Patents

Literature

189results about How to "Guaranteed positional relationship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

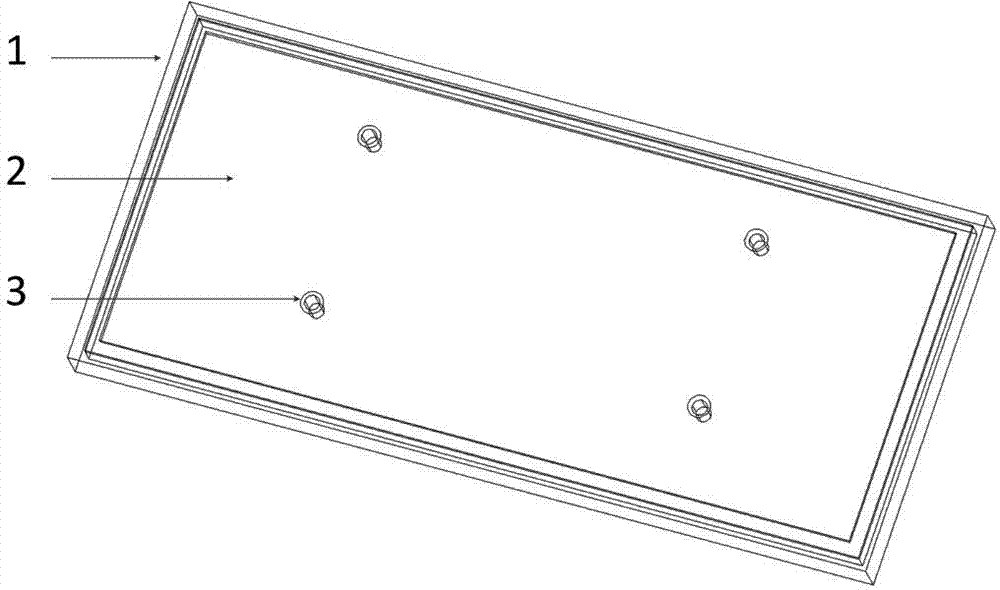

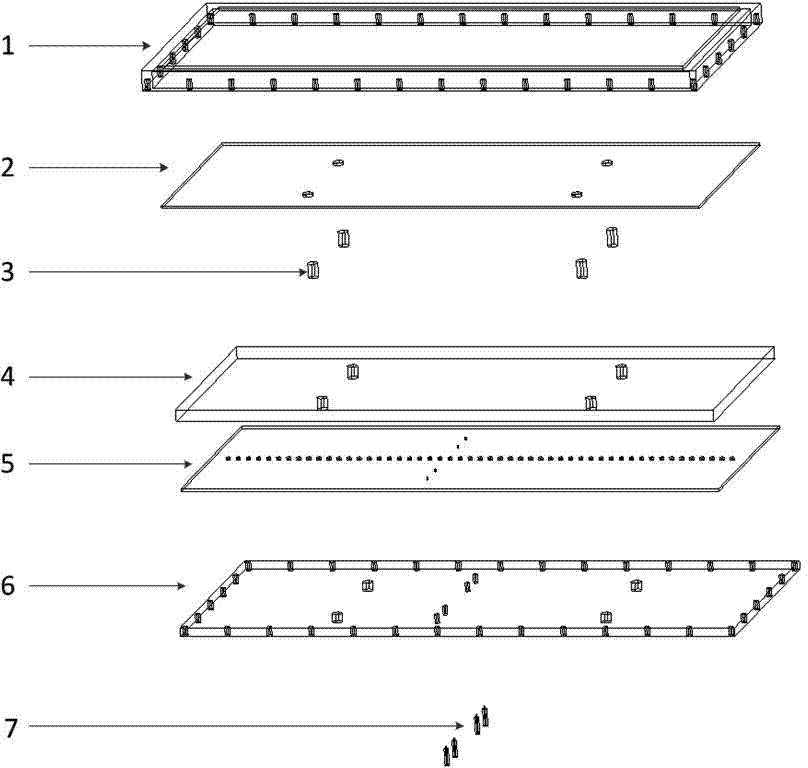

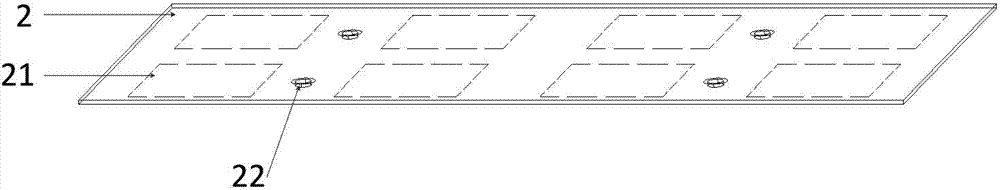

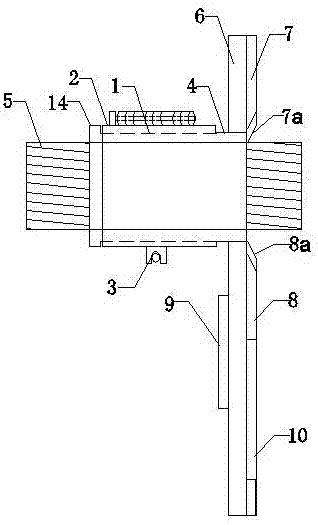

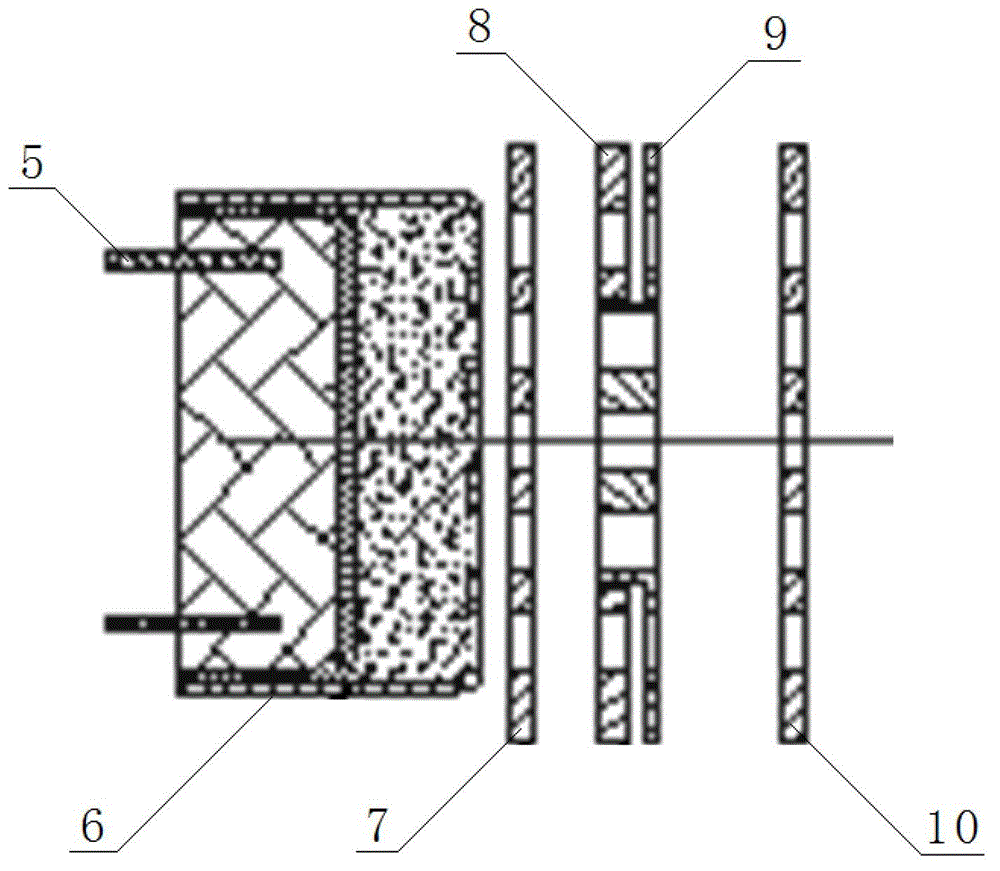

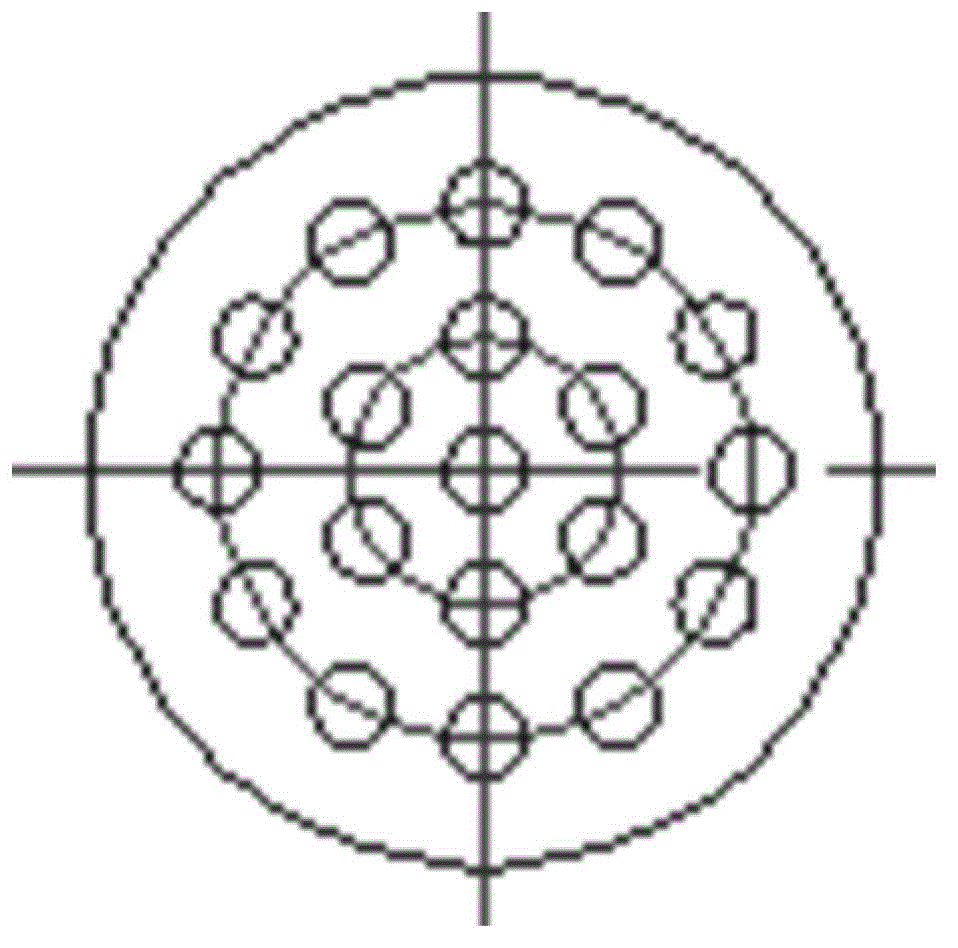

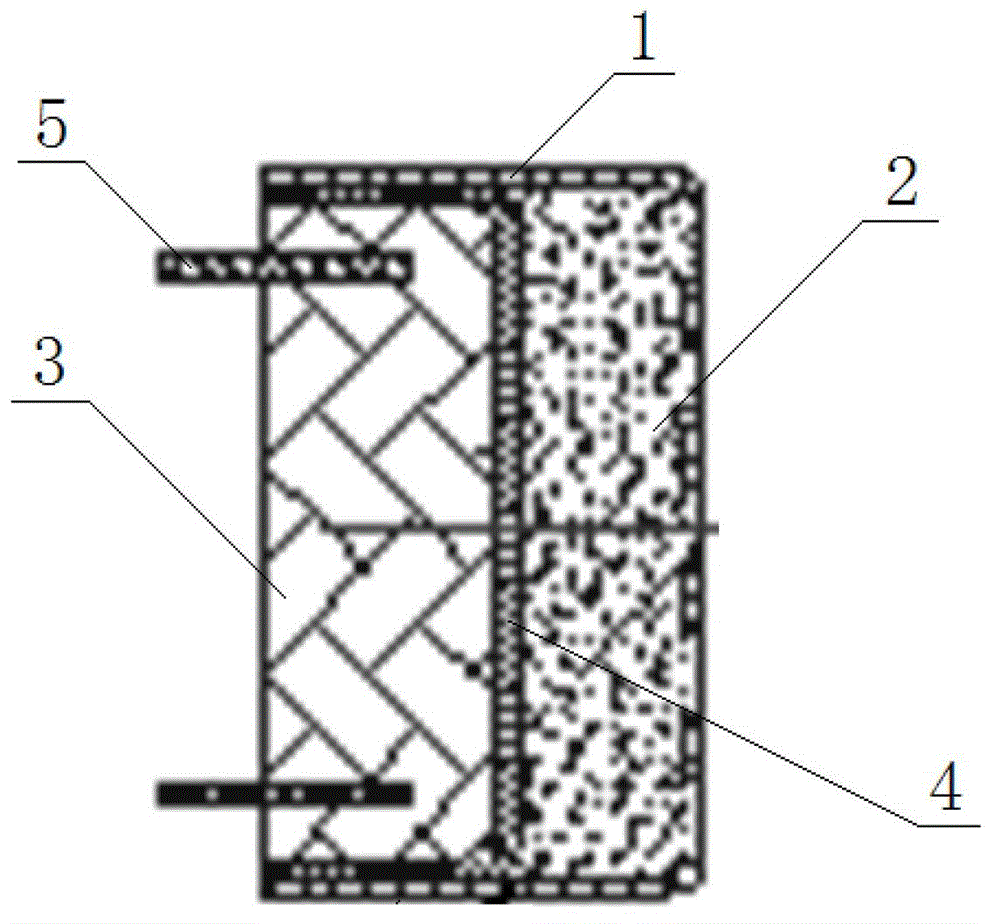

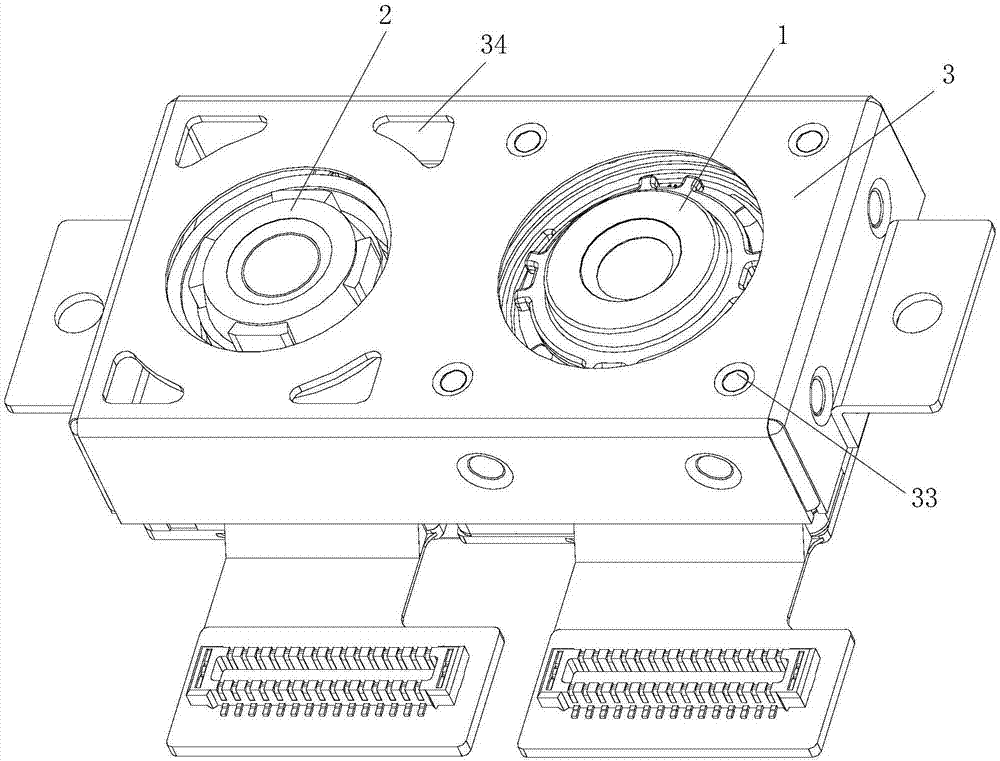

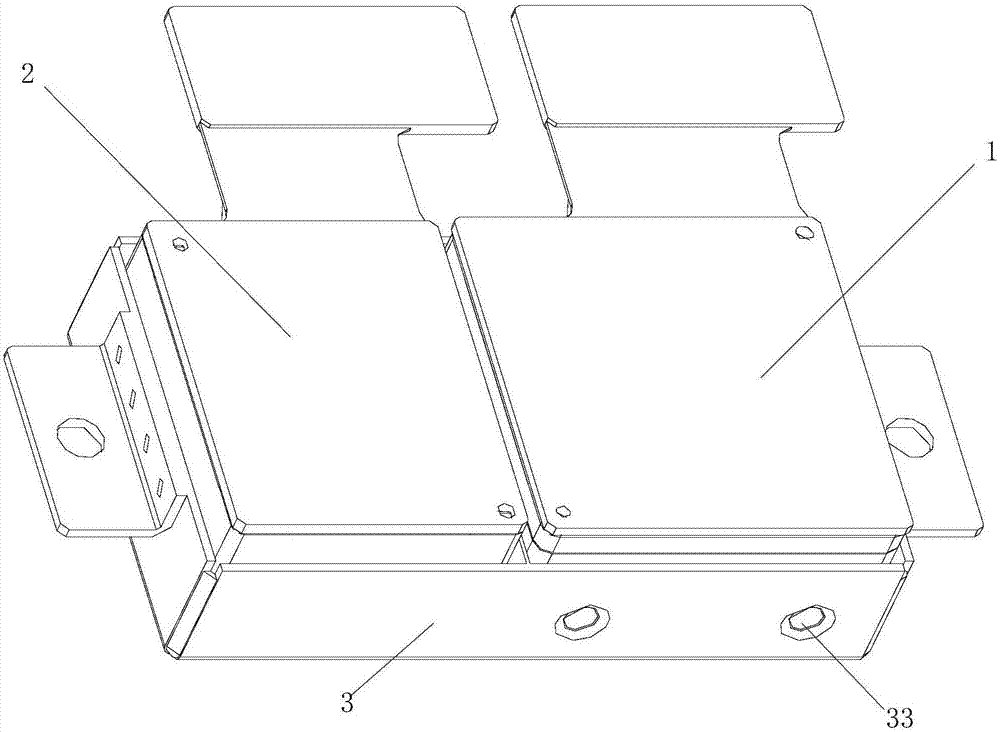

Dual-circular polarization microstrip antenna array

ActiveCN104505588ARealize the function of dual circular polarizationImprove confidentialityRadiating elements structural formsPolarised antenna unit combinationsMicrostrip antenna arrayImpedance matching

The invention discloses a dual-circular polarization microstrip antenna array which comprises a metal frame, a radiation microstrip board, metal columns, foam, a feeder microstrip board, a metal floor and connectors. Directional couplers, power dividers, radiation patches and isolation hole arrays are integrated by the feeder microstrip board, so that dual-circular polarization radiation functions can be realized. Impedance matching and bandwidth broadening functions can be realized by the radiation microstrip board and a foam board. The connectors are used as interfaces of the dual-circular polarization microstrip antenna array and feeder line systems. Grounding and protection effects can be realized by a frame which comprises the metal frame and the metal floor. Interlayer positioning, structure strengthening and resonant effect eliminating functions can be realized by the metal columns. The dual-circular polarization microstrip antenna array has the advantages that double-layer microstrip patch antennas, circular polarization power division feeder, positioning and supporting, resonance eliminating, mutual coupling isolation and environmental protection technologies are combined with one another, accordingly, merits of low profiles, costs and cross polarization of the traditional circular polarization microstrip patch antennas are inherited, and the dual-circular polarization microstrip antenna array is simple and firm in structure and convenient to process and can be used as a communication or radar dual-circular polarization phased-array antenna.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

