Patents

Literature

311 results about "Deformation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

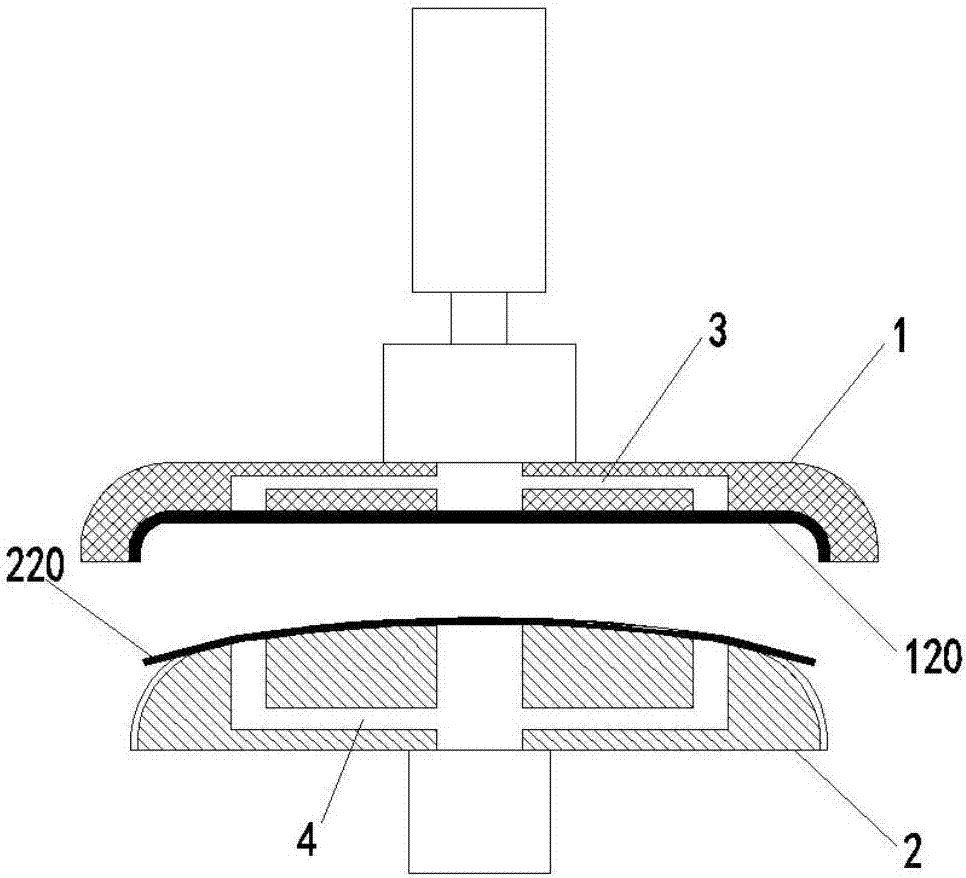

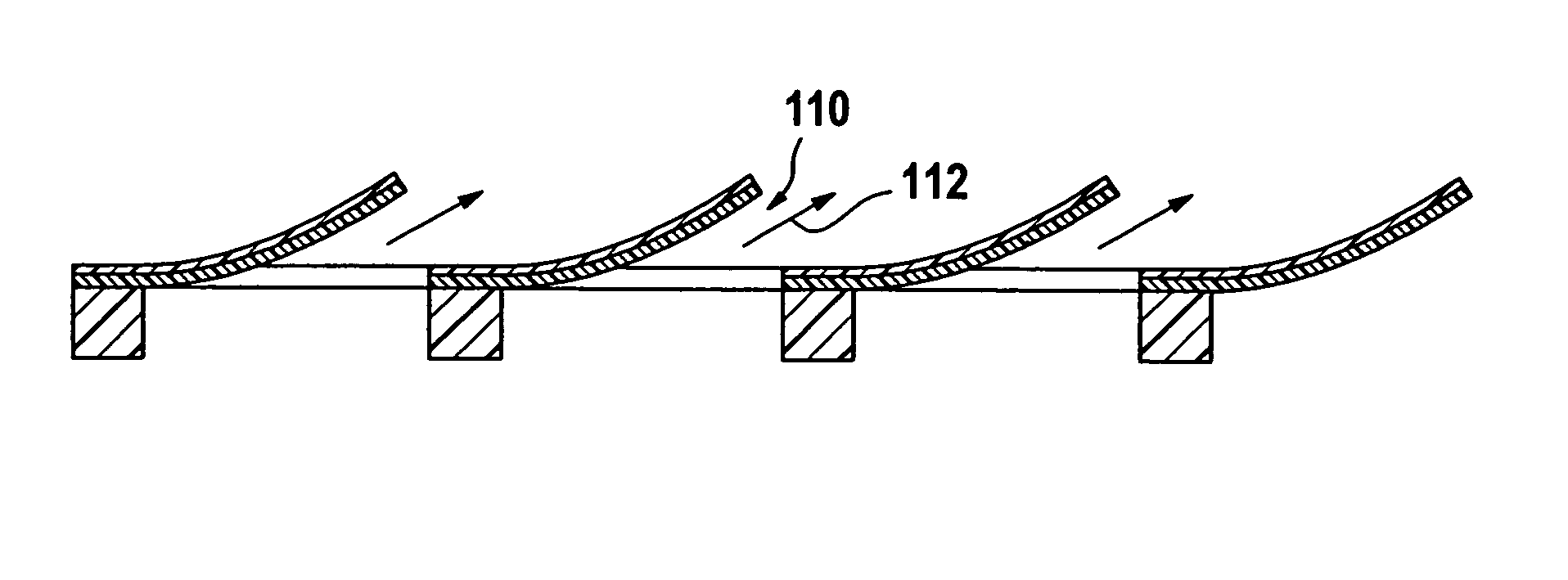

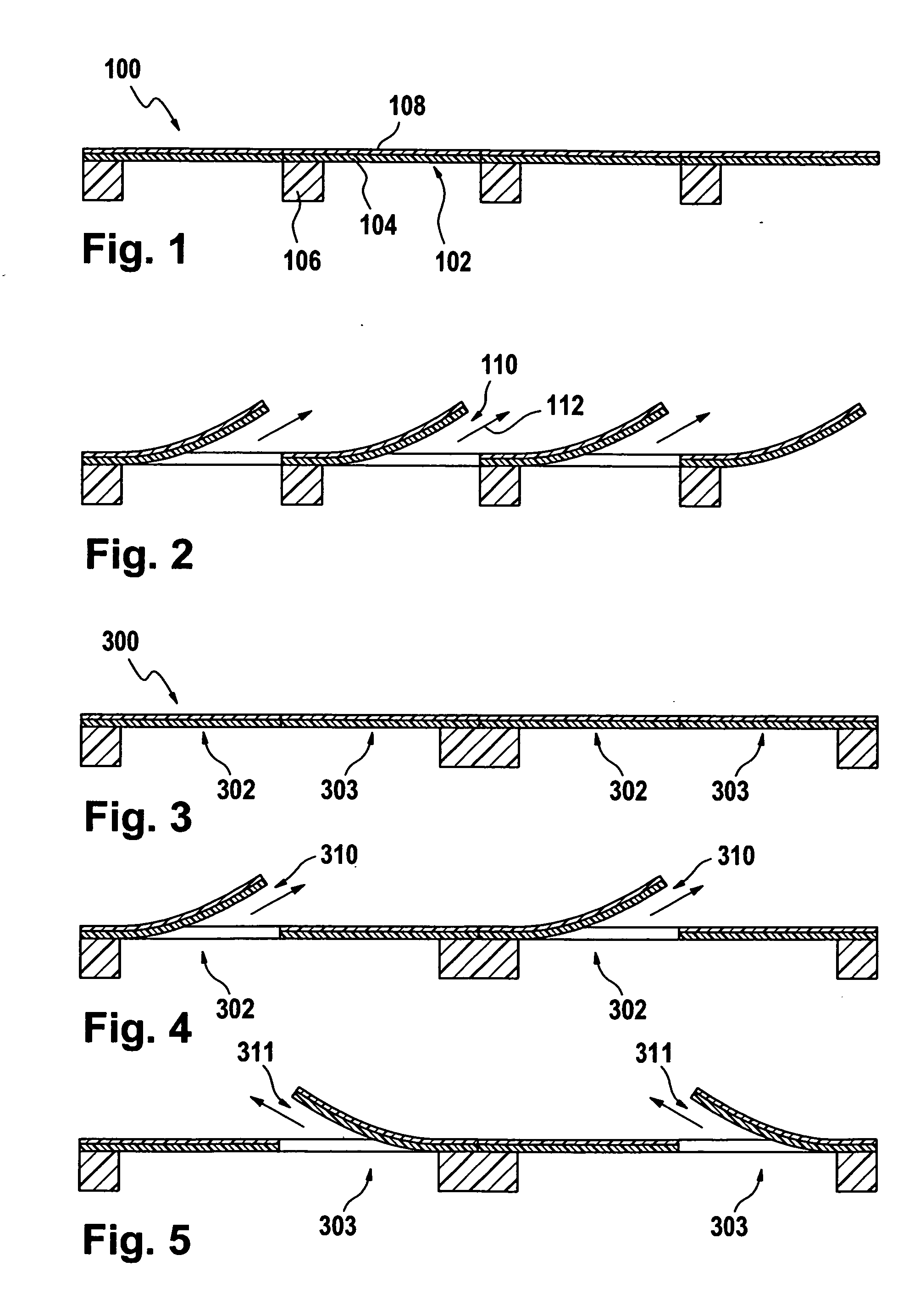

Flexible panel curved-surface adhering device and method

ActiveCN107016936AGuaranteed surface fitReduce incidenceSolid-state devicesIdentification meansGeneration rateDeformation effect

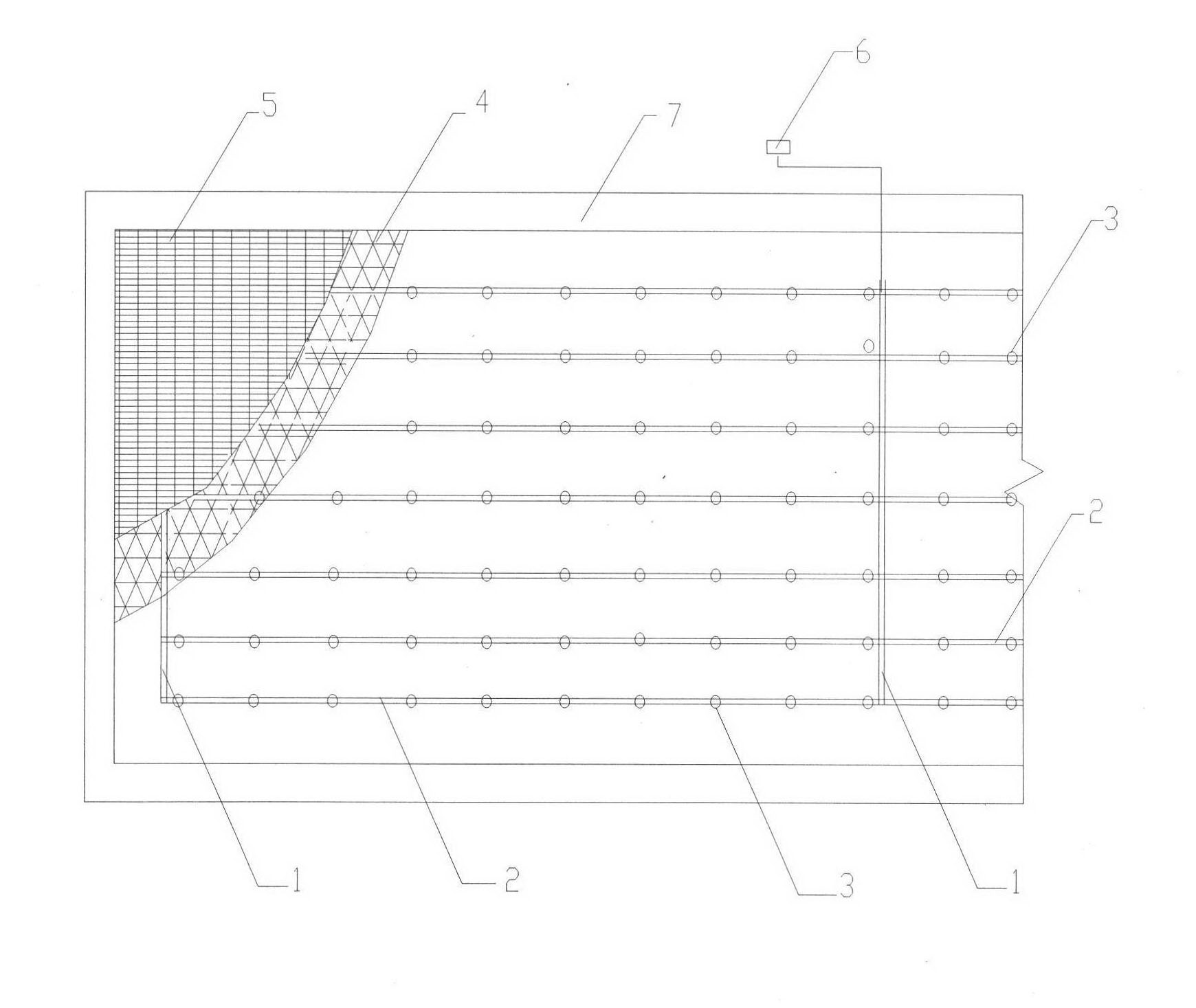

The invention provides a flexible panel curved-surface adhering device and method. Sucking hole channels are formed in a flexible panel sucking table, a second working contact surface of the flexible panel sucking table is divided into multiple areas, any one area can be independently controlled to release vacuum of the sucking hole channel in the area so as to stop suction to a flexible panel in the area. During suction, the sucking hole channel in one area is selected to firstly release vacuum, then the vacuum of the sucking hole channel in the area adjacent to the area without vacuum is released, circulation is performed till the vacuums of the sucking hole channels in all the area are released, accordingly flexible panels are sequentially adhered to a curved-surface cover plate, air is extruded out of the space between the two parts, and the air bubble generation rate is reduced. The deformation of a buffer material for the flexible panel sucking table is not produced in implementation. Therefore, the product quality problem caused by higher bubble generation rate due to poor quality, hardness and deformation effect of the buffer material or the service life of the buffer material is well solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

