Magnetic head and its mfg. method

A manufacturing method and magnetic head technology, which is applied in the direction of magnetic recording head, manufacturing magnetic head surface, manufacturing magnetic head with a structure composed of multiple magnetic heads, etc., can solve the problems of small fixing force, distortion of residual stress, deterioration of magnetic characteristics, etc., and achieve guaranteed position relationship, preventing uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

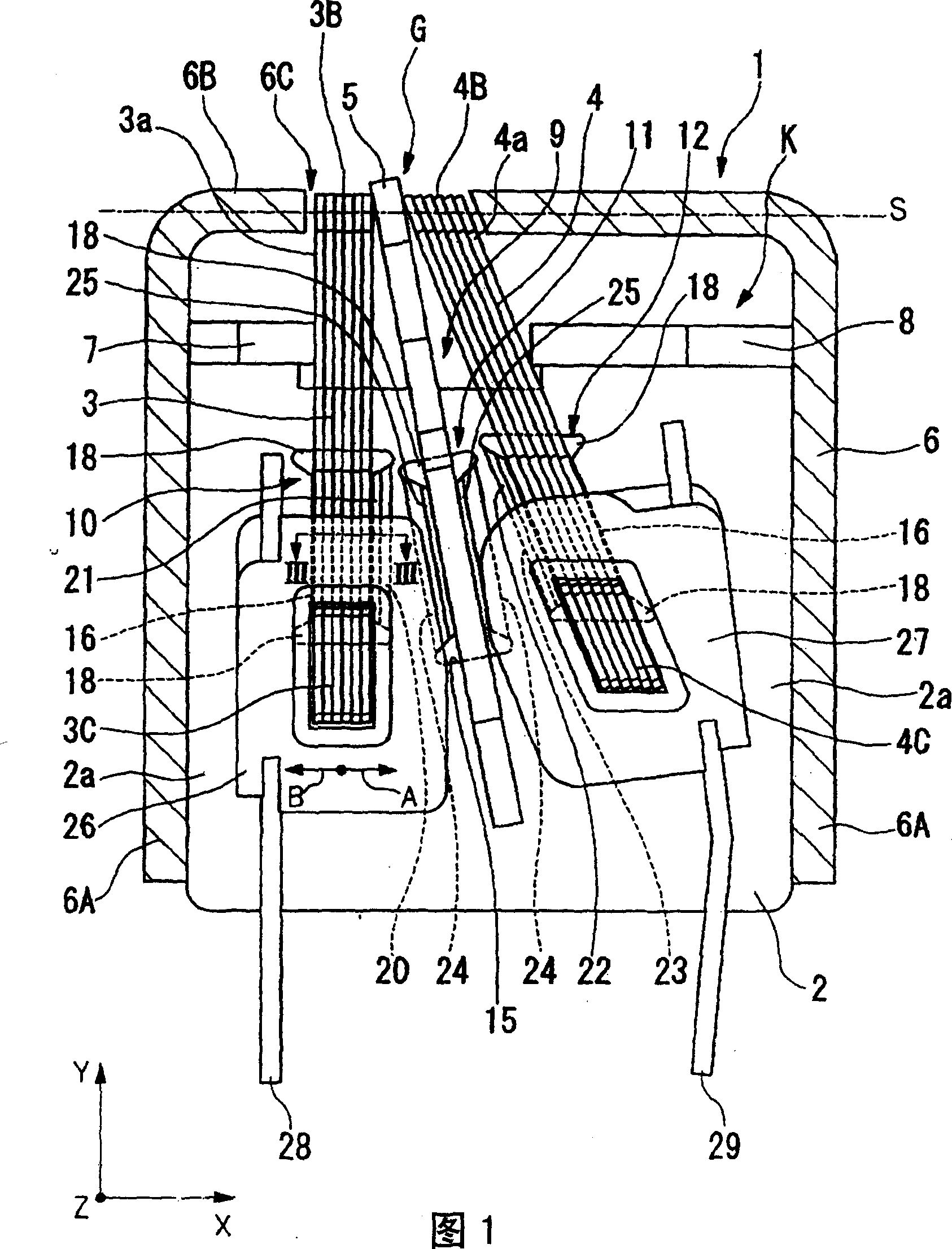

