Thin-film solar photovoltaic cell with nano wire array structure and preparation method for thin-film solar photovoltaic cell

A technology of nanowire arrays and thin-film solar energy, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of difficult large-area production and preparation, high preparation costs, and difficult control of the microstructure of element ratio materials, and achieve convenient large-area Application, low preparation cost, and the effect of reducing the probability of hole and electron recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

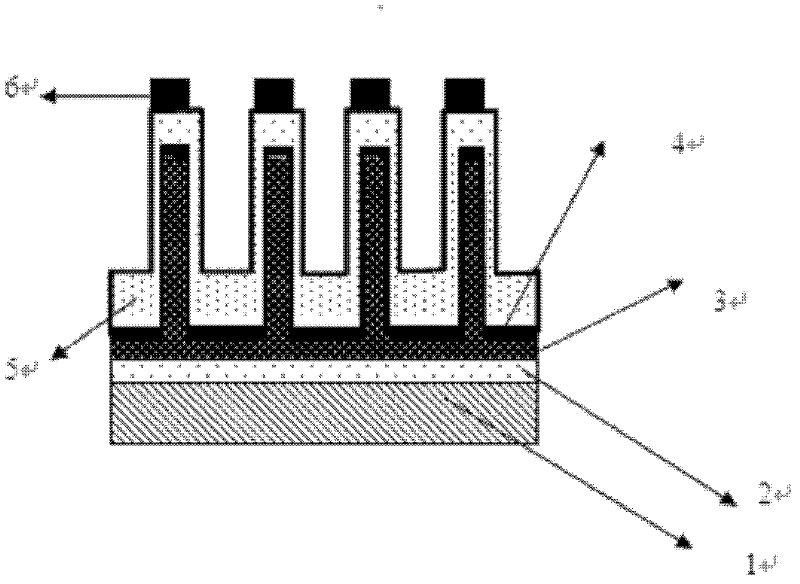

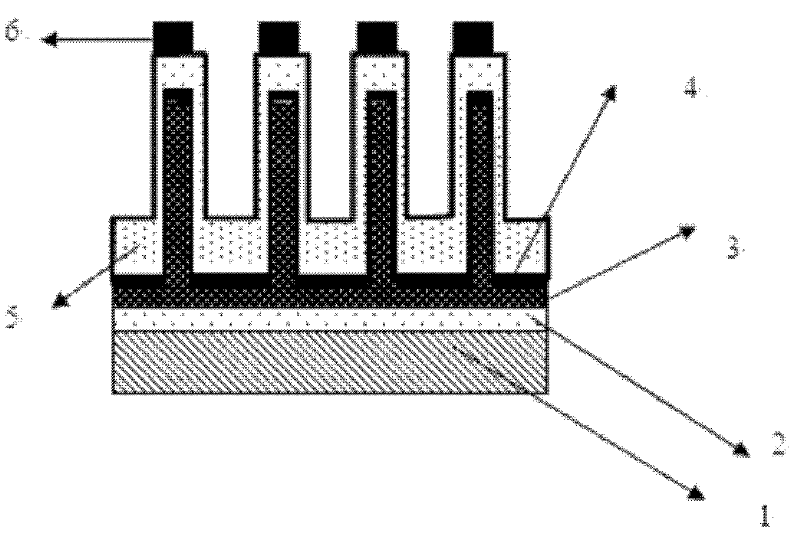

[0034] This example chooses CuInS 2 As the composition of the semiconductor nanowire array, CdS as the n-type layer, infiltration as the means of depositing cadmium sulfide layer, Al-doped ZnO layer as the window layer, thermal evaporation as the deposition of In, Al-doped ZnO layer, metal grid electrode, back The means of electrode and copper film, the back electrode is made of Mo, the metal grid electrode is made of Ti, and the substrate is made of glass.

[0035] Specific steps are as follows:

[0036] (1) After cleaning with 1mol / L NaOH solution and 1mol / L hydrochloric acid solution respectively, deposit a Mo layer with a thickness of 800nm on the glass substrate which has been ultrasonically cleaned in sequence with absolute ethanol and deionized water ;

[0037] (2) evaporating a layer of copper film with a thickness of 10um on the substrate after thermal evaporation deposition of Mo;

[0038] (3) Put the substrate with the copper film evaporated obtained in step (2...

Embodiment 2

[0045] This example selects Cu(In, Ga)(S, Se) 2 As the composition of the semiconductor nanowire array, CdS is used as the n-type layer, the aluminum-doped zinc oxide layer is used as the window layer, spin coating is used as the means of depositing the cadmium sulfide layer, and magnetron sputtering is used as the deposition of In, Ga, Se, aluminum-doped zinc oxide layer , Metal grid electrode, back electrode and copper film, the back electrode is made of Al, the metal grid electrode is made of Cu, and the substrate is made of silicon wafer.

[0046] Specific steps are as follows:

[0047] (1) After cleaning with 1mol / L NaOH solution and 1mol / L hydrochloric acid solution, a layer of Al is deposited on the silicon wafer substrate that has been ultrasonically cleaned with absolute ethanol and deionized water in sequence, and the thickness of Al is 800nm ;

[0048] (2) Sputter a layer of copper film with a thickness of about 1um on the substrate after Al is deposited by magnet...

Embodiment 3

[0056] In this example, Cu(In 0.7 , Ga 0.3 )(Se,S) 2 As the composition of the semiconductor nanowire array, ZnS is used as the n-type layer, the aluminum-doped zinc oxide layer is used as the window layer, and the chemical bath is used as the means of depositing ZnS. Electron beam evaporation is used as a means of depositing In, Ga, Se, aluminum-doped zinc oxide layer, metal grid electrode, back electrode and copper film. W is used for the back electrode, Ni is used for the metal grid electrode, and mica is used for the substrate.

[0057] Specific steps are as follows:

[0058] (1) Deposit a layer of W on the newly cut mica sheet substrate, and the thickness of W is 800nm;

[0059] (2) On the substrate after electron beam evaporation W, evaporate a layer of copper film with a thickness of about 1um;

[0060] (3) Put the substrate with the copper film evaporated obtained in step (2) into a reactor, and after 10 minutes of passing through a mixed gas with a volume ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com