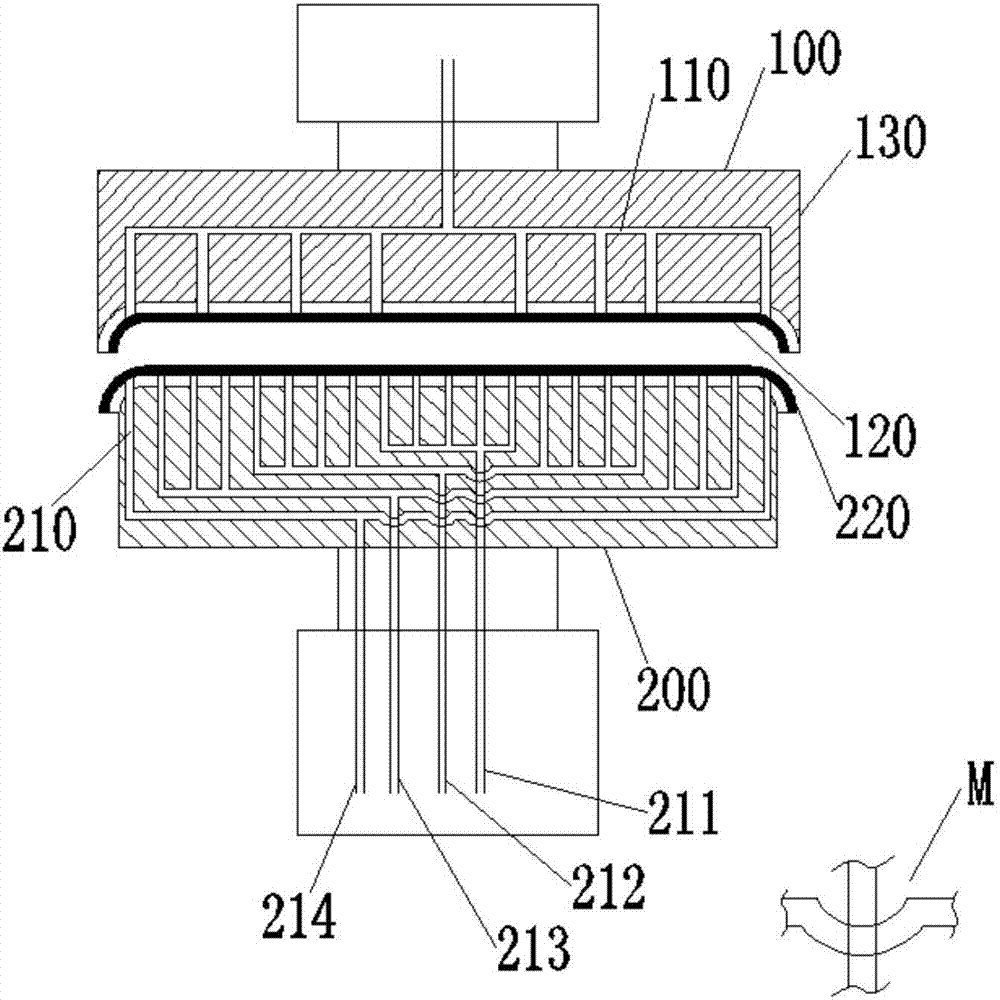

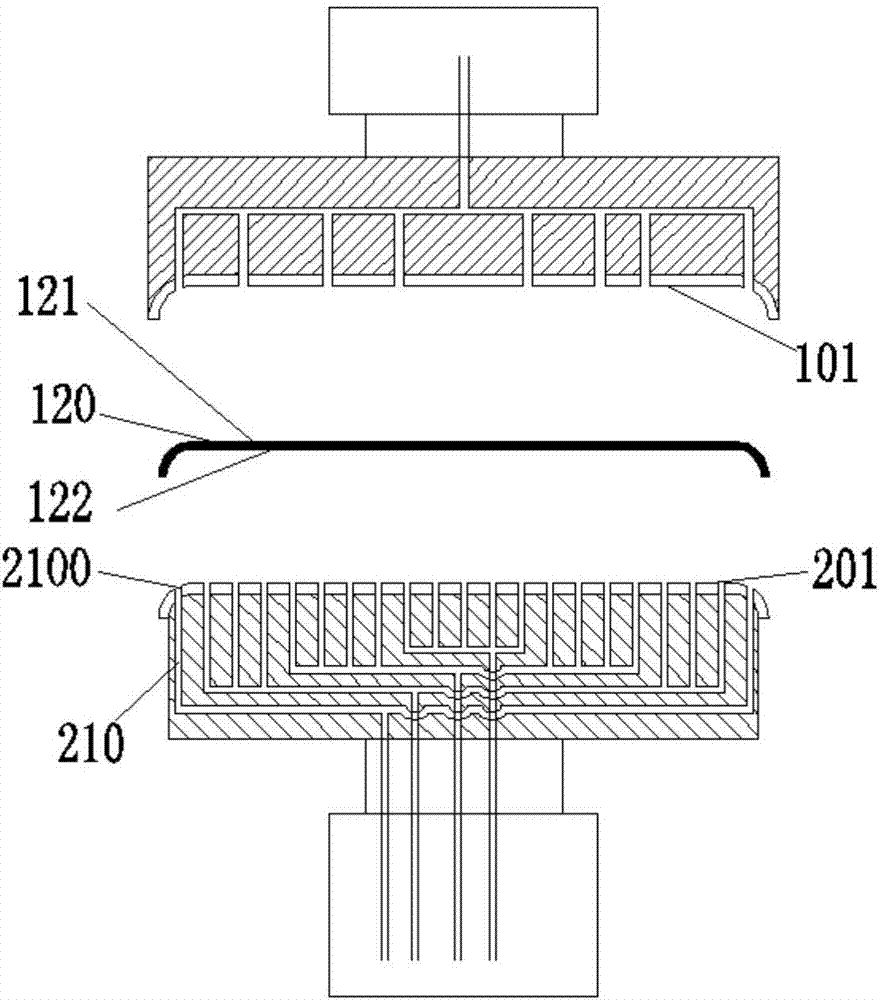

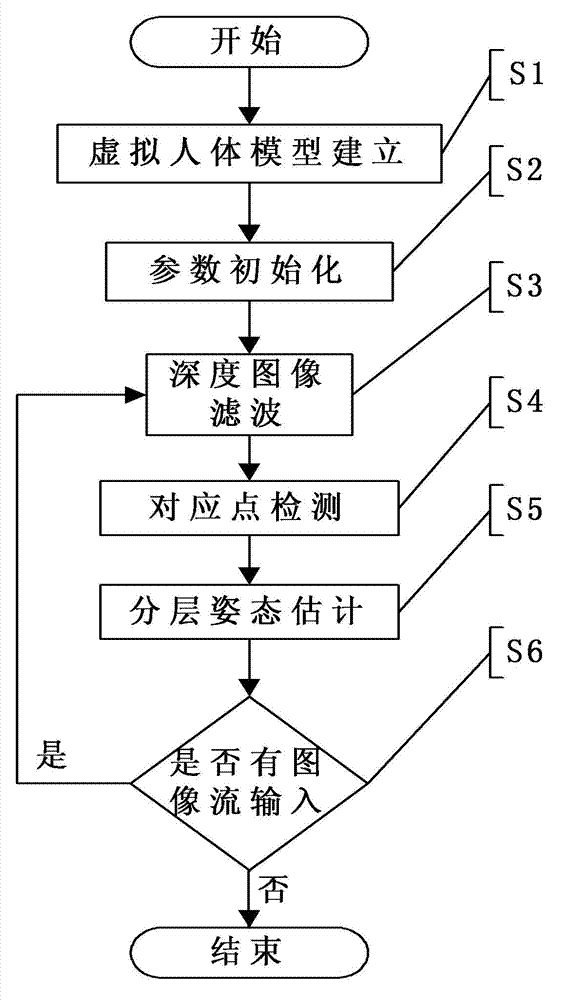

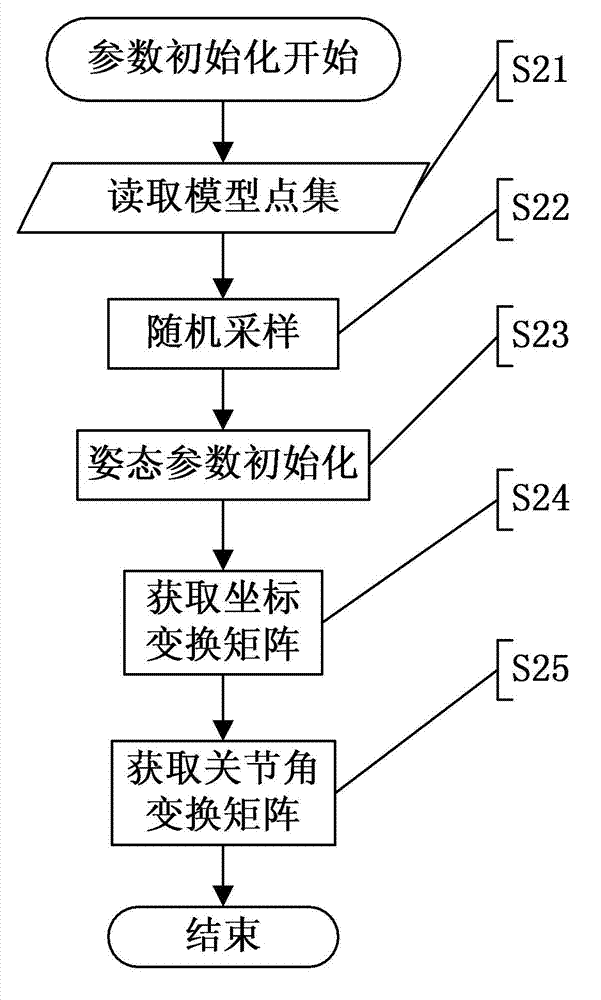

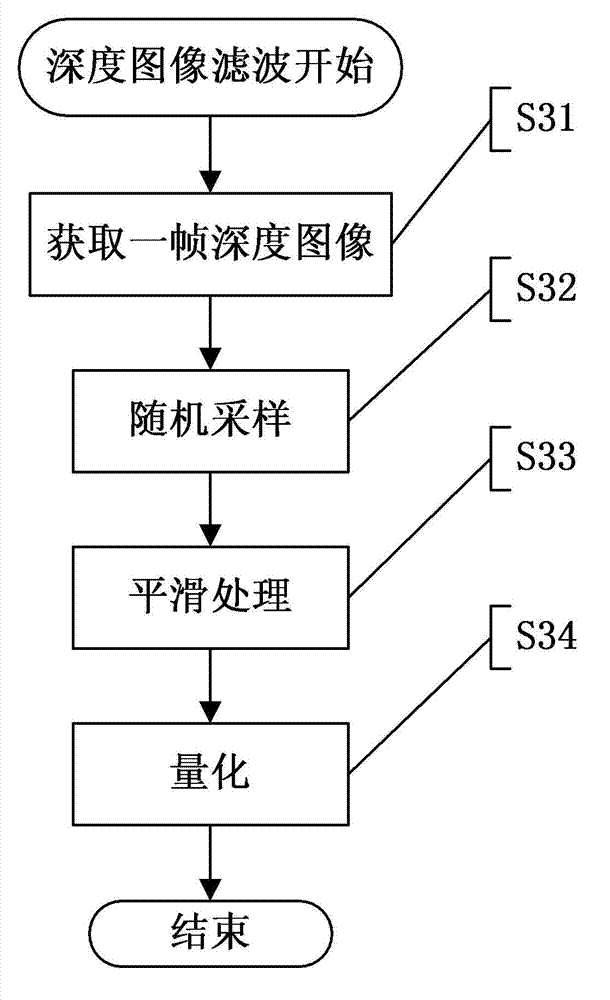

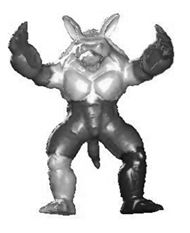

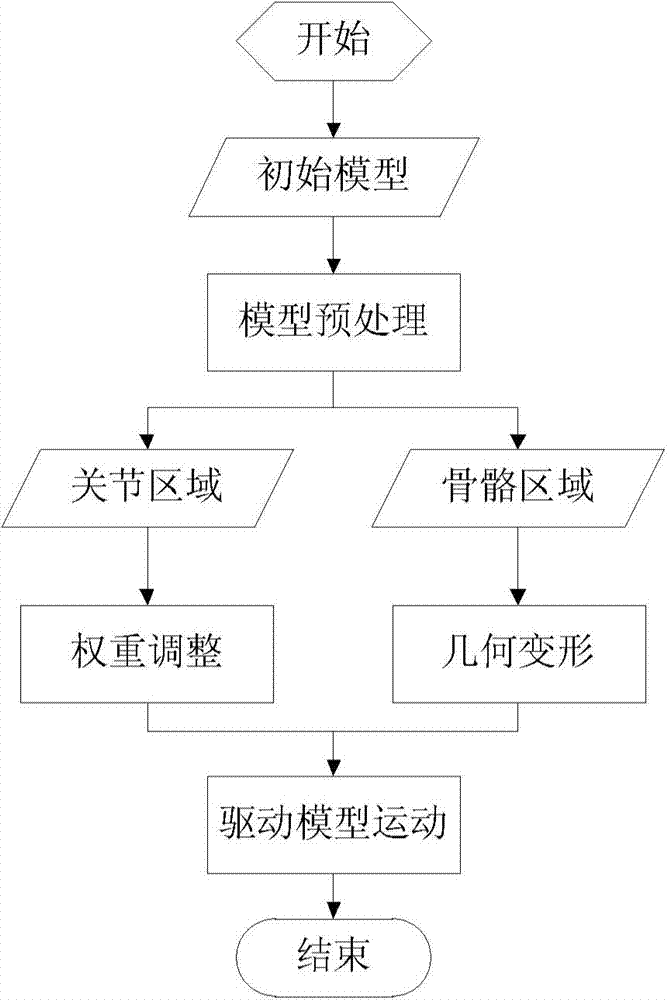

Estimation method of human posture based on depth image

ActiveCN102855470AIncrease freedomPose estimation converges fastCharacter and pattern recognitionHuman bodyDeformation effect

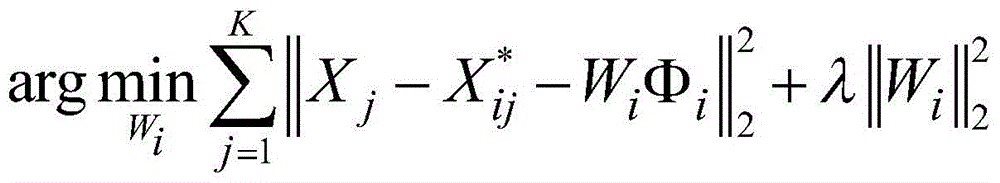

The invention discloses an estimation method of a human posture based on a depth image. The method estimates the human posture according to the depth image of a human body and simulates the human body in the image through a virtual human body model. The depth image includes a plurality of frames. The method includes the steps of building the virtual human body model composed of a skeleton model and a skin model; initializing parameters of the virtual human body model; filtering a current frame of the depth image; performing corresponding point detection on the virtual human body model and the depth image; and building and optimizing an objective function for the current frame of the depth image according to results of the corresponding point detection, and updating a current posture of the virtual human body model through the value of a minimized objective function, wherein the objective function is used for describing the posture difference between the virtual human body model and the depth image. The virtual human body model built in the estimation method is high in degree of freedom and good in skin deformation effect, the convergence rate of posture estimation is high, errors are small, simultaneously, a depth camera is used for obtaining depth images, so that devices of a human motion posture estimation system are simple, and popularization and application are facilitated.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

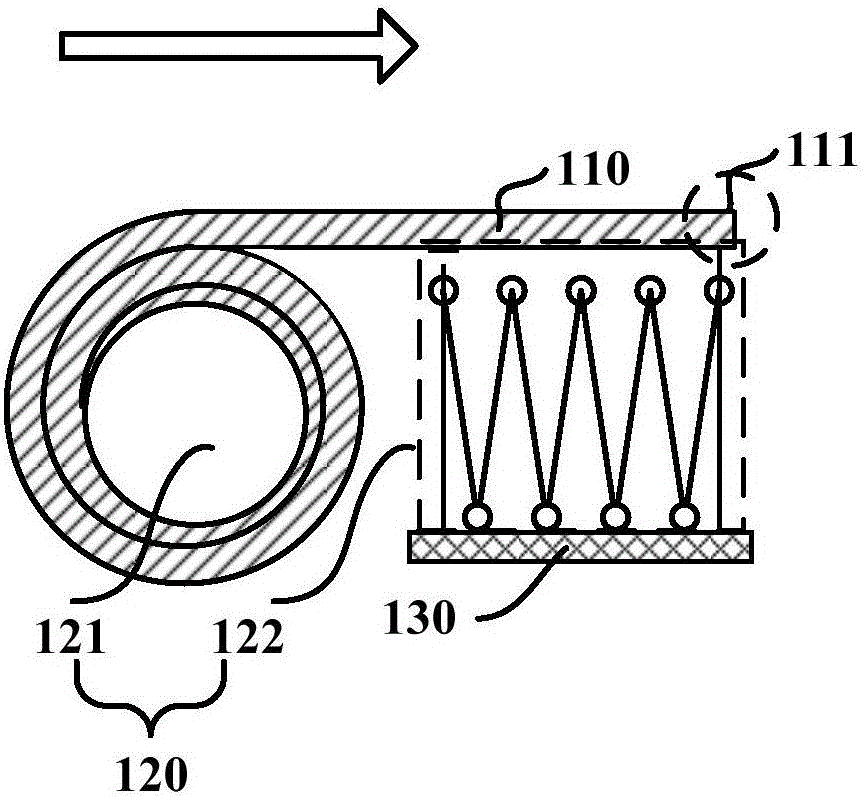

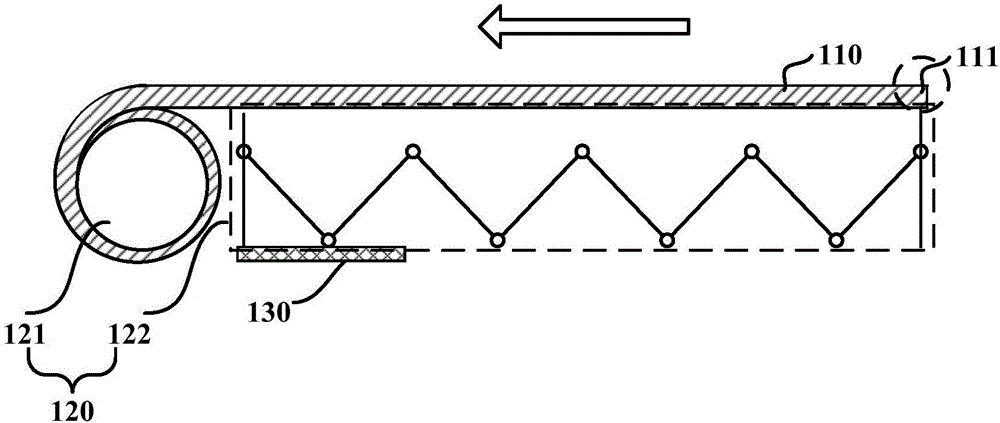

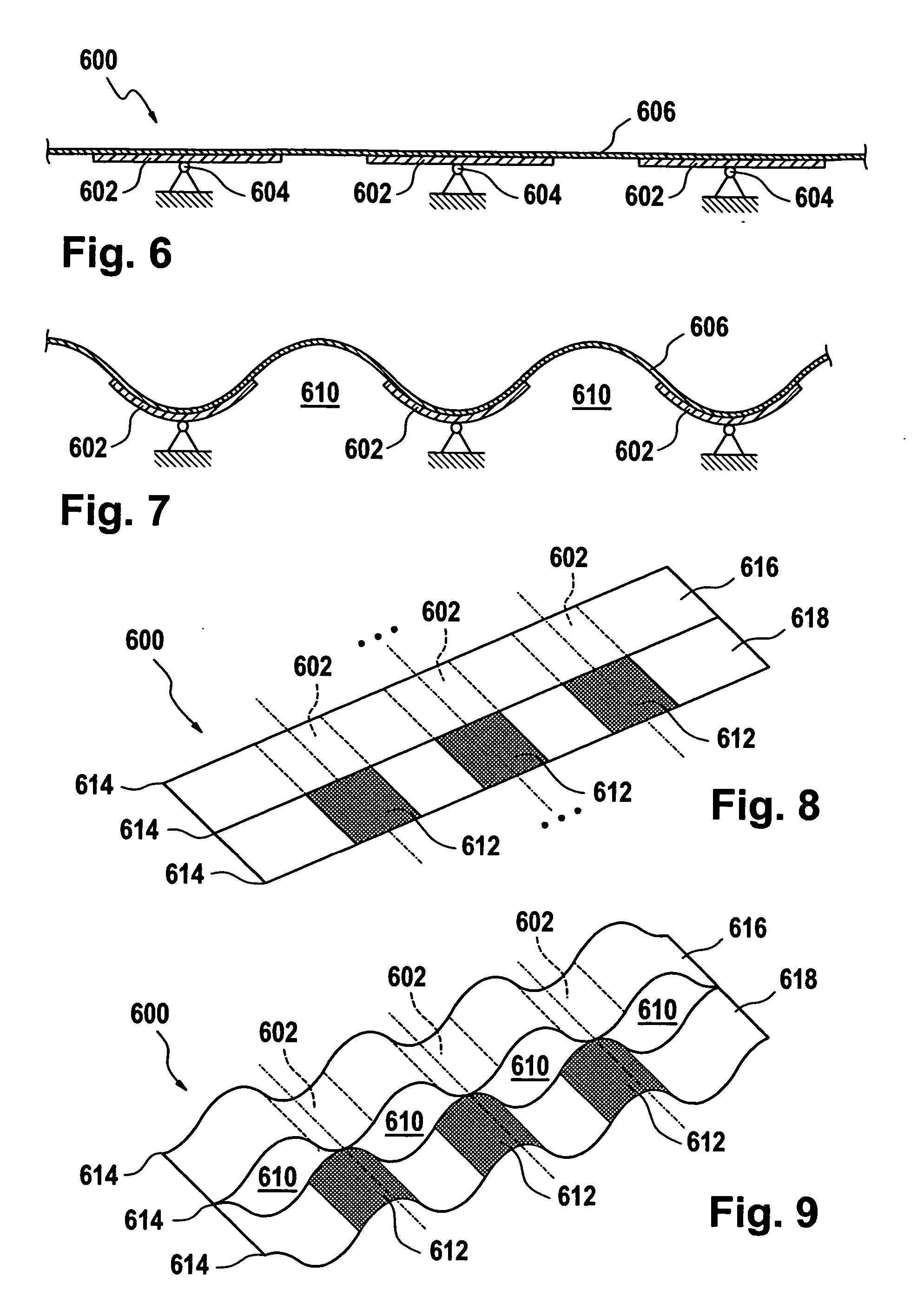

Flexible display device

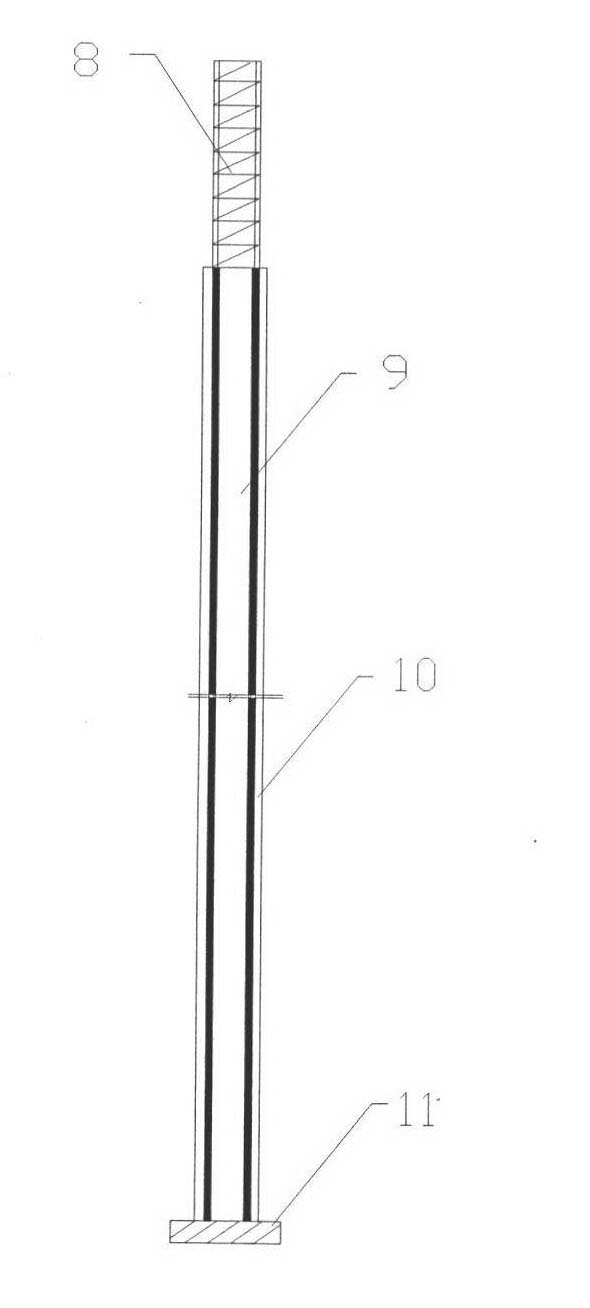

The invention discloses a flexible display device which comprises a flexible display screen, a winding mechanism and a base plate, wherein the flexible display screen comprises a first lateral edge and a second lateral edge which are oppositely arranged; the winding mechanism comprises a rotating shaft and a support component, wherein the rotating shaft is fixed with the first lateral edge, and the support component is used for supporting the flexible display screen; the support component comprises a first stretchable component; and one end of the first stretchable component is fixedly connected with the second lateral edge of the flexible display screen, the other end of the first stretchable component is fixedly connected with the base plate, and the first stretchable component is used for stretching or contracting under the driving of the flexible display screen. According to the scheme of the embodiment disclosed by the invention, the flexible display screen of the unfolded part can be unfolded into a plane, so that the display picture displayed on the flexible display screen can not distort under the bending deformation effect of the flexible display screen.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Preparing method for high-performance magnesium alloy bar

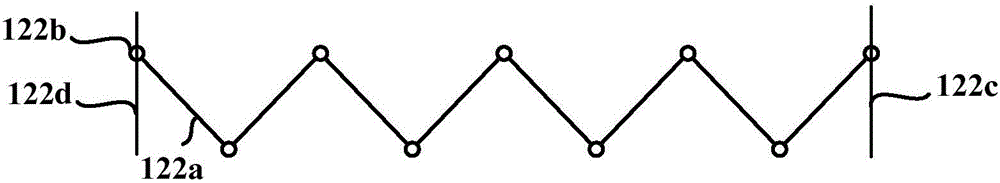

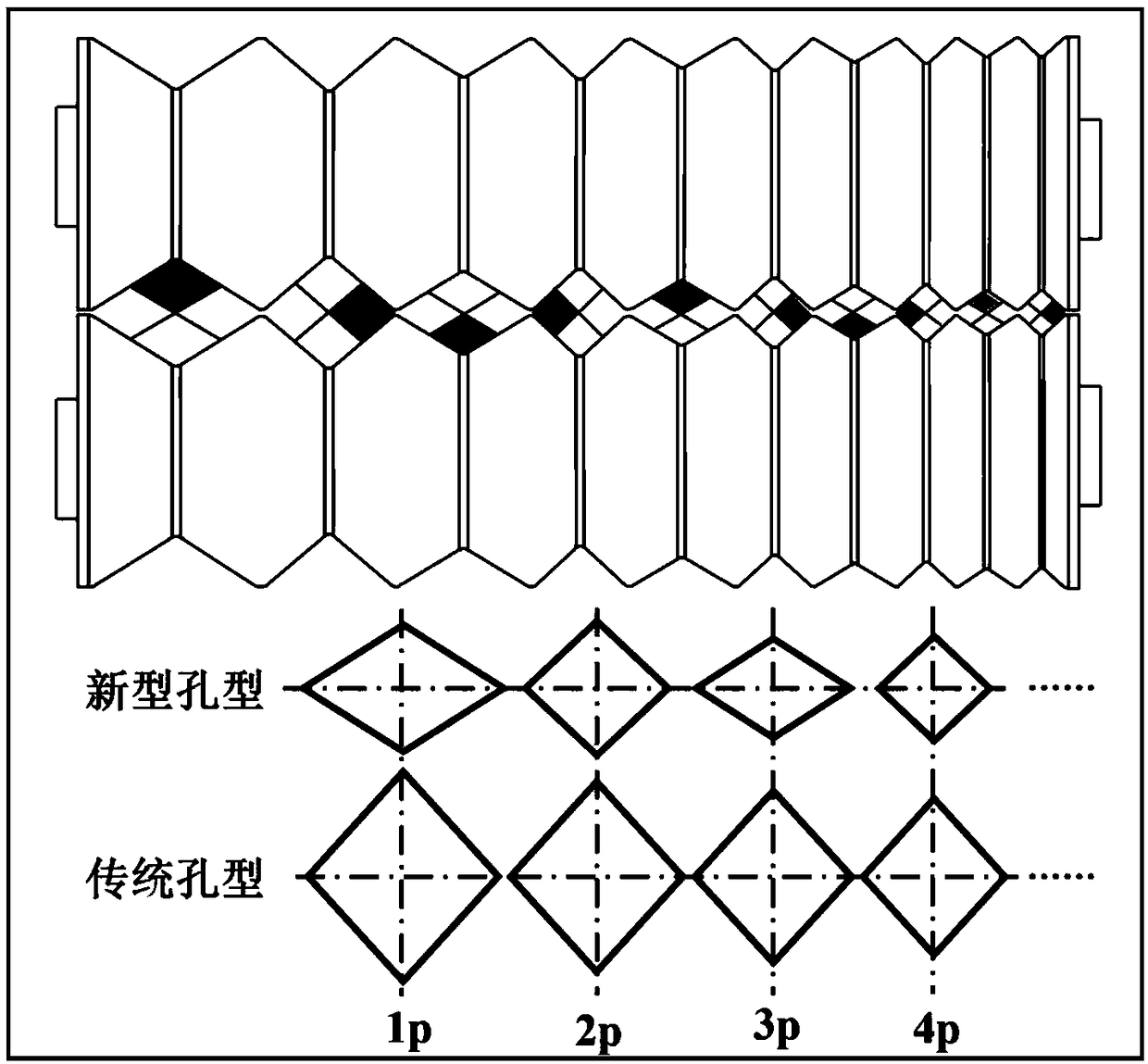

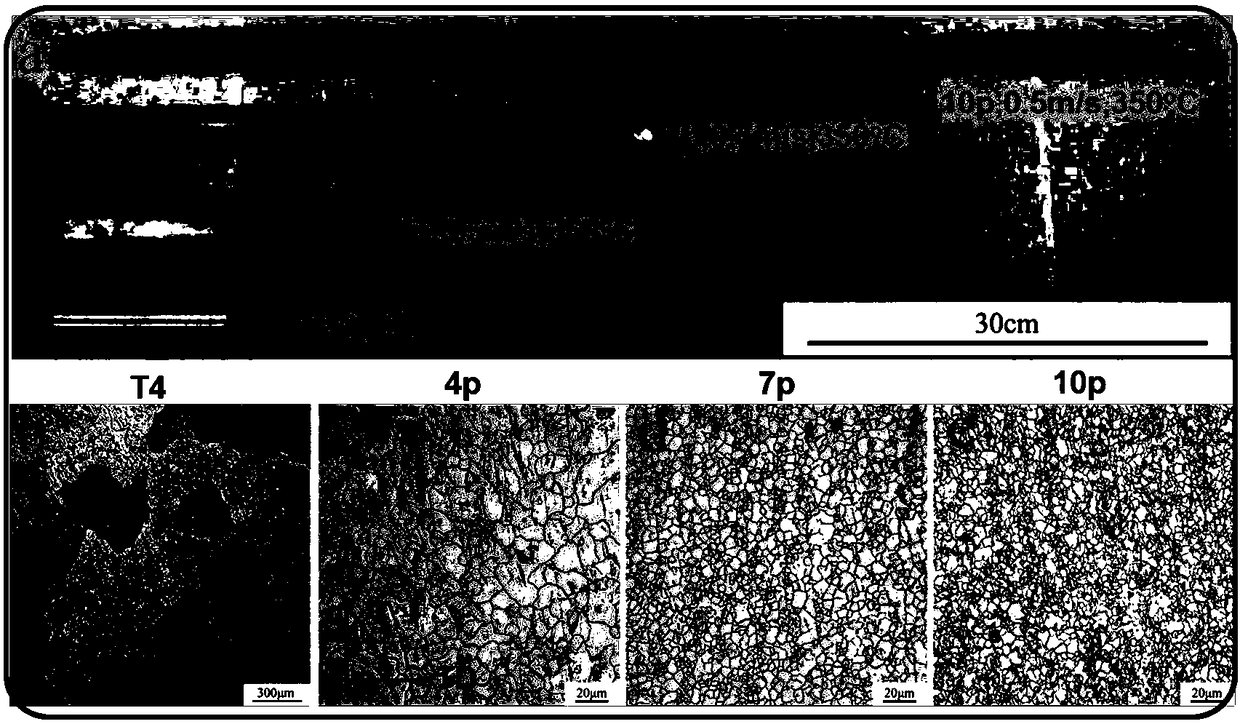

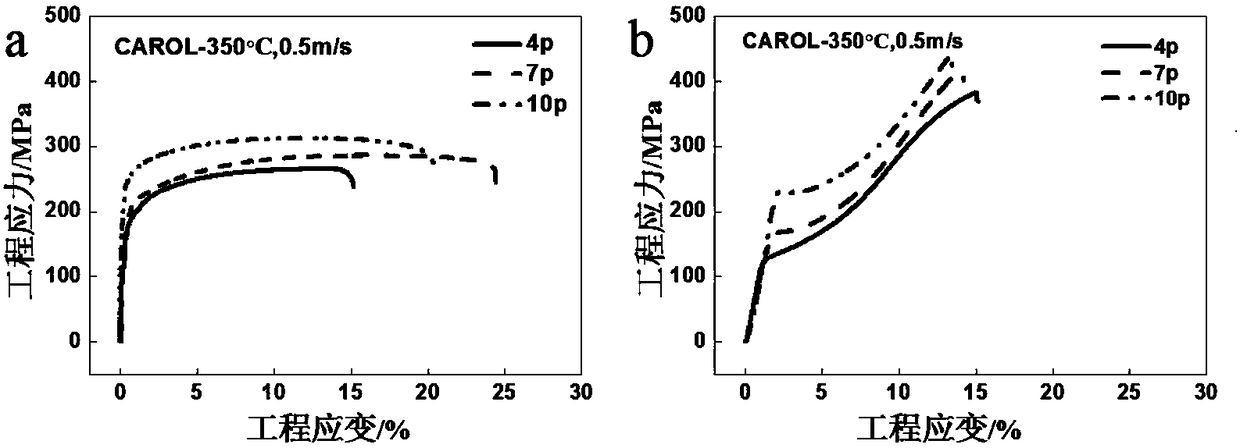

ActiveCN108220725AImprove toughnessOvercome the disadvantage of low strainRollsMetal rolling arrangementsDeformation effectRoom temperature

The invention discloses a preparing method for a high-performance magnesium alloy bar. The method comprises the following steps that a magnesium alloy raw blank is ground, subjected to homogenizationtreatment, pretreated and preheated, groove rolling machining is conducted, the roller speed ranges from 0.1 m / s to 0.5 m / s, 6-10 rolling passes are adopted, the area of each pass is reduced by 19.8%-24.6%, and the accumulated reduction amount is 71.9%-88.0%. In the groove rolling process, the rhombic hole pass and the square hole pass are alternately conducted, and square hole rolling is adoptedas final rolling; and after rolling of each pass is finished, rolling of the next pass is immediately conducted after the bar is rotated by 90 degrees. After groove rolling is finished, room-temperature cooling is conducted. According to the preparing method, the toughness of the alloy can be obviously improved, and the anisotropy of the alloy is improved. Meanwhile, the multi-direction deformation effect is improved through the adopted novel hole pattern, large strain can be more effectively guided in, the production efficiency is improved, and the preparing method is suitable for producing the high-performance magnesium alloy material in the industrial short process.