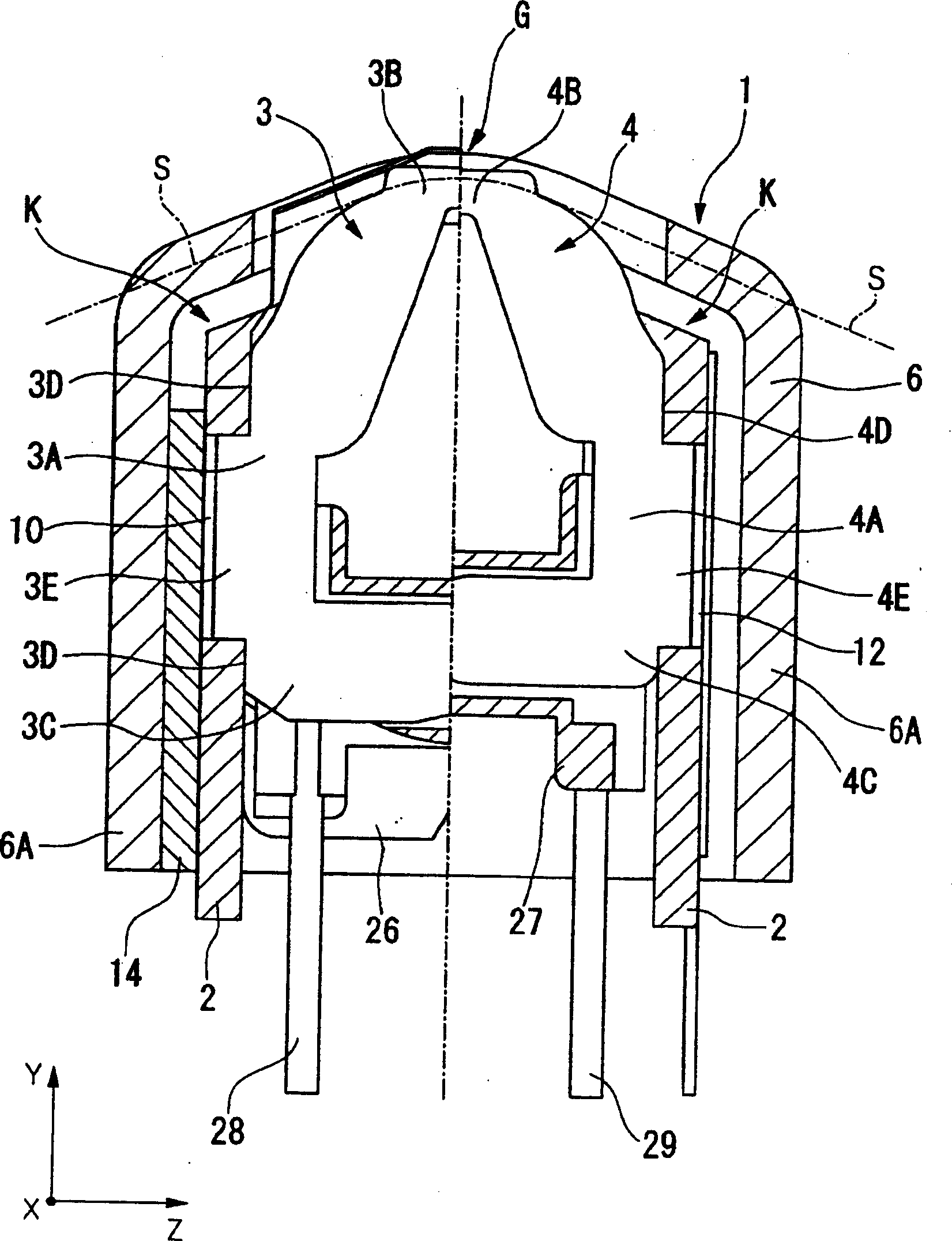

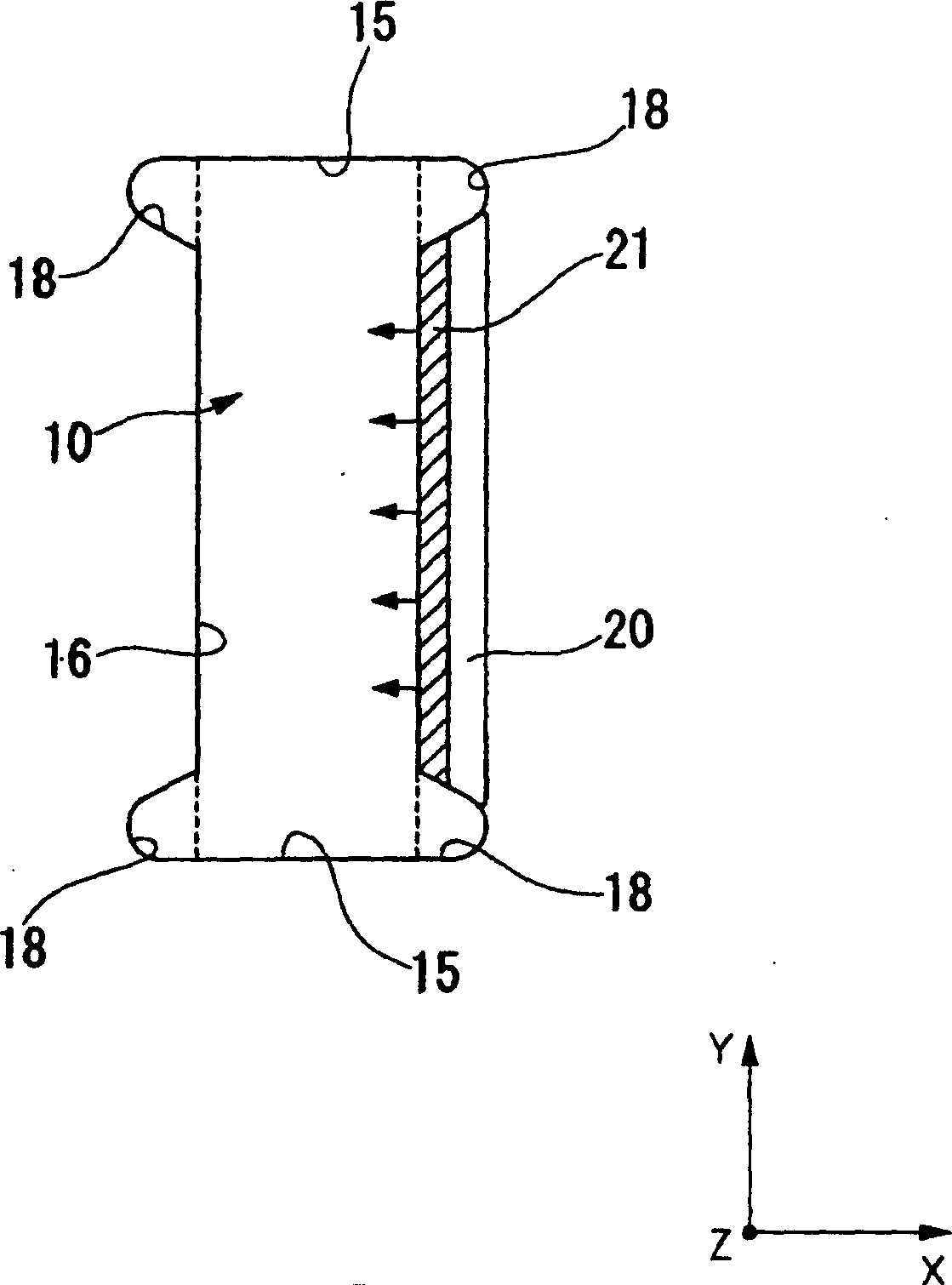

[0087] Next, the magnetic head and its manufacturing method according to the first embodiment of the present invention will be described with reference to the drawings.

[0088] As shown in FIGS. 1 and 2 , the magnetic head 1 of the present embodiment is composed of two magnetic core assemblies K mounted in a sealed case 6. Magnetic core assembly K of the magnetic core halves 3 , 4 and the sealing plate 5 .

[0089] In this embodiment, the above-mentioned airtight casing 6 is composed of a square barrel peripheral wall 6A and a front wall 6B formed in a shape that closes the opening on one side of the peripheral wall 6A, and is integrally formed by deep drawing (deep drawing processing) of a metal material. A window portion 6C is formed on a part of the front wall 6B. Additionally, Figure 1 and figure 2 The shown cross-sectional shape of the magnetic head shows the state before the grinding of the front wall 6B of the sealed case 6 along the grinding line S is completed. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com