Patents

Literature

78results about How to "Increase push force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

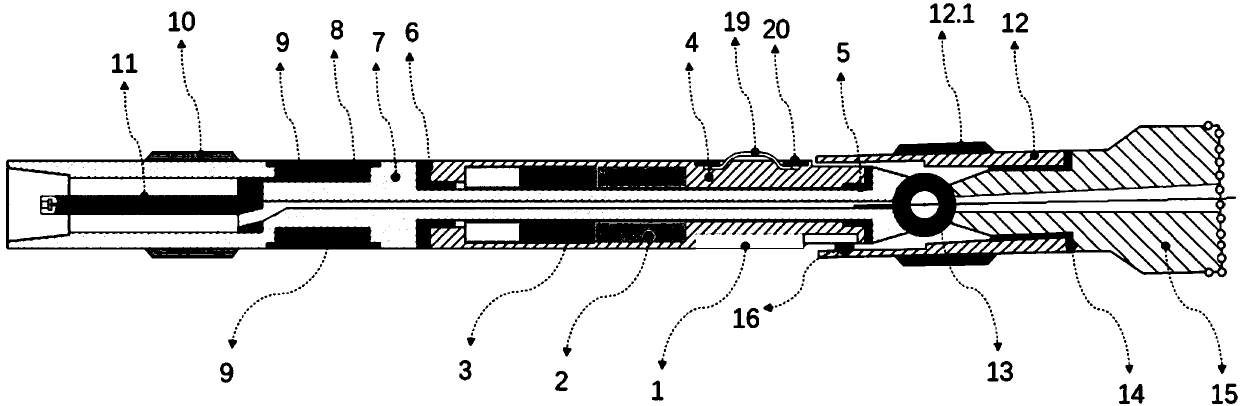

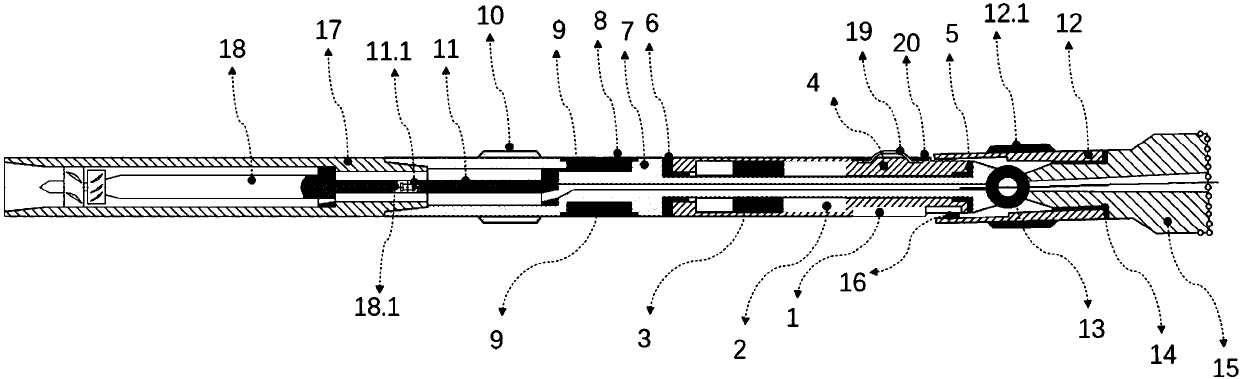

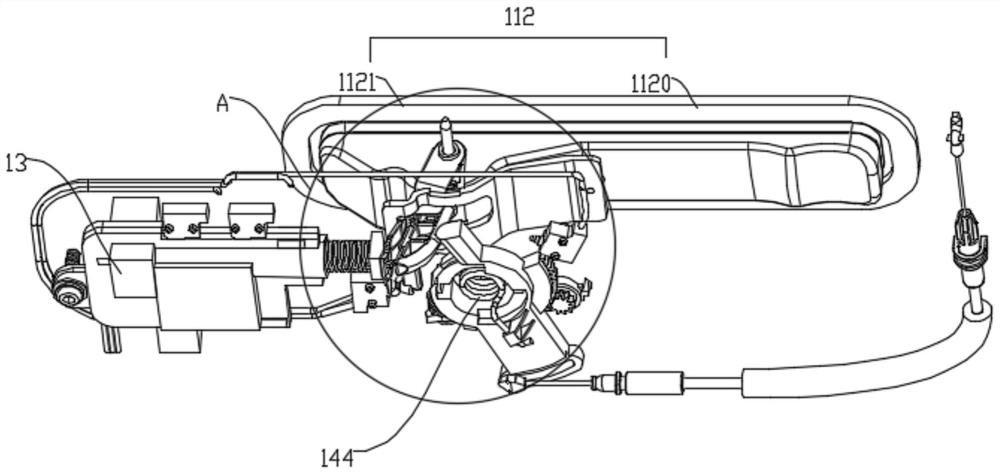

Static internal pushing hinged-type high-deflecting-rate rotary guiding tool and control method

ActiveCN107701107AEasy to bendReduce bending stressDirectional drillingAutomatic control for drillingWell drillingPressure difference