Owner:HEBEI UNIV OF TECH

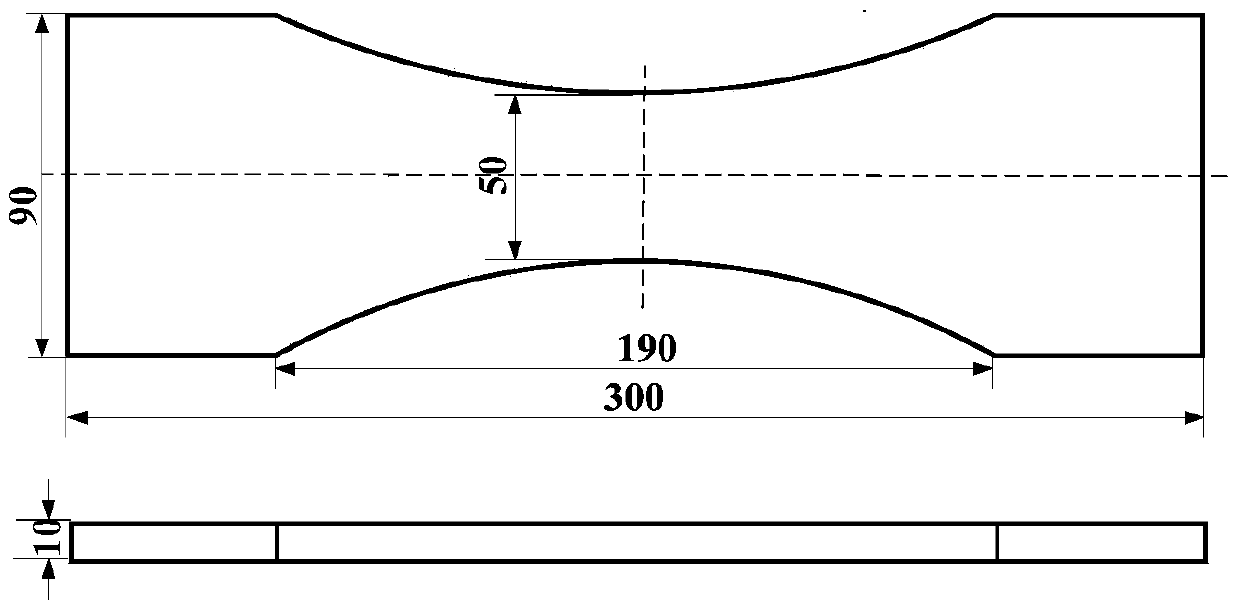

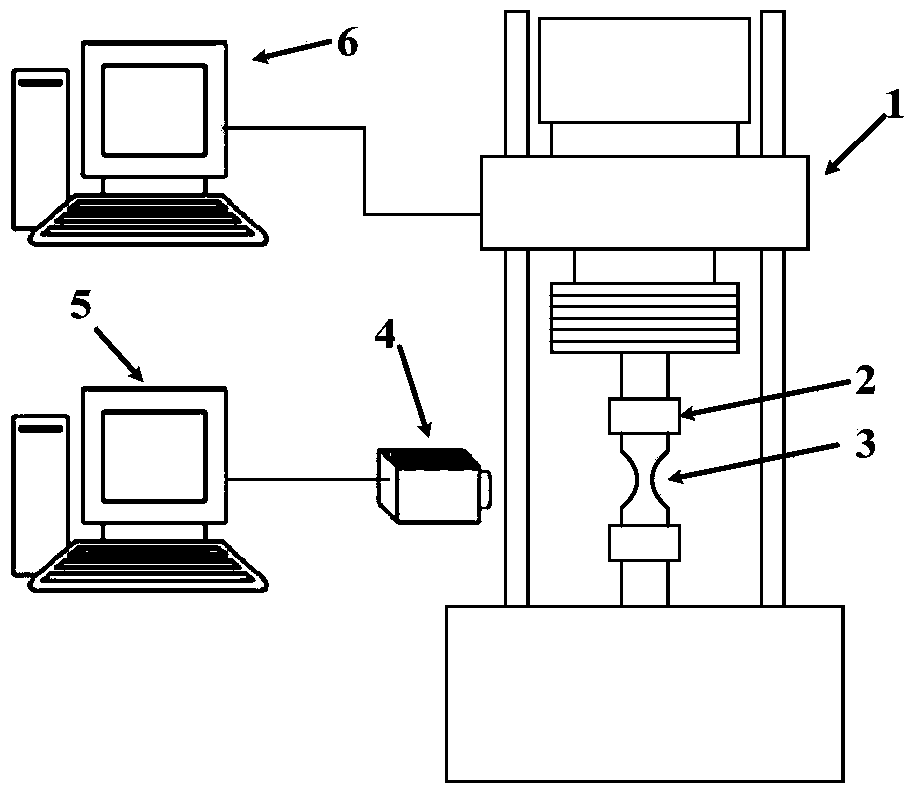

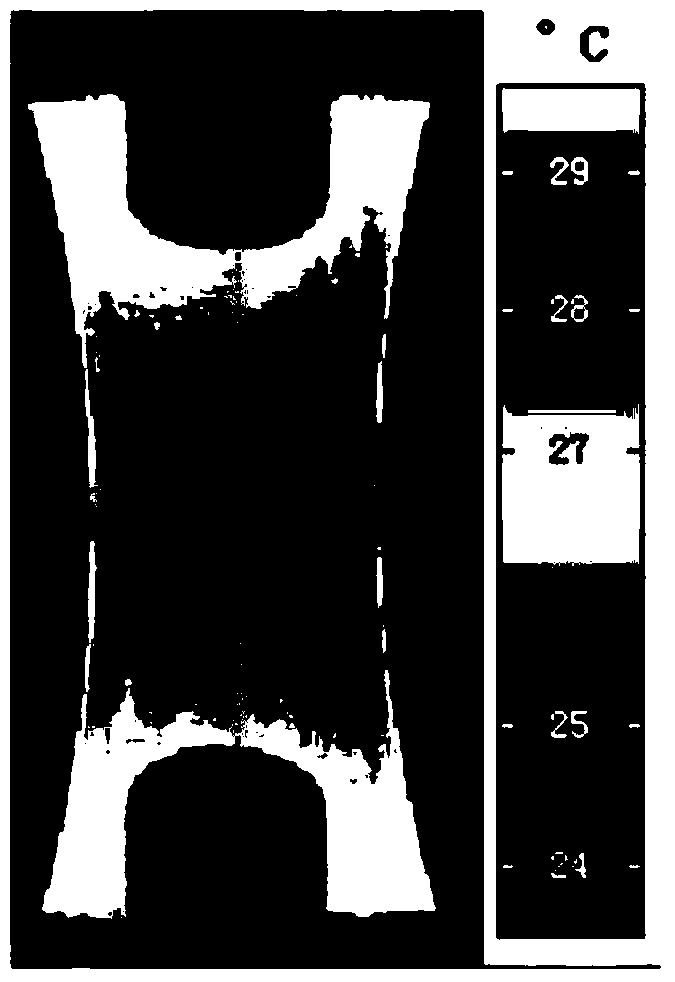

Fatigue analysis method based on magnesium alloy test piece surface temperature characteristics

ActiveCN104007007AReduce in quantityShorten test timePreparing sample for investigationPyrometry using electric radation detectorsStress distributionDeformation effect

The invention provides a fatigue analysis method based on magnesium alloy test piece surface temperature characteristics, and belongs to the technical field of magnesium alloy material mechanics properties. The method is characterized in that in terms of uneven stress distribution in a test piece under the fatigue load action of magnesium alloy, surface temperature of the test piece changes due to the elasticoplastic deformation effect, and a relation curve between the surface temperature of the test piece and local stress is obtained; curve shape features are analyzed, so that the stress condition of the test piece under fatigue is determined and the fatigue limit of the magnesium alloy is solved. According to the method, the test piece does not need to be loaded until fatigue failure occurs or loaded by specific cyclic times, the relation between internal stress of the test piece under fatigue and the fatigue limit of the magnesium alloy can be quickly determined through fatigue loading only for 3 minutes, and the method has the advantages of being convenient, fast, accurate and the like.

Owner:TAIYUAN UNIV OF TECH

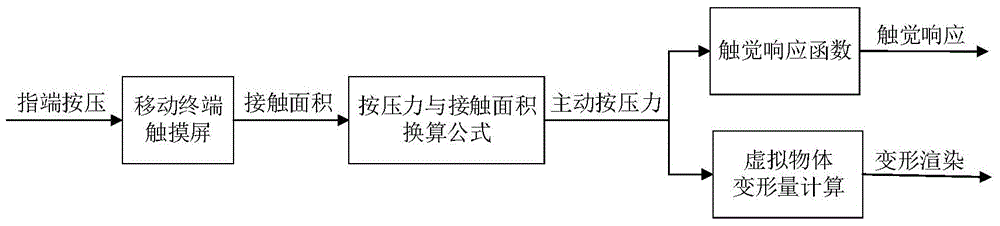

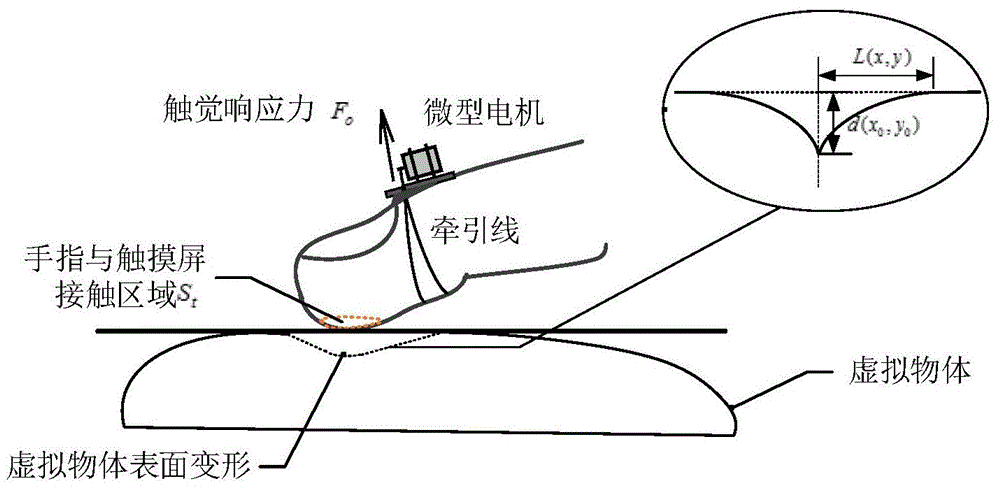

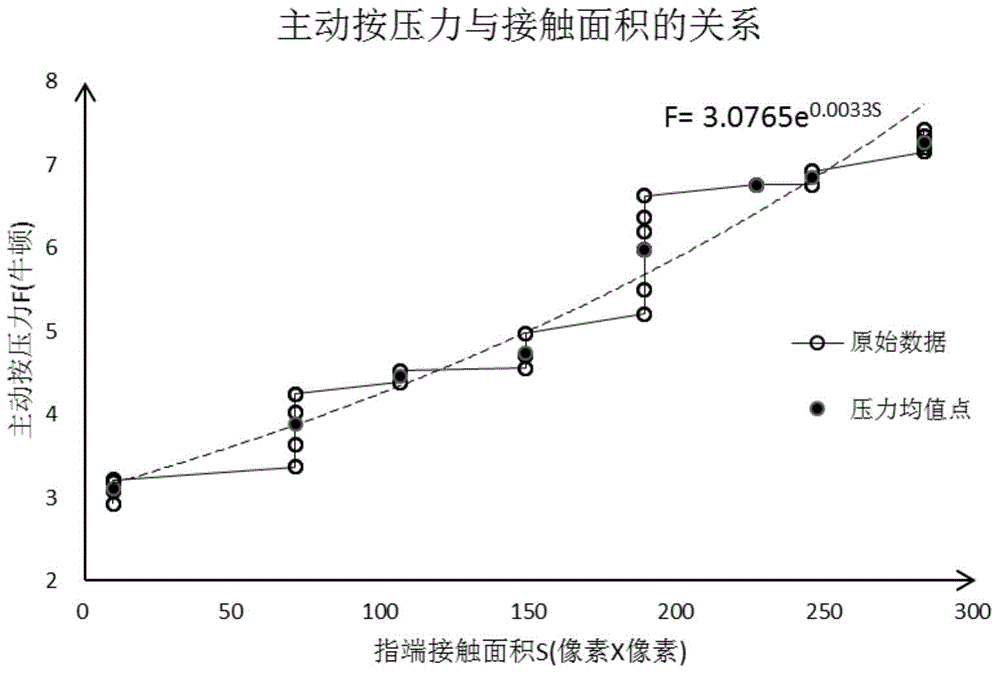

Flexible object tactile modeling and expressing method applied to mobile terminal

InactiveCN104834380AReal tactile experienceAccurate interactionInput/output for user-computer interactionGraph readingRelative displacementTouch Perception

The invention discloses a flexible object tactile modeling and expressing method applied to a mobile terminal. The method is characterized in that the change of a contact area between a human finger end and a touch screen is obtained in real time on the mobile terminal by utilizing a contact area detection function of the mobile terminal, then the magnitude of finger press force is calculated according to pre-marked relation between the press force and the contact area and is used for calculating tactile response and virtual flexible object deformation, then contact force is fed back to a user in virtue of a certain tactile reproduction device, and meanwhile a deformation effect is displayed on the mobile terminal. The method has the advantages that 1, the problem that traditionally, in case of touch screen-based tactile reproduction, only tangential displacement is detected, and normal direction relative displacement cannot be directly detected is solved; 2, based on a principle that acting force and counter-acting force are balanced, the accurate calculation of virtual contact force is realized; 3, by considering object hardness and the magnitude of the finger active press force, deformation rendering and touch interaction with sense of reality are realized.

Owner:SOUTHEAST UNIV

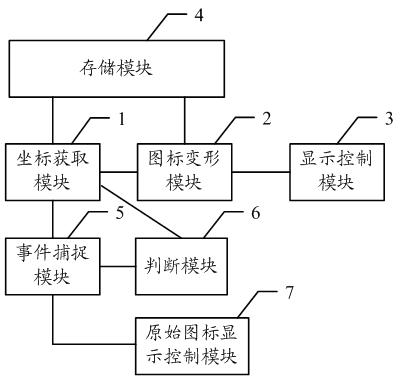

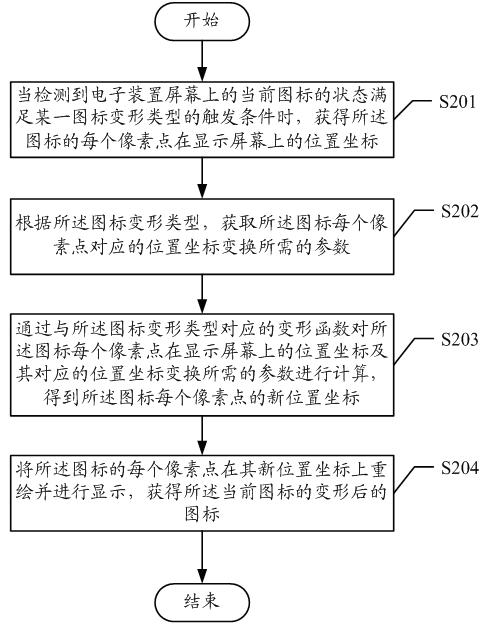

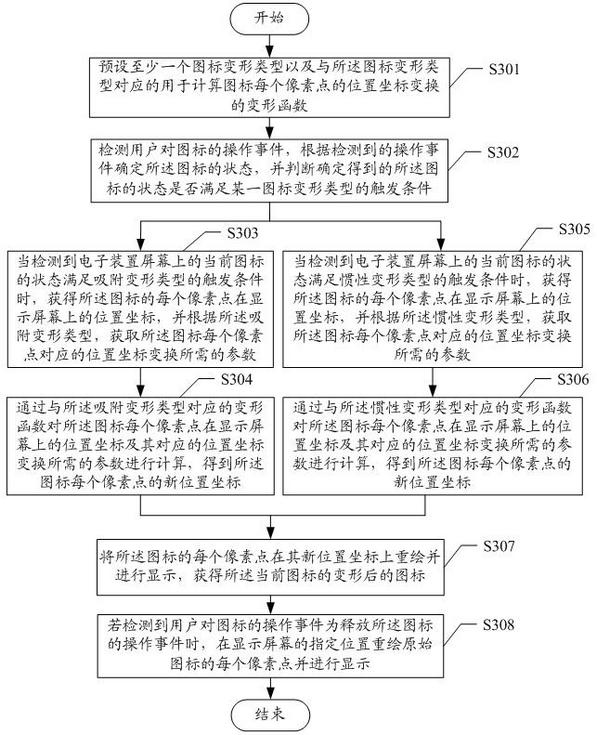

Method and device for implementing icon deformation

InactiveCN102163129AVarious shapesDynamic display effectInput/output processes for data processingDeformation effectComputer graphics (images)

The embodiment of the invention discloses a method for implementing icon deformation. The method comprises the following steps of: when the state of a current icon on a screen of an electronic device meets the trigger condition of a certain icon deformation type is detected, acquiring position coordinates of each pixel point of the icon on the display screen; acquiring parameters required for converting the position coordinates corresponding to each pixel point of the icon according to the icon deformation type; obtaining new position coordinates of each pixel point of the icon according to the position coordinates and the parameters required for converting the corresponding position coordinates; and redrawing and displaying each pixel point of the icon on the new position coordinates to acquire the deformed icon of the current icon. The embodiment of the invention also discloses a device for implementing icon deformation. By adopting the method and the device, the deformation effects such as adsorption deformation, inertia deformation and the like can be generated, so that the shape of the icon during moving is diverse, and dynamic visual experience is brought to users.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

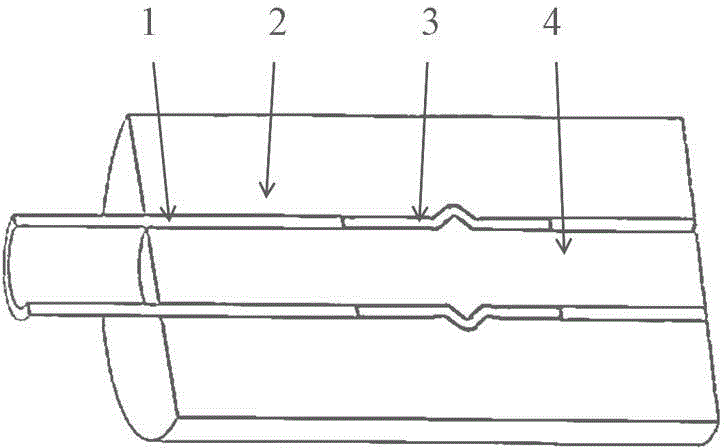

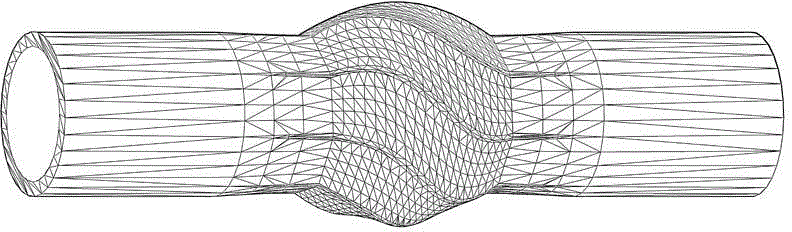

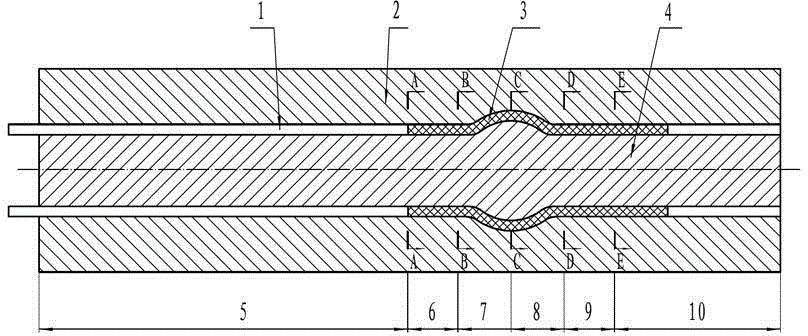

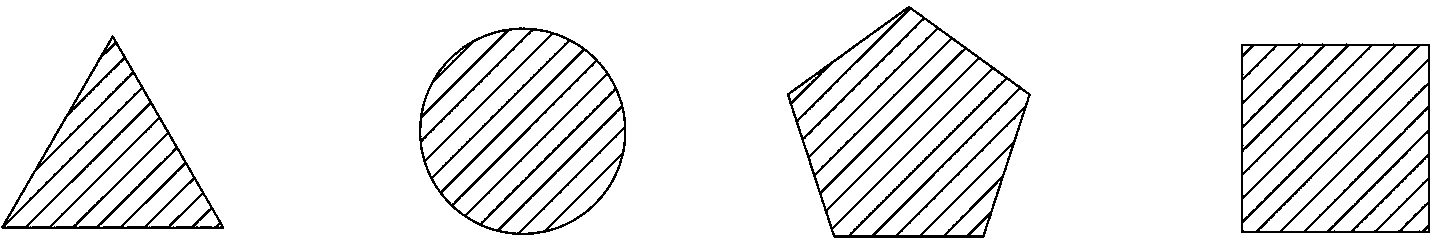

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

Method for processing soft soil foundation of high vacuum drainage filter pipe capable of being grouted

InactiveCN102206939ASlow down the vacuum decay rateShorten drainage consolidation timeSoil preservationDeformation effectEngineering

The invention relates to a method for processing a soft soil foundation of a high vacuum drainage filter pipe capable of being grouted, comprising the following steps of: sinking the high vacuum vertical drainage filter pipe: putting a plate machine in place, installing a traction device of the high vacuum vertical drainage filter pipe in a pile pipe of the plate machine, sinking in place, and lifting the pile pipe of the plate machine; pre-pressing and draining the high vacuum vertical drainage filter pipe: arranging a vacuum pipeline system, draining and pre-pressing the high vacuum vertical drainage filter pipe and then downloading in a vacuum way; and grouting the high vacuum vertical drainage filter pipe: trying to grout so as to determine pressure and single-hole grouting quantity of double grouting processes, grouting cement paste firstly, grouting cement mortar secondarily, and compositely maintaining the foundation. By means of the method, the disadvantages, such as continuous secondary solidification and sedimentation of post-construction field soil, damages of the foundation and the structure and high maintenance cost, can be solved; the vacuum transfer loss is reduced;the secondary hole-forming cost is reduced; the property of soft soil is changed; the bearing capacity of the field soil is improved; and the sedimentation and deformation effects can be reduced.

