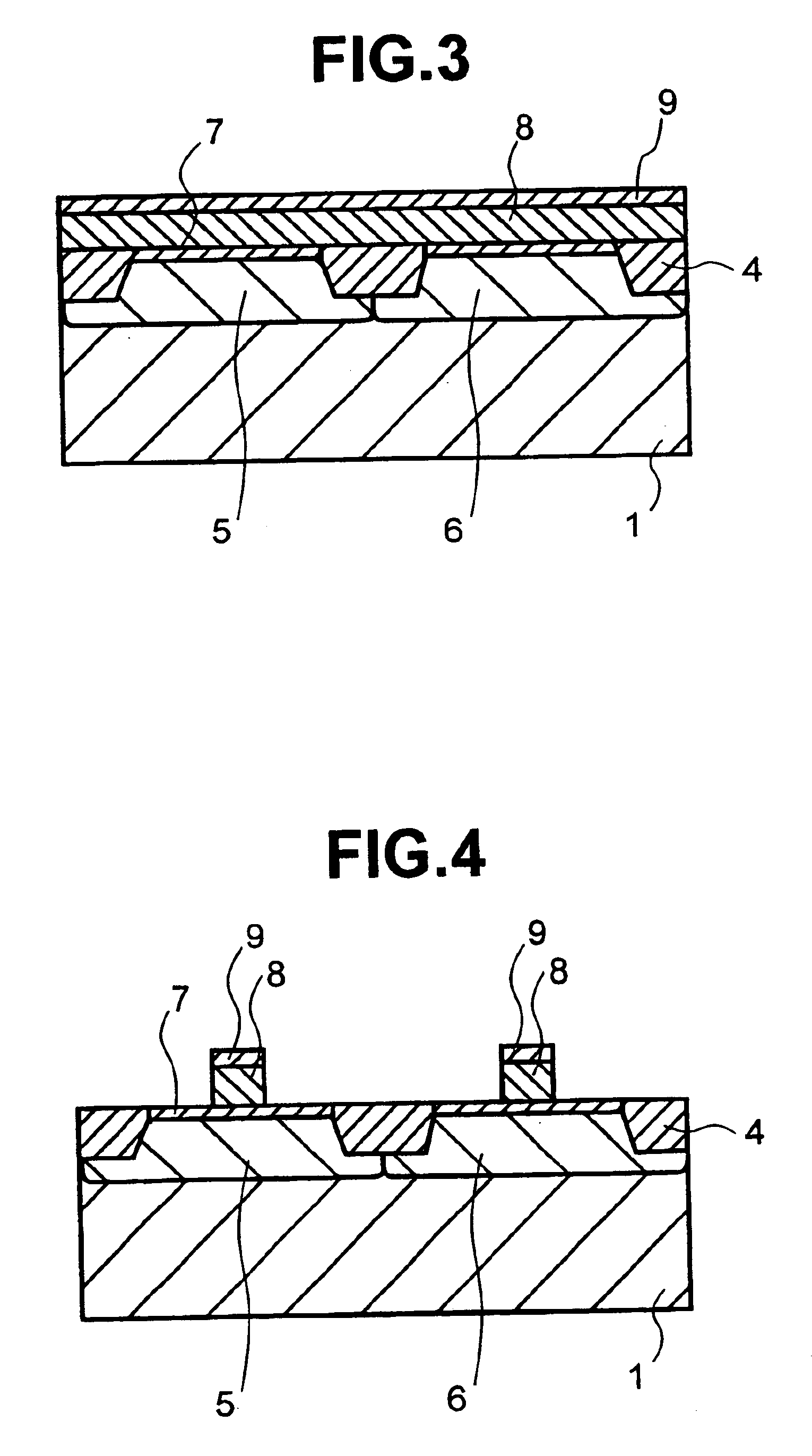

Method for manufacturing composite piezoelectric substrate and piezoelectric device

ActiveUS20110278993A1Improve featuresLess piezoelectric degradationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyIon implantation

A piezoelectric device is manufactured in which the material of a supporting substrate can be selected from various alternative materials. Ions are implanted into a piezoelectric substrate to form an ion-implanted portion. A temporary supporting substrate is formed on the ion-implanted surface of the piezoelectric substrate. The temporary supporting substrate includes a layer to be etched and a temporary substrate. The piezoelectric substrate is then heated to be divided at the ion-implanted portion to form a piezoelectric thin film. A supporting substrate is then formed on the piezoelectric thin film. The supporting substrate includes a dielectric film and a base substrate. The temporary supporting substrate is made of a material that produces a thermal stress at the interface between the temporary supporting substrate and the piezoelectric thin film less than the thermal stress at the interface between the supporting substrate and the piezoelectric thin film.

Owner:MURATA MFG CO LTD

Copper chromium zirconium alloy and preparing method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

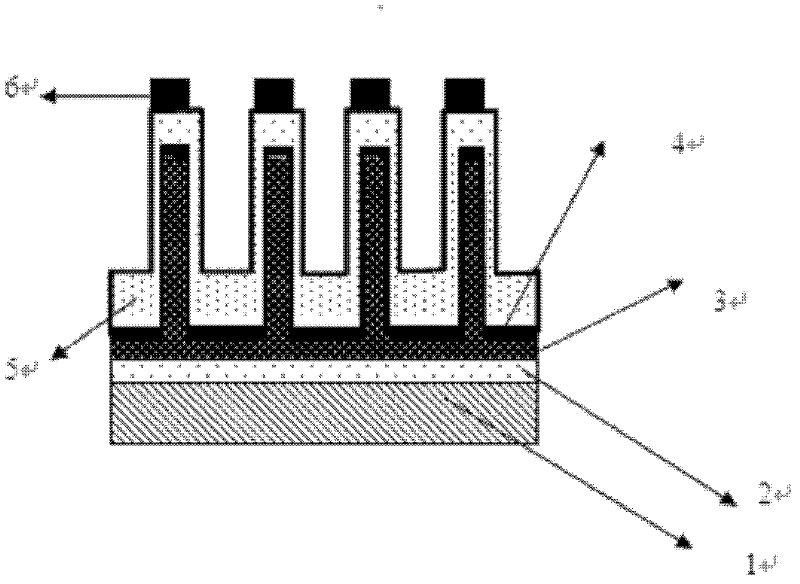

Thin-film solar photovoltaic cell with nano wire array structure and preparation method for thin-film solar photovoltaic cell

InactiveCN102569508ALow costImprove photoelectric conversion efficiencyFinal product manufactureVacuum evaporation coatingGas phaseCuprous sulfide

The invention discloses a method for preparing a thin-film solar photovoltaic cell with a copper indium gallium selenide (CIGS) nano wire array structure. The method comprises the following steps of: growing a large-area cuprous sulfide or copper sulfide nano wire array by adopting a gas-solid reaction method, and converting the cuprous sulfide or copper sulfide nano wire array into a CIGS nano wire array by physical vapor deposition and heat treatment methods. The component, the phase structure and the energy band structure of the semiconductor nano wire array can be regulated by controlling the categories of deposition elements, the deposition sequence, the deposition process, post treatment and the like, so that solar photovoltaic cells with different structures and properties are prepared. Through the cell, light reflection is reduced, light absorption is increased, the probability of producing current carriers can be increased, the probability of recombination of holes and electrons is reduced, and the photoelectric conversion efficiency is greatly improved. The method is low in cost, the preparation processes are controllable, the prepared nano wire array is uniform in structure distribution, and preparation of the nano structural thin-film solar photovoltaic cell with large area and high photoelectric conversion efficiency can be realized.

Owner:SUN YAT SEN UNIV

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

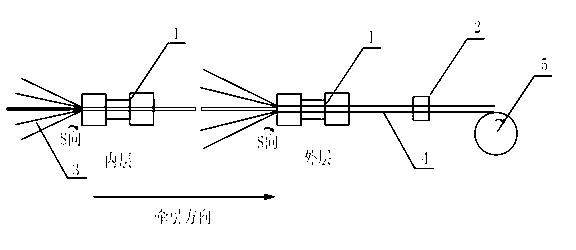

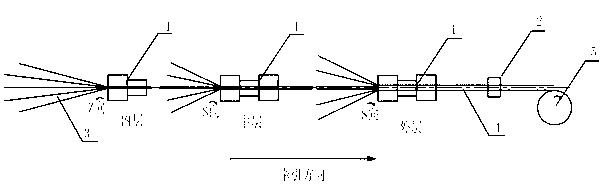

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

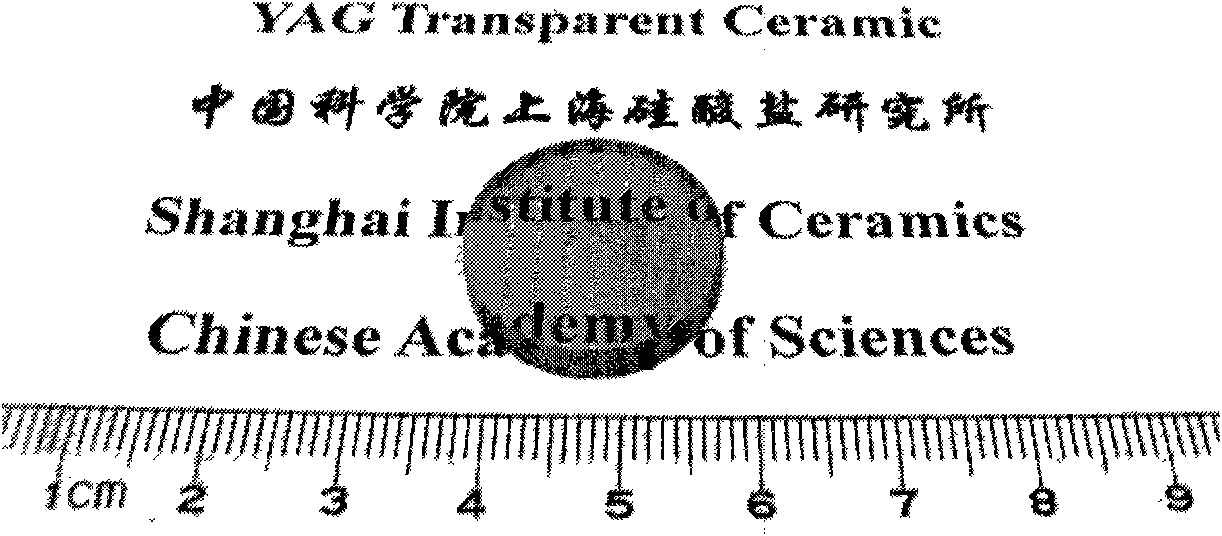

Active ion controlled doping yttrium aluminum garnet base laser transparent ceramic material and preparation method thereof

The invention relates to an active ion controlled doping yttrium aluminum garnet base laser transparent ceramic material and a preparation method thereof. The method comprises the following steps of: (1) carrying out ball mill mixing on oxide ceramic powder body raw materials, sintering auxiliary agents, binding agents and absolute ethyl alcohol to prepare ethyl alcohol base slurry, wherein the slurry comprises the following ingredients through being metered by mass: 40 to 70 percent of oxide ceramic powder body raw materials, 0.01 to 1 percent of sintering auxiliary agents, 0 to 2.5 percent of binding agents and the balance absolute ethyl alcohol; (2) drying the ethyl alcohol base slurry prepared in the first step, then, carrying out sieving and granulation, or carrying out direct spray granulation on the slurry; (3) loading powder body spherical particles prepared in the second step through granulation into clean bags filled with air and uniformly mixing the powder body spherical particles; (4) directly pressing and forming the powder body spherical particles uniformly mixed in the third step or carrying out the pressing forming after the pre-calcination treatment; and (5) carrying out vacuum sintering on ceramic blanks prepared in the fourth step through pressing and forming, then, carrying out annealing and mechanical processing treatment and obtaining the active ion controlled doping yttrium aluminum garnet base laser transparent ceramic material.