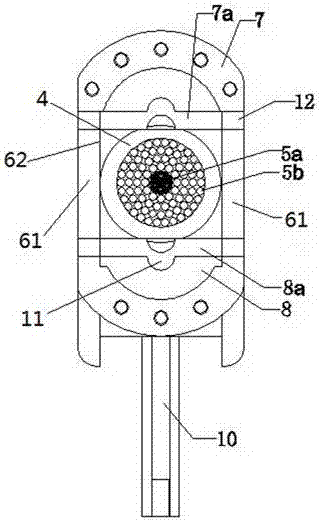

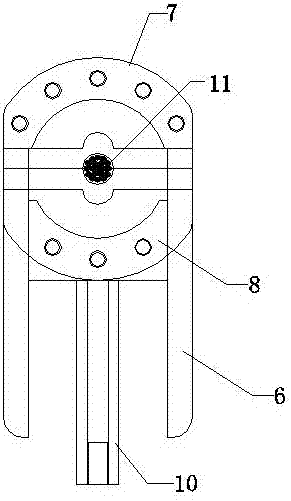

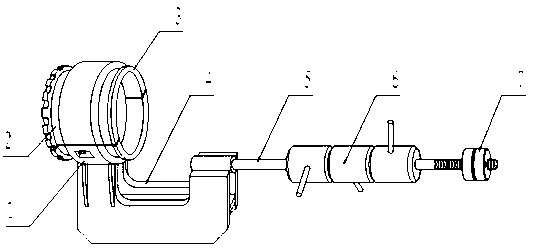

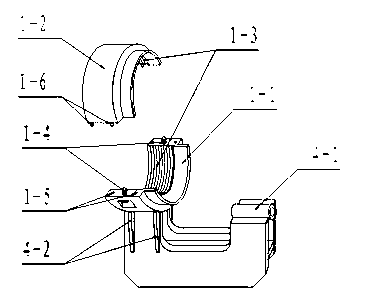

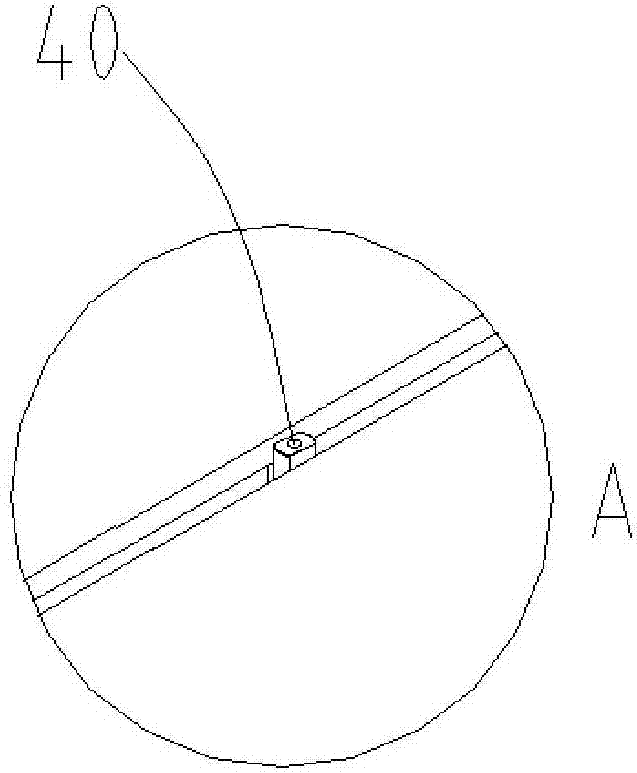

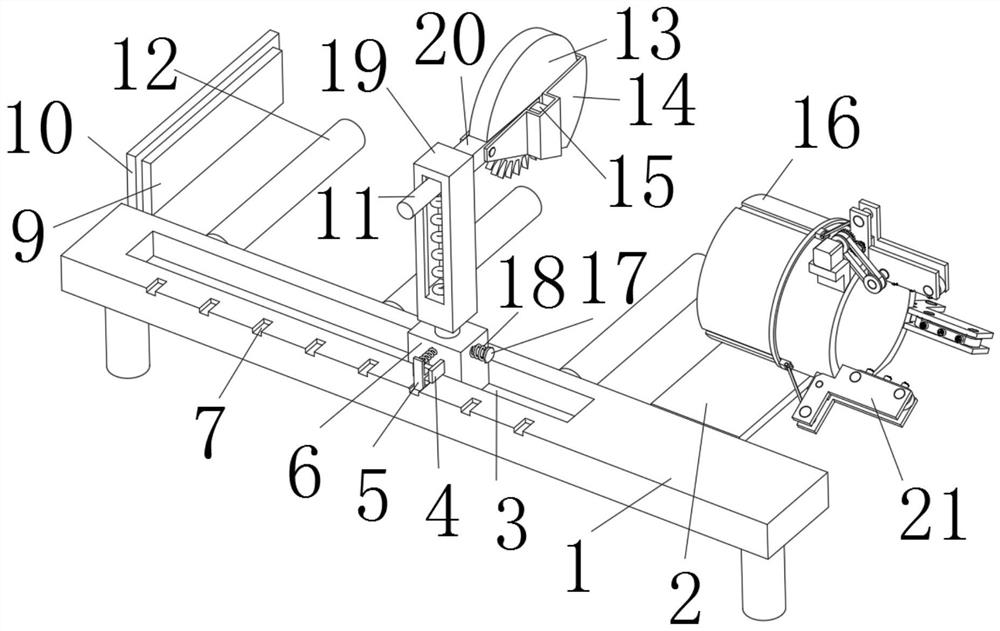

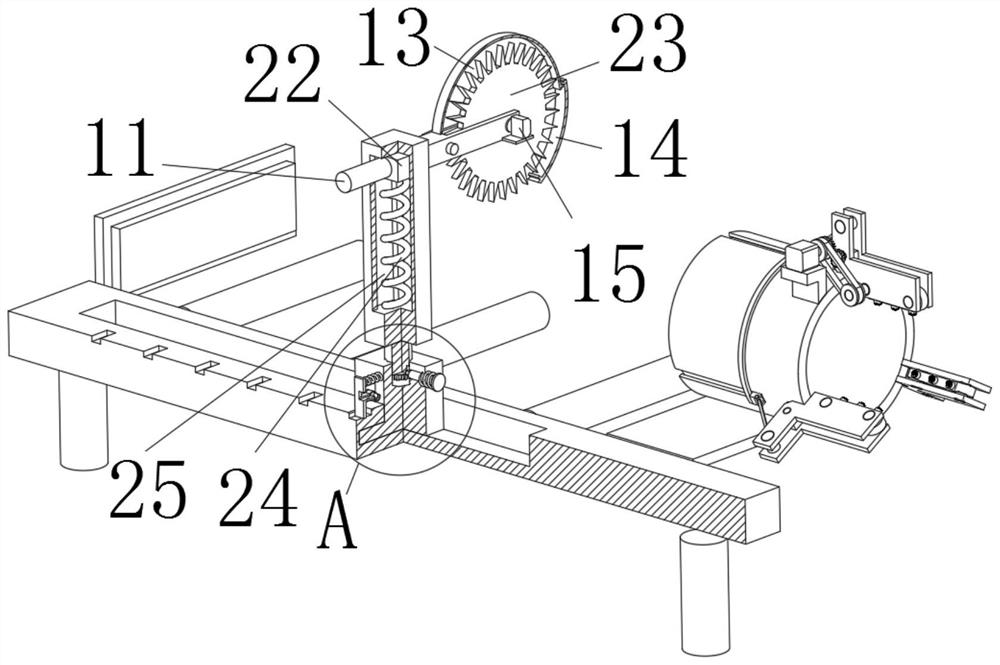

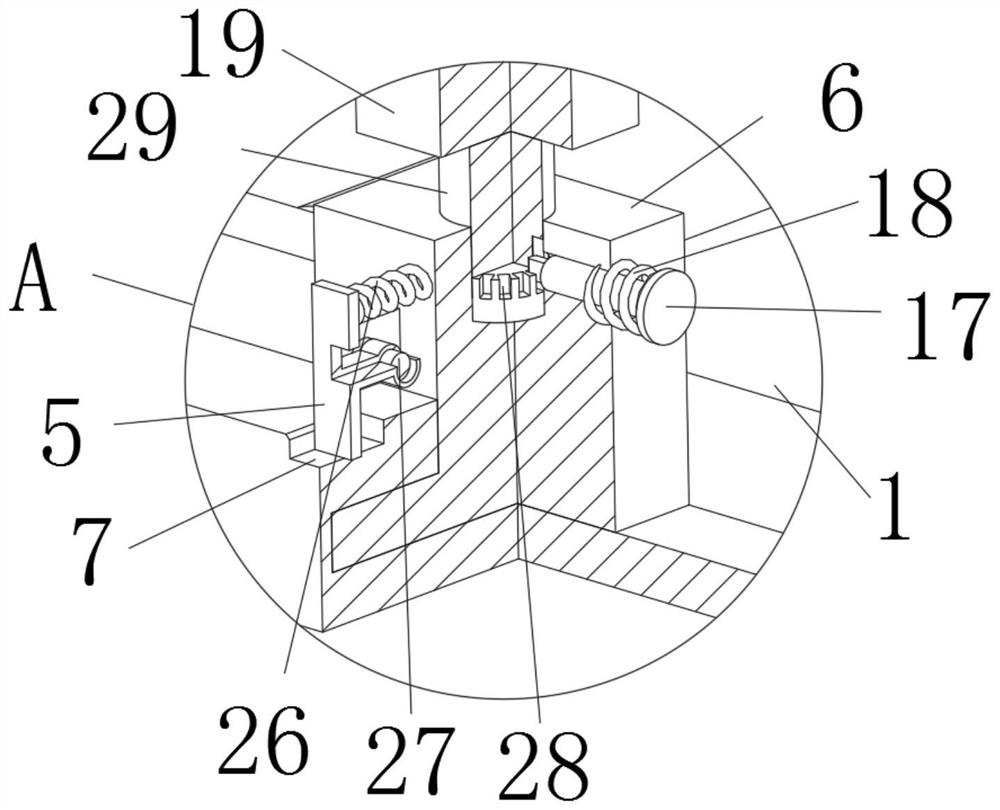

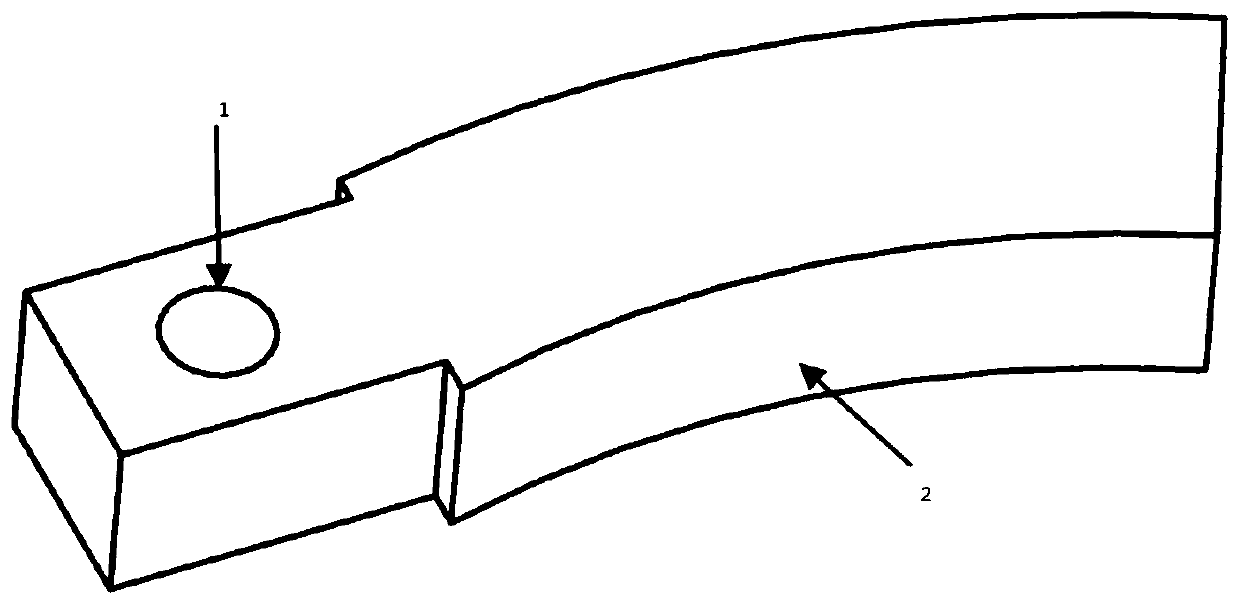

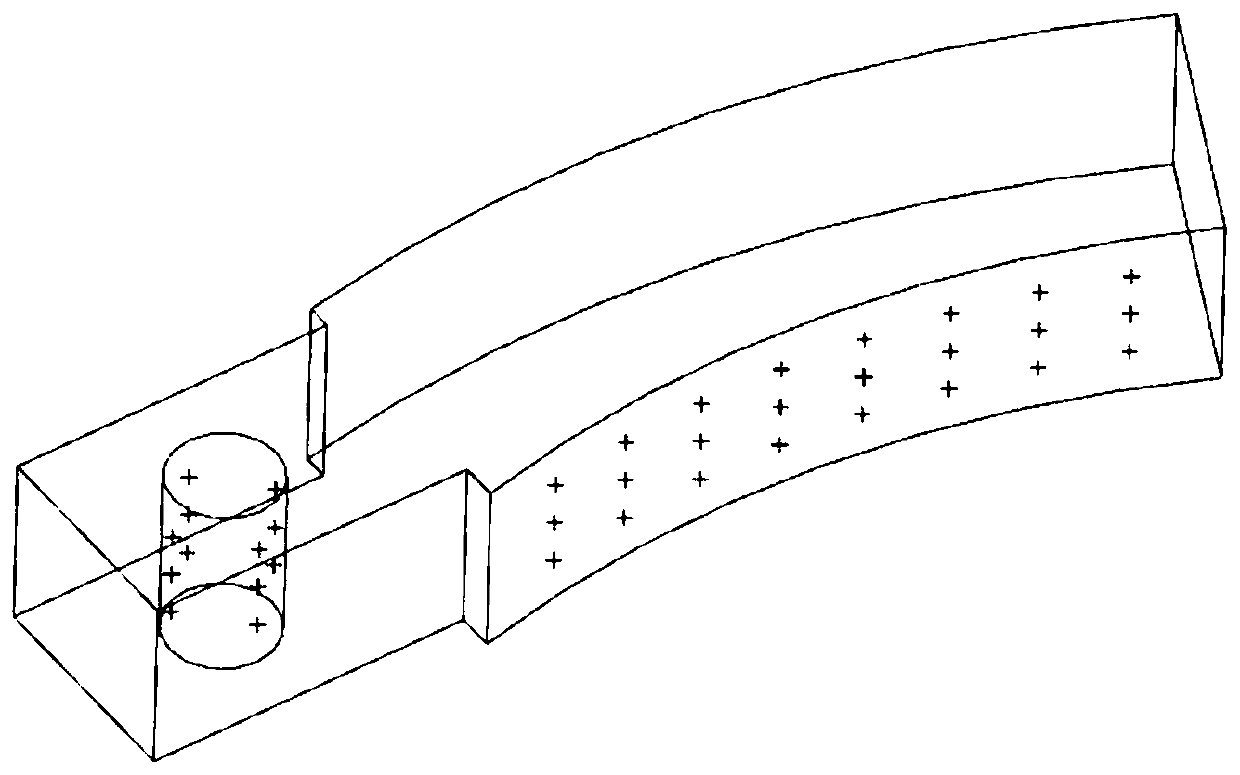

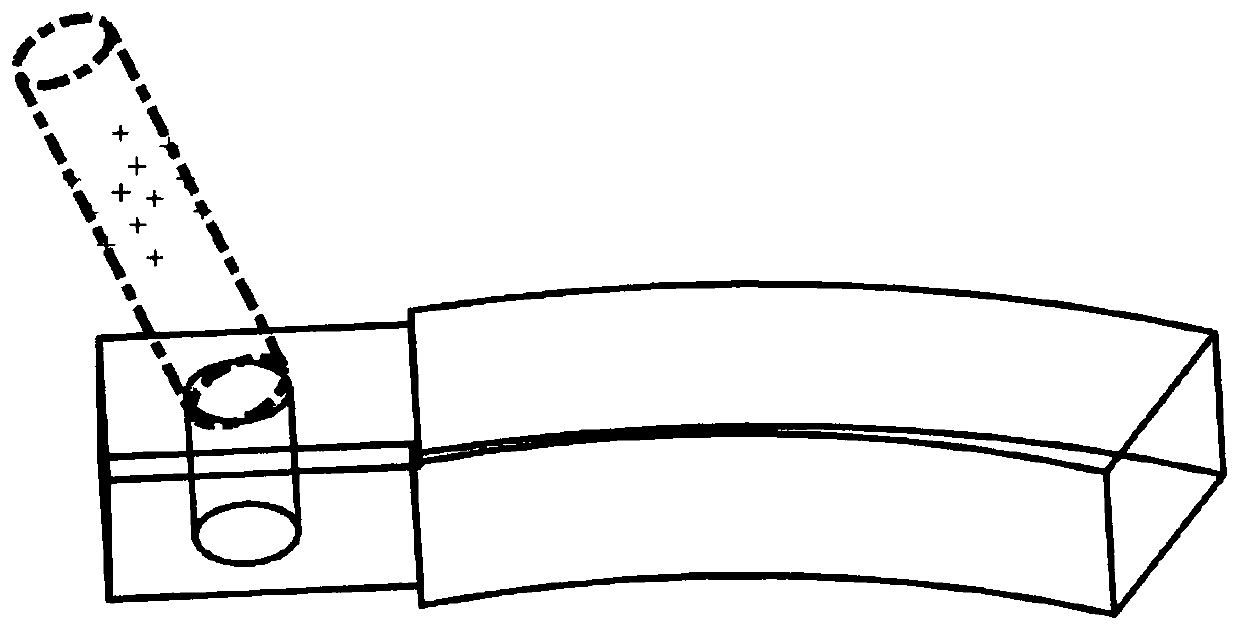

Wire stripping tool

ActiveCN107147050APrevent scurryingGuaranteed radial position relationshipApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to a wire stripping tool comprising a cutting mechanism and a cable locating sleeve, wherein the cable locating sleeve is provided with an inner hole having an axial line extending along the left and right direction and used for locating and penetrating through a corresponding cable, the cutting mechanism comprises a mechanism seat, a locating sleeve guide mechanism forming guide movement fit with the cable locating sleeve along a direction vertical to the left and right direction is arranged on the mechanism seat, two cutter bodies used for cutting an aluminum stranded wire on the outer side of a steel core are further arranged on the mechanism seat, wherein at least one cutter body is a movable cutter body in guide movement fit with the mechanism seat, the guide movement direction of the movable cutter body is consistent with the guide movement direction of the cable locating sleeve relative to the mechanism seat, and steel core evasion grooves used for evading the corresponding steel core are formed in the cutting edges of the fixed cutter body and the movable cutter body. The wire stripping tool provided by the invention solves the problem that a conducting wire or the wire stripping tool needs to be rotated, resulting in complex wire stripping operation in the prior art.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

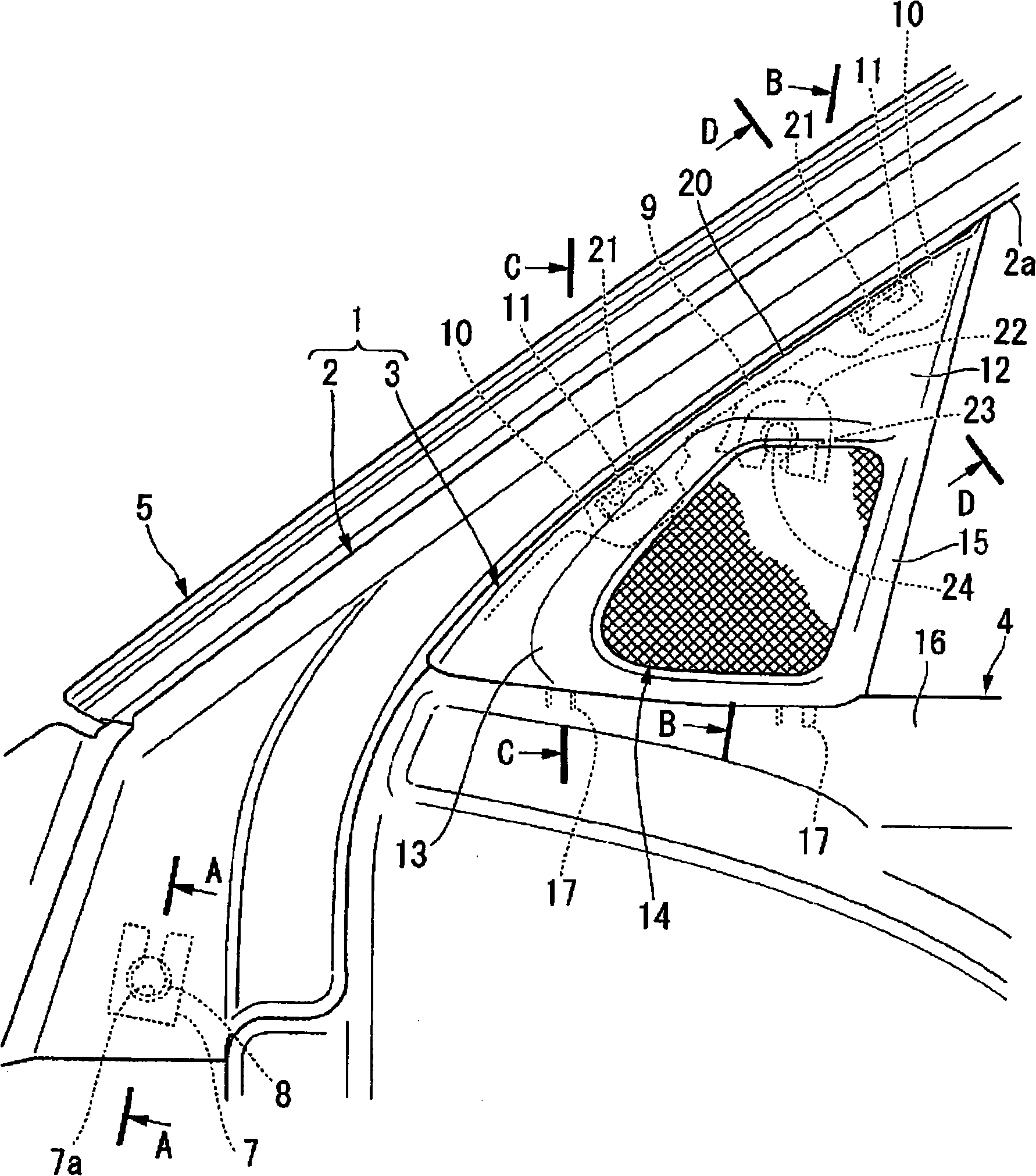

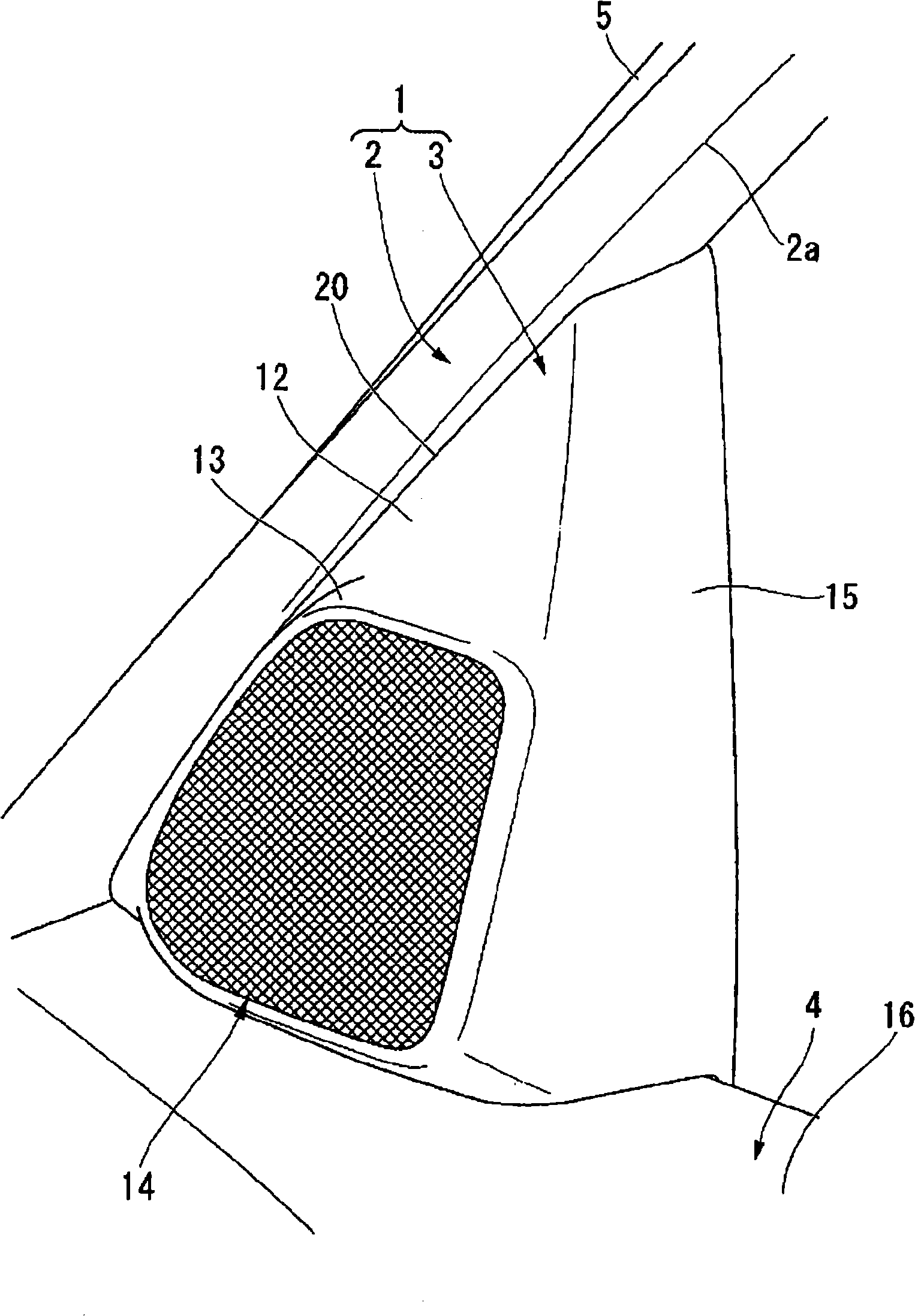

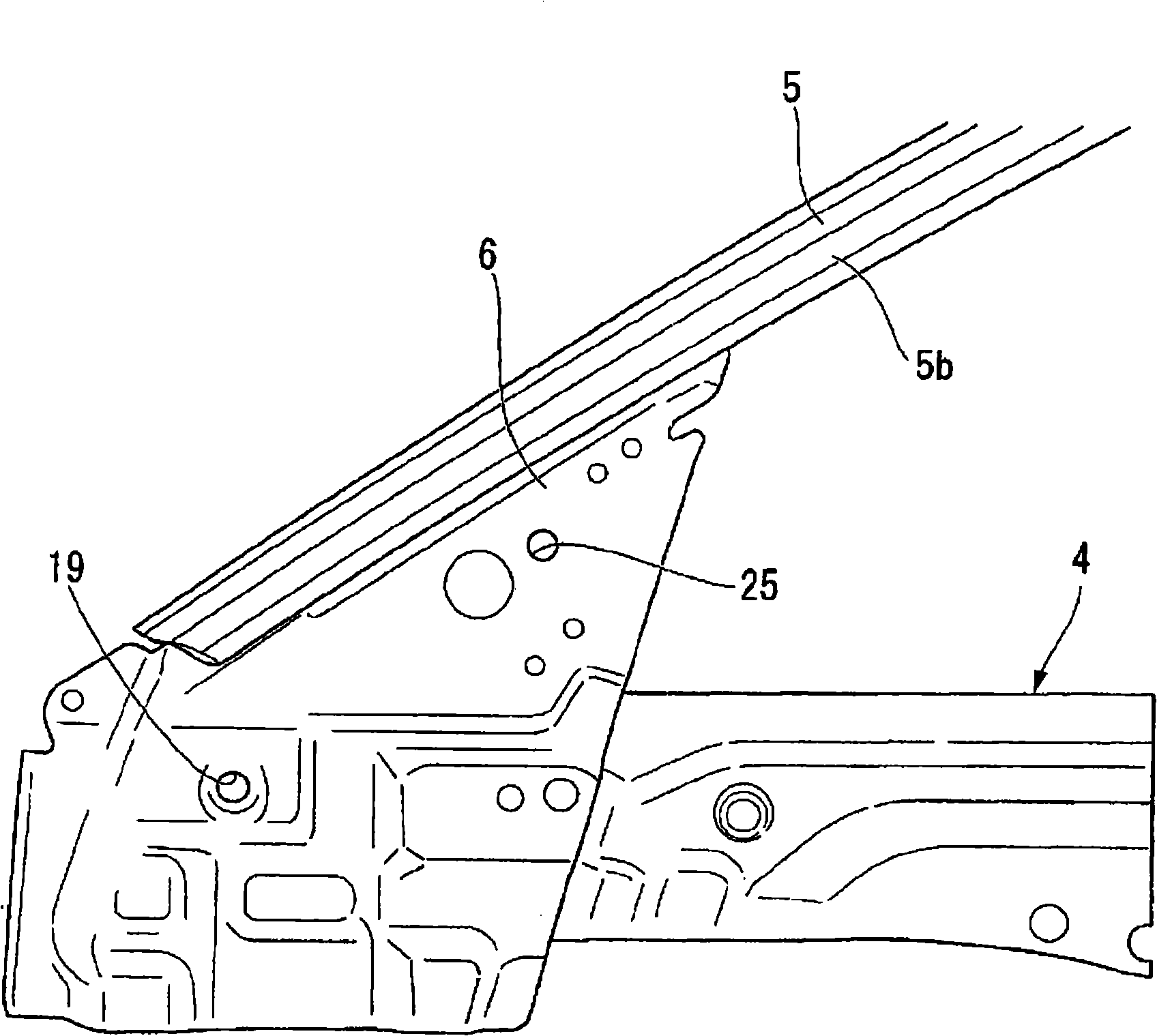

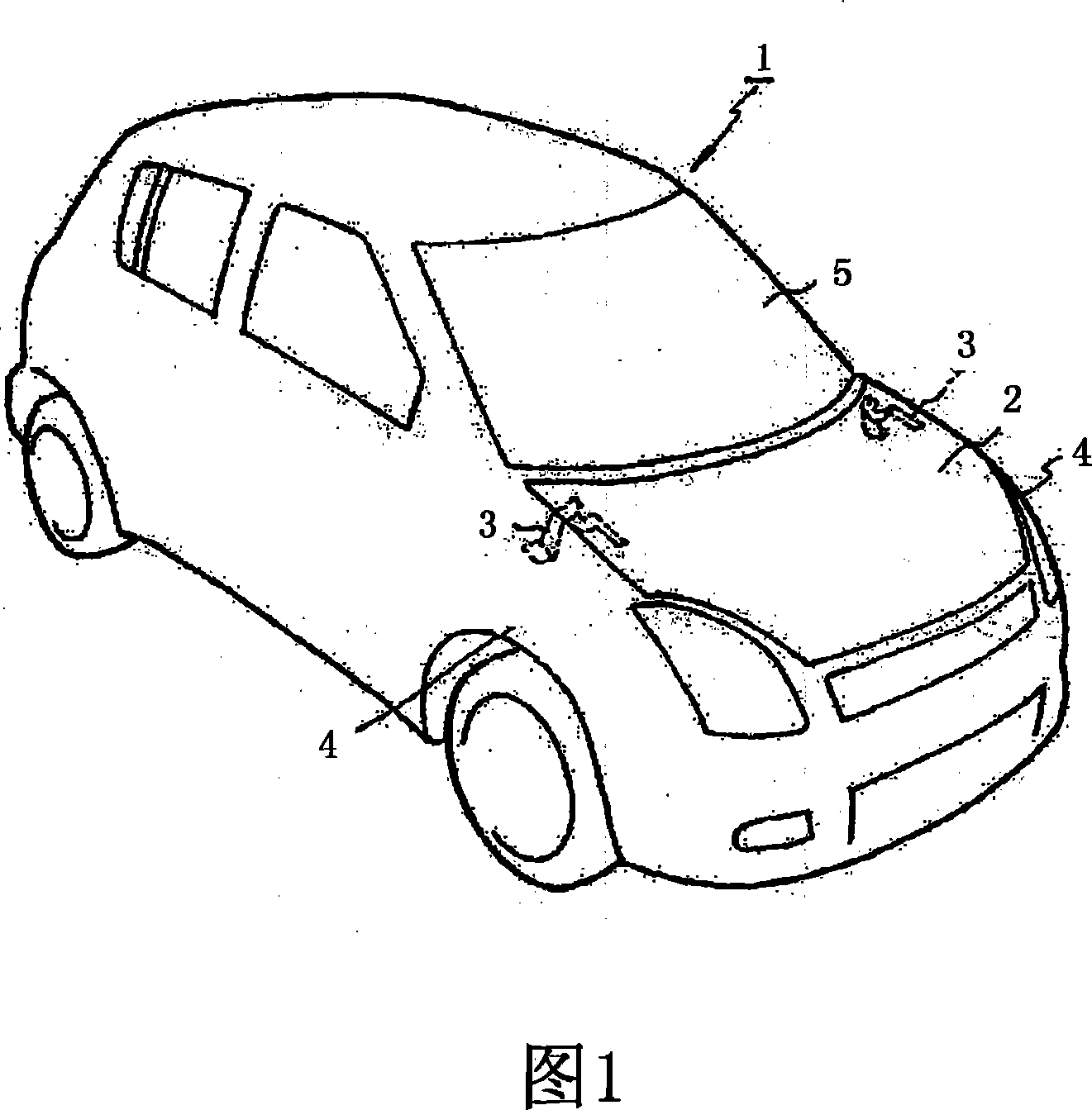

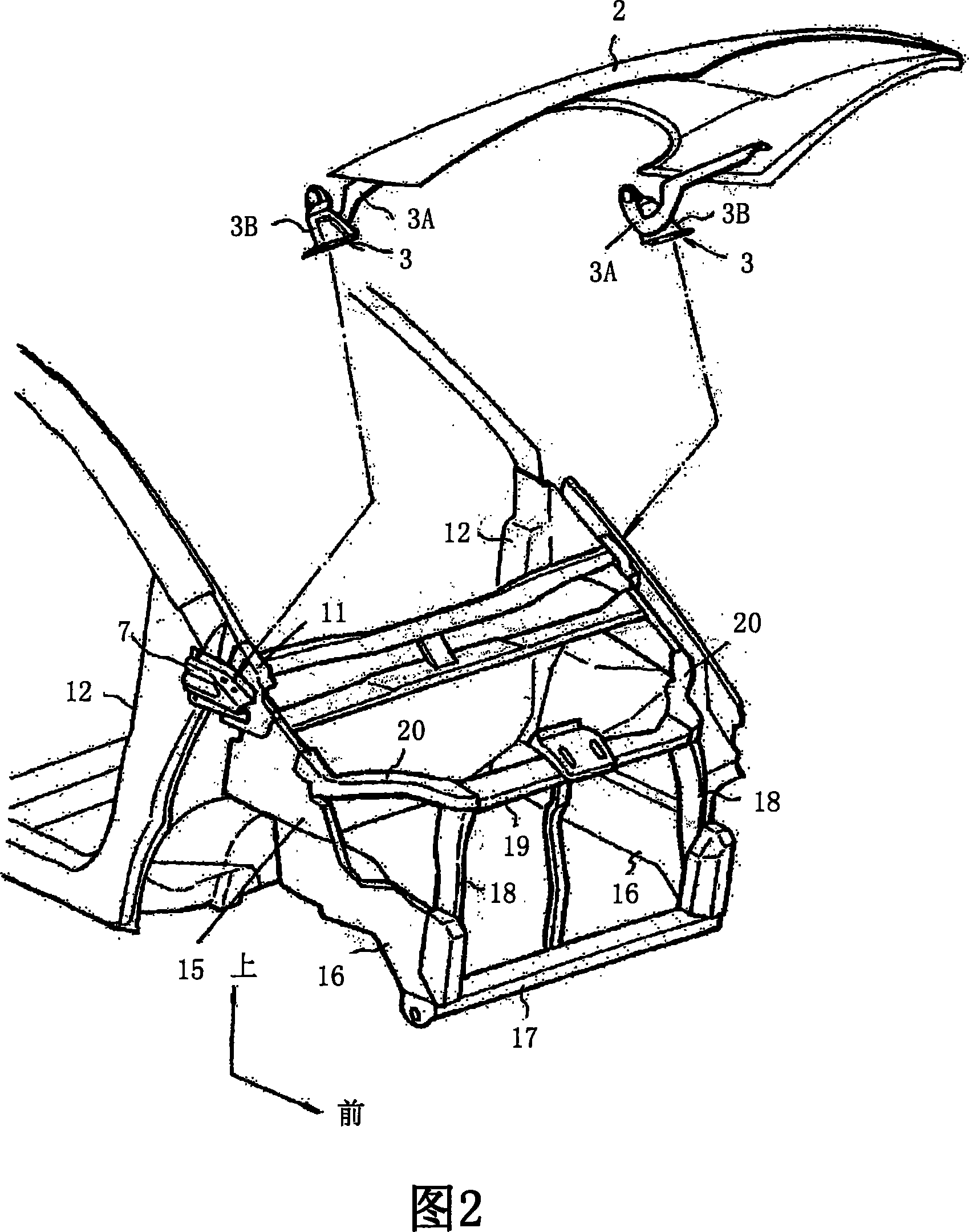

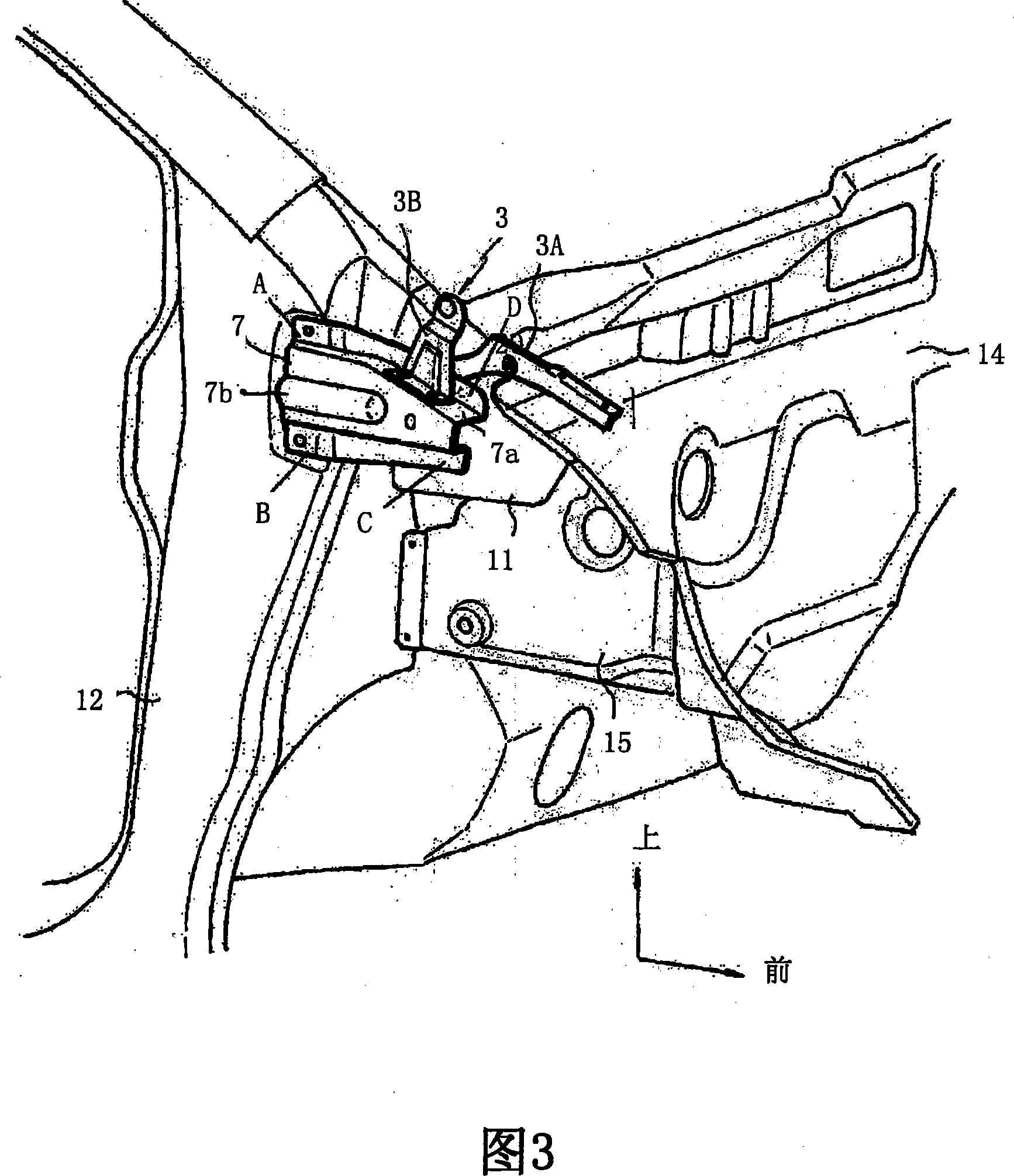

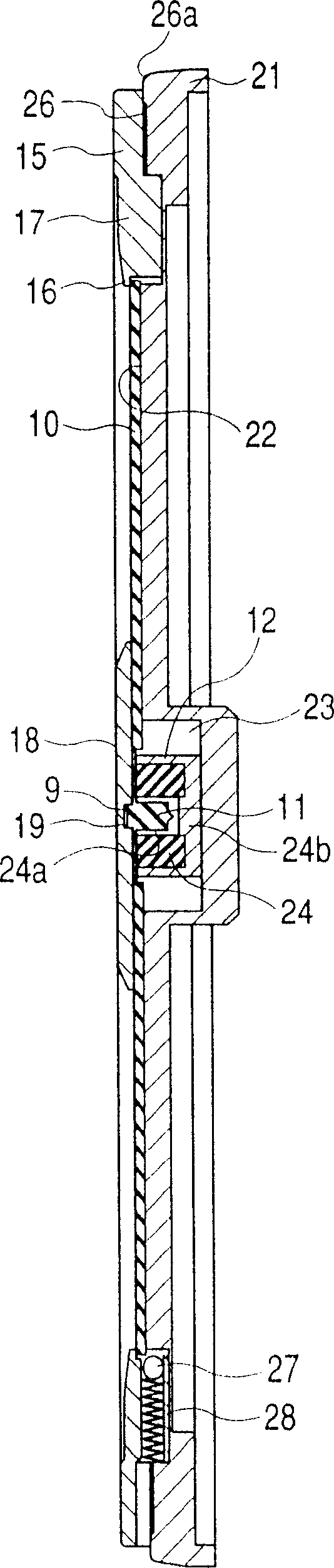

Assembling portion structure of vehicle interior decorating piece

ActiveCN101353008AImprove appearance qualityEnsuring Sound PerformanceSuperstructure subunitsDoorsCar doorEngineering

The invention provides an assembly portion structure of vehicle internal gadgets. Usage of the decorative portion structure of vehicle internal gadgets can not only eliminate a gap between mutually abutting portions of a front portion lower end of a window internal gadget and an upper edge portion of a corner gadget both created due to assembly error, but also promote appearance quality. The assembly portion structure is that a lower edge of the window internal gadget (2) is provided with a lock aperture (11), the upper edge portion of the corner gadget (3) is provided with an upper lock claw (21). Inner surface of the corner gadget (3) is provided with a U-shaped groove (23) opening downwards, the U-shaped groove (23) is internally engaged with a buckle (24) and the buckle (24) is able to be moveable up and down within the U-shaped groove (23). A vehicle door window frame (5) is mounted with the window internal gadget (2), the corner gadget (3) is locked with a corner reinforcement member via the buckle (24), in the meantime, the upper lock claw (21) of the corner gadget (3) is tabled with the lock aperture (11) of the window internal gadget (2).