Owner:李燕青

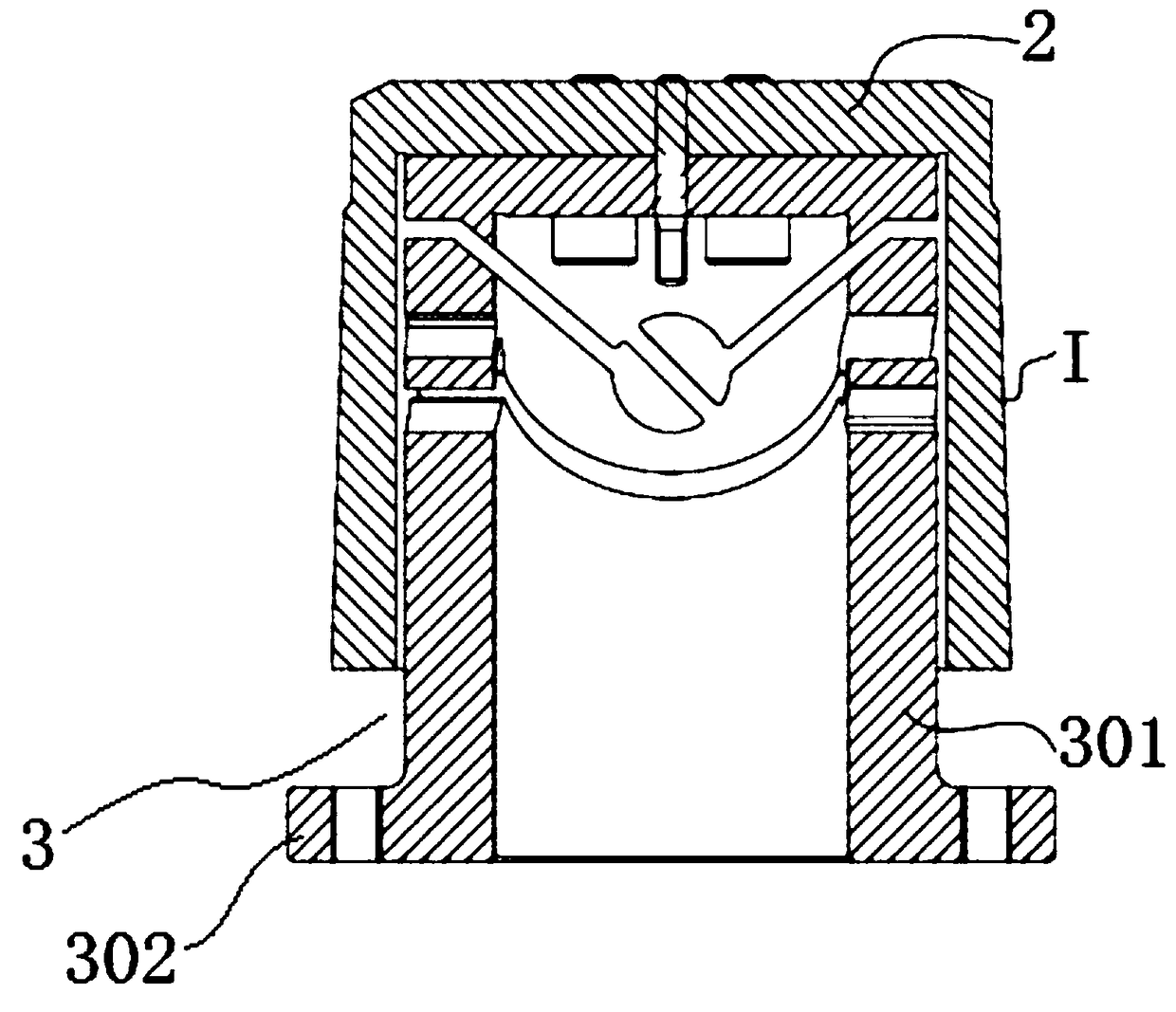

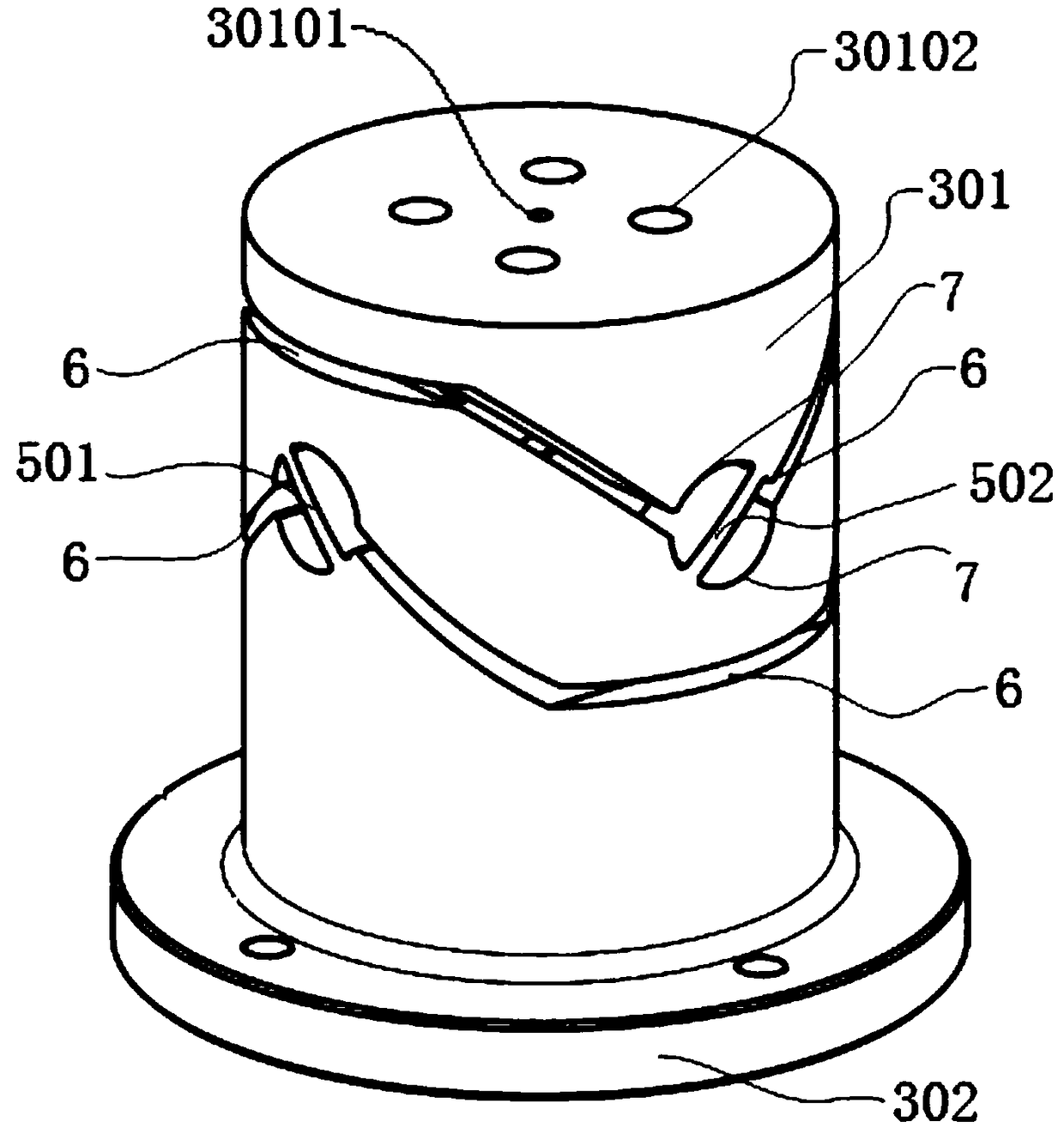

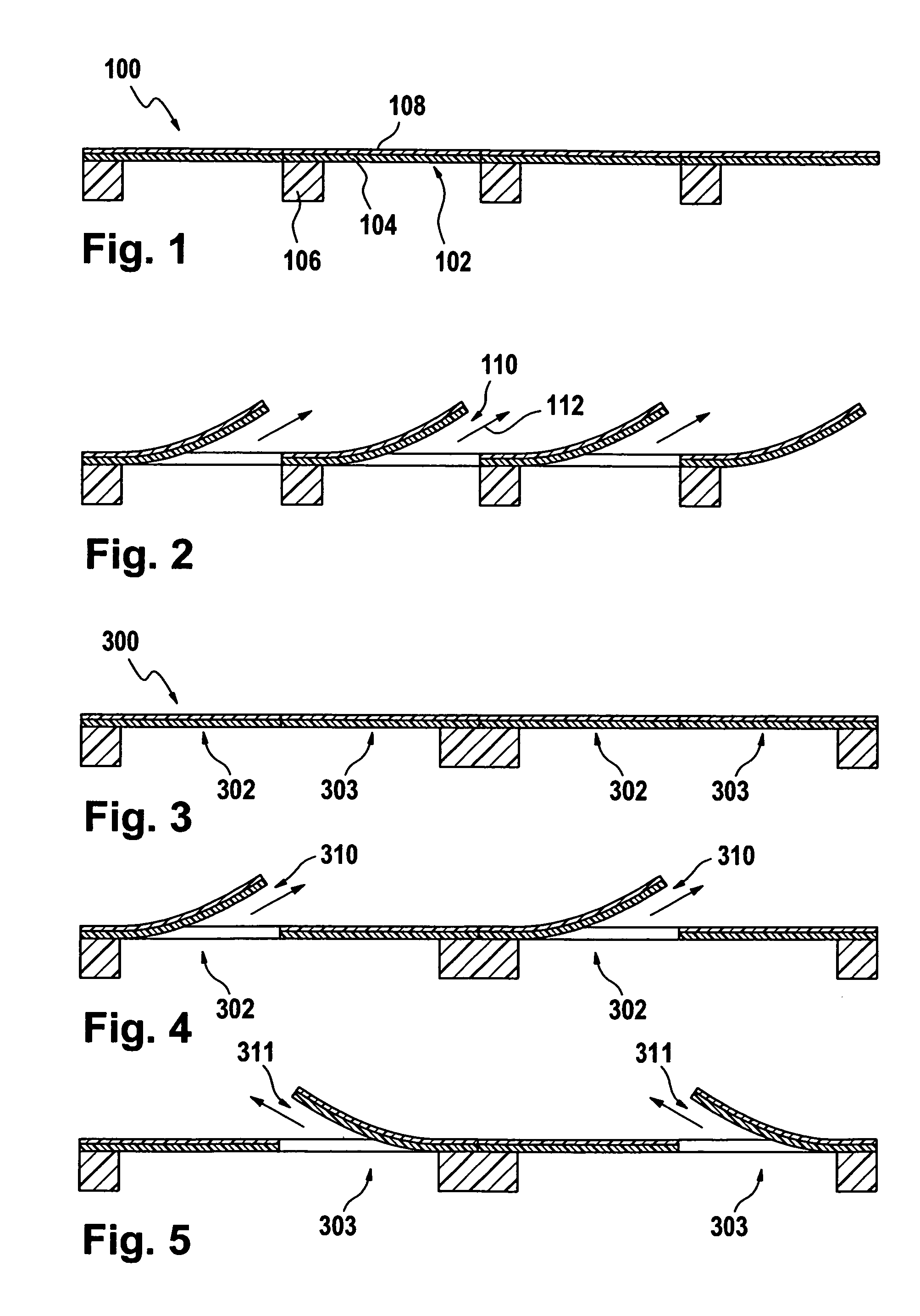

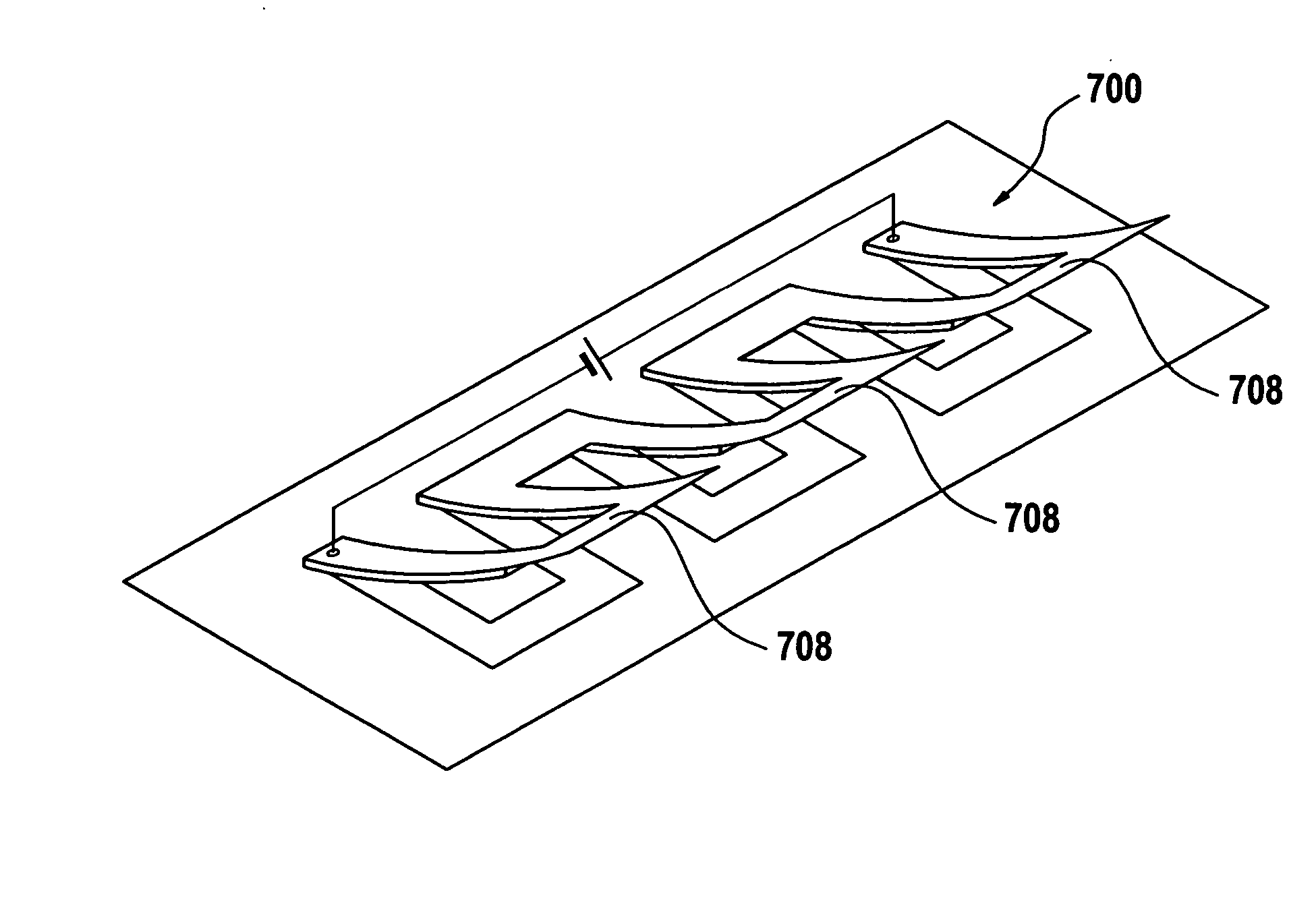

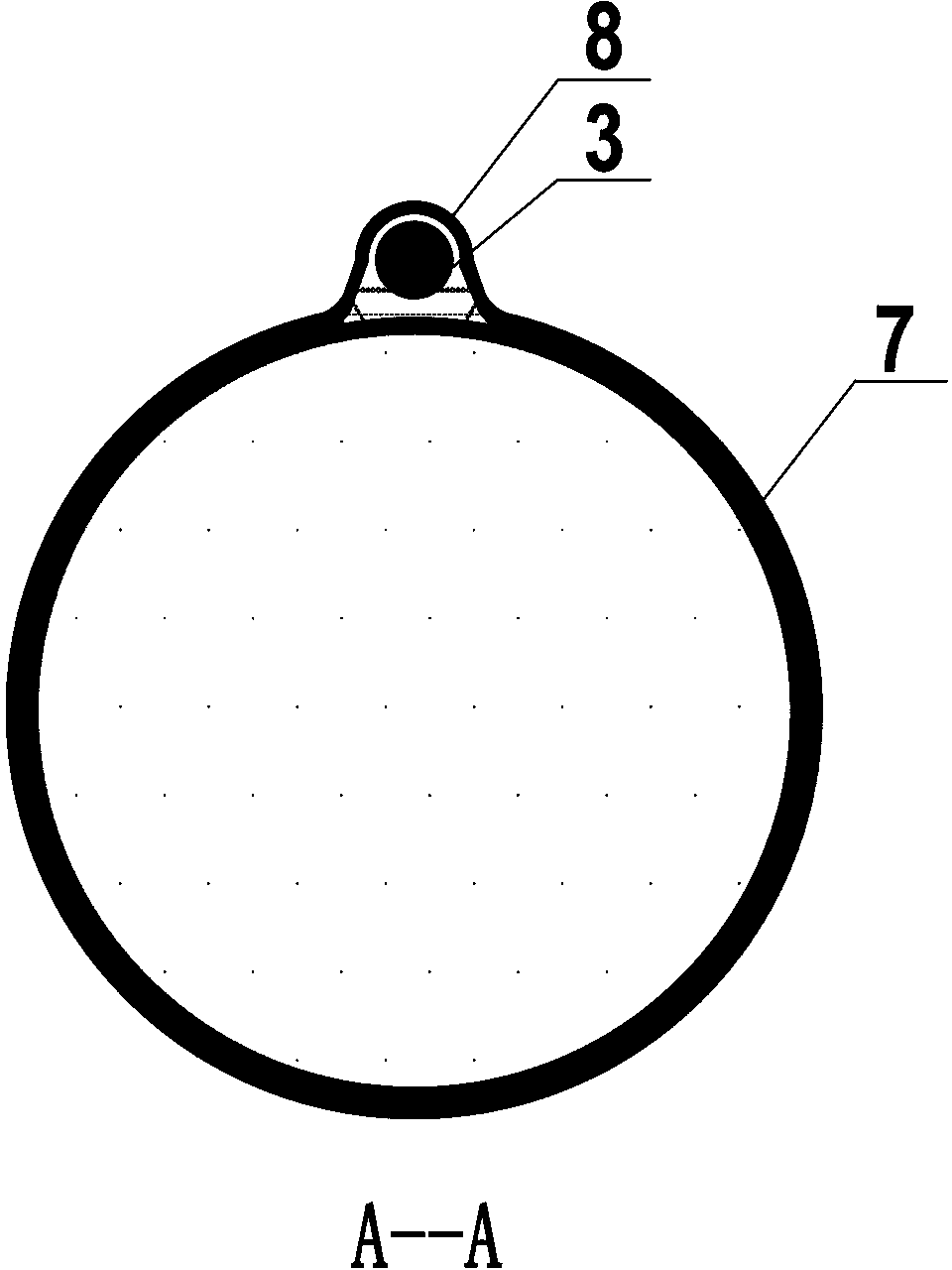

Flexible support structure for large circular reflector of space optical remote senor

ActiveCN109239887AGuaranteed Surface AccuracyReduce stress concentrationMountingsStress concentrationDeformation effect

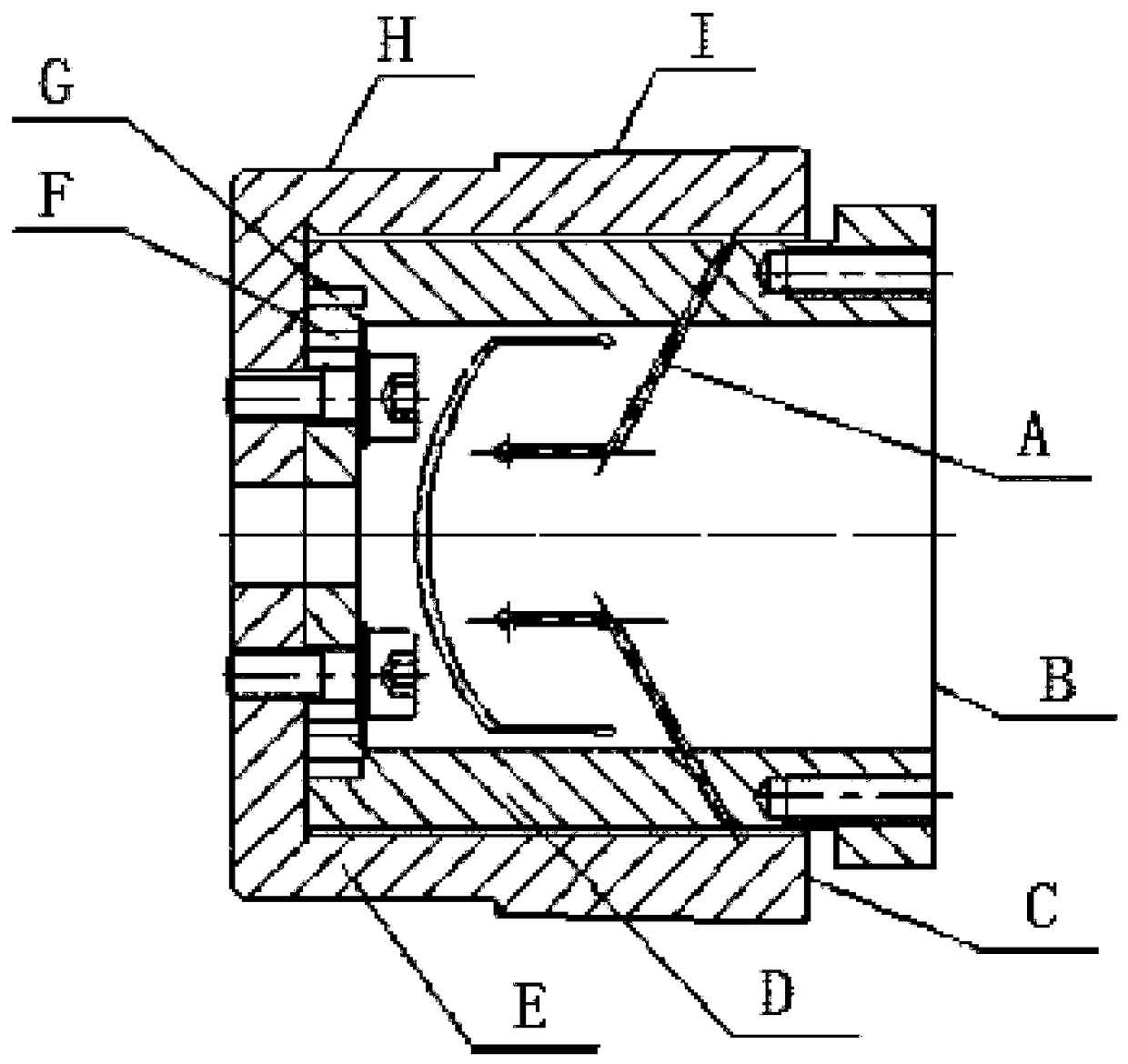

The invention discloses a flexible support structure for a large circular reflector of a space optical remote senor. A flexible support unit provided with a flexible spring belt hinge and a flexible curved groove is a main stress eliminating structural body; the main stress eliminating structural body is integrated on a large circular reflector component of the space optical remote senor, and cantransfer acting force acted on the flexible support structure to the flexible curved groove; stress is eliminated through the deformation effect of the flexible curved groove; therefore, the acting force is prevented from being continuously transferred onto the reflector body of the space optical remote senor; stress concentration of the reflector under the gravity action is reduced; and the factthat the surface figure accuracy of the reflector is not beyond the optical design tolerance value can be ensured.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

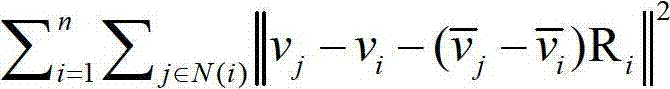

Grid deformation method based on local rigidity

InactiveCN102054296AHigh speedGuaranteed local detail featuresImage data processingDeformation effectGrid deformation

The invention belongs to the field of digital and geometric processing in computer graphics, and in particular to a 3D grid model deformation editing method based on the local rigidity principle. The invention aims at providing a deformation editing method having a fine deformation effect and a satisfactory deformation interaction speed, which is used for model reuse. The method uses grid segmentation and manifold Laplace transform to increase the local rigidity-based deformation editing speed and comprises the following steps: segmenting a 3D model into multiple parts by the grid segmentation, deforming parts which need to be deformed, and splicing the multiple parts, thereby greatly increasing the deformation speed and simultaneously avoiding distortion conditions at the joints. Besides, the manifold Laplace transform can greatly reduce the dimension of linear system of equations of corresponding deformation, thereby achieving higher result controllability.