Owner:中国科学院上海硅酸盐研究所苏州研究院

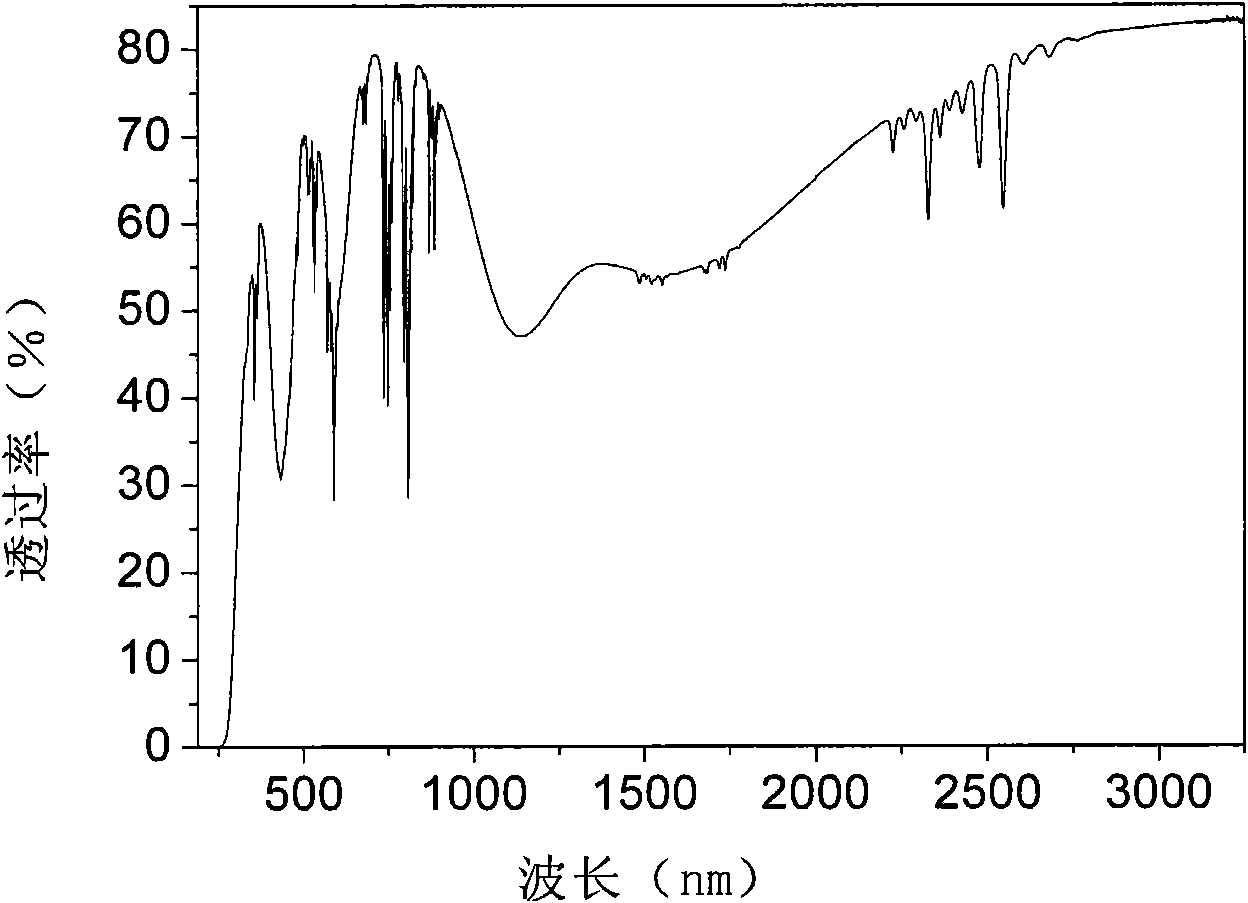

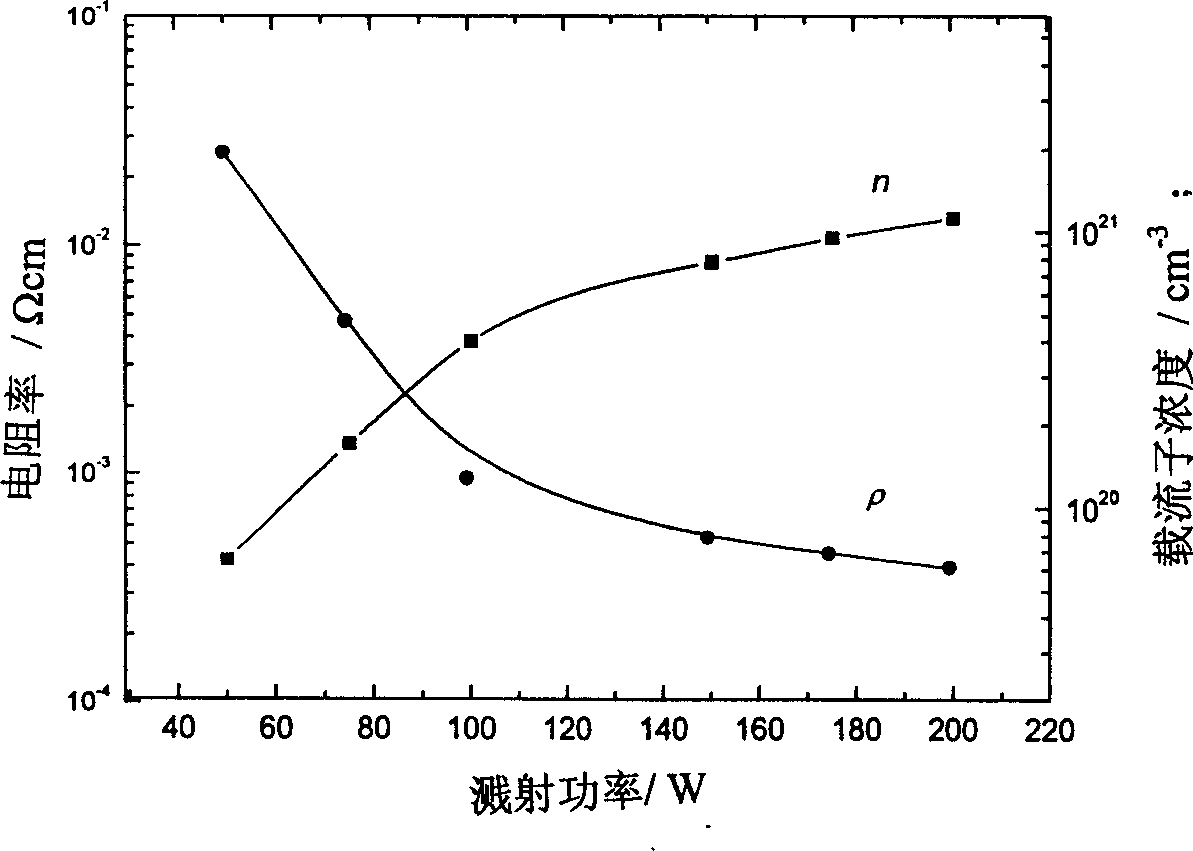

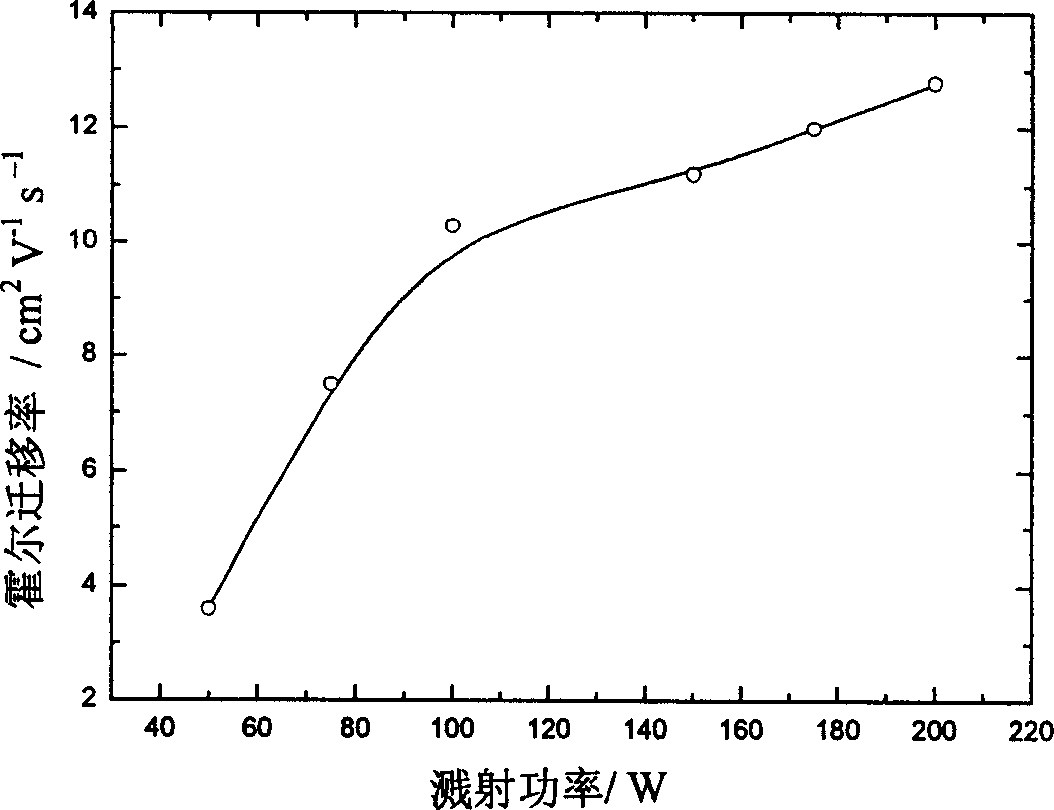

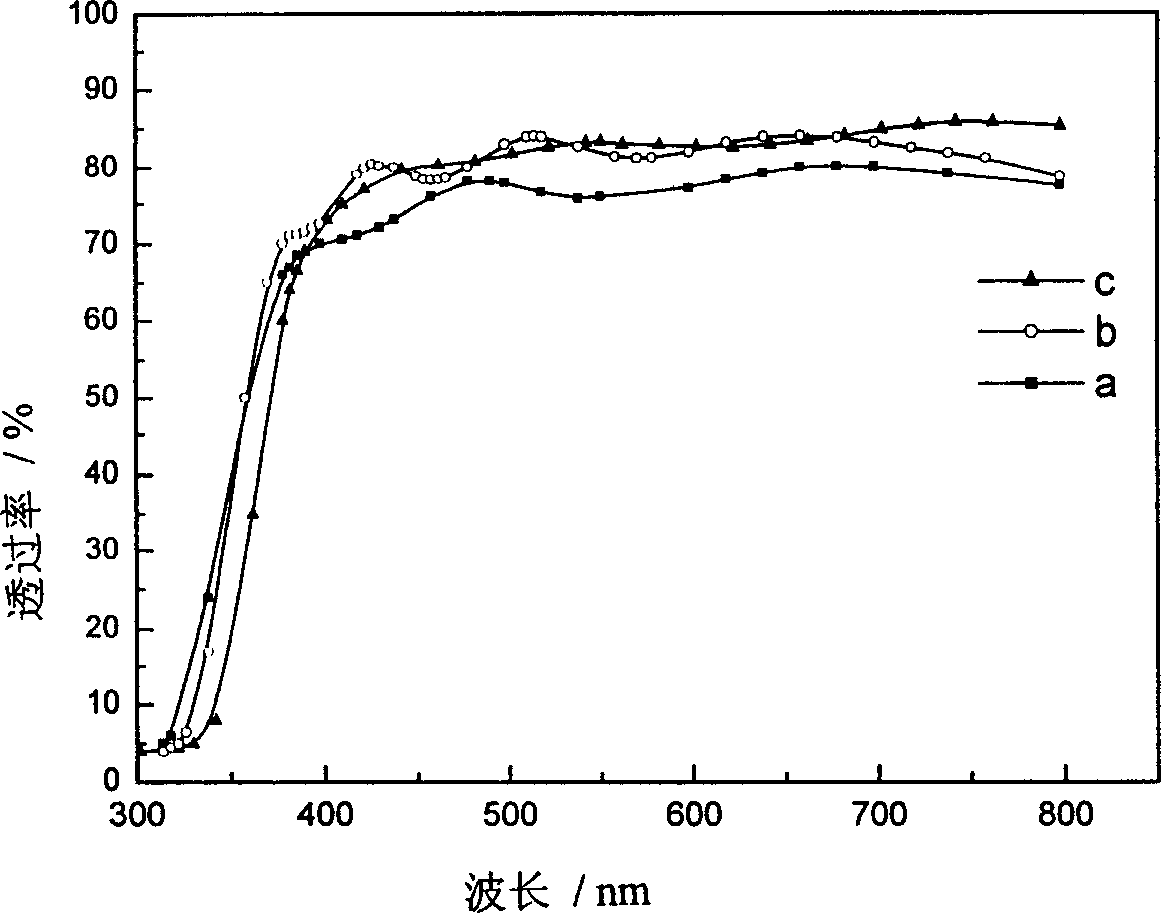

Preparation method of gallium adulterated zinc oxide transparent conductive film

InactiveCN1718840AGood photoelectric performanceImprove stabilityVacuum evaporation coatingSputtering coatingElectrically conductiveCharge carrier

A process for preparing the electrically conductive transparent film of Ga doped zinc oxide used for photoelectronic devices includes such steps as providing ZnO film and doping Ga in the ZnO film by magnetically controlled bias RF sputter to prepare said ZnO:Ga film. The ceramic target for sputter is composed of ZnO and Ga2O3. The sputtering parameters are also disclosed.

Owner:SHANDONG UNIV

Centrifugal ceramic composite vertical mill roller sleeve and manufacturing method thereof

The invention discloses a centrifugal ceramic composite vertical mill roller sleeve and a manufacturing method thereof. The centrifugal ceramic composite vertical mill roller sleeve comprises an inner layer and an outer layer. The outer layer is high-chromium cast iron, and ceramic particles are embedded in the outer layer. The high-chromium cast iron is prepared from, by weight, 2.3-3.3% of C, 0.3-1.0% of Si, 0.6-1.2% of Mn, 18-22% of Cr, 0.7-1.7% of Ni, 1.5-3.0% of Mo, 0-0.03% of P, 0-0.03% of S and the balance Fe and inevitable impurities. According to the vertical mill roller sleeve, the material proportion of the inner layer and the outer layer is optimized; high-alloy elements are adopted by the outer layer, the matrix can be effectively reinforced by increasing the content of alloy such as C, Cr, Mo and V, the total amount of carbide is increased, and therefore the smoothness of a friction surface can be effectively improved; the outer layer of the roller sleeve is made to be high in abrasion resistance, high in strength and enough in toughness, and the service life of the roller sleeve is effectively prolonged. According to the manufacturing method, a heat treatment technique of annealing, quenching and tempering is adopted, the purposes of improving the carbide form, promoting structural transformation and refining structures are achieved, so that the abrasion resistance and fracture toughness of the roller sleeve are improved.

Owner:河北津西钢铁集团重工科技有限公司

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

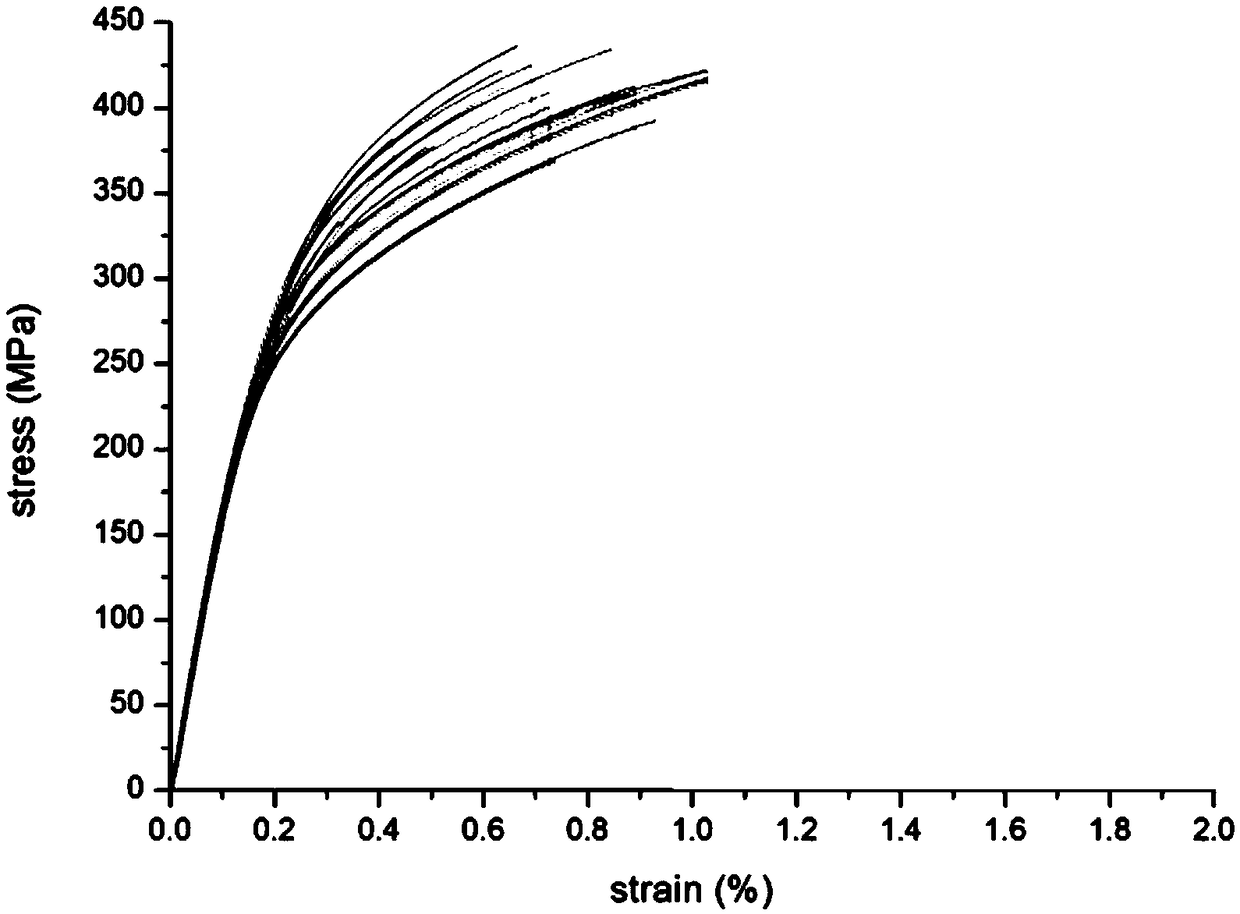

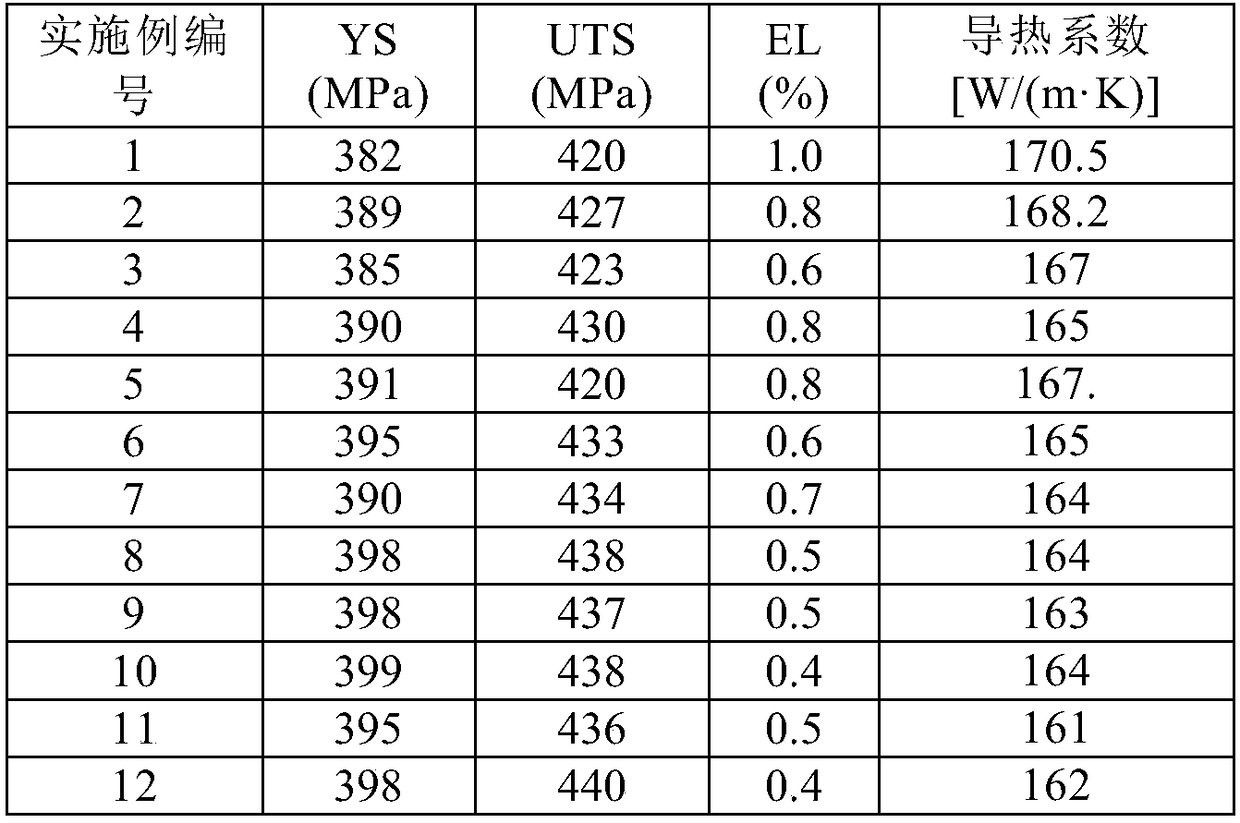

Semi-solid state extrusion casting aluminum alloy for new energy automobile and preparation method thereof

The invention relates to a semi-solid state extrusion casting aluminum alloy for a new energy automobile and a preparation method thereof. The alloy comprises, by weight, 5%-8% of Si, 3.5%-4% of Cu, 0.40%-0.80% of Fe, 0.00%-0.5% of Mg, less than or equal to 0.05% of other impurities, and the balance Al. The alloy melt is subjected to 50Hz mechanical vibration treatment within the temperature interval of 650-680 DEG C, and semi-solid state slurry is obtained after 180-240 s. Compared with the prior art, the aluminum alloy provided by the invention has the solid-liquid phase interval of 510-630DEG C, thereby having the semi-solid state extrusion casting performance. The aluminum alloy melt starts to be subjected to 50Hz mechanical vibration treatment within the temperature interval of 650-680 DEG C, and the semi-solid state slurry can be obtained after 180-240 s. The slurry is subjected to extrusion casting, heat treatment at 450 DEG C for 2 h and artificial ageing at 170 DEG C for 10 h. Eutectic silicon particles are distributed densely. Al2Cu serves as a main precipitated phase in the material, and a small number of Al5Cu2Mg8Si6 and Al8Mg3FeSi2 are generated simultaneously. The aluminum alloy has the tensile strength greater than 420 MPa, the yield strength greater than 380 MPa and the heat conductivity coefficient greater than 160 W / m.K under the enhancement effect of the precipitated phase.