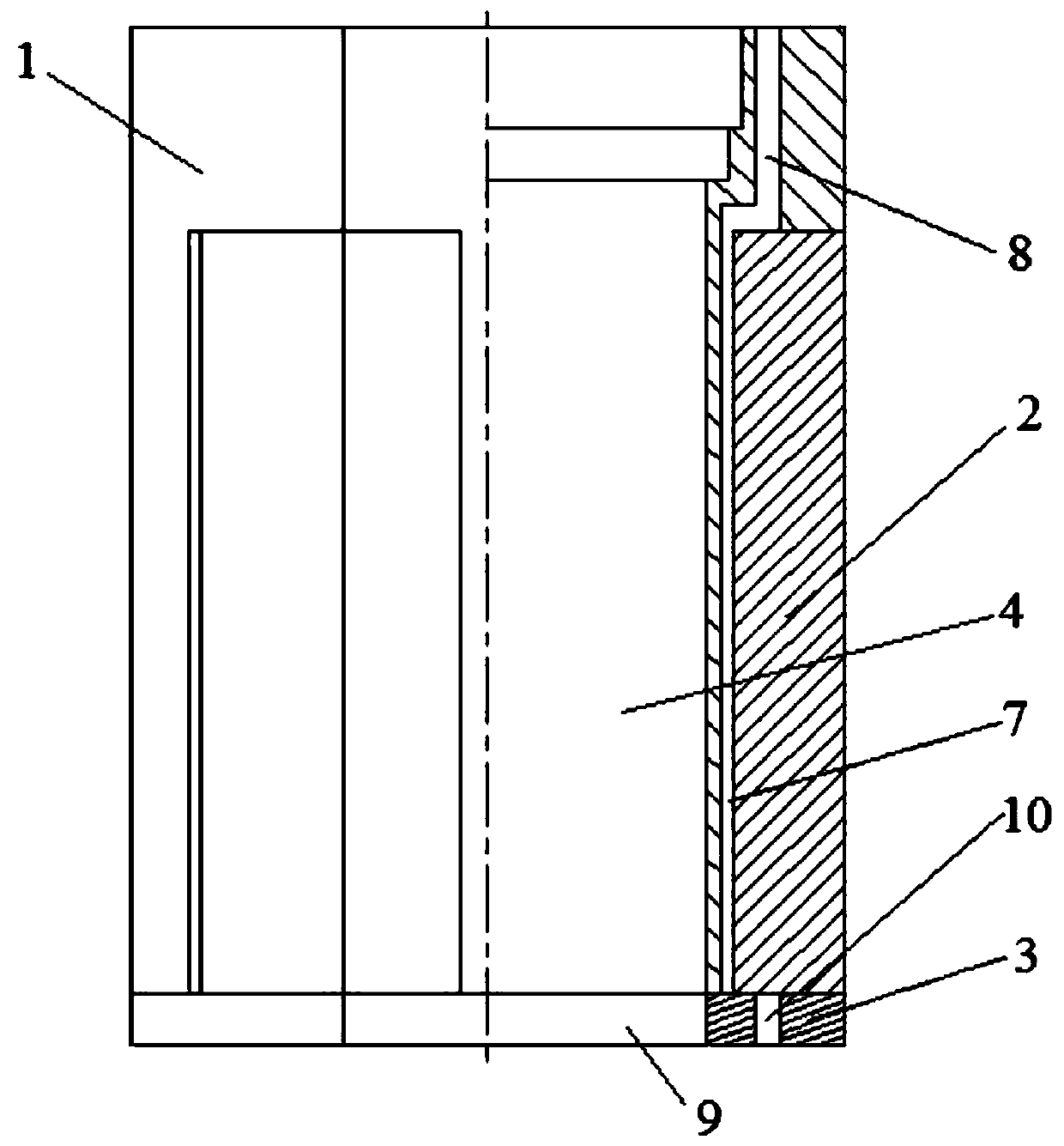

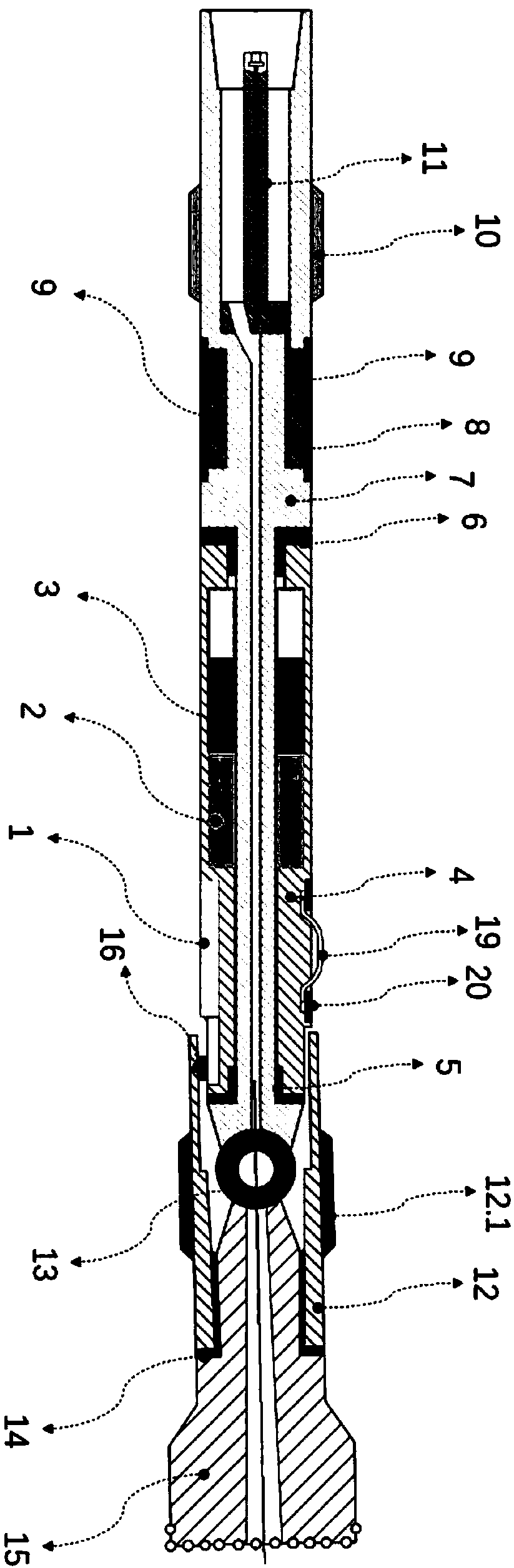

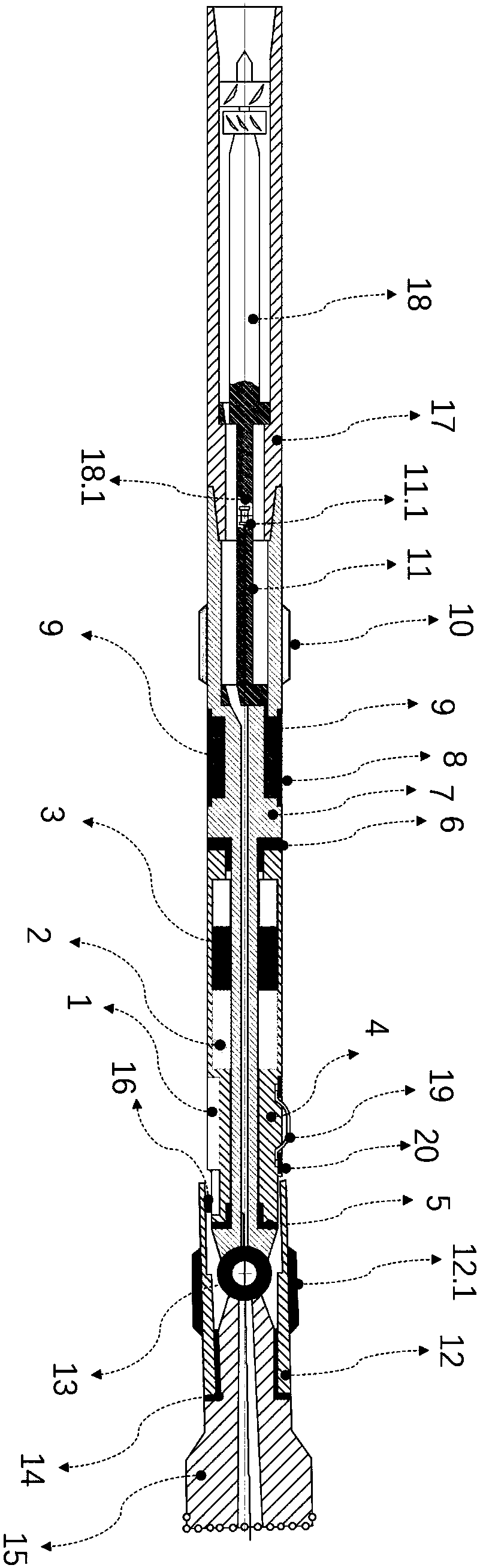

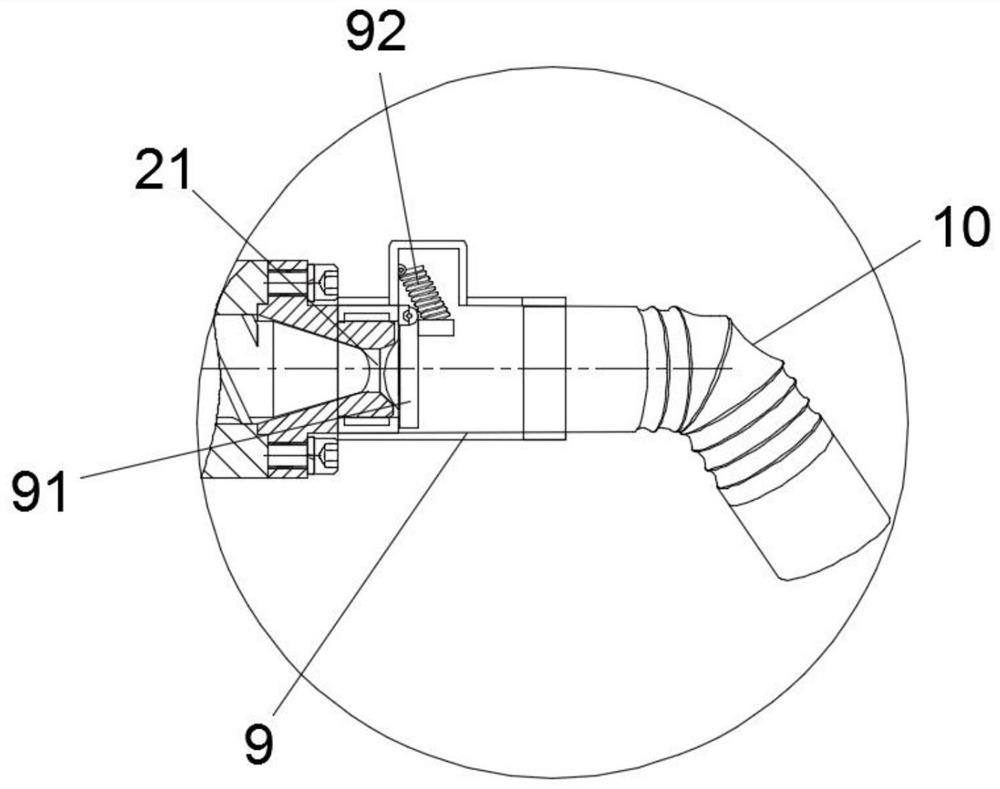

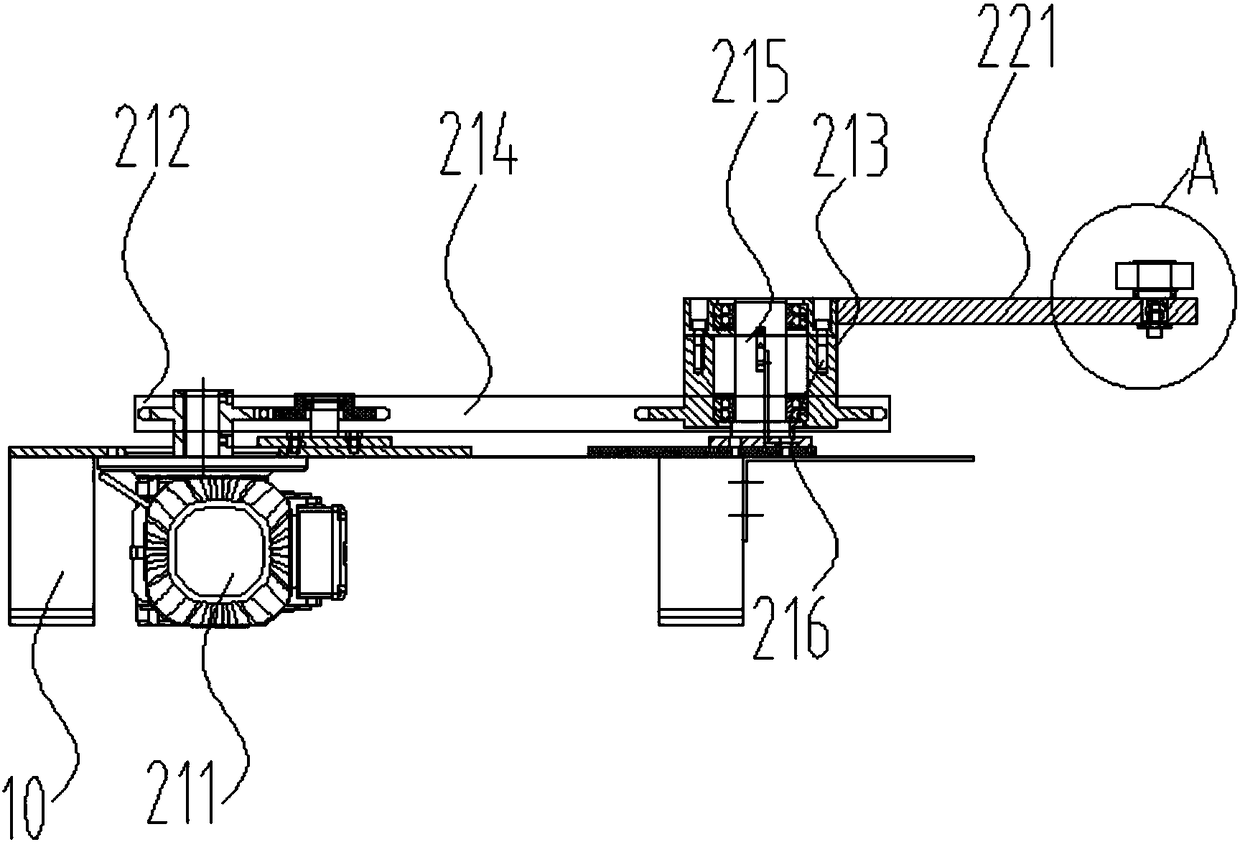

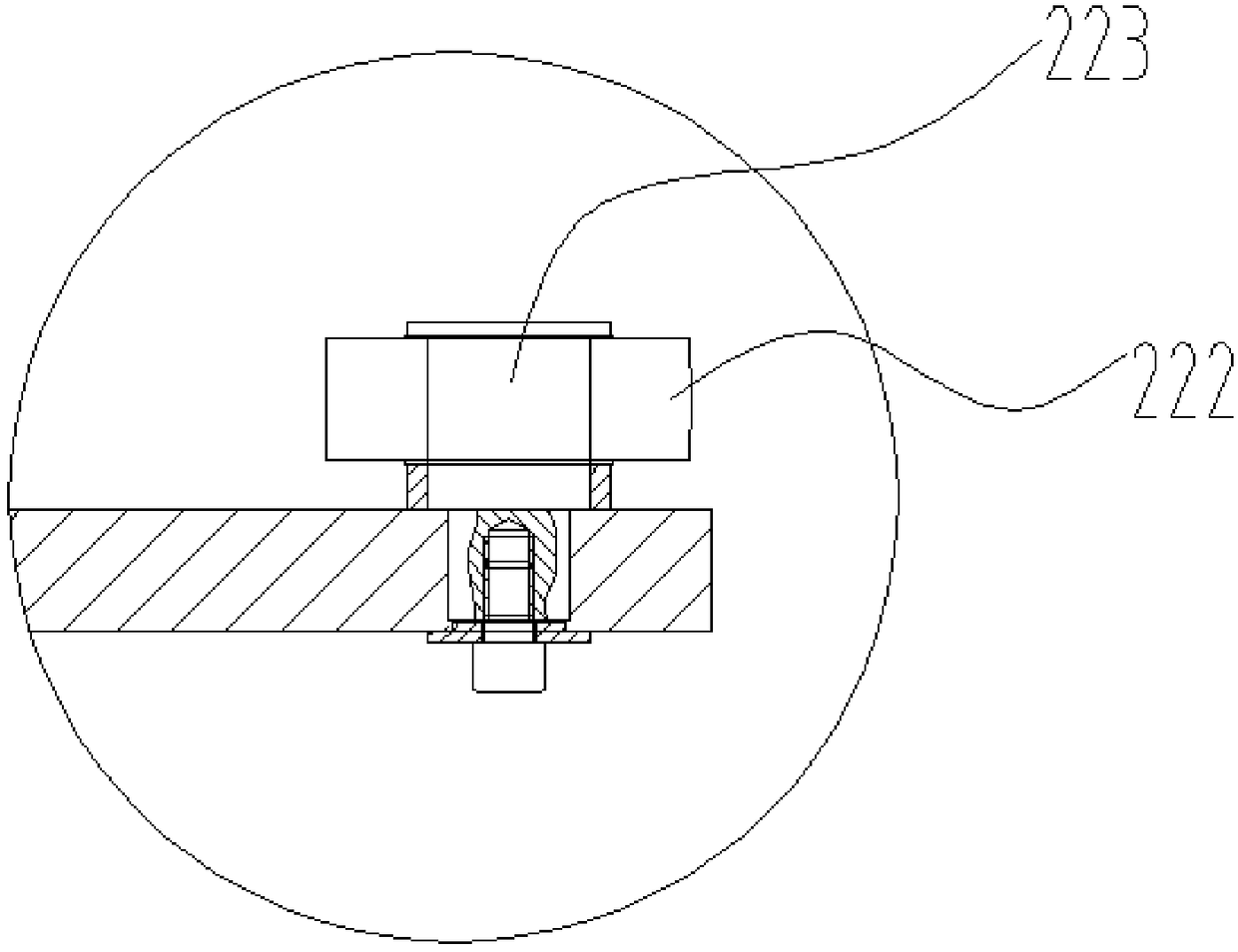

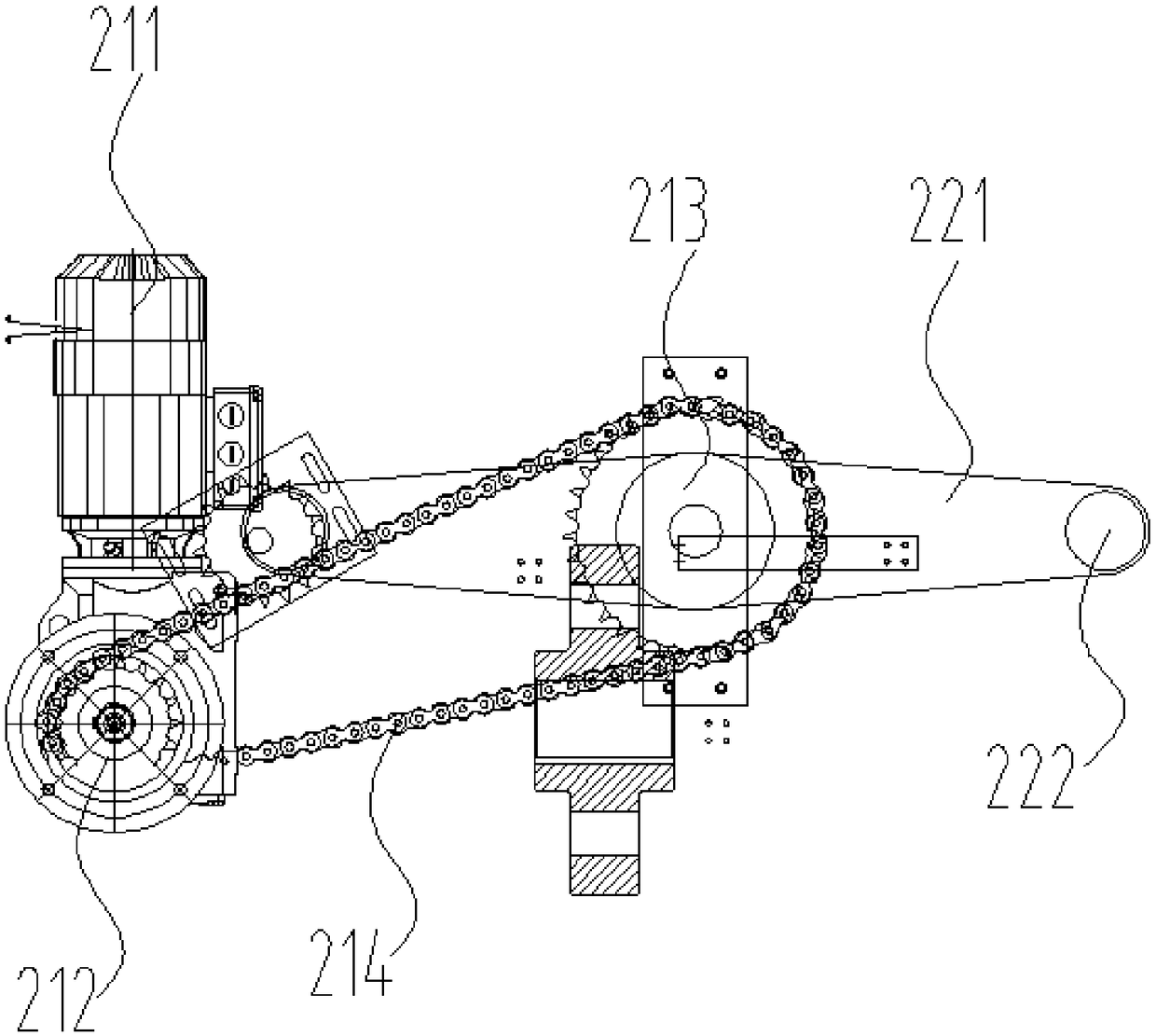

The invention mainly belongs to the technical field of rotary guiding systems and particularly relates to a static internal pushing hinged-type high-deflecting-rate rotary guiding tool and a control method thereof. According to the static internal pushing hinged-type high-deflecting-rate rotary guiding tool, static internal pushing hinged-type design is adopted, a non-rotation measurement and control body and a non-rotation executing mechanism body are hinged, and a non-integral-type structure is achieved; and a drilling tool is prone to bending in a well, the bending stress on the upper portion of the guiding tool is small, and consumption of pushing force used for drilling tool bending deformation reaches the minimum. Rotary friction does not exist between a bearing executing mechanism body outer sleeve and the well wall, and only axial sliding exists, so that the service life is long; meanwhile, the mode of the hydraulic pressure instead of the mud pressure difference is adopted toact on a piston to form the pushing force, the pushing force is greatly increased, and the sealing service life of the piston is also prolonged; and thus, the higher deflecting rate is easy to achieveon the guiding tool, and the advantage that the well drilling service life is long is achieved.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