Owner:NORTHWEST UNIV(CN)

Vehicle ventilating device

InactiveUS7517279B2Easy to useAir-treating devicesVehicle heating/cooling devicesDeformation effectActuator

The invention concerns an air outlet for a vehicle with an actuator for an air outflow, with the actuator featuring a temperature-inducible deformation effect, and means to trigger the deformation effect.

Owner:FAURECIA INNENRAUM SYST

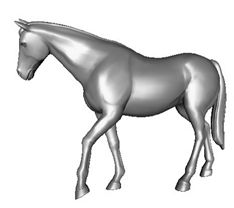

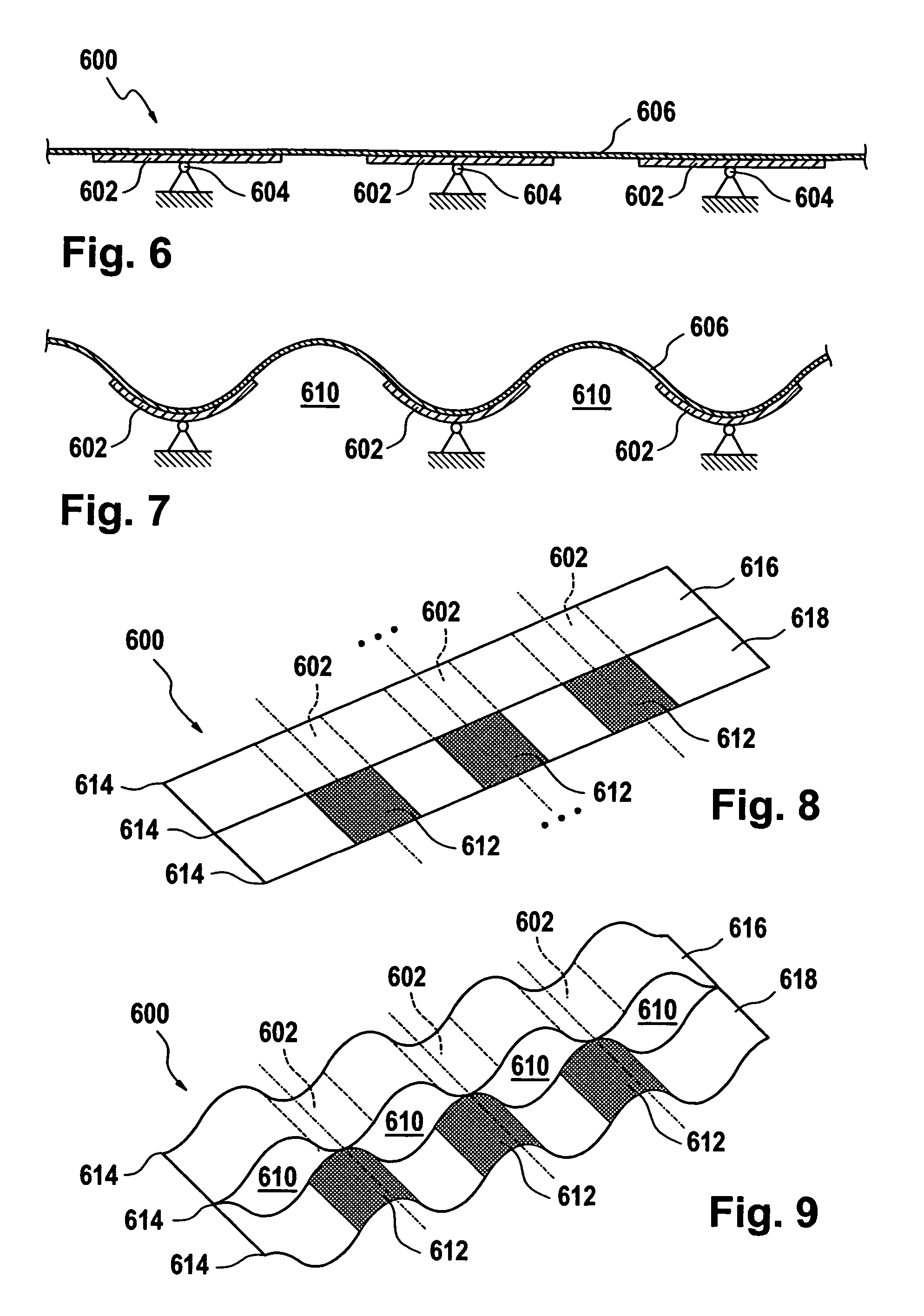

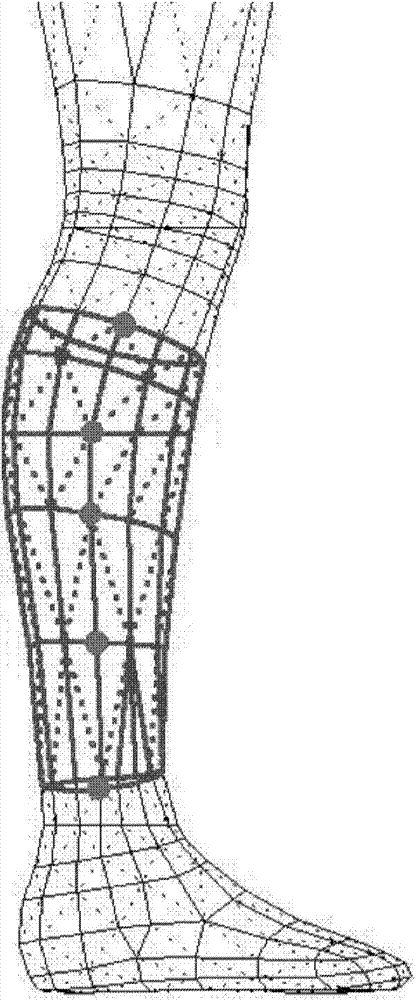

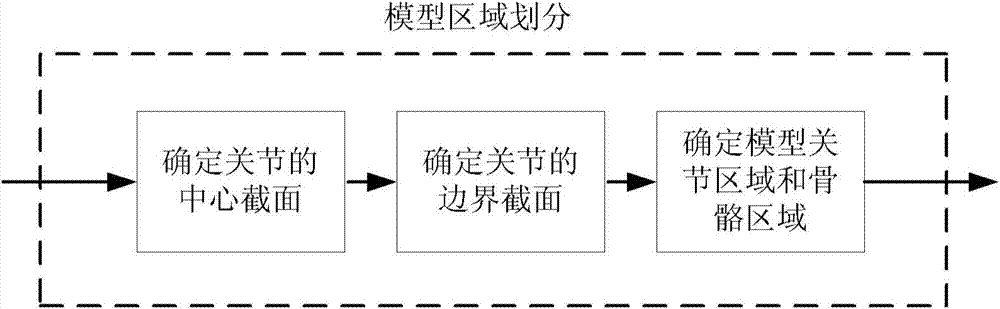

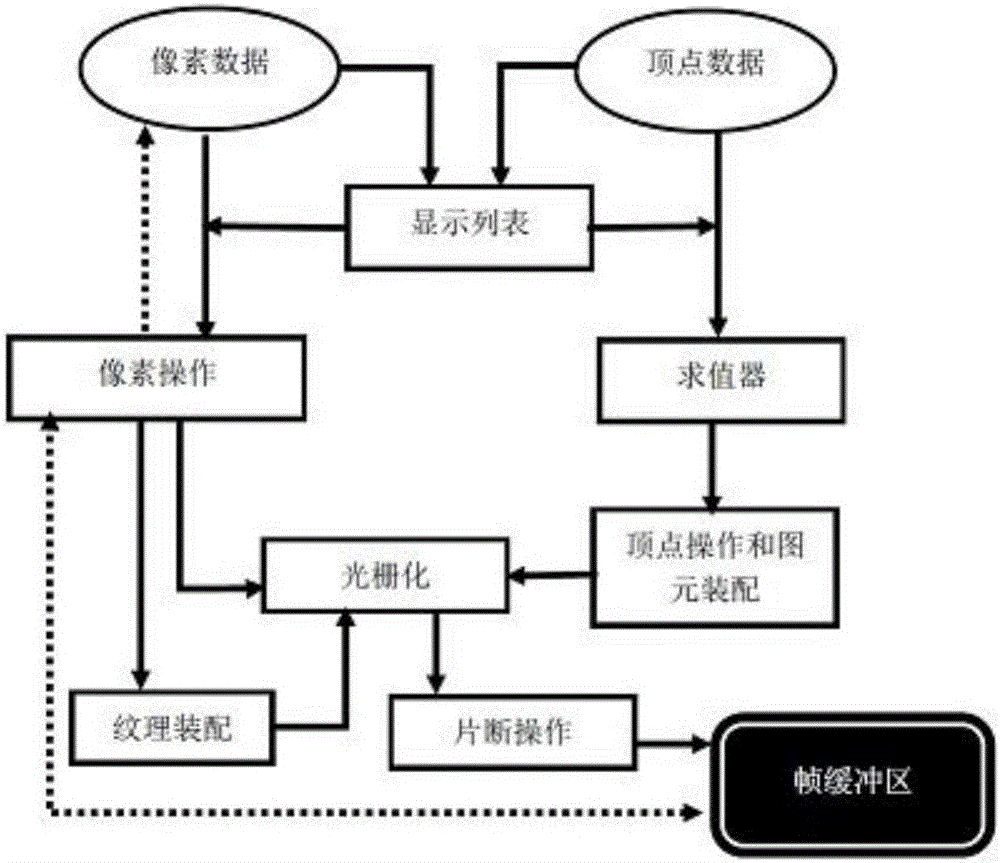

Geometric deformation based skin deformation method for three-dimensional animated character model

ActiveCN103679783AOvercome the disadvantages of prone to distortionImprove production efficiencyAnimationDeformation effectBone area

The invention relates to a geometric deformation based skin deformation method for a three-dimensional animated character model. The method comprises the steps that according to the skeleton structure of an initial character model, the initial character model is divided into joint areas and bone areas, and deformation control points among the bone areas are calibrated manually; according to the body zoom parameters set by a user and the calibrated deformation control points, geometric deformation is implemented on the bone areas of the initial character model based on a free deformation technology; after the geometric deformation, influence of joints on apexes is adjusted; and according to the influence of the joints on the apexes of the joint and bone areas, the character model is driven to make translational and rotary movement via a dual-quaternion method to generate vivid and lifelike skin deformation effect. The skin deformation method of the invention can overcome the defects as collapse and shape explosion caused by large moving amplitude of the model, and obtains more real skin deformation while ensuring the instantaneity.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

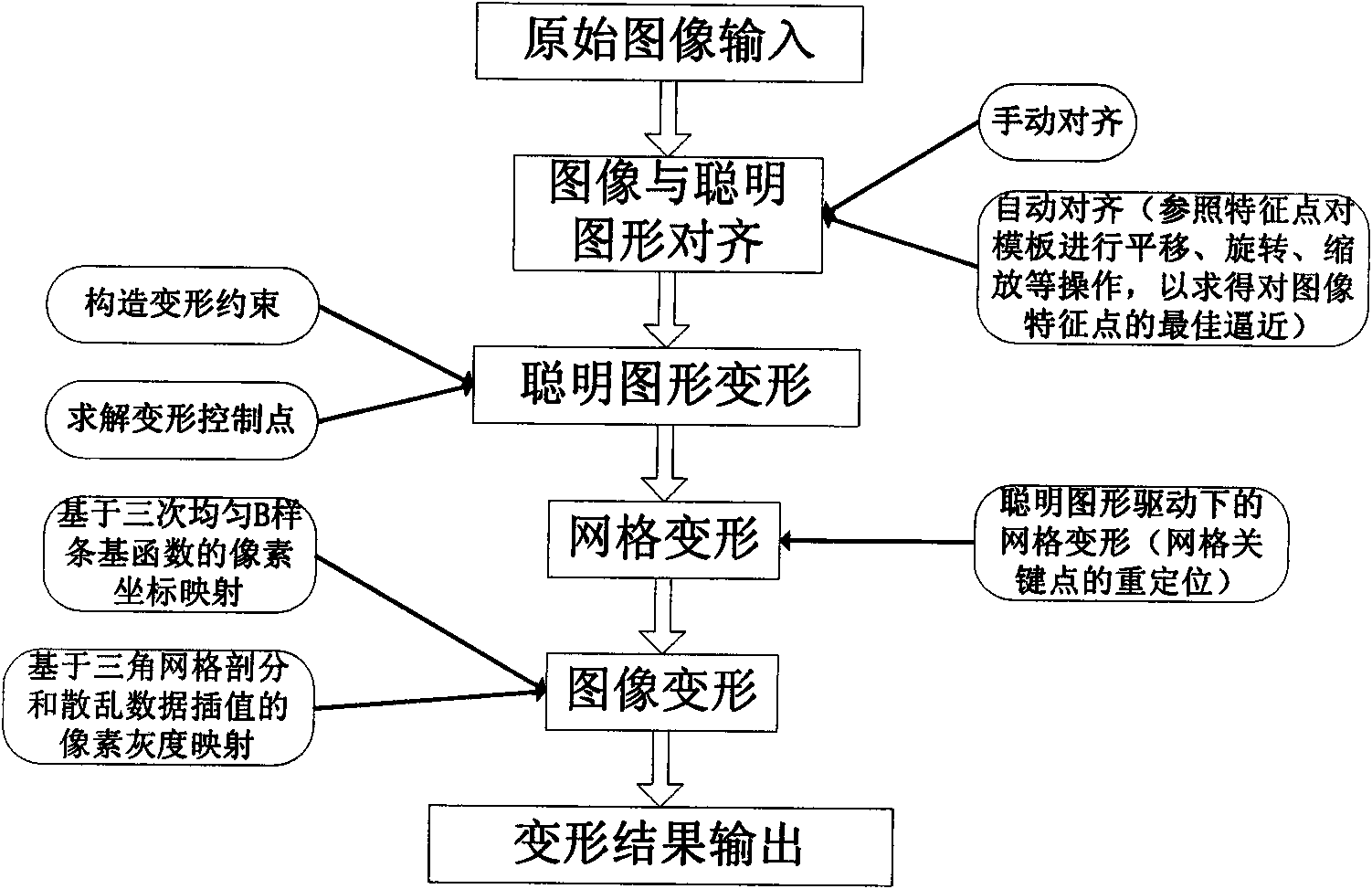

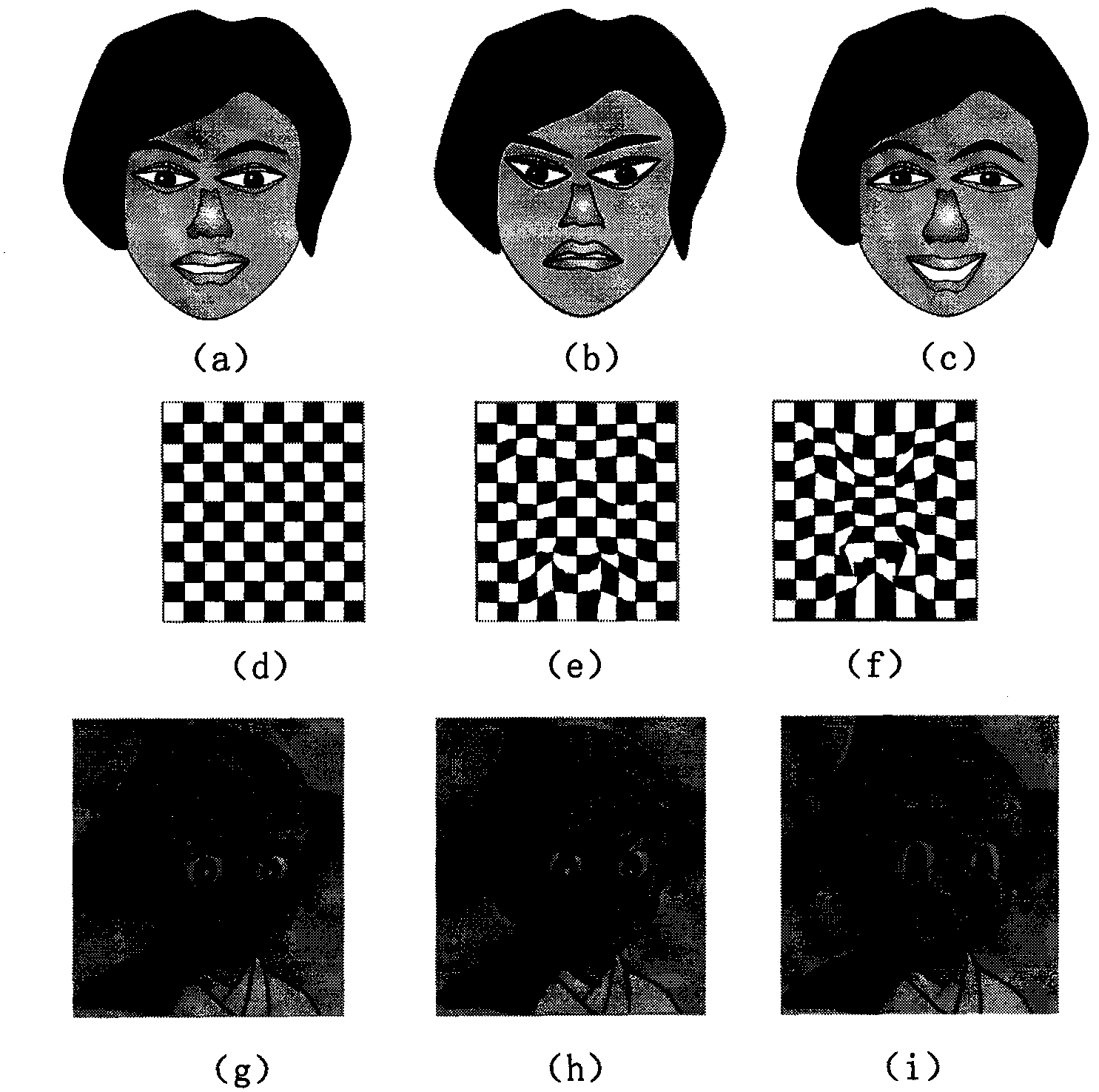

Method for deforming smart graph-driven grid image

InactiveCN101887593ATroubleshoot imprecise image warpingQuick buildAnimationInteraction controlGraphics

The invention relates to a method for deforming a smart graph-driven grid image. In the method, global deformation parameters of the image are mapped to a two-dimensional grid to drive the grid to deform; the grid drives an embedded image of the grid to deform so as to solve the problems of non-accurate image deformations similar to cartoon animation deformations; and a user can quickly acquire an image deformation result through the interaction control of a control point on a smart graph. The method adopts a smart graph-based deformation driving template which has the characteristics of an embedded deformation rule and multi-component coordinative deformation, and can automatically generate appropriate grid driving parameters according to the global deformation parameters so as to generate a grid effect in real time. Besides, by performing cross regulation on different deformation weight coefficients, the method can control the deformation intensity. The method can acquire a two-dimensional grid deformation result of the embedded deformation rule at an interactive real-time speed, and can conveniently and quickly generate a deformation effect of a two-dimensional cartoon animation image by further solving the coordinate mapping and the gray mapping of an image pixel under grid driving.