Owner:苏州慧驰轻合金精密成型科技有限公司

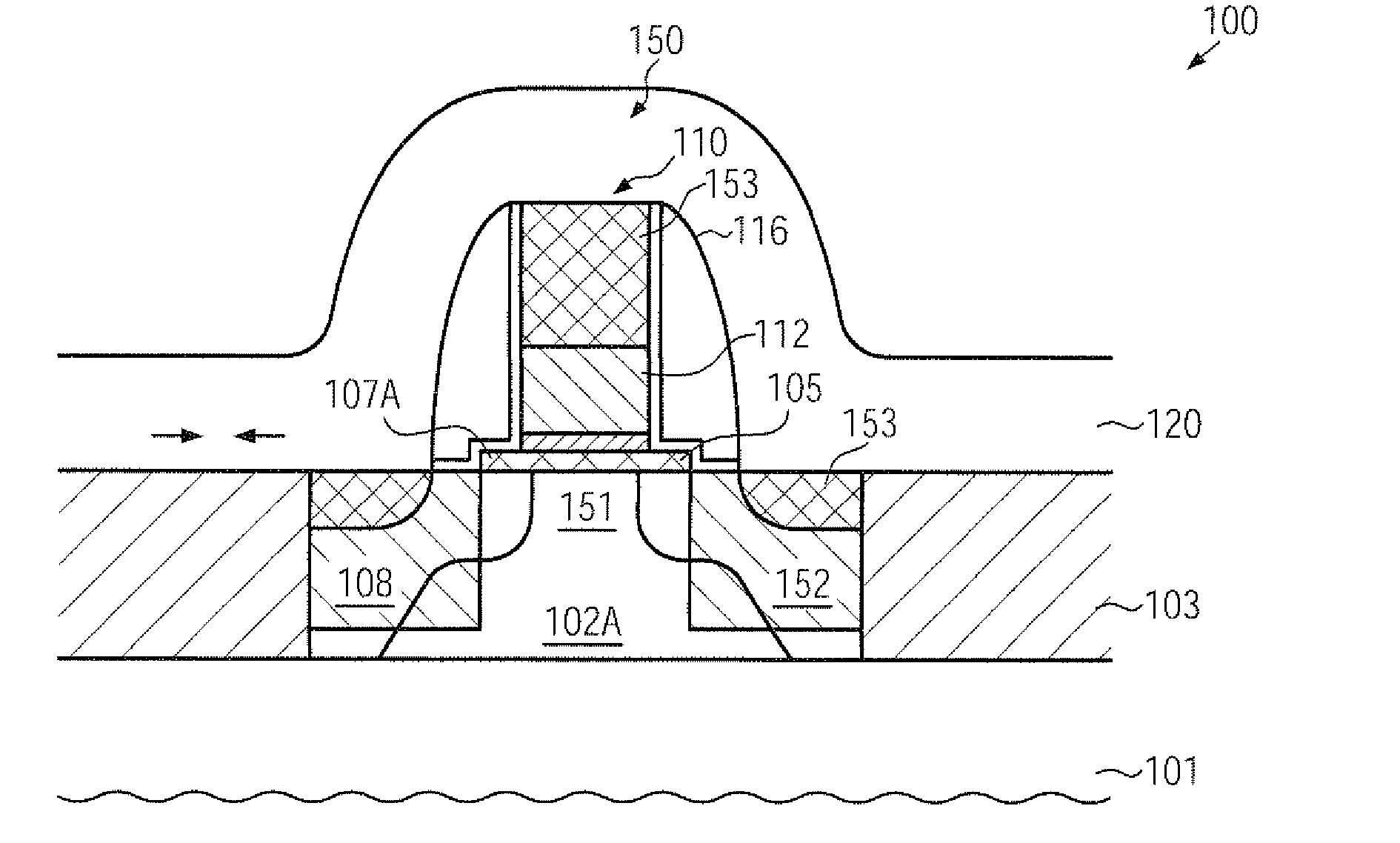

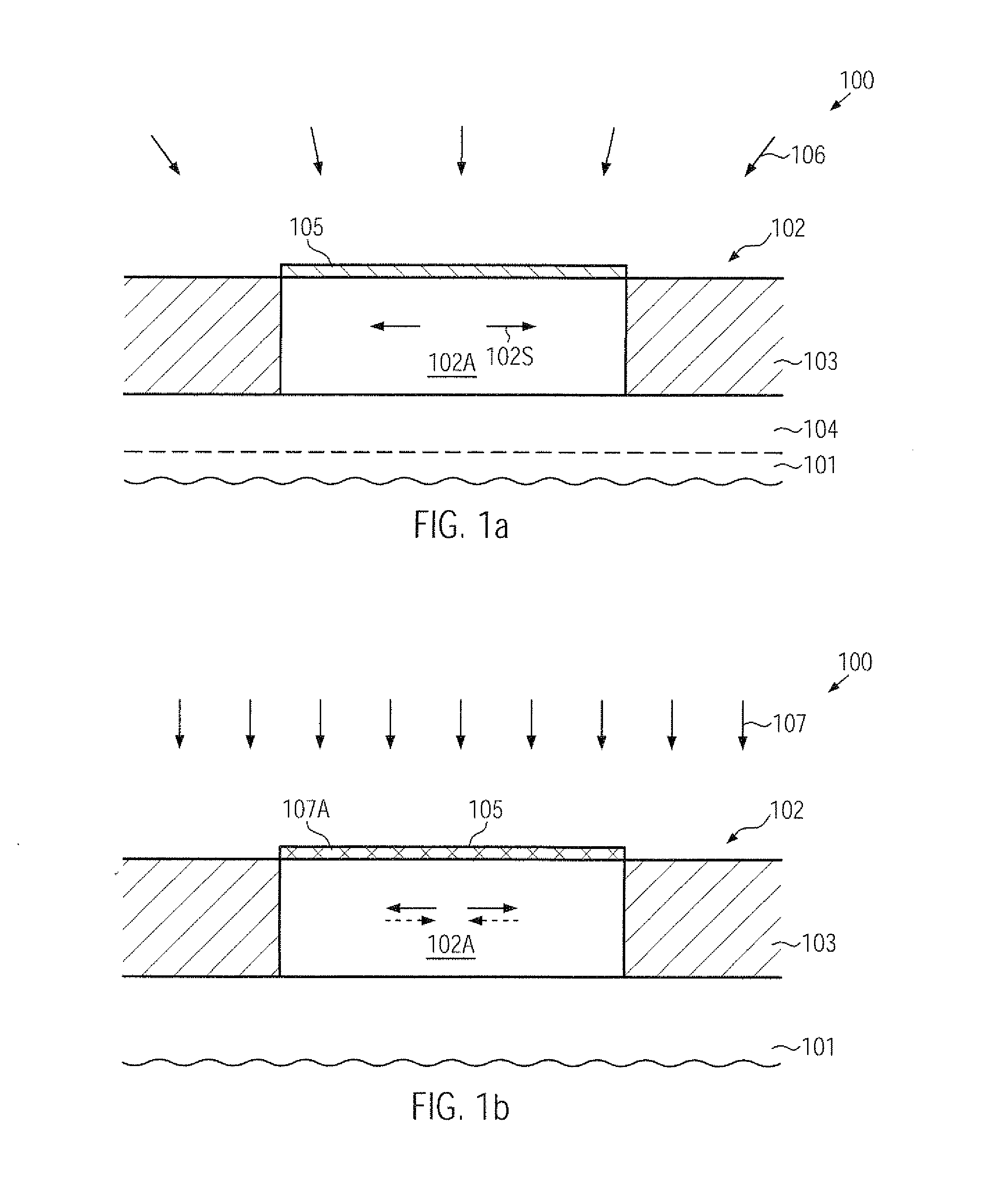

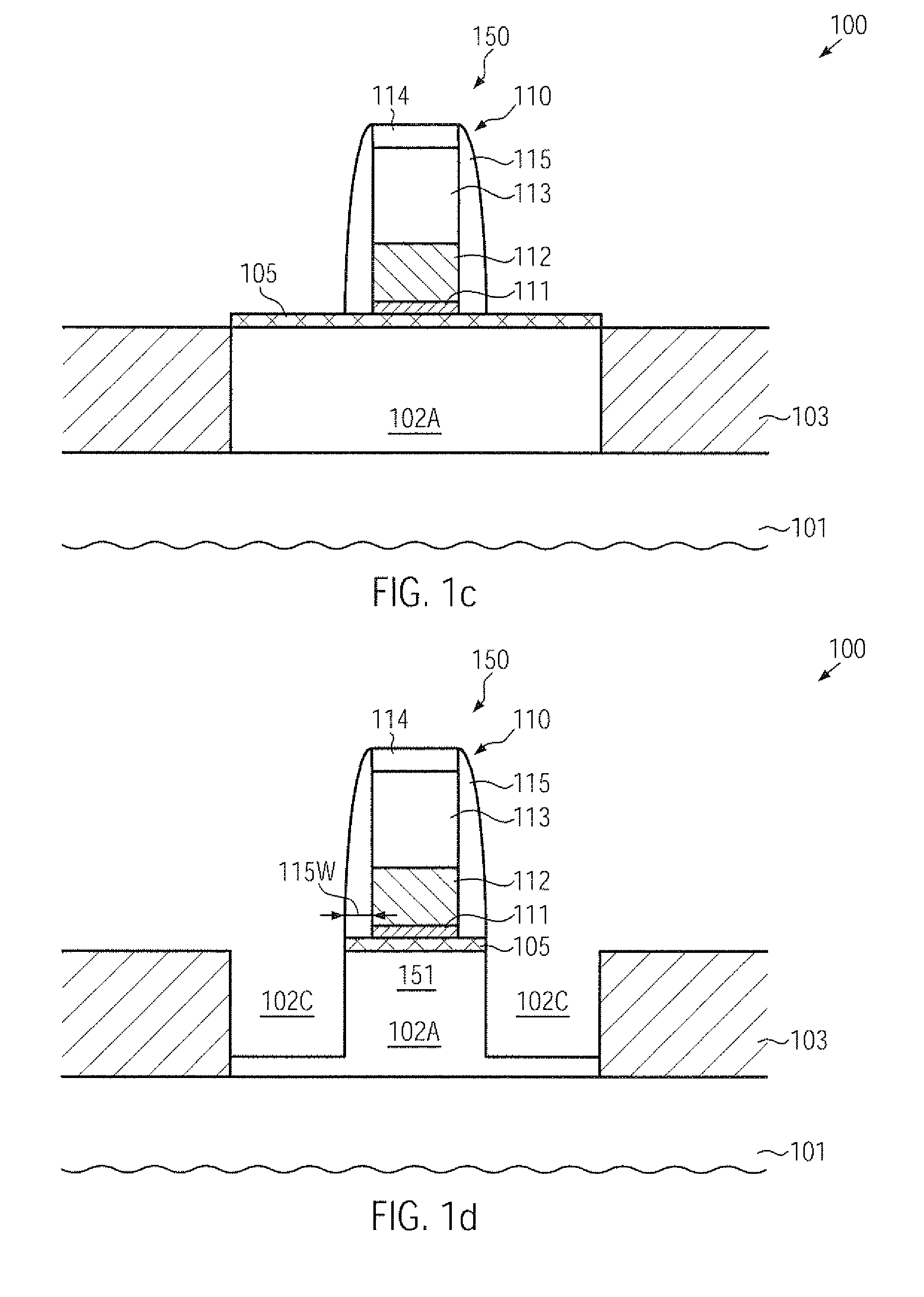

Adjusting of strain caused in a transistor channel by semiconductor material provided for threshold adjustment

ActiveUS20100164016A1Negative effectReduce lattice distortionSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor alloys

The threshold voltage of a sophisticated transistor may be adjusted by providing a specifically designed semiconductor alloy in the channel region of the transistor, wherein a negative effect of this semiconductor material with respect to inducing a strain component in the channel region may be reduced or over-compensated for by additionally incorporating a strain-adjusting species. For example, a carbon species may be incorporated in the channel region, the threshold voltage of which may be adjusted on the basis of a silicon / germanium alloy of a P-channel transistor. Consequently, sophisticated metal gate electrodes may be formed in an early manufacturing stage.

Owner:TAIWAN SEMICON MFG CO LTD

Novel production method of c-orientation sapphire single crystal

InactiveCN103215646AHigh material utilizationImprove crystal qualityPolycrystalline material growthSingle crystal growth detailsCrucibleRoom temperature

The invention discloses a novel production method of a c-orientation sapphire single crystal. The novel production method comprises the following steps of: placing c-orientation sapphire seed crystals in the seed crystal groove of a crucible; filling high-purity aluminum oxide raw materials; vacuumizing and subsequently heating to completely melt the aluminum oxide raw materials and partially melt the seed crystals; slowly cooling at a speed of 0.01-10DEG C / h; controlling a solid-liquid interface to a plane having a certain angle with a c-surface; annealing at a cooling speed of 2-50 DEG C / h after the growth of the crystals is ended; and cooling to the room temperature and subsequently taking the crystal out. According to the invention, by adopting a method for deviating a crucible symmetry axis, a heater symmetry axis and a lateral reflecting screen symmetry axis, the solid-liquid interface in the growth process of the sapphire single crystal is a plane having a certain angle with the c-surface, and the material utilization rate of grown c-orientation crystal ingots can be greatly improved in comparison with the material utilization rate of a-orientation crystal ingots; and compared with the traditional growth method of the c-orientation crystal ingots, the crystal quality of the crystal ingots can be improved and the distortions of crystal boundaries and crystal lattices normally occurring during the growth of the c-orientation crystal ingots can be reduced.

Owner:苏州海铂晶体有限公司

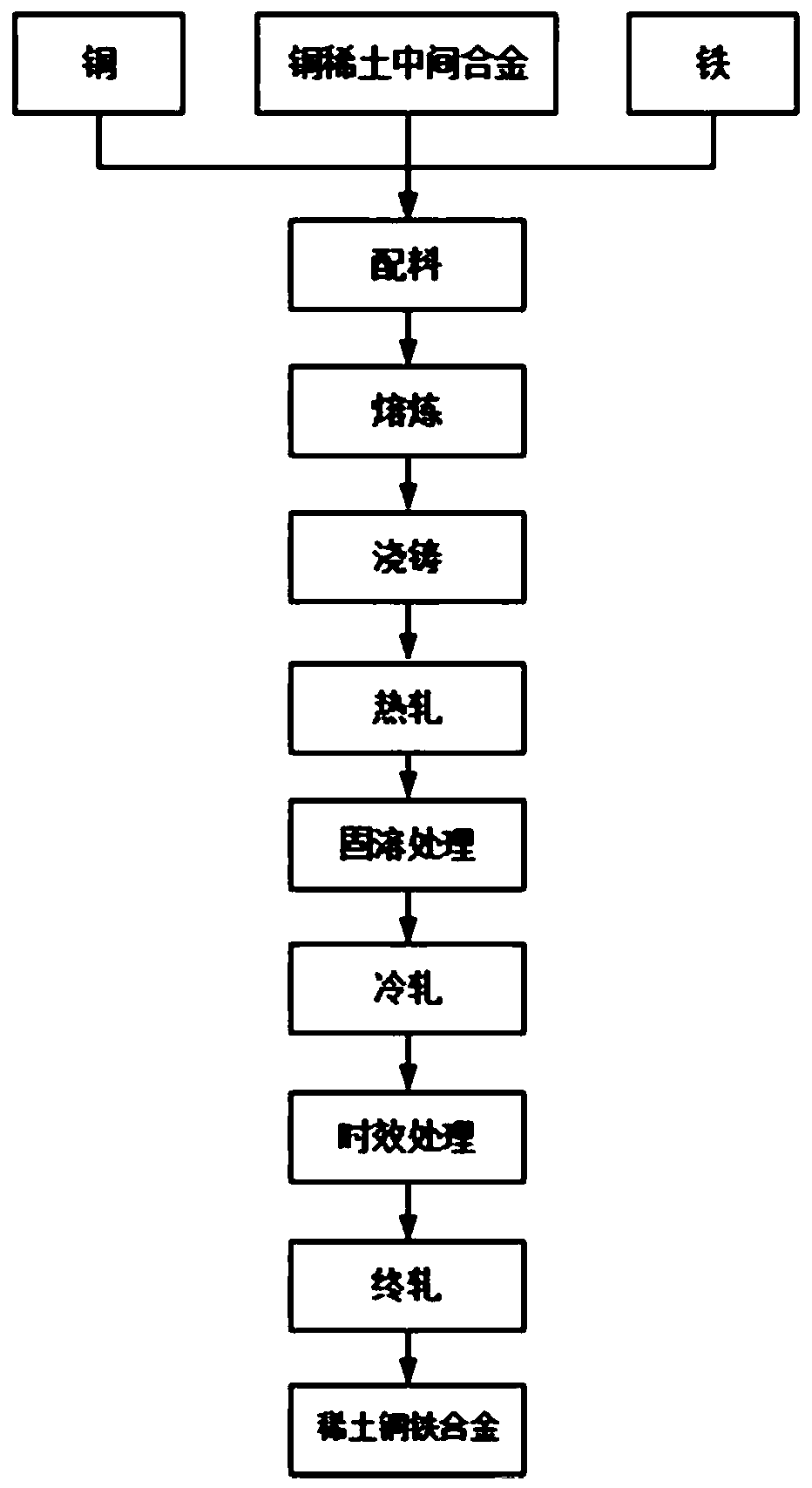

Rare earth copper and iron alloy and preparation method and application

The invention provides a rare earth copper and iron alloy and a preparation method and an application, belonging to the technical field of nonferrous metal materials. The rare earth copper and iron alloy provided by the invention, in percentage by mass, comprises 0.25-0.5% of rare earth elements, 8-20% of Fe and the balance Cu. According to the invention, the rare earth elements are added in the Cu-Fe alloy, functions of purifying the alloy, refining crystalline grains and prompting separation of a Fe phase are realized, and conductivity of the Cu-Fe alloy is improved; in the alloy, content ofan iron element is high, dosage of copper is low, and thus, production cost is reduced; and dosage of the rare earth elements is relatively higher, and thus, affection of the iron element on conductivity of the alloy can be reduced. A result of an embodiment shows that the rare earth copper and iron alloy provided by the invention has conductivity of more than 56% IACS, strength of extension of more than 768 MPa and rate of elongation of more than 2.9%.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