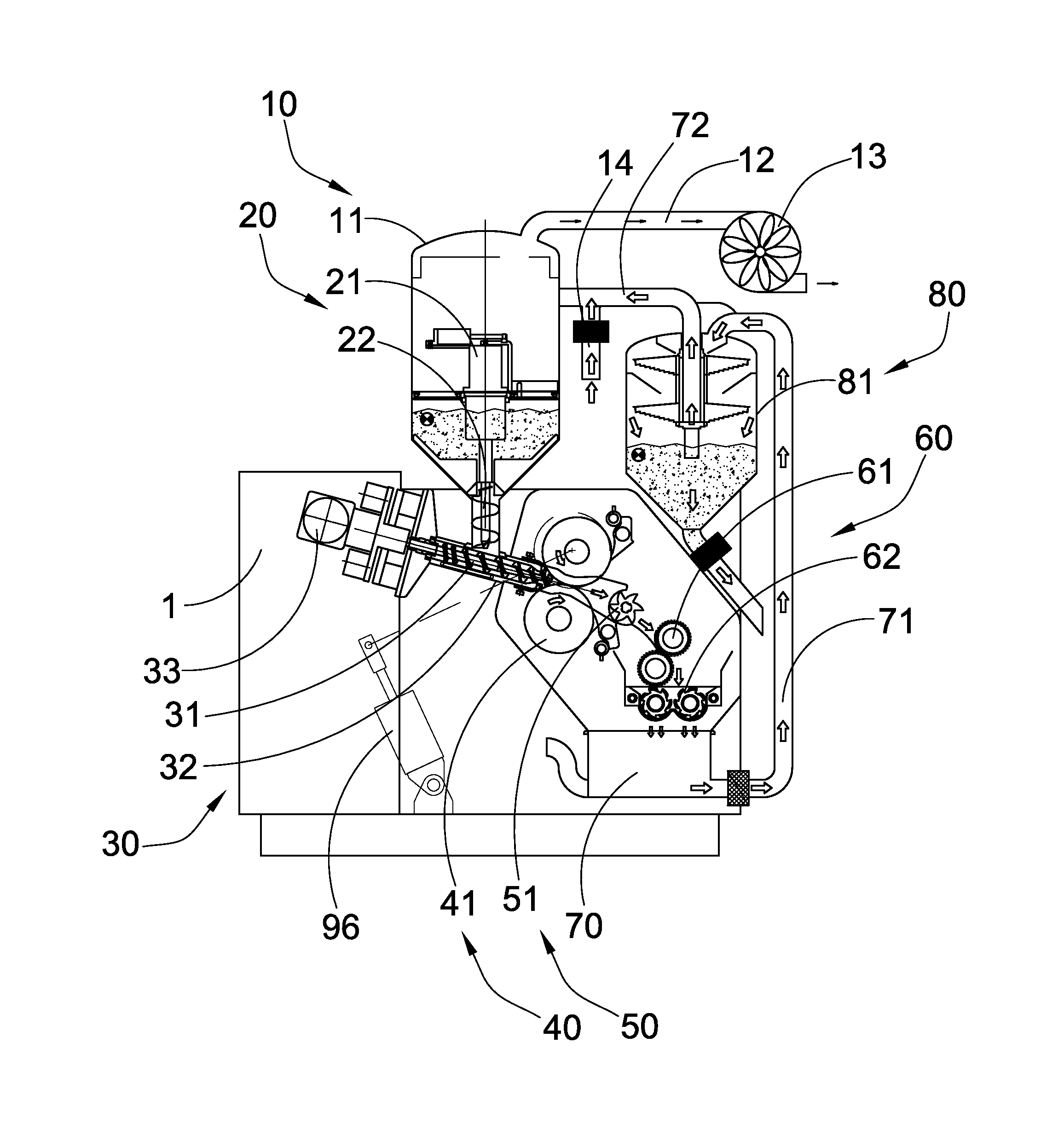

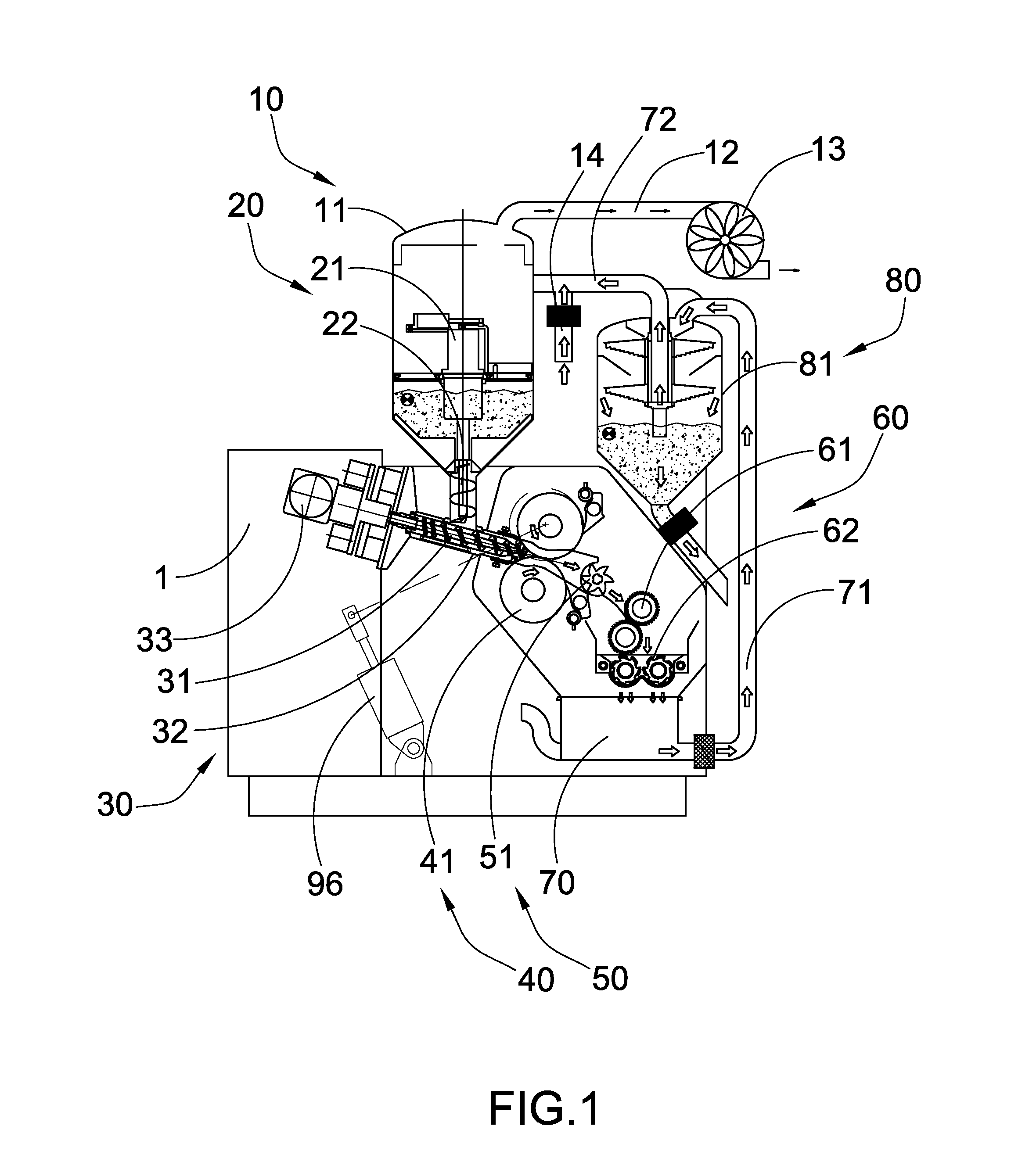

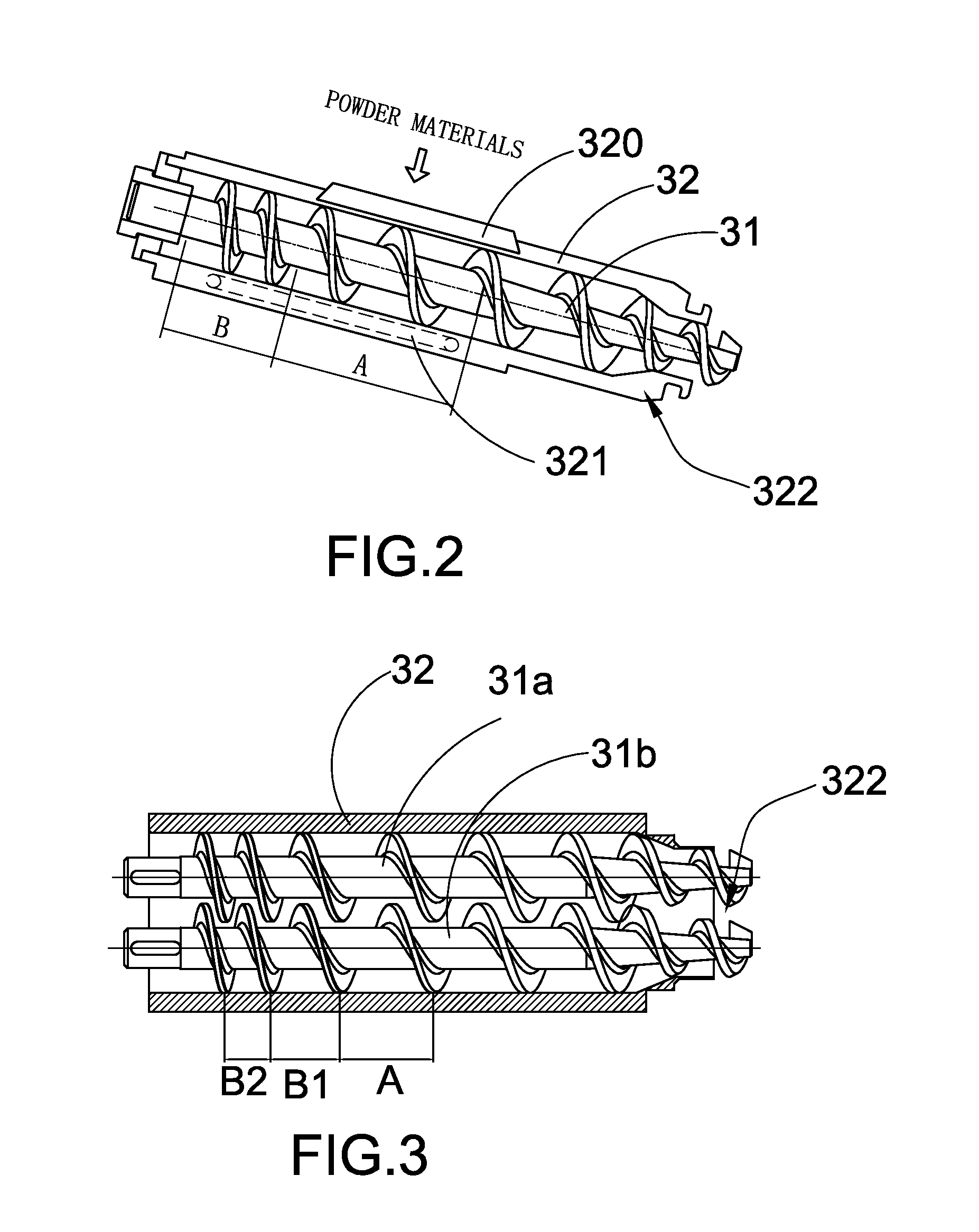

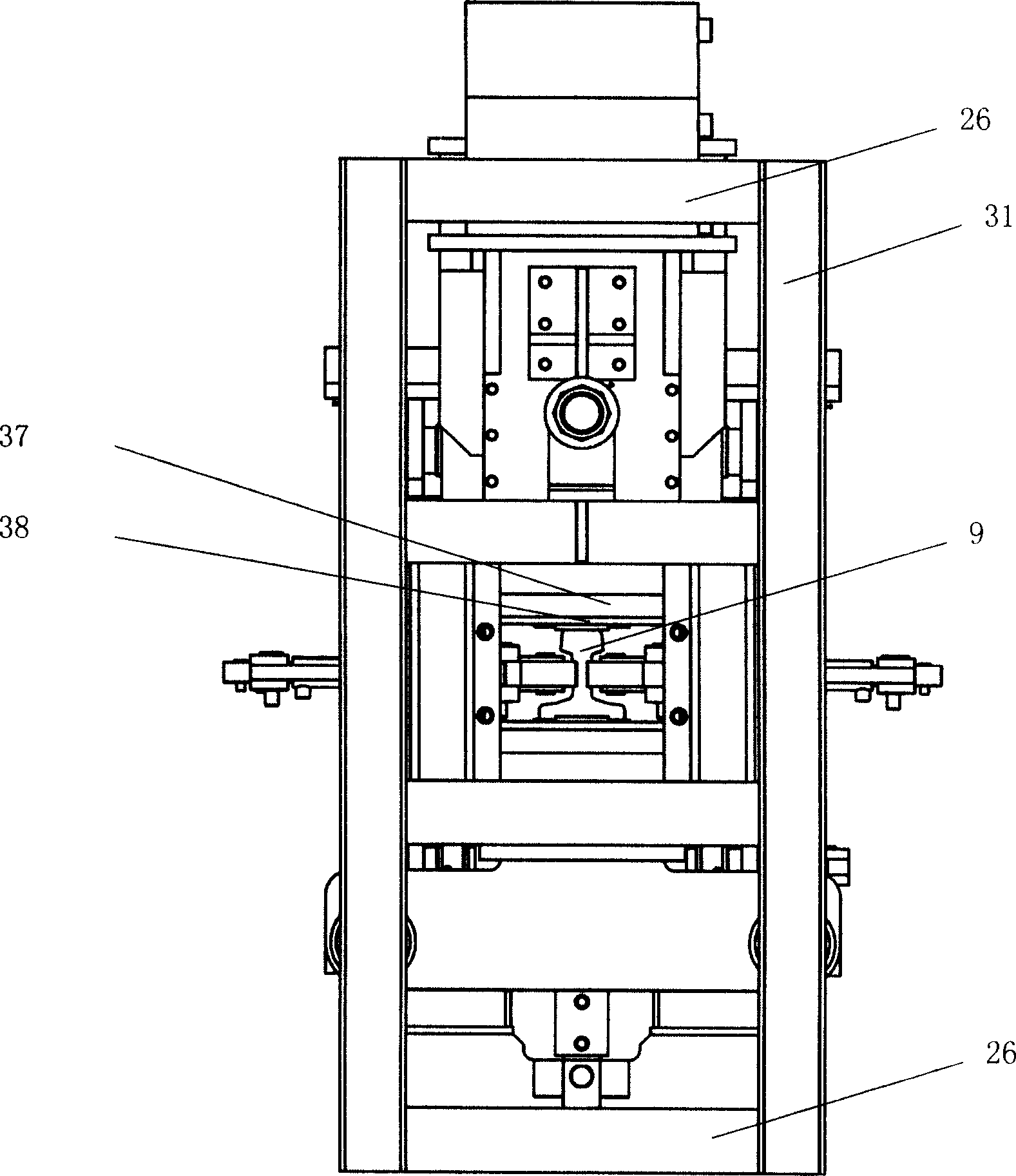

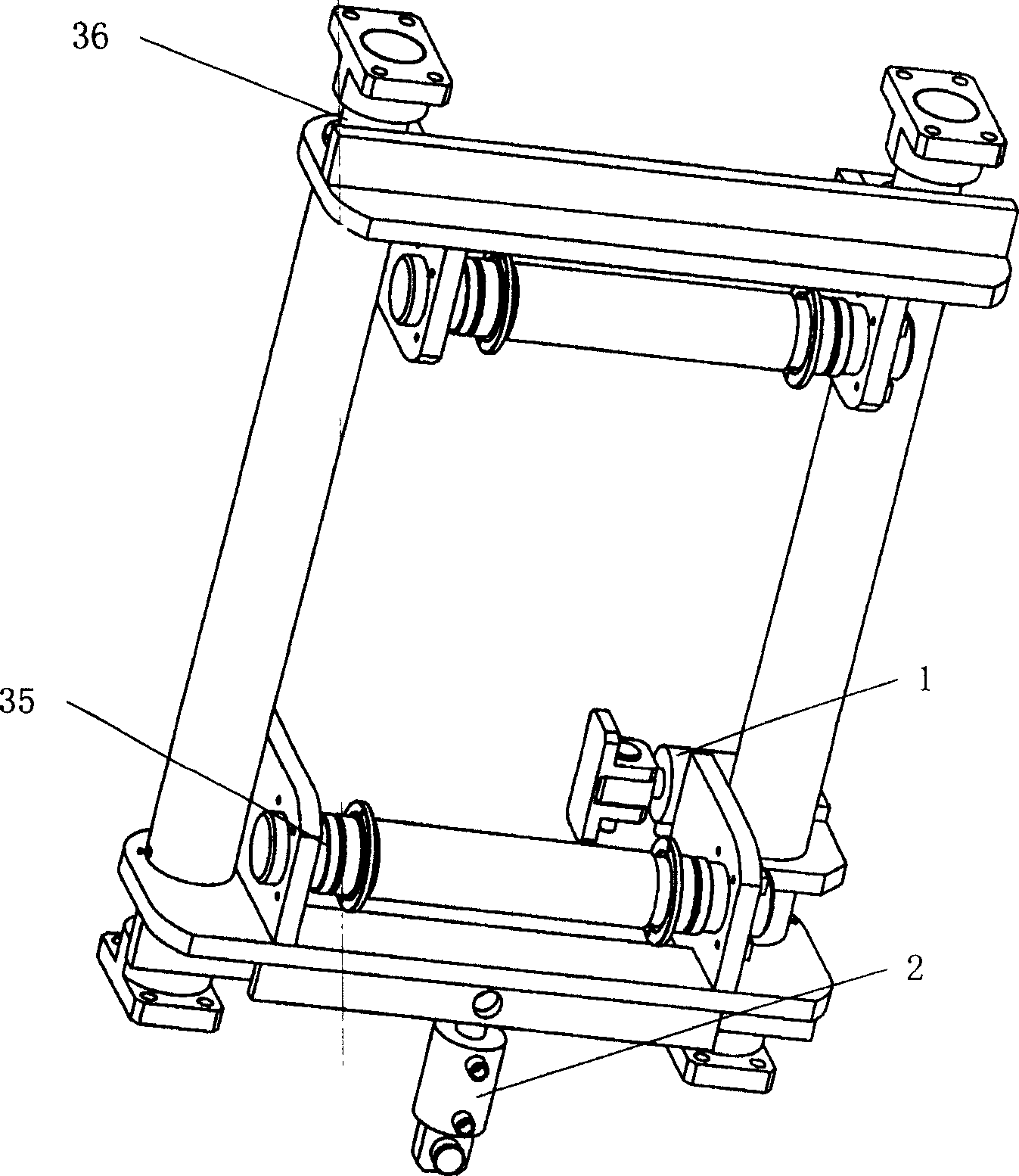

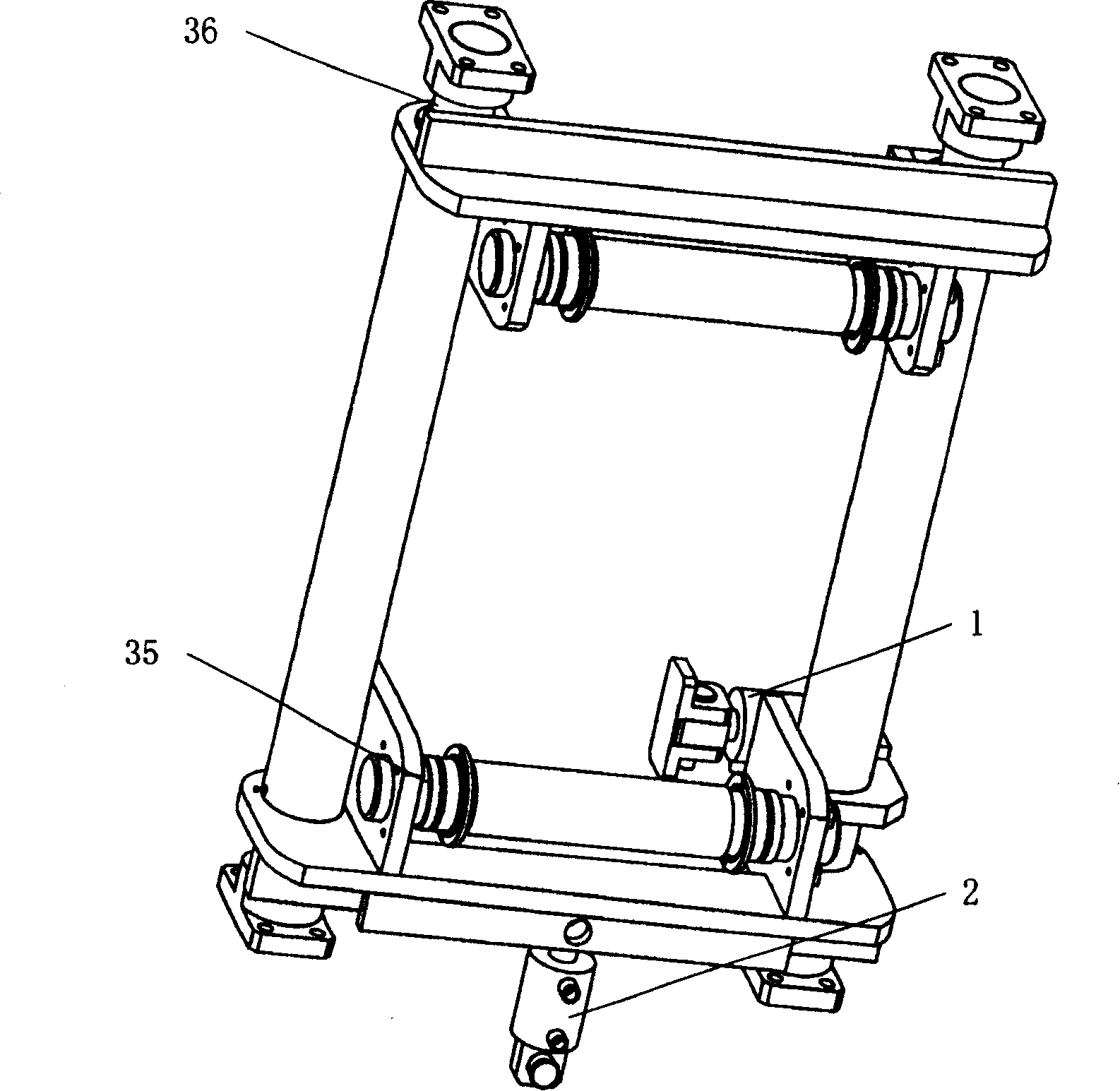

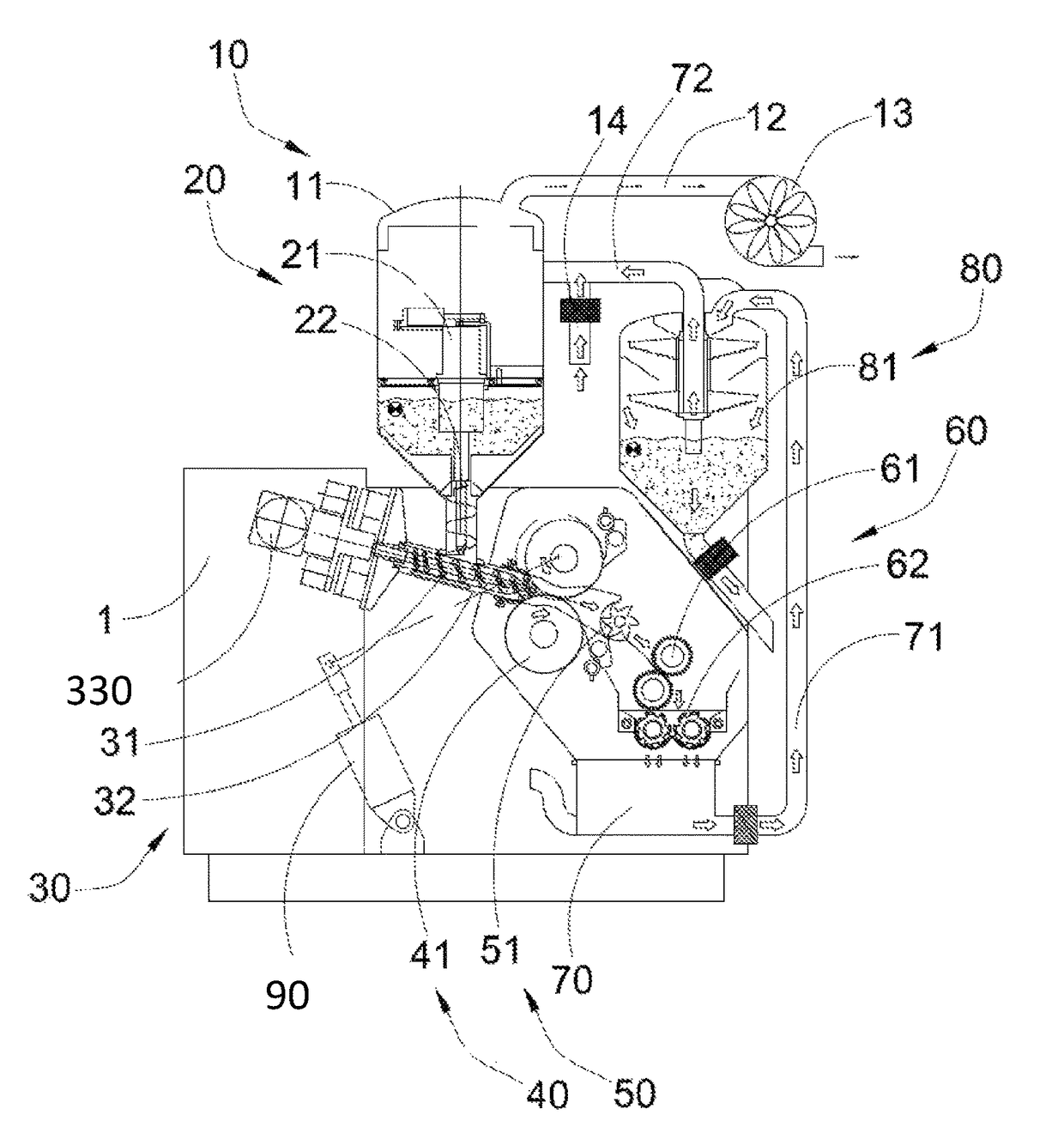

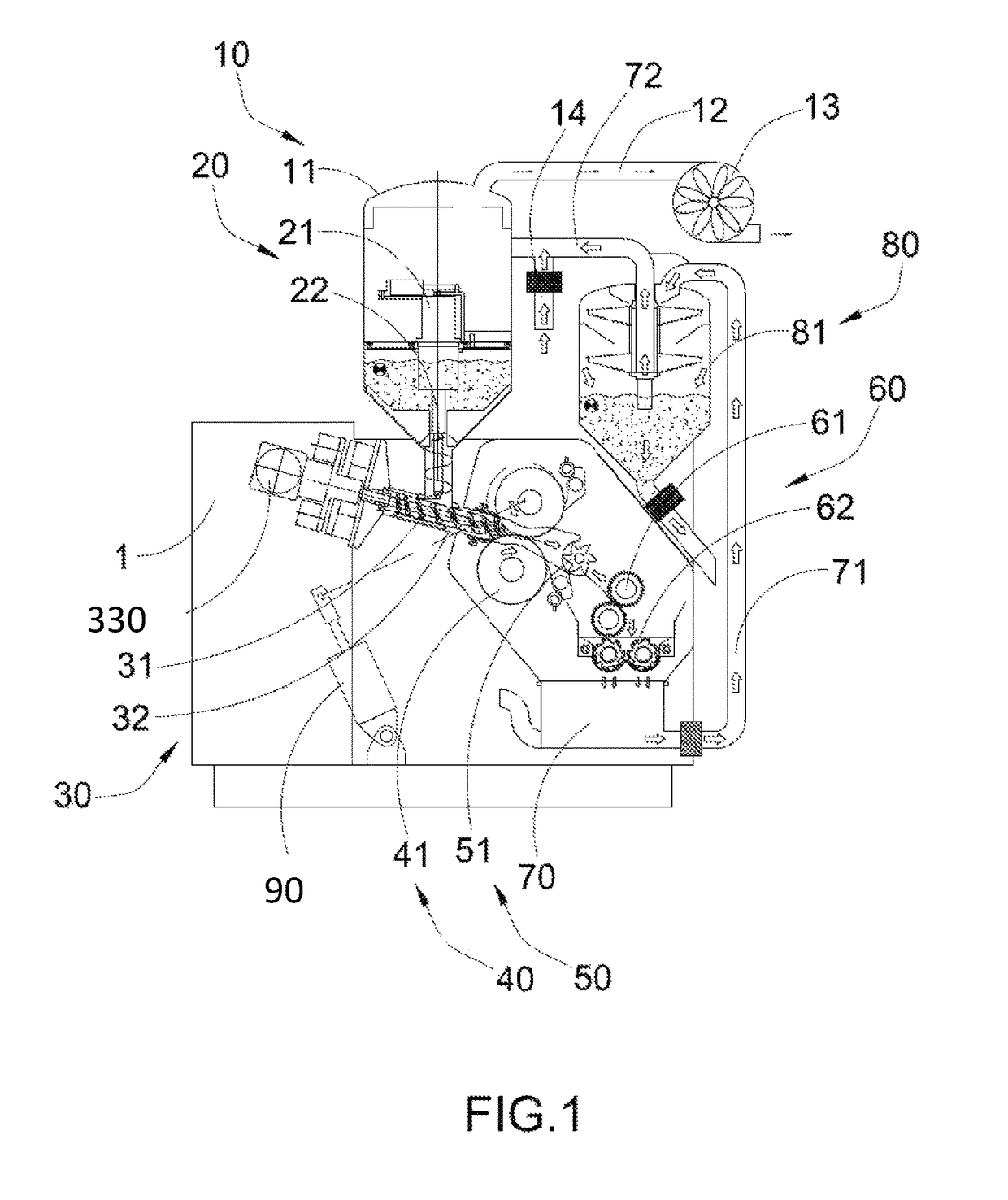

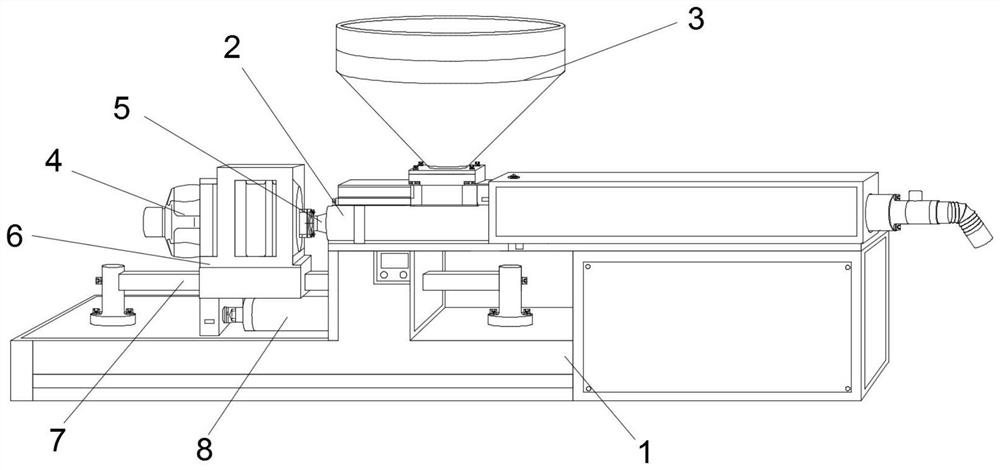

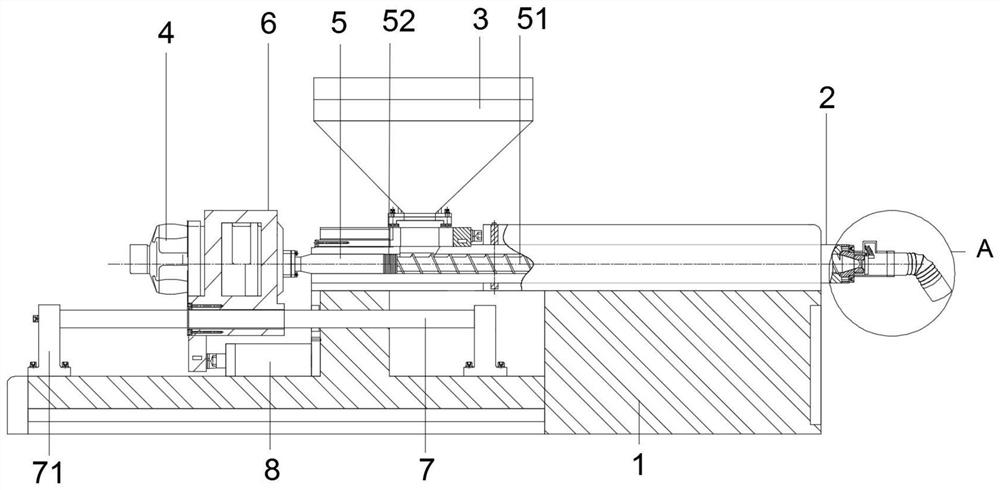

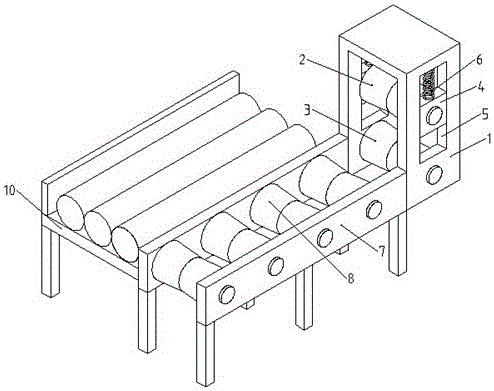

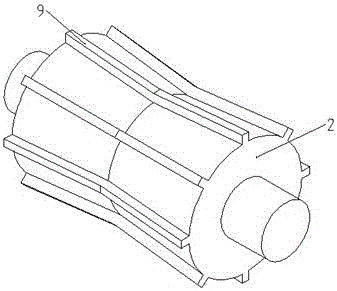

Dry Granulator

ActiveUS20150239152A1Compact structureImprove sealingDough homogenizationFrozen sweetsHardnessMaterials science

A dry granulator includes a feeding mechanism applied to suck powder materials into the material tanks; a vertical feeding mechanism to deliver the power materials to a bottom outlet of the material tank; a pressing mechanism to compress the powder materials into powder sheets with qualified hardness and thickness; an oblique feeding mechanism to deliver the powder materials to from the vertical feeding mechanism to the pressing mechanism; a crushing mechanism to crush the powder sheets into crushed powder sheets; a granulating mechanism to granulate the crushed powder sheet into finished particles products, so as to deliver to a collection storage; a sieving mechanism to separate the finished particle products with fine powders; a pressing wheel regulator applied to adjust an axial position of the lower and the upper pressing wheel; and a floating sealing device applied to provide a reliable sealing effect for the feeding mechanism.

