Optical device coupling device and coupling method

A technology of coupling device and optical device, which is applied to the coupling of optical waveguides, optical components, light guides, etc., can solve the problems of low coupling and welding efficiency of optical devices and adapters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

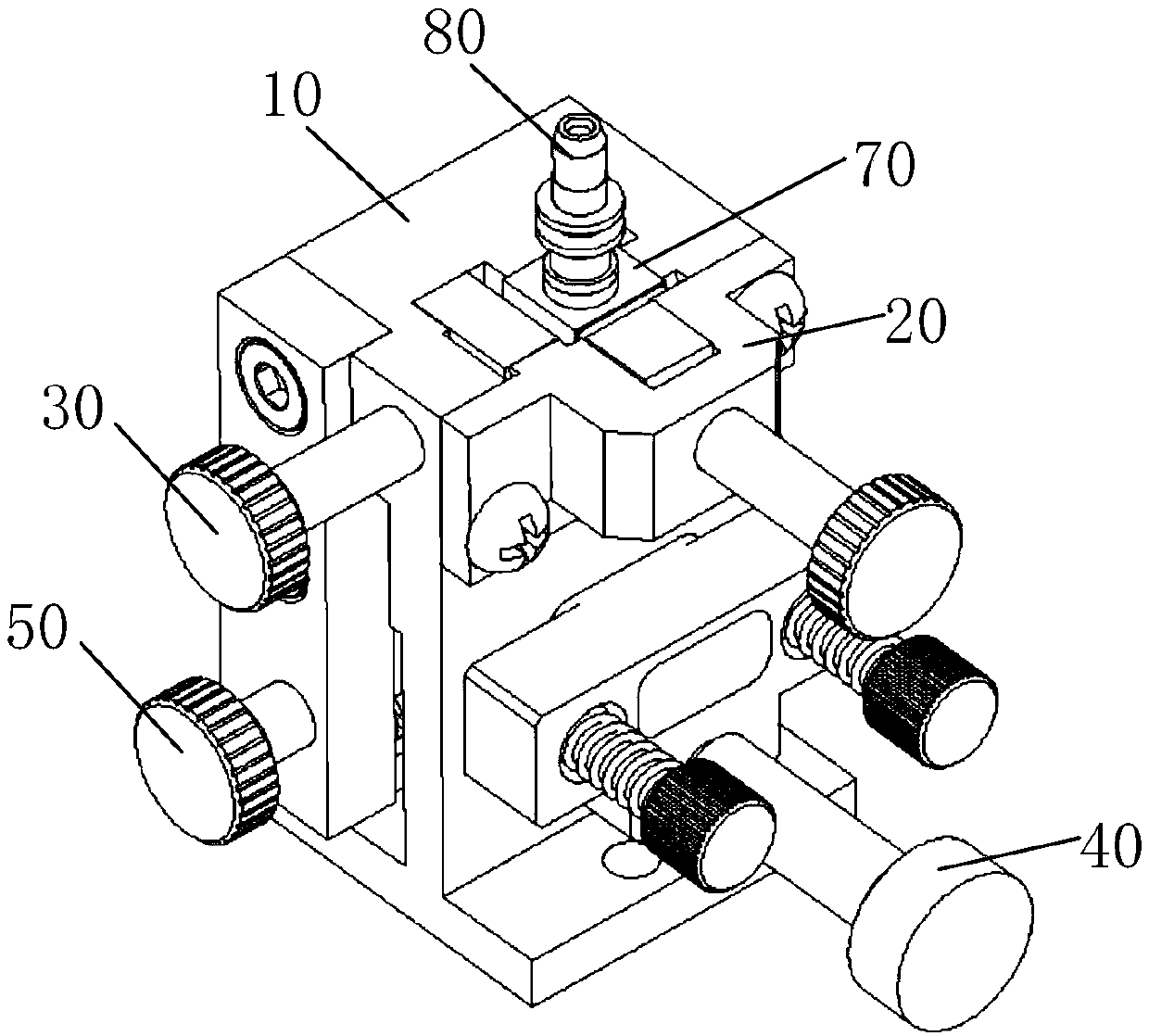

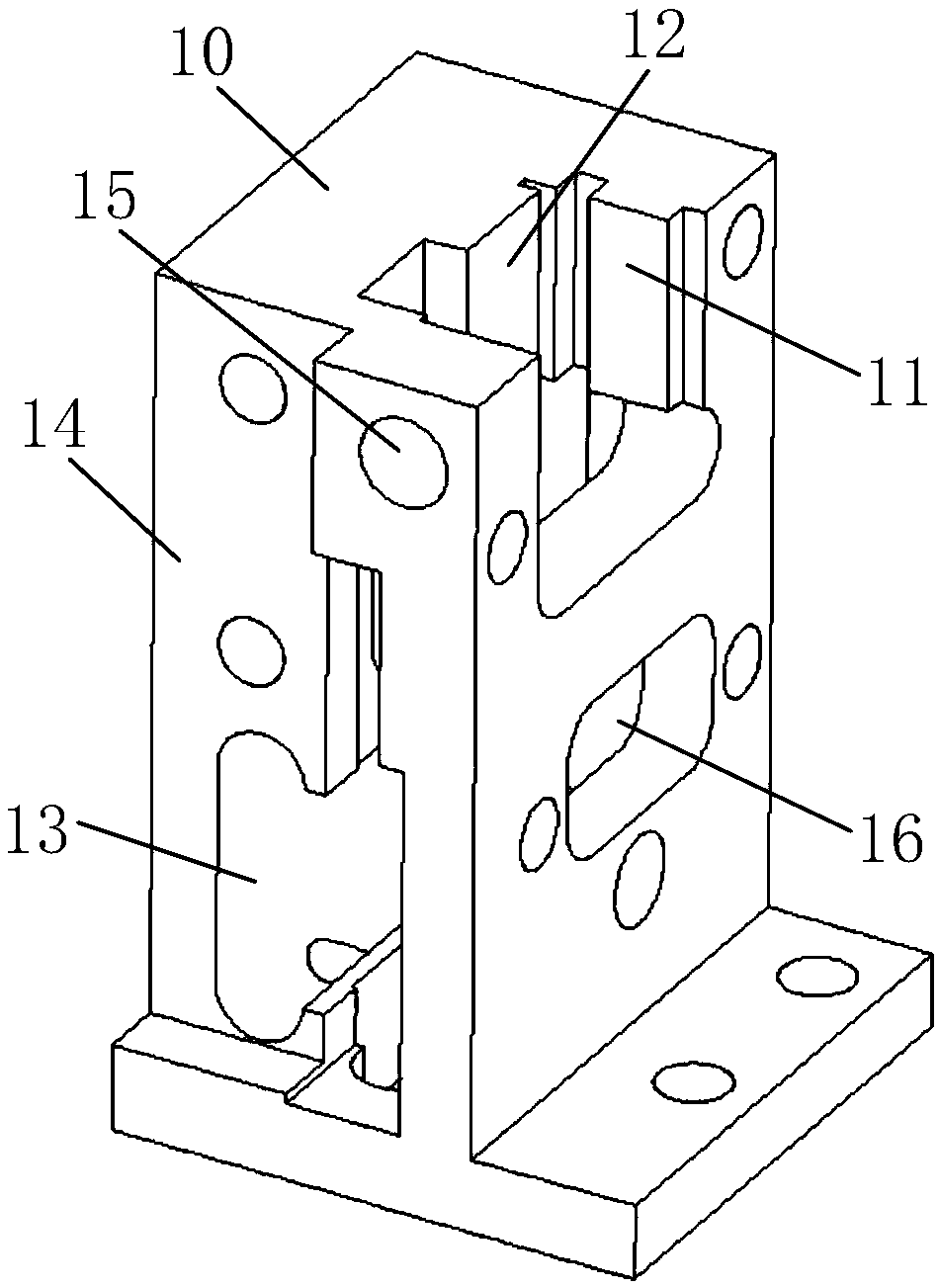

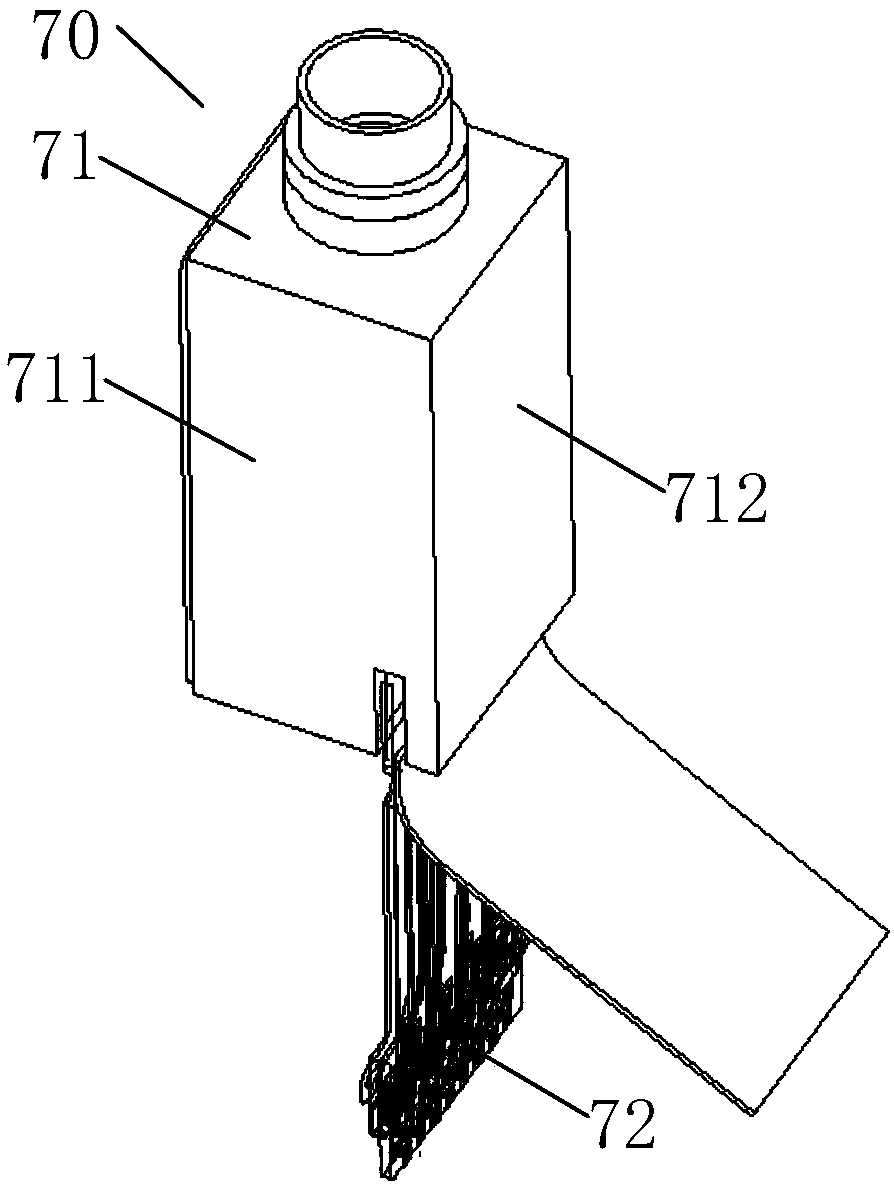

[0037] Embodiment 1 of the present invention provides an optical device coupling device, such as figure 1 As shown, it is an assembly diagram of an optical device coupling device provided by an embodiment of the present invention, including a coupling base 10, a top pressure component 20, a side pressure component 30, a soft belt pressure component 40, a PCB