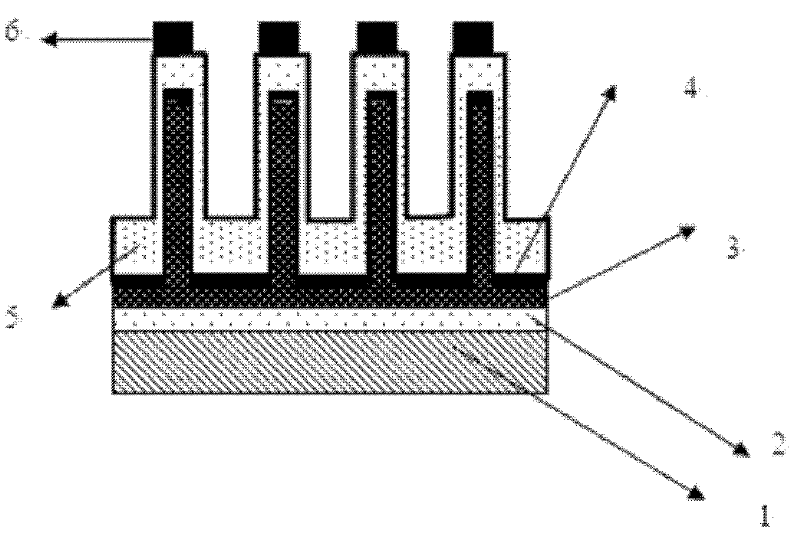

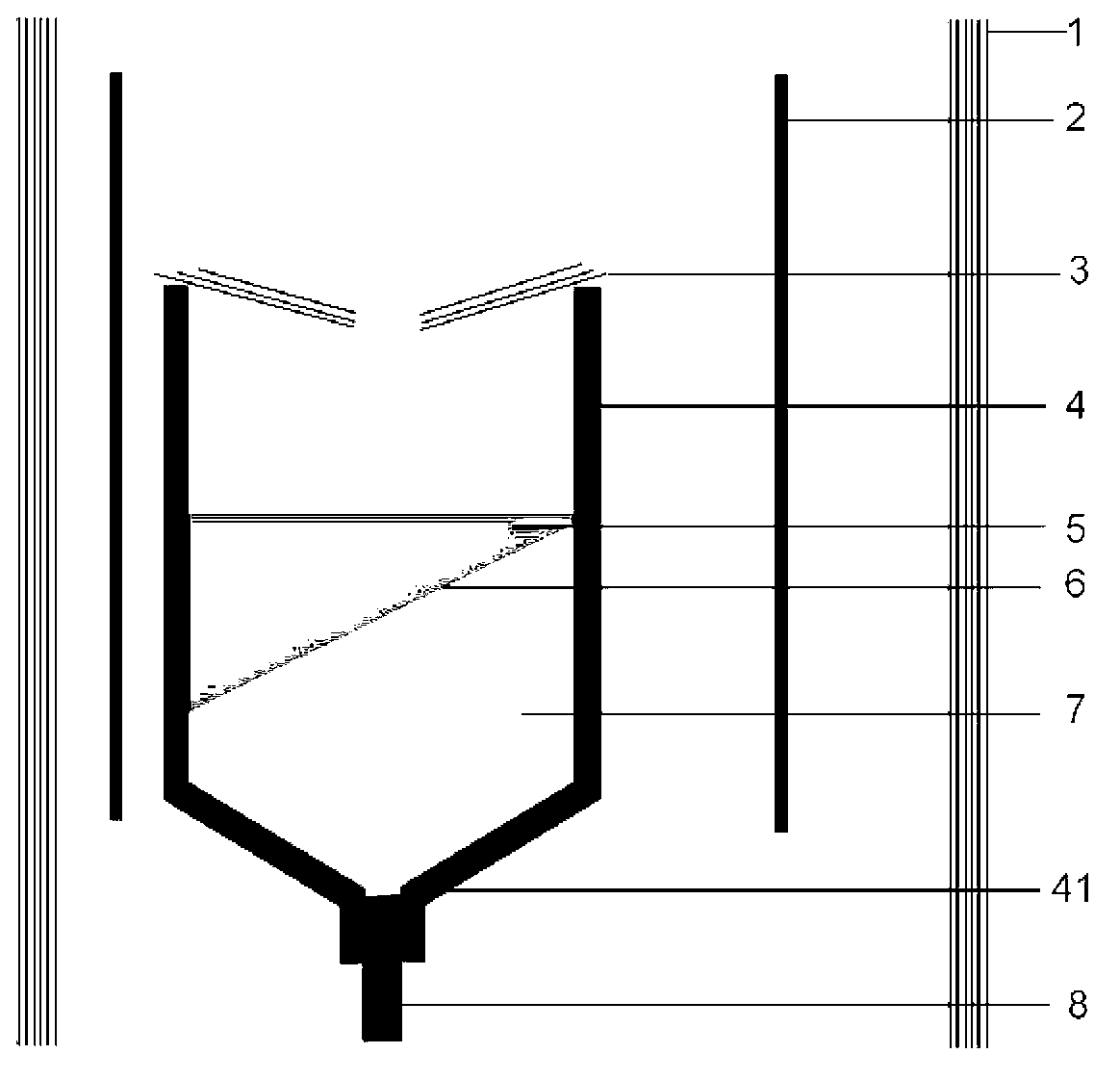

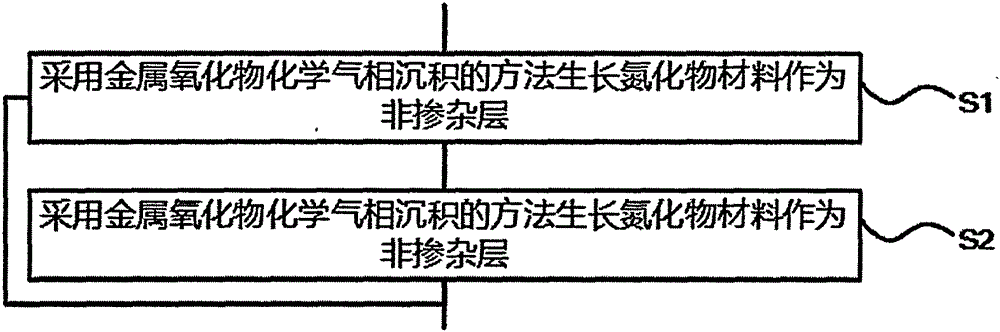

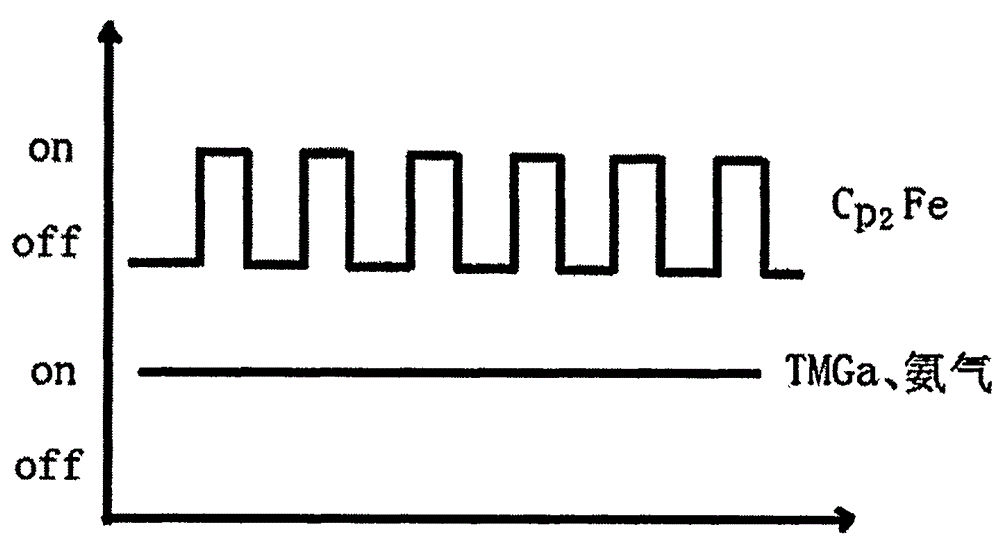

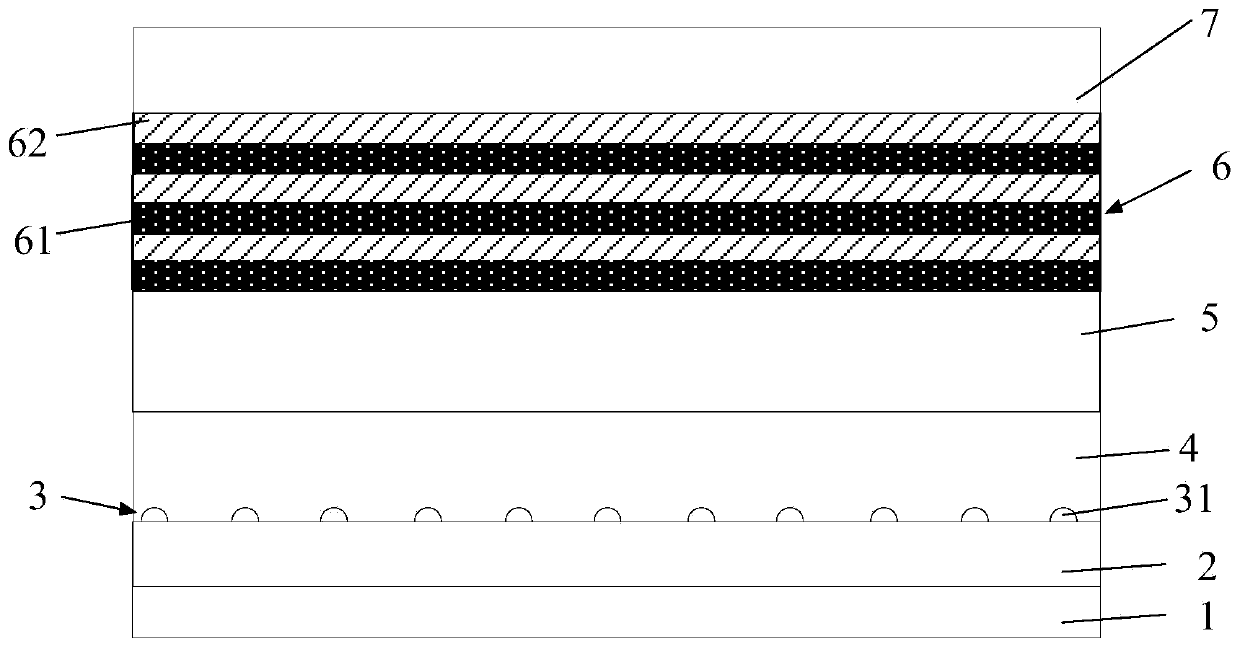

High-resistance substrate for high-electron-mobility transistor and growing method thereof

ActiveCN105047695AReduce lattice distortionGood crystal qualitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh-electron-mobility transistorHigh resistance

The present invention provides a high-resistance substrate for a high-electron-mobility transistor and a growing method thereof. The high-resistance substrate comprises a supporting substrate and a high resistance layer at the surface of the supporting substrate, wherein the material of the high resistance layer is nitride. The high-resistance substrate is characterized in that the high resistance layer comprises a periodic structure consisting of a plurality of doped layers and a plurality of non-doped layers, the doped layers and the non-doped layers are arranged alternately, the material of the doped layer is nitride containing a deep-energy-level doped material. The high-resistance substrate of the present invention has the advantages of capacity of well ensuring excellent crystal quality of an epitaxial layer while ensuring that a high resistance characteristic is resulted from deep-energy-level doping concentration.

Owner:SHANGHAI SIMGUI TECH

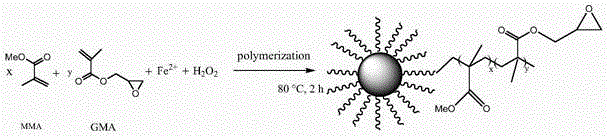

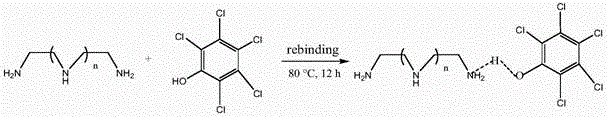

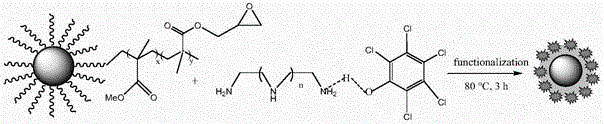

Magnetic field-induced preparation method of molecularly-imprinted magnetic enrichment material of trace quantity of chlorophenol pollutant molecules in seawater

InactiveCN104130441AAvoid easy reunionAvoid low magnetic contentOther chemical processesSeawater treatmentSolid phase extractionAmino functionalized

The invention discloses a magnetic field-induced preparation method of a molecularly-imprinted magnetic enrichment material of trace quantity of chlorophenol pollutant molecules in seawater. The preparation method comprises that under magnetic field induction, an epoxy group-functionalized magnetic polymer is prepared by suspension polymerization and in-situ oxidation, a chlorophenol environmental pollutant polyamine template molecule is obtained by an intermolecular hydrogen bonding self-assembling technology, an amino-functionalized magnetic molecularly-imprinted composite material bonding with the template molecule is prepared under magnetic field induction, and in the presence of an acid / alcohol extractant, through pH adjustment, the template molecule is eluted and the chlorophenol molecule-imprinted magnetic composite material is obtained. The preparation method has simple processes and a low cost and realizes uniform particle size distribution and stable properties of the desired product. The molecularly-imprinted magnetic enrichment material can realize high-efficiency and high-selectivity adsorption and removal of trace quantity of chlorophenol pollutants in seawater and can be used for base dispersion-magnetic solid phase extraction detection of trace quantity of chlorophenol pollutants in seawater.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

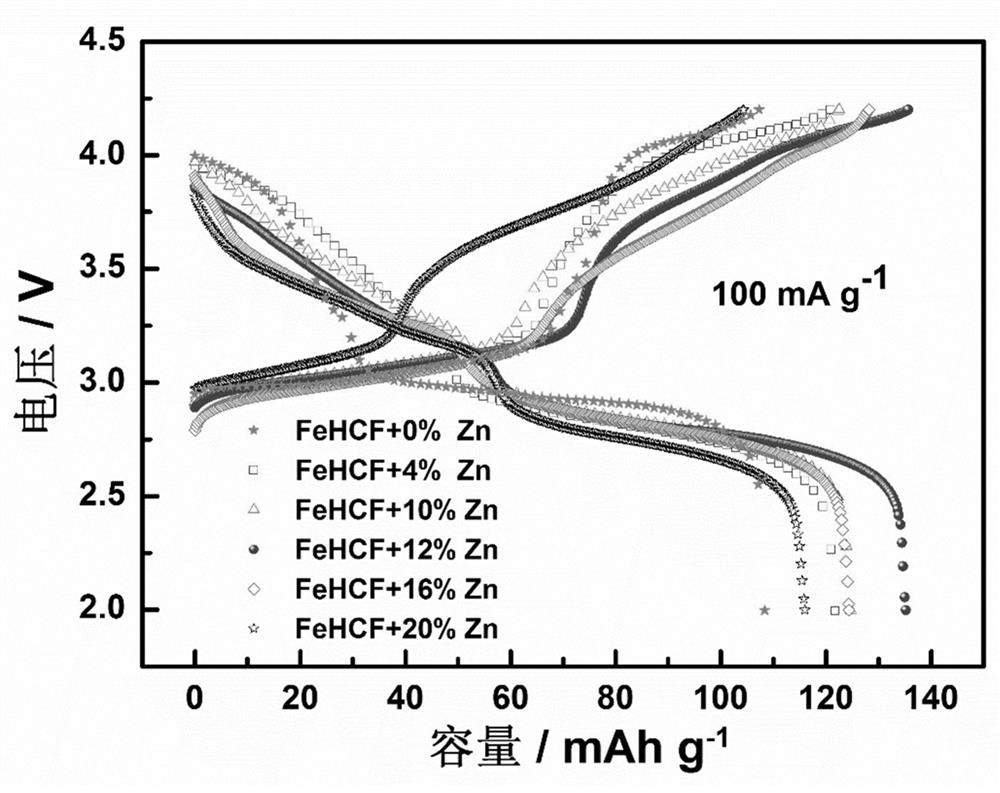

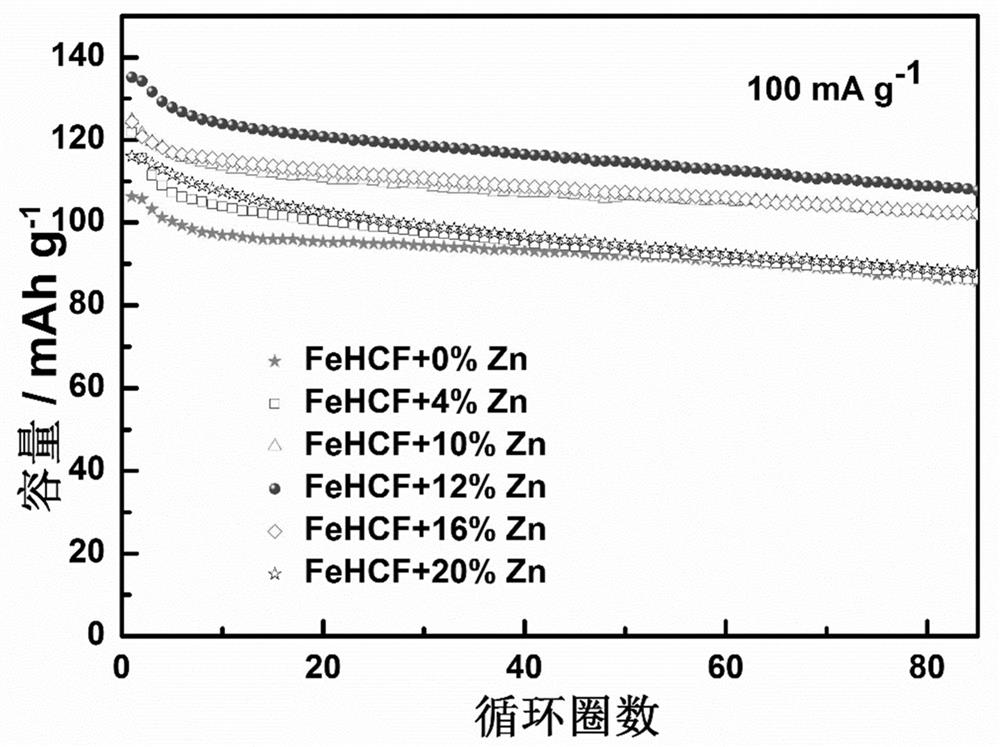

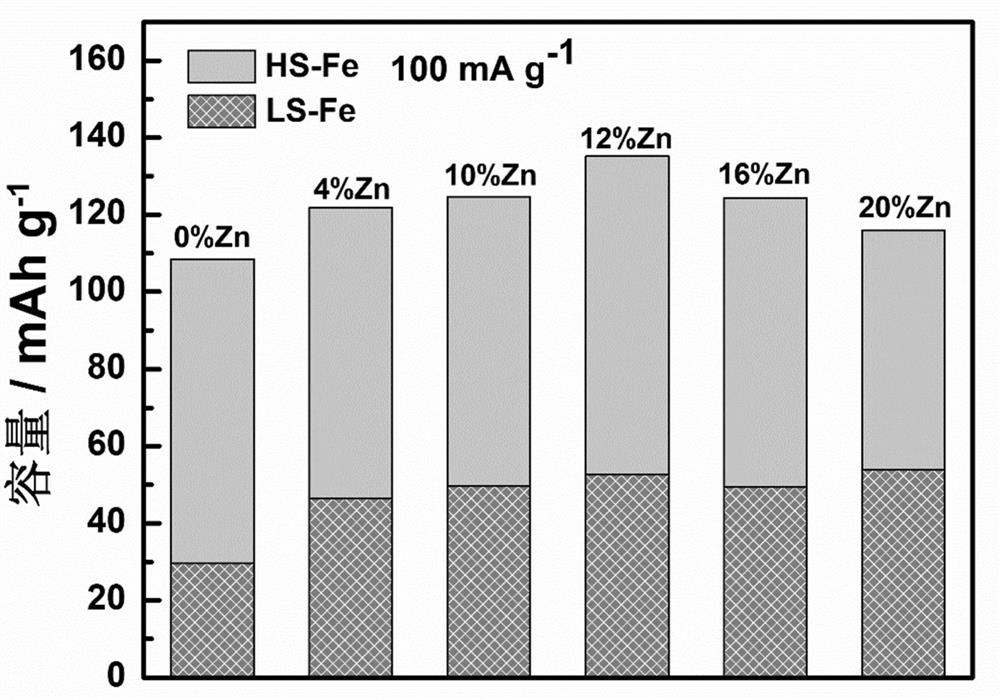

Inert transition metal element doped iron-based Prussian blue sodium ion battery positive electrode material

InactiveCN113104863AImprove cycle stabilityActivation activityIron cyanidesCell electrodesPeristaltic pumpPyrrolidinones

The invention relates to an inert transition metal element doped iron-based Prussian blue sodium ion battery positive electrode material and a preparation method thereof, wherein an inert transition metal element zinc Zn is used for replacing high spin iron connected with N in cyanide in iron-based Prussian blue according to a certain proportion. The preparation method comprises the following steps: dissolving ferrous sulfate heptahydrate, zinc acetate and sodium citrate in deionized water to form a solution A, dissolving sodium ferrocyanide decahydrate and ascorbic acid in deionized water to form a solution B, and dissolving polyvinylpyrrolidone and sodium chloride in deionized water to form a solution C; simultaneously adding the solution A and the solution B into the solution C through a peristaltic pump, and stirring while heating in an N2 atmosphere until the solution becomes white suspension liquid after dropwise adding is completed, namely, a solution D; and continuously stirring the solution D under the same condition, finally aging at room temperature, then centrifugally washing with deionized water and absolute ethyl alcohol three times respectively, and carrying out vacuum drying to obtain the zinc-doped iron-based Prussian blue Zn-FeHCF positive electrode material.

