Corrosion-resistant rare earth bearing steel and preparation method thereof

A technology of bearing steel and rare earth, which is applied in the field of metallurgical engineering, can solve problems such as limitations in application fields, influence on RE steel production, and backward equipment, and achieve the effects of improving internal and external quality, improving steel quality, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

[0032] The preparation process of the present invention adopts electric furnace smelting→LF furnace refining+VD vacuum degassing treatment→continuous casting (electromagnetic stirring)→slow cooling→rolling into lumber→slow cooling process.

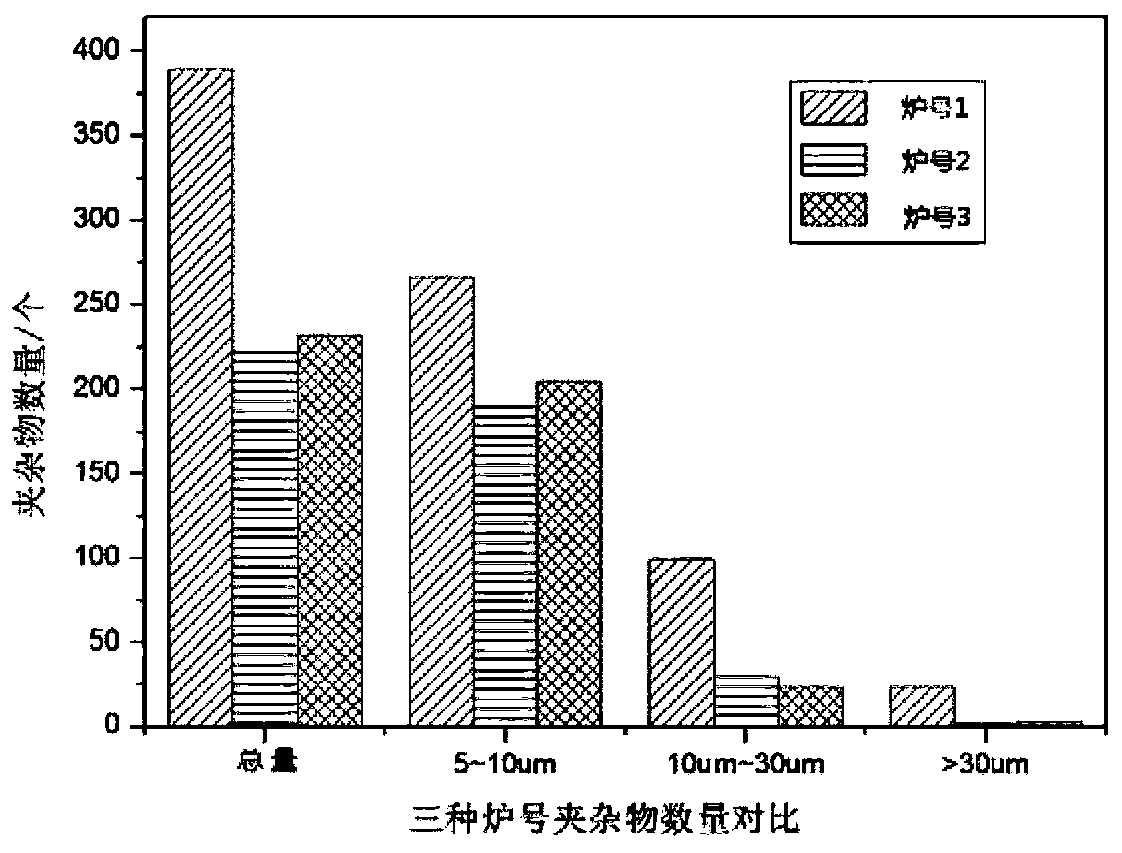

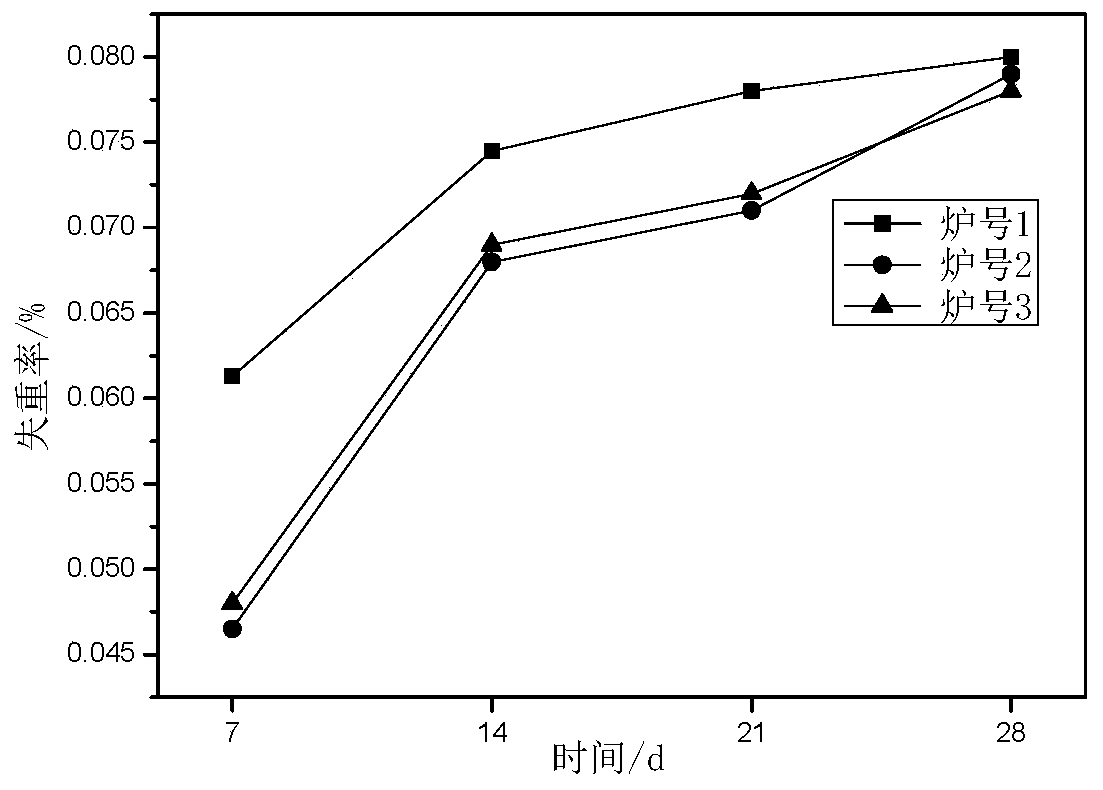

[0033] 1. Electric furnace smelting: electric furnace smelting followed by LF refining, VD vacuum degassing, the chemical composition of the smelted billet by weight percentage is: C 0.90-1.10, Si 0.20-0.40, Mn 0.20-0.50, Cr 1.35-1.70, Cu 0.12-0.26 、Al t 0.015-0.035, P≤0.020, S≤0.010, (La+Ce) 0.003~0.005, the balance is Fe and unavoidable impurities. The actual electric furnace smelting composition is shown in Table 1. Furnace number 1 does not add rare earth and copper, furnace numbers 2 and 3 add rare earth and copper, and the three furnaces are used for performance comparison experiments. Control the basicity of the final slag to 3.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com