Owner:SUN YAT SEN UNIV

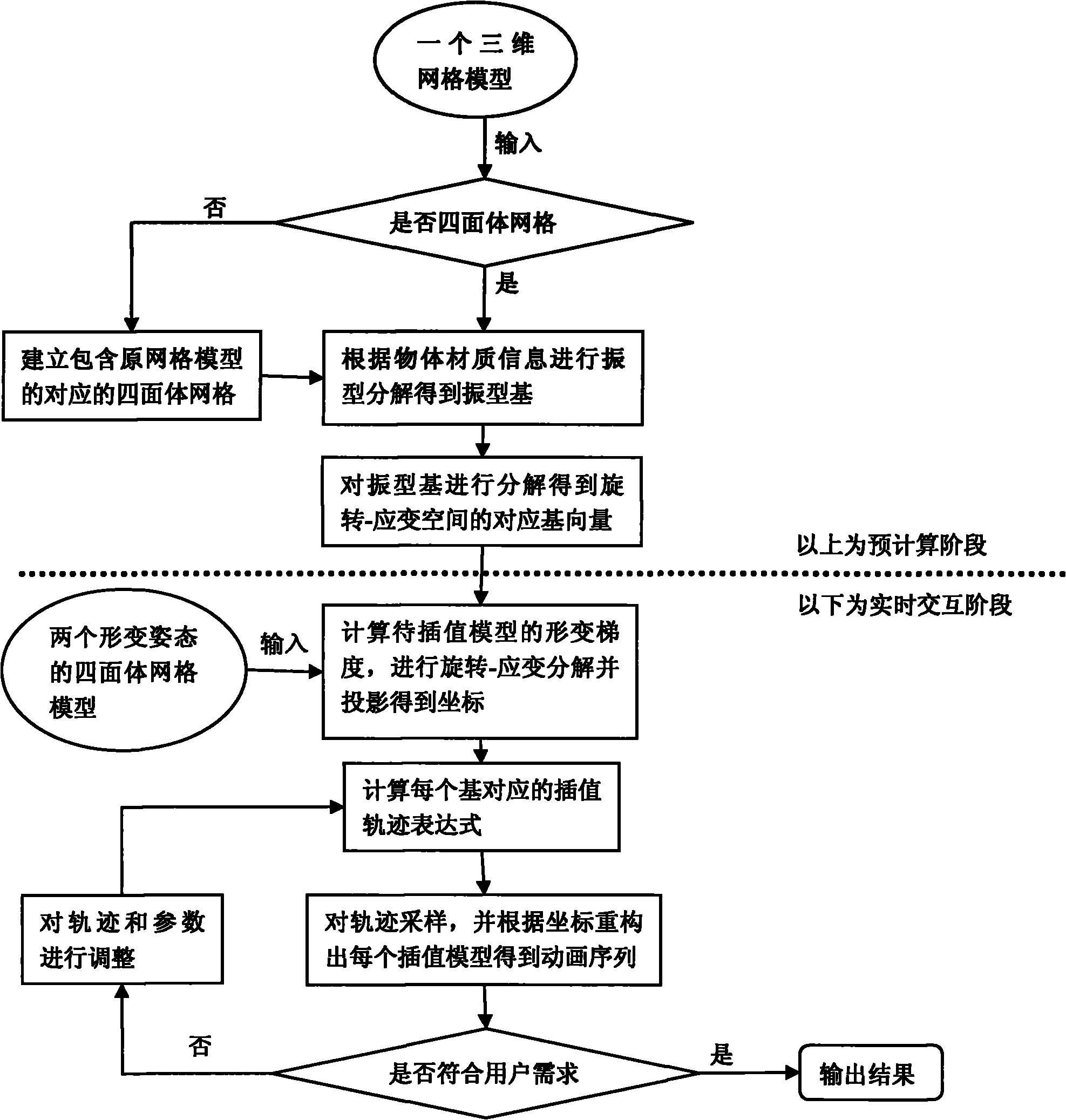

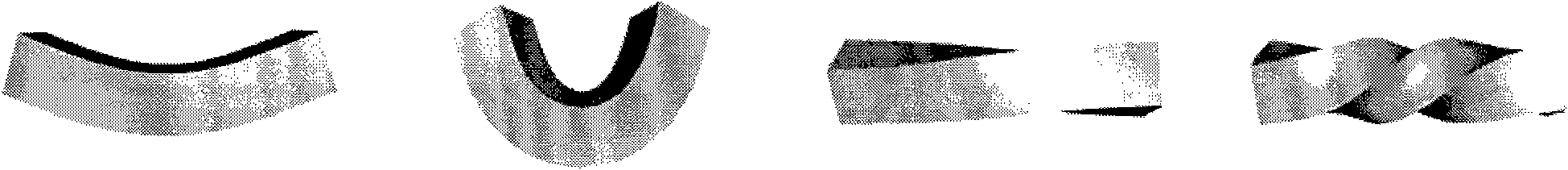

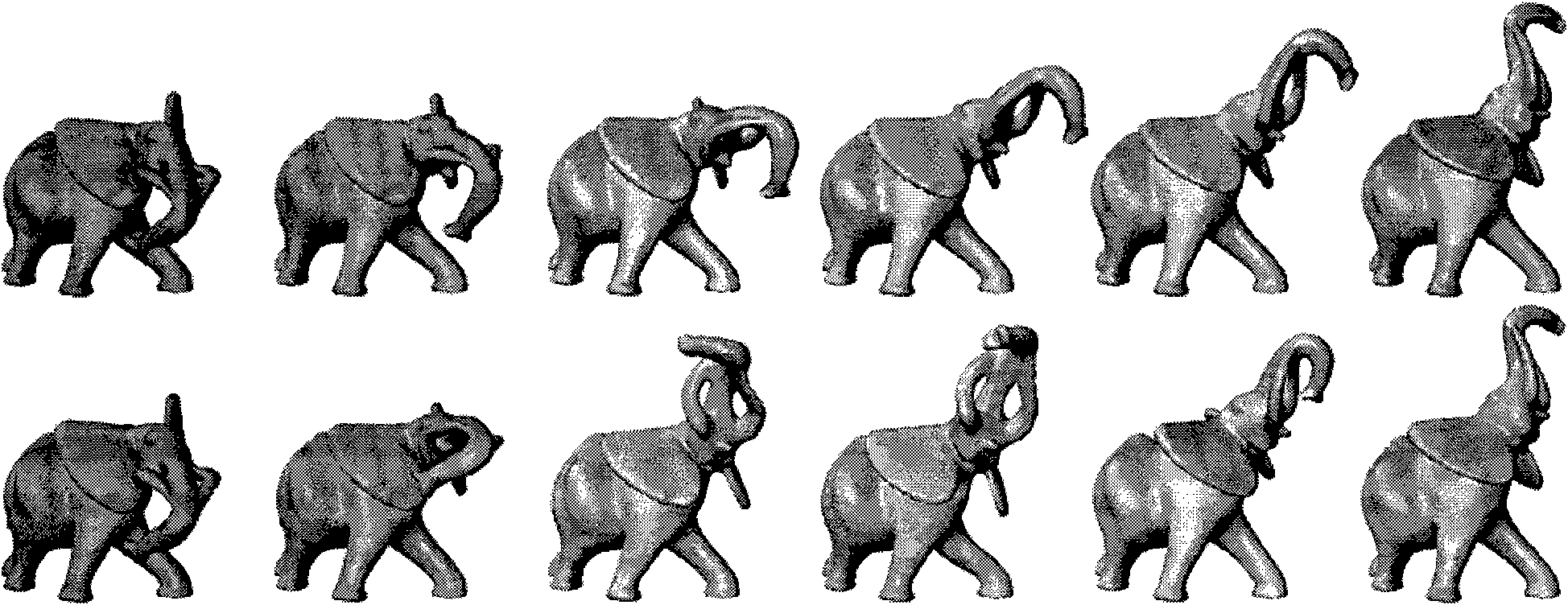

Controllable dynamic shape interpolation method with physical third dimension

InactiveCN101833785AImprove visual effectsEnhanced physical realism3D-image renderingDeformation effectDecomposition

The invention discloses a controllable dynamic shape interpolation method with physical third dimension. According to the method, a rotation-strain space definition is provided, and a set of conversion mode from a three-dimensional model to a rotation-strain space coordinate is established, so that the primary nonlinear deformation can be expressed by linear operation of the coordinate in the rotation-strain space; and the method greatly reduces the algorithm complexity and improves the solving efficiency by combining the traditional mode shape decomposition to perform dimension reduction. The method comprises the following steps of: decomposing a base vector acquired by the traditional mode shape decomposition into rotation and strain parts, and constructing a deformation subspace by using rotation-strain corresponding to the main component bases; obtaining a rich dynamic deformation effect by editing and regulating mode shape coordinate motion interpolation curve parameters in the subspace; and finally, obtaining a new model pose sequence through a reconstruction process according to the interpolated mode shape coordinate.

Owner:ZHEJIANG UNIV

Vehicle Ventilating Device

InactiveUS20060270332A1Easy to useAir-treating devicesRailway heating/coolingDeformation effectActuator

The invention concerns an air outlet for a vehicle with an actuator for an air outflow, with the actuator featuring a temperature-inducible deformation effect, and means to trigger the deformation effect.

Owner:FAURECIA INNENRAUM SYST

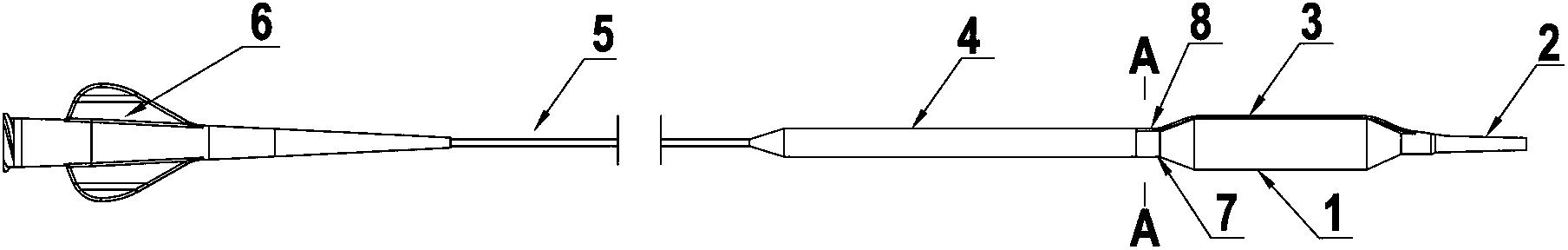

Single-guide wire cutting balloon catheter

InactiveCN103949002AOvercoming balloon banana deformation effectReduce riskBalloon catheterSurgeryDeformation effectBalloon catheter

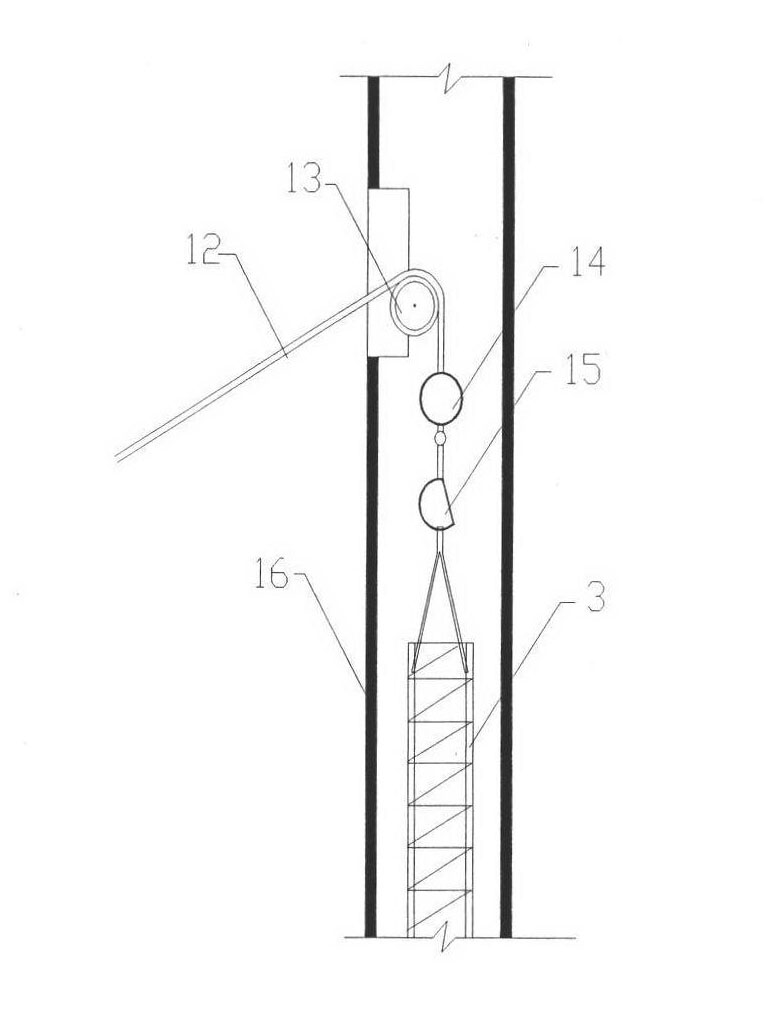

The invention discloses a single-guide wire cutting balloon catheter. The single-guide wire cutting balloon catheter is characterized by comprising a Luer joint, a pipe body, a balloon, a tip and a cutting guide wire, wherein a connecting pipe is arranged at a near end of the balloon; a limiting catheter is arranged on the outer wall of the connecting pipe; one end of the cutting guide wire is fixed on the far end outer wall of the balloon, and the other end thereof is stretched in the limiting catheter; the cutting guide wire slides back and forth in the limiting catheter along with the expansion and shrinkage of the balloon to reduce pressure of the cutting guide wire to the balloon when the balloon is expanded. According to the single-guide wire cutting balloon catheter disclosed by the invention, the cutting guide wire fixed method in the conventional single-guide wire cutting balloon is changed, the conventional two-end fixation is changed into one-end fixation, while the other end is movably connected, so that the cutting guide wire can stretch out and draw back freely in the balloon axial direction, and the banana-shaped deformation effect of the balloon can be avoided; in the meantime, the single cutting guide wire can cut the lesion plaque into monolete suture, and then the plaque can be faded away through follow-up pharmaceutical action; the surgery is safe and reliable, and high in success rate without complication.

Owner:GUANGDONG BROSMED MEDICAL DEVICE CO LTD

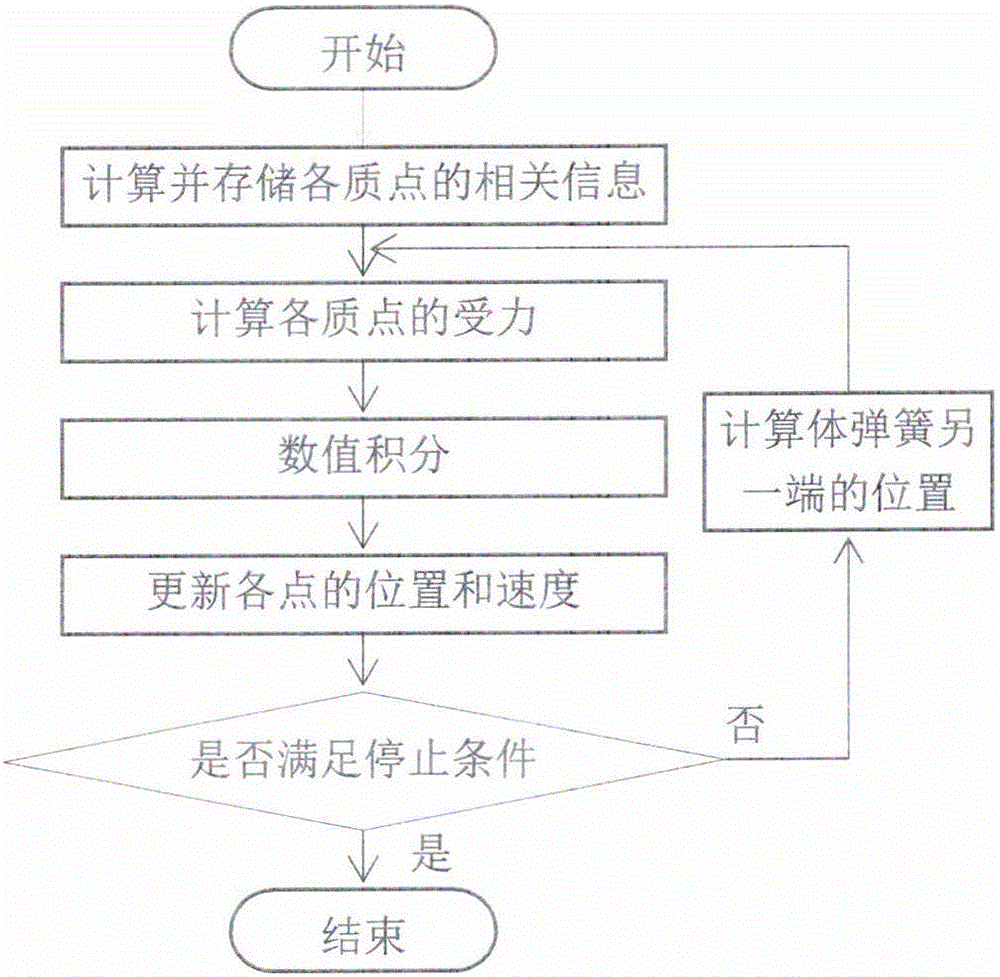

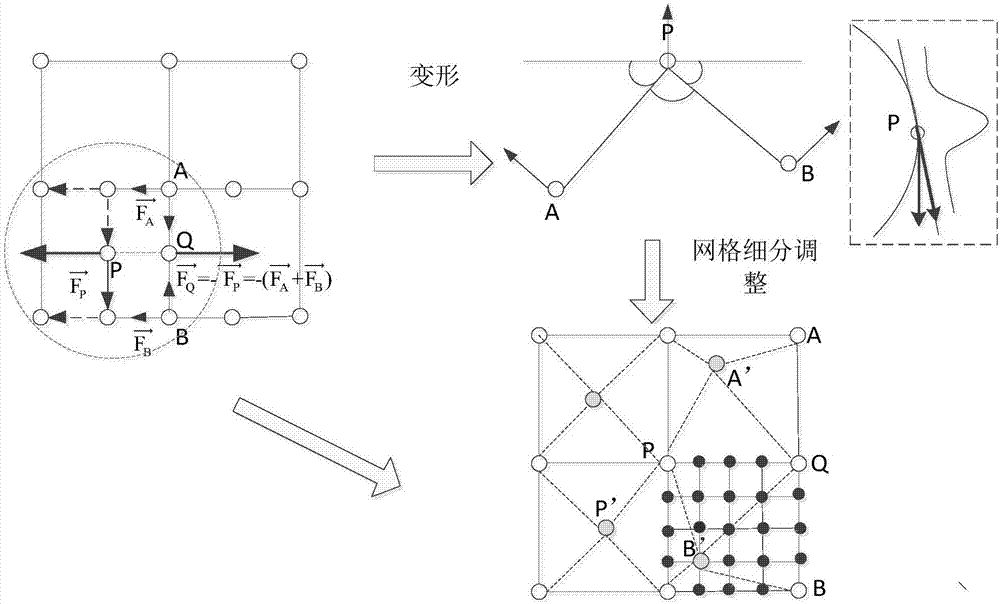

Gingival deformation simulation method based on mass-spring model of long axis of tooth

ActiveCN106504329ATo achieve the simulation effectDeformation effect is fullMedical simulationSpecial data processing applicationsDeformation effectLong axis

The invention discloses a gingival deformation simulation method based on a mass-spring model of the long axis of a tooth. The method comprises steps of: determining a gingival model; calculating the position of the long axis of the tooth; storing the initial position, the adjacent point, and the mapping point, corresponding to the long axis of the tooth, of a mass point; determining the position, the speed, and the borne force of the mass point in each time step, namely each iteration; calculating the new position of the long axis of the tooth according to a moving matrix when a dental crown is dragged; and determining a stop condition and outputting a simulation result. The gingival deformation simulation method achieves a good simulation effect because an improved mass-spring model is better than a simplified mass-spring model in the deformation effect and is greatly reduced in time consumption.

Owner:秦皇岛知聚科技有限公司

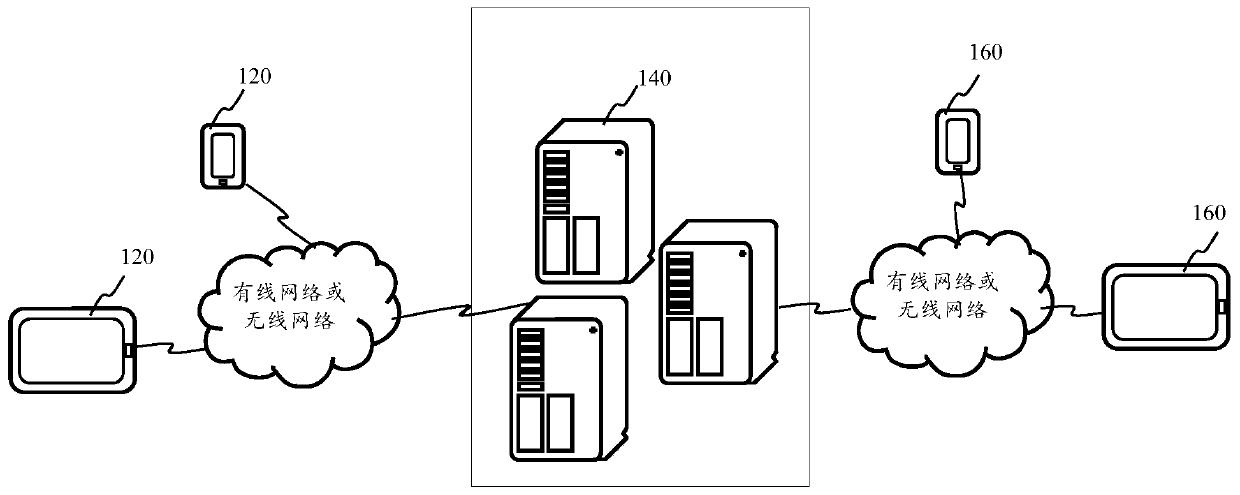

Interactive prop control method and device, terminal and storage medium

ActiveCN110721468AFree from fireRich interactive methodsVideo gamesDeformation effectCollision detection

The invention discloses an interactive prop control method and device, a terminal, and a storage medium, and belongs to the technical field of multimedia. When a putting operation on an interactive prop is detected, a putting status of a putting position is displayed in a virtual scene, and when the putting status is permissible to put, the interactive prop is displayed in the putting position; and when a first target prop is detected to be fallen into a collision detection range of the interactive prop, the first target prop is controlled to trigger a deformation effect at a target position deviating from an original deformation position, so that the first target prop can be detonated in advance. An interactive mode provided for the first target object is enriched, the fun of the interactive process is improved, and the interactive effect and user experience are optimized.

Owner:TENCENT TECH (SHENZHEN) CO LTD

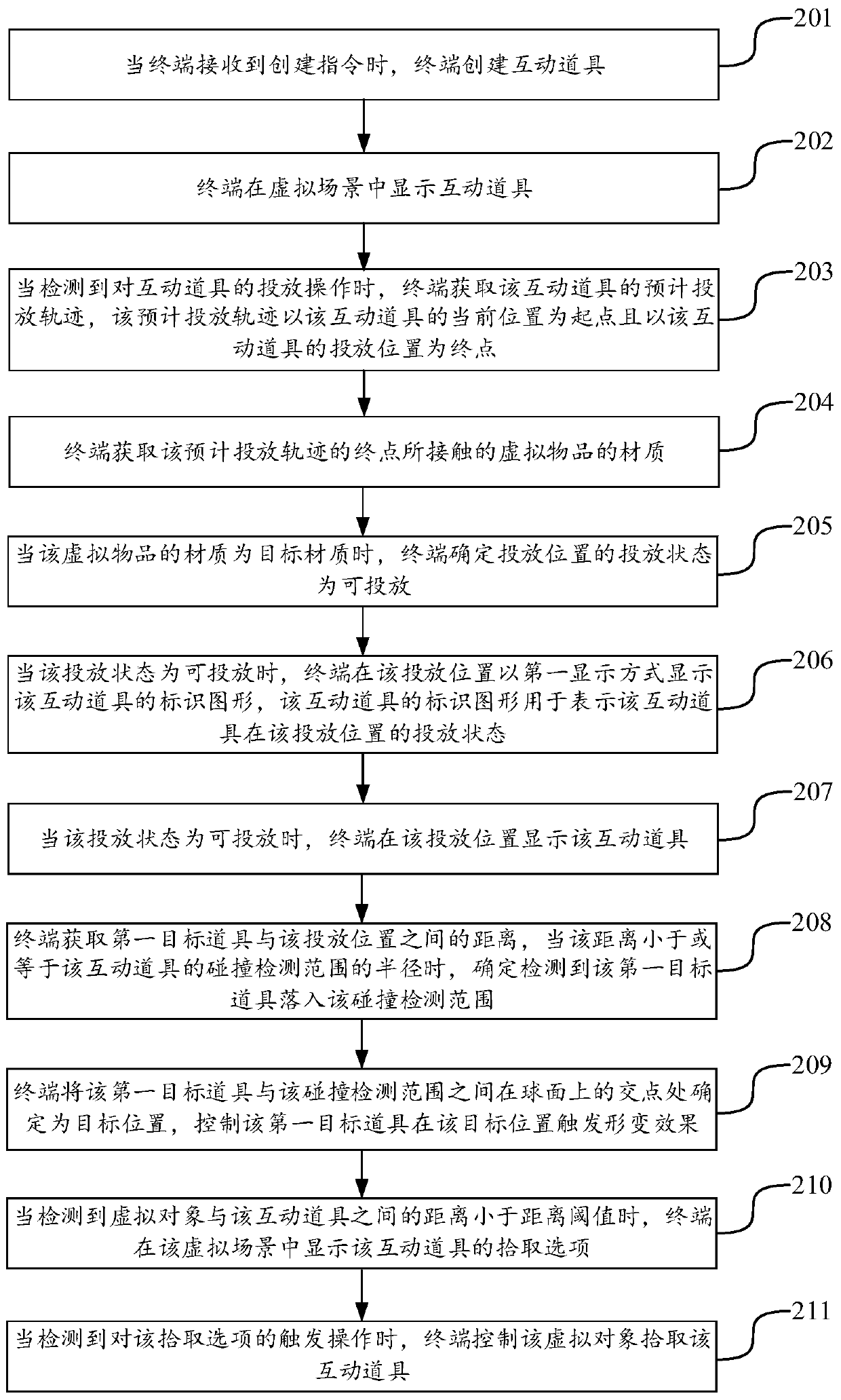

Fold distortion QR code correcting method

ActiveCN108629221ATroubleshoot Correction Recognition IssuesSolve the detection speed is slowSensing by electromagnetic radiationElectricityDeformation effect

The invention relates to a fold distortion QR code correcting method. The method comprises three parts of two-dimensional code corner point detection, linear deformation correction and fold correction. If one pair of sides of a two-dimensional code pattern are not distorted and the other pair of sides are distorted, linear deformation effect caused by shooting angle and the like is eliminated to acquire a first corrected image, and then a shortest curve external connection method is used to carry out fold distortion correction on the first corrected image to acquire a second corrected image. On the basis of the second corrected image, a QR code is decoded and recognized. The step of fold distortion correction comprises edge contour extraction, edge contour interference electricity removing, edge contour multi-function fitting, fitting function screening, internal point mapping function selection, mapping transformation correction and the like. According to the invention, the detectionspeed and the recognition rate are greatly improved, and the fold distortion two-dimensional code is corrected and recognized.