Owner:CHINA THREE GORGES UNIV

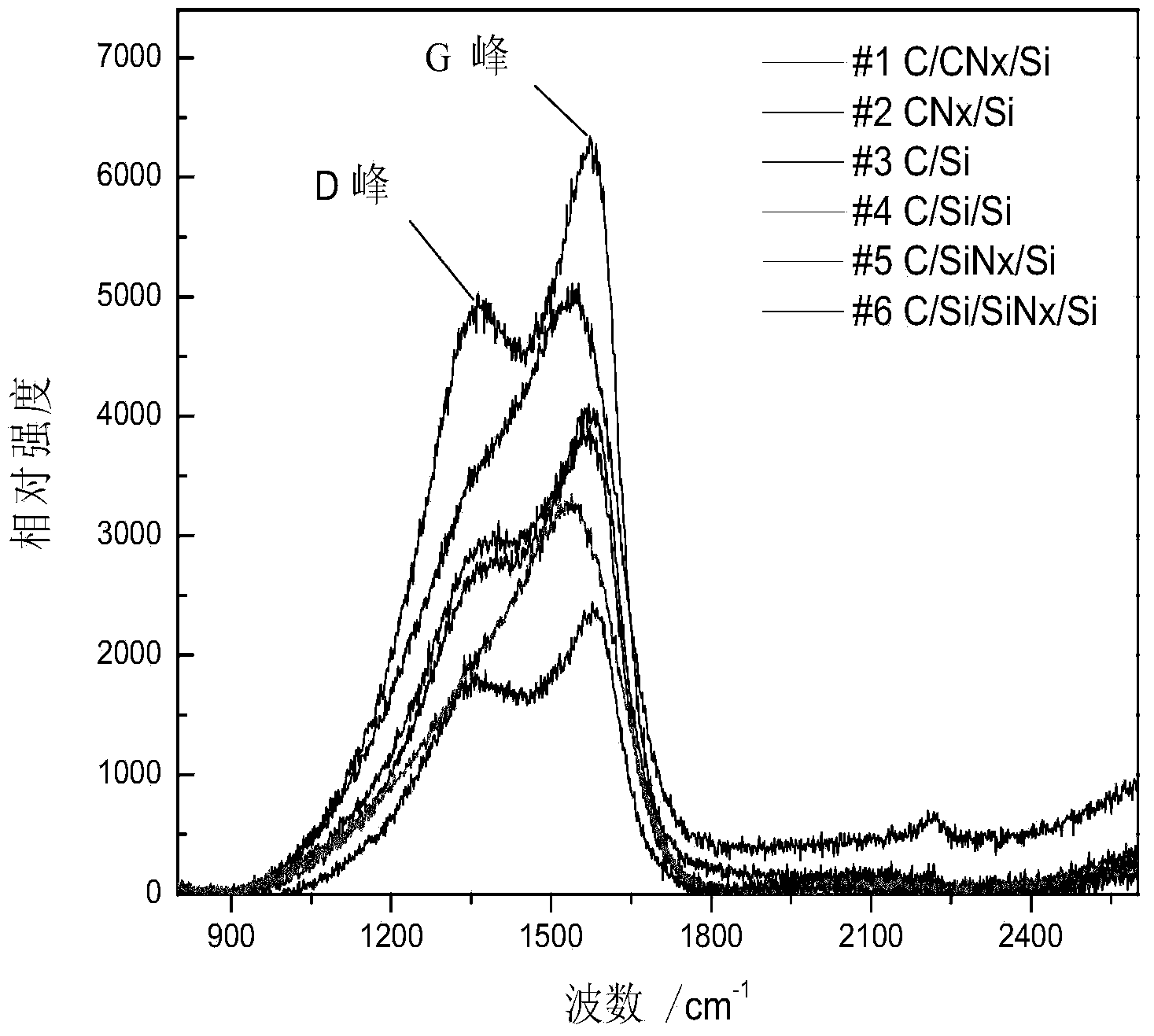

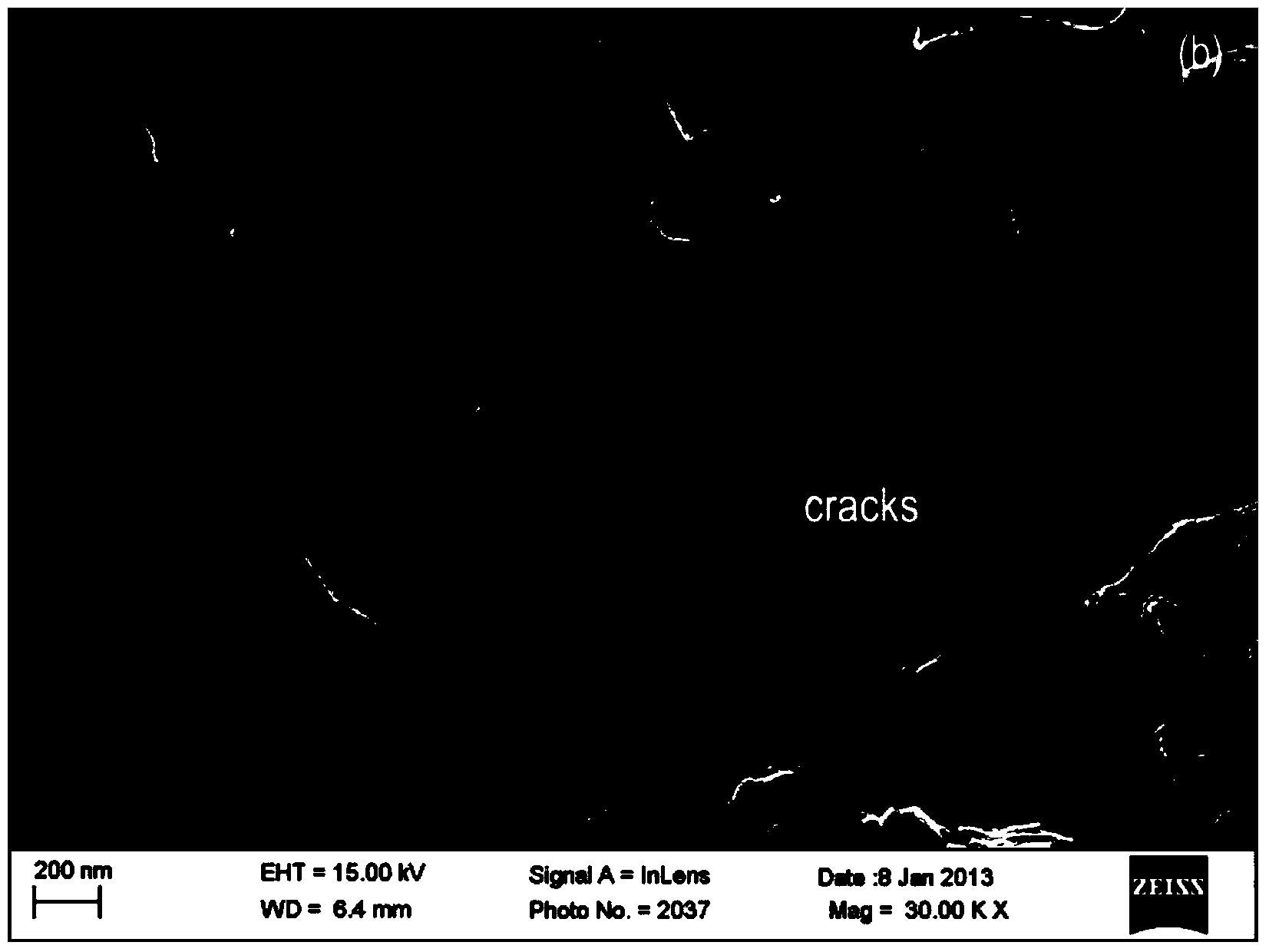

Method of preparing diamond-like membrane by film sputtering in SiNx middle layer

InactiveCN103849847ASimple preparation processGood repeatabilityVacuum evaporation coatingSputtering coatingSputteringOptoelectronics

The invention discloses a method of preparing a diamond-like film by magnetron sputtering in a SiNx middle layer. The method comprises the following steps: after cleaning a substrate Si chip, firstly forming a buffer layer SiNx thin film on the surface of the chip; and then, by taking a high purity carbon target as a target and Ar as a working gas, forming the diamond-like film on the SiNx thin film. The preparation process disclosed by the invention is simple and good in repeatability. The film can be deposited at low temperatures. The method is energy-saving, and the stress residue of the film cooled is reduced to prevent the film from falling. The diamond-like film prepared by the method disclosed by the invention has the advantages of low internal stress, good film quality, uniformity and compactness and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

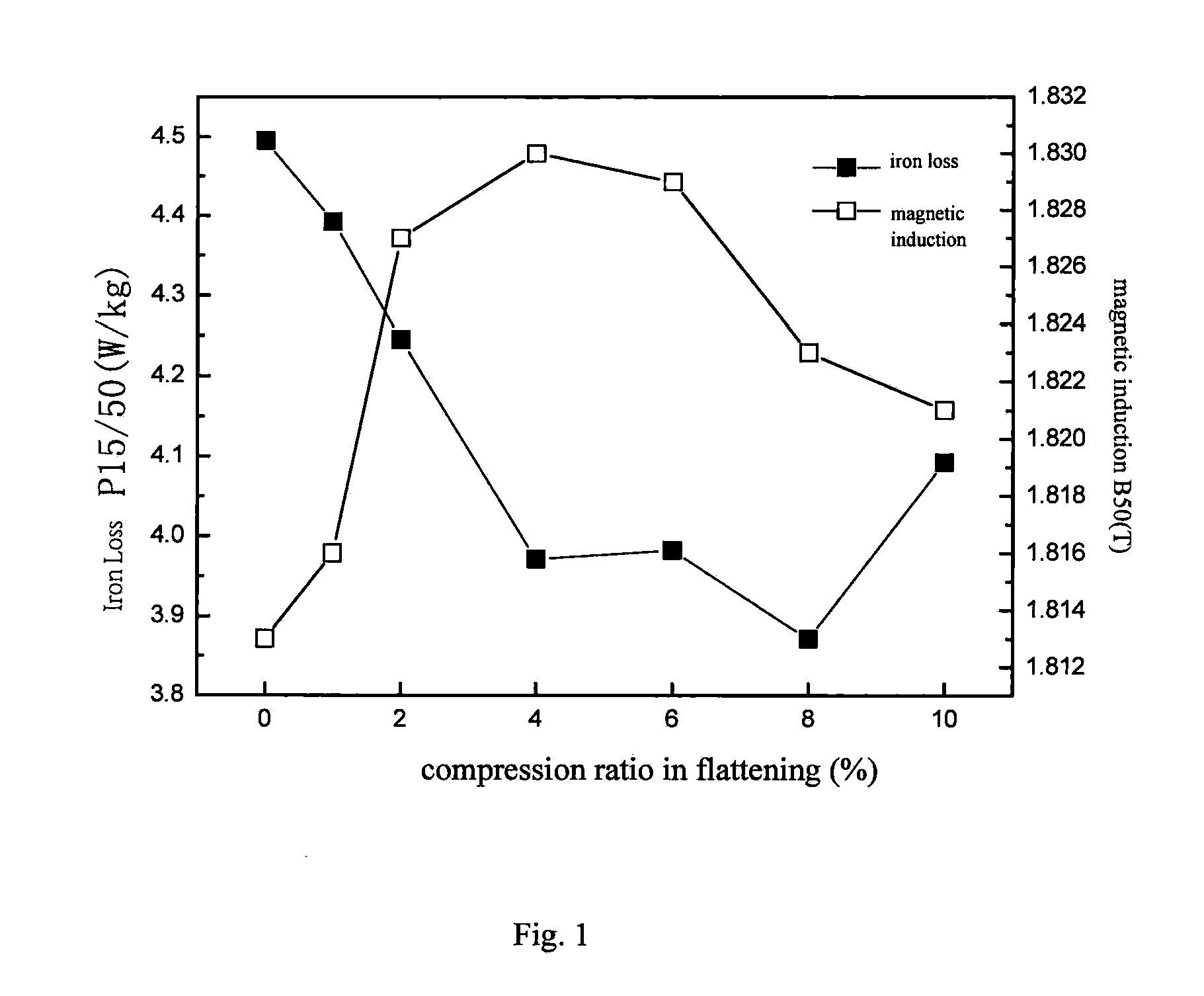

Manufacture Process Of Non-Oriented Silicon Steel With High Magnetic Induction

InactiveUS20120285584A1Increase the granular structureImprove textureInorganic material magnetismMetal rolling arrangementsChemical compositionSilicon

A manufacture process of non-oriented silicon steel with high magnetic induction includes smelting and casting steel having a chemical composition by weight percent: Si 0.1˜1%, Al 0.005˜1.0%, C≦0.004%, Mn=0.10˜1.50%, P≦0.2%, S≦0.005%, N≦0.002, Nb+V+Ti≦0.006%, and the rest is Fe. The steel is cast into a billet, which is heated and hot-rolled to 1150˜1200° C. into a plate at a finish-rolling temperature 830˜900° C. The plate is cooled to a temperature ≧570° C. and cold-roll flattened at compression ratio 2˜5%. The flattened plate is normalized at temperature not below 950° C. for 30˜180s, and then pickled and cold-rolled into a sheet with thickness of the finished product. The sheet is finish-annealed quickly heating the sheet to 800˜1000° C. at temperature rise rate ≧100° C. / s, soaking the heated sheet for 5˜60s at the temperature, and then slowly cooling the sheet to 600˜750° C.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-cost high-plastic-deformation magnesium alloy

The invention discloses a low-cost high-plastic-deformation magnesium alloy. The magnesium alloy comprises the following components in percentage by mass: 0.5-4.0% of Mn, 0.1-0.5% of Al and the balance of magnesium and inevitable impurities. In an Mg-Al-Mn ternary system, elements manganese and aluminum define an aluminum-manganese phase, and a rich manganese element defines an elemental manganesephase. In a preparation process, an extrusion process at a relatively low temperature is adopted to prepare a high-plasticity magnesium alloy material which is suitable for 3C product shells, bearingstructures for leisure goods as well as aerospace parts and the like; and the material is simple in preparation process, is low in cost, and has a very good industrialized prospect.

