Cylindrical thin-walled workpiece machining and forming tool and method

A technology of thin-walled parts processing and forming methods, which is applied in metal processing equipment, metal processing machine parts, positioning devices, etc., can solve the problems of increasing processing allowance, high processing difficulty, waste of materials, etc., and achieves reduction of processing difficulty, welding Small amount of deformation, the effect of eliminating the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

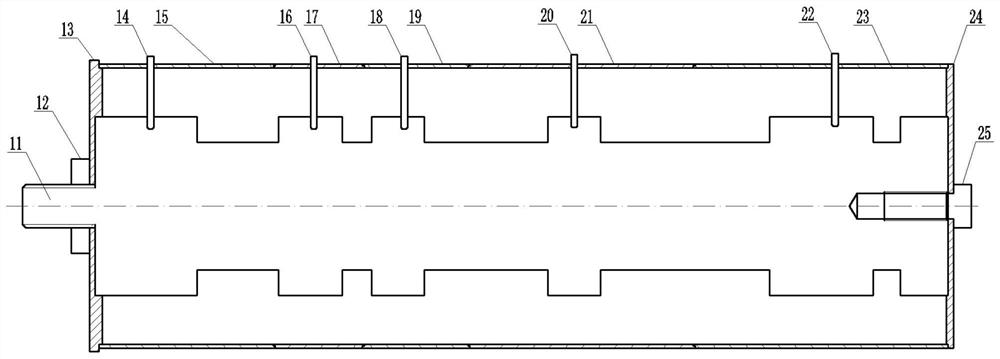

[0086] In the present embodiment, take the manufacture of TC4 titanium alloy cylinder as an example to illustrate the specific implementation of the method. The overall length of the cylinder is 617-637mm, and the wall thickness is 1.2-2.3mm. It is difficult to adopt traditional methods. Processing:

[0087] The main chemical composition of TC4 titanium alloy is:

[0088]

[0089] Step 1: Blank Forging

[0090] The forging is produced according to the maximum outline size of the cylinder. According to the shape of the blank and the forging method, the forging of the cylinder blank includes: sawing, heating, upsetting, punching, mandrel elongation, and hole expansion.

[0091] The sawing step is: sawing the alloy bar according to preset specifications.

[0092] The heating step is: heating the sawn alloy bar to 40°C±10°C below the phase transition point, and the shortest holding time=0.8min / mm×alloy bar diameter;

[0093] The upsetting step is: using an air hammer to upse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com