Owner:HONDA MOTOR CO LTD

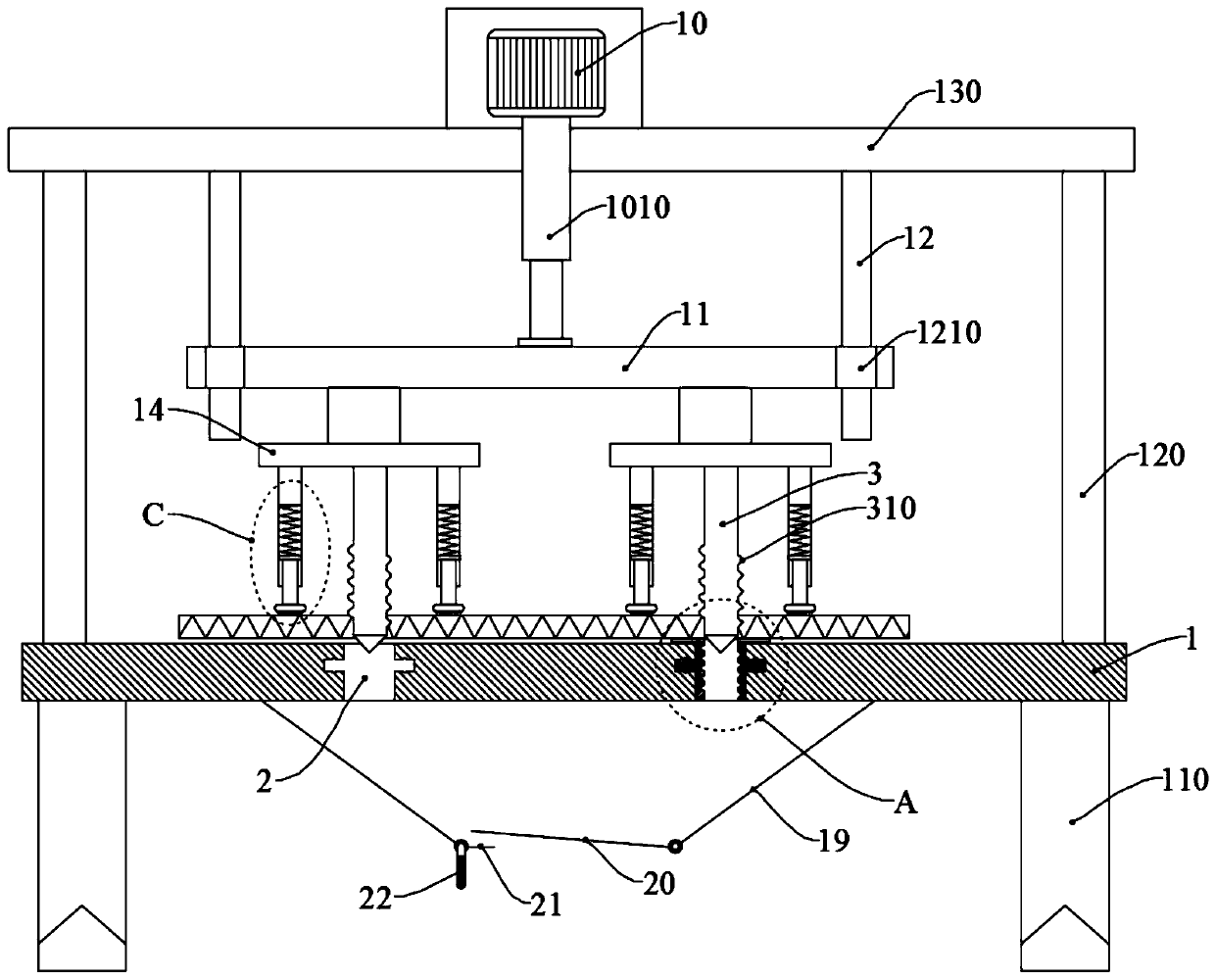

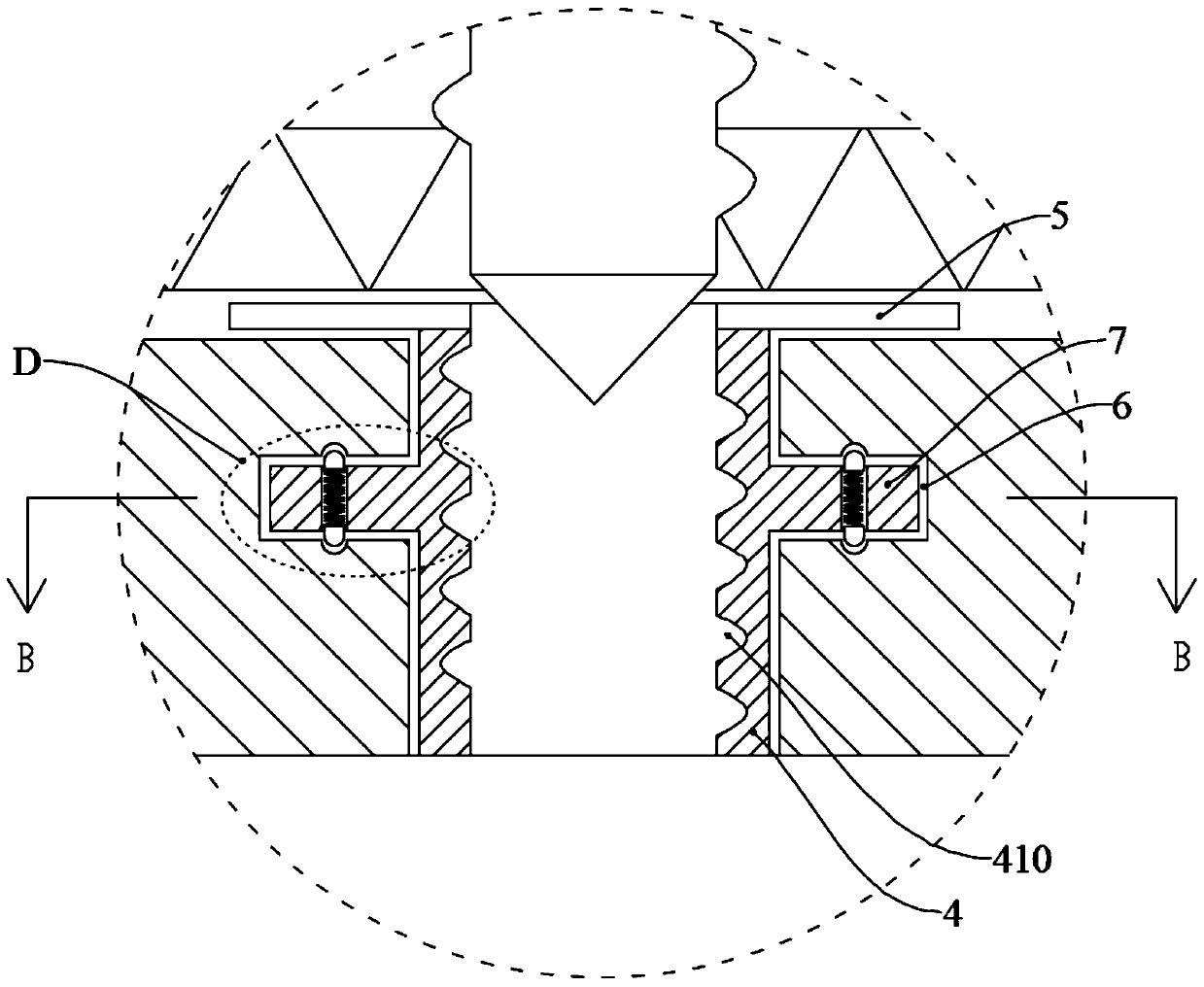

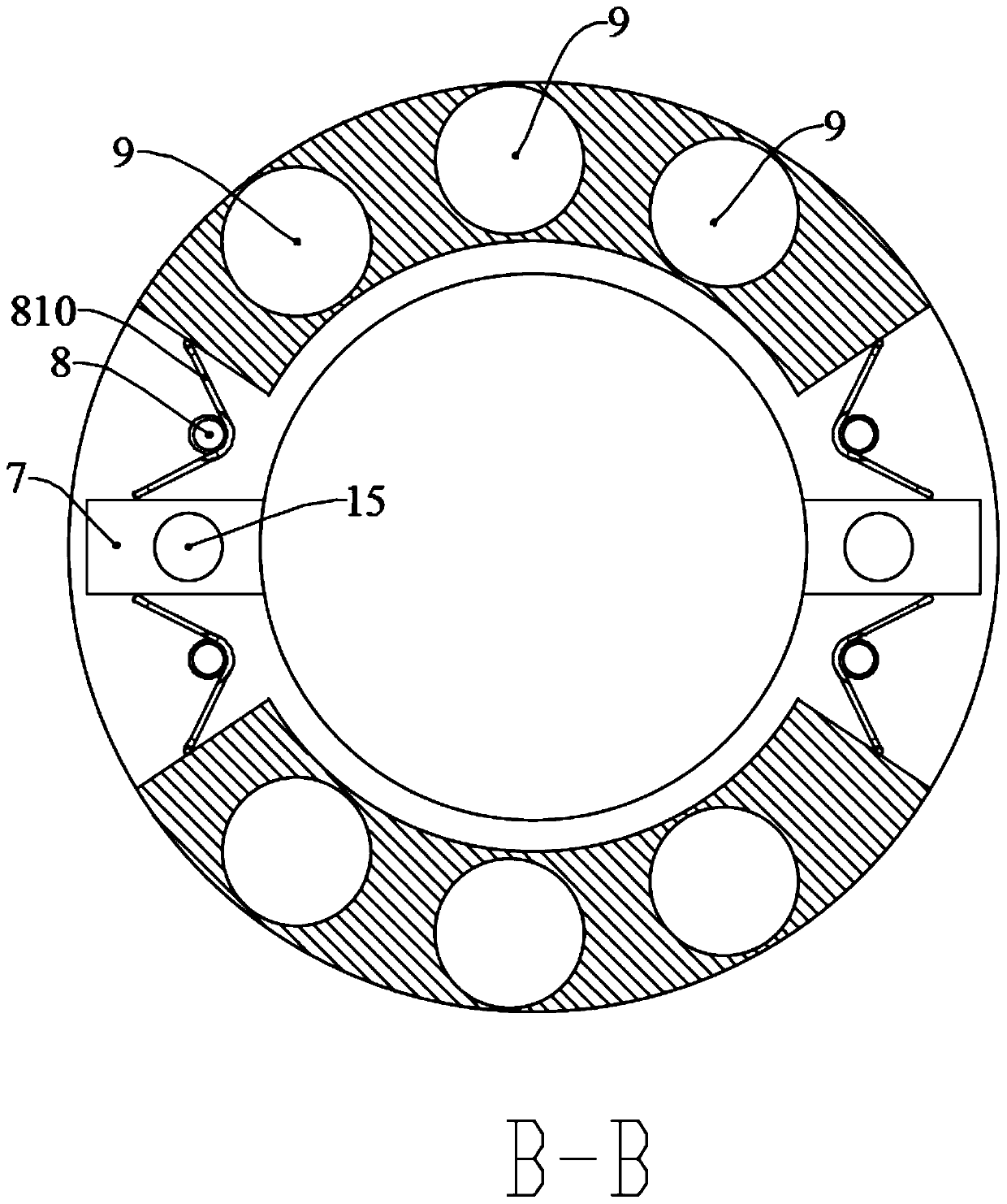

Punching device for paperboard

PendingCN110000855AReduce punching processPlay the role of support limitMetal working apparatusPunchingPaperboard

The invention discloses a punching device for paperboard, belongs to the technical field of paper punching devices and aims to solve the problem that waste chips generated when the paperboard is punched in an existing way cannot be completely separated from the paperboard. The punching device comprises a workbench, wherein a plurality of receding holes penetrate through the workbench, and a plurality of punching needles are arranged above the workbench; a reinforcing rib is arranged at the lower end of any punching needle; a sleeve is arranged in any receding hole; spiral guide grooves matchedwith the reinforcing ribs are formed in the inner wall of the sleeves in the height direction; the upper ends of the sleeves extend out of the receding holes to be connected with a plurality of blades; a storage groove is formed in the middle of each receding hole; positioning blocks are symmetrically connected to the outer wall of the sleeves; positioning columns are arranged on two sides of anypositioning block, and the positioning columns are sleeved with torsion springs; one end of each torsion spring is connected with the corresponding positioning block, and the other end of each torsion spring is connected with the inner wall of the corresponding storage groove; and a plurality of chip removal grooves penetrate through the periphery of any receding hole.

Owner:武威福民汇科技开发有限公司

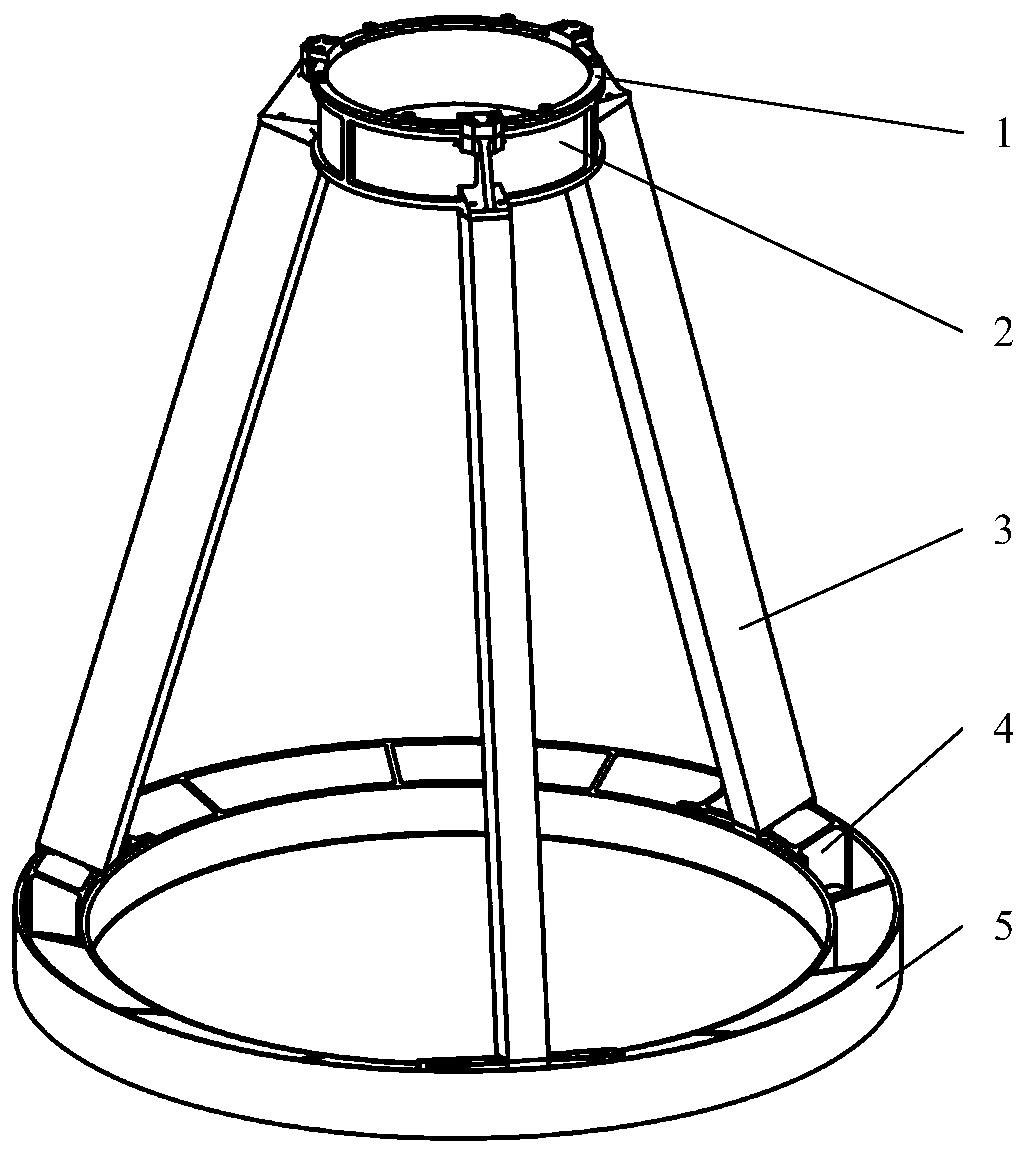

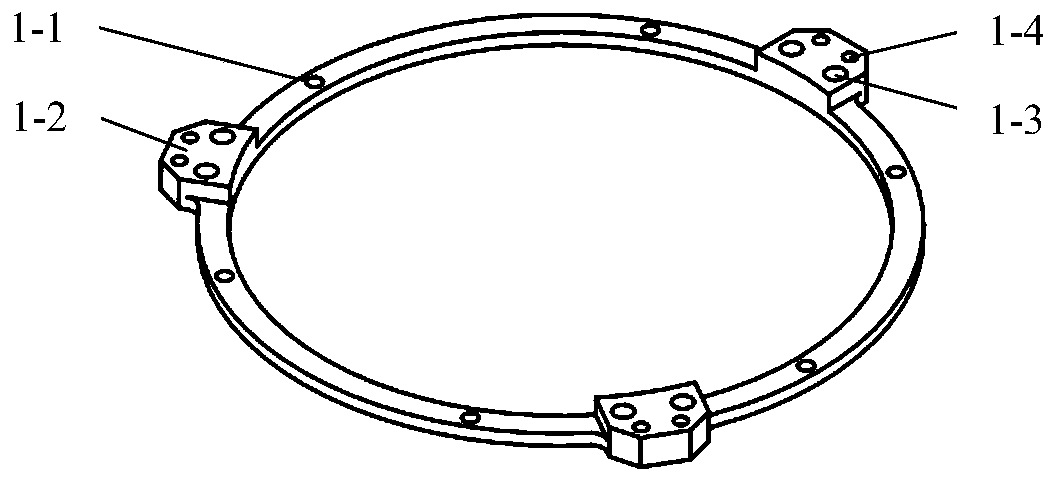

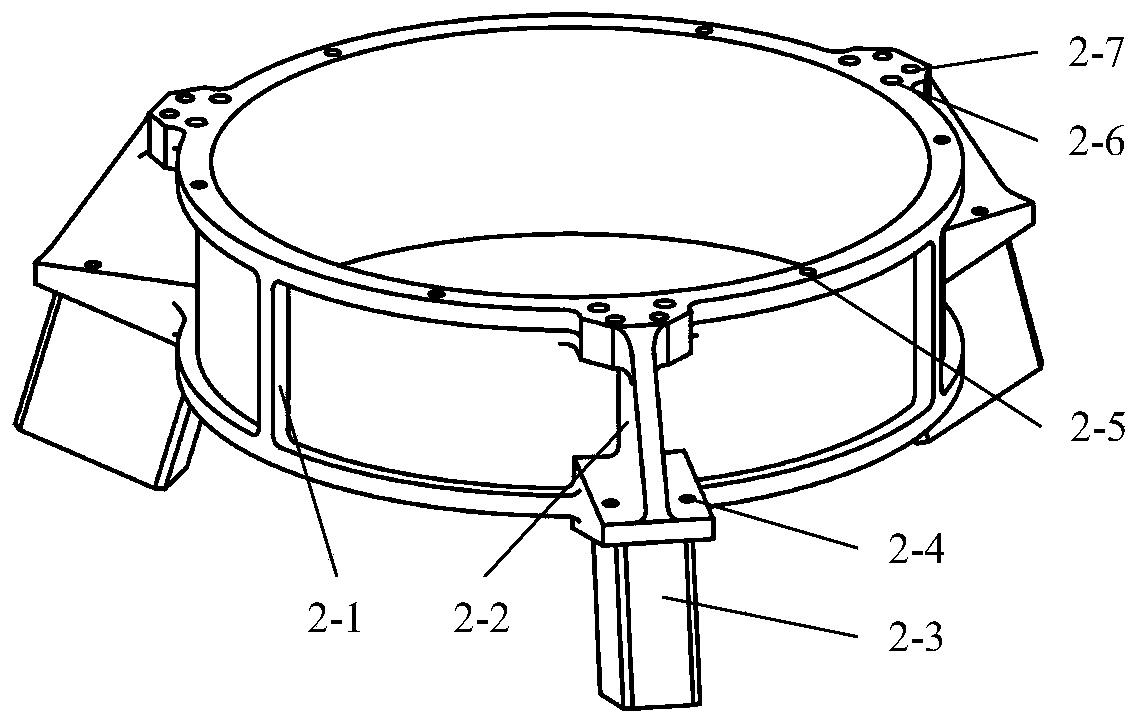

Push-condensing integrated high-resolution space optical load ultra-light carbon fiber truss support structure

ActiveCN110231689AGuaranteed verticality requirementsGuaranteed parallelismMountingsFiberEngineering

The invention relates to a push-condensing integrated high-resolution space optical load ultra-light carbon fiber truss support structure. The structure comprises an adjusting gasket, a secondary lenschamber, a truss rod, a metal embedded part and a support ring. A boss at the upper end of the adjusting gasket is an installation plane of a secondary mirror component, and a boss at the lower end of the metal embedded part is an installation plane of a truss and a primary mirror component. The adjusting gasket, the secondary lens chamber and the metal embedded part are made of titanium alloy materials, and the truss rod and the support ring are made of carbon fiber composite materials. The cross section of the truss rod is concentric-square-shaped, and the cross section of the support ringis concave-shaped. The truss support structure is less than 2.2 kg in total mass and is 1 / 3-1 / 2 times of the mass of a traditional metal truss. The truss support structure is simple, light in weight,good in strength, rigidity, structural stability and other index characteristics, can resist the influence of a complex mechanical environment on a space optical load in the transmitting process, ensures the position relation among optical elements, and meets the requirement of the push-condensing integrated high-resolution space optical load on the support structure.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

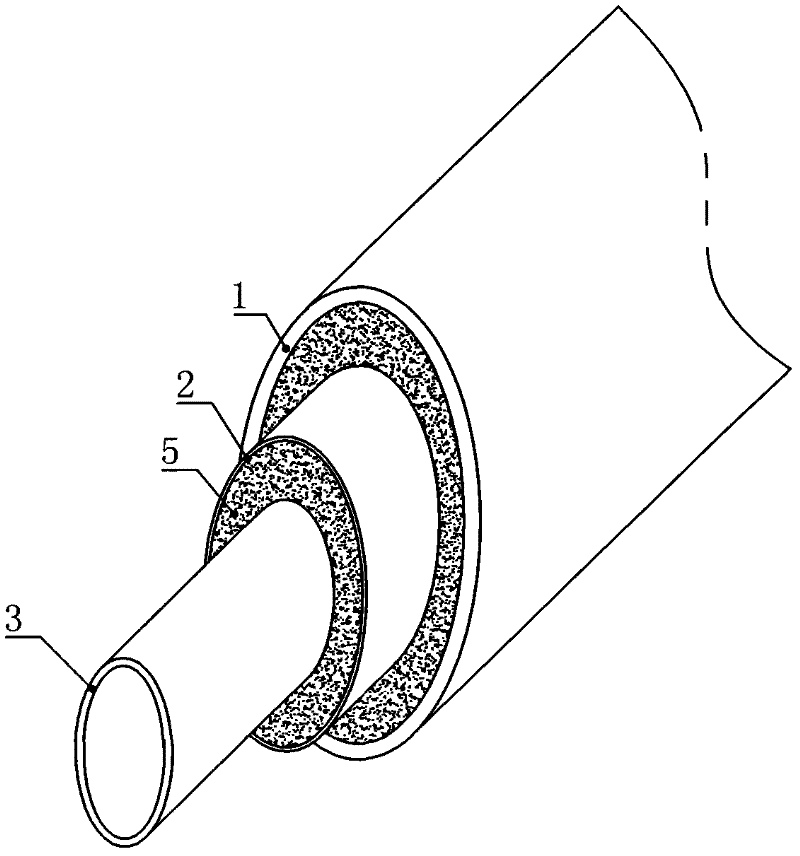

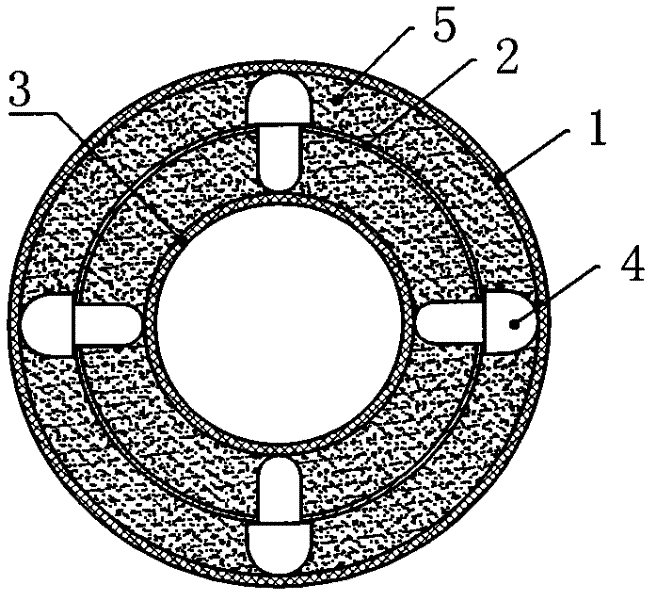

Steel plastic composite pipe for greenhouse framework and production method thereof

InactiveCN102246670AIncrease stiffnessGuaranteed stiffnessClimate change adaptationGreenhouse cultivationGreenhouseArchitectural engineering

The invention discloses a steel plastic composite pipe for a greenhouse framework and a production method thereof. The steel plastic composite pipe comprises an outer-layer plastic pipe, an intermediate-layer steel pipe and an inner-layer plastic pipe which are sequentially sleeved together from outside to inside; a supporting device for an inner pipe and an outer pipe is arranged on the intermediate-layer steel pipe, wherein the outer end part of the supporting device is supported against the inner wall of the outer-layer plastic pipe; the inner end part of the supporting device is supported against the outer wall of the inner-layer plastic pipe; filler for fastening the outer-layer plastic pipe, the intermediate-layer steel pipe and the inner-layer plastic pipe together is filled between the outer-layer plastic pipe and the inner-layer plastic pipe; the inner pipe and the outer pipe are plastic pipes; filler is poured between the inner pipe and the outer pipe and is used for fastening the inner pipe, an intermediate pipe and the outer pipe together; the relative position relation among the inner pipe, the intermediate pipe and the outer pipe is ensured by using the supporting device between the inner pipe and the outer pipe; the steel pipe is positioned between the inner pipe and the outer pipe and is free from contact with air, thus the steel pipe can be prevented from being corroded by acid and alkali; in addition, the rigidity of the composite pipe can be ensured by using the steel pipe; and the composite pipe has the advantages of strong corrosion resistance, high rigidity and long service life.

Owner:WEIFANG TAIWEI AGRI TECH

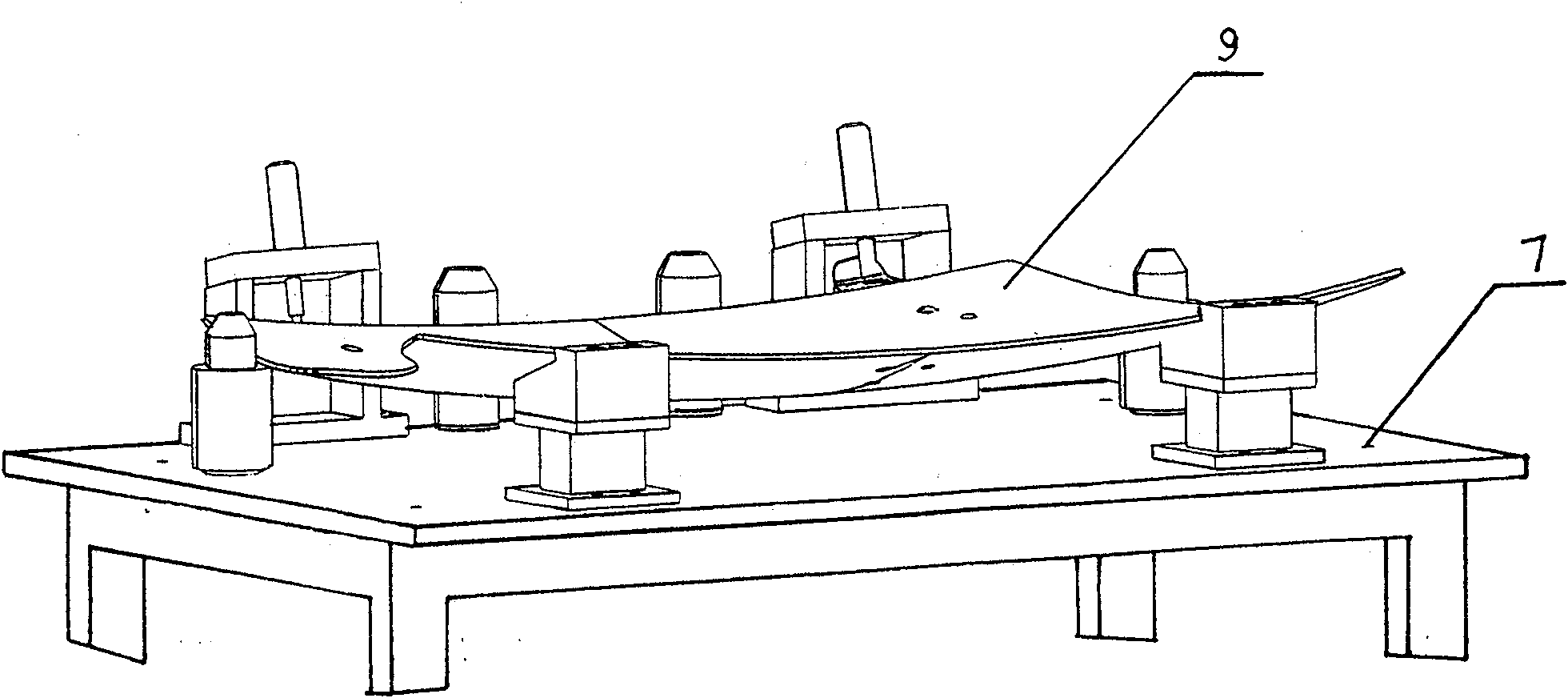

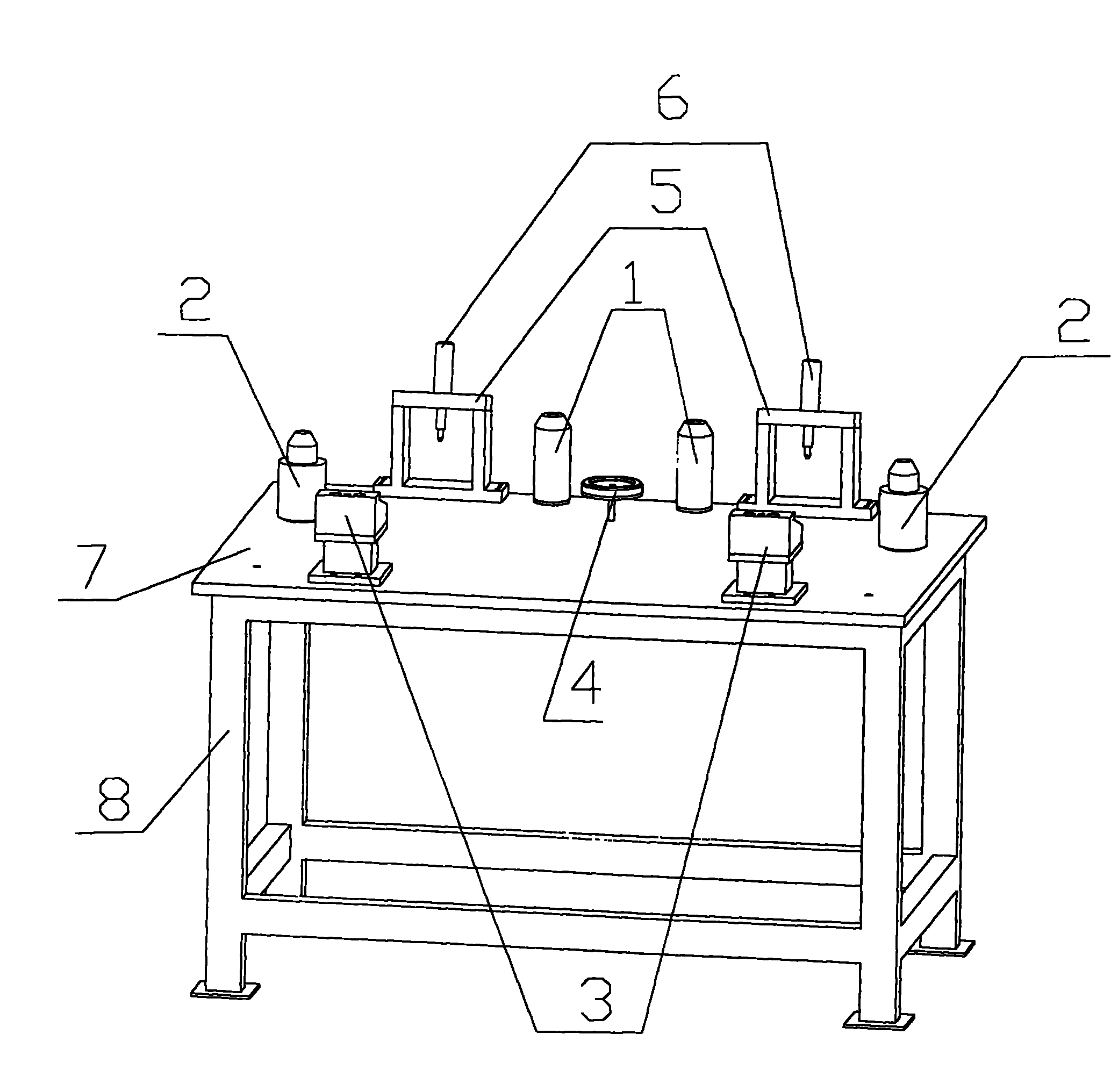

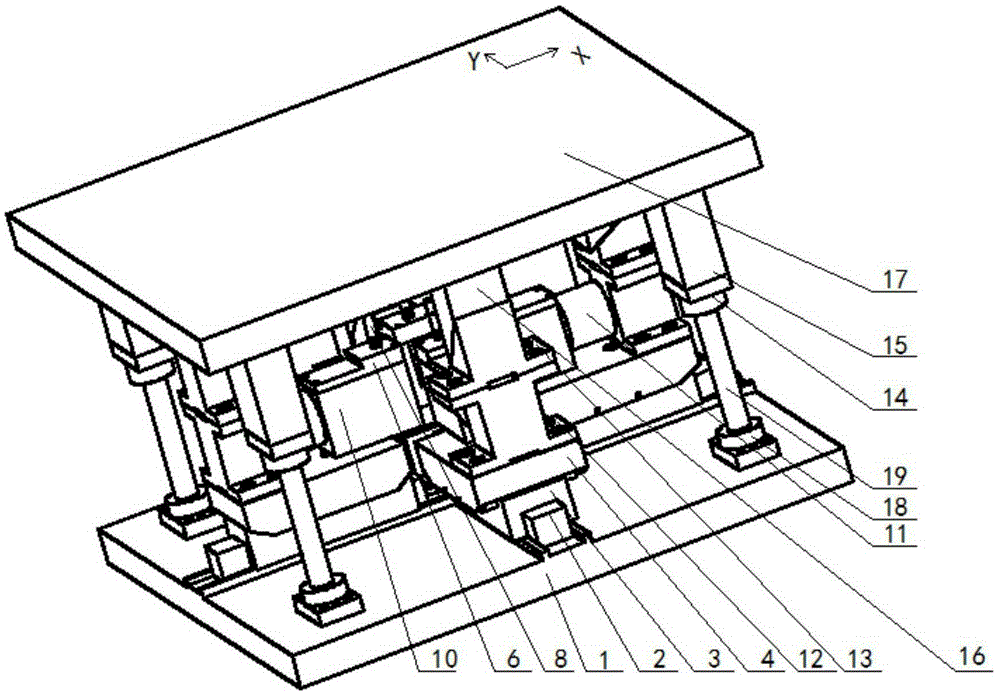

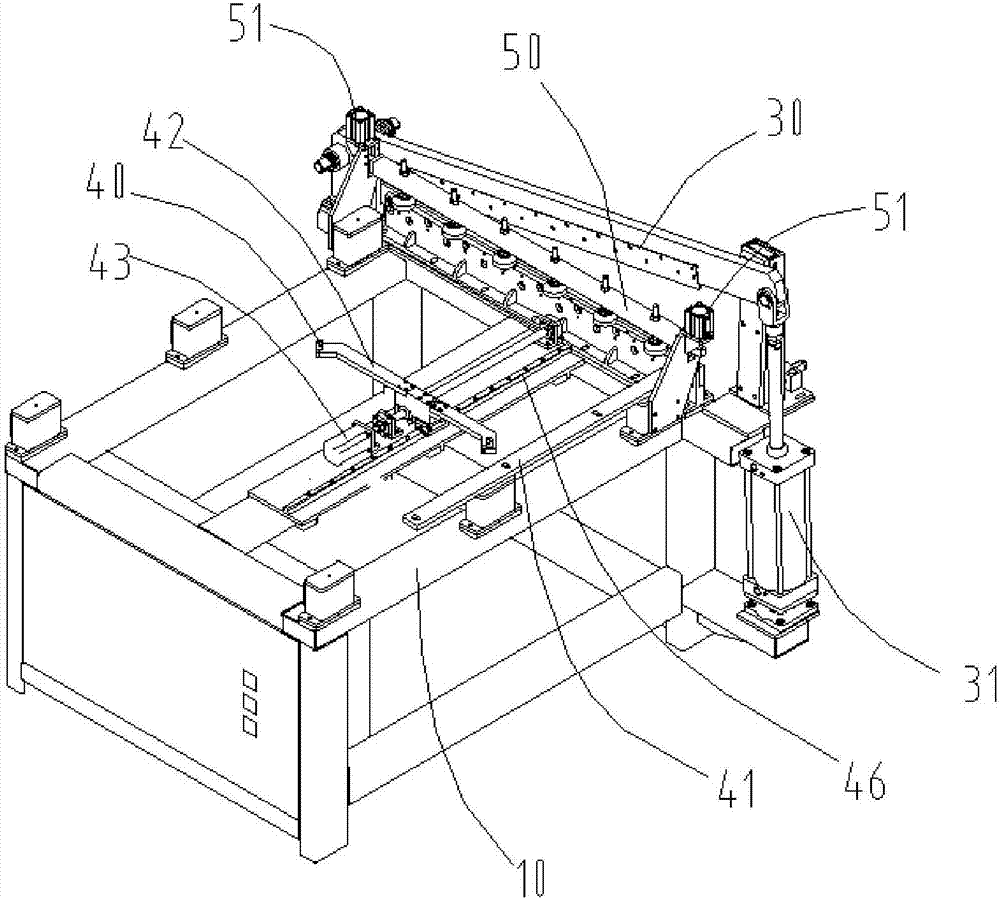

Split-assembling fixture of car backdoor

InactiveCN101791789AGuaranteed positional relationshipHigh positioning accuracyWork holdersEngineeringElectrical and Electronics engineering