Owner:CHONGQING UNIV

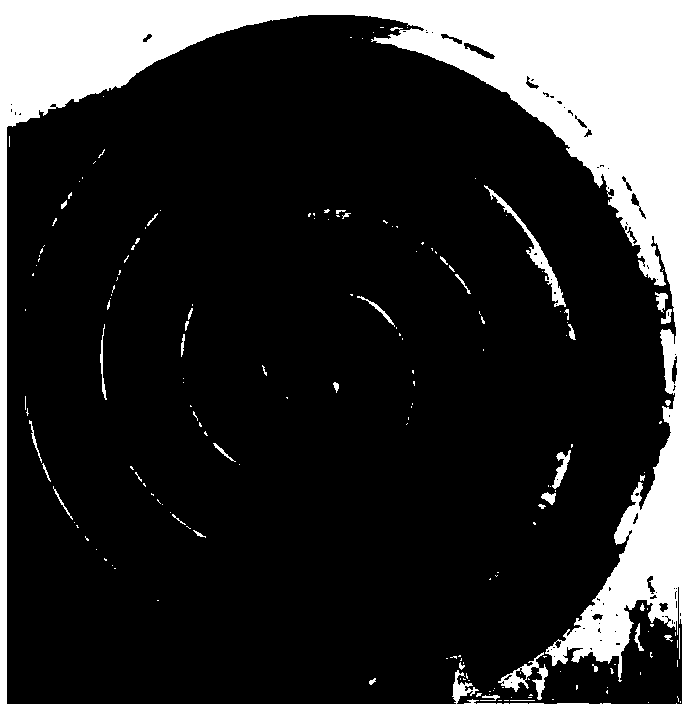

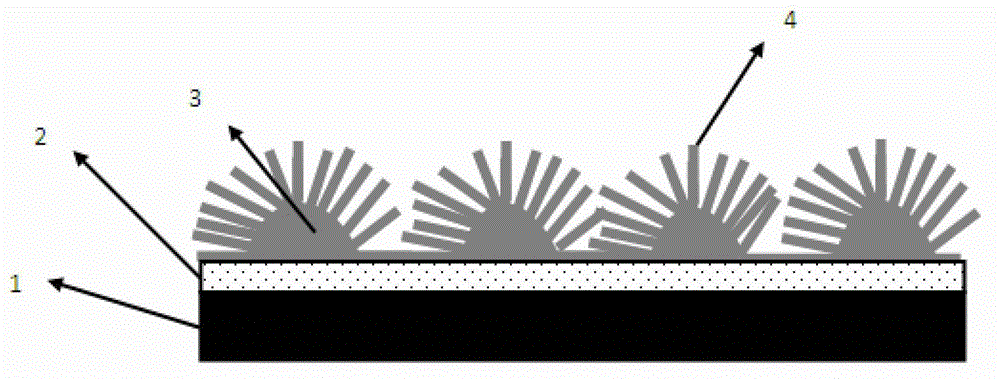

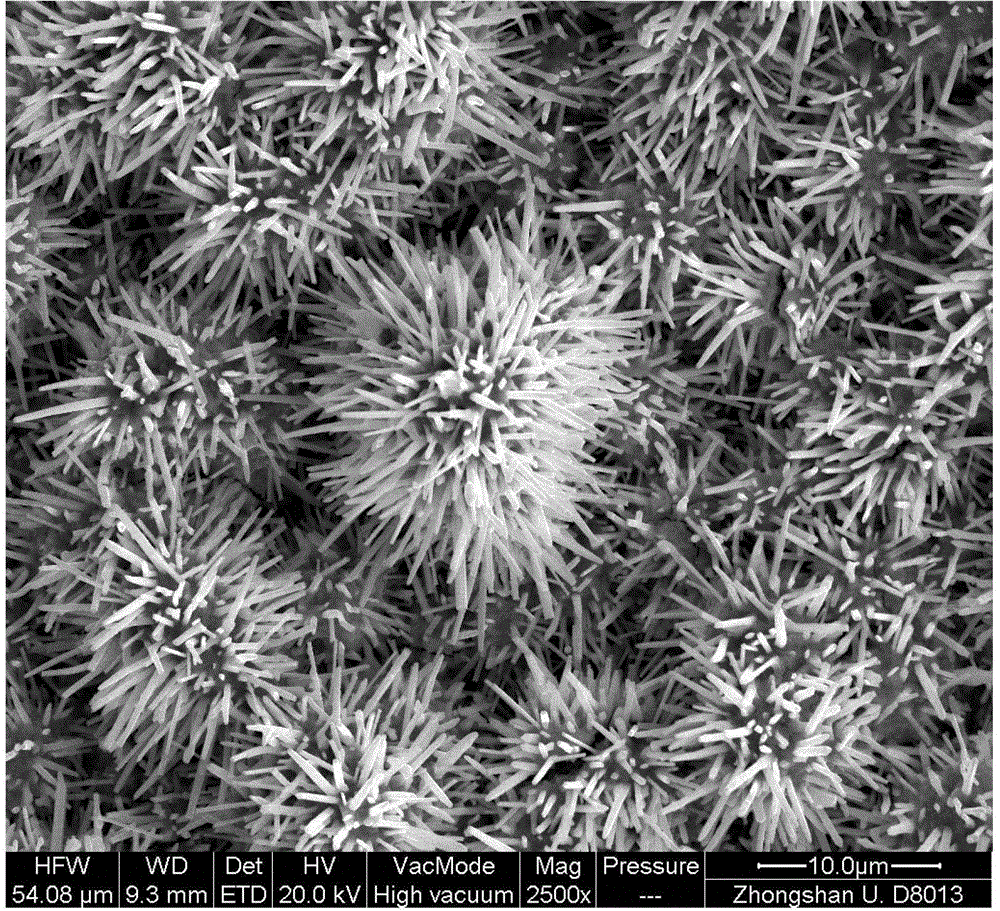

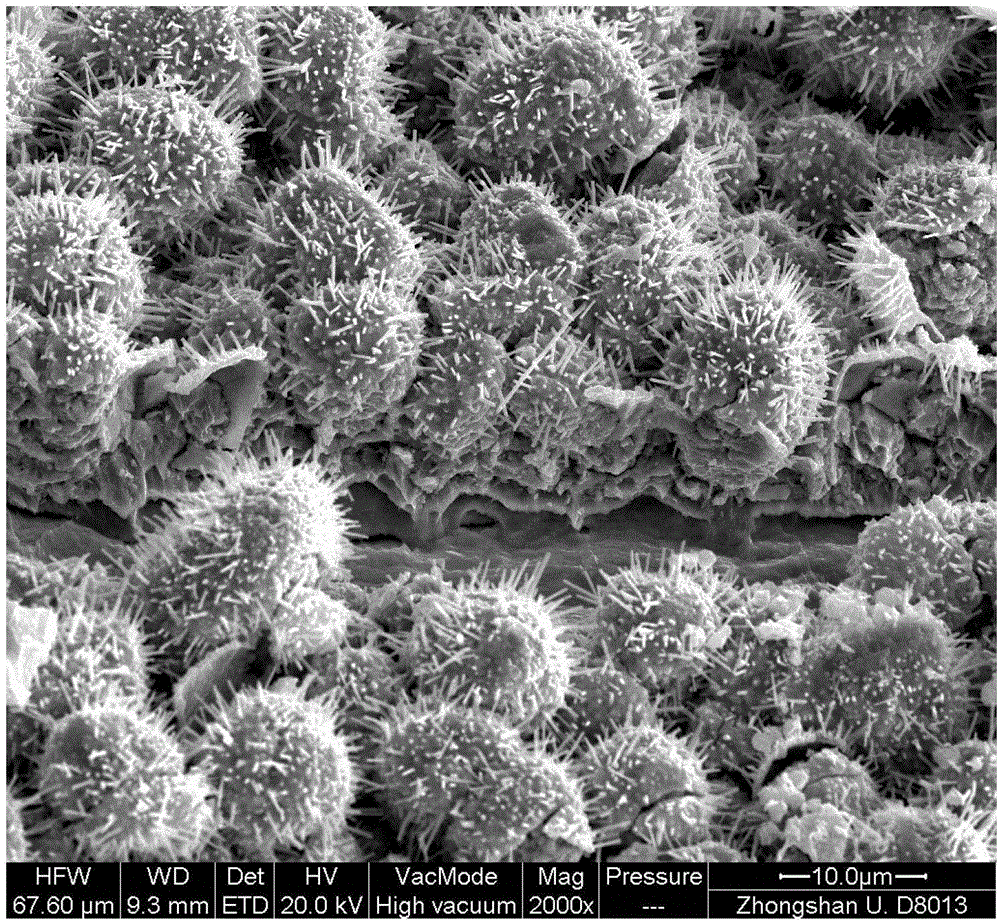

Micro/nanometer secondary surface array and preparation method and application thereof

InactiveCN103151397AIncrease the chance of occurrenceSmall absorption changeSolar heat devicesFinal product manufactureMicron scaleNanowire

The invention discloses a 'cactus' micro / nanometer secondary surface array structure, a preparation method and application of the 'cactus' micro / nanometer secondary surface array structure. The micro / nanometer secondary surface array is formed in the manner that nanoscale copper 2 sulphur (Cu2S) nanometer lines grow on the surface of micron scale Cu2S spherical crowns, and the Cu2S spherical crowns are periodically distributed on the surface of a substrate. Compared with a common plane nanometer line array, the Cu2S'cactus' micro / nanometer secondary surface array further increases specific surface area, and increases probability of generation of charge carriers. Meanwhile, when the angle of incident light changes, change of relative position between the nanometer lines and light rays is small, and change of light absorption is small, so the light absorption can maintain good performance within the wide light incident angle. When the Cu2S'cactus' micro / nanometer secondary surface array is applied to the field of solar energy, the Cu2S'cactus' micro / nanometer secondary surface array can overcome the defects of degrading the performance along with the position of the sun, or changing angles of devices continuously along with the change of illumination angles to cause complexity of structure of the devices and increase of cost.

Owner:SUN YAT SEN UNIV

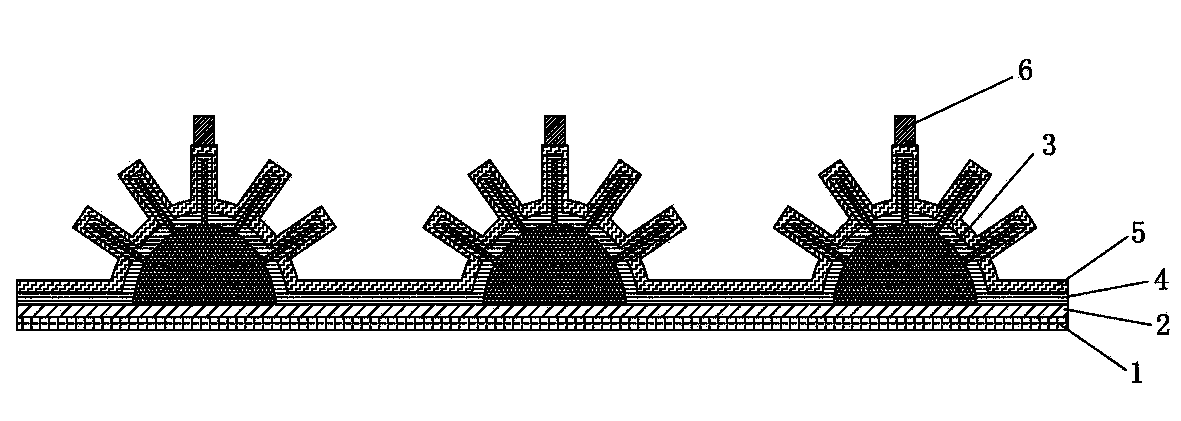

Thin-film solar cell with micron-nanometer two-stage array structure and manufacturing method thereof

ActiveCN103715280AImprove photoelectric conversion efficiencyEasy to prepareMaterial nanotechnologyFinal product manufactureThin membraneEngineering

The invention belongs to the technical field of solar photovoltaic cells, and particularly relates to a thin-film solar cell with a micron-nanometer two-stage array structure and a manufacturing method of the thin-film solar cell. The thin-film solar cell comprises a substrate, wherein a back electrode, a p-type semiconductor micron-nanometer two-stage array, an n-type semiconductor layer, a window layer and a metal grid electrode are sequentially arranged on the substrate. An absorbing layer of the thin-film solar cell with the micron-nanometer two-stage array structure is manufactured on the basis of a Cu2S micron-nanometer two-stage array through the chemical bath deposition technology, and the manufacturing method is simple; compared with a method that high vacuum conditions or high temperature conditions are needed for manufacturing the absorbing layer, the manufacturing method has the advantages that the cost is low, the requirements for equipment are low, reactants are easy to obtain, the preparation temperature is low, reaction conditions are easy to control, and the manufacturing method can be conveniently and widely applied.

Owner:SHANGQIU NORMAL UNIVERSITY

High thermal conductivity aluminium alloy and preparation method thereof

PendingUS20210062304A1Improve conductivityImprove performanceSemiconductor/solid-state device detailsFerrosiliconSemi solid

The present invention provides a high thermal conductivity aluminum alloy, which comprises the following components in percentage by weight: Al: 80%-90%; Si: 6.5%-8.5%; Fe: 0.2%-0.5%; Zn: 0.8%-3%; V: 0.03%-0.05%; Sr: 0.01%-1%; graphene: 0.02%-0.08%. In the high thermal conductivity aluminum alloy of the present invention, alloying elements including Si, Fe, and Zn are optimized; Sr, V, graphene, among others are added. The amount of each component is controlled so that they coordinate to ALLOW high thermal conductivity, good casting performance and excellent semi-solid die-casting property. Graphene is introduced to the high thermal conductivity aluminum alloy of the present invention to exploit the good thermal conductivity of graphene, allowing the formation of a high thermal conductivity aluminium alloy.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

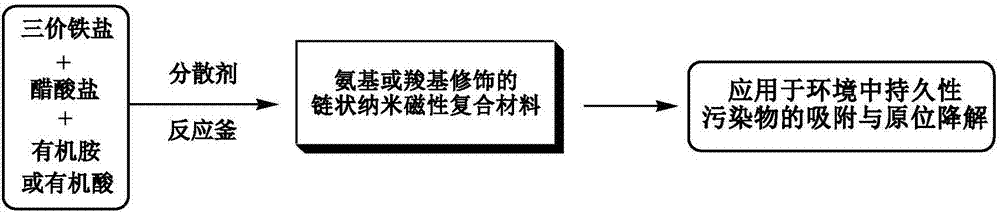

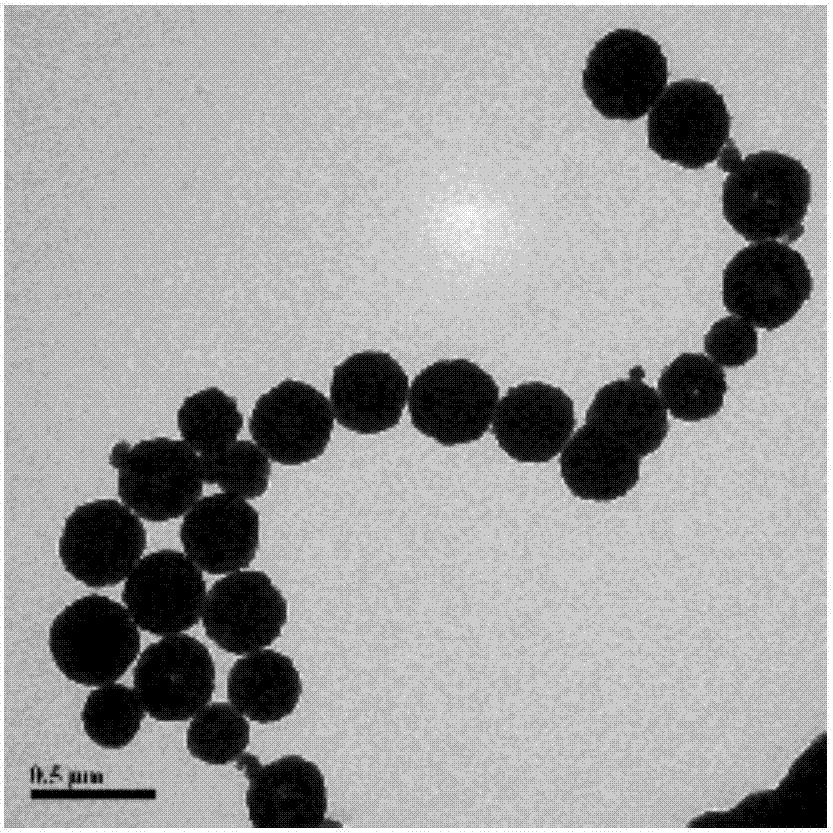

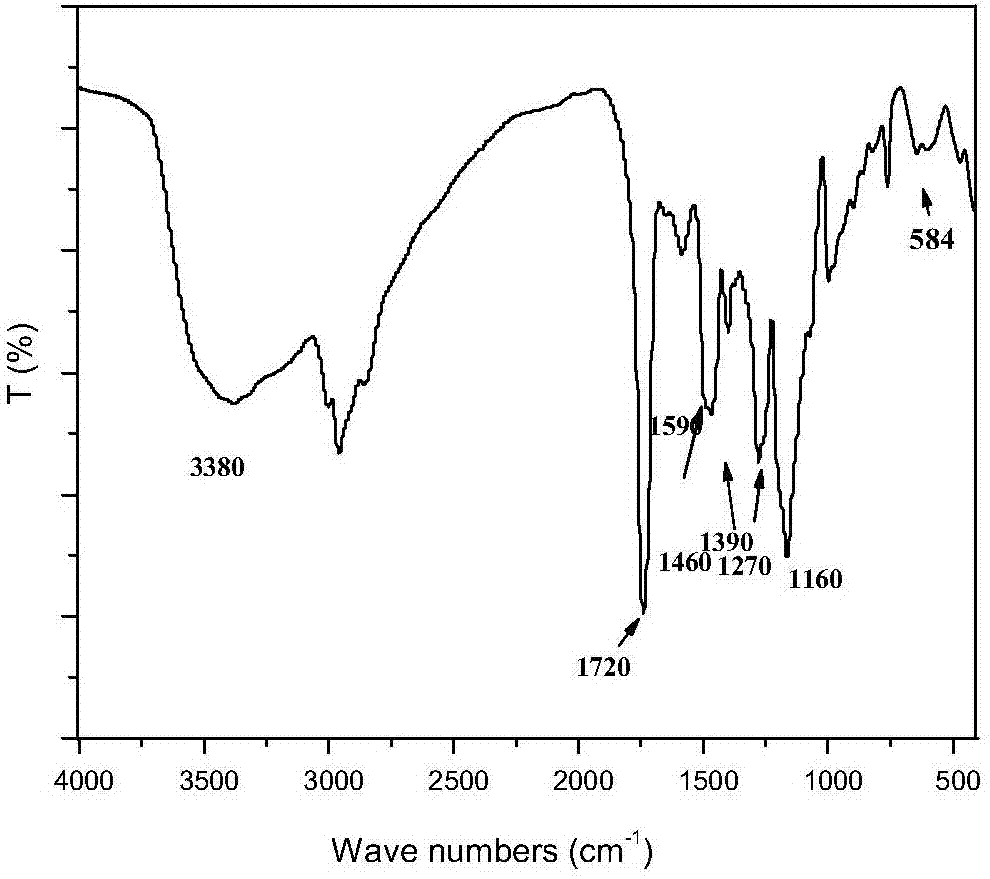

Chain-like nanometer magnetic material, preparation method and application thereof

InactiveCN107282026AOrderly self-assemblyUniform particle size distributionOther chemical processesWater contaminantsMicrosphereControllability

The invention discloses a chain-like nanometer magnetic material, a preparation method and an application thereof. The chain-like nanometer magnetic material is characterized by containing the following raw materials: ferric iron, acetate, dispersing agent and organic amine or organic acid; the mass concentrations of the ferric iron and the acetate in the dispersing agent are respectively 5-500g / L and 10-800g / L; the mass concentration of the organic amine or organic acid in the mixed solution after adding is 1-800g / L. According to the invention, various organic acids and organic amine are expanded; an amino or carboxyl modified chain-like nanometer magnetic composite material is acquired through a one-step process; the material with the chain-like structure can be acquired in the manner of inducing the composite material through hydrogen bond and magnetic field; the invention obviously innovates the controllability of the aggregation state structure of the material. The traditional method is performed in multiple steps, a covalent organic frame magnetic composite microsphere with a porous structure is acquired, the preparation process of the material is complex, the nonmagnetic components of the material are increased, the magnetic content of the acquired material is reduced and the method is adverse to magnetic separation.

