Silicon waveguide spot size converter based on multilayer polymer structure and preparation method thereof

A mode spot converter and silicon waveguide technology, which is applied to optical waveguides, light guides, instruments, etc., can solve the problem of low coupling efficiency between mode spot converters and ordinary single-mode fibers, and facilitate large-scale optical circuit integration and improve coupling. Efficiency and the effect of improving the matching degree of mode spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

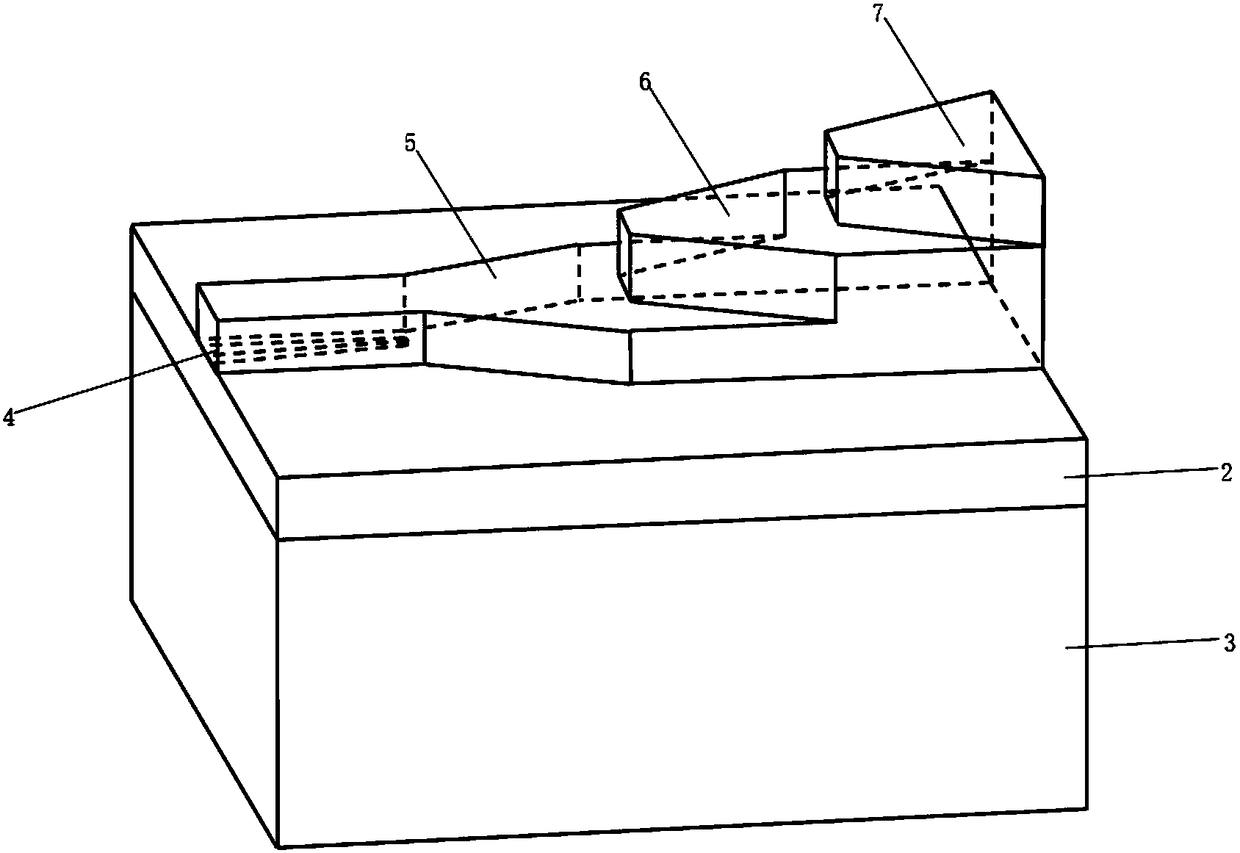

[0049] Such as figure 1 , Figure 15As shown, in this embodiment, a silicon waveguide mode spot converter based on a multilayer polymer structure includes an upper cladding layer 1, an insulator layer 2, a substrate 3, a first optical waveguide 4, a second optical waveguide 5, and a third optical waveguide. Optical waveguide 6 , fourth optical waveguide 7 , support body 8 . In a common silicon photonics chip, the thickness of the insulator layer 2 is usually between 1-5um, and the thickness of the first optical waveguide 4 is usually below 500nm.

[0050] In the silicon waveguide mode speckle converter based on the multilayer polymer structure described in this embodiment, the substrate 3 is silicon, and the insulator layer 2 is fabricated on the substrate 3. A first optical waveguide 4 is fabricated on the surface of the insulator layer 2 , and the material of the first optical waveguide 4 is silicon, which includes a section of reverse tapered optical waveguide and is plac...