The invention relates to a split-assembling fixture of a car backdoor comprising a glass positioning device connected on a rectangular bottom plate and a hinge positioning device, and is characterized in that the glass positioning device comprises an auxiliary supporting block connected with rear middle part of the rectangular bottom plate, two first glass limiting piles symmetrically arranged behind the rectangular bottom plate, two glass limiting piles symmetrically connected with the left and the right sides of the rectangular bottom plate, and two auxiliary limiting blocks symmetrically connected with the front side of the rectangular bottom plate; the hinge positioning device comprises two hinge positioning pin supporting seats and two hinge positioning pins symmetrically connected with the rear part of the rectangular bottom plate and positioned outside two first glass limiting piles. The positioning precision is high; the peripheral gap between backdoor glass and car body is finely adjusted or even not adjusted during assembling process; and the invention can not only satisfy the assembling quality requirement but also improve the assembling efficiency.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

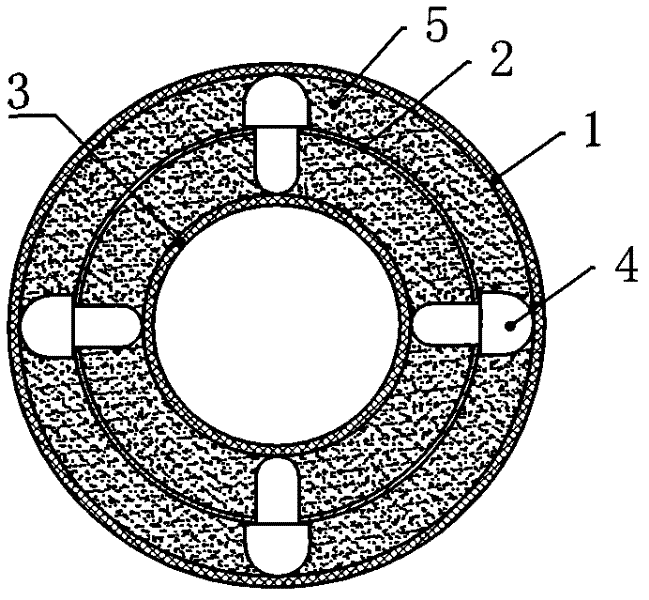

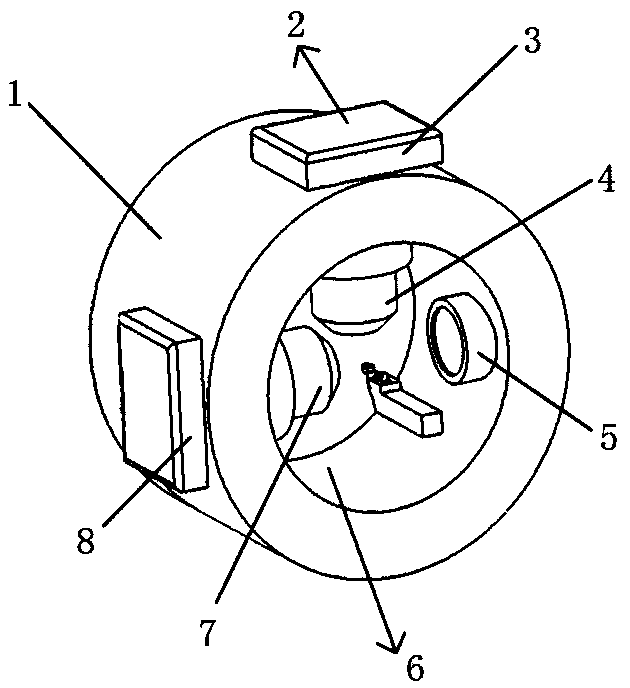

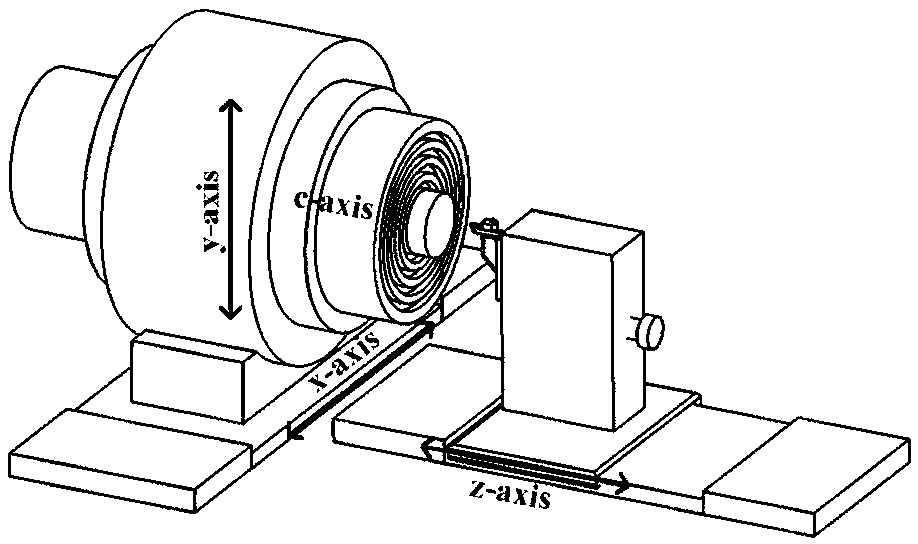

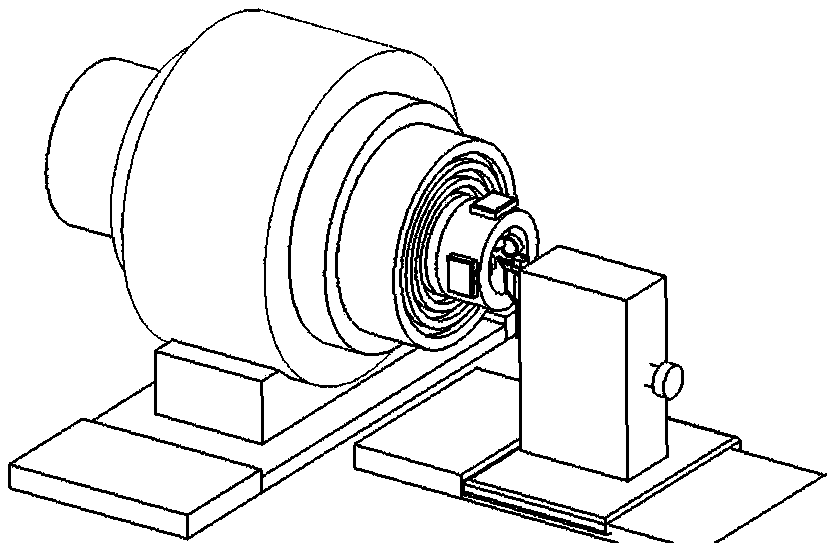

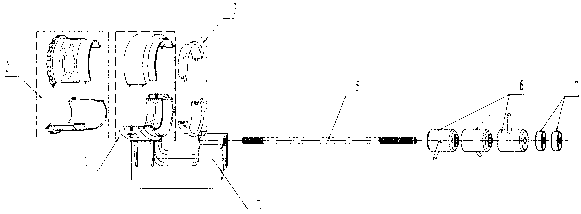

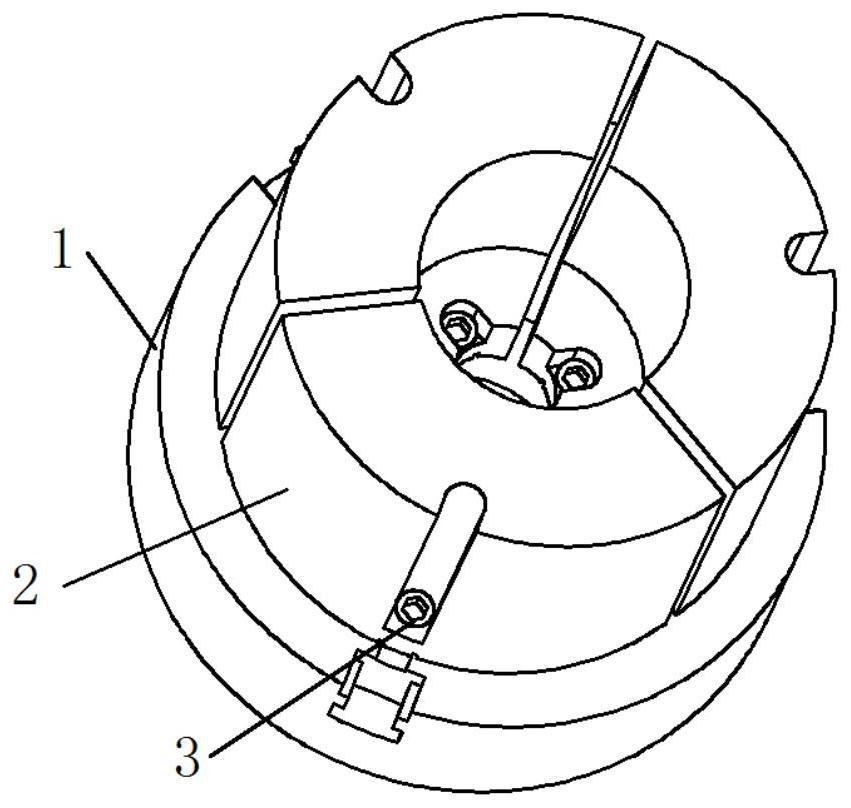

Non-contact precise tool setting gauge of ultra-precise diamond turning tool and tool setting method

PendingCN108942413AAvoid the disadvantage of poor repeat positioning accuracyGuaranteed positional relationshipAutomatic control devicesMeasurement/indication equipmentsDiamond turningTool wear

The invention relates to a non-contact precise tool setting gauge of an ultra-precise diamond turning tool and a tool setting method. The tool setting gauge comprises a supporting ring body, lenses inthe X direction and the Y direction, CCDs and a lighting source in the X direction. The lens in the X direction and the CCD of the lens in the X direction are arranged at the position, correspondingto the X-axis direction of the lathe coordinates, of the supporting ring body, the lens in the Y direction and the CCD of the lens in the Y direction are arranged at the position, corresponding to theY-axis direction of the lathe coordinates, of the supporting ring body, the lenses in the X direction and the Y direction are located on the inner side of the supporting ring body, the CCDs in the Xdirection and the Y direction are located on the outer side of the supporting ring body, and the lighting source is arranged at the position, facing the lens in the X direction, of the inner side of the supporting ring body. The tool setting gauge and the tool setting method thereof replace a traditional trial cutting method, ultra-precise machining tool high-precision optical online detection isachieved, the problems that an ultra-precise machining tool is long in position adjusting period, and tool wear is hard to avoid are solved, machining efficiency is greatly improved, the tool is freeof wear, and the wide application prospects and the large popularization value are achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Motorhauben-gelenkhalterung und befestigungsstruktur

InactiveCN101152880AEasy to adjustGuaranteed positional relationshipWing accessoriesSuperstructure subunitsHinge angleEngineering

Owner:SUZUKI MOTOR CO LTD

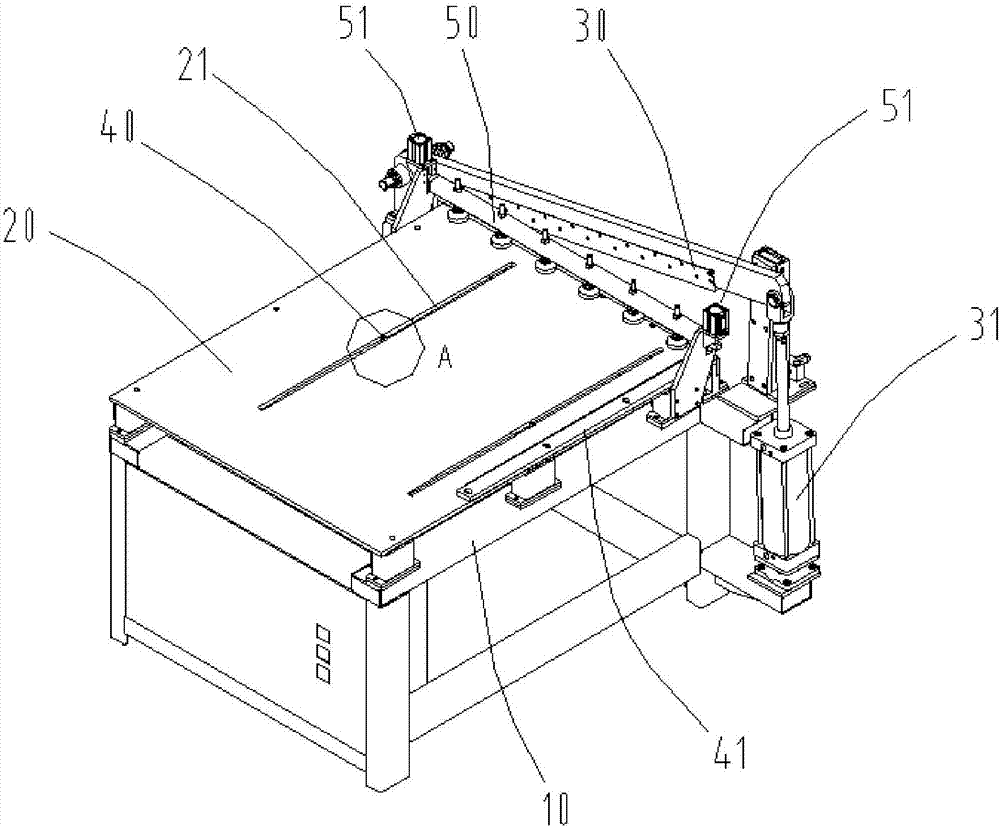

Sheet metal bidirectional stretching apparatus based on die technology

InactiveCN105424471ALow costSimple structureMaterial strength using tensile/compressive forcesTest materialEngineering

The invention discloses a sheet metal bidirectional stretching apparatus based on a die technology. The sheet metal bidirectional stretching apparatus comprises a work bench, a camera, a cross test piece, four groups of stretching mechanisms containing tension sensors, a top board, four groups of seat-type guiding mechanisms and a computer control system; by applying downward driving force to the top board, the top board performs downward movement through the four groups of seat-type guiding mechanisms, and drives the four groups of stretching mechanisms to outwardly move on a cross chute, so that the four groups of stretching mechanisms can form stretching structures in four directions to the cross test piece; a deformation signal and a pulling force signal of the cross test piece can be respectively obtained through the camera and the tension sensors by the computer control system, and strain and stress of the cross test piece can be calculated. By realizing simultaneous loading with different proportions, practicality of stress and strain of the bidirectional tensile test materials can be developed.

Owner:HEFEI UNIV OF TECH

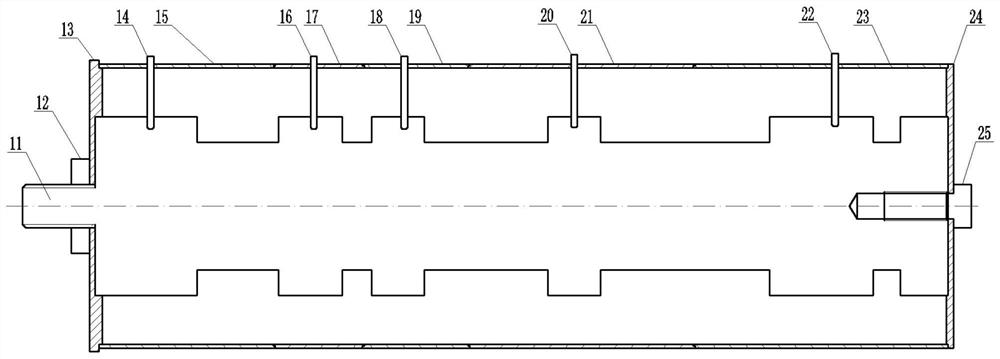

Dual-mode multi-beam electronic gun for dual-mode traveling wave tube and method for controlling dual-mode multi-beam electronic gun

ActiveCN102945781ASimple processConsistent launch trajectoryTransit-tube electron/ion gunsTransit-tube cathodesDual modeEngineering

The invention discloses a dual-mode multi-beam electronic gun for a dual-mode traveling wave tube and a method for controlling the dual-mode multi-beam electronic gun. The dual-mode multi-beam electronic gun comprises a cathode, a shade gate, an internal grid, an external grid and an anode, which are arranged in sequence, wherein the cathode comprises a cathode molybdenum tube, the inside of which is divided into two parts along the axis of the cathode molybdenum tube; the two parts are separated by insulating ceramic; a cathode sponge body is mounted in one part, and a filament filling and sealing insulator is mounted in the other part and is internally provided with a filament; the end face of the cathode molybdenum tube is provided with a plurality of holes; the internal grid controls the electronic beams in partial holes, and the external grid controls the electronic beams in the rest holes so as to implement dual-mode operation. According to the dual-mode multi-beam electronic gun and the method, a high-mode operation state and a low-mode operation state can be provided, and the control voltage is consistent, so that the electronic beams in two modes can be focused by the same magnetic field.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

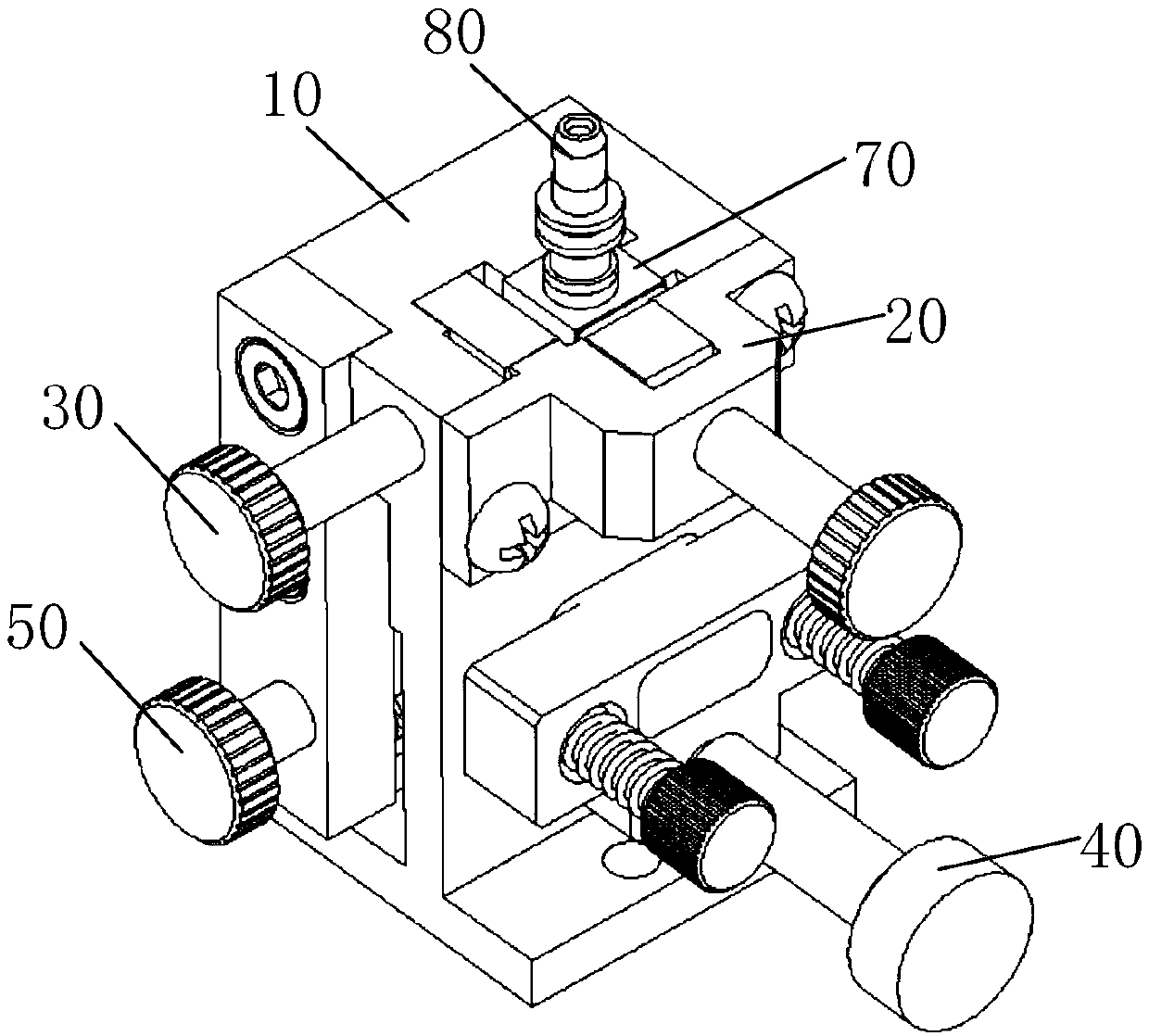

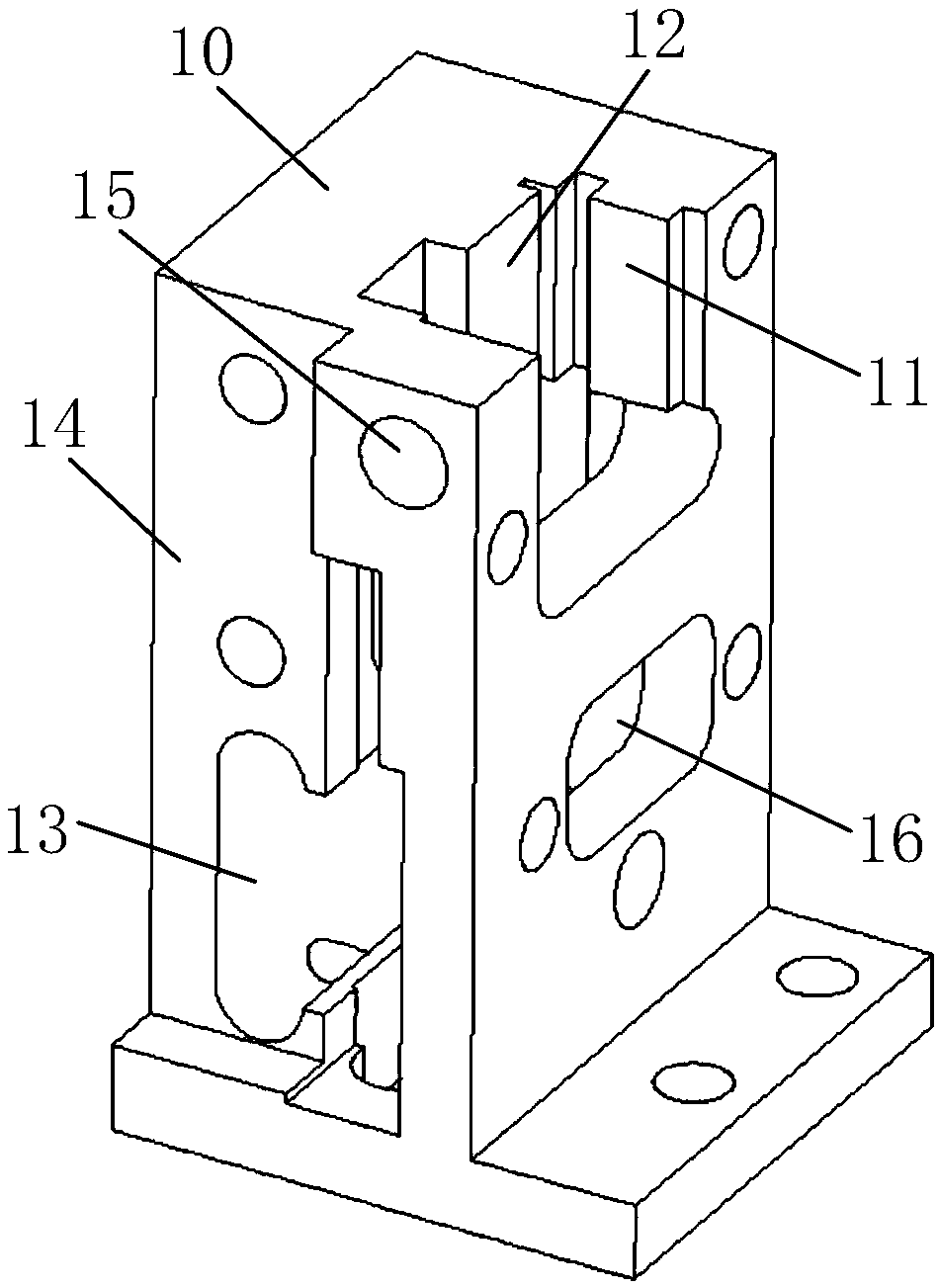

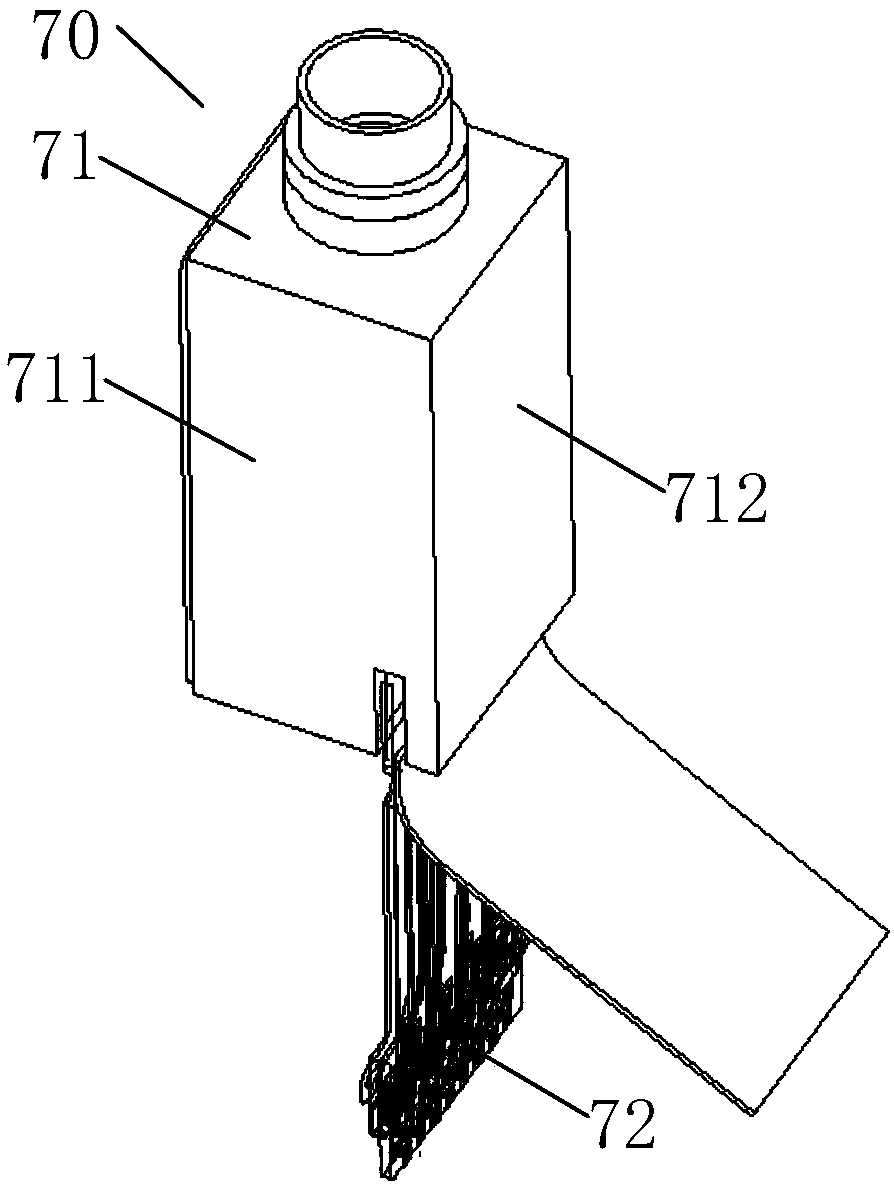

Optical device coupling device and coupling method

InactiveCN109633831AImprove coupling efficiencyQuality improvementCoupling light guidesMulti dimensionalCoupling efficiency

The invention discloses an optical device coupling device and a coupling method. The coupling device comprises a coupling base, a top pressing assembly, a side pressing assembly, a soft belt pressurization assembly, a PCB adjusting assembly and an electrifying PCB, wherein the top pressing assembly, the side pressing assembly, the soft belt pressurizing assembly and the PCB adjusting assembly areconnected with the coupling base, the electrifying PCB is arranged on the PCB adjusting assembly, the top pressing assembly and the side pressing assembly are used for positioning the main body part of the optical device, and the PCB adjusting assembly and the soft belt pressurizing assembly are used for connecting the soft belt of the optical device with the electrifying PCB. When the optical device and an adapter are coupled for welding, a multi-dimensional fine adjustment frame is not needed, the top pressing assembly and the side pressing assembly of the optical device coupling device areadjusted to position the optical device, meanwhile, the relative position relation between the optical device and the adapter is ensured, the soft belt pressurizing assembly and the PCB adjusting assembly are adjusted to enable the soft belt of the optical device and the electrifying PCB to be electrified smoothly, so that the coupling efficiency and the coupling quality of the optical device andthe adapter are improved.