Owner:NANJING UNIV OF POSTS & TELECOMM

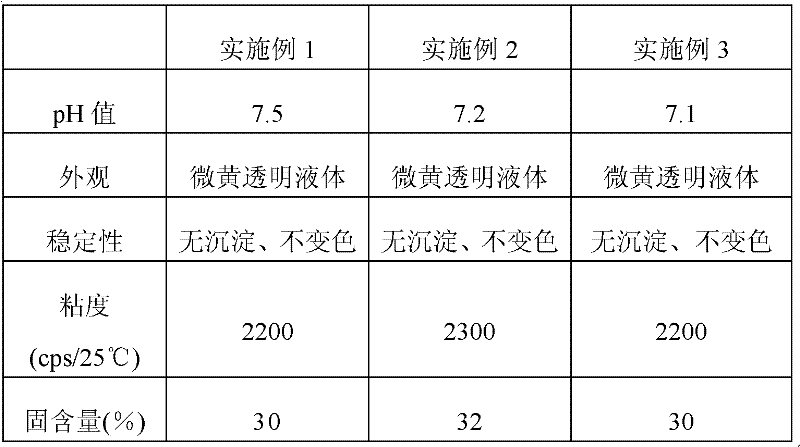

Veneering water-kneading pressure-deformable resin for synthetic leather and preparation method thereof

InactiveCN102182068AComply with environmental standardsPastel colorFibre treatmentWaxDeformation effect

The invention relates to a veneering water-kneading pressure-deformable resin for synthetic leather and a preparation method thereof. The veneering water-kneading pressure-deformable resin for synthetic leather comprises the following components: a polyurethane resin, DMF (dimethyl formamide), acetone, temperature change powder, color-changing wax powder, silica extinction powder and an organic silicon leveling agent. The synthetic leather adopting the veneering water-kneading pressure-deformable resin for synthetic leather has good extinction effect and gentle gloss; the leather surface after water kneading is soft and comfortable; and after plate pressing, a good pressure deformation effect is obtained, and the pressure deformation does not restore.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Cutting technology for thin-wall titanium alloy part

InactiveCN104227019AIncreased durabilityAvoid vibrationWorkpiecesTurning toolsDeformation effectTitanium alloy

The invention relates to a cutting technology for a thin-wall titanium alloy part. According to the cutting technology for the thin-wall titanium alloy part, tool materials, angles and cutting factors suitable for machining of titanium alloy materials are selected, the machining durability of tools is improved, the deformation effect of workpieces is reduced remarkably, and the machining quality of the workpieces is improved. A machining result of 1000 workpieces in multiple batches shows that the qualified rate of the workpieces is only 70 percent before the technology is improved, and the qualified rate of the workpieces is increased to about 97 percent after the technology is improved.

Owner:无锡市森信精密机械厂

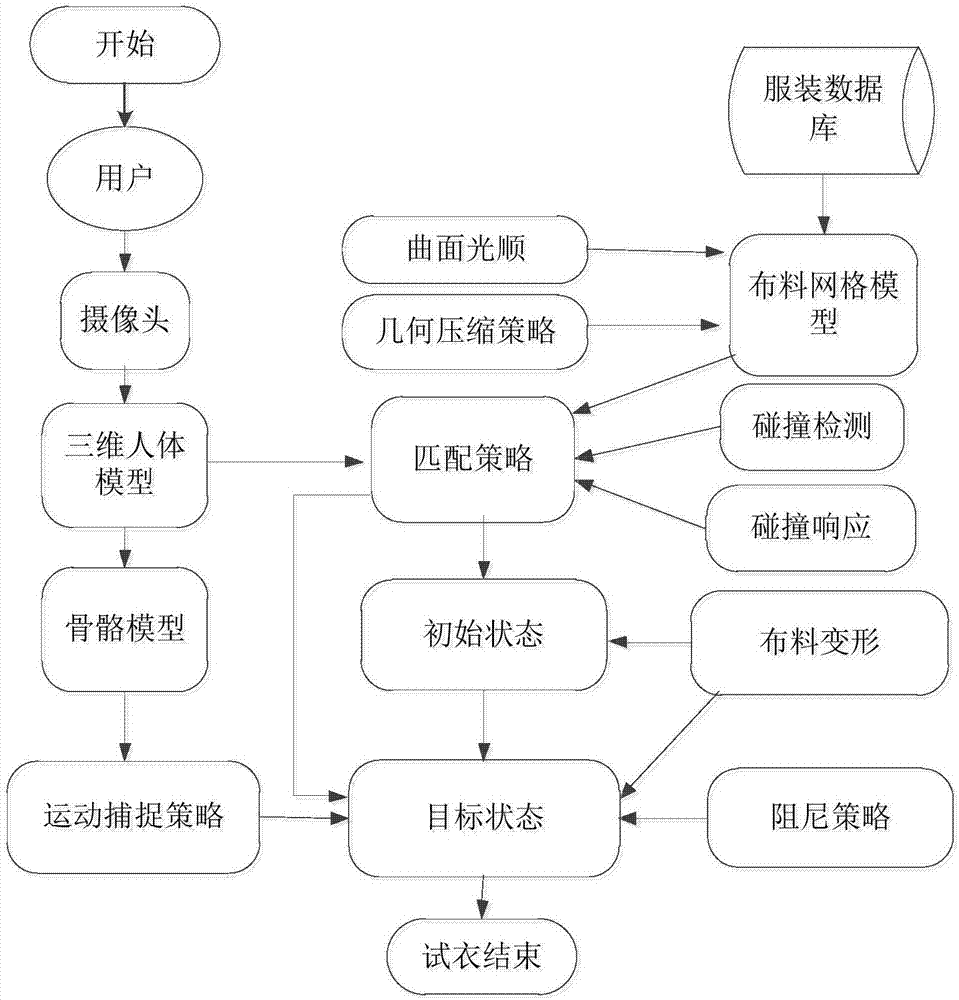

Three-dimensional real human body online virtual fitting system

ActiveCN107578323AUnreasonable penetrationGuaranteed positional relationshipBuying/selling/leasing transactionsImage data processingWrinkle skinDeformation effect

The invention discloses a three-dimensional real human body online virtual fitting system. A topological structure of cloth particles is simulated by clothing mechanical cloth models, by adding of connecting sides, a triangular mesh is constructed by the cloth models, the cloth is seen as a set of a group of discrete particles, and mechanical models are established for the particles on the basis of consideration on a constraint force of cloth; bending and wrinkling behaviors of the cloth are realized by continuous movement generated by interaction forces of the particles, characterized bendingdeformation behaviors of cloth which is made of different materials or has different precisions are simulated, therefore, the reality of the bending deformation effect is improved, and a user can rotate circularly in front of a camera or walk to appreciate fitting effects at different angles, and can feel garment material quality, drooping style, wrinkles and fitting degree; and moreover, by recognition of human intention, the wearing effect after the user does different actions is achieved in real time. In addition, the system can be realized by only one camera.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Mosaic variegation digital camouflage pattern setting on surface of shelter

InactiveCN102778176AEasy to camouflageFusion simpleCamouflage devicesProtective buildings/sheltersNatural satelliteAviation

The invention discloses a mosaic variegation digital camouflage pattern setting on the surface of a shelter. The technical scheme adopted by the invention is realized by the following steps: selecting a southern woodland type camouflage as a reference, wherein the middle green area accounts for 45 percent, the dark green area accounts for 30 percent, the lime-clay area accounts for 15 percent, the bright green area accounts for 10 percent, the size of each small check color block is 100mm*100mm; enabling a boundary lapping line of each small spot check to be at least 100mm; combining ten kinds of checks such as middle green, dark green, lime-clay and bright green into modules with different shapes and a digital camouflage pattern of the shelter; and automatically spraying the digital camouflage pattern to the shelter by a computer according to a digital camouflage pattern setting scheme. From a great distance, the digital camouflage pattern can achieve the deformation effect required by a traditional blotch design; spots with different colors can generate space mixing color and are easily fused with a surrounding background; and the digital camouflage pattern can simulate surface characteristics of background communities such as forests and mountains, so that enemy aviation and satellite imaging detection are difficult in differentiating.

Owner:贵州航天特种车有限责任公司

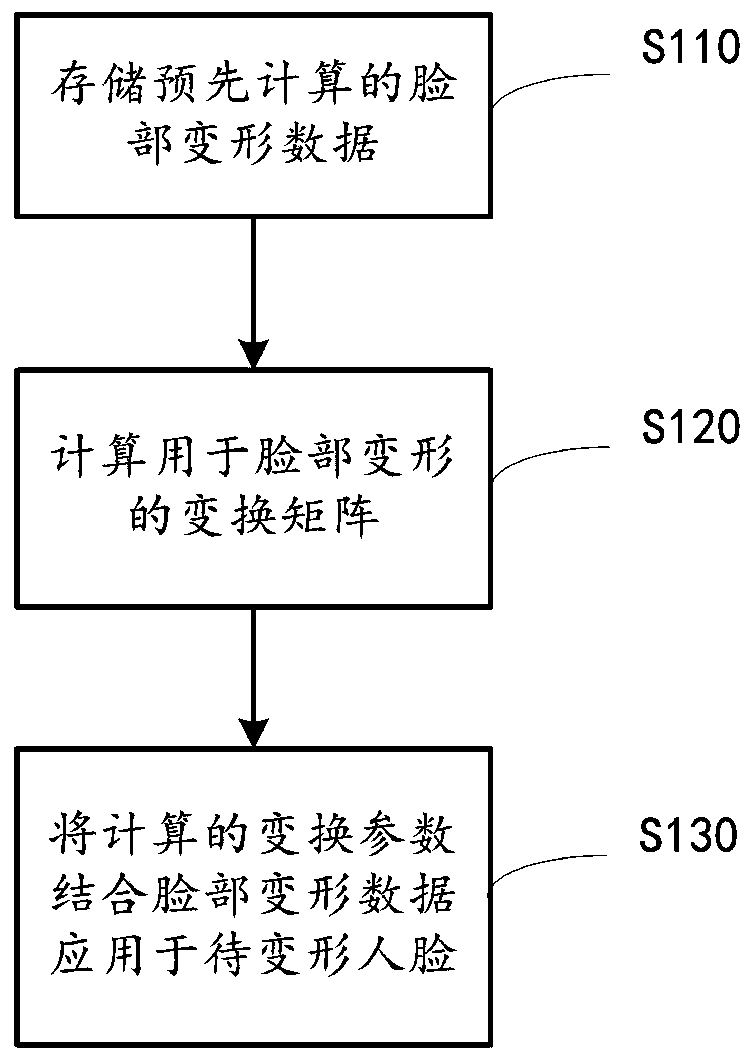

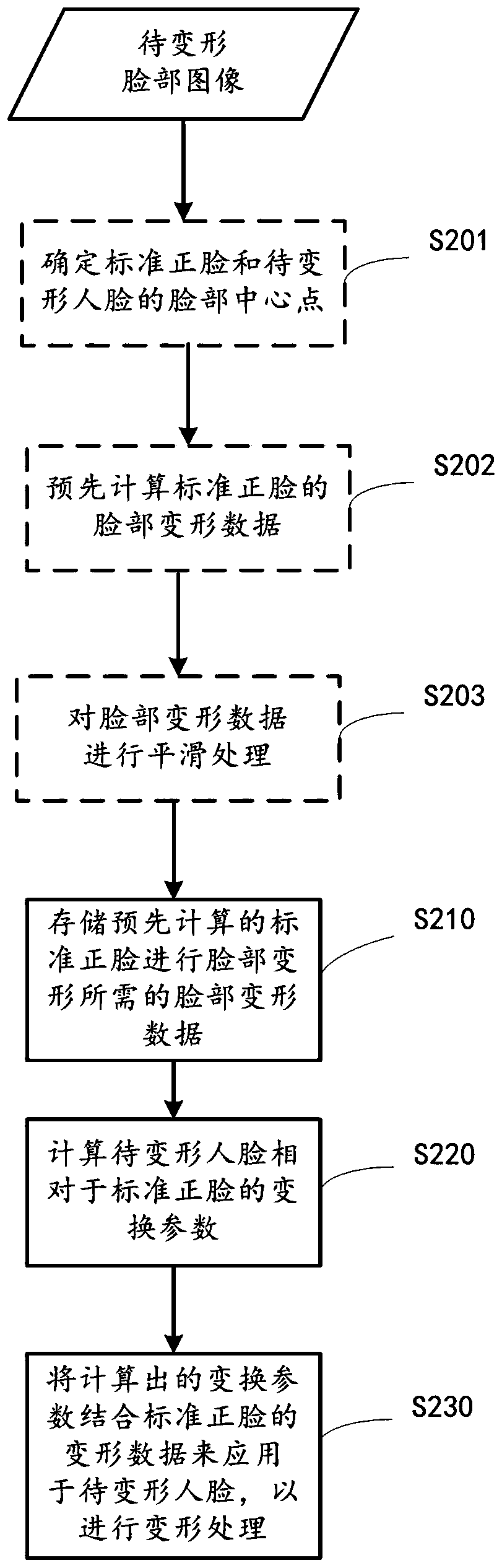

Face image processing method and device, image processing device and medium

PendingCN109859097AReduce usageQuick responseGeometric image transformationPattern recognitionImaging processing

The invention discloses a face image processing method and device, an image processing device and a medium. The face image processing method comprises the following steps: storing pre-calculated facedeformation data of a standard front face, wherein the face deformation data comprises offset information in the horizontal direction and the vertical direction, which is required for performing specific deformation on a specific point on the standard front face; calculating transformation parameters of the to-be-deformed face in the face image relative to the standard front face; and applying thecalculated transformation parameters in combination with the face deformation data of the standard front face to the to-be-deformed face, and performing deformation processing on the to-be-deformed face to obtain a deformed face image. According to the method, the pre-calculated face deformation data is stored, and the deformation processing is performed on the to-be-deformed face by combining the transformation parameters of the to-be-deformed face relative to the standard front face, so that the use of processing and computing resources can be reduced, the response speed is increased, and arelatively good deformation effect can be obtained.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

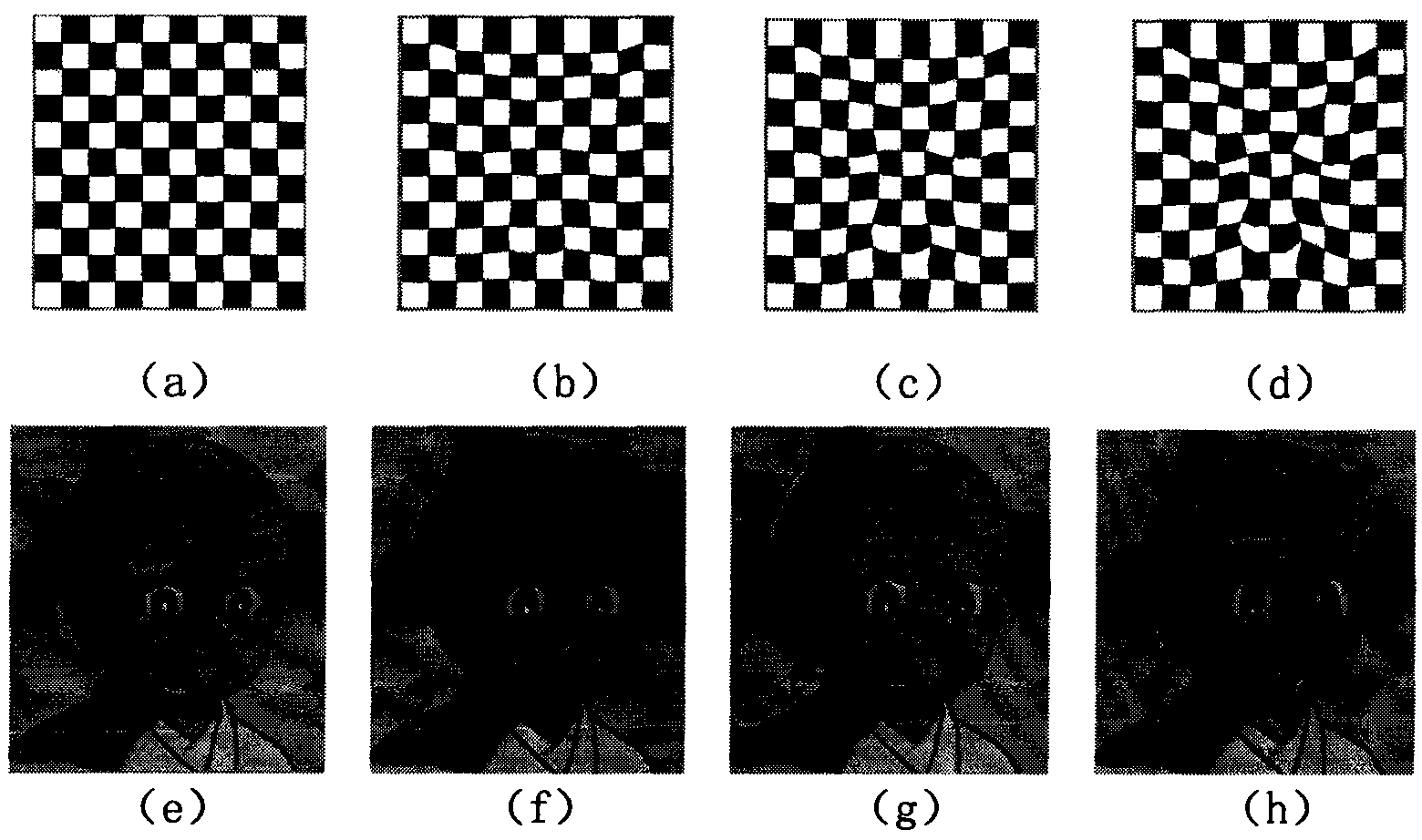

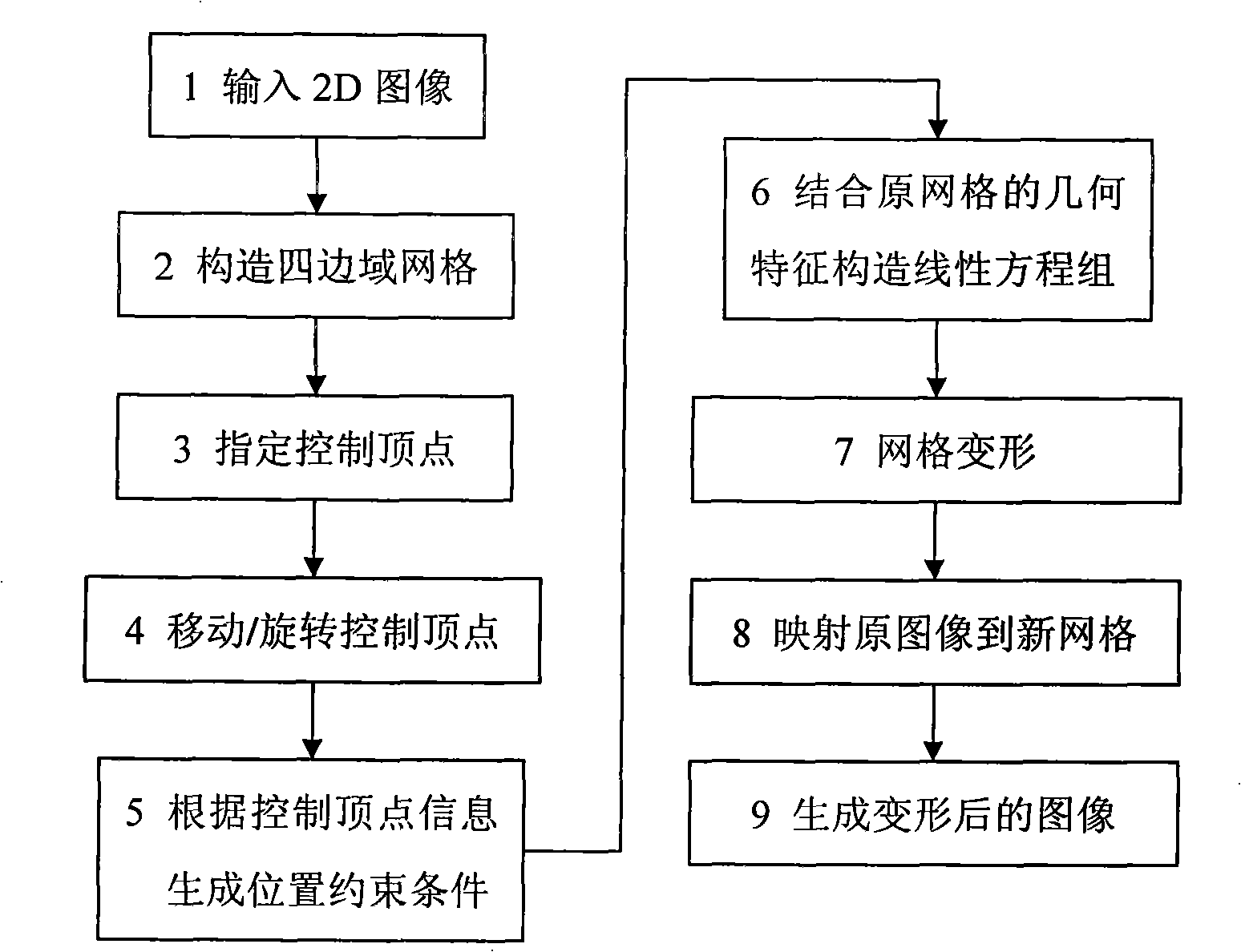

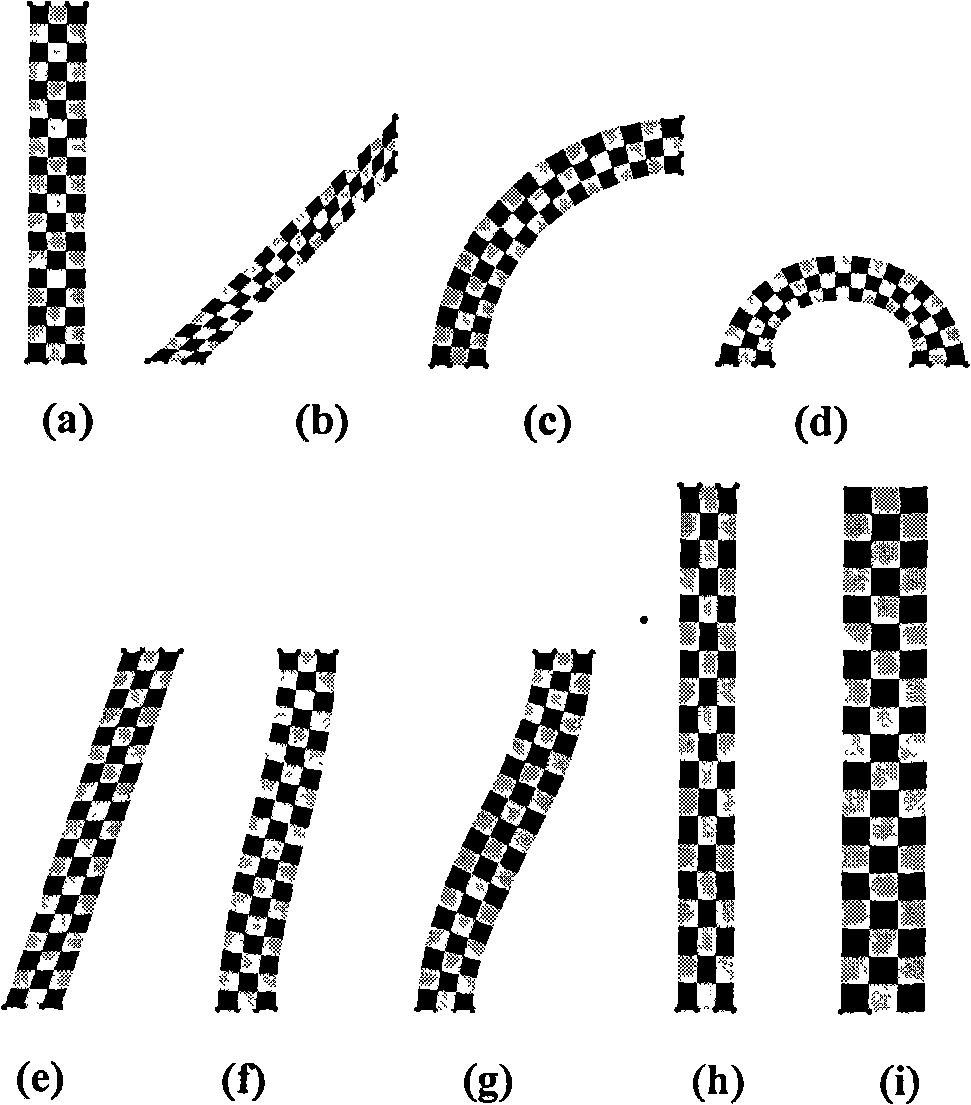

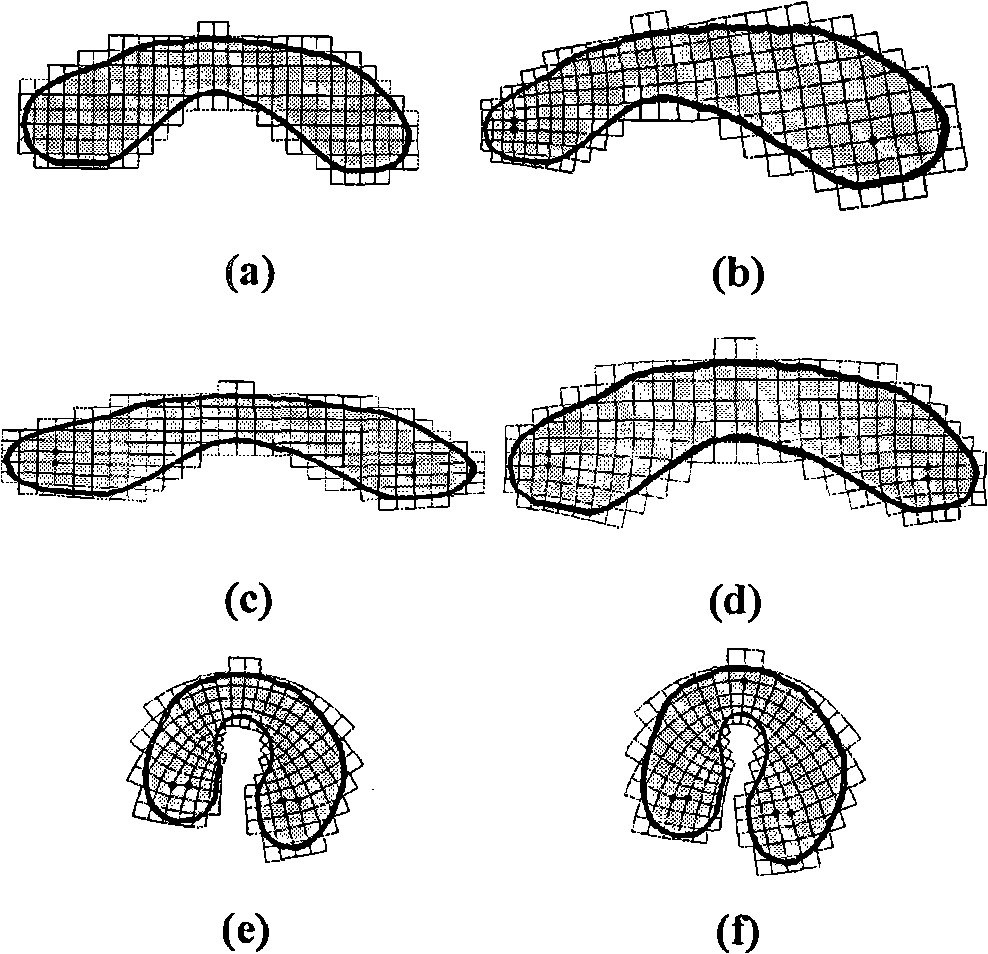

Linear constrained image distortion method based on local coordinates

InactiveCN101276474AGet deformation resultGet deformation results quicklyAnimationDeformation effectImage conversion

The invention relates to a linear image deformation method based on a local coordinate. The method comprises transforming an image into a corresponding four-side-territory grid, presenting the geometrical characteristics of the grid by affine and angle linearity restriction, constructing a boundary restriction condition based on a user-appointed control culmination, solving a linear equations set, rapidly computing the deformed image. According to the method, the deformation effect with translation sensibility can be obtained by an interaction speed, the proportion of affine deformation can be controlled by adjusting the weights of two kind of linearity restriction, complex deformation effects, such as good bend, translation sensibility, anisotropy zoom, etc., are realized.