adjustment component 50, an optical device 70 is disposed on the coupling base 10 , and the adapter 80 is installed on the optical device 70 to facilitate welding with the optical device 70 . The top pressure assembly 20 and the side pressure assembly 30 are used to position the main body of the optical device 70; the PCB adjustment assembly 50 and the soft belt pressurization assembly 40 are used to connect the flexible belt of the optical device 70 to the power PCB. connect. Among them, the pressing assembly 20 and the flexible belt pressing assembly 40 are arranged on the front of the coupling base 10, and the pressing...

Embodiment 2

[0045] Embodiment 2 of the present invention provides an optical device coupling method, using the structure of the optical device coupling device described in Embodiment 1, such as Figure 9 as shown, Figure 9 It is a flow chart of an optical device coupling method provided by an embodiment of the present invention. The following optical device coupling methods are combined Figure 1 to Figure 8 To illustrate, optical device coupling methods include:

[0046] Step 100: Adjust the top pressure component, the side pressure component and the soft belt pressure component, and place the optical device in the coupling base;

[0047] Adjust the pressing assembly 20, the side pressing assembly 30 and the soft belt pressing assembly 40, that is, unscrew the pressing rod 22 of the pressing assembly 20, and the pressing rod 22 drives the pressing slide block 23 to retreat; the side pressing assembly 30 The side pressure pull rod 31 is unscrewed, and the side pressure pull rod 31 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com