1000MPa-grade high-toughness and high-magnetism hot-rolled magnetic yoke steel and production method thereof

A technology of 1.1000mpa and production method, which is applied in the field of 1000MPa high-toughness and high-magnetic hot-rolled yoke steel and its production field, can solve the problem that the magnetic properties cannot meet the requirements of the yoke steel for hydropower, and achieve good magnetic properties, high and low temperature Toughness and residual internal stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

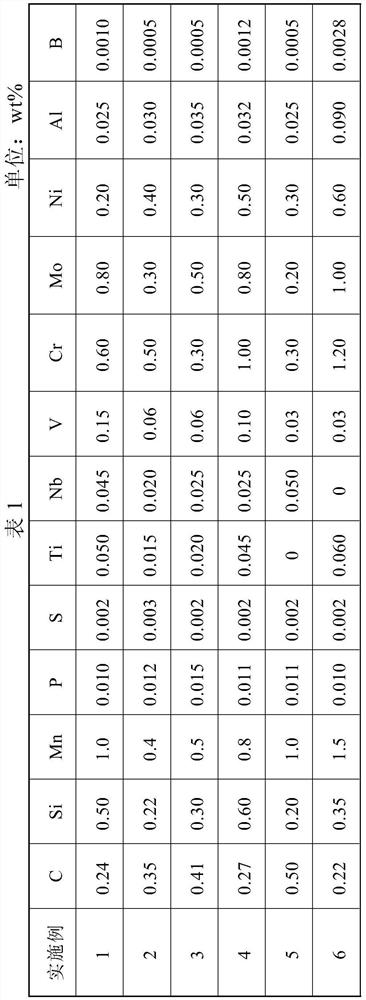

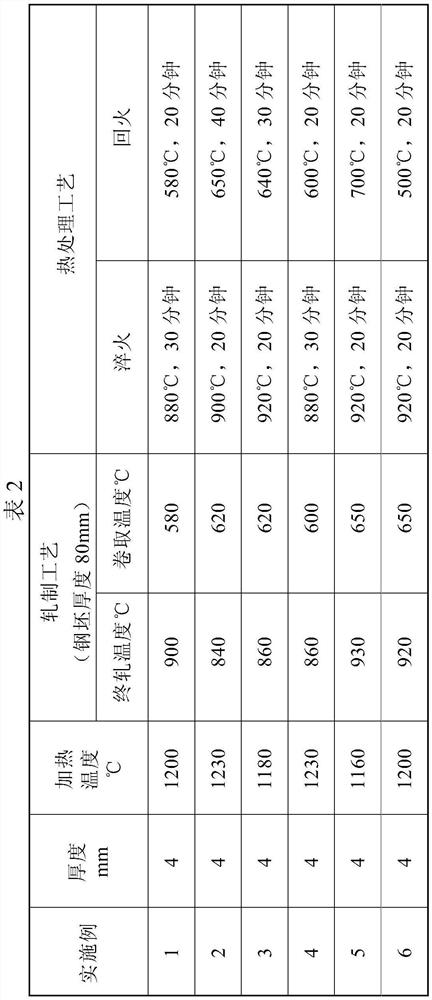

[0042] Table 1 shows the composition of the steel of the embodiment of the present invention, table 2 shows the production process parameters of the steel of the embodiment of the present invention, table 3 shows the mechanical properties of the steel plate of the embodiment of the present invention, and table 4 shows the steel plate of the embodiment of the present invention magnetic properties.

[0043] As can be seen from Table 3 and Table 4, Examples 1 to 6 of the present invention can all satisfy yield strength ≥ 1000MPa, tensile strength ≥ 1050MPa, elongation ≥ 14%, and longitudinal impact energy KV at -20°C 2 ≥40J, magnetic induction performance B 50 ≥1.58T, B 100 ≥1.73T, B 200 ≥1.90T, B 300 ≥1.93T.

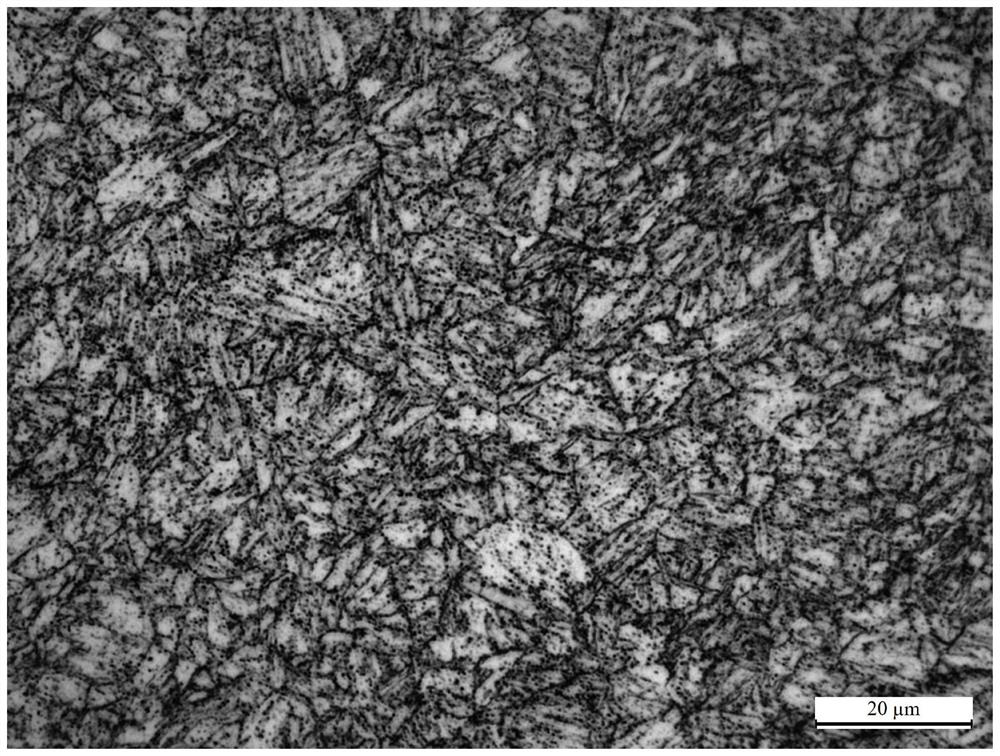

[0044] figure 1 Typical metallographic photographs of the steels tested in the examples are given. It can be seen from the metallographic ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com