Antifriction lead-free copper-based sliding bearing material and preparation method thereof

A sliding bearing, copper-based technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of poor interface bonding, achieve the effects of improving friction reduction and anti-adhesion, improving friction and wear performance, and reducing crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific preparation operation steps of a friction-reducing lead-free copper-based sliding bearing material are as follows:

[0028] (1) Ball milling

[0029] Weigh 220.8g (92%) bronze powder, 14.4g (6%) ferrous sulfide powder and 4.8g (2%) bismuth powder, 240g in total; put 240g of materials into four grinding tanks with a volume of 200mL The total mass of a single grinding canned powder is 60g, and the process control agent stearic acid is added by 0.5wt% of the mass of the mixed material to be ground; bronze powder, ferrous sulfide powder, bismuth powder and process control agent form the mixed material to be ground.

[0030]

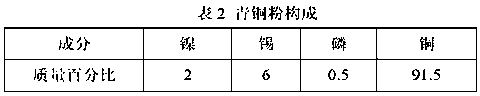

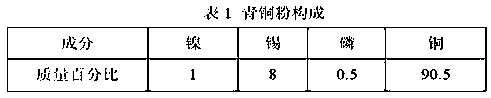

[0031] The mass percentage composition of bronze powder is shown in Table 1.

[0032] The mass ratio of grinding balls to the mixed material to be ground is 10:1, and the total mass of grinding balls in a single grinding tank is 600g, including 250g of large balls and 350g of small balls.

[0033] Vacuumize, fill with high-purity argo...

Embodiment 2

[0041] The specific preparation operation steps of a friction-reducing lead-free copper-based sliding bearing material are as follows:

[0042] (1) Ball milling

[0043] Weigh 276g (92%) bronze powder, 18g (6%) ferrous sulfide powder and 6g (2%) bismuth powder, 300g in total. Put 300g of material into four grinding tanks with a volume of 200mL respectively; the total mass of powder in a single grinding tank is 75g, and add the process control agent stearic acid according to the mass of the mixed material to be ground at 0.5wt%; bronze powder and ferrous sulfide powder , bismuth powder and process control agent to form the mixed material to be ground.

[0044]

[0045] The mass percentage composition of bronze powder is shown in Table 2.

[0046] The mass ratio of grinding balls to the mixed material to be ground is 8:1, and the total mass of grinding balls in a single grinding tank is 600g, including 250g of large balls and 350g of small balls.

[0047] Vacuumize, fill w...

Embodiment 3

[0055] In this embodiment, the ball milling process control agent is ethanol.

[0056] Others are with embodiment 1.

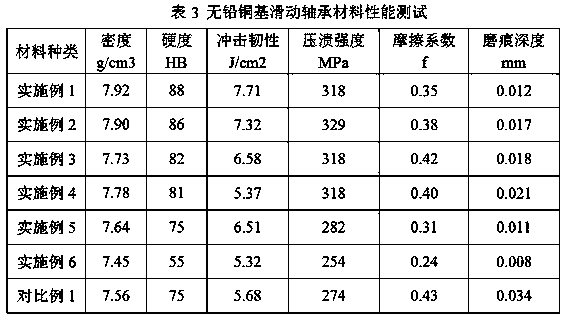

[0057] The mechanical properties of the sample obtained in this embodiment and the test results of the tribological properties after 30 minutes of the test are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com