Owner:ZHEJIANG FUTURE MACHINERY

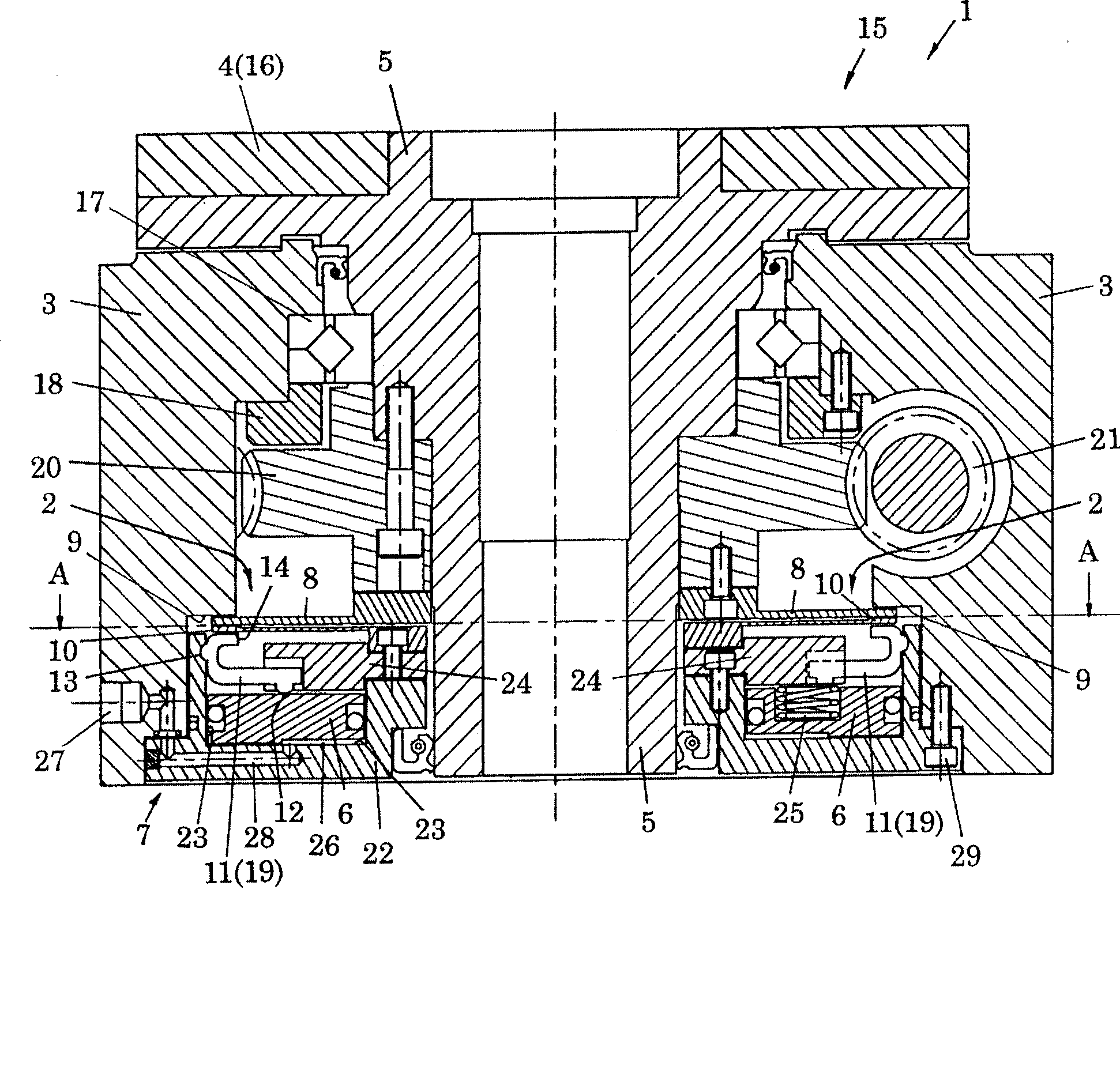

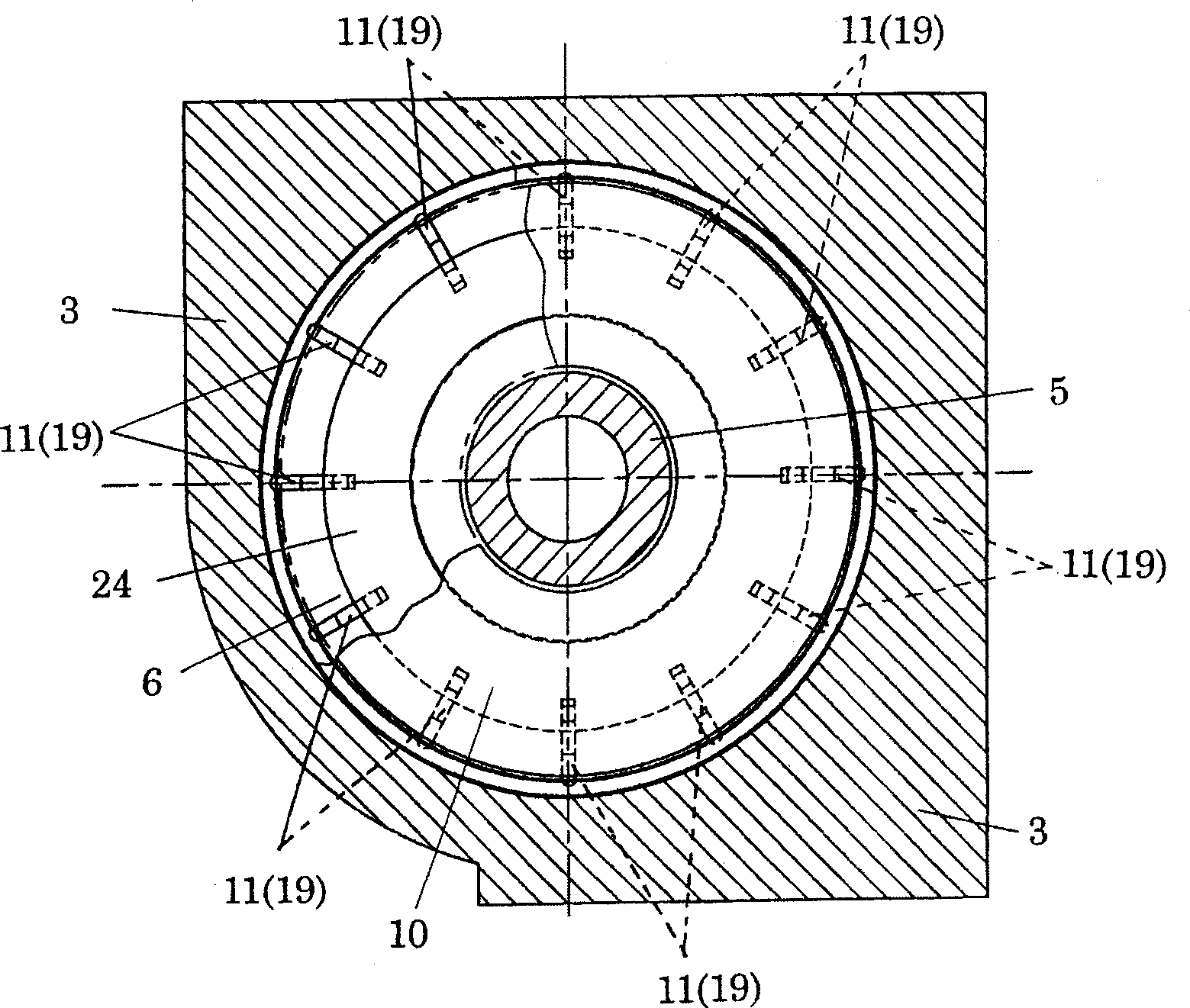

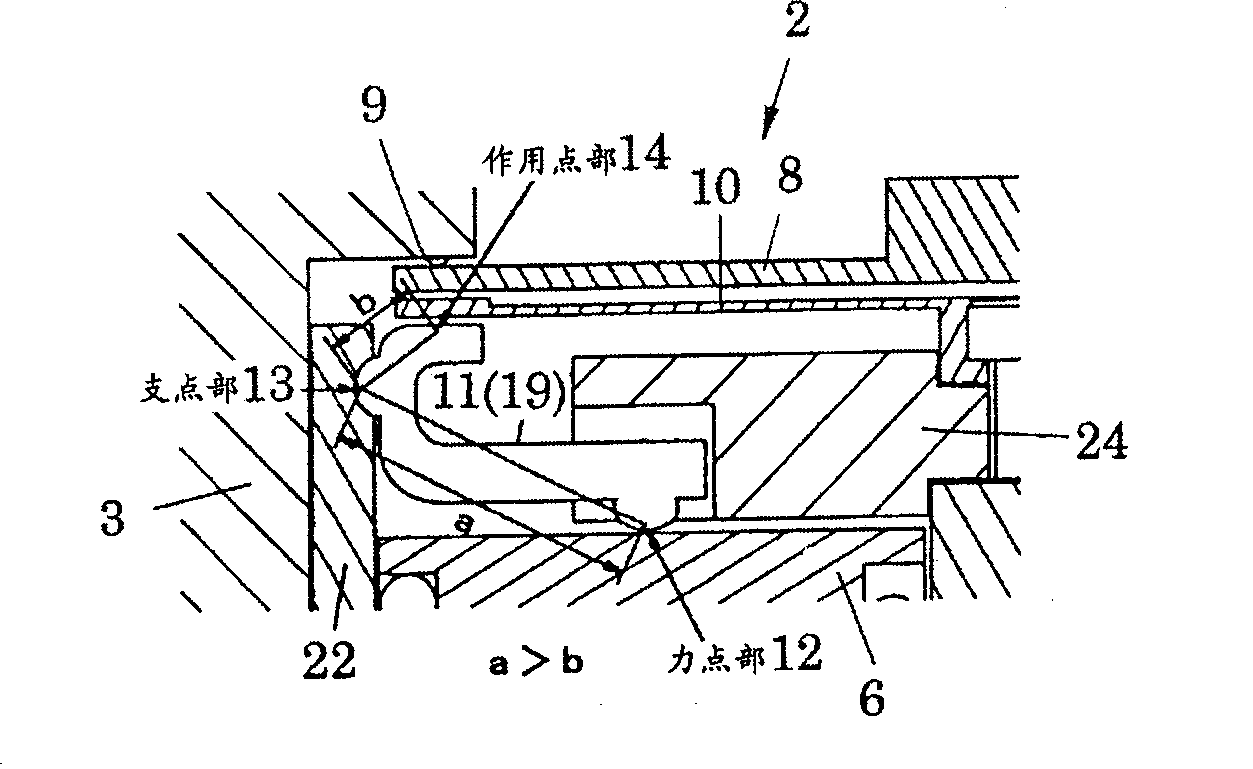

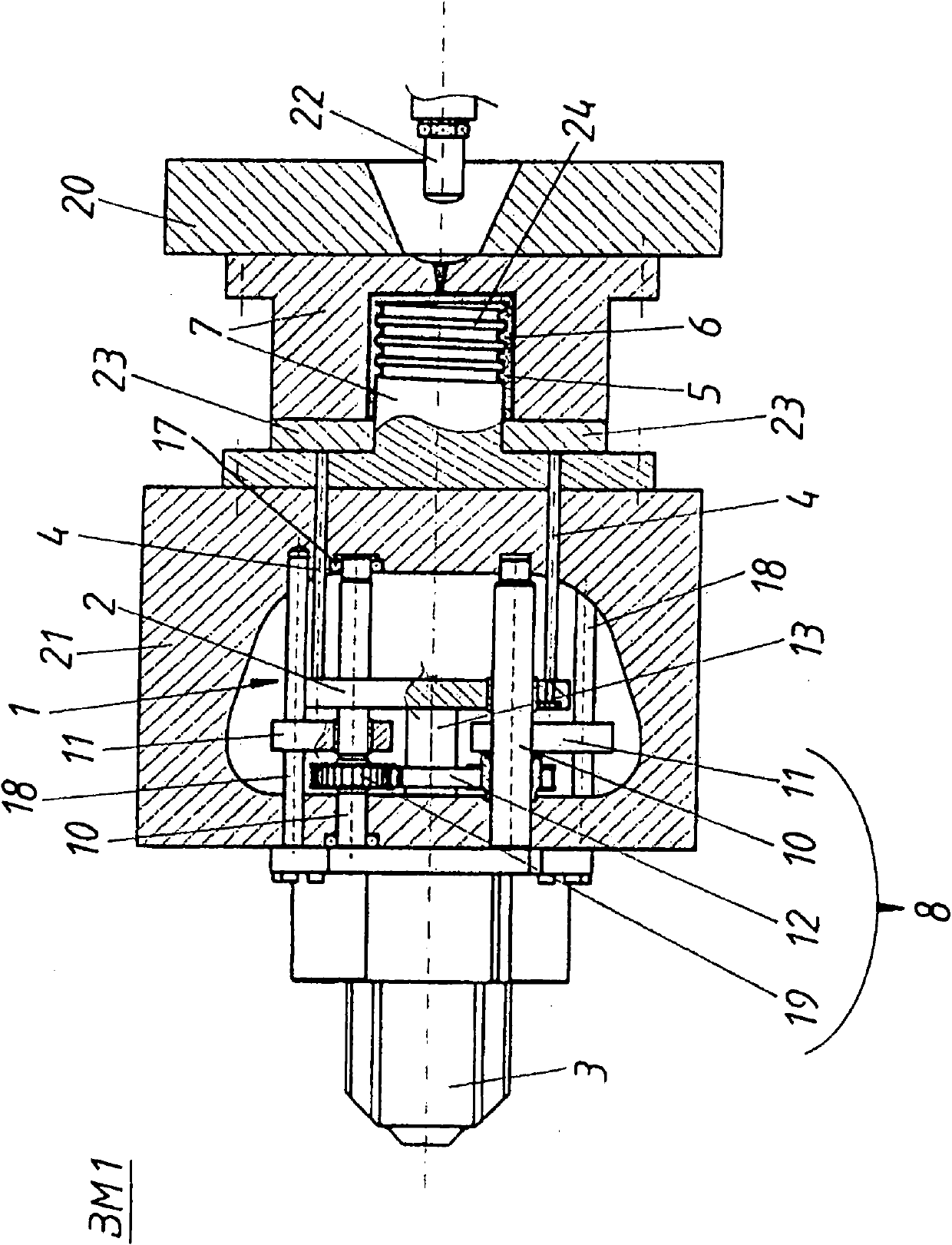

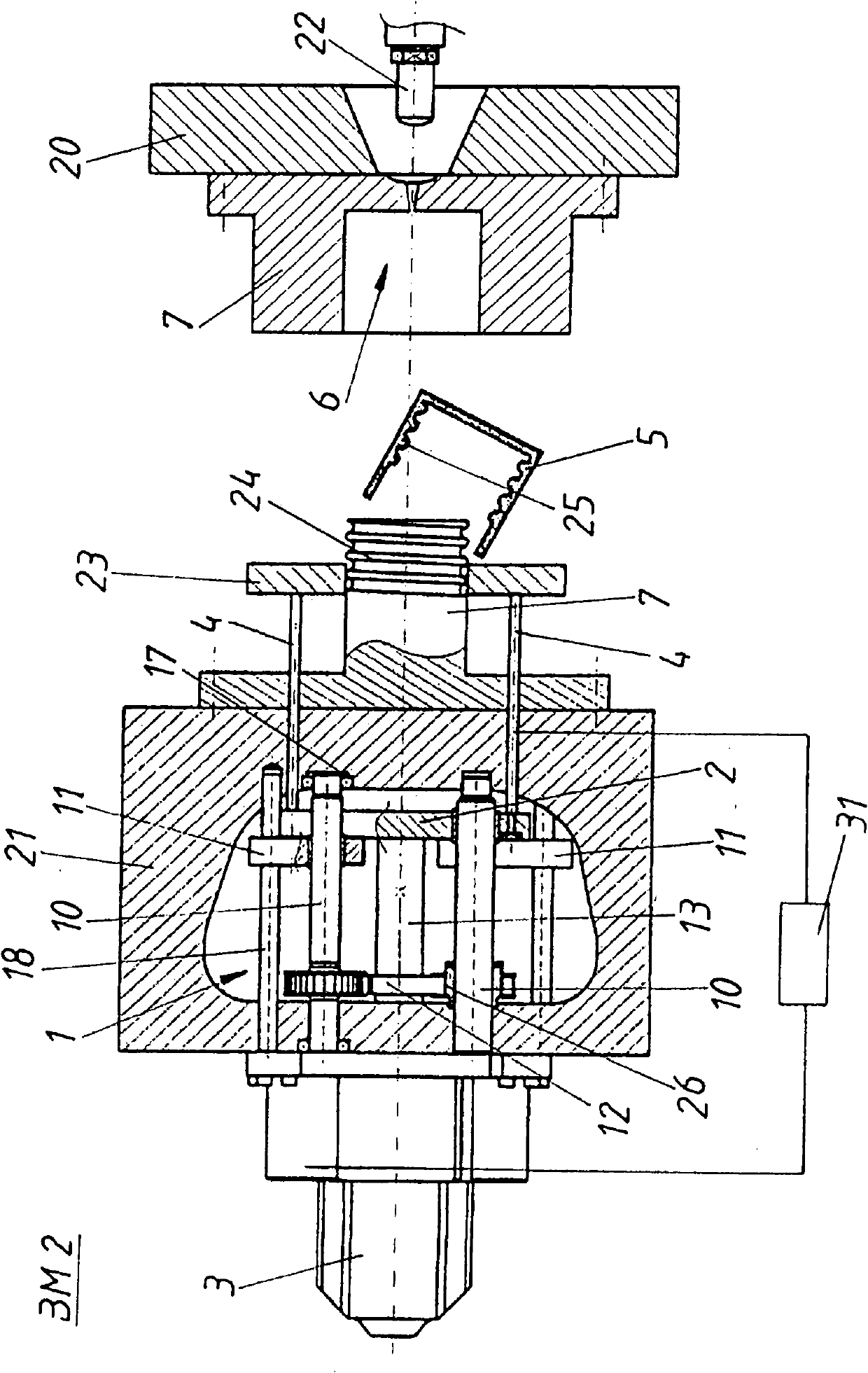

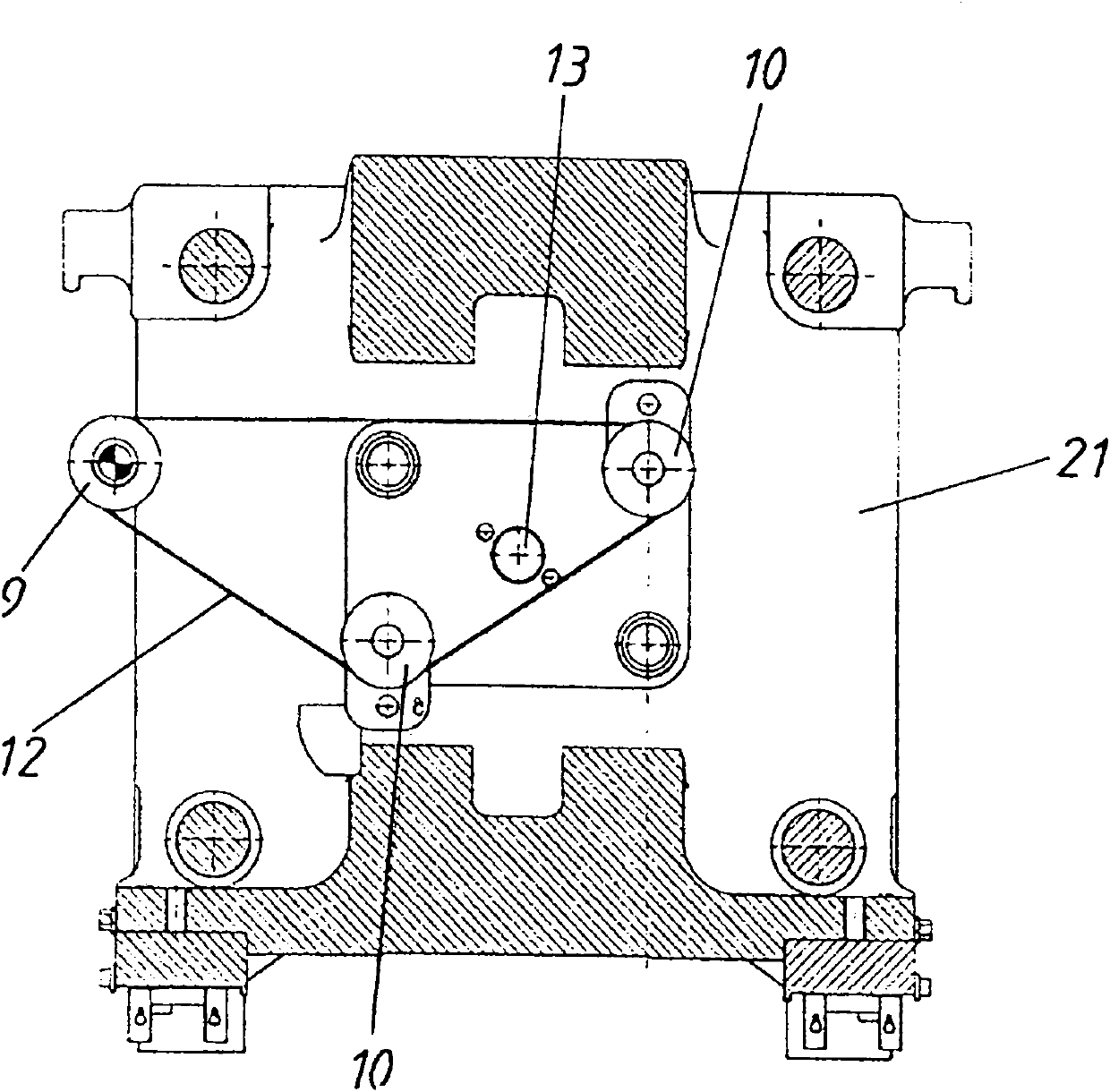

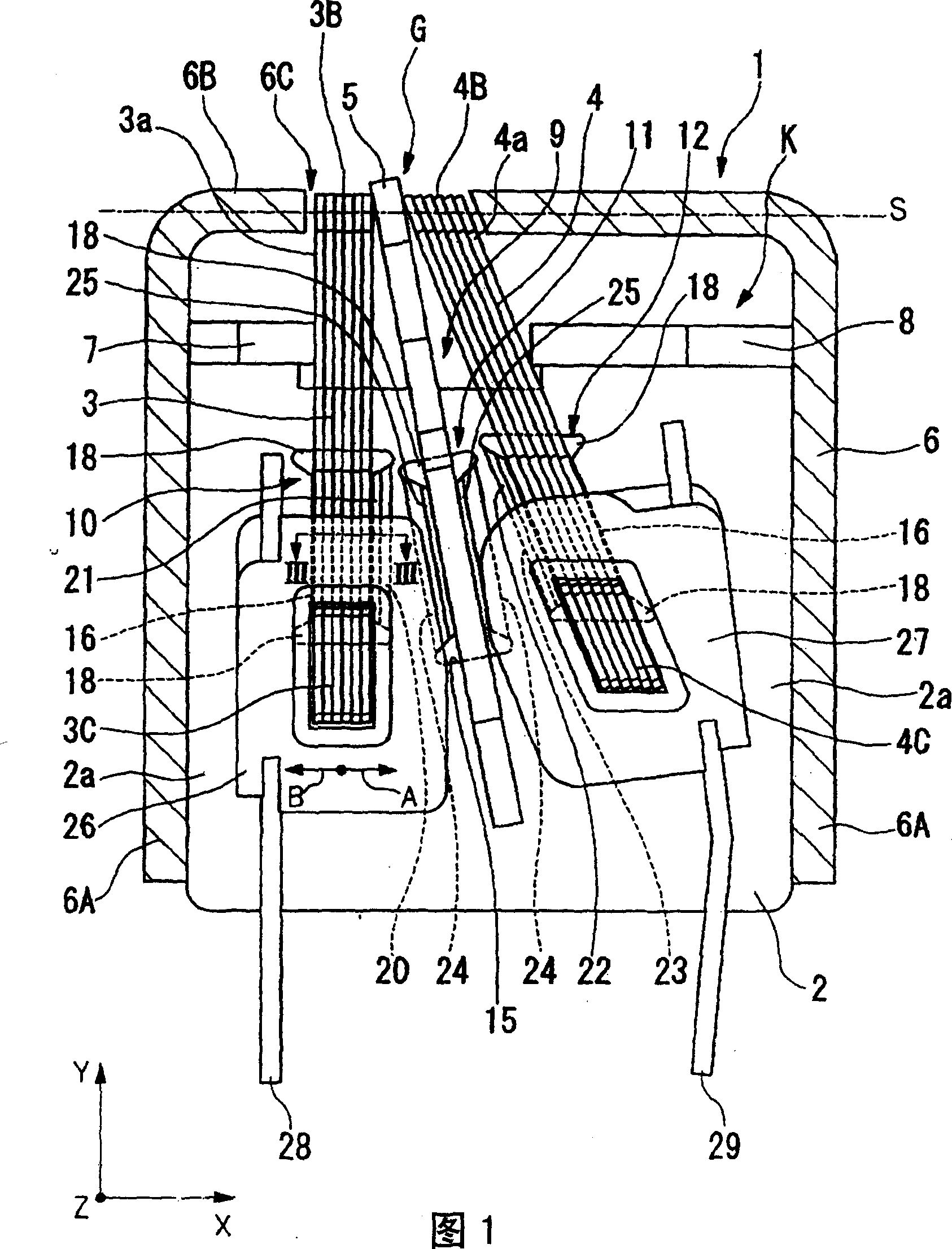

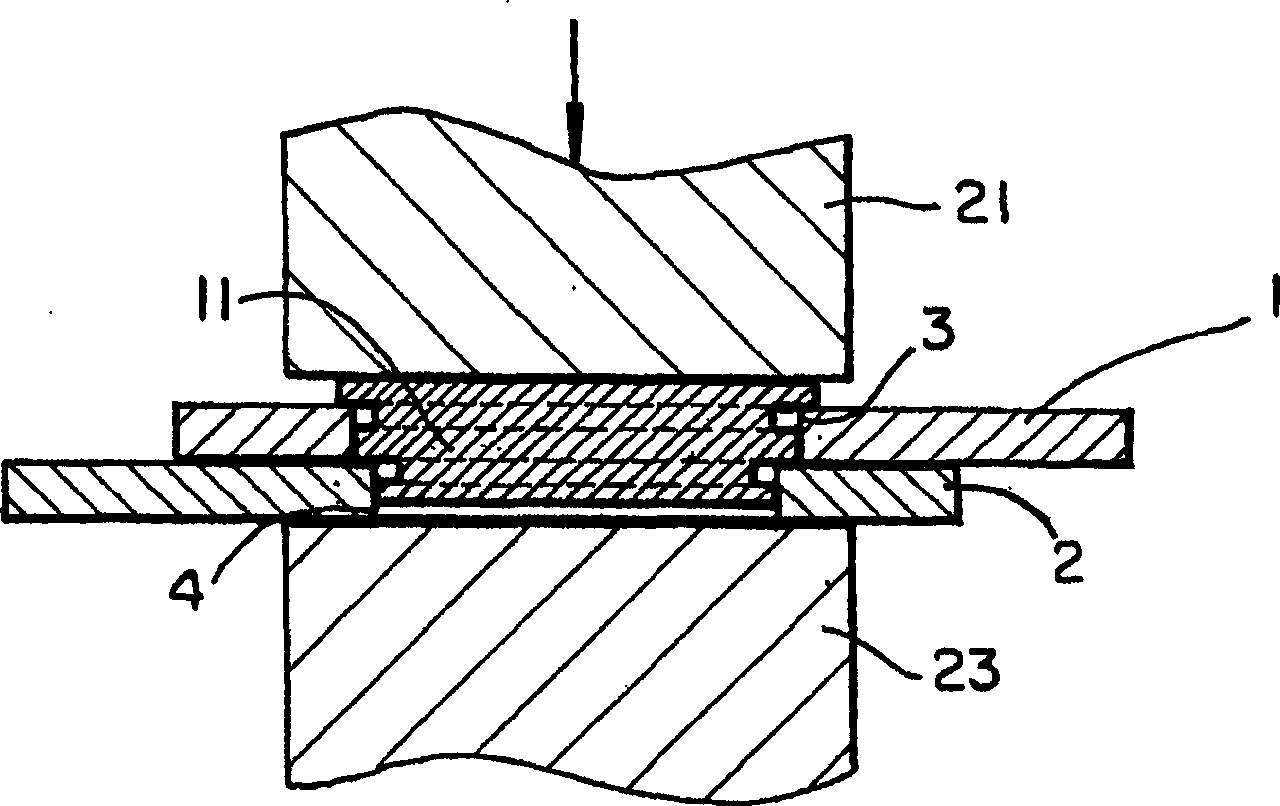

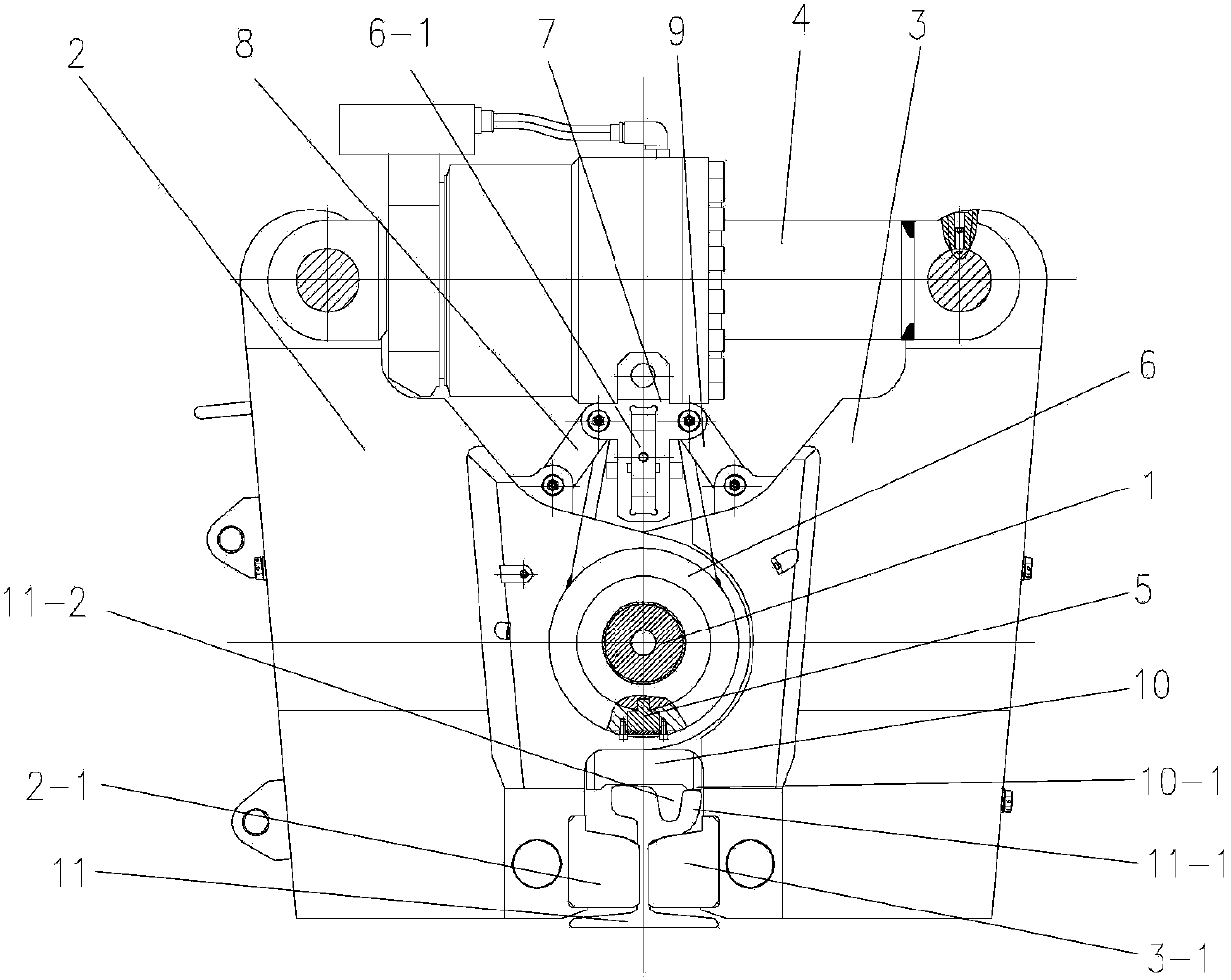

Clamping device for rotation dividing device for machine tool

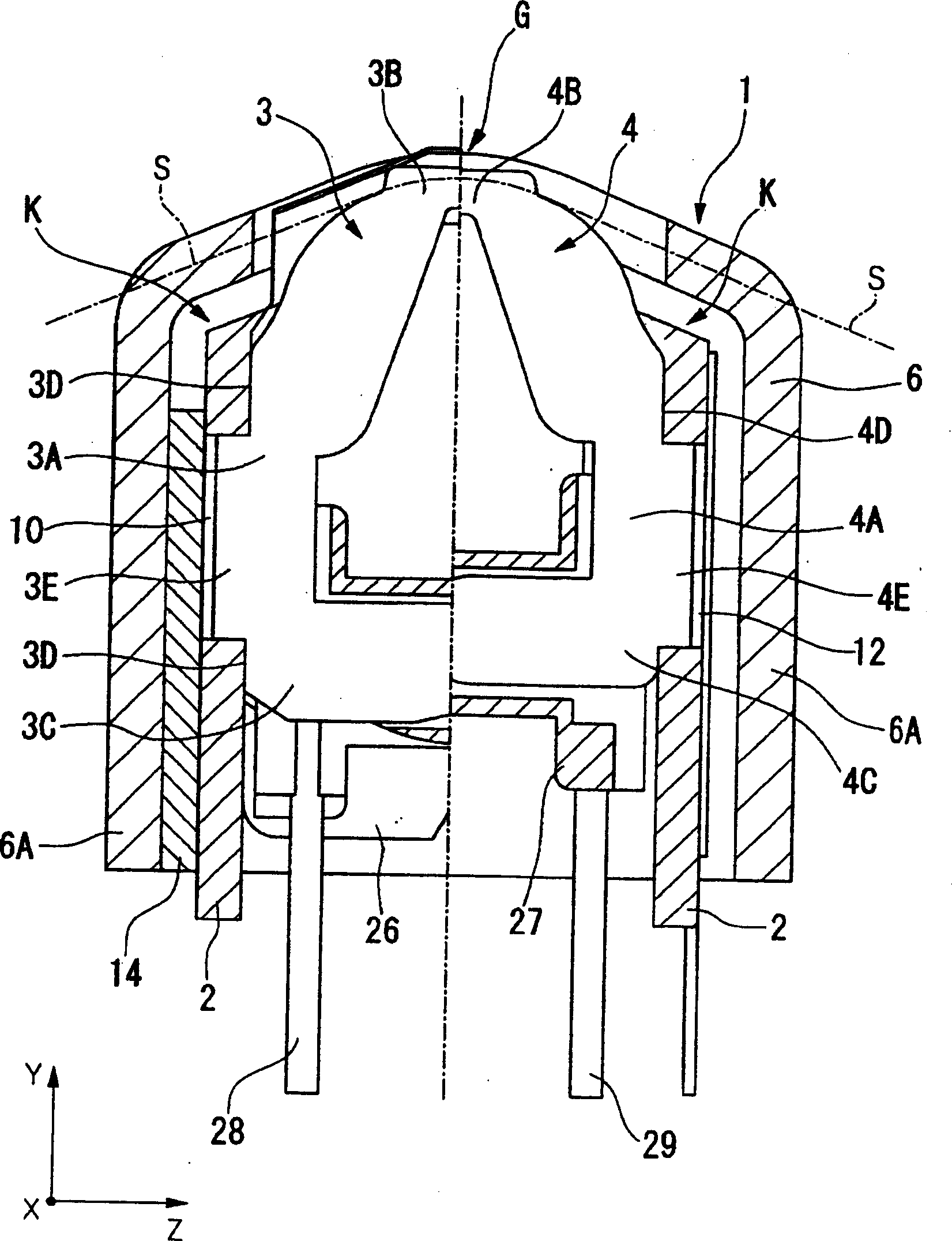

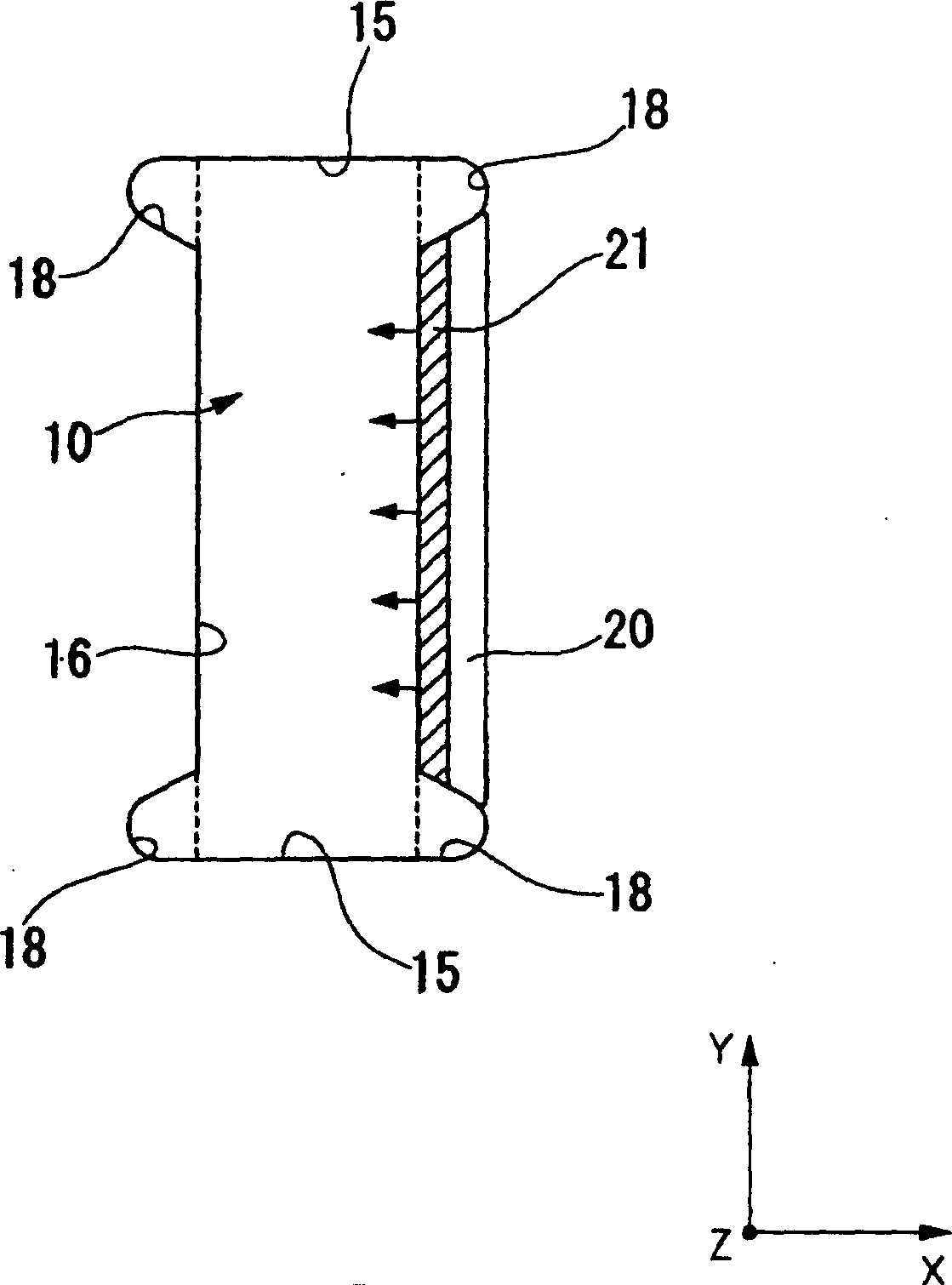

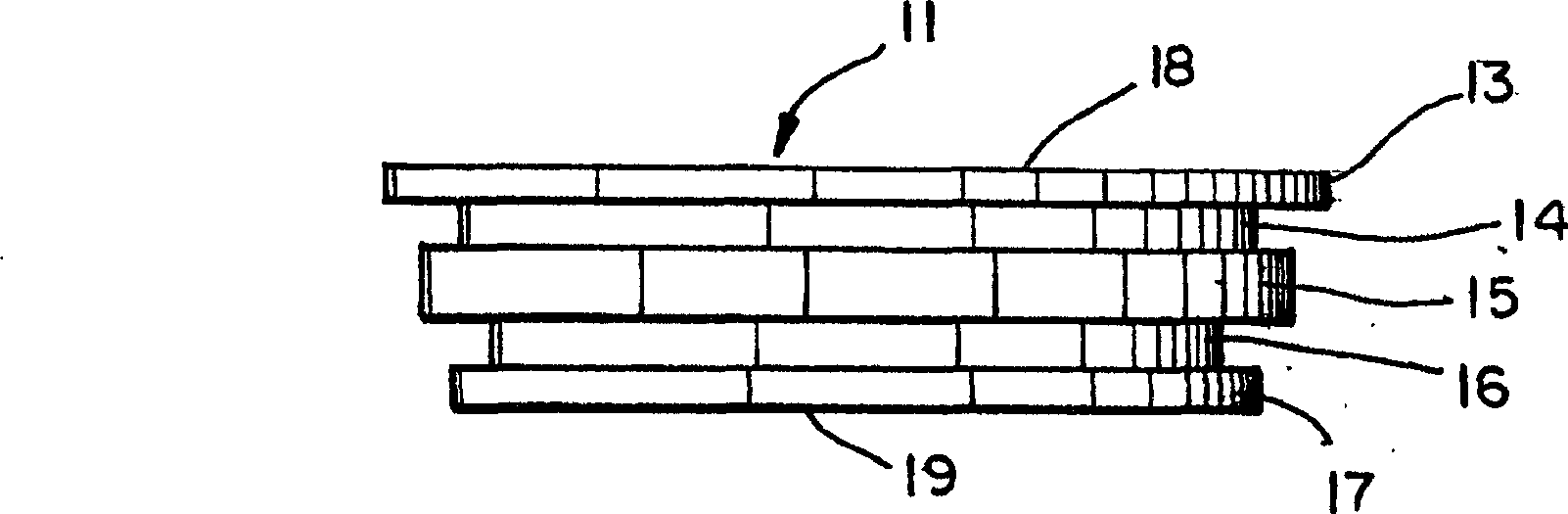

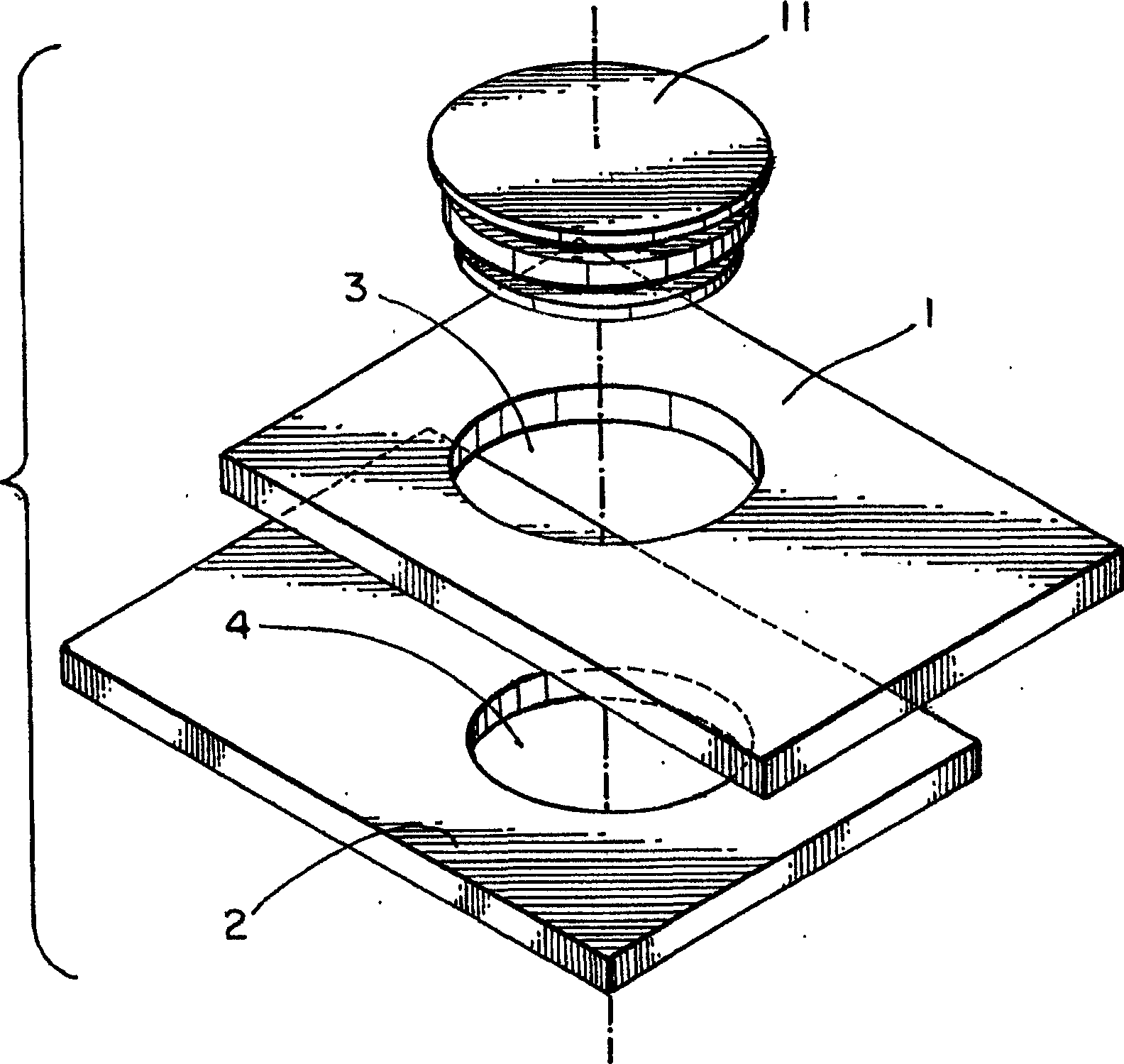

InactiveCN101396797APrevents reduction in machining accuracyMiniaturizationPrecision positioning equipmentMachine tool componentsPistonRotational axis

The present invention relates to a clamping device of a rotation indexing device used by a machine tool. The invention provides a clamping mechanism which can endure high-load procession and generates enough clamping force in the clamping device of a rotation indexing device used by a machine tool. The clamping device (2) is provided with a clamping mechanism which is set with a mode of extending along a radius direction of rotation axis (5) and is composed of more than three lever components (11) between a clamping disc (8) and a piston component (6). The pulling force of the piston component (6) is increased through a lever principle and is acted on the clamping disc (8).

Owner:TSUDAKOMA KOGYO KK

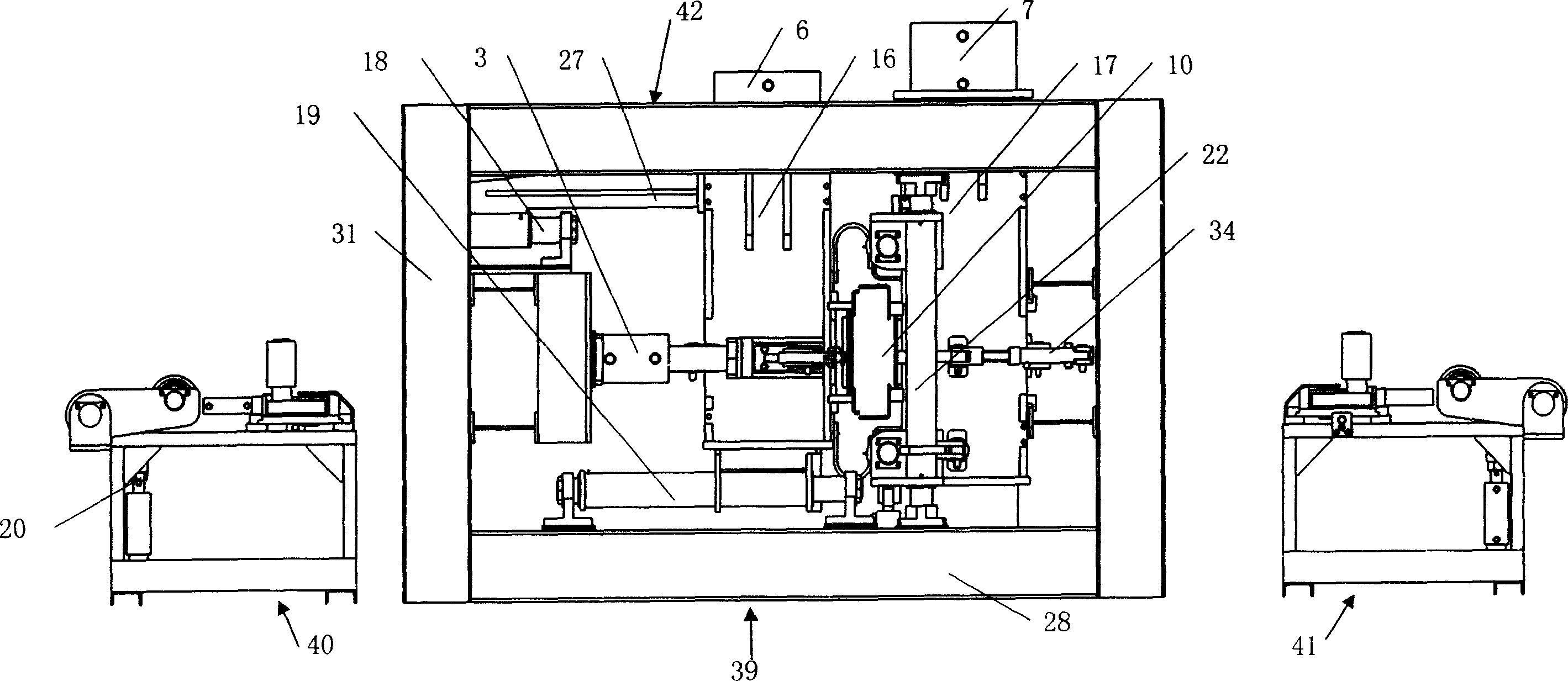

