Multi-core reducing multi-ladle co-casting method and device for casting large composite steel ingots

The technology of a composite device and a casting method is applied in the field of multi-core reduction, multi-pack co-casting, composite casting of large-scale steel ingots and devices, and can solve the problems of difficult fixing of bars and cumbersome distribution, so as to save the heating process, improve the internal quality of the steel ingot, and improve the quality of the ingot. The effect of low expansion stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

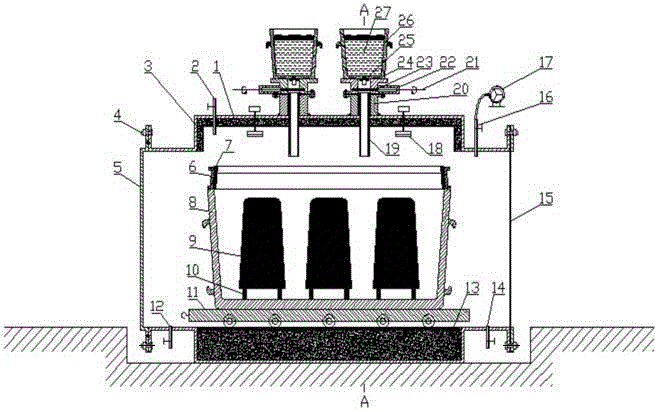

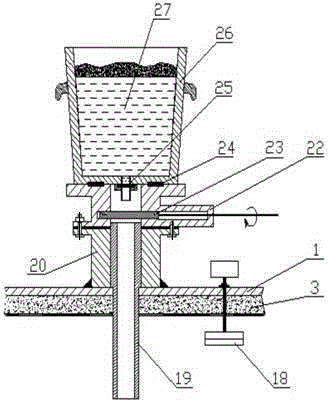

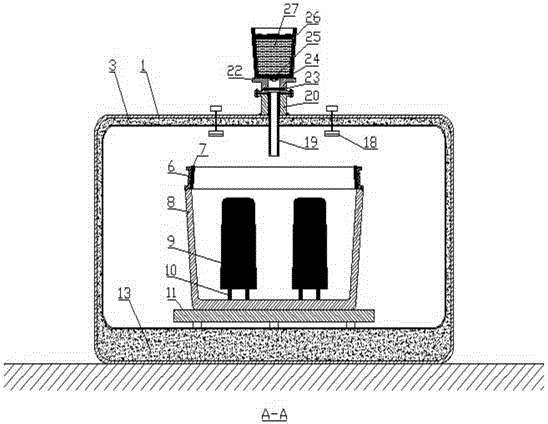

[0030] like figure 1 As shown, a method for multi-core reduction and multi-package co-casting composite casting of large steel ingots, one time reduction casting composite production of 215-220 tons of large steel ingots, the method steps are as follows:

[0031] Select 6 rectangular steel ingots with a weight of 18 tons that have been cast. The composition of the steel ingots is 45# steel. 9. Adjust the temperature of the six core blanks 9 to 1000°C-1050°C, and use iron sand to remove the thicker primary oxide scale on the surface of the core blanks 9; place the steel ingot mold 8 of a 220-ton large steel ingot on the trolley 11, Place 24 pieces of cylindrical pad iron 10 with a diameter of 80 mm and a height of 100 mm at the bottom of the mold 8. The composition of the pad iron 10 is 45# steel. Enter in the ingot mold 8, 6 core blanks 9 such as Figure 4 As shown, they are evenly arranged at the bottom of the steel ingot mold 8, respectively supported by pad irons 10 for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com