Owner:SUN YAT SEN UNIV

Volumetric mesh deformation method

The invention discloses a volumetric mesh deformation method. The method is used for the interactive design of a simulation system for a hump nose plastic surgery; in the system, the Laplace coordinate-based deformation method on surface meshes is popularized to the volumetric meshes, and a high-quality volumetric mesh deformation effect is achieved in a simple and convenient interactive operation mode, so that the geometric detail characteristic and model volume are kept invariant as much as possible; meanwhile, the influence of non-uniform material parameters on deformation is considered fully to achieve a similar effect of physical deformation. In the simulation system for the hump nose plastic surgery, the original input data is computed tomography (CT) scanning volumetric data of patients and is imported into an image segmentation module and a three-dimensional model reconstruction module.

Owner:HANGZHOU PUREINFO INFORMATION TECH

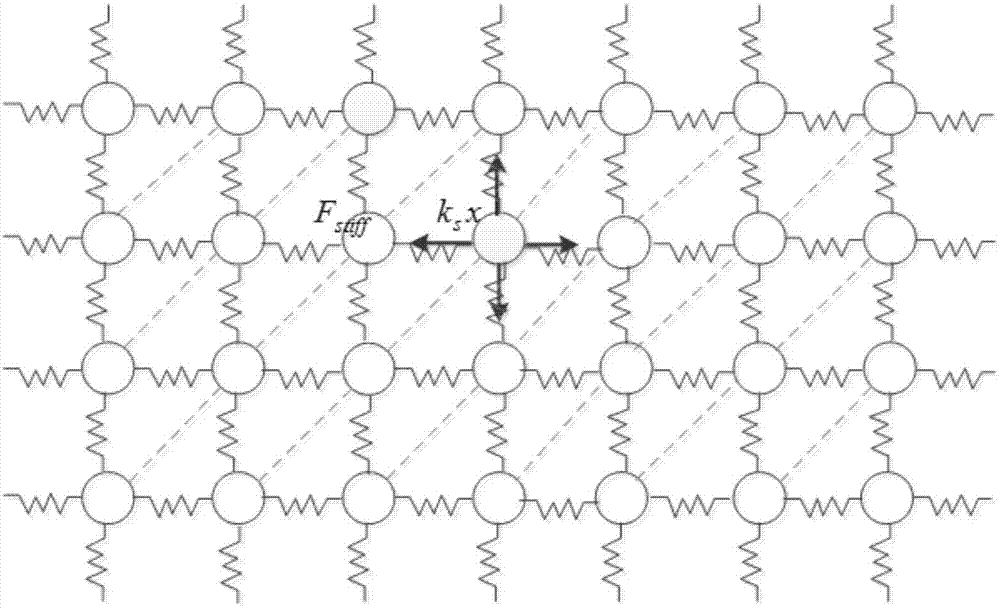

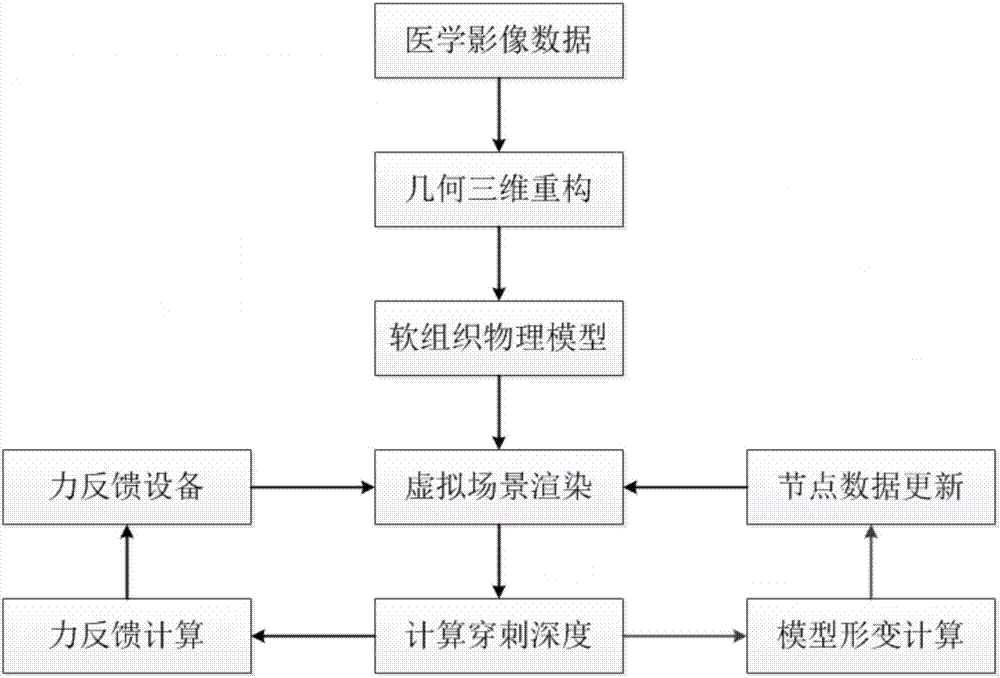

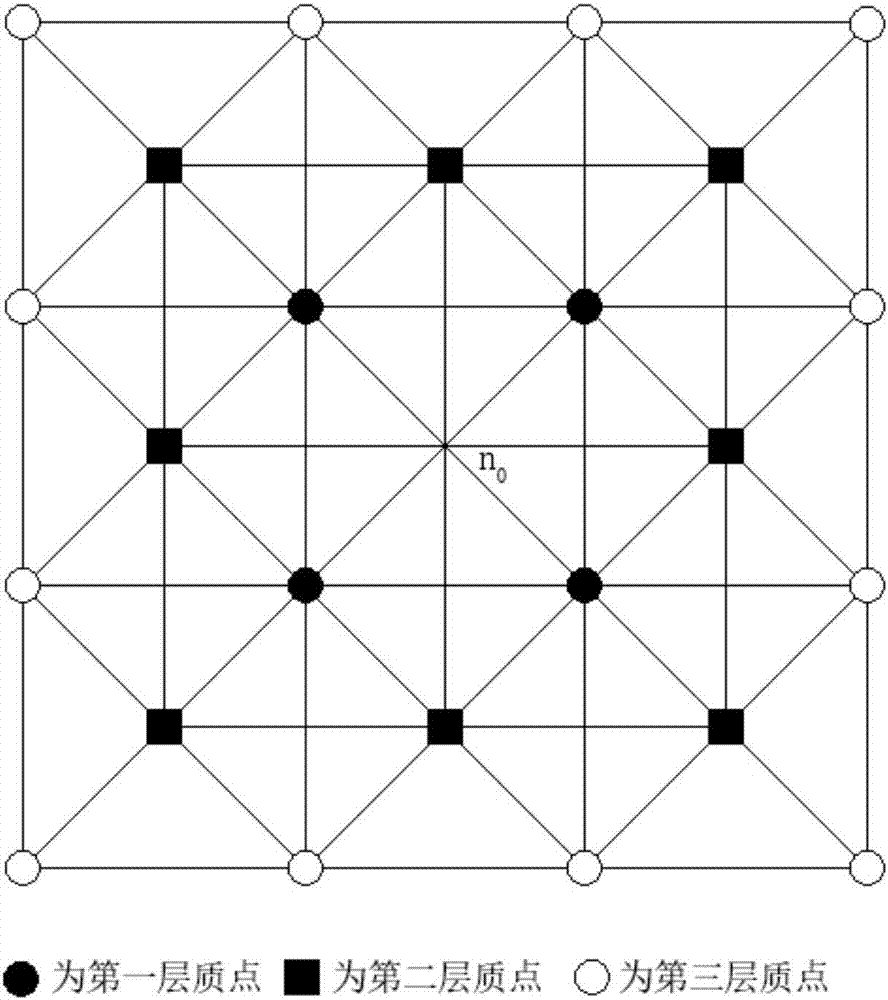

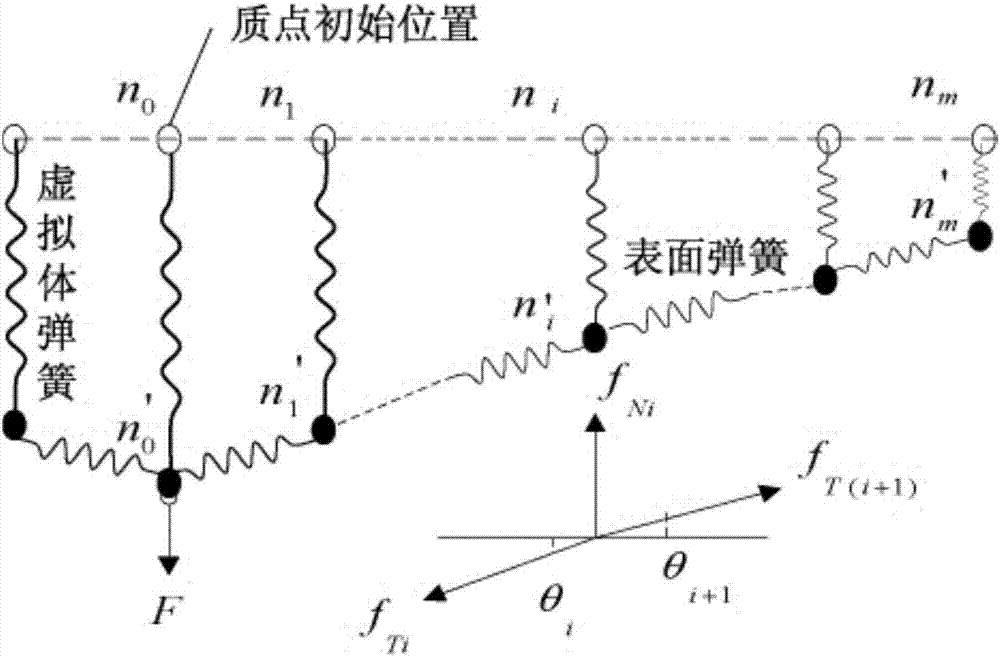

Soft tissue deformation modeling method based on virtual springs

InactiveCN107992672AReal-time feedbackGuaranteed high refresh rate requirementsDesign optimisation/simulationSpecial data processing applicationsDeformation effectNet force

The invention discloses a soft tissue deformation modeling method based on virtual springs. The soft tissue deformation modeling method based on virtual springs is based on the spring-particle model to establish an improved real-time deformation model of soft tissue, virtual body springs are added by the topological structure soft tissue surface model combining the square and the isosceles right triangle, so that a more real deformation effect is achieved; at the position of each particle in the system, the superposition of surface springs variable is equivalent to the surface deformation of an object, the resultant force of the elastic forces of the virtual springs is equivalent to the contact force on the surface of the object; the model inherits the advantages of the classical spring particle model that the principle is simple, the model is easy to establish, the calculation speed is quick, at the same time, the model has an ability to control the deformation area.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

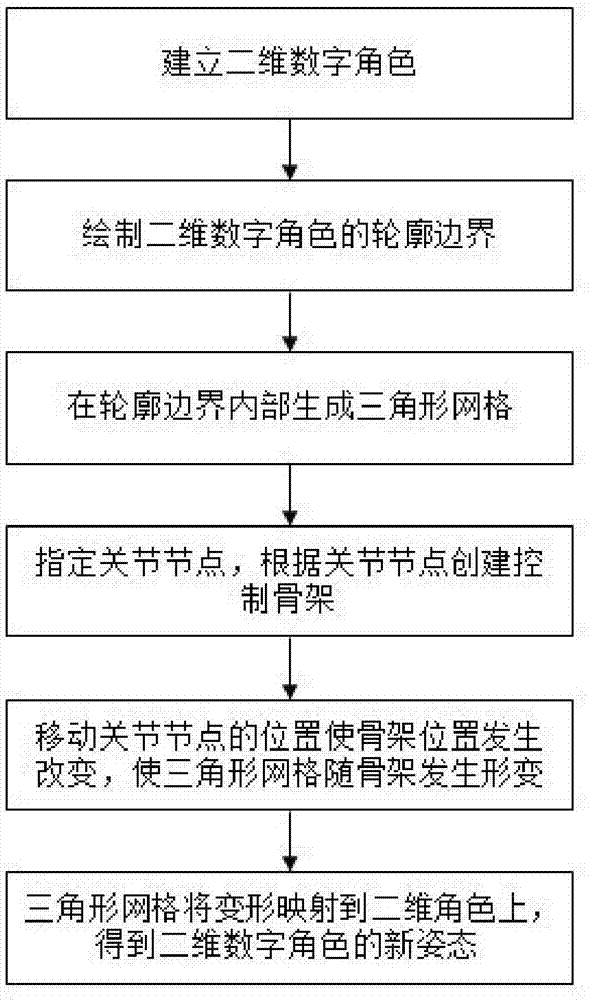

Shape-considered two-dimensional digital character skeleton operation method

InactiveCN102903138AAvoid local distortionImprove practicalityAnimationBoundary contourDeformation effect

The invention discloses a shape-considered two-dimensional digital character skeleton operation method, which comprises the following steps: 1, setting up a two-dimensional digital character; 2, drawing the boundary contour of the two-dimensional digital character; 3, generating a triangular net in the boundary contour; 4, specifying a joint node on the two-dimensional digital character by a user, and creating a control skeleton according to the joint node; 5, changing the position of the skeleton through moving the position of the joint node by the user, and enabling the triangular net to deform with the skeleton through minimizing a geometric deformation energy function; and 6, mapping the deformation of the triangular net to the two-dimensional digital character so as to obtain a new posture of the two-dimensional digital character. The method disclosed by the invention is intuitive and simple, and can generate a more natural and visually realistic deformation effect, therefore, the method is applicable to animation design implemented by common users.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

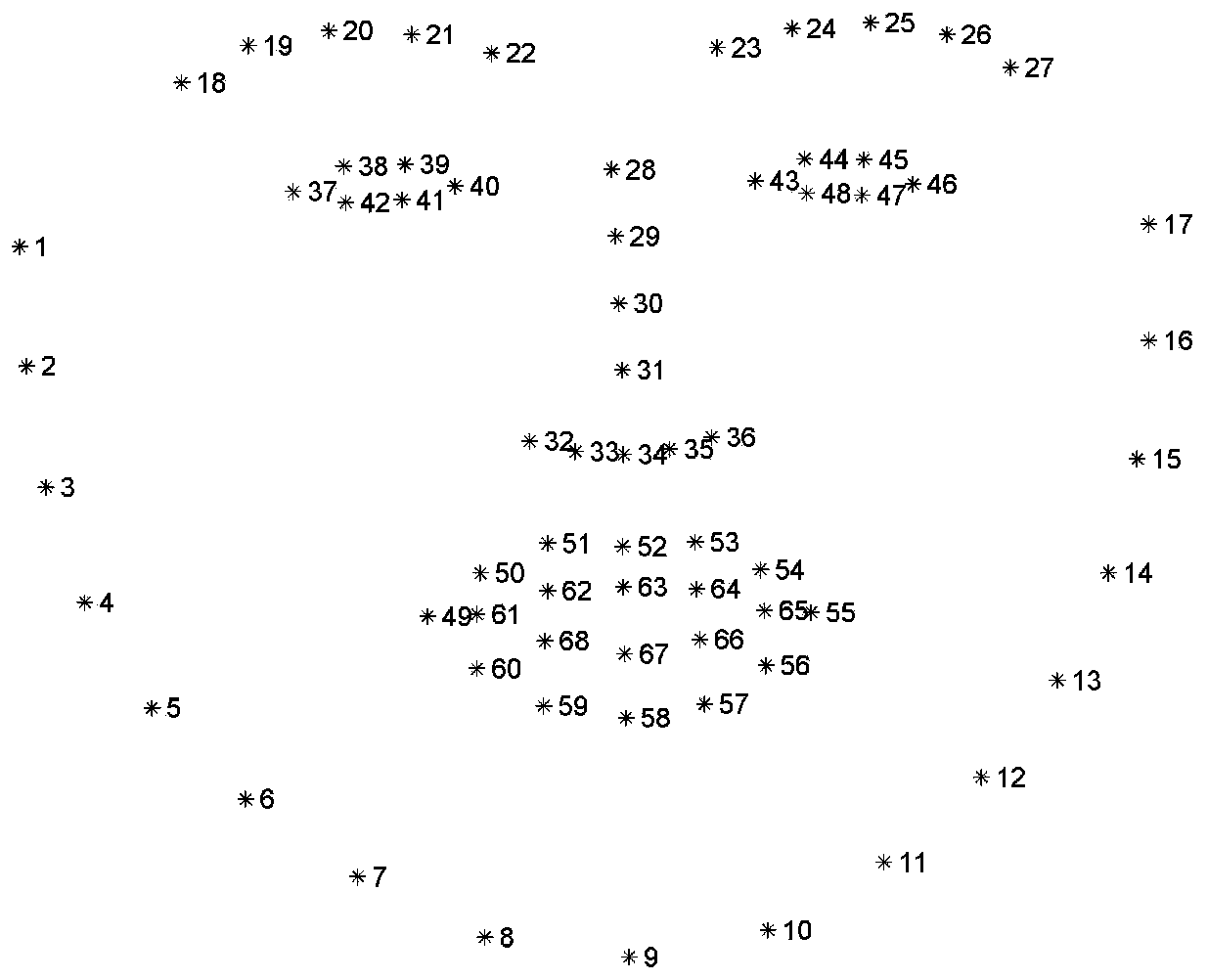

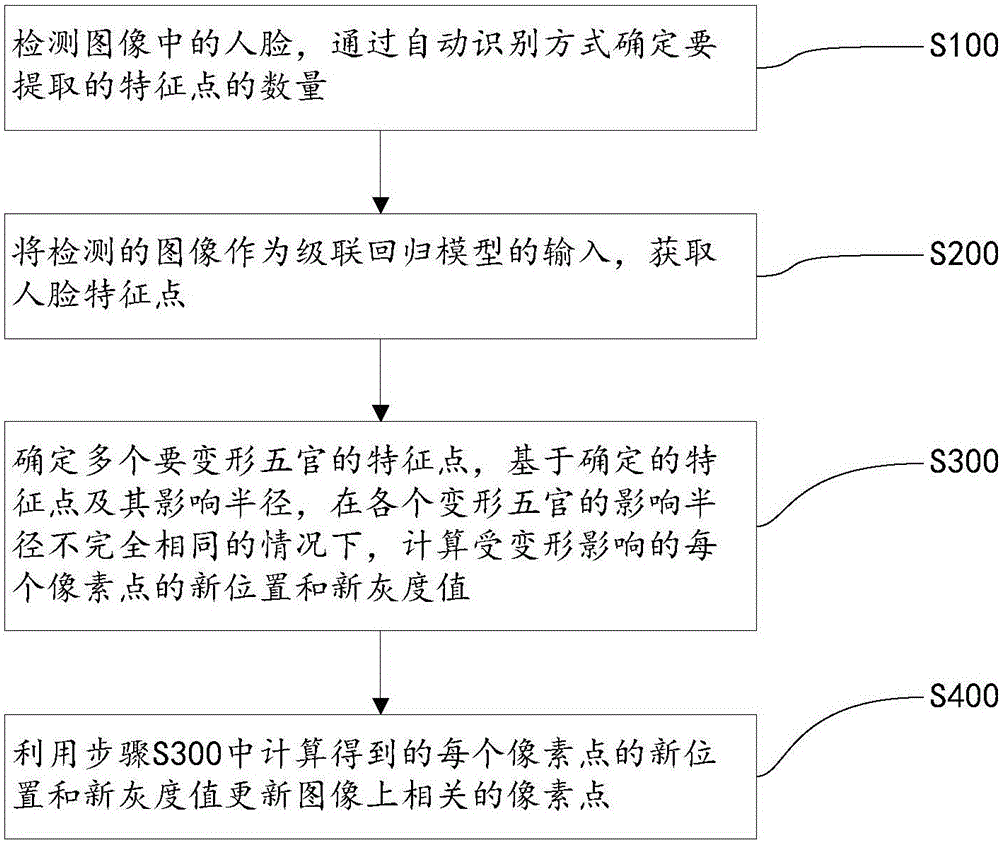

Real-time human face deforming method and system

The invention relates to a real-time human face deforming method and system. The method comprises: detecting a human face in an image, and determining the number of feature points to be extracted in the automatic identification way; taking the detected image as input of a cascade regression model, and obtaining human face feature points; determining multiple feature points of the five sense organs to be deformed, and on the basis of the determined feature points and influence radiuses thereof, calculating a new position and a new gray value of each pixel point that is affected by deformation, in the condition that influence radiuses of the five deformed sense organs are not completely the same; and updating related pixel points on the image by using the new position and the new gray value of each pixel point which is obtained by calculation. The system is realized based on the method and provides convenience for application of the method. The method and the system of the invention have the characteristics of rapid human face feature point extraction, accurate positioning and natural overall human face deformation effect.

Owner:SHENZHEN SENSETIME TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com