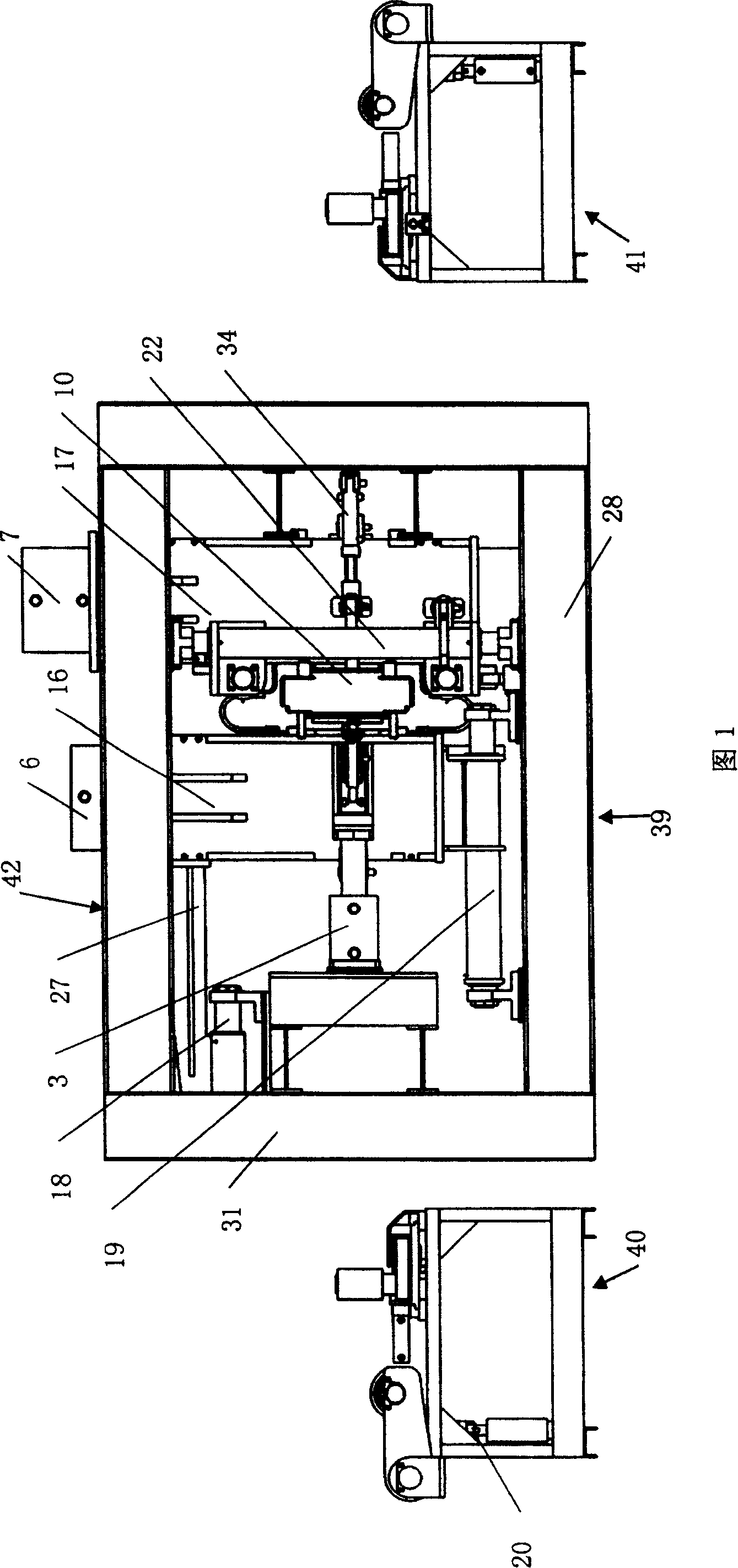

Flash welding machine for fixed steel rail

ActiveCN1876306AImprove working conditionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to a stationary rail flash welder, comprising main frame and two primary rail racks 40 and 41. The main frame rack 42 is equipped with moving rack 16, static rack 17 and centering rack 22. The moving and static rack are connected with moving rack rail clamping cylinder 6 and static rack rail clamping cylinder 7 on the upper side respectively, static rack rail clamping cylinder 7 is connected with potential transformer cover 37, and the lower part of potential transformer is connected to rail electrode 38. The moving rack 16 is connected with cradle 42vthrough supporting axis 18 and lower supporting axis 19, and the insulated heading cylinder 3 is connected with cradle 42 and moving rack 16. The horizontal centering cylinder I on right of centering rack 22 is connected with static rack 17, and vertical centering cylinder 2 is connected with cradle 42. The moving and static rack is equipped with a unit of horizontal adjusting and locating device respectively. The horizontal clamping device of primary rail racks 40 and 41 on rail bottom is drove by cylinder 21 through rack bar 30, and rack bar 30 drives two gears to rotate and locate rail in horizontal direction. The vertical location for rail is finished by lifting gearing. The invention can obviously improve welder working condition and increases welding quality.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +2