High-strength and abrasion resisting copper alloy contact wire and preparation technology thereof

InactiveCN109504872AHigh chemical activityHigh affinityTrolley linesRare-earth elementSolution treatment

The invention relates to the field of copper alloy technical processing, in particular to a high-strength and abrasion resisting copper alloy contact wire and a preparation technology thereof. The high-strength and abrasion resisting copper alloy contact wire is prepared from the raw materials in percentage by weight: 0.01-0.30% of a rare earth element, 0.01-0.10% of a metallic oxide, and the balance of the copper alloy. The preparation method comprises alloy product preparation, semi-solid state treatment, horizontal continuous casting, continuous extrusion, first cold working, solution treatment, second cold working, two-stage aging, and drawing forming. The high-strength and abrasion resisting copper alloy contact wire has good electrical conductivity, high strength, high high-temperature resistance, and abrasion resistance, and can be used as a contact wire material for high speed railways, especially for a high-speed railway with speed of more than 400 kilometers per hour.

Owner:SHANDONG YANGGU CABLE GROUP

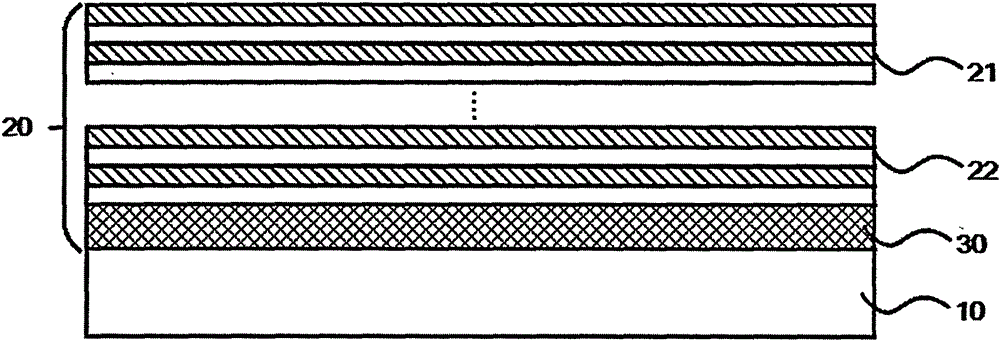

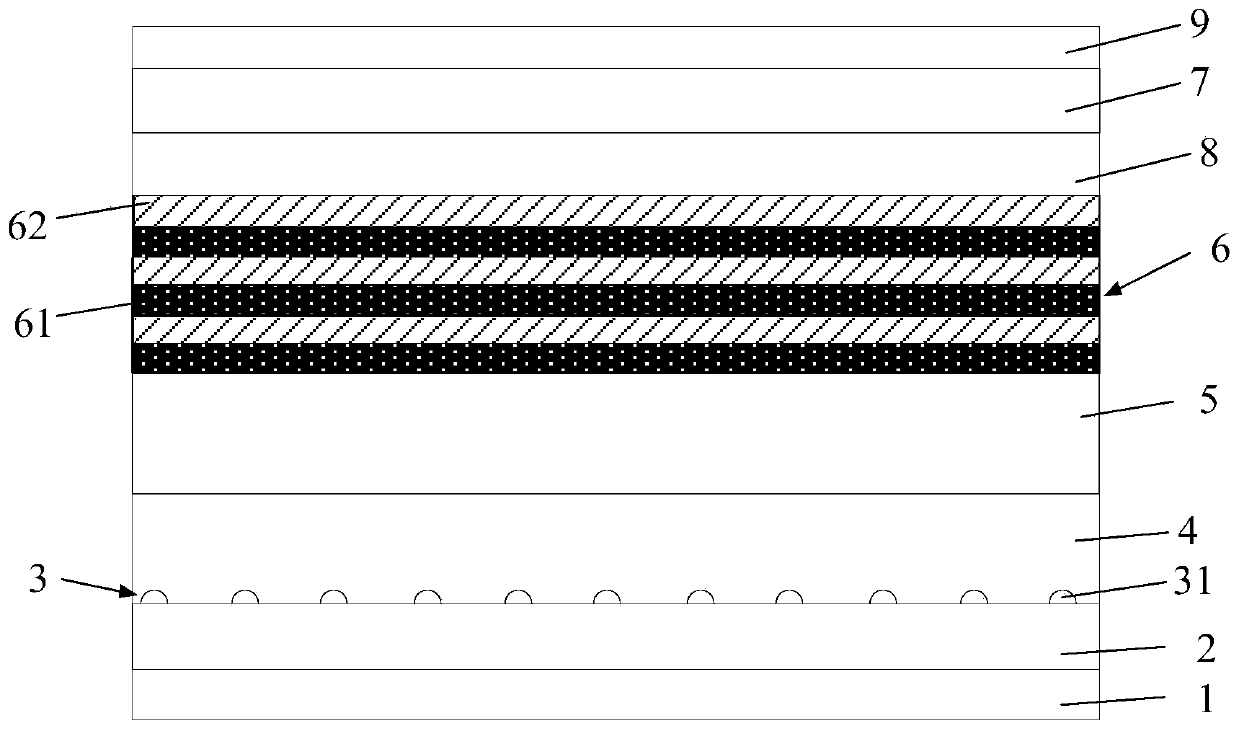

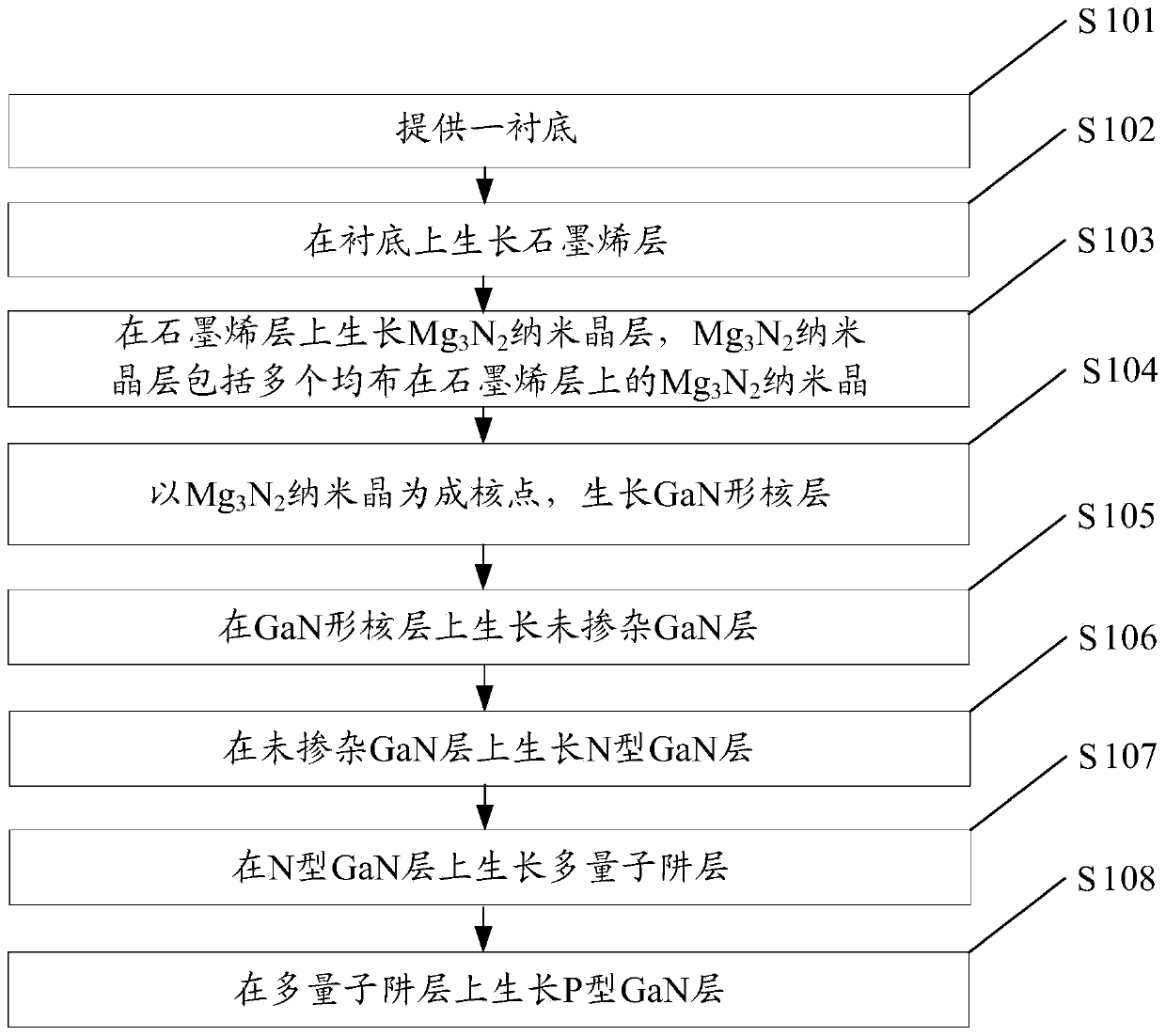

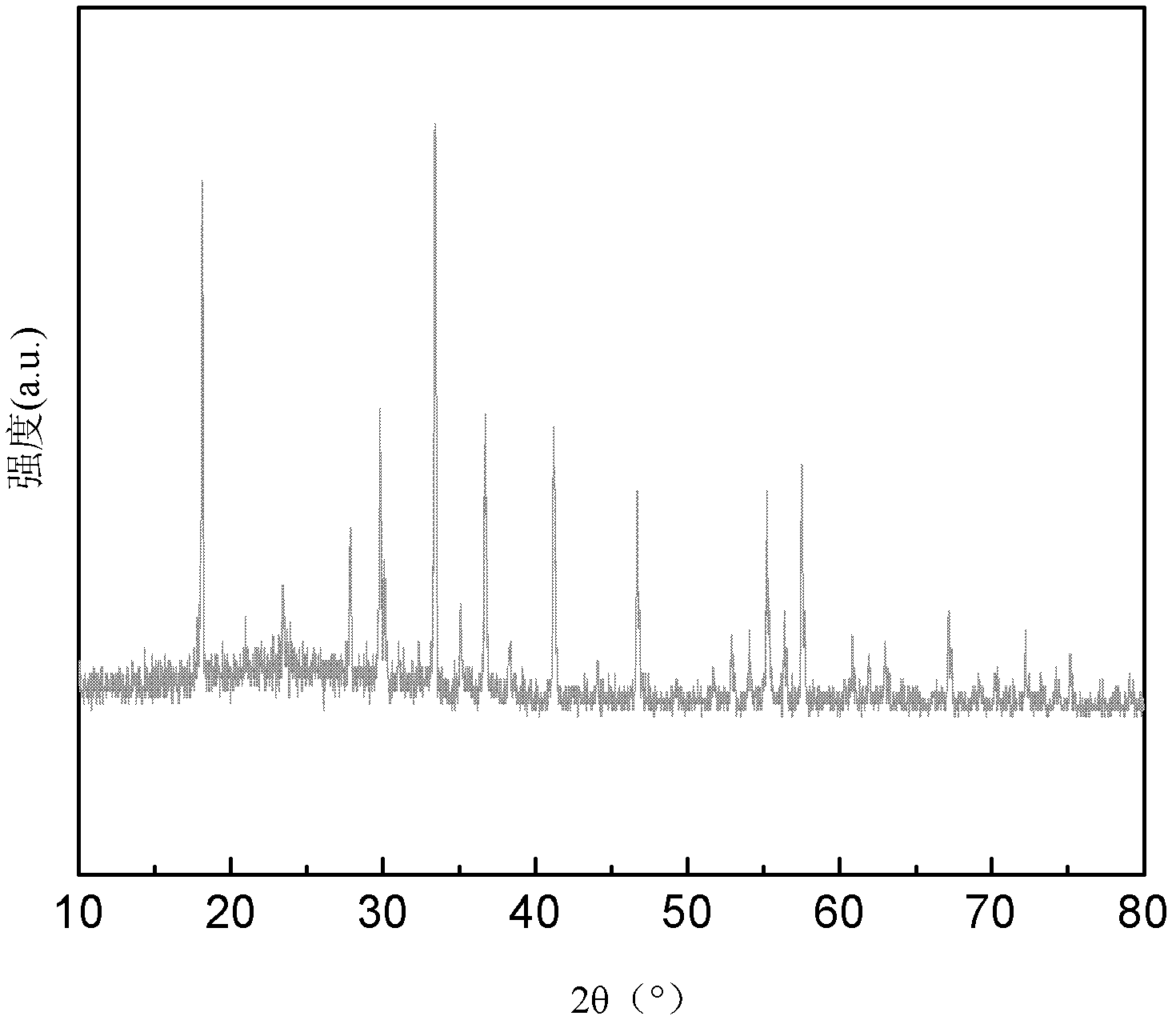

Epitaxial wafer of light-emitting diode and preparation method thereof

ActiveCN109786518AQuality improvementClosely connectedMaterial nanotechnologySemiconductor devicesNucleationGraphene

The invention discloses an epitaxial wafer of a light-emitting diode and a preparation method thereof and belongs to the field of light-emitting diode manufacturing. The epitaxial wafer has the beneficial effects that a Mg3N2 nanocrystalline layer is laminated on a graphene layer, a plurality of Mg3N2 nanocrystals in the Mg3N2 nanocrystalline layer have low surface potential energy points and highchemical activity and can serve as nucleation points of a GaN nucleating layer and the GaN nucleating layer is easier to grow on the Mg3N2 nanocrystals to ensure that a plurality of island structurescan be uniformly formed on the graphene layer by the GaN nucleation layer; when an un-doped GaN layer continues to grow, more Ga atoms and N atoms are attracted by the island structures to continue to grow; and the distance between the island structures is appropriate and the migration and the diffusion of the atoms are relatively less, thereby reducing the lattice distortion and defects caused by atoms on the island structures in the moving diffusion process and increasing the crystal quality of the un-doped GaN layer.

Owner:HC SEMITEK ZHEJIANG CO LTD

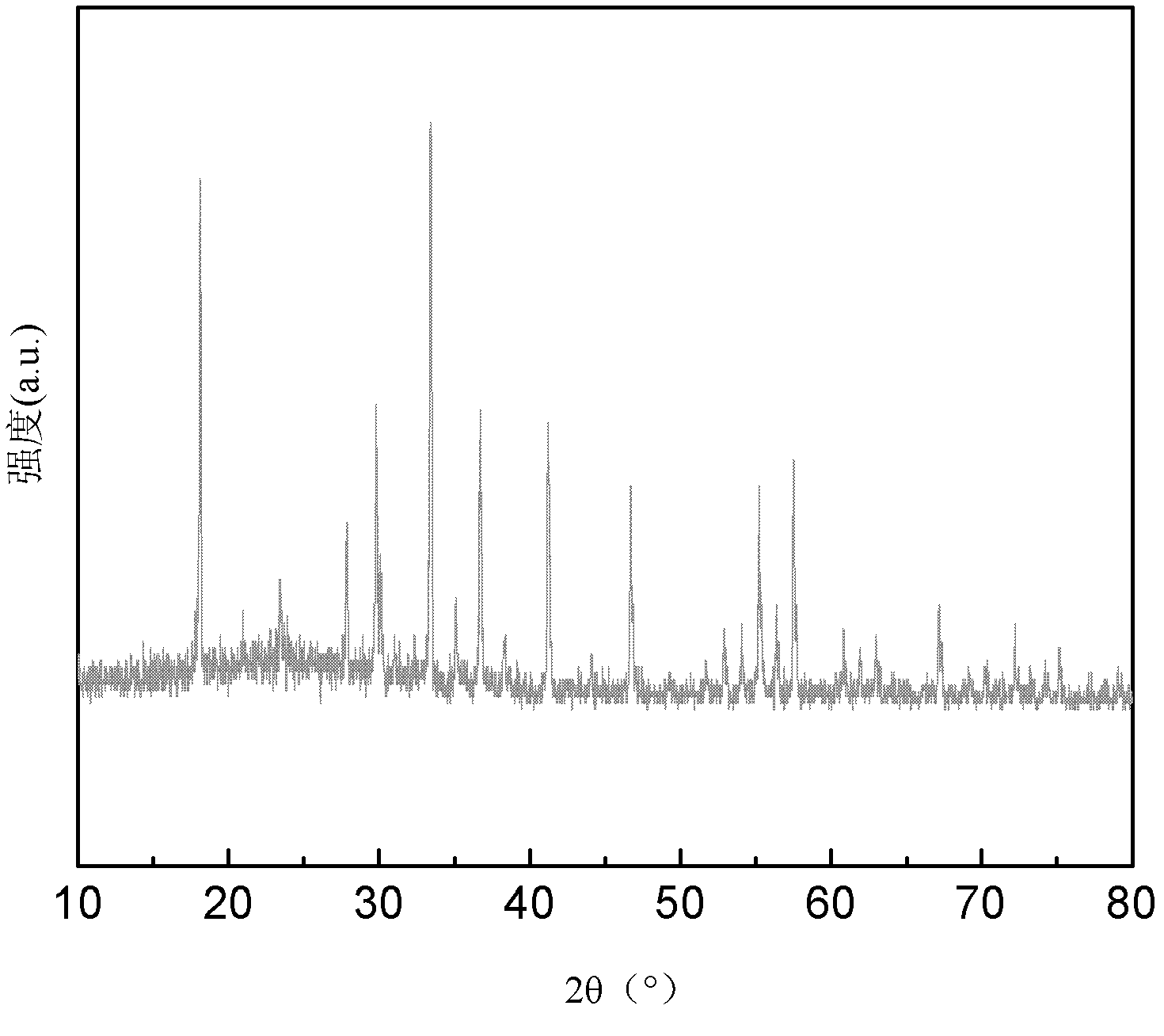

Pulling method for growing Ca12Al14O33 monocrystal in non-stoichiometric ratio melt

InactiveCN102383186AReduce lattice distortionShorten the annealing cyclePolycrystalline material growthBy pulling from meltIridiumCrucible

The invention relates to a pulling method for growing a Ca12Al14O33 monocrystal in a non-stoichiometric ratio melt and relates to a method for growing the Ca12Al14O33 monocrystal. The invention aims to solve the technical problems that an iridium crucible is corroded severely, light transmissivity is greatly reduced, crystal lattices are distorted and cracked, size limitation is high and the like in the conventional method for growing the Ca12Al14O33 monocrystal. The method comprises the following steps of: 1, weighing CaO and Al2O3 respectively; 2, mixing and grinding uniformly, tabletting, putting into a corundum crucible, keeping constant temperature and cooling to room temperature; 3, repeating the step 2 for 2 to 3 times; and 4, growing the crystal by using the pulling method to obtain the Ca12Al14O33 monocrystal. Due to the unique structure of a C12A7 material in the optical aspect, the C12A7 doped material can be applied to a semiconductor laser material in the aspects of blue light emission and white light tuning.

