Veneering water-kneading pressure-deformable resin for synthetic leather and preparation method thereof

A technology for veneer water and synthetic leather, which is applied in fiber treatment, textiles and papermaking, etc. It can solve difficult problems and achieve the effects of reducing production costs, simple preparation methods, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

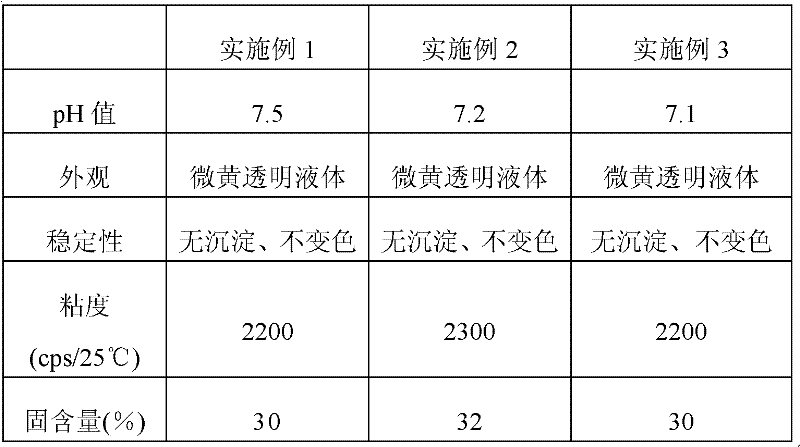

Embodiment 1

[0022] The veneer water kneading pressure-change resin for synthetic leather consists of 30 parts by weight of polyurethane resin, 30 parts by weight of DMF, 18 parts by weight of acetone, 8 parts by weight of temperature-changing powder, 8 parts by weight of color-changing wax powder, and 5 parts by weight of silica matting powder. The silicone leveling agent consists of 0.25 parts by weight.

[0023] The preparation method of the above-mentioned veneer water kneading pressure-change resin for synthetic leather is: under normal temperature and pressure, 30 parts by weight of DMF, 18 parts by weight of acetone, 8 parts by weight of temperature-changing powder, 8 parts by weight of color-changing wax powder, 5 parts by weight of Mix the silica matting powder, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 30 parts by weight of polyurethane resin and 0.25 parts by weight of silicone leveling agent to the obtained mixture, stir for at least 30...

Embodiment 2

[0026] The water-kneading pressure-change resin for veneer of synthetic leather consists of 40 parts by weight of polyurethane resin, 20 parts by weight of DMF, 25 parts by weight of acetone, 5 parts by weight of temperature-changing powder, 12 parts by weight of color-changing wax powder, and 3 parts by weight of silica matting powder. The silicone leveling agent consists of 0.3 parts by weight.

[0027] The preparation method of the above-mentioned veneer water kneading pressure-change resin for synthetic leather is: under normal temperature and pressure, 20 parts by weight of DMF, 25 parts by weight of acetone, 5 parts by weight of temperature-changing powder, 12 parts by weight of color-changing wax powder, 3 parts by weight of Mix the silica matting powder, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 40 parts by weight of polyurethane resin and 0.3 parts by weight of silicone leveling agent to the obtained mixture, stir for at least...

Embodiment 3

[0030] The veneer water kneading pressure-changing resin for synthetic leather consists of 35 parts by weight of polyurethane resin, 25 parts by weight of DMF, 20 parts by weight of acetone, 6 parts by weight of temperature-changing powder, 10 parts by weight of color-changing wax powder, and 3.8 parts by weight of silica matting powder. The silicone leveling agent consists of 0.2 parts by weight.

[0031] The preparation method of the above-mentioned veneer water kneading pressure-change resin for synthetic leather is: under normal temperature and pressure, 25 parts by weight of DMF, 20 parts by weight of acetone, 6 parts by weight of temperature-changing powder, 10 parts by weight of color-changing wax powder, 3.8 parts by weight of Mix the silica matting powder, stir for at least 30 minutes, grind and filter, and discard the filter residue. Add 35 parts by weight of polyurethane resin and 0.2 parts by weight of silicone leveling agent to the obtained mixture, stir for at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com