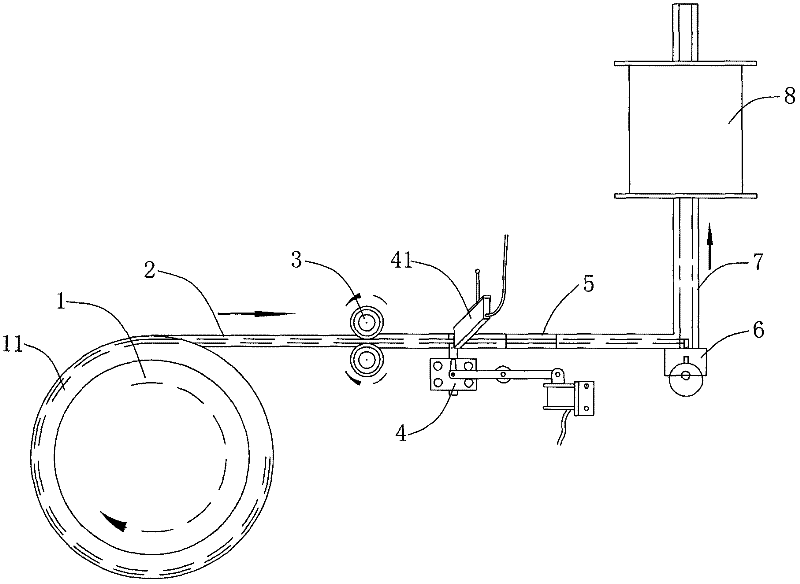

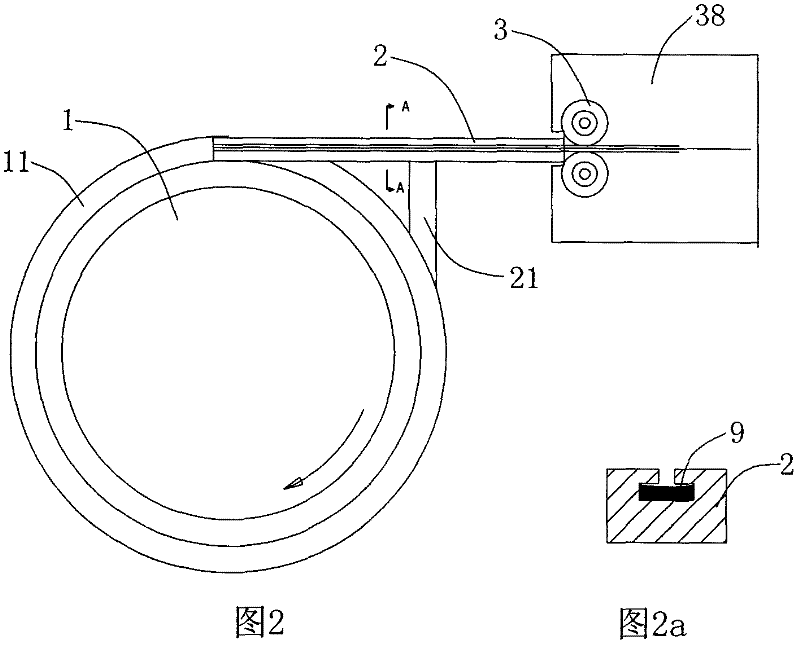

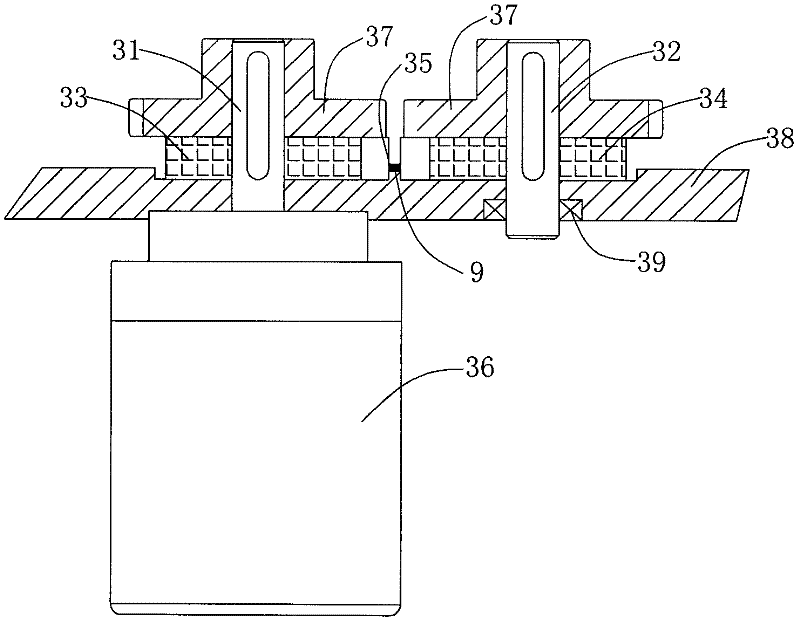

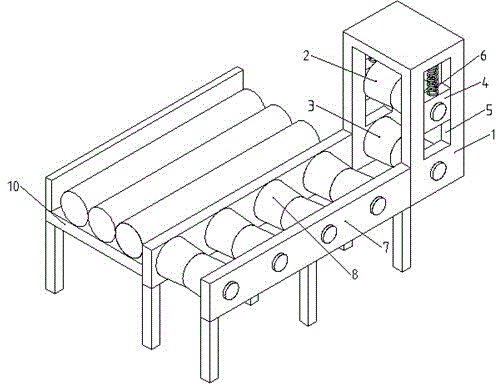

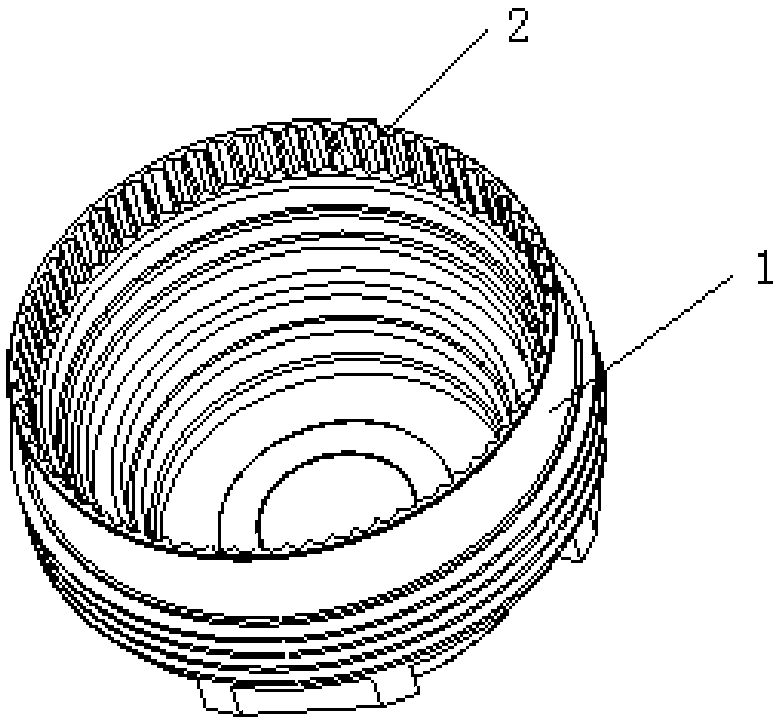

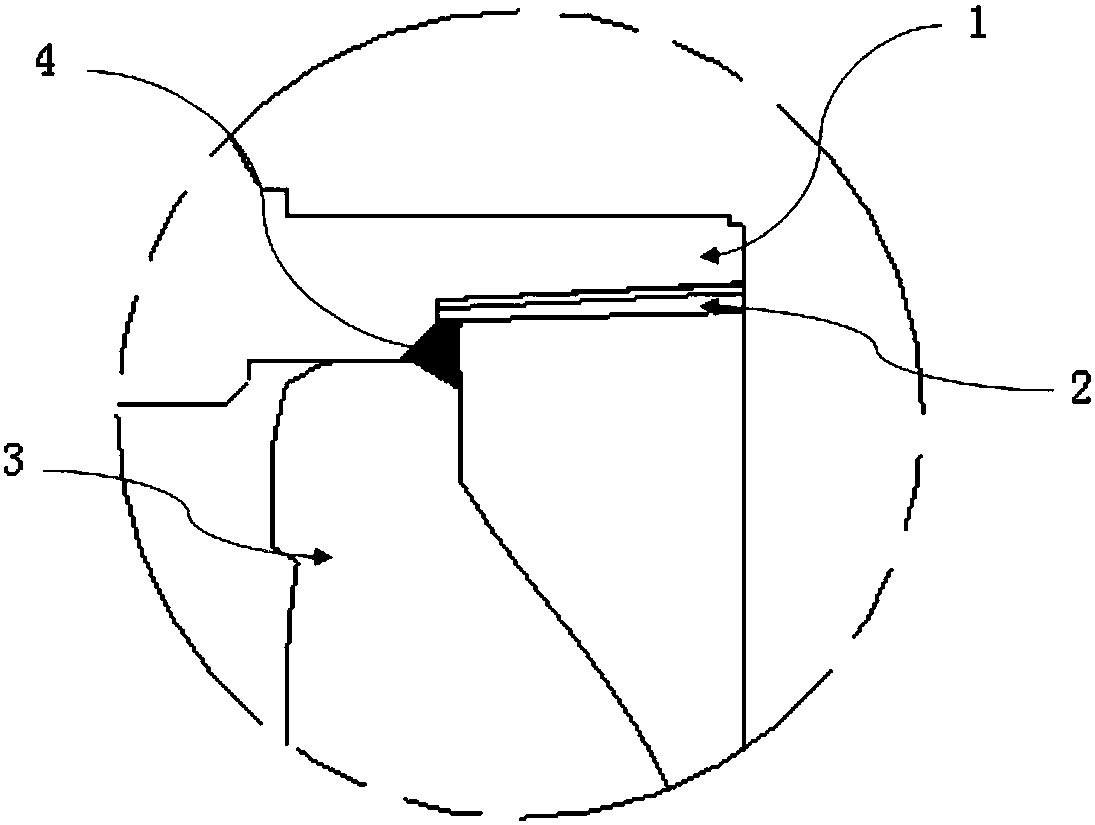

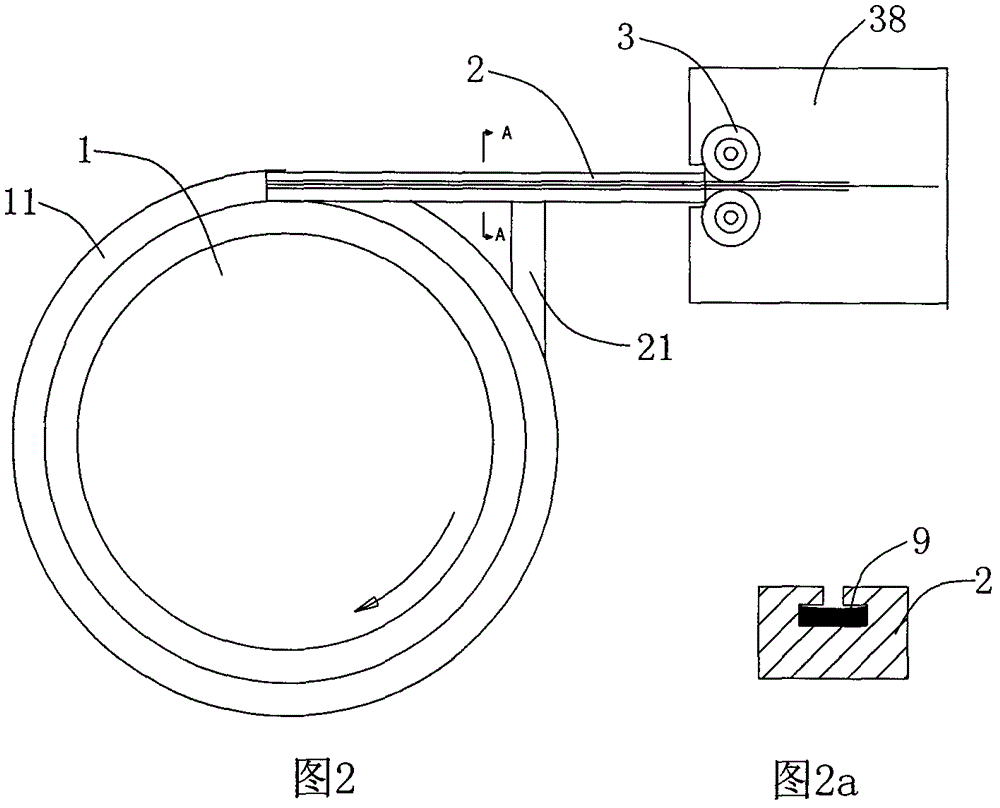

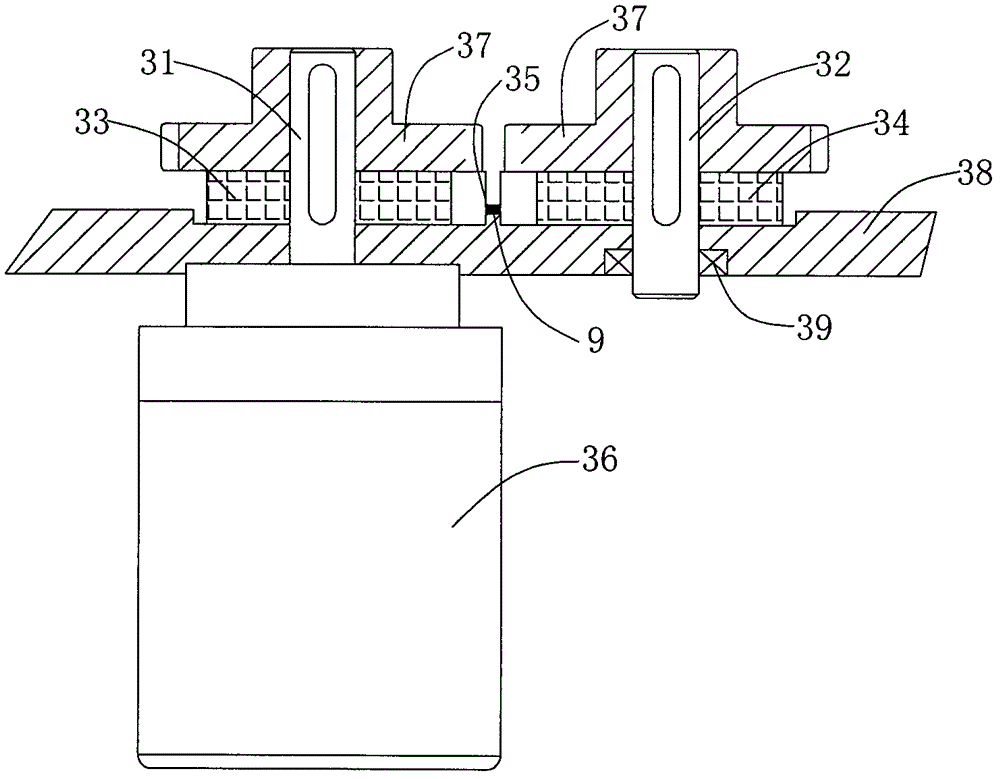

Equipment for automatically piling up and magnetizing blocky magnetic materials

InactiveCN102360712AIncrease push forceTo achieve the work needs of magnetizationMagnetic bodiesInductances/transformers/magnets manufactureMagnetizationEngineering

The invention provides equipment for automatically piling up and magnetizing blocky magnetic materials. The equipment comprises a vibration disc; the inner wall of the vibration disc is provided with a spiral type conveying channel and the outlet end of the spiral type conveying channel is connected with a vibration disc output rail. A work piece pushing mechanism is arranged on the vibration disc output rail, an ejection opening is arranged at one side of the vibration disc output rail and an ejection mechanism is arranged at the other side of the vibration disc output rail. A photoelectric detection inductive switch is arranged above the ejection opening, and the photoelectric detection inductive switch is electrically connected with the ejection mechanism and is used for driving a work piece which is ejected by the ejection mechanism. A work piece leaning device is connected to the rear side of the ejection opening and an output rail of the work piece leaning device is connected with a work piece stacking and conveying rail and an elastic ejecting and stacking mechanism. The equipment provided by the invention is rational in structure design, small in energy consumption and low in noise and can be used for identifying magnetic product work pieces in the same direction and conveying and stacking the magnetic product work pieces at a high speed, so that the full automation, the high efficiency and 100% of saturated magnetization are realized, the manual work is avoided and the work efficiency is improved.

Owner:于洁 +1

Ejector device having auxiliary-ejection force

ActiveCN101992529AIncrease push forceAchieve conversionDomestic articlesEngineeringInjection moulding

Owner:ENGEL AUSTRIA

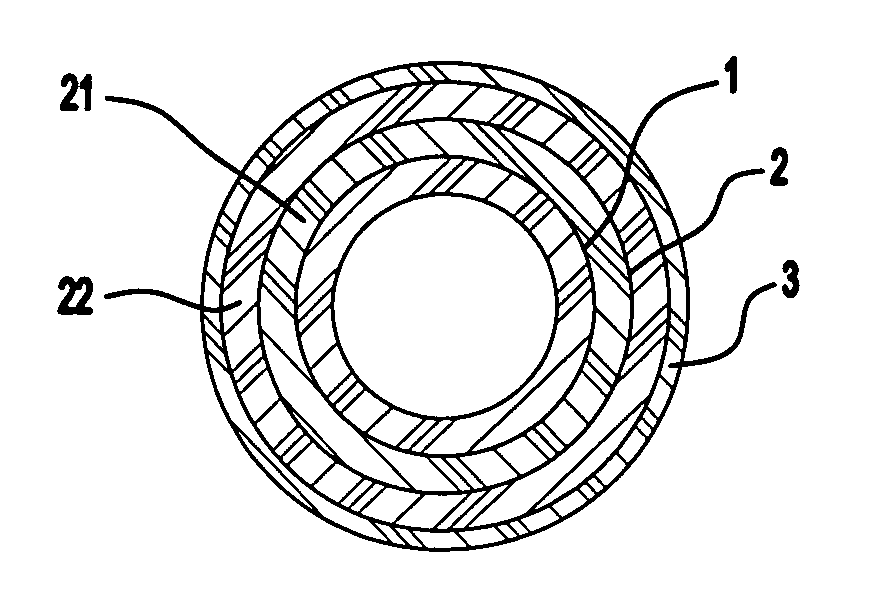

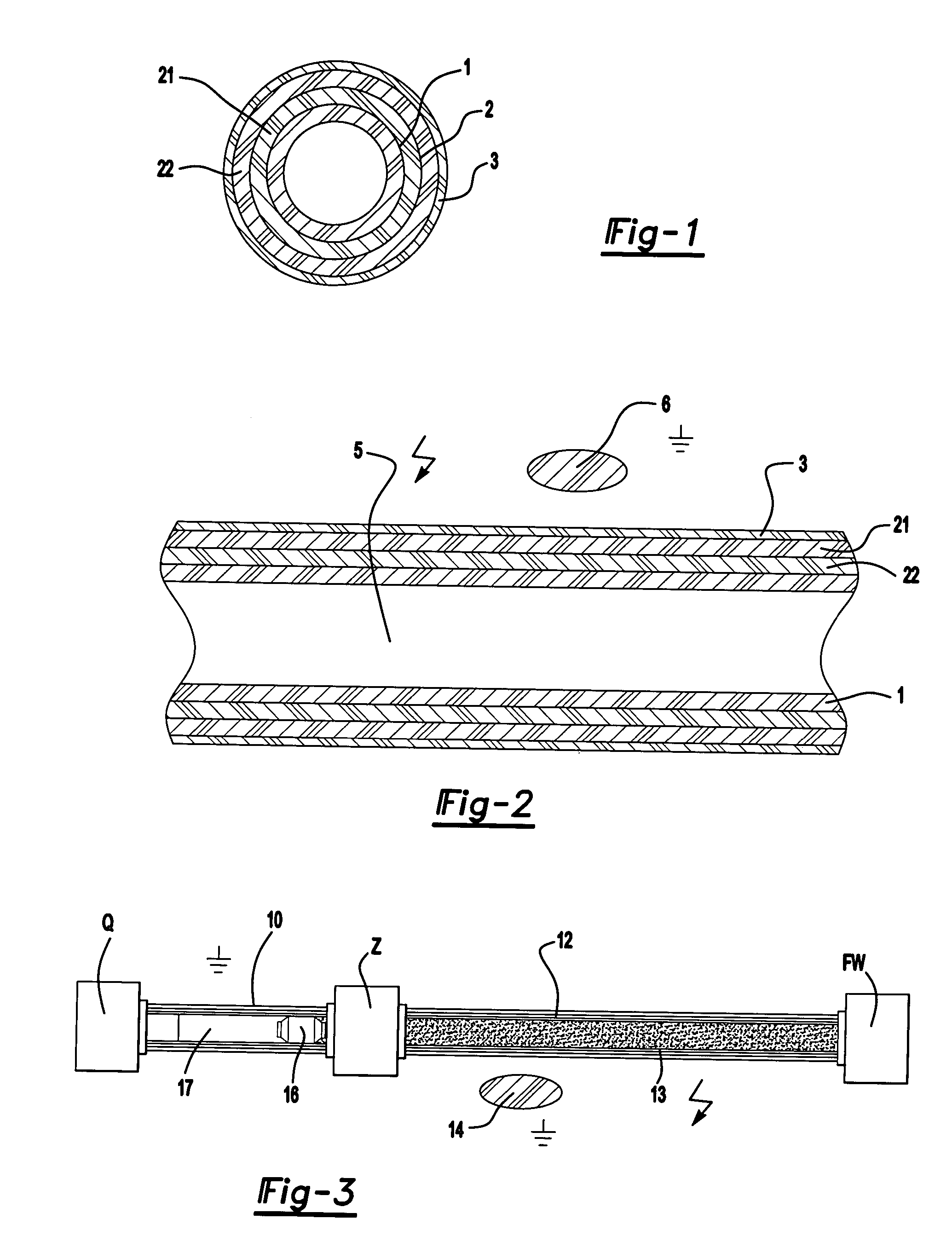

Tube for the electrostatic coating of workpieces

ActiveUS6986366B2Easy to produceLow costLiquid supply arrangementsLayered productsElectrostatic coatingBiomedical engineering

For the pig delivery of the coating material at high voltage in a system for electrostatic mass-production coating of workpieces in the vicinity of grounded parts of the system, a multi-layer tube is provided, whose innermost layer forms the piggable inner wall, while a second layer consists of a high-voltage-resistant isolation material and is surrounded by a protective outer layer.