Owner:GUANGXUN SCI & TECH WUHAN

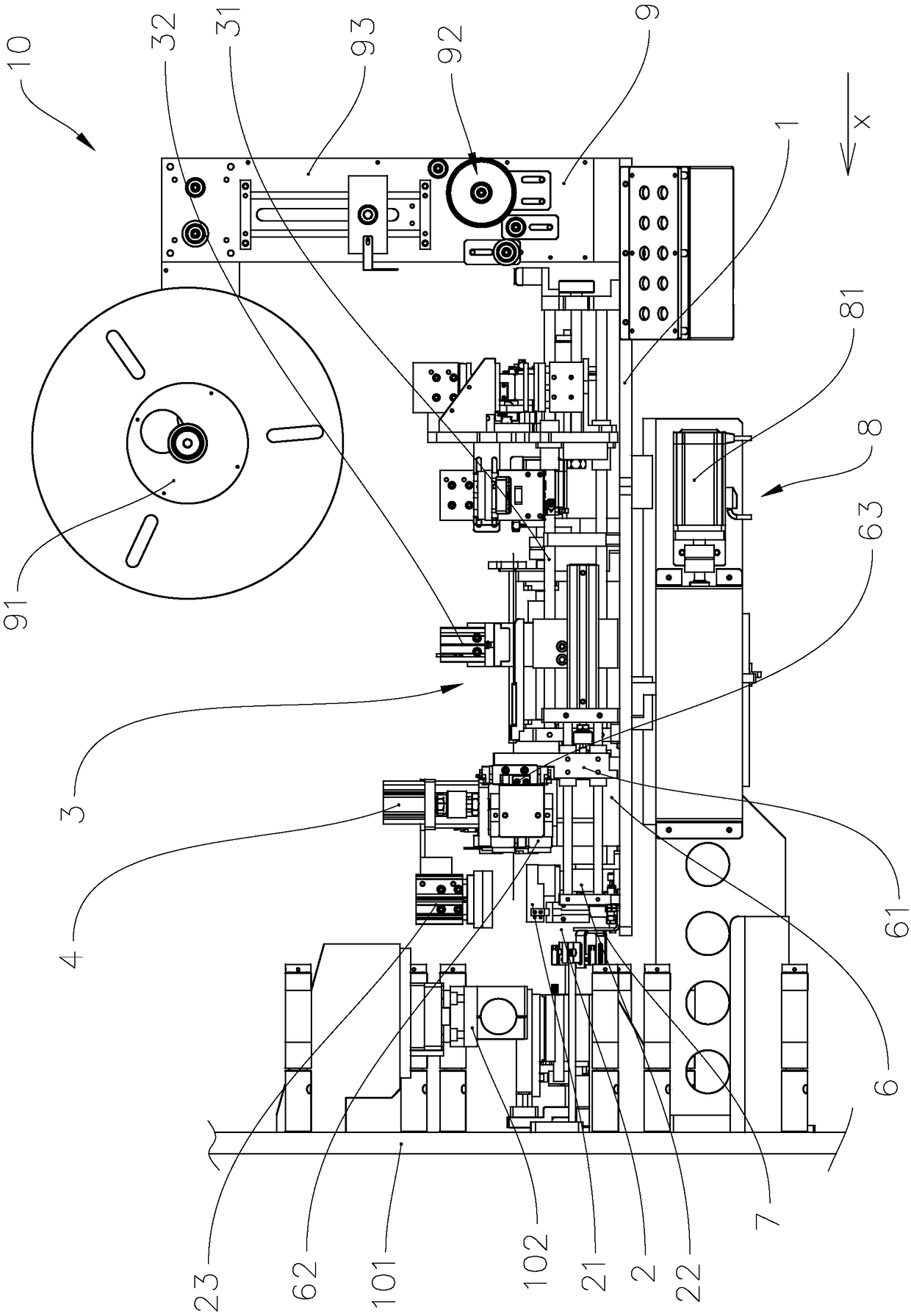

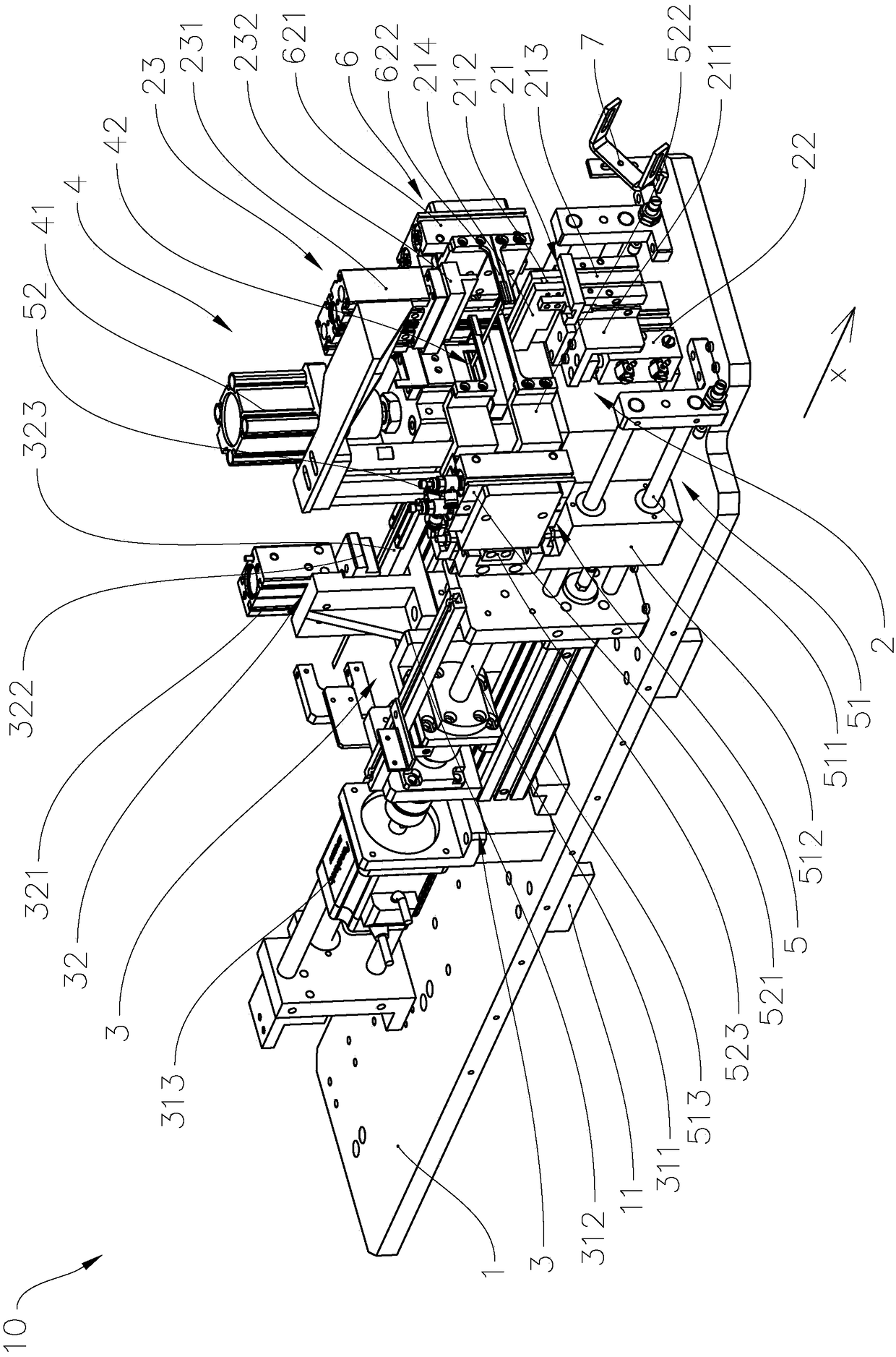

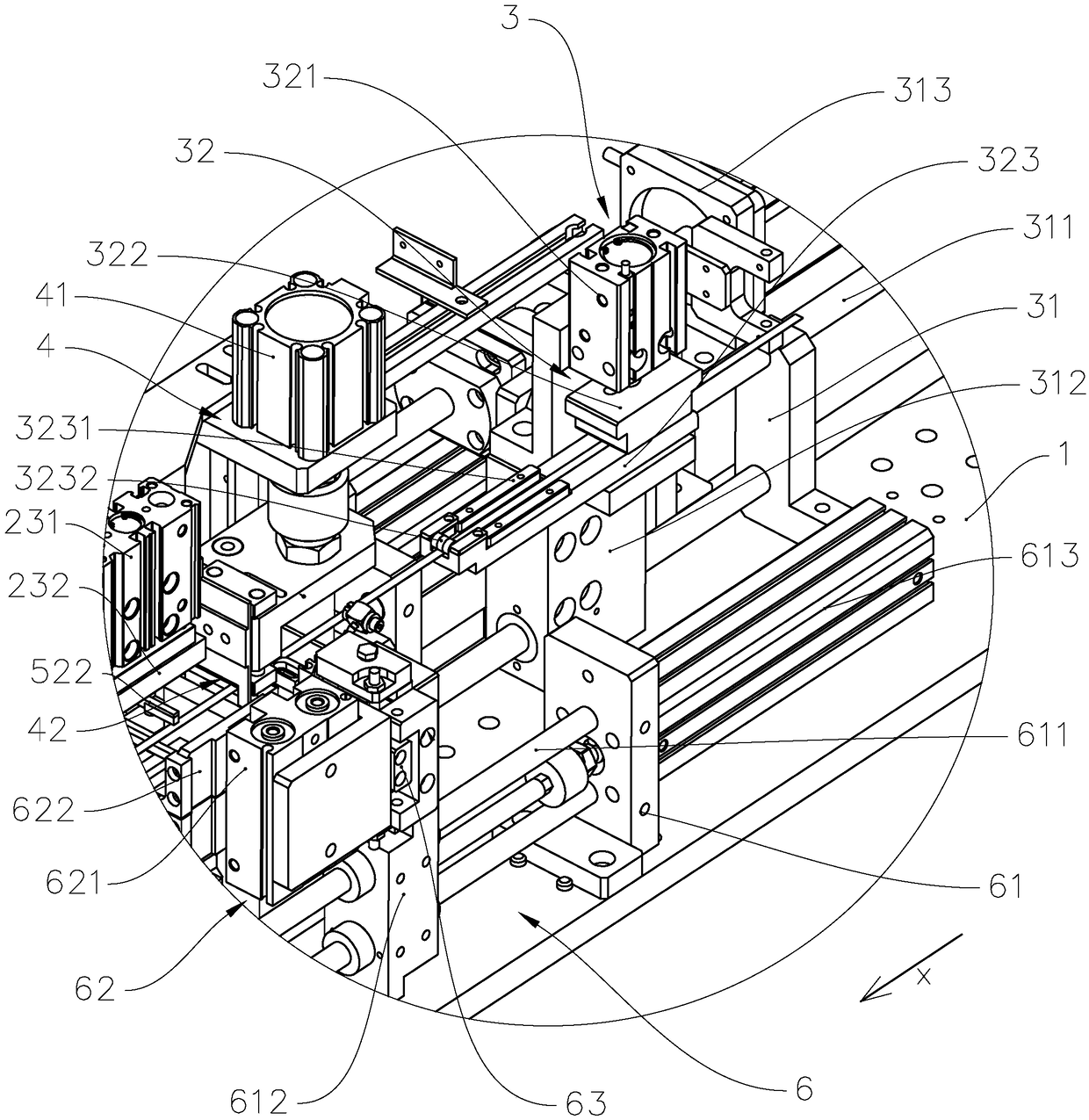

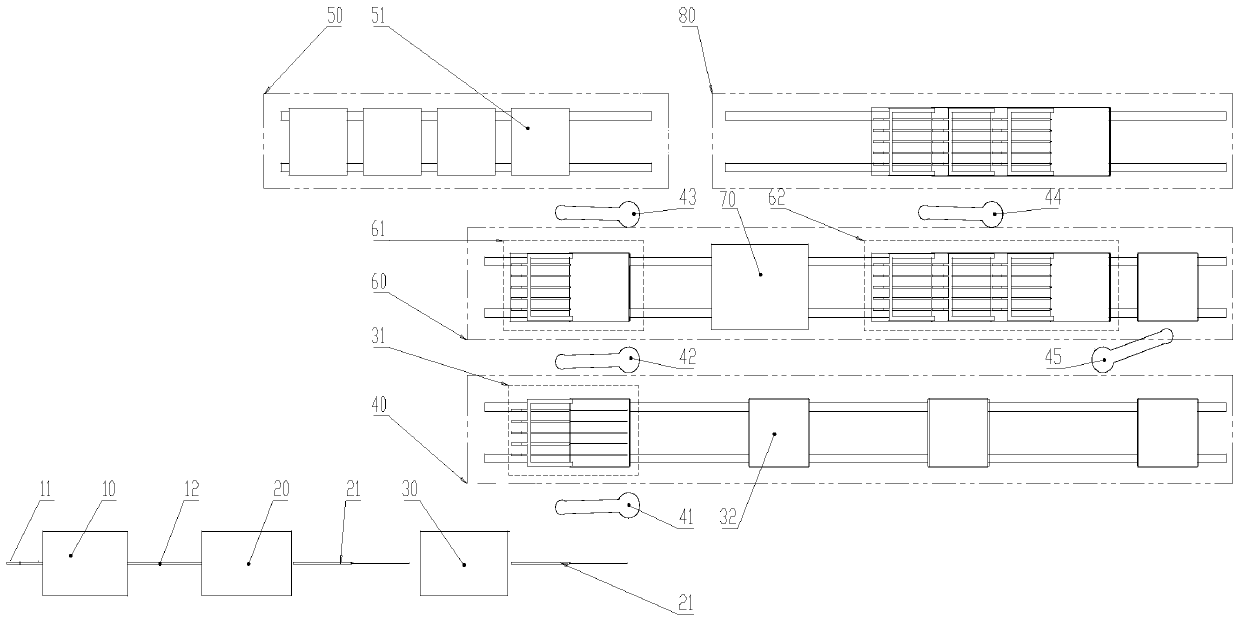

Tab shaping and transferring device, working method of tab shaping and transferring device and cylindrical cell piece production winder

PendingCN108649177AImprove processing qualityIncrease productivityPrimary cell manufactureAssembling battery machinesPole pieceEngineering

The invention provides a tab shaping and transferring device, a working method of the tab shaping and transferring device and a cylindrical cell piece production winder. The tab shaping and transferring device comprises a shaping unit for carrying out position correction on a tab, a traction unit for loading to the shaping unit, a cutting unit for carrying out cutting on a tab material coil, and afirst clamping unit and a second clamping unit which are used for alternatively transferring a pole piece subjected to position correction to a tab welding device of the cylindrical cell piece production winder. The invention further relates to the working method of the tab shaping and transferring device and the cylindrical cell piece production winder with the tab shaping and transferring device. The tab shaping and transferring device, the working method of the tab shaping and transferring device and the cylindrical cell piece production winder have the advantages that machining quality ishigh; production efficiency is high; perpendicularity between the pole piece and the tab can be ensured.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Method for delivery of substrate to film forming device for disk-like substrate, substrate delivery mechanism and substrate holder used for the method, and method of manufacturing disk-like recording

InactiveCN1662978AGuaranteed positional relationshipVacuum evaporation coatingSputtering coatingBiomedical engineeringThin membrane

The present invention relates to a method of delivering a substrate capable of holding the disk-like substrate without a center hole in the air and capable of easily transferring the substrate to a spattering device. In the present invention, a projected part is provided at both face center parts of the disk-like substrate and the substrate formed integrally with an outer mask and an inner mask covering the outer peripheral end part and the center part thereof for transportation, the inner mask and the outer mask are held by a magnetic force in a delivery mechanism, the inner and outer masks are held simultaneously by a magnetic force also in a substrate holder for receiving the substrate and, at the time of delivery, the magnetic force on a delivery mechanism side is reduced.

Owner:TDK CORPARATION

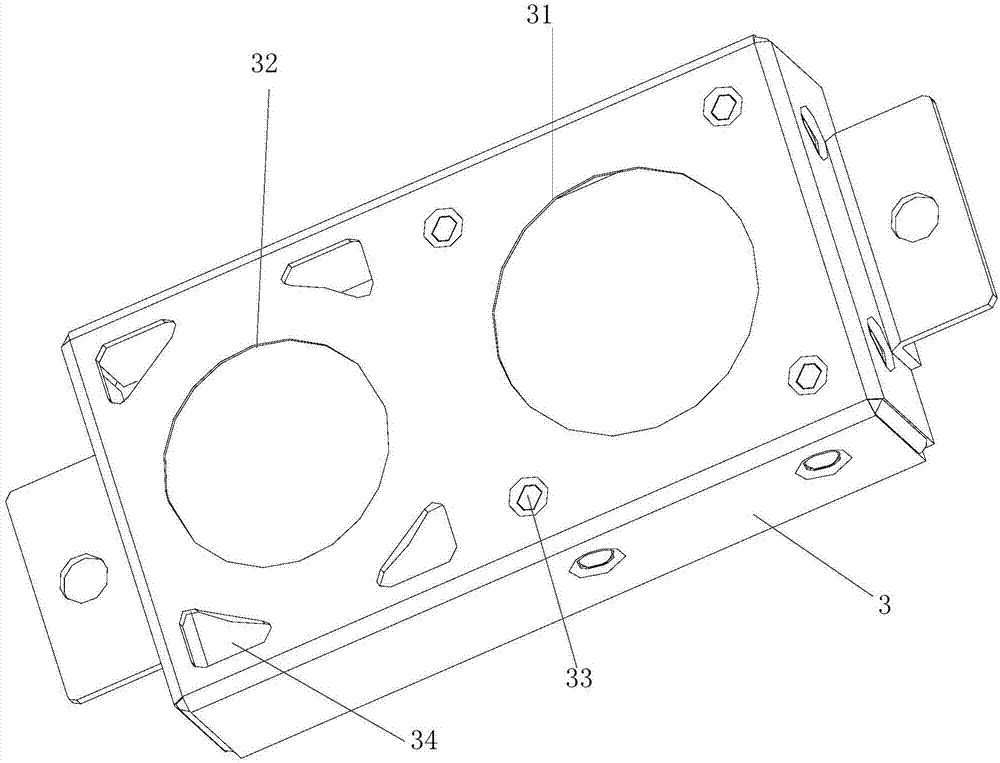

Electronic device

InactiveCN107197129AGuaranteed positional relationshipEasy to installTelevision system detailsColor television detailsComputer visionElectronic equipment

The invention discloses an electronic device and relates to the field of the electronic device. The main technical scheme provided by the invention is that the electronic device comprises a first camera assembly, a second camera assembly and a metal holder. The metal holder is used for containing and fixing the first camera assembly and the second camera assembly. The first camera assembly and the second camera assembly are fixed together according to first arrangement. The metal holder is equipped with a first through hole and a second through hole. The first through hole is used for exposing a first lens of the first camera assembly. The second through hole is used for exposing a second lens of the second camera assembly. The metal holder is fixedly mounted in the shell of the electronic device, so the first camera assembly and the second camera assembly are fixedly mounted in the shell. The main purpose is that the two camera assemblies in the electronic device are assembled together through the metal holder and then are mounted in the shell of the electronic device. The effect of improving the strength and facilitating the positioning is achieved.