Embodiment 2

[0052] This embodiment provides a method for preparing the above-mentioned silicon waveguide mode spot converter based on a multilayer polymer structure, and the specific steps are as follows:

[0053] (1) growing an insulator layer on the substrate;

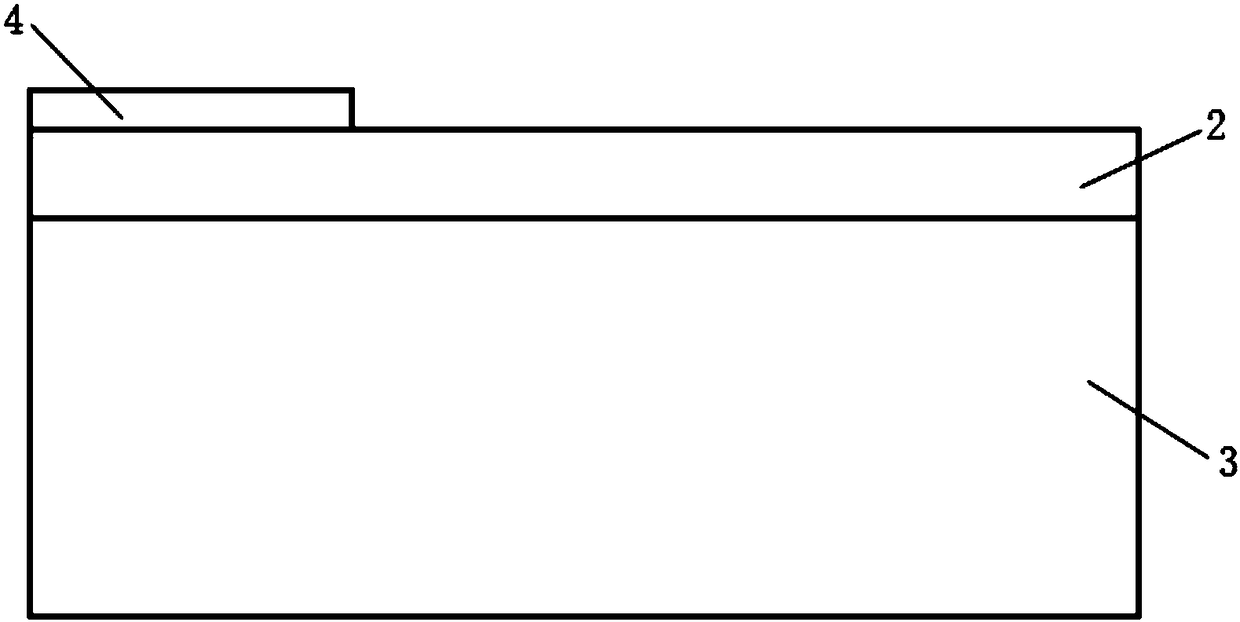

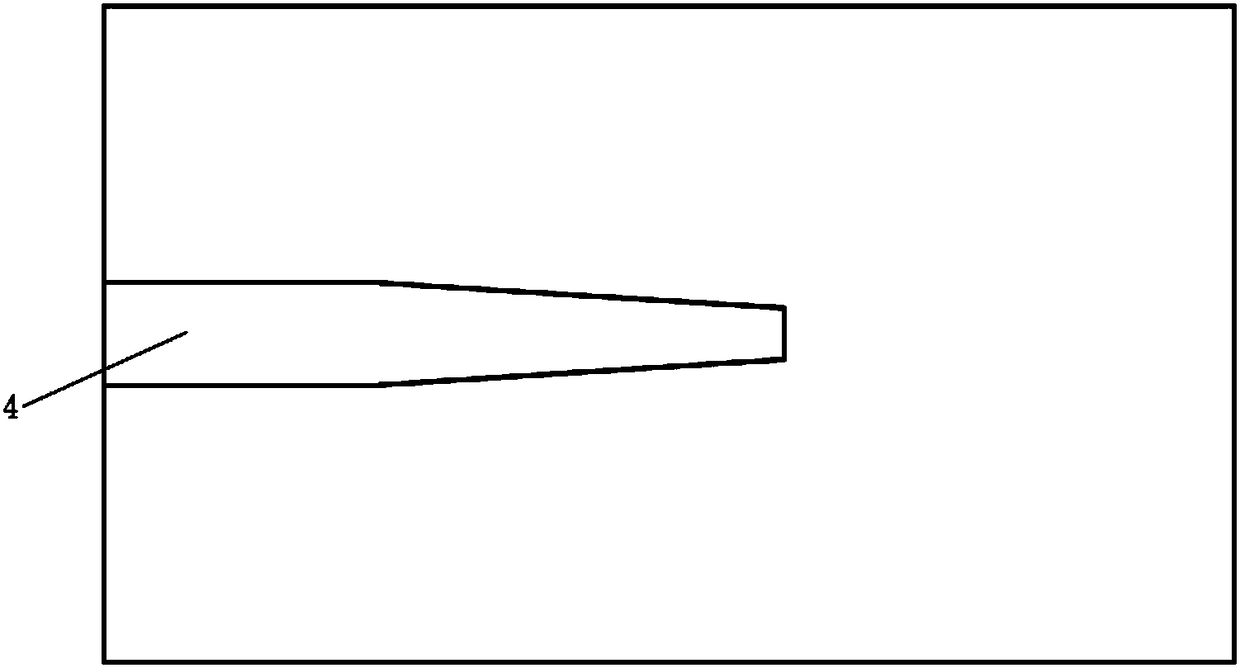

[0054] (2) On the silicon substrate on the insulator layer, the first optical waveguide is manufactured by using an integrated microelectronic process such as electron beam lithography or deep ultraviolet exposure and dry etching. After this step is completed, its structure is as follows figure 2 , 3 , 4 shown.

[0055] (3) The second optical waveguide is made on the chip obtained in step 2 by means of spin coating, photolithography, and development, and supports 8a distributed on the left and right sides of the second optical waveguide are produced. After this step is completed, its structure Such as Figure 5 , 6 , 7 shown.

[0056] (4) Fabricate a third optical waveguide on the chip obtained in step 3 by means of spin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com