Owner:DURR SYST INC

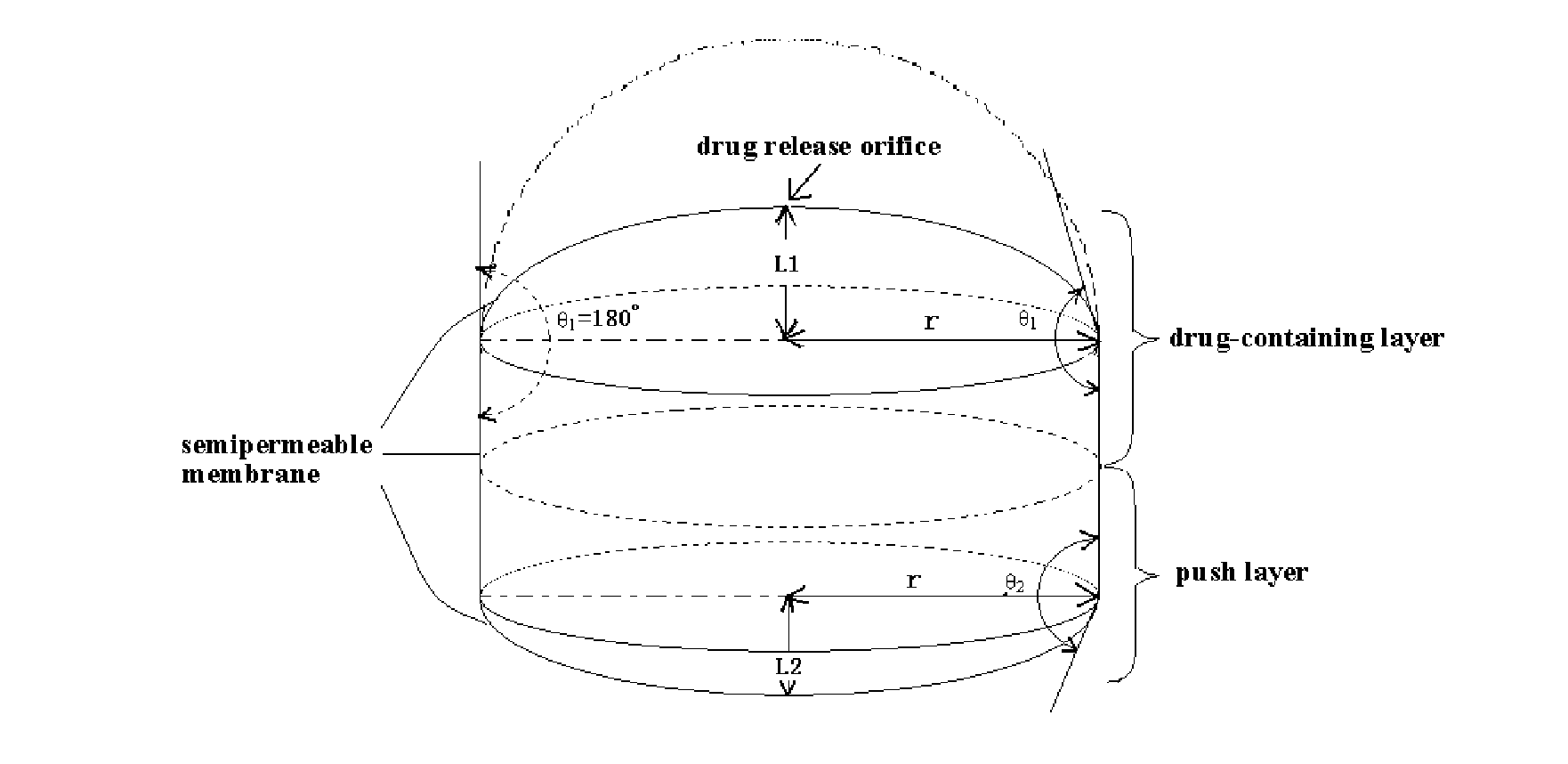

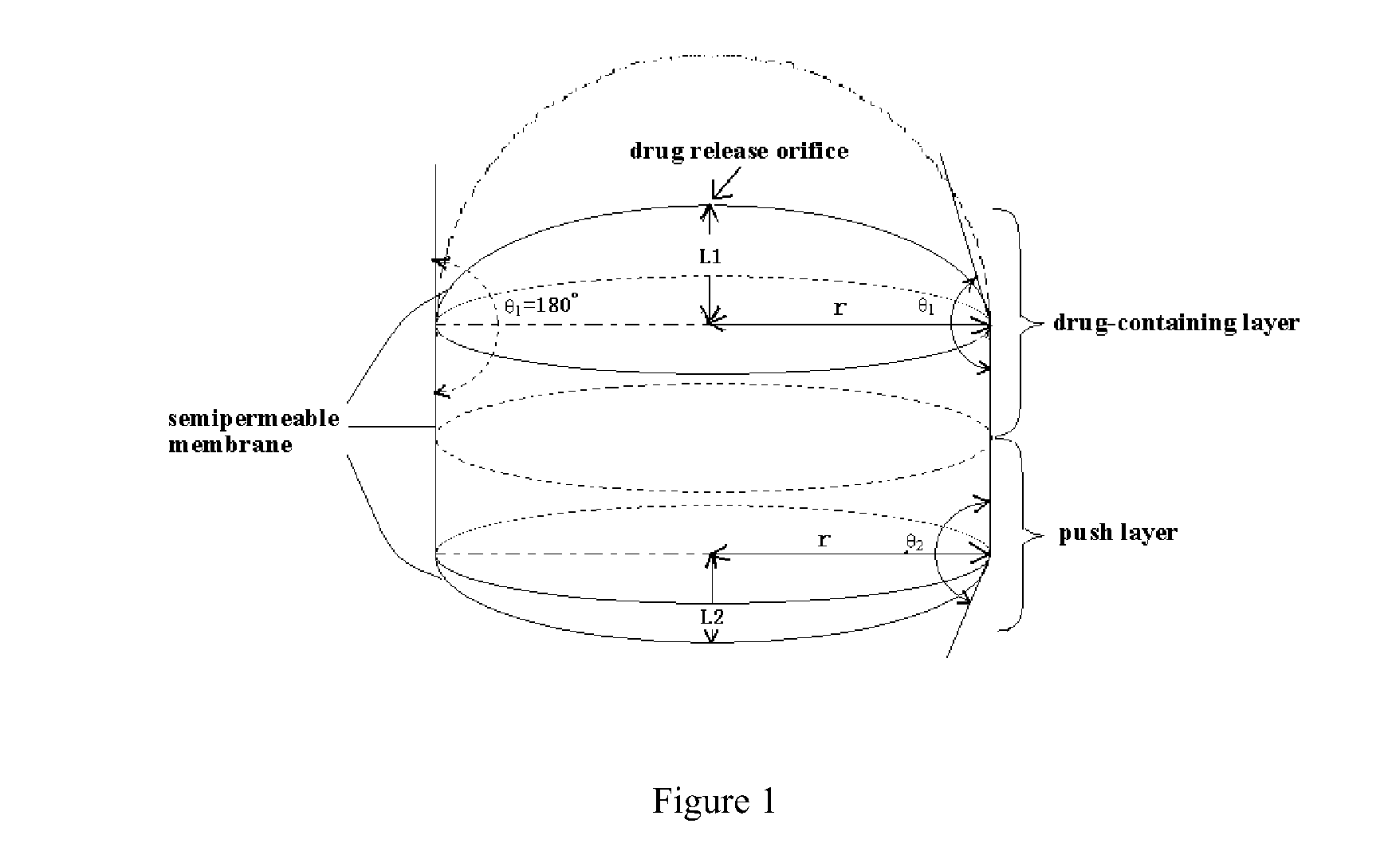

Osmotic pump controlled release tablet and preparation method thereof

InactiveUS20120171287A1Inhibition of burst releaseReduce expansion forcePharmaceutical non-active ingredientsPill deliverySemipermeable membraneControlled Release Tablet

An osmotic pump controlled release tablet and the preparation method thereof are disclosed. The osmotic pump controlled release tablet is composed of tablet core, semipermeable membrane and optional film coating. The material of said semipermeable membrane is composed of ethyl cellulose and povidone in the ratio of 1:1˜1:4 by weight. Said tablet core comprises drug containing layer and push layer. The osmotic pump controlled release tablet also characterizes in that; (1) the angle θ1 formed by the outer curved surface of the drug containing layer and the lateral surface is 120°-180°; and / or (2) the ratio of L1 to r is 0.27-1.0, wherein L1 is the vertical distance from the central vertex of the outer curved surface of the drug containing layer to the plane formed by the intersection line between the outer curved surface of the drug containing layer and the lateral surface, and r is the radius of the tablet core.

Owner:BEIJING TEAM HOSPITAL MANAGEMENT

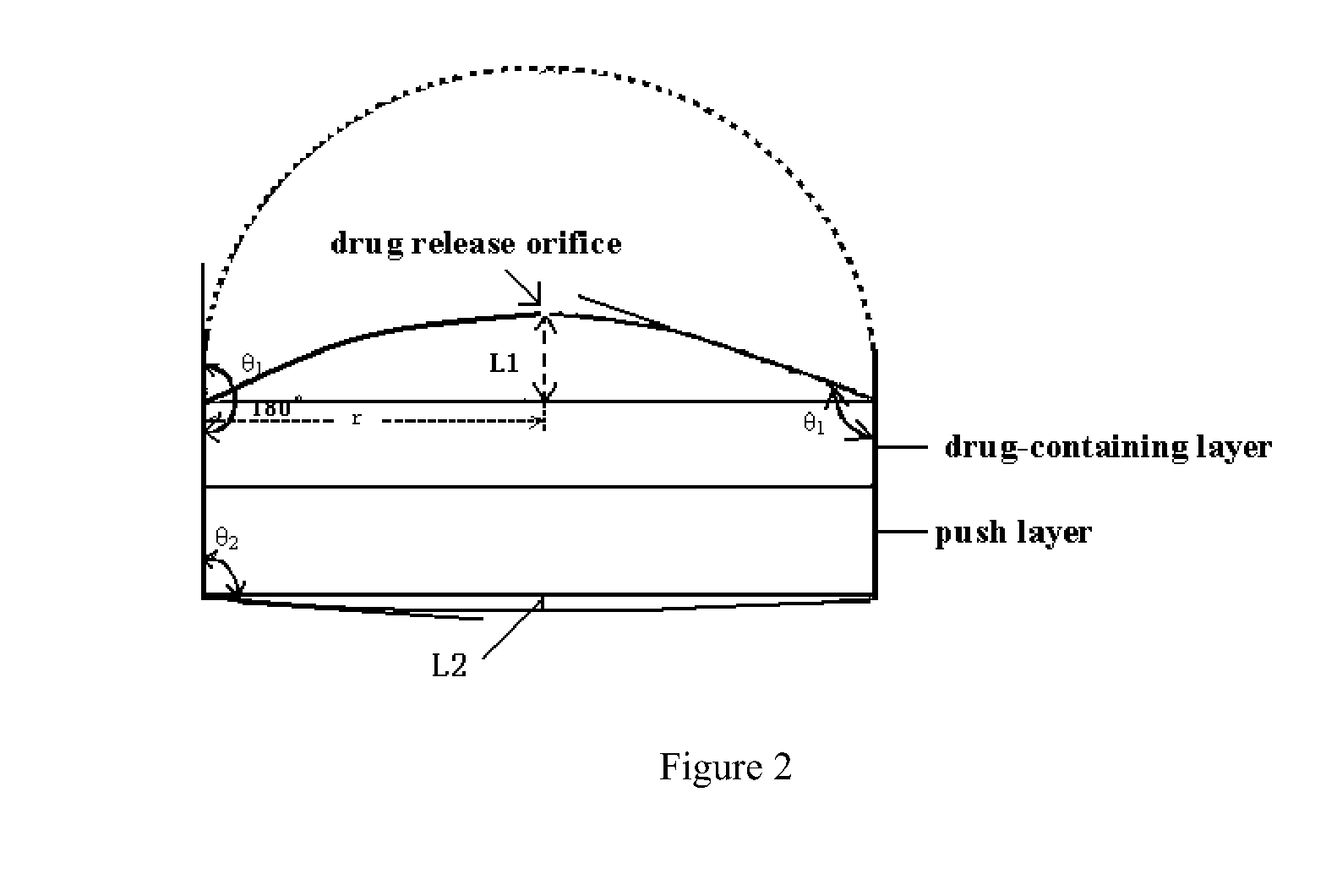

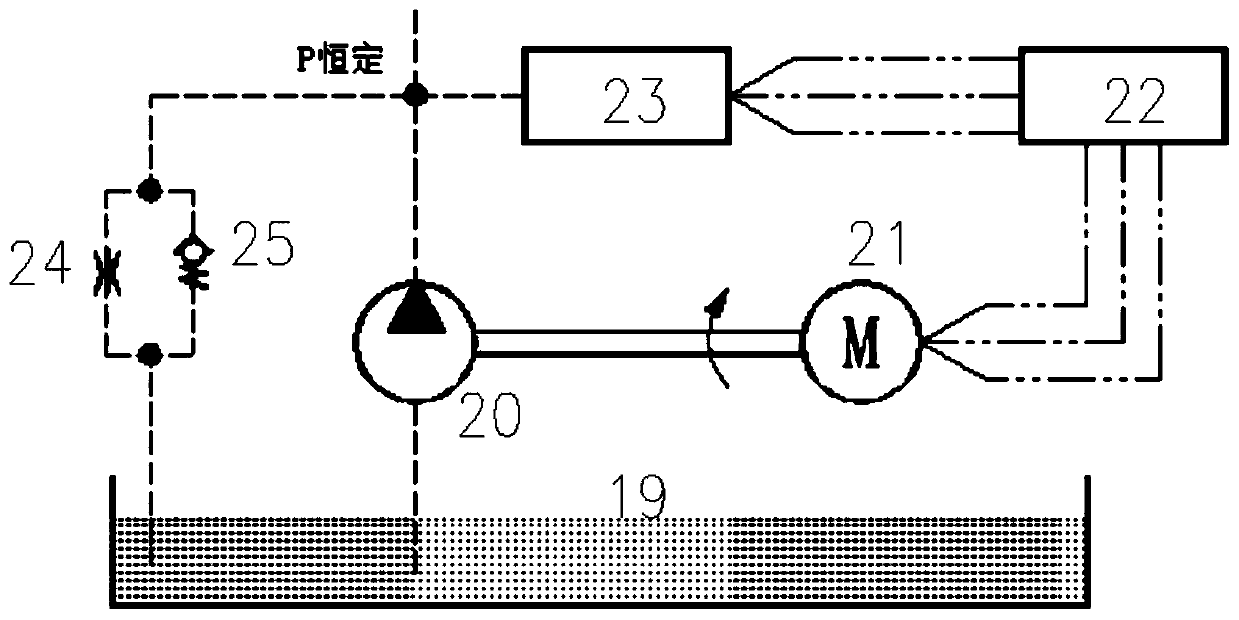

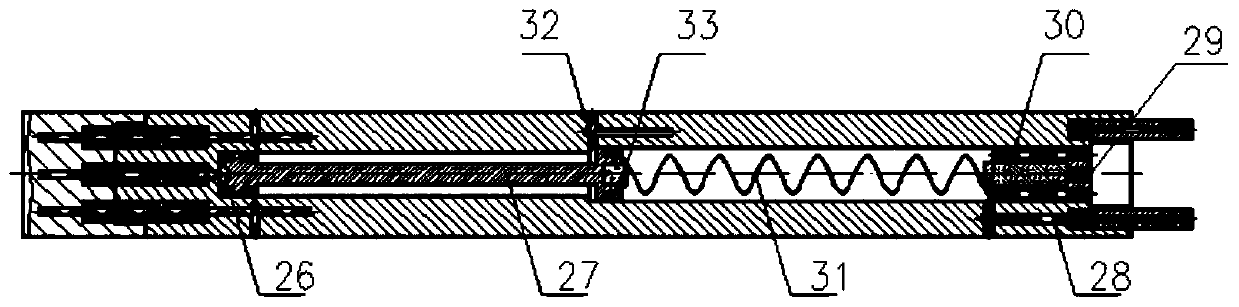

Method and device for measuring downhole formation fluid pressure

ActiveCN110230490AStable pressureIncrease or decrease the pressure valueSurveyDepth in a wellWireless transceiver

The invention discloses a method and device for measuring downhole formation fluid pressure. The device comprises ground equipment and downhole apparatus, wherein the downhole apparatus is connected with the ground equipment; the ground equipment comprises a vertical pipe, a three-way pipe is installed on the vertical pipe, a pressure sensor is installed at the position of the three-way pipe, thepressure sensor is connected with a wireless pressure sensor main machine through a data line, the wireless pressure sensor main machine is connected with a sucker antenna, the sucker antenna is in signal connection with a wireless transceiver, and the wireless transceiver is connected with a data processing meter; and the downhole apparatus comprises a thrust assembly, and a thrust module and a probe module are installed on the thrust assembly. According to the method and device for measuring the downhole formation fluid pressure, the magnitude of different thrust force is set according to different well depths, when shallow well measurement is carried out, the energy consumption of the downhole apparatus can be reduced, and meanwhile, the risk of pressure damage to the well wall due to too large thrust force is reduced; and when deep well measurement is carried out, the thrust force is reasonably increased to enable the seal between a sealing probe and a well wall mud cake to be reliable, the influence of annulus pressure on formation fluid is reduced, and thus the accuracy of the measurement is improved.

Owner:BEIJING LIUHE GREATNESS TECH

Flash welding machine for fixed steel rail

ActiveCN100396421CImprove working conditionImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesTransformerFlash welding

The invention relates to a stationary rail flash welder, comprising main frame and two primary rail racks 40 and 41. The main frame rack 42 is equipped with moving rack 16, static rack 17 and centering rack 22. The moving and static rack are connected with moving rack rail clamping cylinder 6 and static rack rail clamping cylinder 7 on the upper side respectively, static rack rail clamping cylinder 7 is connected with potential transformer cover 37, and the lower part of potential transformer is connected to rail electrode 38. The moving rack 16 is connected with cradle 42vthrough supporting axis 18 and lower supporting axis 19, and the insulated heading cylinder 3 is connected with cradle 42 and moving rack 16. The horizontal centering cylinder I on right of centering rack 22 is connected with static rack 17, and vertical centering cylinder 2 is connected with cradle 42. The moving and static rack is equipped with a unit of horizontal adjusting and locating device respectively. The horizontal clamping device of primary rail racks 40 and 41 on rail bottom is drove by cylinder 21 through rack bar 30, and rack bar 30 drives two gears to rotate and locate rail in horizontal direction. The vertical location for rail is finished by lifting gearing. The invention can obviously improve welder working condition and increases welding quality.