Owner:LENOVO (BEIJING) LTD

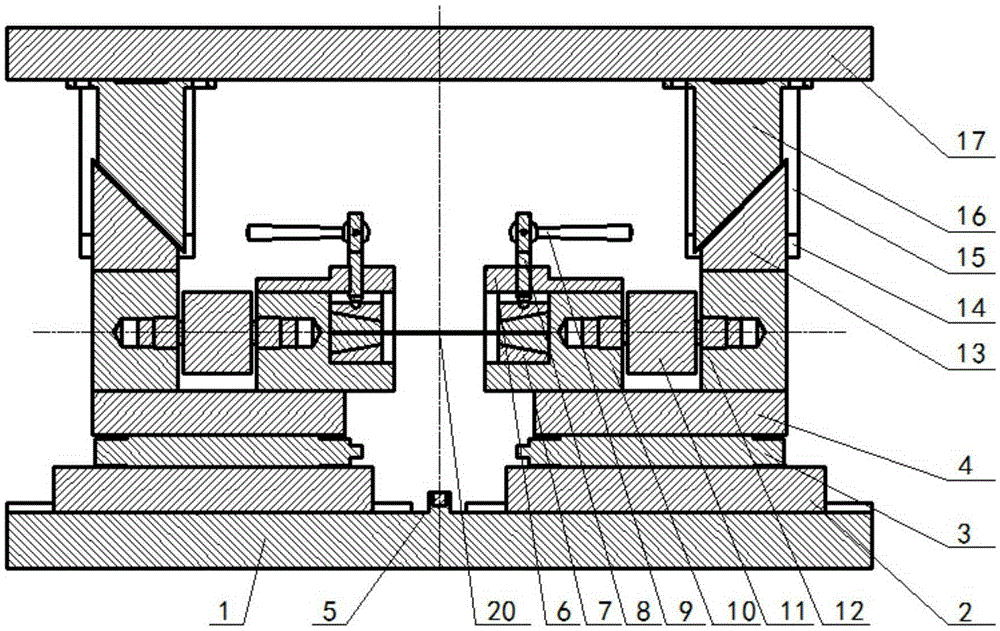

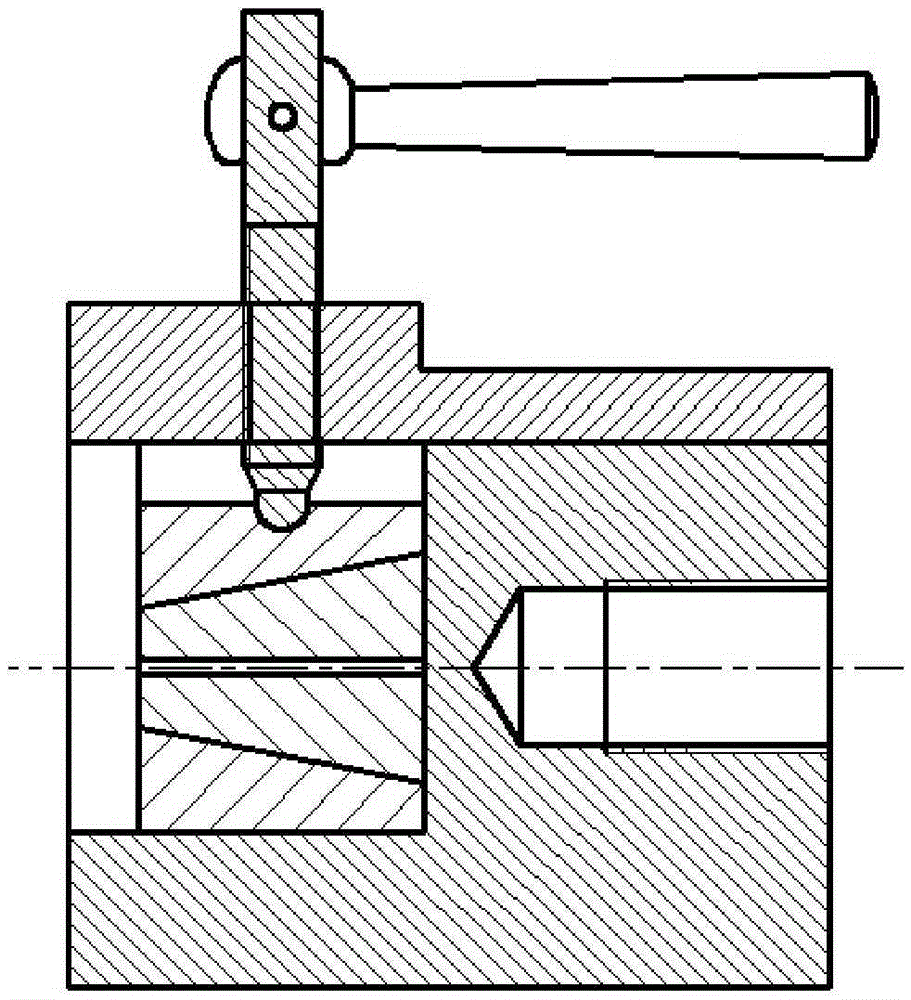

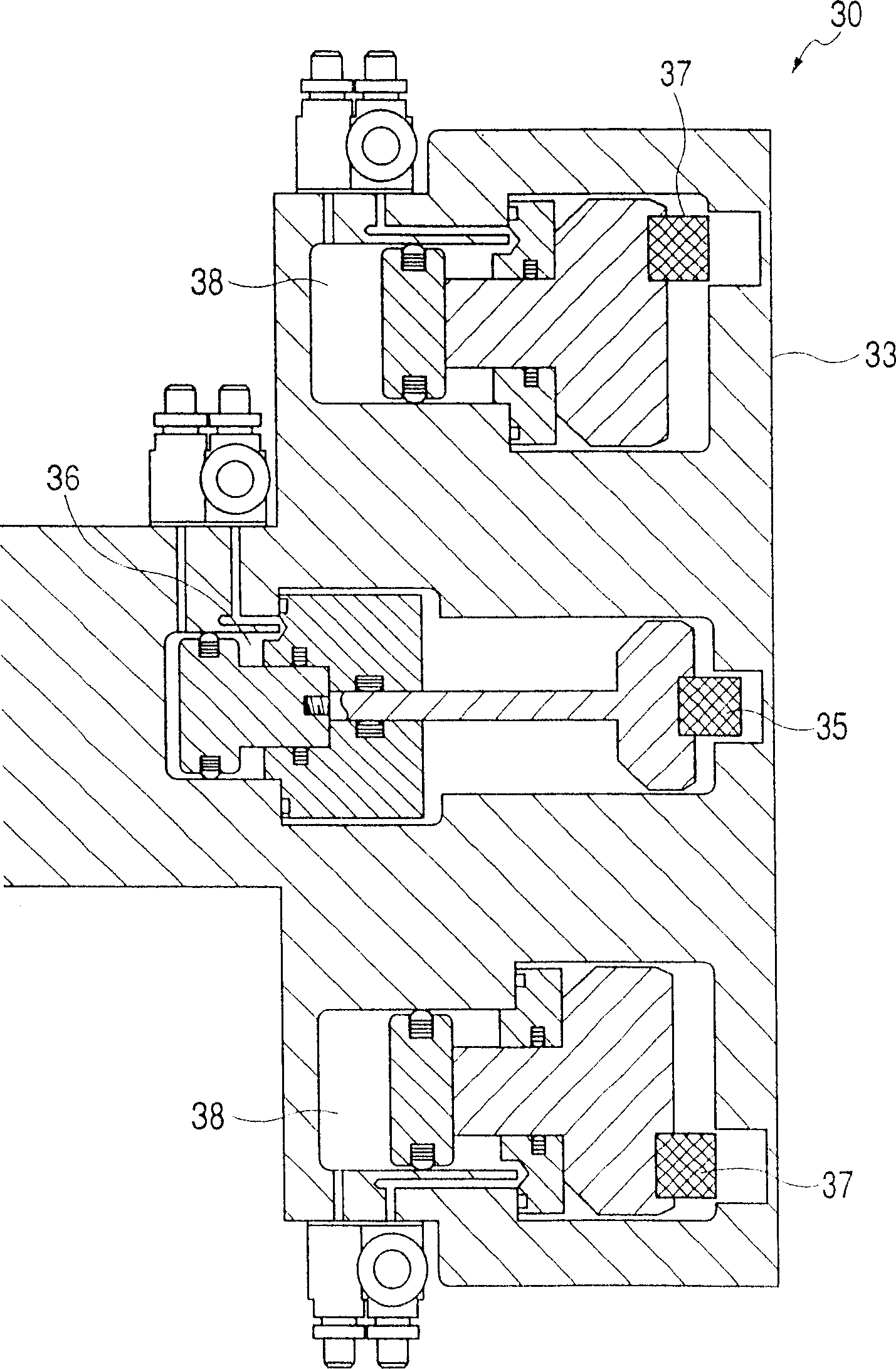

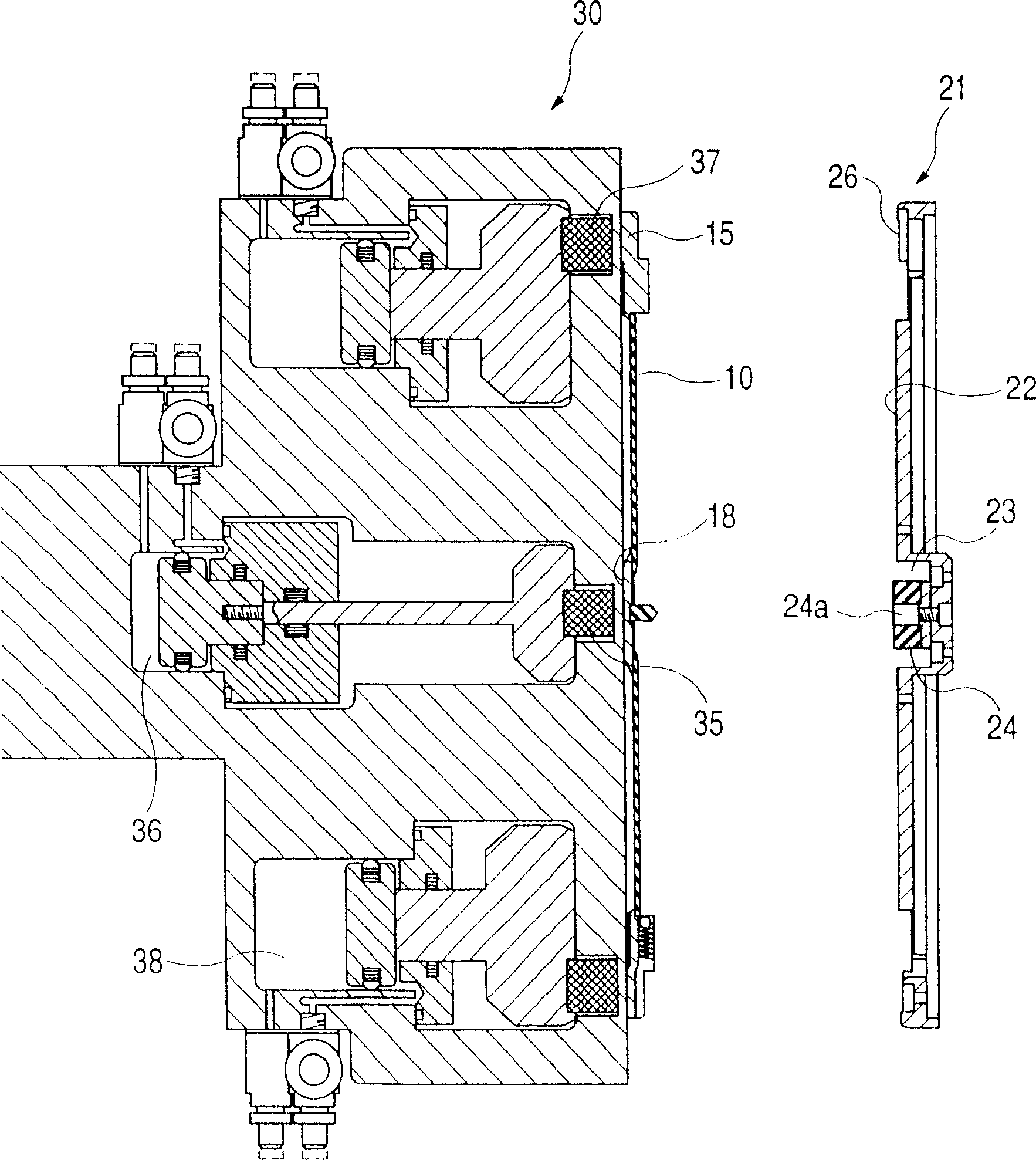

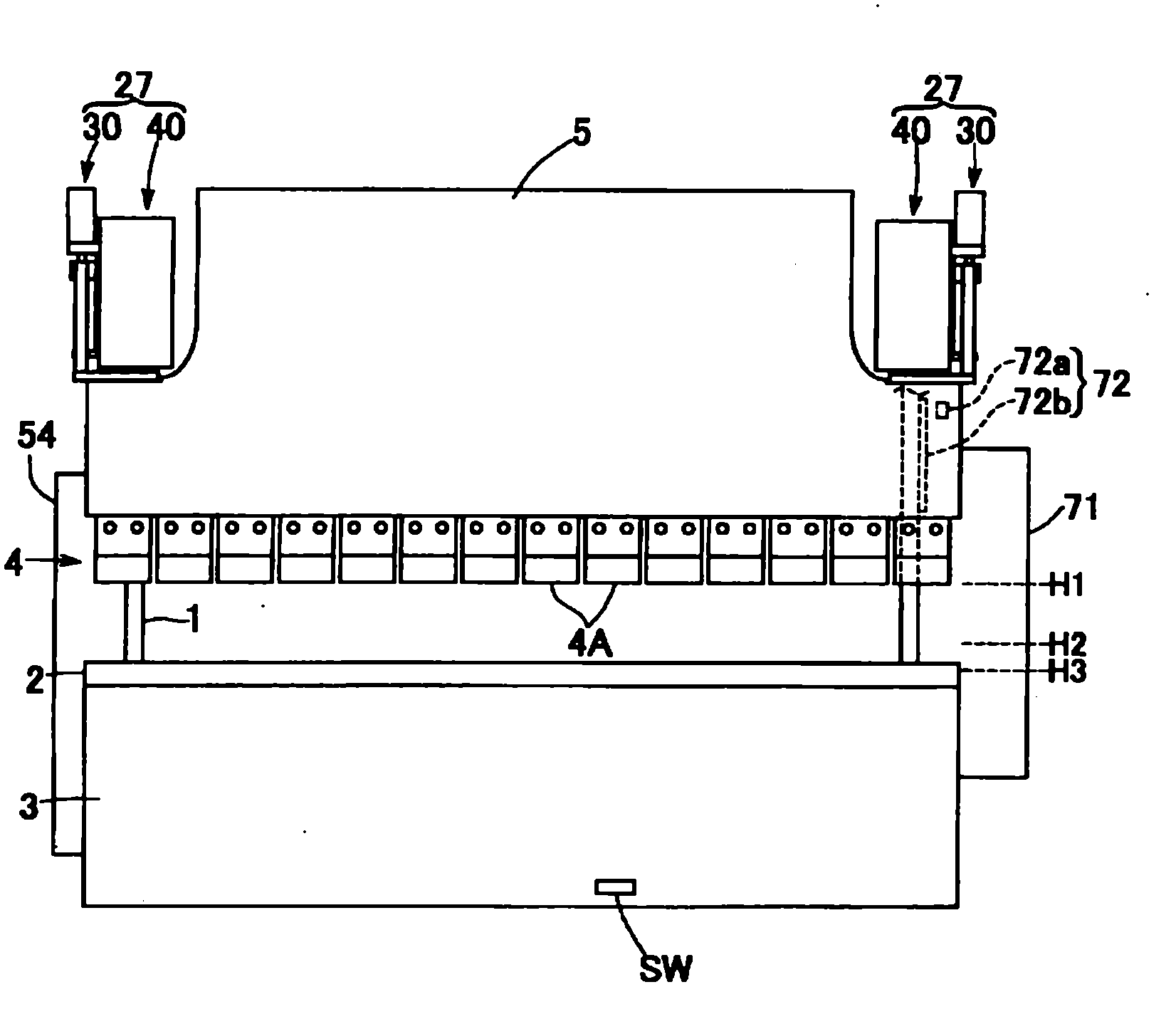

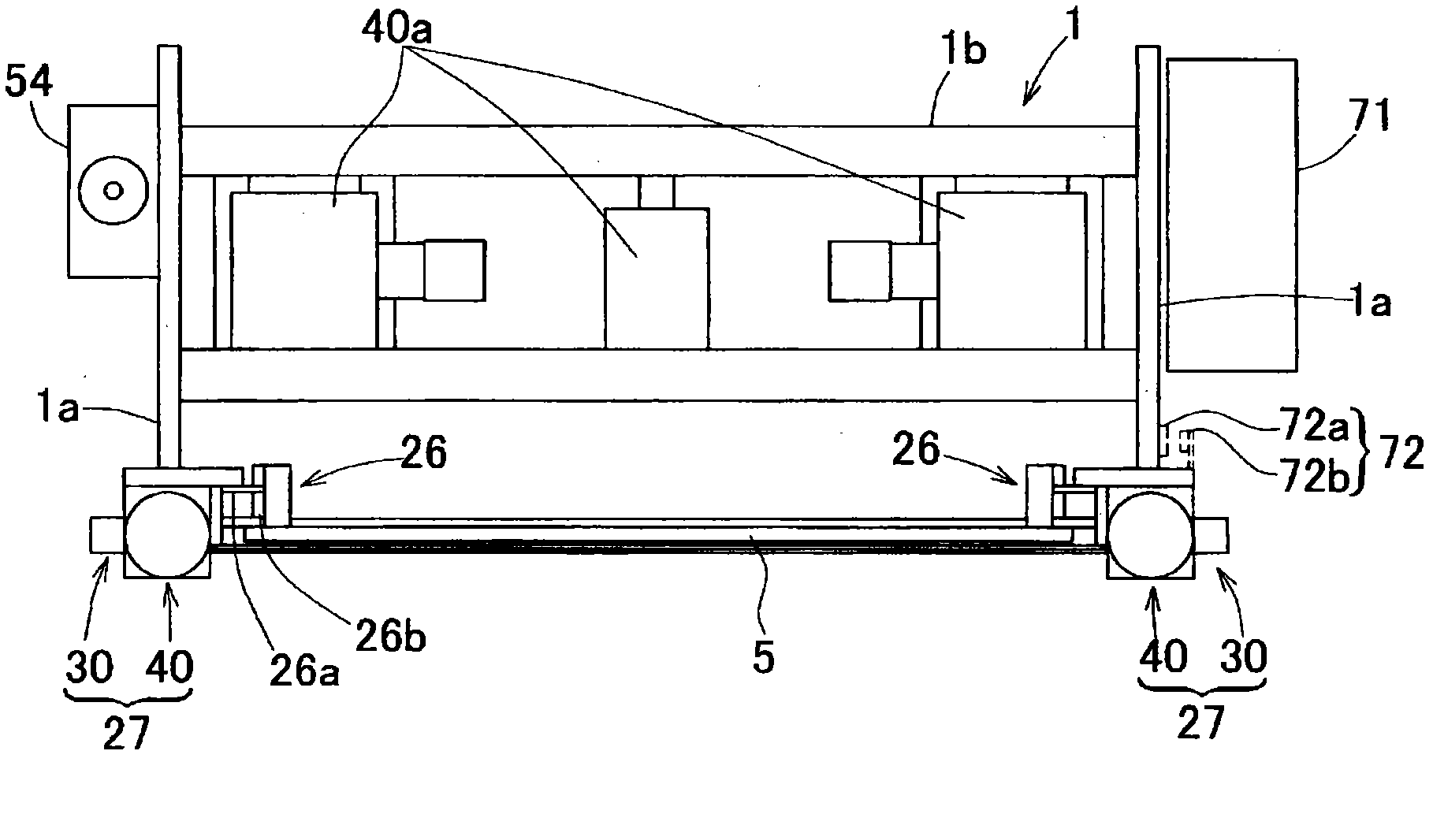

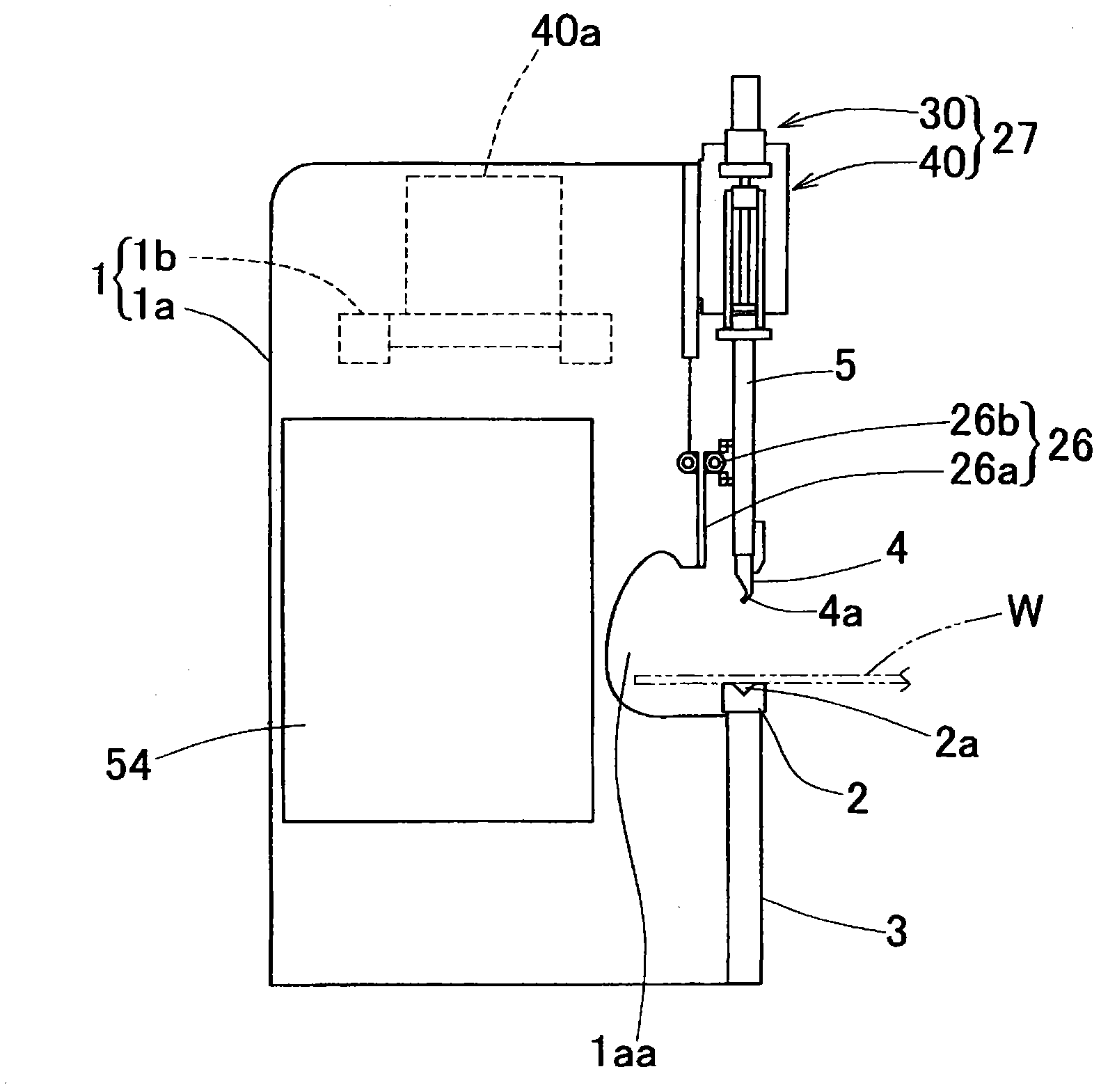

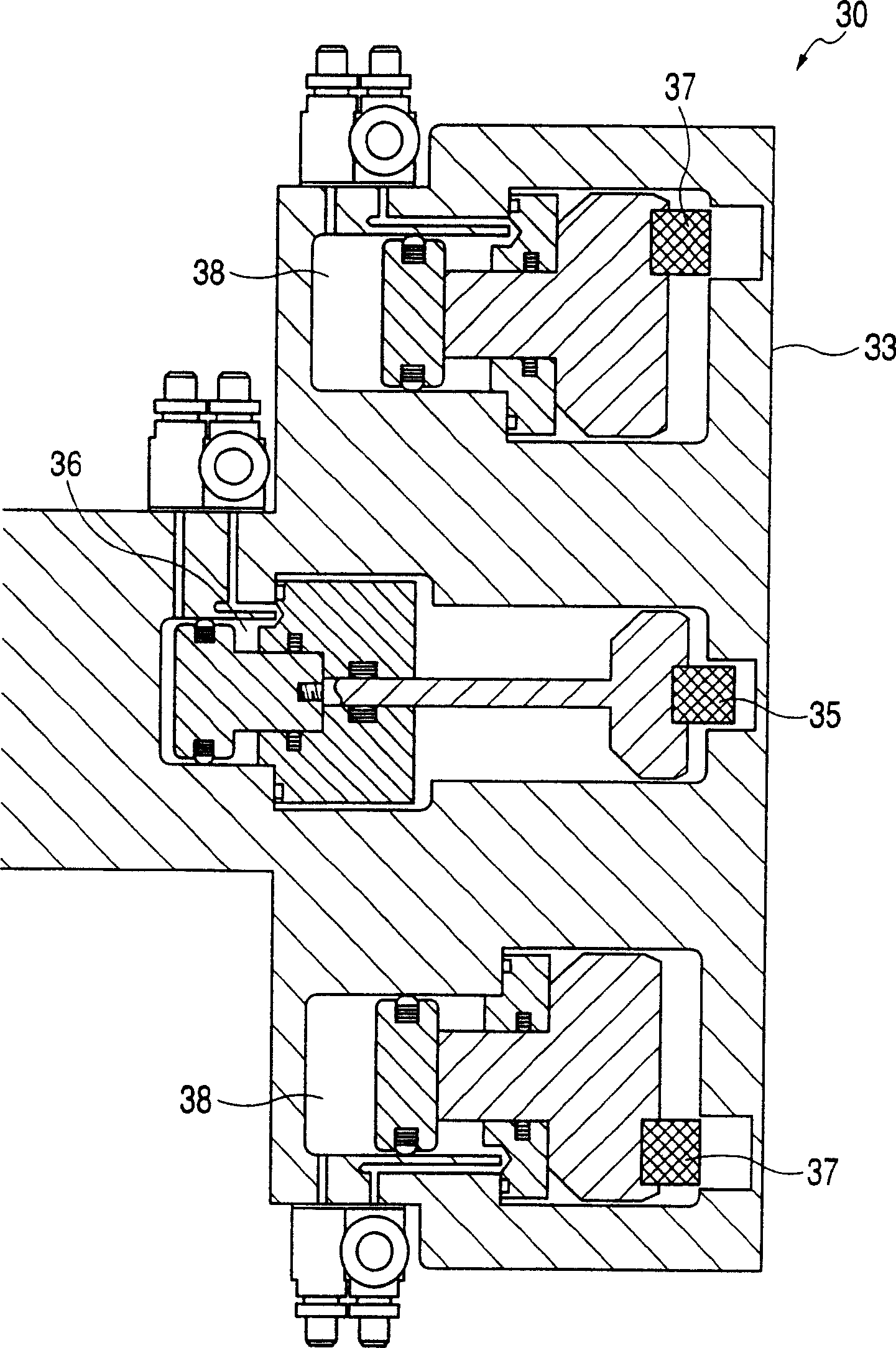

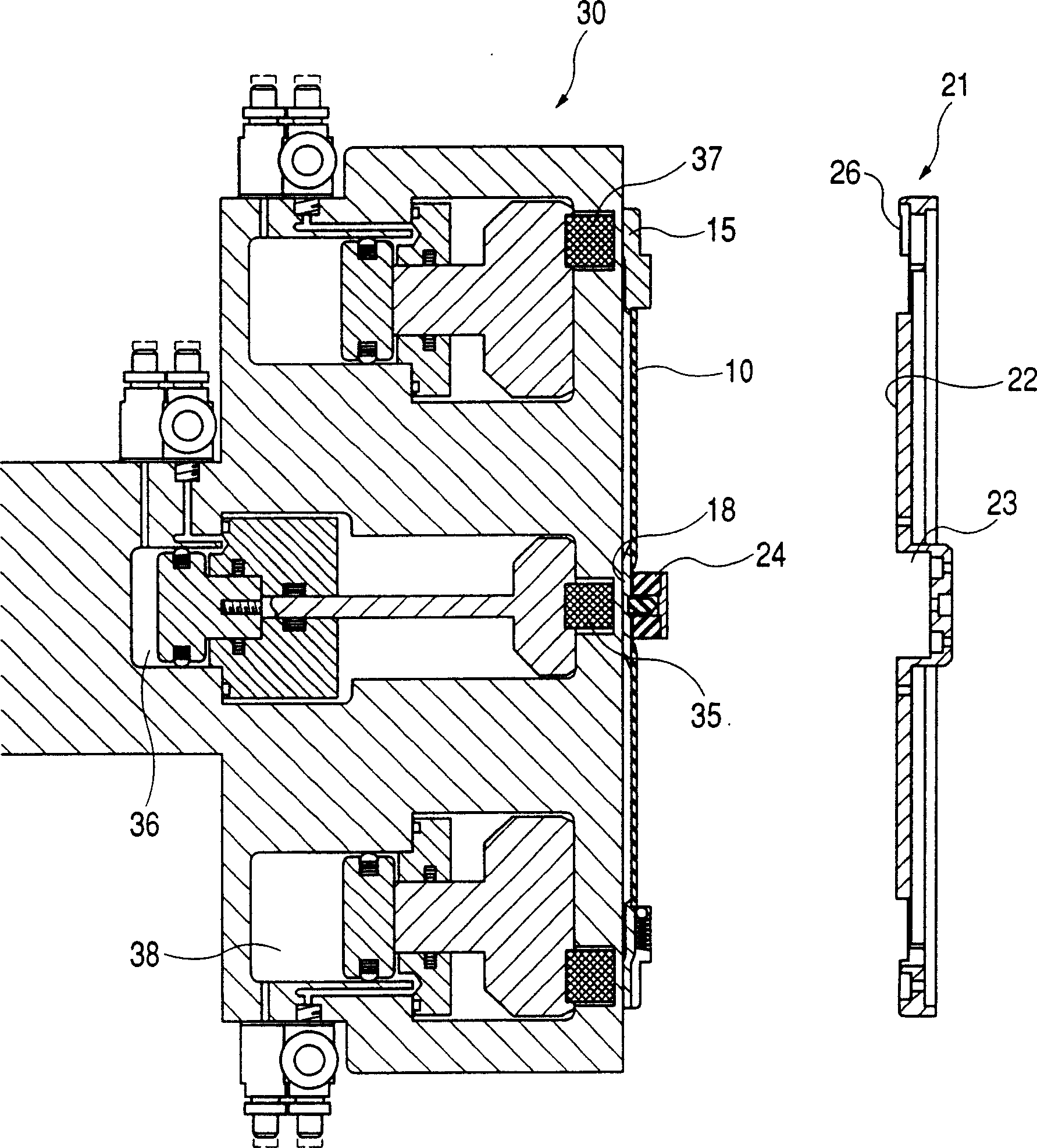

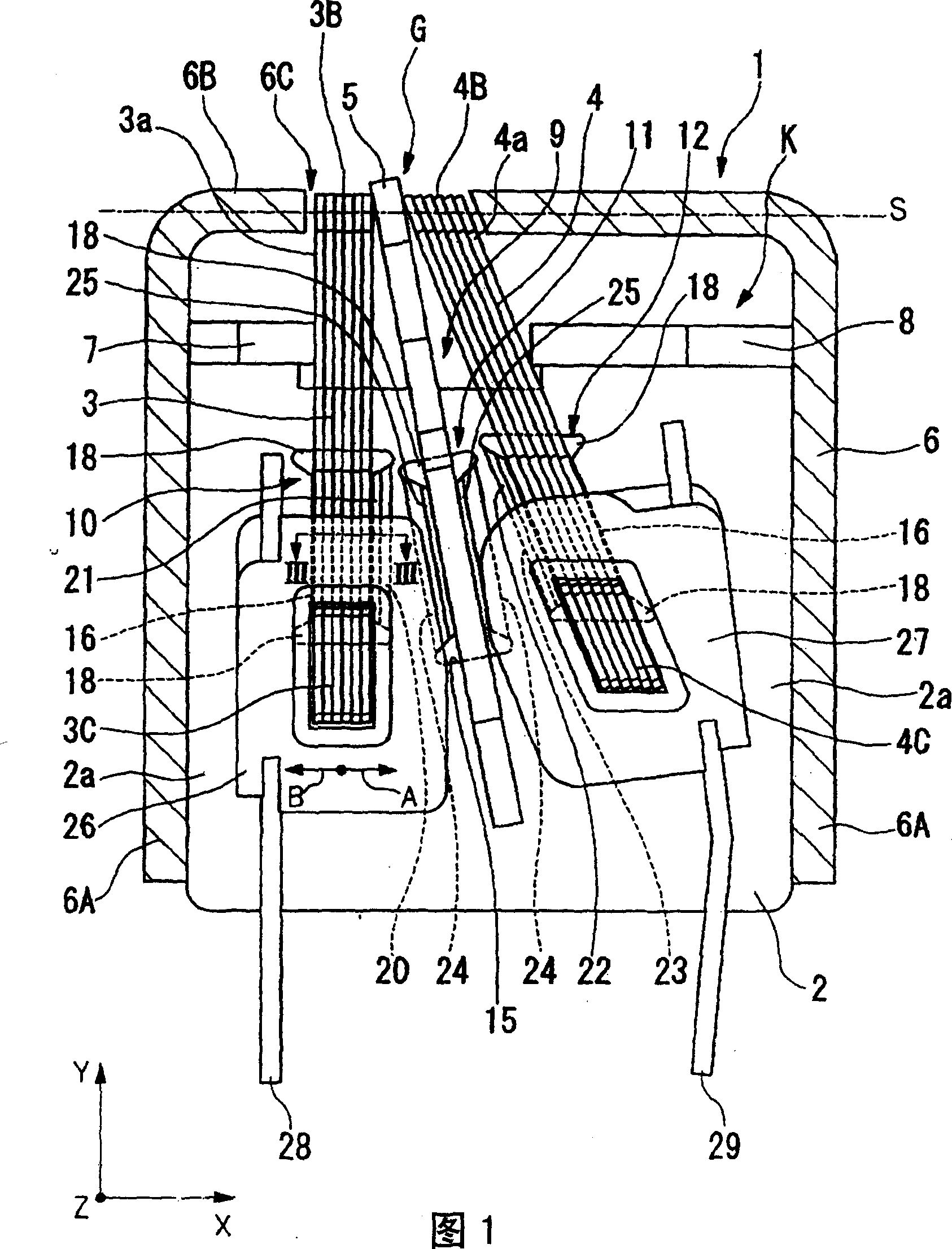

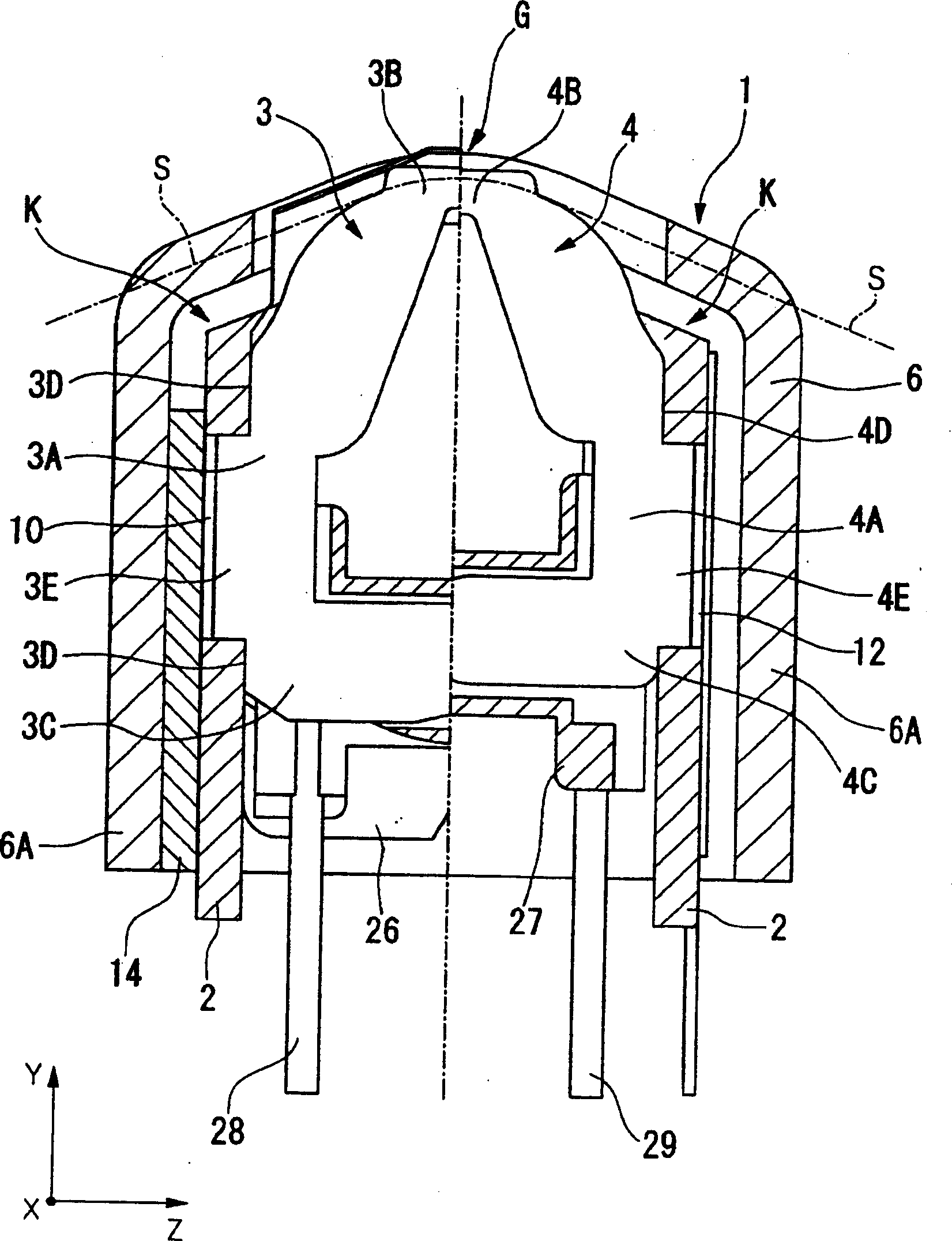

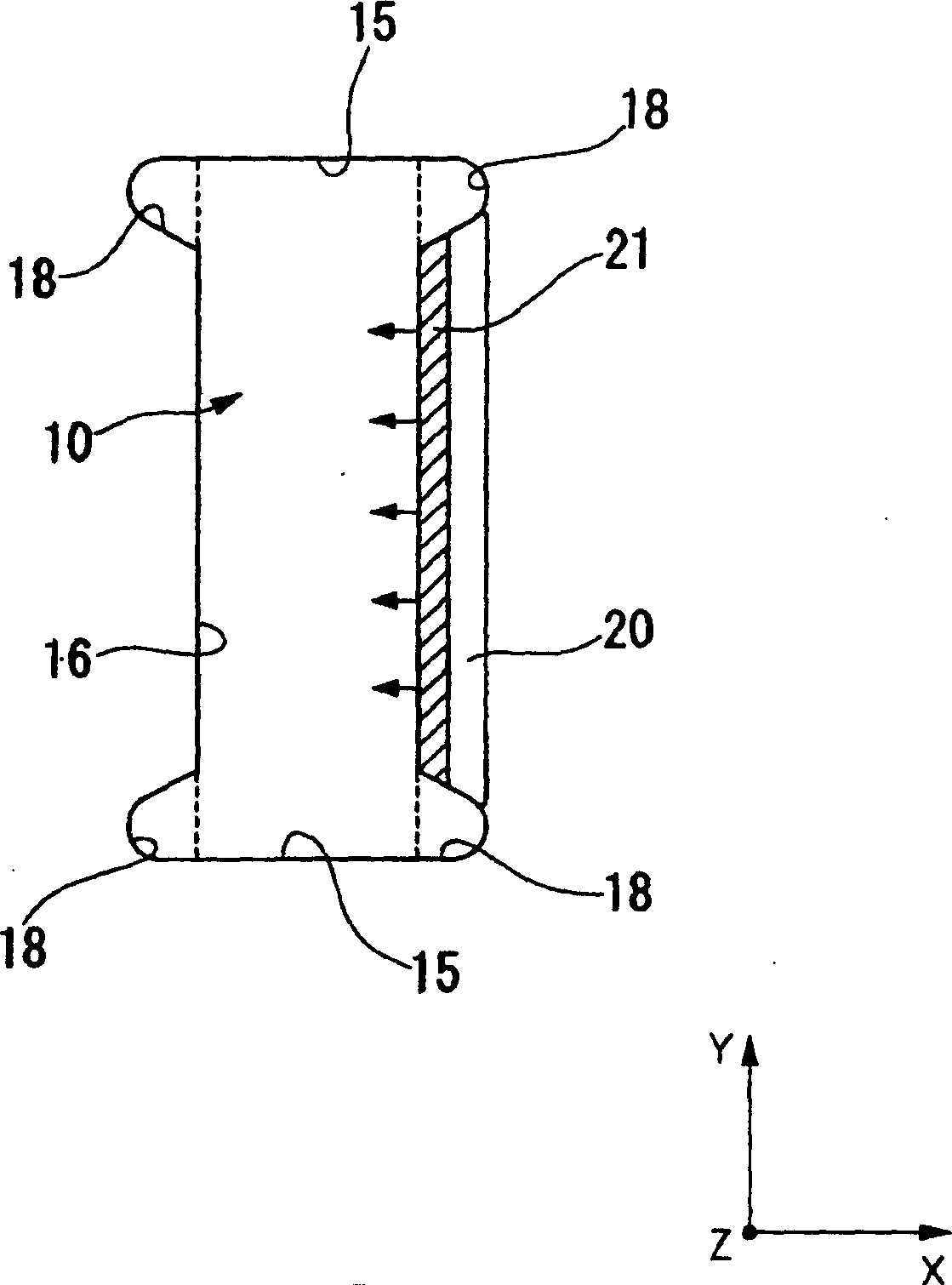

Flexibility rectification adjusting device of punching machine

The invention provides a flexibility rectification adjusting device of a punching machine, which can properly keep the position relationship between an upper mold and a lower mold during a punching process and ensure enough tolerance relative to the pressurization process. The flexibility rectification adjusting device (6) adjusts the height of the upper mold or the lower mold, for example the upper mold (4A). The flexibility rectification adjusting device (6) is fixed on a support part (5) of a support mold through a mold fixing mechanism (7) in a way to have the height adjustable. Intermediate wedge-shaped parts (8) are equipped on the horizontal direction between the mold (4A) and the support part (5). The intermediate wedge-shaped part face contacting with the mold (4A) is inclined along the front-to-back direction. The intermediate wedge-shaped parts each further have a cylindrical face (8b) recessed on the projecting side of the mold (4A). The intermediate wedge-shaped part (8) can freely slide along the front-to-back direction of the mold (4A) and the circumferential direction of the cylindrical face. A vertical position change mechanism (21) is equipped to make the vertical position of the intermediate wedge-shaped part (8) change.

