Nanocarbon clad titanium carbide enhanced nickel-based composite coating material and laser cladding process thereof

A carbon-coated titanium carbide and composite coating technology, applied in the direction of metal material coating process, coating, etc., can solve the problem of increasing the cracking tendency of the coating, and achieve excellent corrosion resistance and friction and wear performance, large-scale and High degree of automation, uniform and dense organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in combination with specific embodiments.

[0027] Select Ni with a particle size of 45-180μm 65.8 Cr 15 B 3.0 Si 3.5 C 0.7 Fe 12 Nickel-based self-fluxing alloy powder is used as the matrix material of the cladding layer, carbon-coated titanium carbide with a particle size of 500nm is selected as the reinforcing phase, and its addition amount is 0.5-14 vol.%. Firstly, the composite powder is prepared according to the stoichiometric ratio. Then, the prepared composite powder is wet-mixed by grinding method. Pre-place the composite powder on the surface of 300M steel (the thickness of the preset layer is 1mm), and use 5KW cross-flow CO under the protection of argon 2 The laser performs multiple overlapping laser cladding. The specific process parameters of laser cladding are: laser power 3.0KW, scanning speed 3.0mm / s, spot diameter 5.0mm, lap rate 20%.

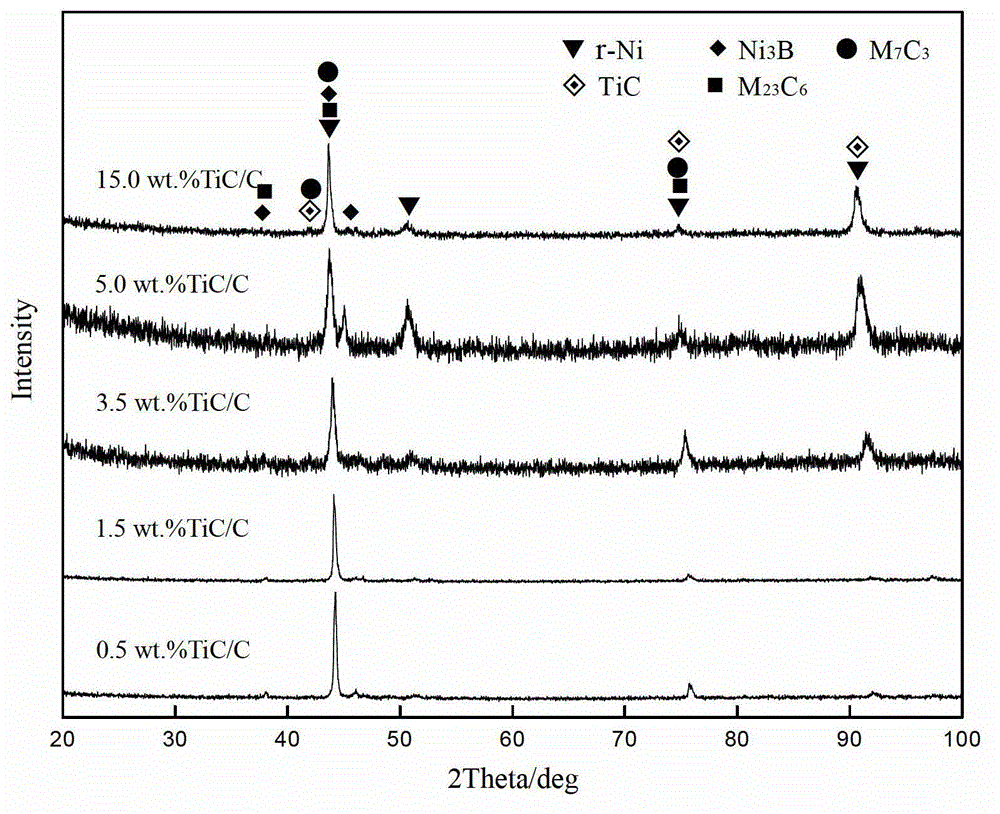

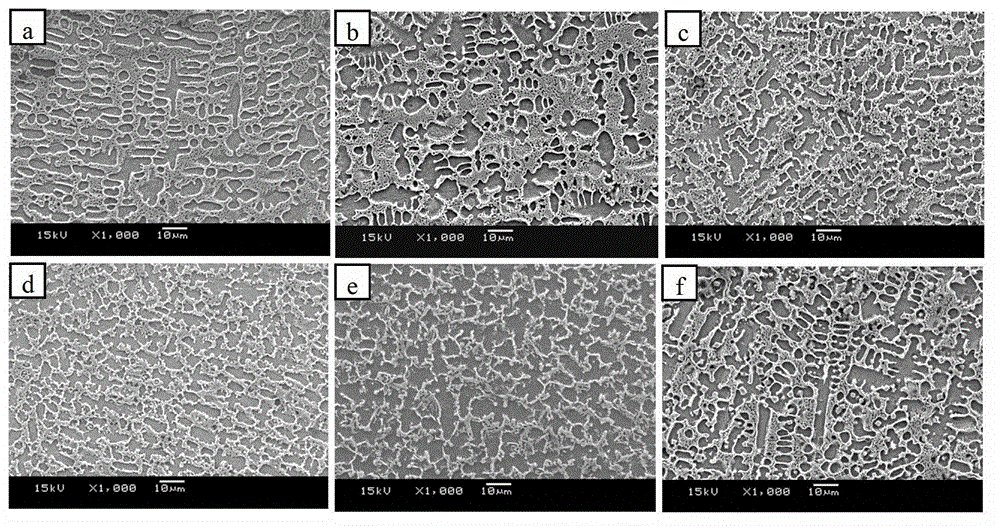

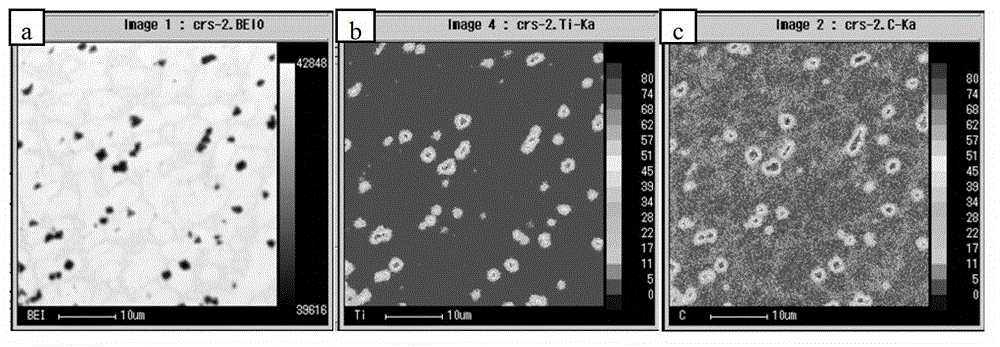

[0028] The XRD pattern of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com