Owner:HARBIN INST OF TECH

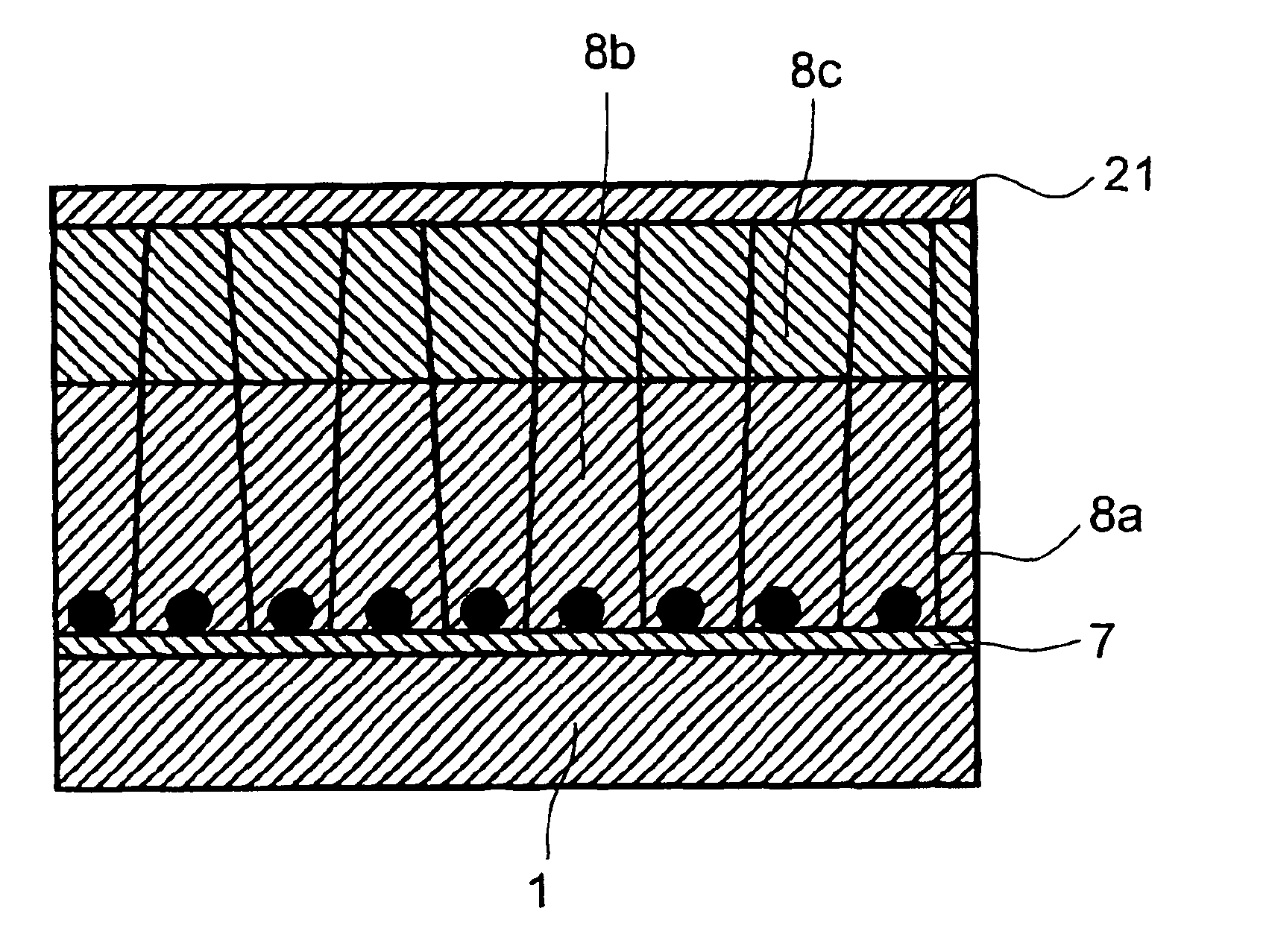

MOS transistor apparatus and method of manufacturing same

InactiveUS6870224B2Suppress depletionReduce lattice distortionTransistorSolid-state devicesThin oxideCrystallite

When polycrystalline silicon germanium film is used for gate electrodes in a MOS transistor apparatus, there have been problems of reduced reliability in the gate insulating film, due to stress in the silicon germanium grains. Therefore, a polysilicon germanium film is formed, after forming silicon fine particles of particle size 10 nm or less on an oxide film. As a result, it is possible to achieve a high-speed MOS transistor apparatus using an ultra-thin oxide film having a film thickness of 1.5 nm or less, wherein the Ge concentration of the polycrystalline silicon germanium at its interface with the oxide film is uniform, thereby reducing the stress in the film, and improving the reliability of the gate electrode.

Owner:HITACHI LTD

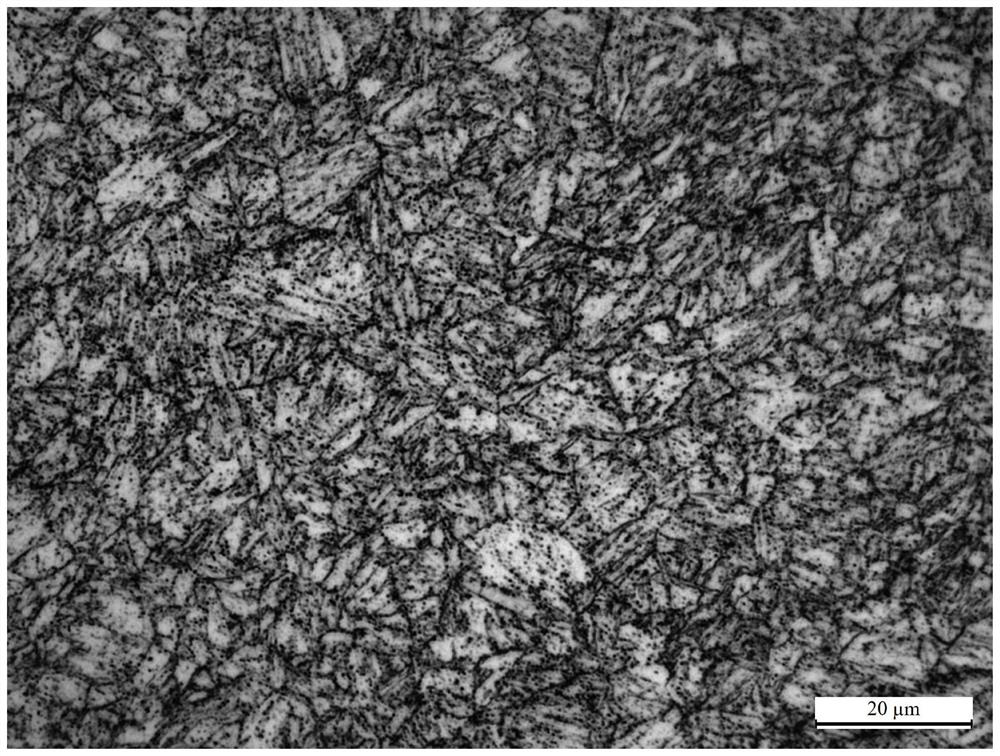

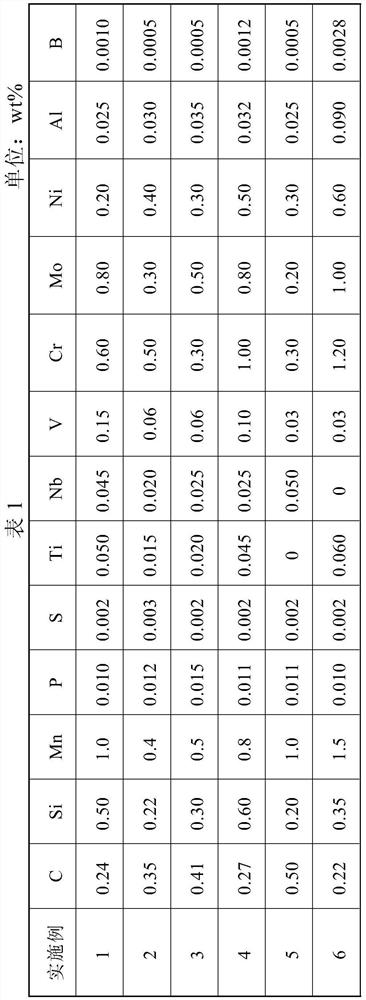

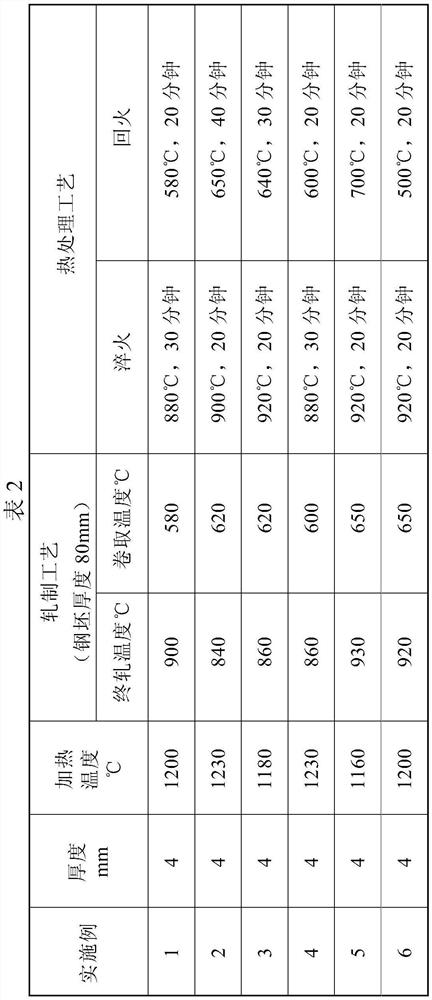

1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel and production method thereof

ActiveCN111748732AReduce lattice distortionReduce residual internal stressUltimate tensile strengthMagnetism

The invention discloses 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel and a production method thereof. The 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel is prepared from the following components in percentage by weight: 0.20 to 0.50 percent of C, 0.2 to 1.0 percent of Si, 0.5 to 1.5 percent of Mn, less than or equal to 0.015 percentof P, less than or equal to 0.005 percent of S, less than or equal to 0.06 percent of Ti, less than or equal to 0.05 percent of Nb, 0.20 to 1.0 percent of Mo, 0.20 to 1.20 percent of Cr, 0.20 to 0.60percent of Ni, 0.03 to 0.15 percent of V, 0.0005 to 0.003 percent of B, 0.015 to 0.10 percent of Al, less than or equal to 0.010 percent of N, less than or equal to 0.0080 percent of O, and the balance of Fe and other unavoidable impurities; and meanwhile Cr+Mo+Ni is larger than or equal to 0.80 percent; Nb+V+Ti is larger than or equal to 0.06 percent; carbon equivalent CEV is larger than or equal to 0.50 percent. The yield strength of the hot-rolled magnetic yoke steel is larger than or equal to 1000MPa, the tensile strength is larger than or equal to 1050MPa; the impact power KV<2> is larger than or equal to 40J at the temperature of 20 DEG C below zero; the magnetic induction performance B<50> is larger than or equal to 1.58T; B<100> is larger than or equal to 1.73T; B<200> is larger than or equal to 1.90T; and B<300> is larger than or equal to 1.93T. The 1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel meets relevant requirements of the hydropower industry on rotor magnetic yoke steel.

Owner:BAOSHAN IRON & STEEL CO LTD

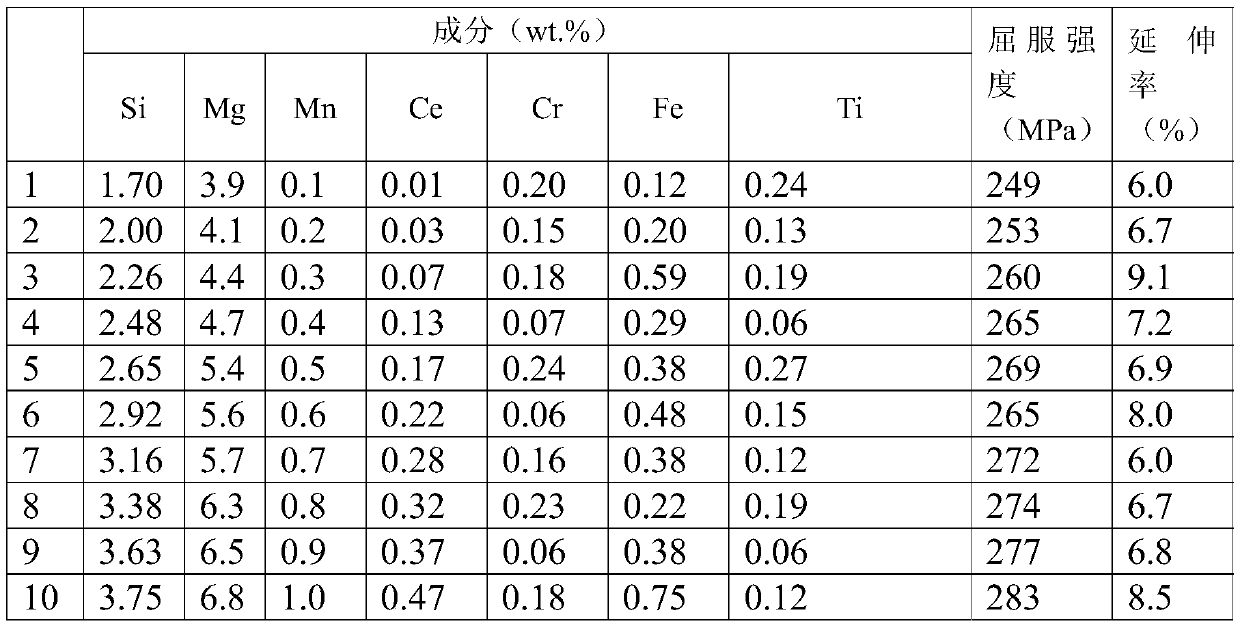

High-yield high-elongation-rate die-casting alloy material for mobile phone medium plate and preparation method

The invention relates to a high-yield high-elongation-rate die-casting alloy material for a mobile phone medium plate and a preparation method thereof. The alloy comprises the following components of2.0wt%-4.0wt% of Si, 4.5wt%-6.8wt% of Mg, 0.6wt%-1.2wt% of Mn, 0.001wt%-1.0wt% of Ce, 0.001wt%-0.5wt% of Cr, 0.2wt%-1.0wt% of Fe, 0.05wt%-0.25wt% of Ti, 1.0wt% or below of the rest of the impurities and the balance Al. Compared with the prior art, the high-yield high-elongation-rate die-casting alloy material for the mobile phone medium plate and the preparation method thereof have the advantagesthat multi-element reinforced phases, namely, the Mn, the Si, the Mg and the Ce are added into the aluminum alloy, and multi-element reinforced phases Mg2Si, MnAl6, CeSi2 and Al11Ce3 are introduced, so that the yield strength and the elongation rate of the material are remarkably improved, and in case of the material when being applied to a thin wall, the yield strength reaches 250 MPa to 280 MPa,and the elongation rate reaches 6% to 12%.

Owner:苏州慧驰轻合金精密成型科技有限公司 +1

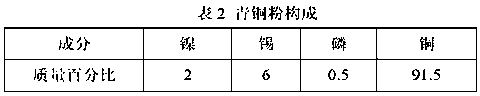

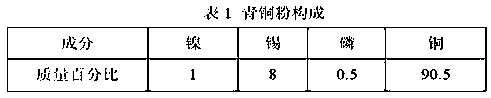

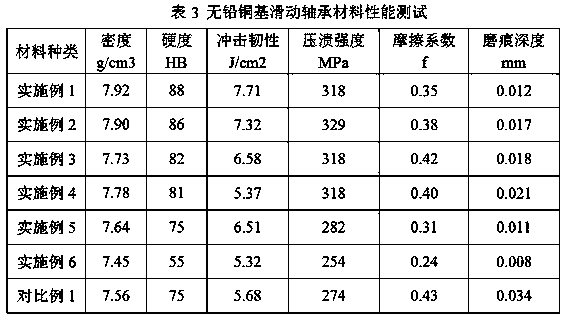

Antifriction lead-free copper-based sliding bearing material and preparation method thereof

InactiveCN108486404AImprove friction and wear propertiesAchieve lead-freeShaftsBearing componentsWear resistantBronze

The invention discloses an antifriction lead-free copper-based sliding bearing material and a preparation method thereof. The ferrous sulfide powder, the bismuth powder and the bronze powder are subjected to mechanical alloying by adopting a ball milling technology to improve the interface adhesive strength of the ferrous sulfide, the bismuth and the bronze, and the phenomenon that the ferrous sulfide is easy to agglomerate when the content of copper matrix is relatively high is improved, the structure of FeS is good in oil storage capacity, the stability of the liquid-solid lubricating film is enabled to be good, so that the process of Bi spalling, the fusion of the low-melting-point component Bi and separating out of the low-melting-point component Bi are relieved, and the liquid-solid lubricating film can also be repaired and completed, so that the antifriction performance of the material is improved; in conclusion, the antifriction and wear-resistant properties of the copper-basedsliding bearing material are improved, the lead which is used as a lubricant in the copper-based bearing material is replaced by the good synergistic effect of the ferrous sulfide and the bismuth, sothat the pollution of lead is avoided; and the antifriction lead-free copper-based sliding bearing material and the preparation method thereof have the advantages of being low in cost and suitable forindustrial production.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com