Owner:MURATA MASCH LTD

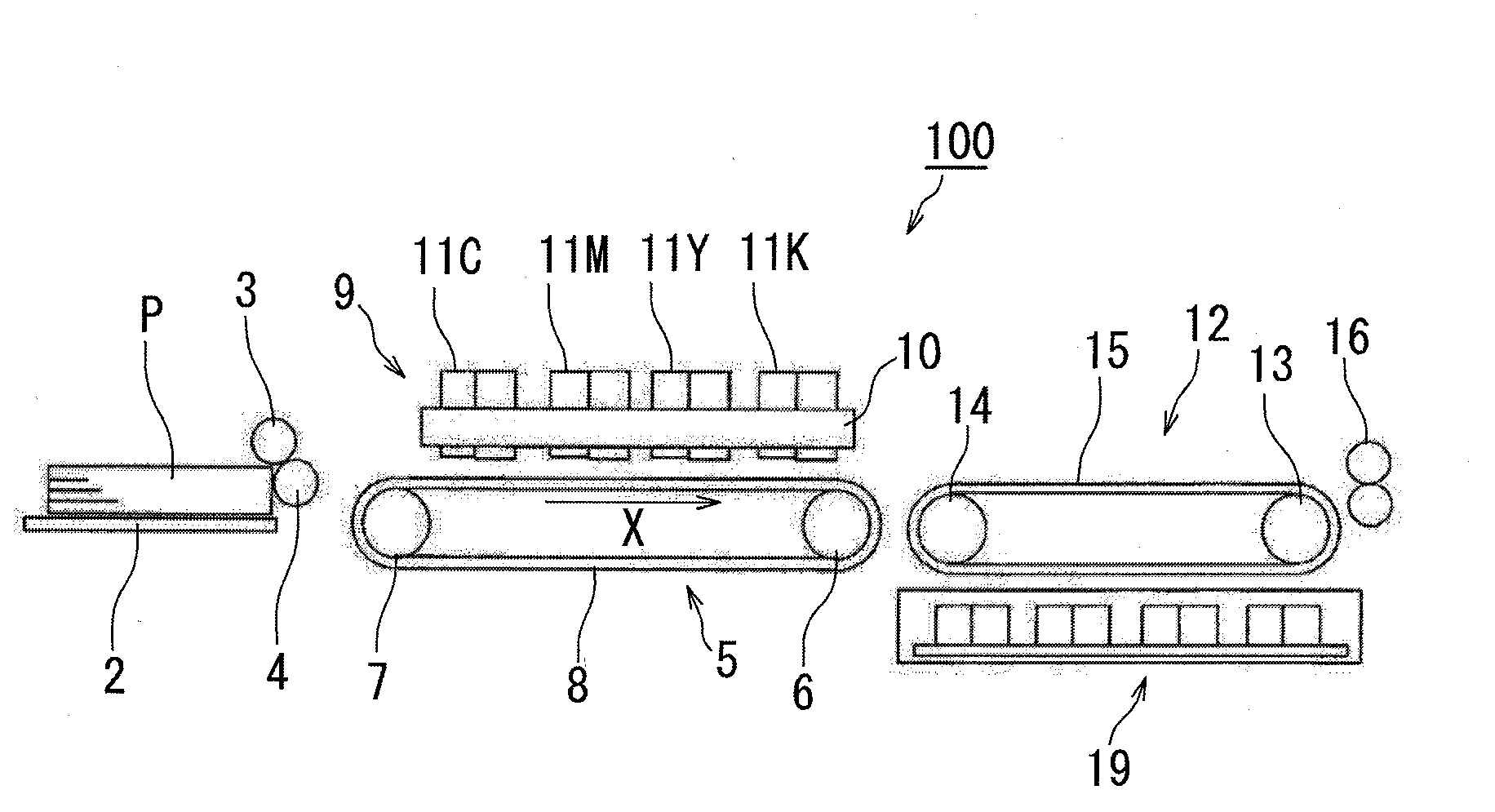

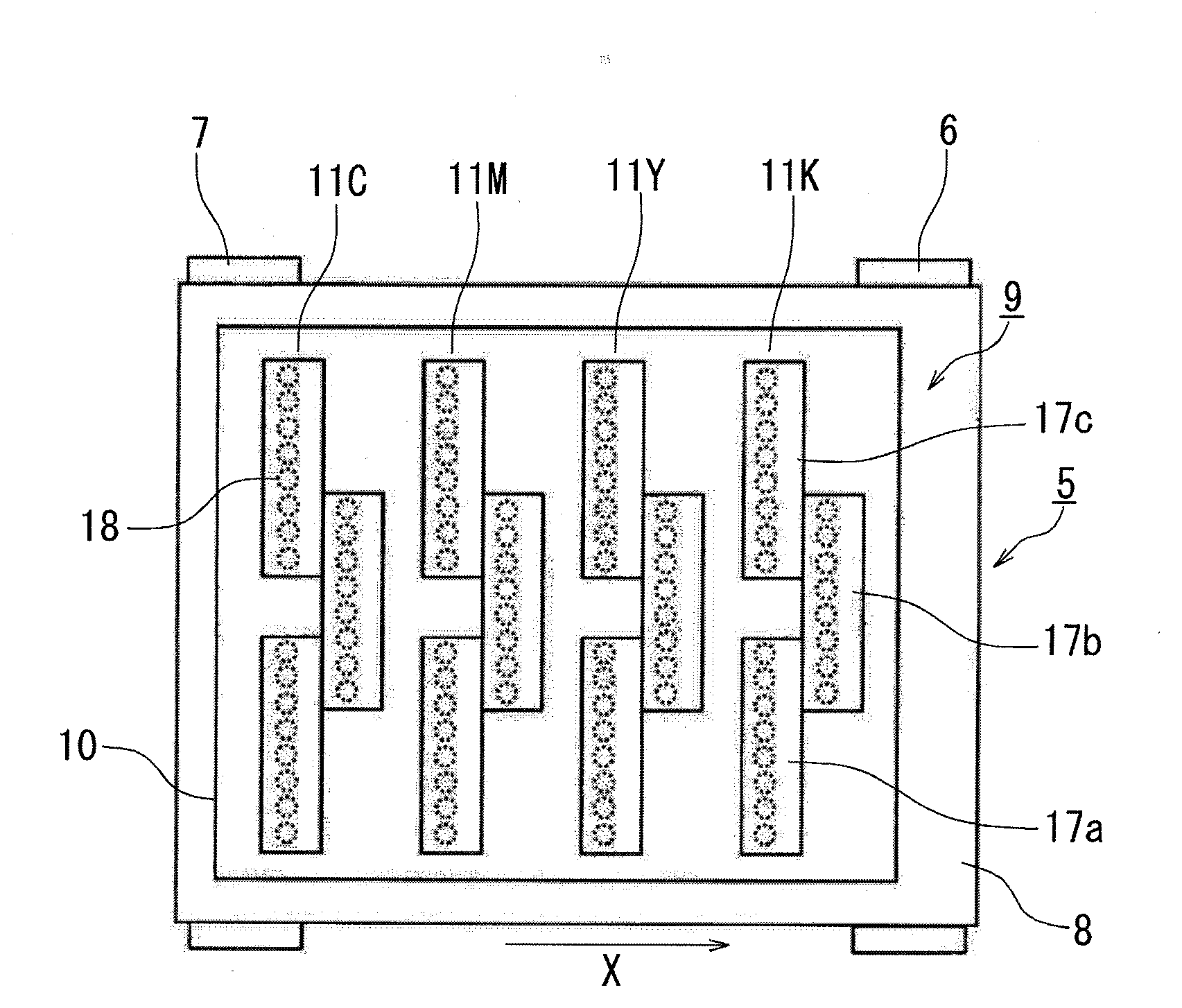

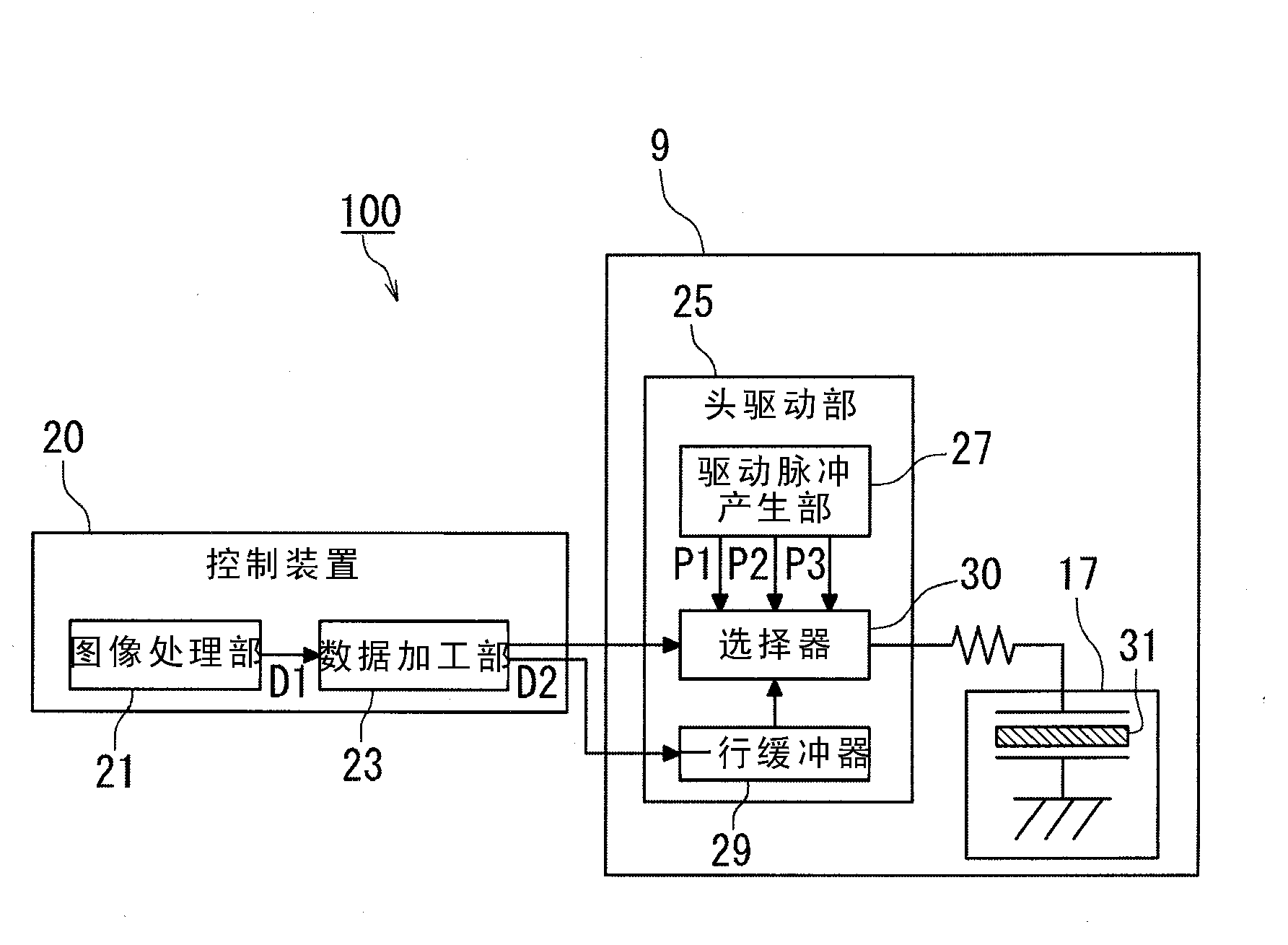

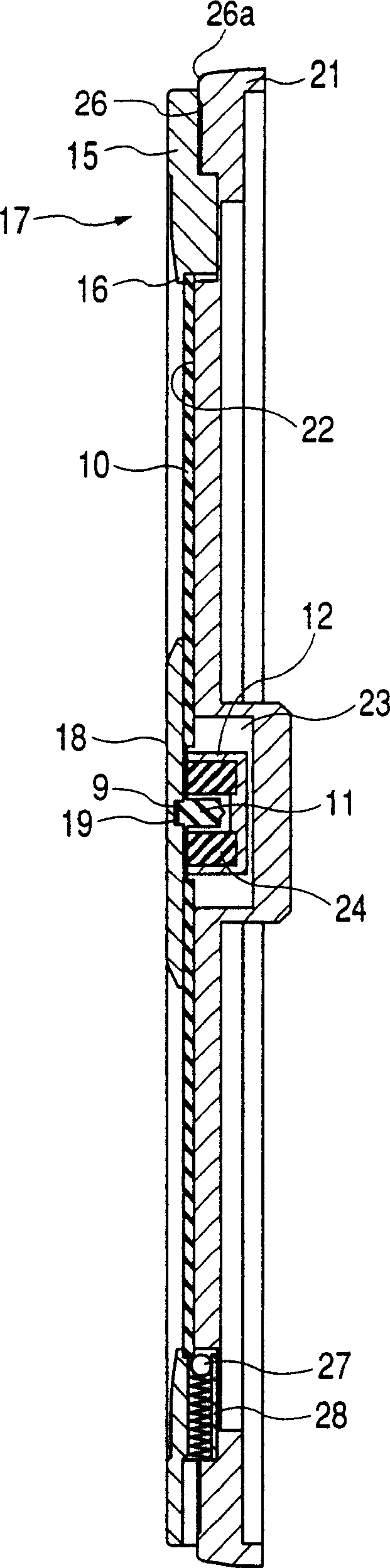

Inkjet recording device and image forming apparatus for stable ink ejection

ActiveCN103223772AGuaranteed positional relationshipReliable wiping actionPrintingElectricityEngineering

An inkjet recording device (100) includes a recording head (17), a head driving unit (25), and a controller (20). A selector (30) of the head driving unit (25) performs selection for individual nozzles so that when the drive waveform selection data for printing one line at this time sent from a data processing section (23) indicates that the number of times of ink ejection is 0, and drive waveform selection data for printing the next one line indicates that the number of times of ink ejection is 0, drive voltage according to none of one or more drive waveforms for ink ejection or a drive waveform for meniscus oscillation is applied to a piezoelectric element (31).

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Method for delivery of substrate to film forming device for disk-like substrate, substrate delivery mechanism and substrate holder used for the method, and method of manufacturing disk-like recording

InactiveCN1662977AGuaranteed positional relationshipVacuum evaporation coatingSputtering coatingSputteringMagnetic tension force

A substrate delivery method capable of holding a disk-like substrate without a center hole in the air and capable of easily transferring the substrate onto a spattering device, wherein projected parts are formed at both surface center parts of the disk-like substrate, the substrate is formed integrally of an outer mask covering the outer peripheral end part and the center part thereof, an inner mask holding the center of the substrate and fixed thereto, and an inner mask fixing magnet, a delivery mechanism holds the outer mask by a magnetic force and, at the same time, a substrate holder receiving the substrate holds the outer mask by the magnetic force, and the magnetic force on the delivery mechanism side is reduced at the time of delivery.

Owner:TDK CORPARATION

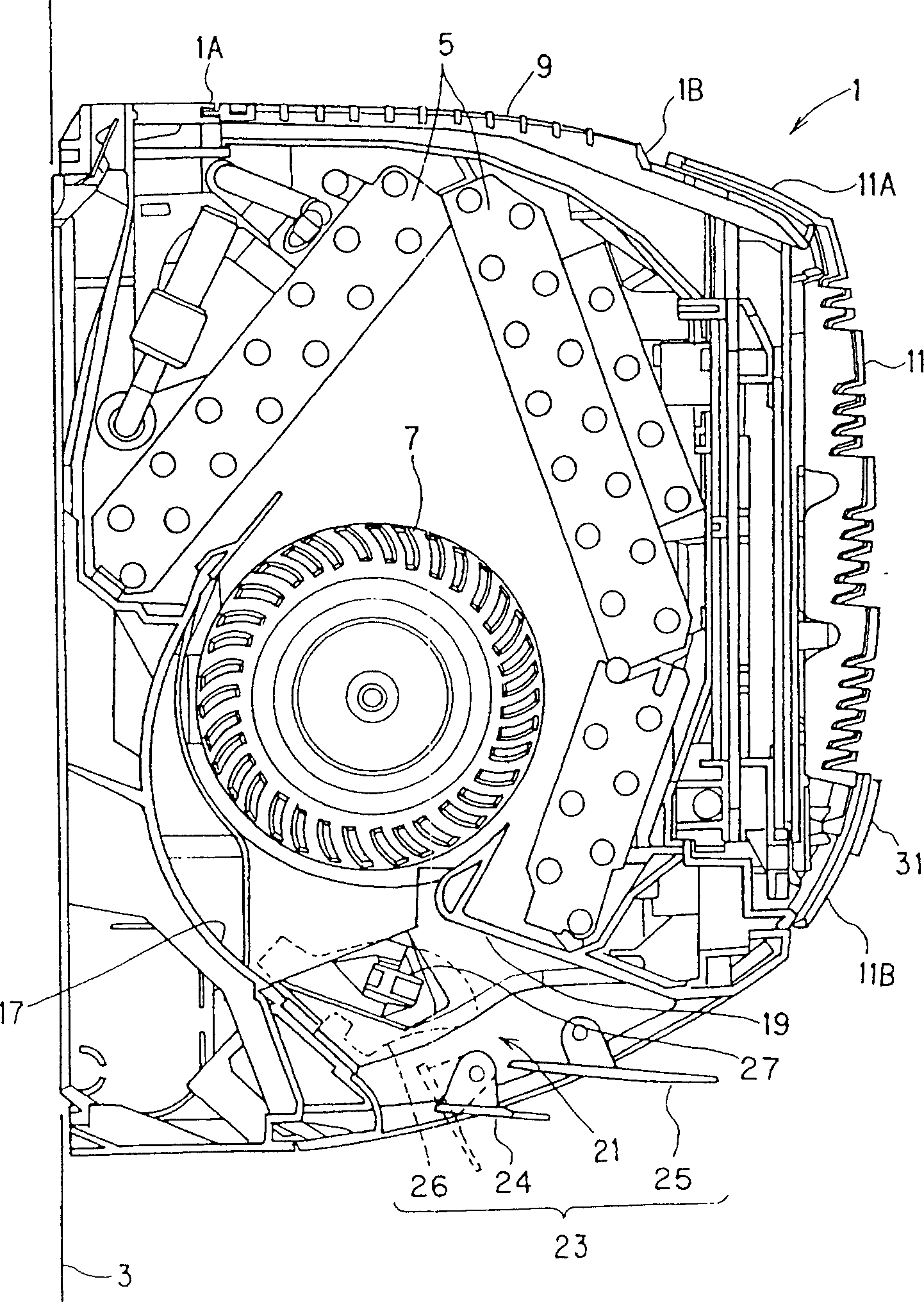

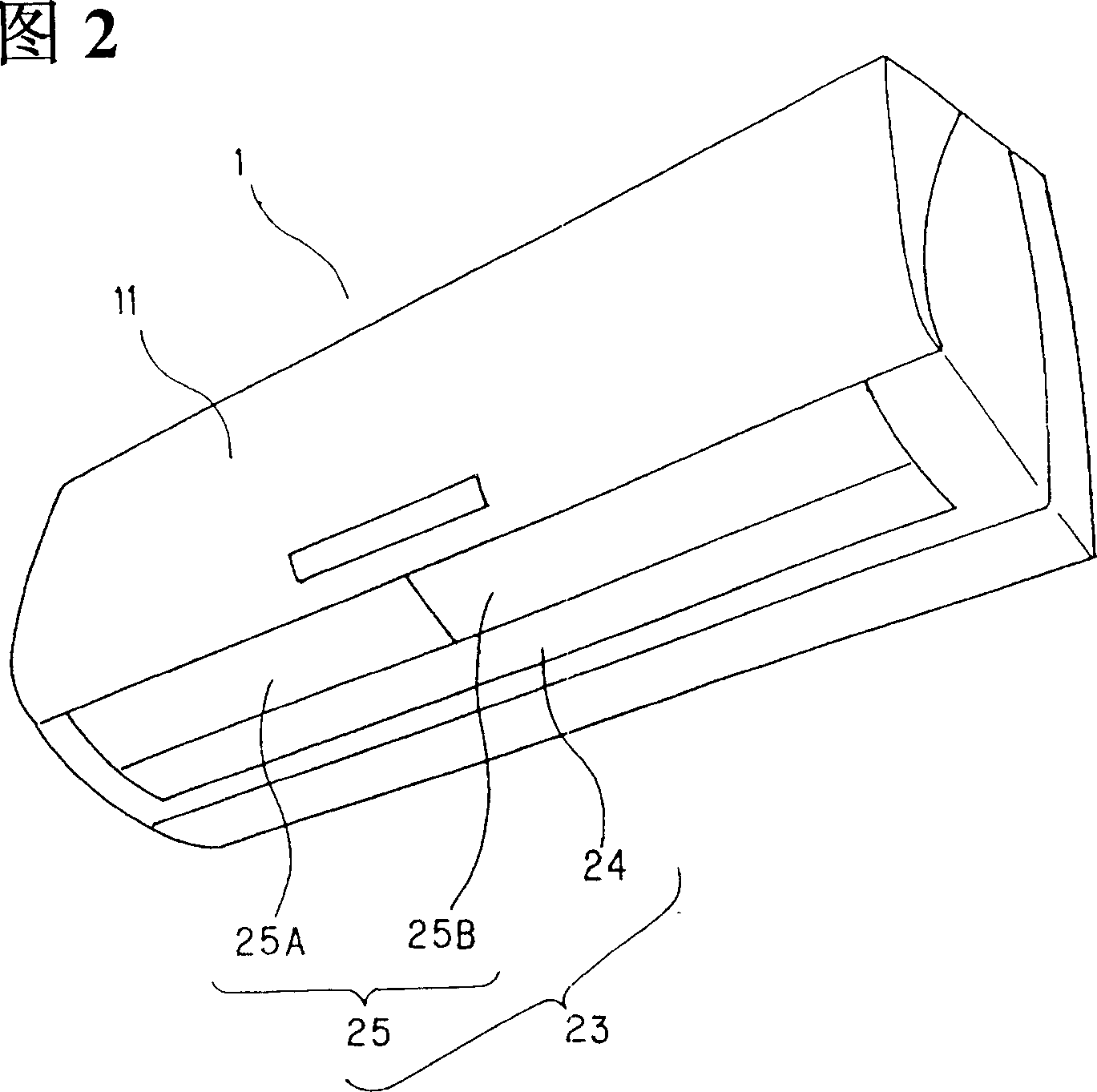

Wall air Conditioner

InactiveCN1415907ARegulation stabilityUniform air conditioningLighting and heating apparatusAir conditioning systemsCold airAir conditioning

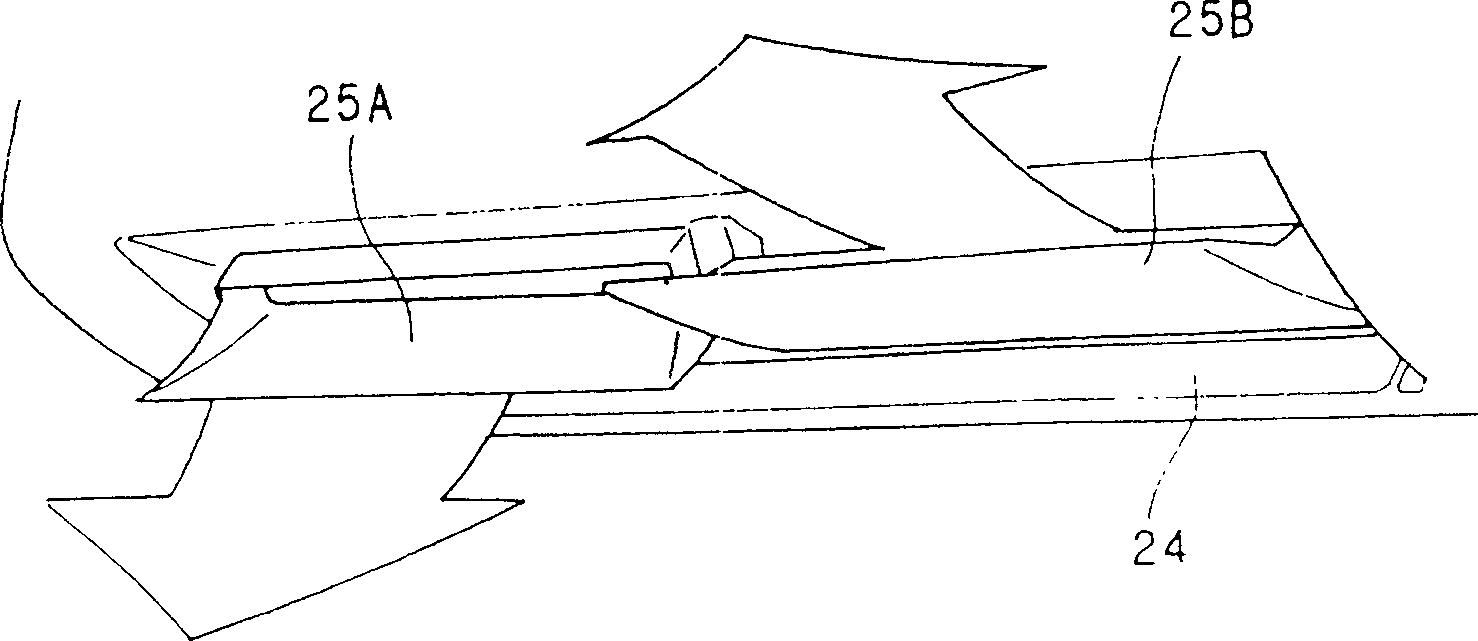

The problem to be solved by the present invention is to uniformly condition an air-conditioned room by having warm air or cold air to reaching every corner of the air-conditioned room. The solution of the present invention is that in a wall-mounted air conditioner, an air-conditioner body 1 with an air flow discharge port comprising air flow orienting plate means 23. The air flow orienting plate means comprises upper side horizontal air gate plates 25A and 25B and a lower side horizontal air gate plate 24, wherein the upper side horizontal air gate plates 25A and 25B are arranged in an upper longitudinal axis direction within the air discharge port, while the single piece of horizontal air gate plate 24 is arranged to extend in a lower longitudinal axis direction. The upper side horizontal air gate plates 25A and 25B are allowed to rotate in opposite directions within an arbitrary range of longitudinal arrangement, while the lower side horizontal air gate plate 24 is allowed to rotate within a range smaller than the rotation range of the upper side air gate plates.

Owner:SANYO ELECTRIC CO LTD +1

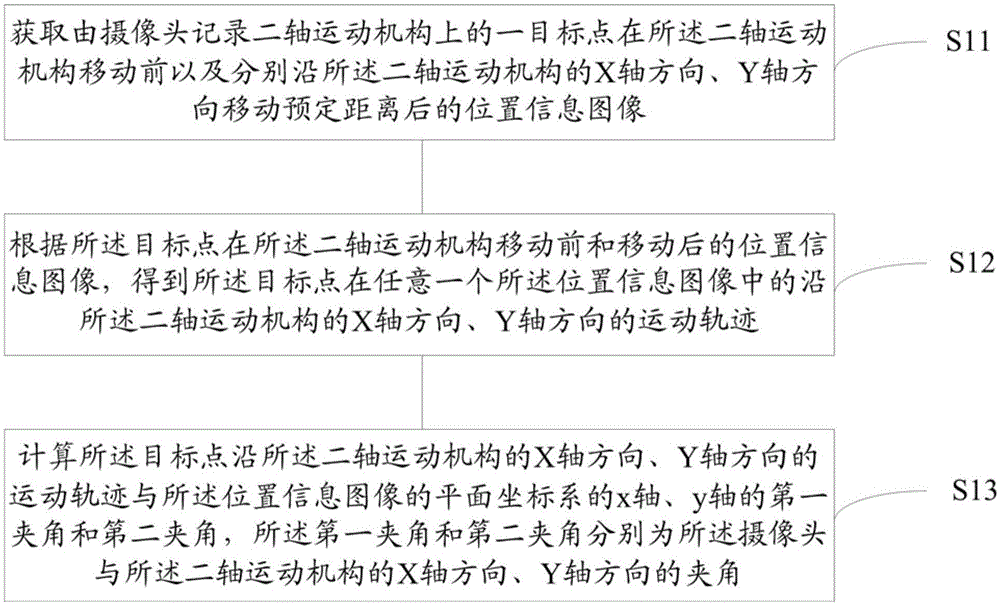

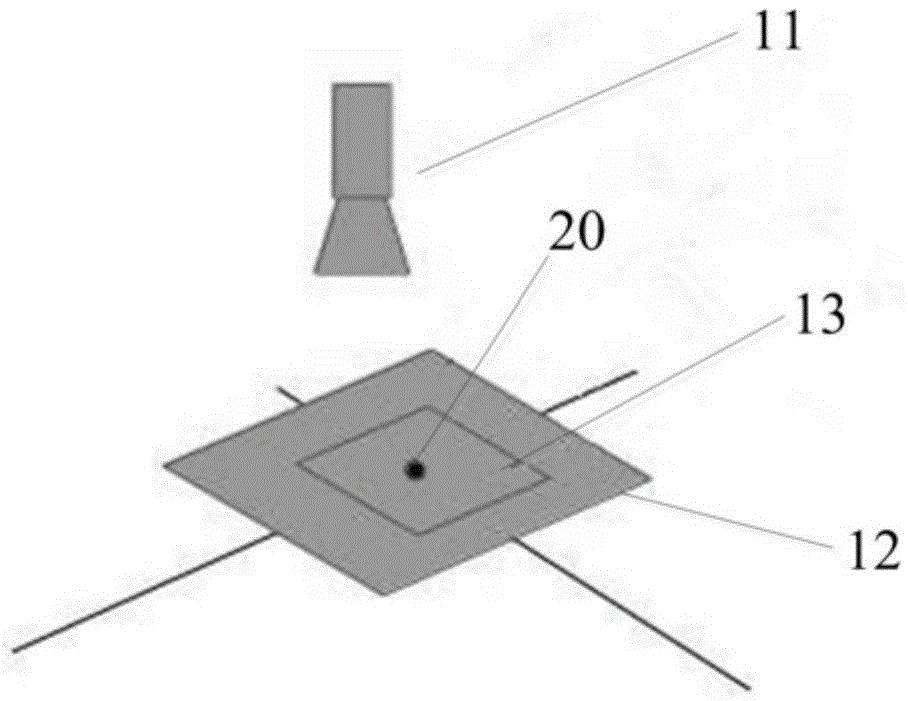

Included angle measurement method and device and angle adjustment method and device

ActiveCN105627954AGuaranteed positional relationshipSatisfy a certain positional relationshipUsing optical meansMeasurement deviceClassical mechanics

The present invention discloses an included angle measurement method which comprises a step of obtaining the motion trajectory of a target point in a two-axis motion mechanism along the X-axis direction and the Y-axis direction of the two-axis motion mechanism, and a step of calculating the first angle and the second angle of the motion trajectory of the target point along the X-axis direction and the Y-axis direction and the x axis and y axis of the imaging plane coordinate system of a camera, wherein the first angle and the second angle are the angles of the camera and the x axis direction and y axis direction of the two-axis motion mechanism. The invention also provides an angle measurement device and an angle adjustment device. By using the embodiment of the present invention, the angle of the camera and the motion mechanism can be accurately measured, and the camera is adjusted based on the measured angle so as to ensure that the camera and the motion mechanism satisfy a certain positional relationship.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Device for detaching suspension arm type component in narrow space

ActiveCN103072114AAvoid damageGuaranteed positional relationshipMetal-working hand toolsMechanical componentsMechanical engineering

Owner:FACTORY 5721 OF PLA

Cutting machine and cutting control device

InactiveCN107009407AEnsure consistencySmall size deviationMetal working apparatusControl systemEngineering

The invention provides a cutting machine and a cutting control device, and relates to the technical field of cutting equipment. The cutting machine includes a frame on which a loading platform for placing materials, a A cutting knife and a positioning piece and a limiting piece for limiting the position of the material on the loading platform; between. The cutting control device includes a control system and the above-mentioned cutting machine, and the control system is electrically connected with the cutting machine. The cutting machine and the cutting control device solve the technical problems in the prior art that the size deviation of the patch stone after cutting is large, affects the subsequent construction, and the cutting efficiency is not high, time-consuming and laborious, and achieves small size deviation after cutting, The cutting process is highly efficient and has the technical effect of saving time and effort.

Owner:浙江久石工研建材科技有限公司

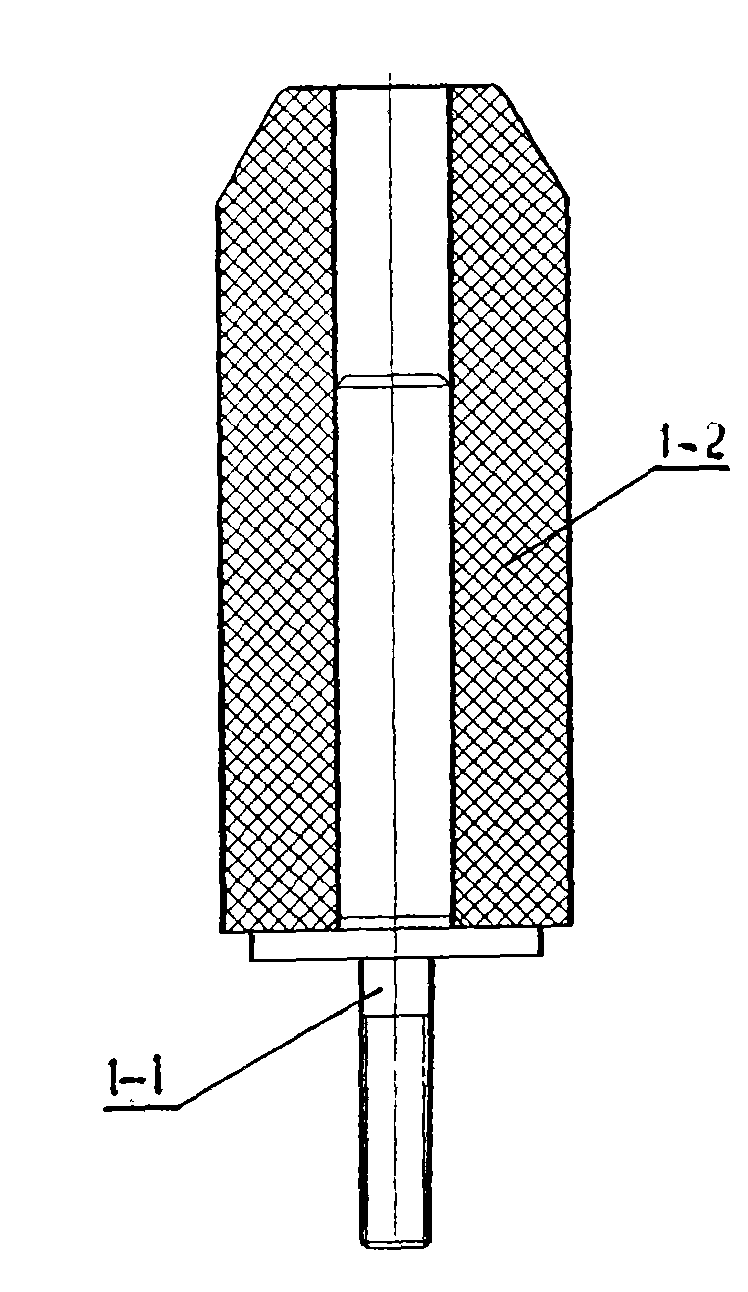

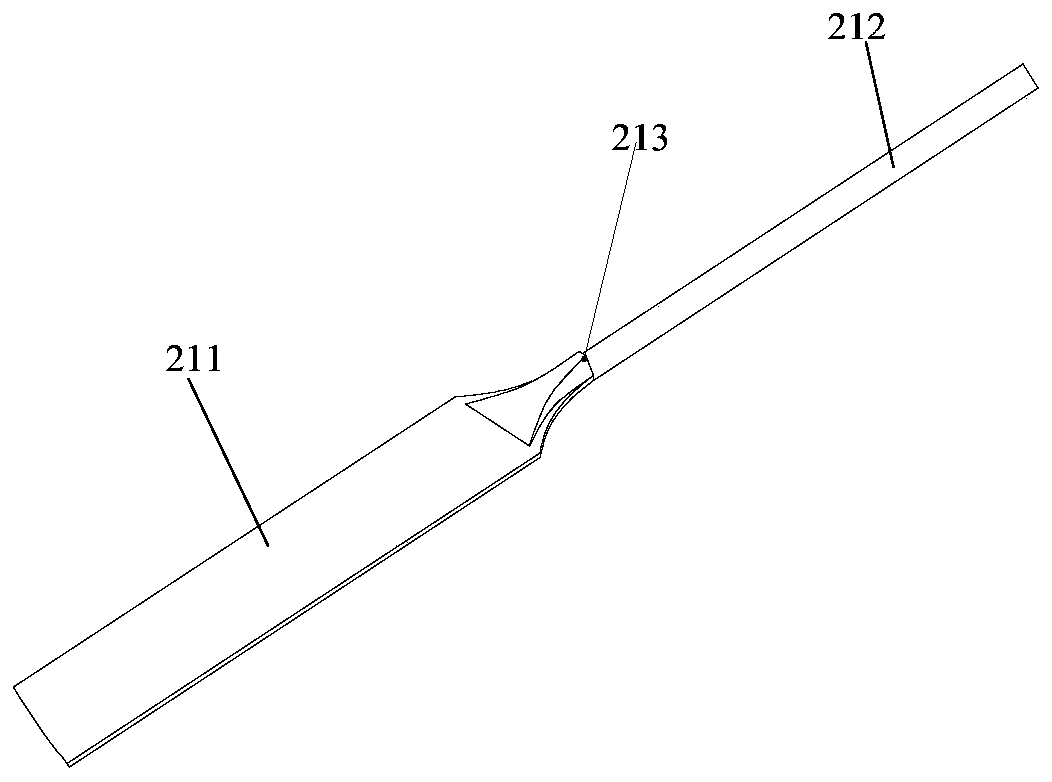

Cylindrical thin-walled workpiece machining and forming tool and method

InactiveCN112338601AImprove performanceGuaranteed dimensional accuracyElectron beam welding apparatusPositioning apparatusMachining processMachine tool

The invention discloses a cylindrical thin-walled workpiece machining and forming tool and method. The method comprises the steps of dividing a to-be-machined cylindrical thin-walled workpiece into aplurality of circular ring structures, accordingly machining each circular ring structure, assembling all machined circular ring structures together, carrying out vacuum electron beam welding so as toobtain a combined component, carrying out vacuum annealing and finish machining on the combined component to obtain the final cylindrical thin-wall workpiece. The machining tool comprises an inner-surface machining tool body, an outer-surface machining tool body and an assembling and welding tool body, the inner-surface machining tool body is used for clamping a circular ring structure when the inner surface of the circular ring structure is machined, the outer-surface machining tool body is used for clamping the circular ring structure when the outer surface of the circular ring structure ismachined, and the assembling and welding tool is used for assembling all the cylinders together when all the circular ring structures are welded into the combined component. According to the tool andmethod, the deformation of the cylindrical thin-walled workpiece in the machining process can be improved and controlled, and the machining precision is guaranteed.

Owner:SHAANXI HEYE SPECIAL STEEL TOOL

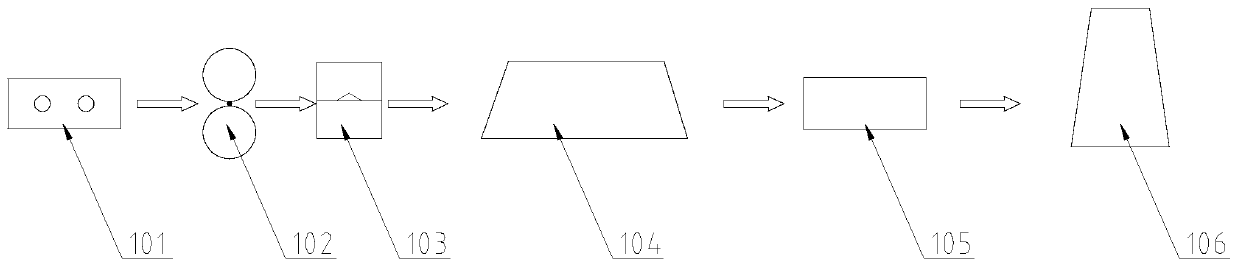

Efficient seamless solar battery assembly series welding method

ActiveCN110783429AImprove flexibilityGuaranteed positioning accuracyFinal product manufacturePhotovoltaic energy generationMetallurgyElectrical battery

The invention relates to an efficient seamless solar battery assembly series welding method. The method is characterized in that a copper strip raw material is pressed into a long-strip-shaped special-shaped solder strip with a plurality of circulating units through a solder strip wiredrawing and coating device; the solder strip is divided into special-shaped solder strip sections of a single circulating unit through a solder strip roll-off device; scaling powder is uniformly coated on a surface of the solder strip through a solder strip coating device; the special-shaped solder strip sectionsare moved to a solder strip jig disc and arranged in the solder strip jig disc according to a battery design pattern, and solder strip disc units are formed after the solder strip jig disc is filledwith the special-shaped solder strip sections; the solder strip disc units are moved to a battery piece stacking transmission line; battery pieces are moved to the battery piece stacking transmissionline; the solder strip disc units and the battery pieces are stacked in a staggered manner to form a preformed battery string; the battery pieces are transmitted to a heating welding device through the battery piece stacking transmission line, and the special-shaped solder strip sections are fully and uniformly welded in the preformed battery string with the battery pieces through temperature heating to form a formed battery string. The method is advantaged in that special-shaped solder strip connection can reduce a connection interval of the battery pieces and improve the power and the lightabsorption effect of a battery assembly.

Owner:江阴德龙能源设备有限公司

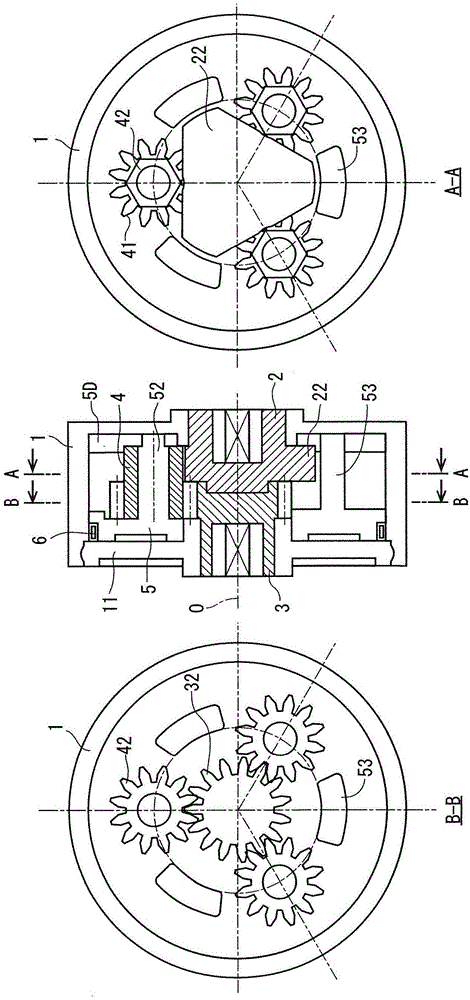

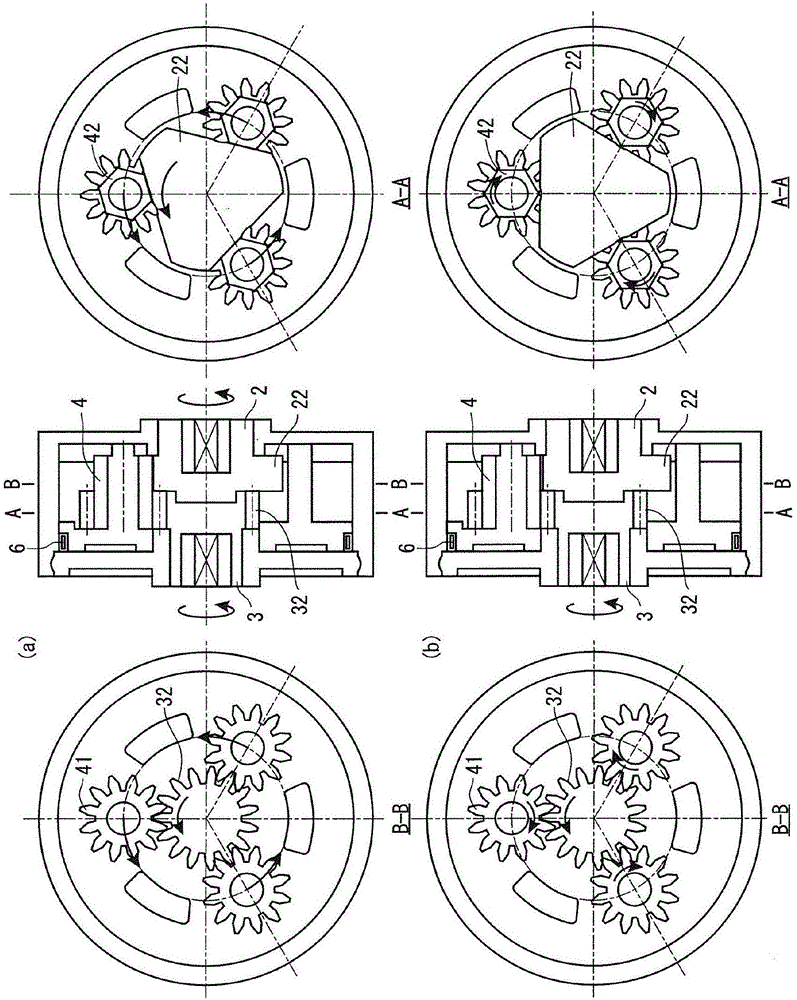

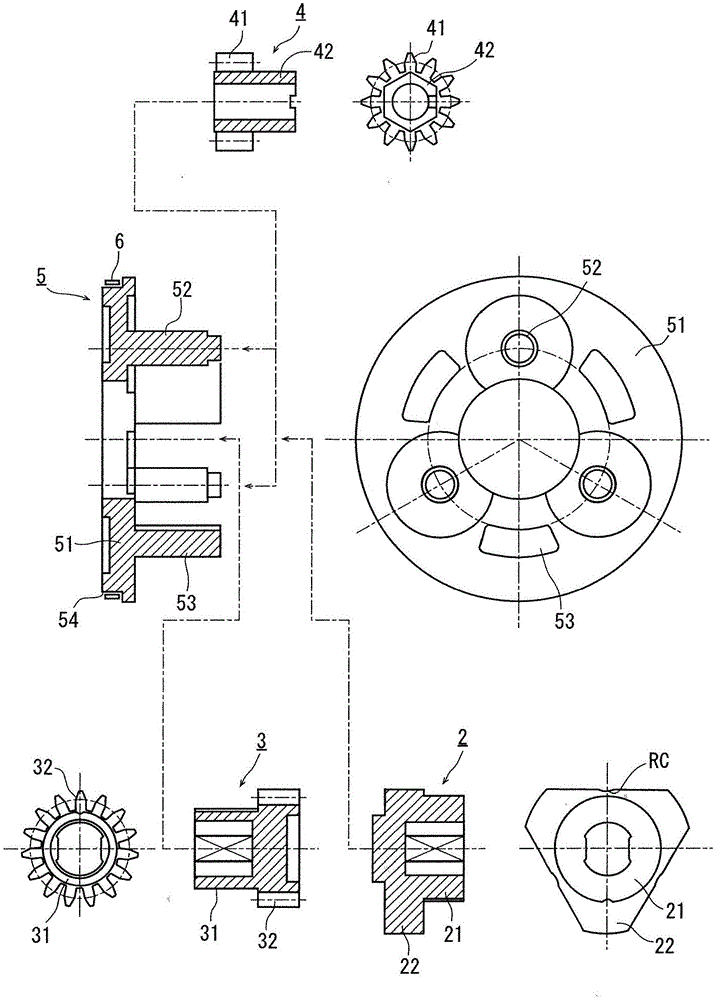

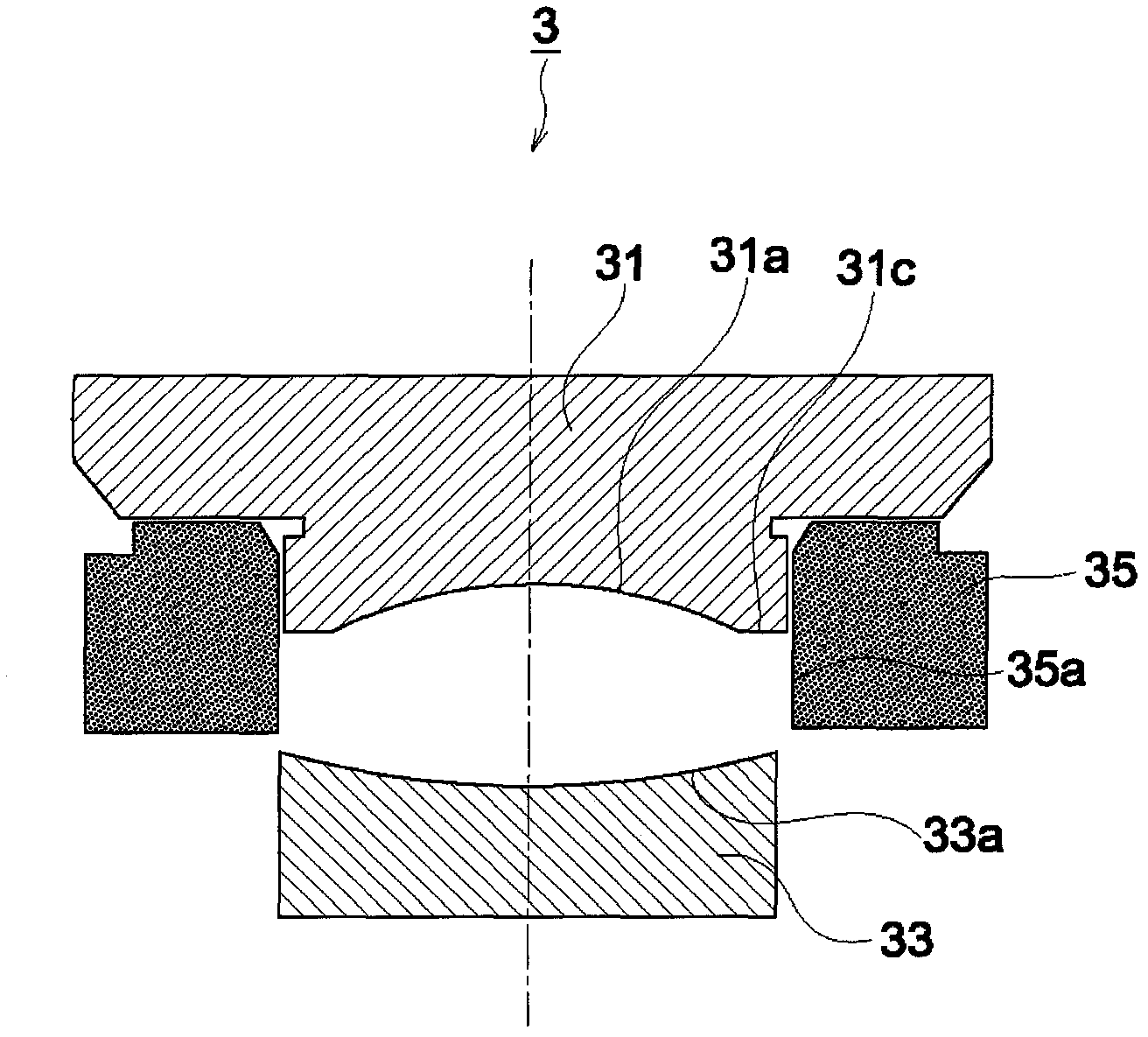

Free bidirectional clutch utilizing gear idle

The invention provides a free bidirectional clutch utilizing gear idle. By the use of the gear capable of idling, rotation of an input shaft can be transmitted to an output shaft and rotation transmission from the output shaft to the input shaft can be cut off. An input shaft and an output shaft with the same rotation axis as the center are disposed in a housing incapable of rotating; a concentric gear is formed on the output shaft; the periphery of the concentric gear is equipped with a planetary gear body of an external gear engaged with the concentric gear; a planetary gear body shaft is supported on a planetary rack; the planetary gear is provided with a protruding part protruding along the axis; the protruding part is configured in a position, where the protruding part can be buckled with an input rotation body formed on the input shaft; a linear part is formed in cross sections of the protruding part and the input rotation body; upon rotation of the input shaft, revolution of the planetary gear is stopped and the planetary gear is locked and rotation can be transmitted to the output shaft; upon rotation of the output shaft, the planetary gear idles and rotation to the input shaft can be cut off.

Owner:ORIGIN CO LTD

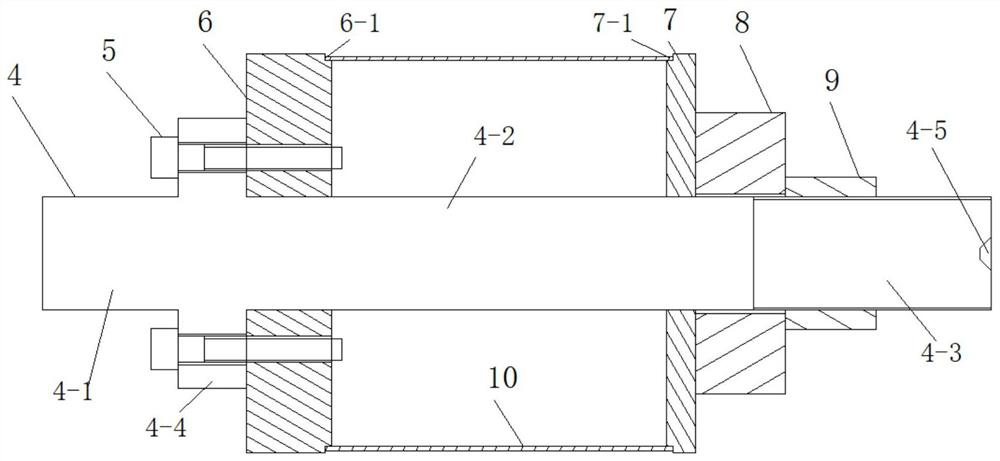

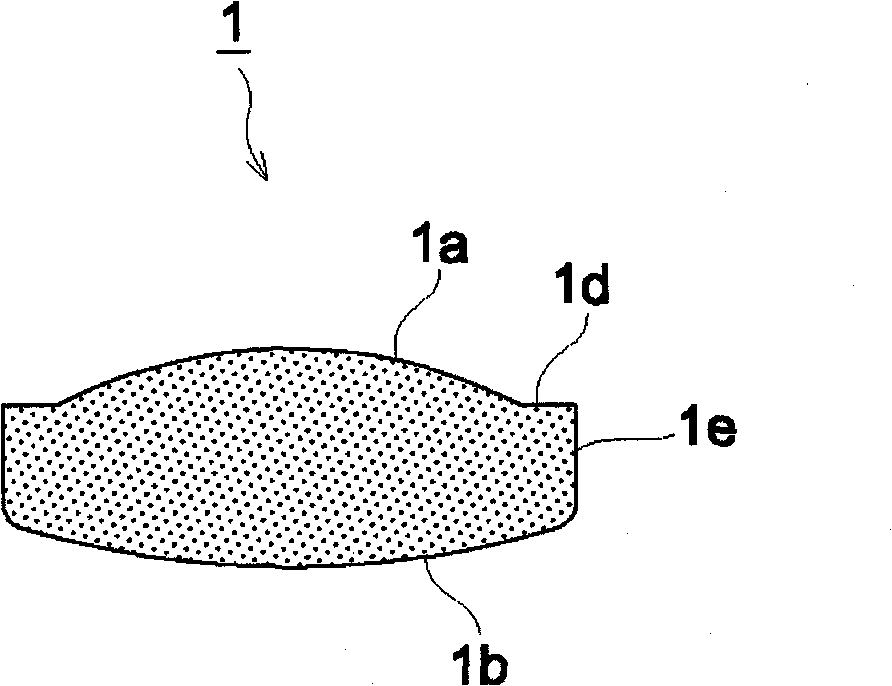

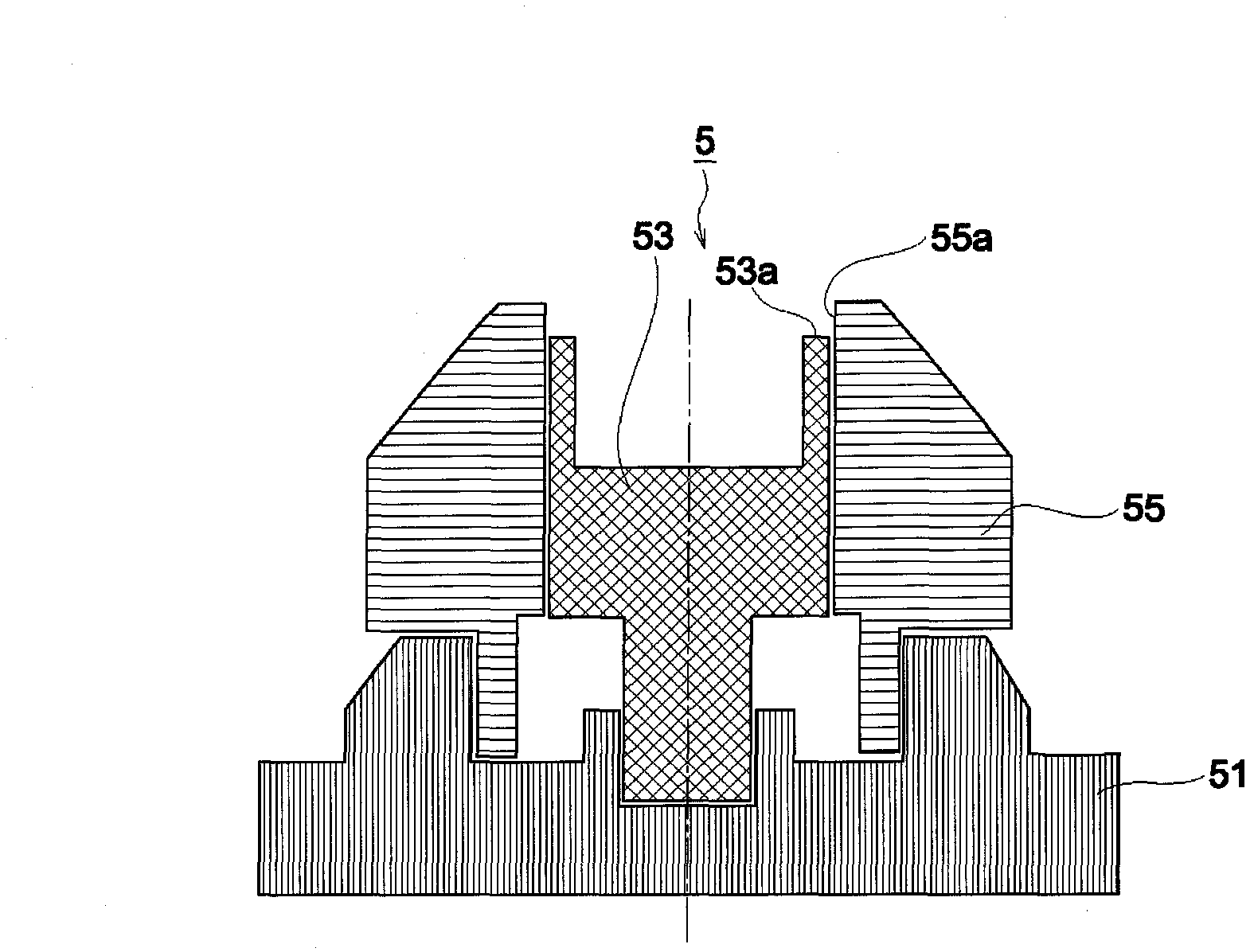

Aspheric lens manufacturing method

InactiveCN102216812AGuaranteed positional relationshipShape is not limitedGlass pressing apparatusGlass press-moulding apparatusAspheric lensOptoelectronics

Provided is an aspheric lens manufacturing method by which an aspheric lens having a desired shape can be manufactured with high accuracy regardless of the shape of a glass compact without reducing productivity. The aspheric lens manufacturing method for forming the aspheric lens by pressing and machining a glass material, comprises a pressing step for pressing the glass material to thereby form the aspheric surface, the flat surface of the peripheral edge of the aspheric surface, and the side surface continuous to the flat surface at the same time and form the glass compact, a mounting step for mounting the glass compact in a work holder which holds and positions the glass compact by being in contact with the flat surface and the side surface of the glass compact formed in the pressing step, and a machining step for machining the other surface of the glass compact mounted in the work holder in the mounting step to thereby form the other surface into a predetermined surface shape.

Owner:KONICA MINOLTA OPTO

Efficient cutting equipment for PVC pipe production and PVC pipe production process

ActiveCN113103324AGuaranteed stabilityReasonable structureMetal working apparatusGear wheelElectric machinery

The invention discloses efficient cutting equipment for PVC pipe production and a PVC pipe production process, and relates to the field of cutting devices. The efficient cutting equipment comprises a base, a mounting plate is fixedly connected to one side of the base, a mounting ring is fixedly connected to the top of the mounting plate, and a PVC pipe clamping mechanism is mounted on the side wall of the mounting ring. A PVC pipe conveying mechanism is mounted on the PVC pipe clamping mechanism, a plurality of round rod shafts are fixedly connected to one side of the base, and hollow rods rotationally sleeve the round rod shafts. The efficient cutting equipment for the PVC pipe production is reasonable in structure, a conveying motor drives a first gear to rotate clockwise, the first gear is matched with a second gear and a third gear to rotate, a half gear is driven to rotate clockwise, when the half gear rotates clockwise, a clamping plate is driven to rotate, and when meshing of the second gear and the half gear is finished, the clamping plate rotates to a limiting position; and at the moment, the second gear is in a continuous tangent process with a last tooth of the half gear during rotation.

Owner:唐山冀鸿节水科技有限公司

Registration method based on datum constraint and allowance constraint of cylindrical surface

ActiveCN110850808AGuaranteed positional relationshipLess freedomProgramme controlComputer controlAlgorithmMachined surface

The invention discloses a registration method based on a datum constraint and an allowance constraint of a cylindrical surface, comprising the following steps of S1, selecting a theoretical cylindrical surface datum according to the cylindrical surface; S2, respectively detecting a to-be-machined surface and a reference portion of a part; S3, fitting cylindrical surface detection points to obtainthe fitted cylindrical surface datum, moving the theoretical cylindrical datum to the fitted cylindrical surface datum to obtain a first rotation matrix R1 and a first translation vector T1, and transforming to-be-machined surface detection points according to the first rotation matrix R1 and the first translation vector T1 to obtain theoretical machining points; S4, establishing a local coordinate system, then establishing a registration model under the local coordinate system. limiting the freedom of motion through the local coordinate system, controlling the machining allowance of the to-be-machined surface through the allowance constraint, and solving the registration model; and S5, converting a registration result calculated in the local coordinate system into a global coordinate system and outputting a final registration result. The registration method is applied to the field of machining.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

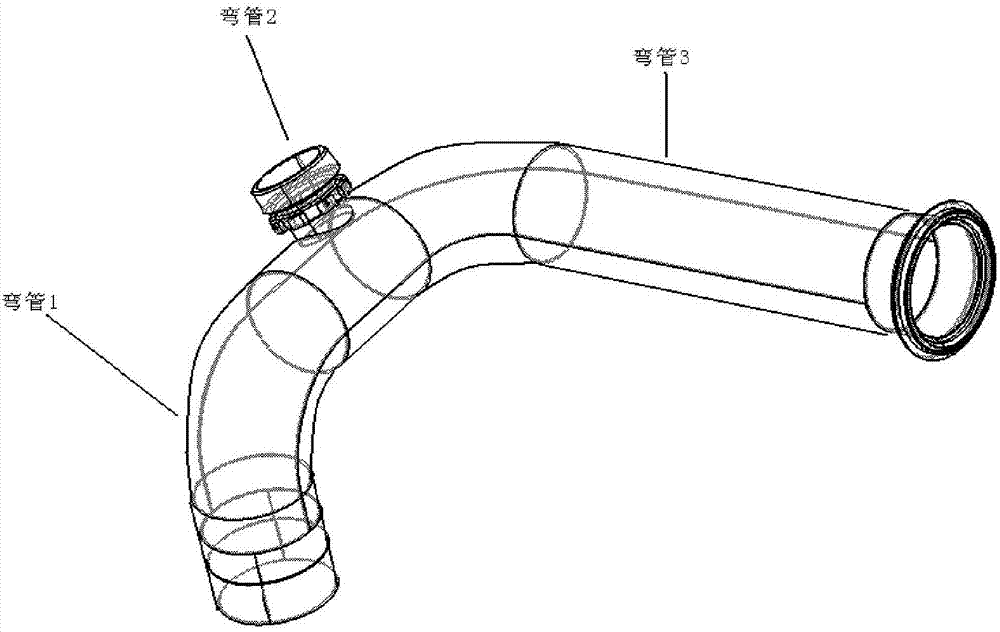

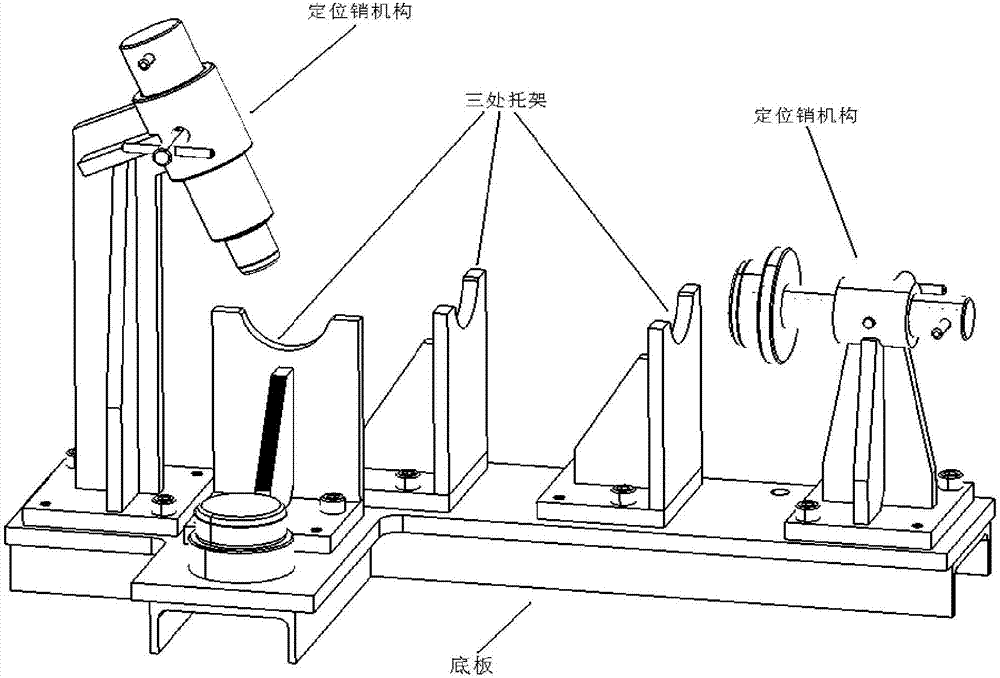

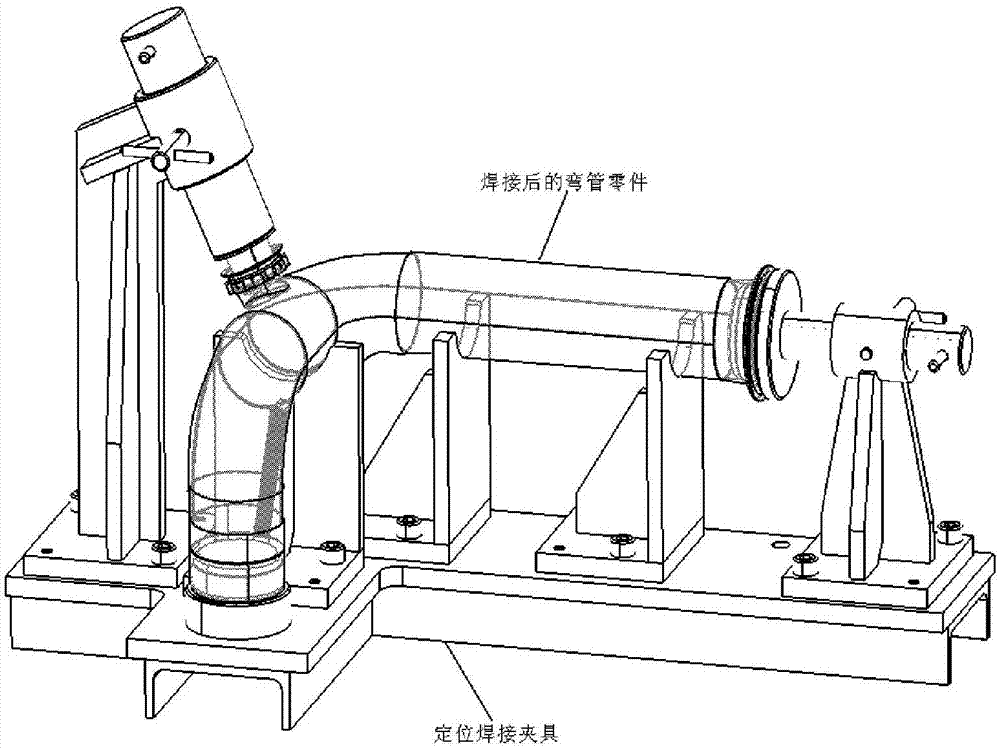

Method for machining positioning welding clamp

ActiveCN106956112AGuaranteed Tolerance RequirementsGuaranteed positional relationshipWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal forces

The invention belongs to the field of machining, and provides a method for machining a positioning welding clamp. The machining method includes the steps that firstly, a bottom plate used for connecting three brackets and two positioning pin mechanisms is machined, and position lines of the brackets and the positioning pin mechanisms are drawn through a numerically-controlled needle; secondly, after single-piece machining and welding are conducted on the brackets and the positioning pin mechanisms, internal force is removed through annealing, the bottom faces of the brackets and the positioning pin mechanisms are milled to be flat through a milling machine, and it is ensured that the brackets and the positioning pin mechanisms are attached to the bottom plate; and thirdly, the whole bottom plate, the whole brackets and the whole positioning pin mechanisms are machined, the bottom plate, the brackets and the positioning pin mechanisms are measured to be qualified after numerically-controlled machining, and inspection is conducted after bench workers polish numerically-controlled machining moulding faces. The machining method has the beneficial effects that due to the adoption of the machining method, the relative position relationship of the three brackets and the positioning pin mechanisms can be ensured, and the tolerance requirement of the positioning and welding clamp can be ensured.

Owner:SHENYANG AIRCRAFT CORP

Magnetic head and its mfg. method

InactiveCN1480922AAvoid unevennessGuaranteed positional relationshipManufacture head surfaceManufacture unitary devices of plural headsEngineeringElectrical and Electronics engineering

In a magnetic head according to the present invention, a base is provided with at least one first positioning hole and a magnetic core half has a back portion which is disposed in the first positioning hole. In addition, the base is further provided with at least one first recess at the periphery of the first positioning hole and the base is partially deformed due to the first recess such that a portion of the base at the periphery of the first positioning hole is shifted to press the back portion of the magnetic core half against an inner side of the first positioning hole. Accordingly, the present invention provides a magnetic head in which the magnetic core half can be reliably fixed to the base and a method for manufacturing the magnetic head.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com