Owner:BEIJING RAILWELD NEW MATERIAL TECH CO LTD +2

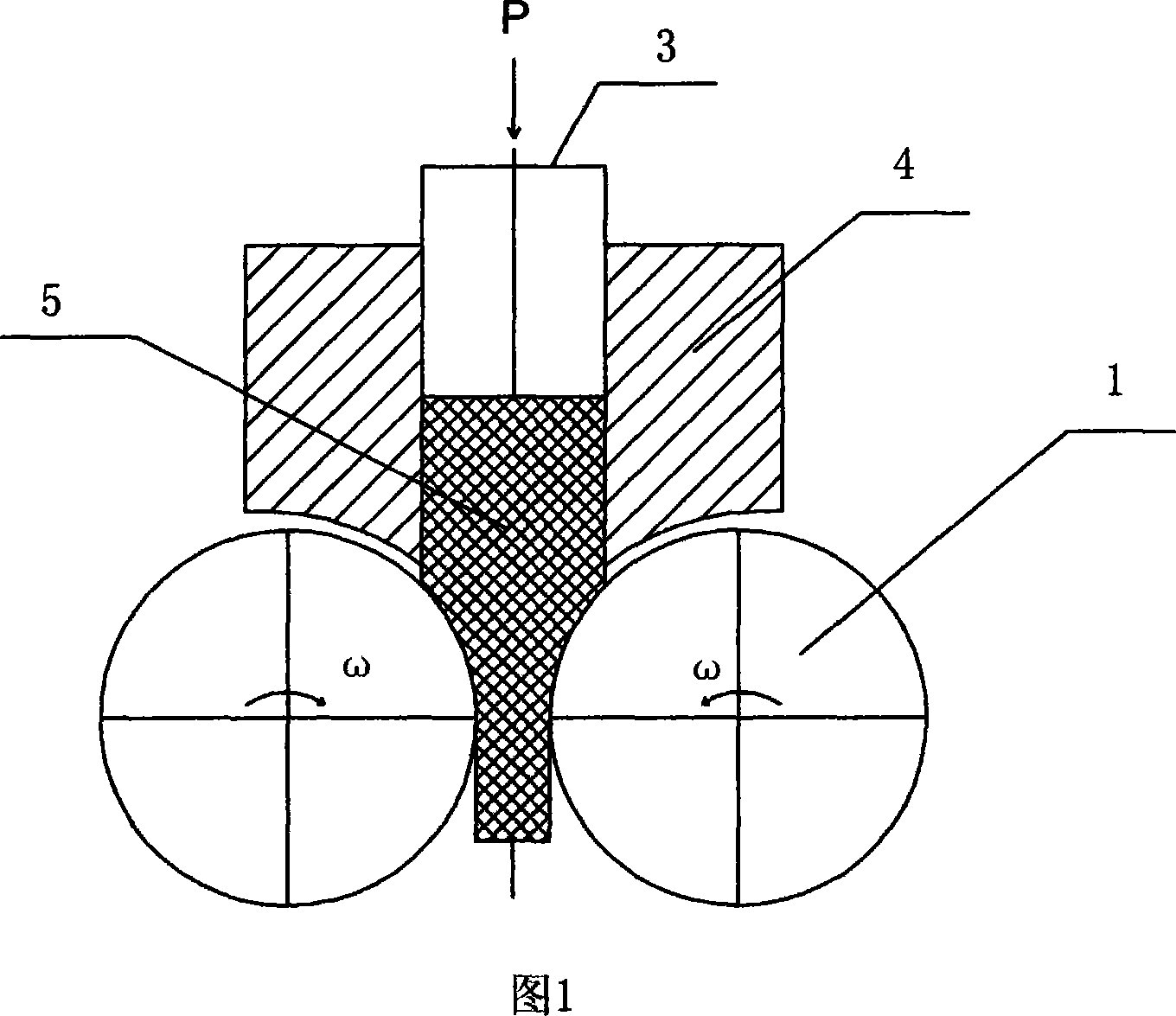

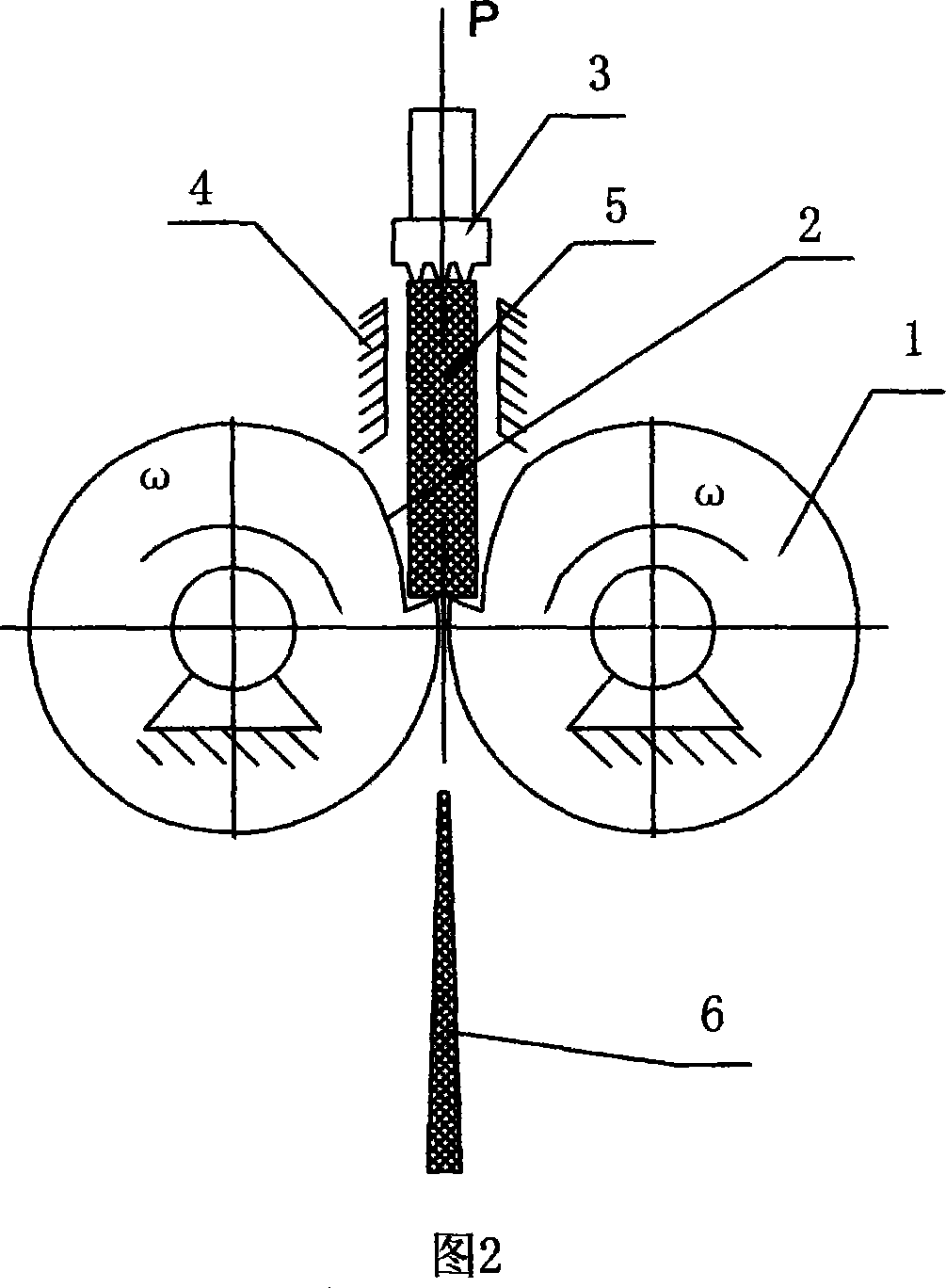

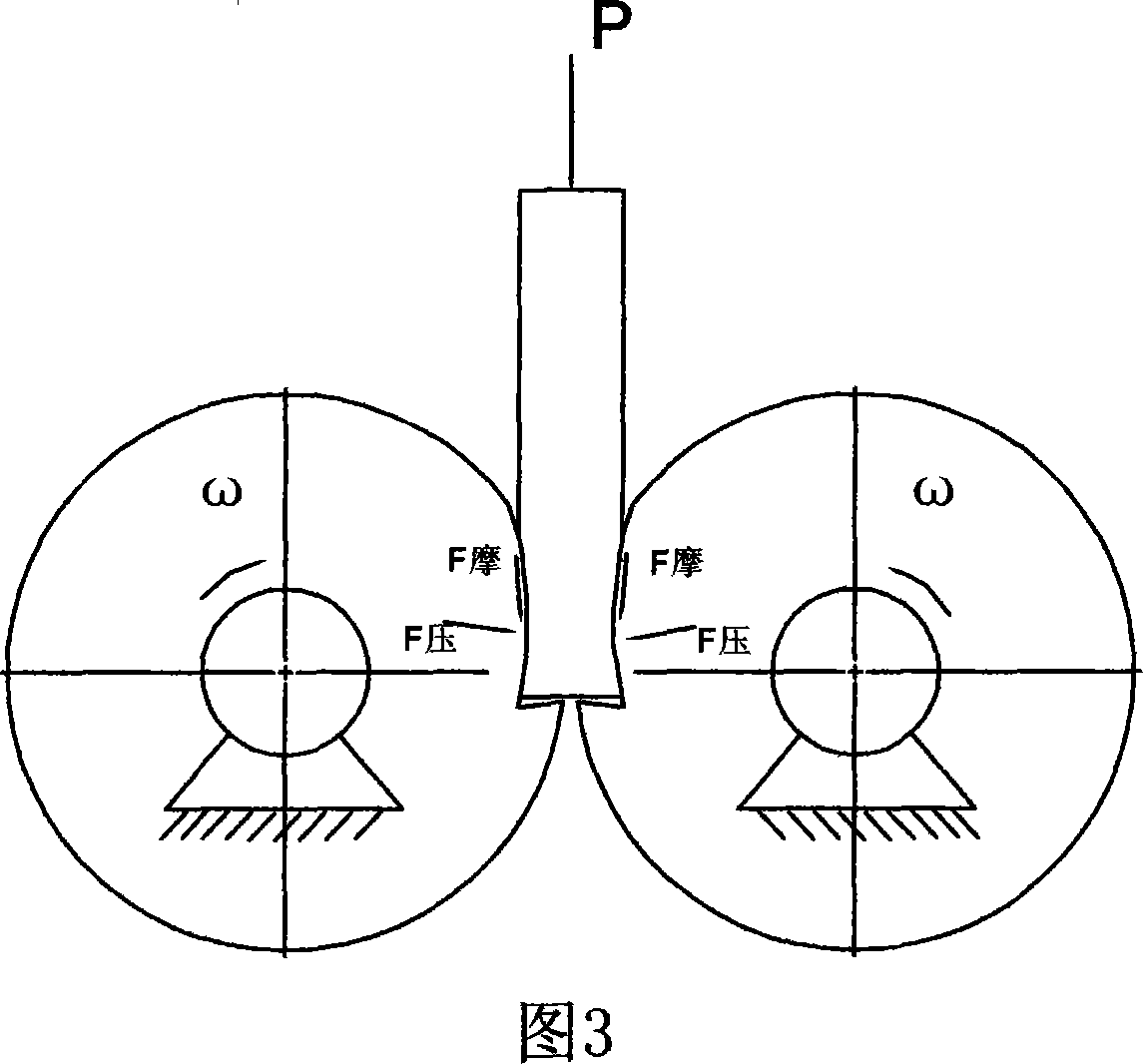

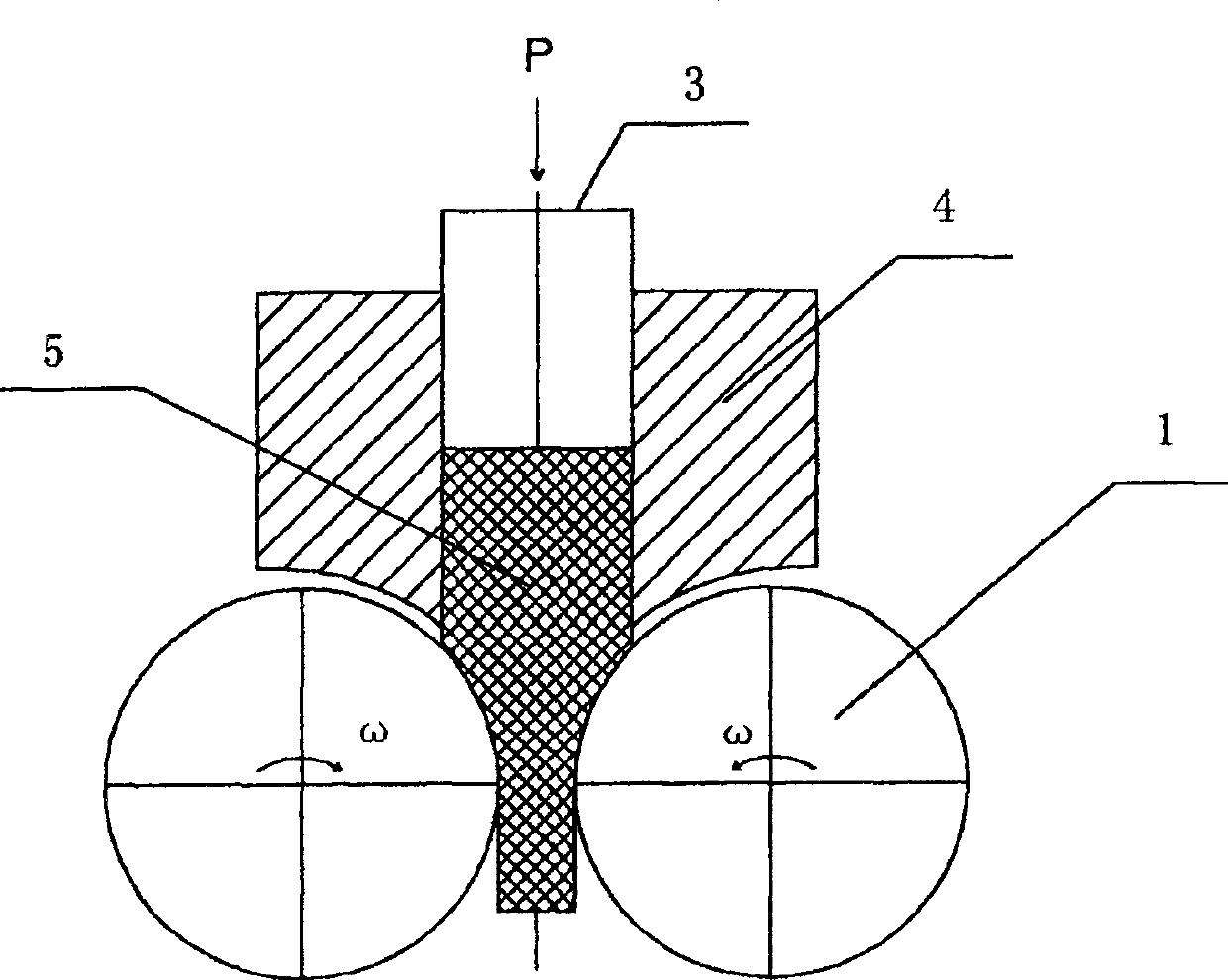

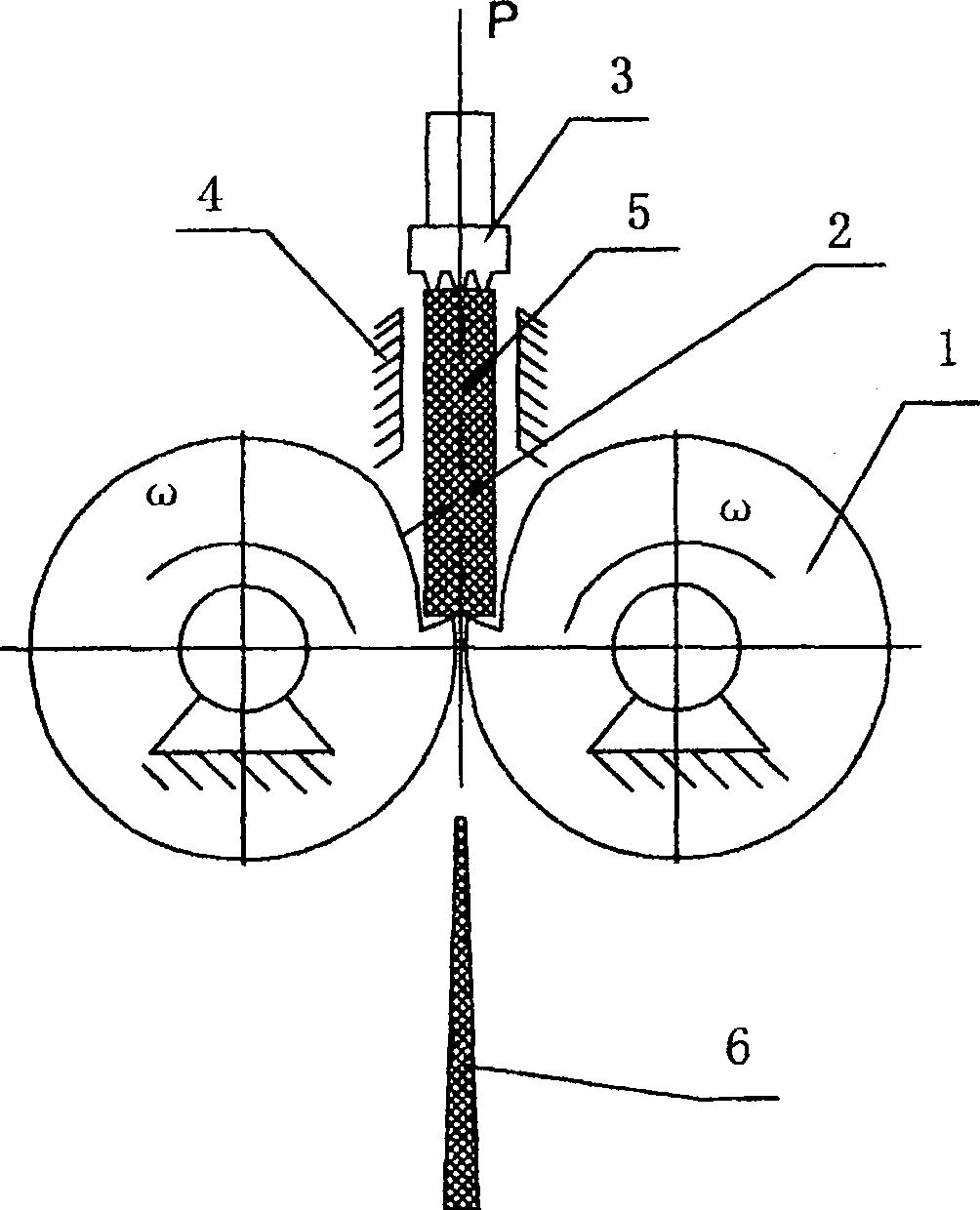

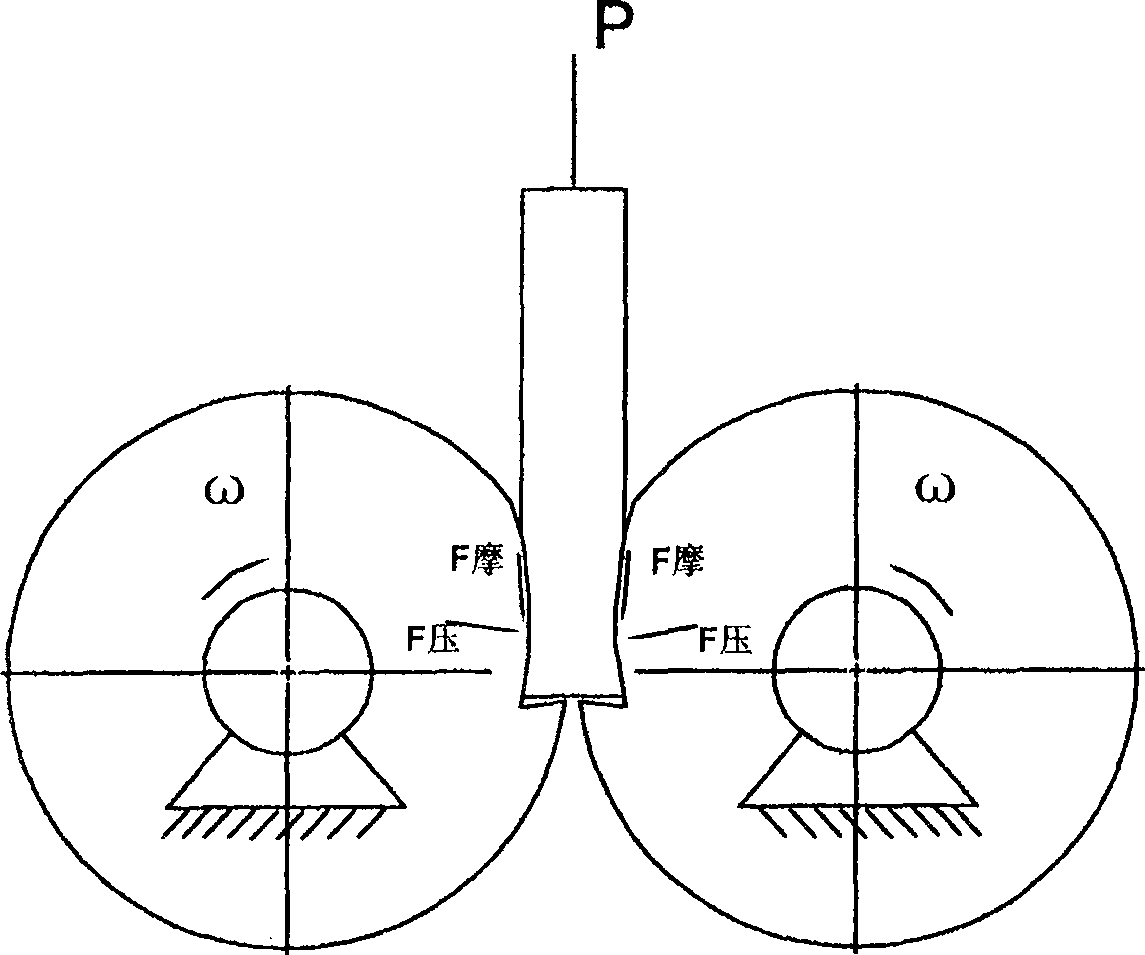

Roller type cavity die extrusion molding method

InactiveCN101062511ASmall tonnageReduce energy consumptionExtrusion diesRams/plungersBending forceFriction force

The invention relates to a roller wheel concave mold compression, using a pair of rolling wheel at the circumference surface of the concave mold cavities, featuring in a set of push rod and compression cylinder. The blank is formed by stuffing the blank into the compression cylinder, pushing the rod to the blank to the rolling wheel concave, with two rolling wheels rotating in the same speed in opposite directions, under the friction on both sides of the blank squeezing the blank to deformation, fostering the flow of the metal, with blank extended in the forwarding, and released out from the space between two rolling wheels. It improves the fluidness of the deformed blank, improved in stress status, forming force, easy to achieve the forming goal, reduced in bended force, improved in mold durability, being able to form in precision.

Owner:ZHONGBEI UNIV

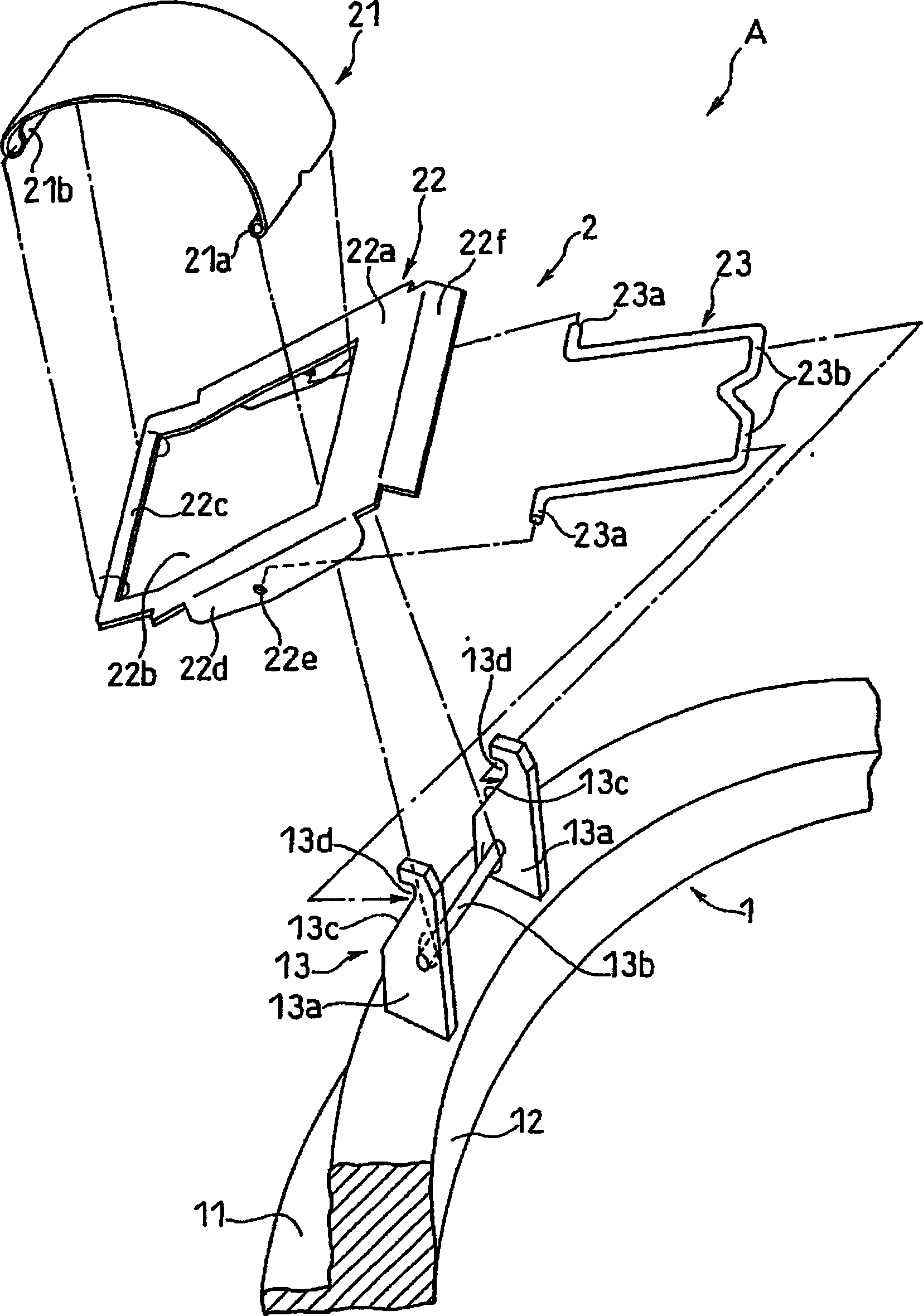

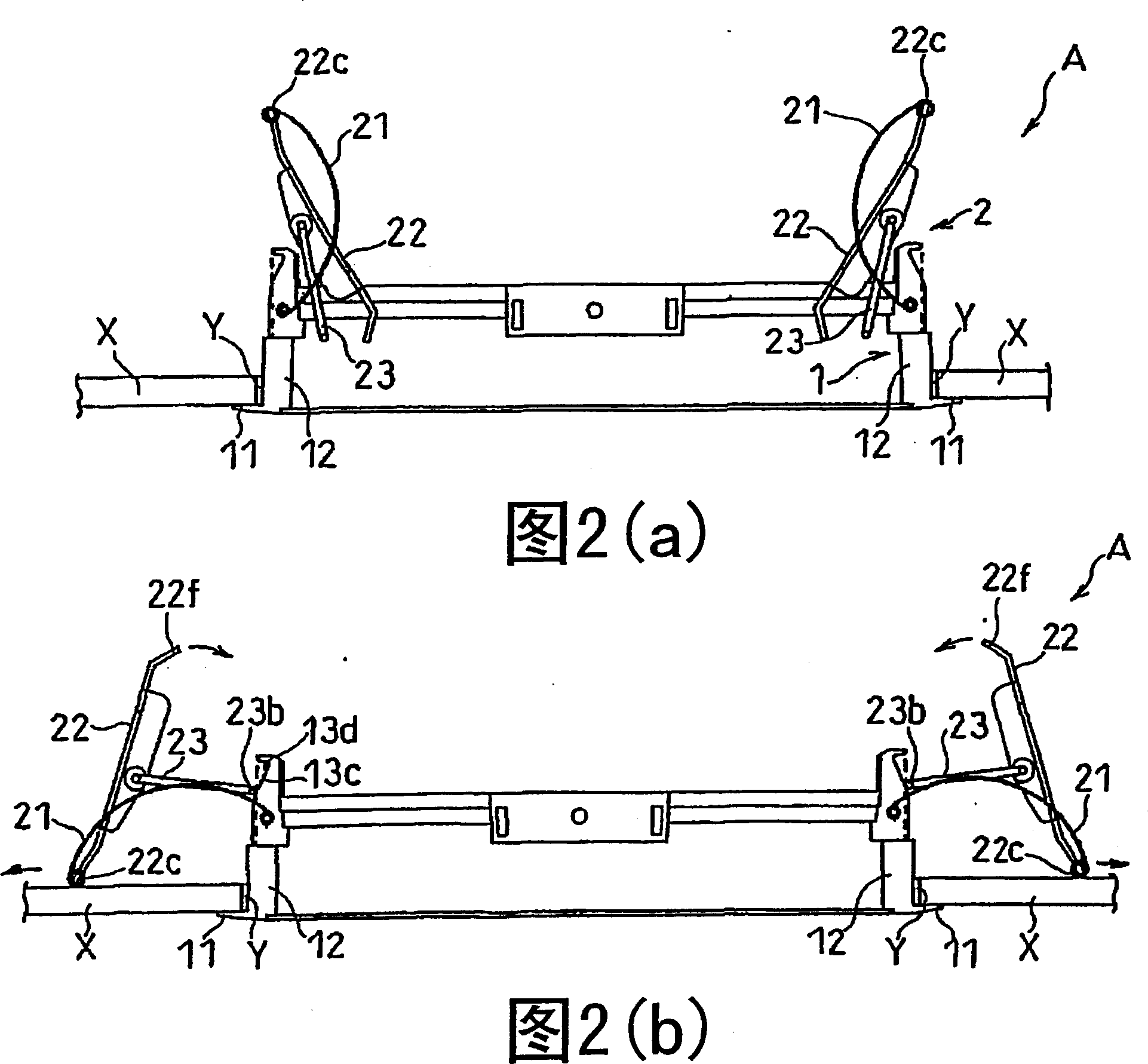

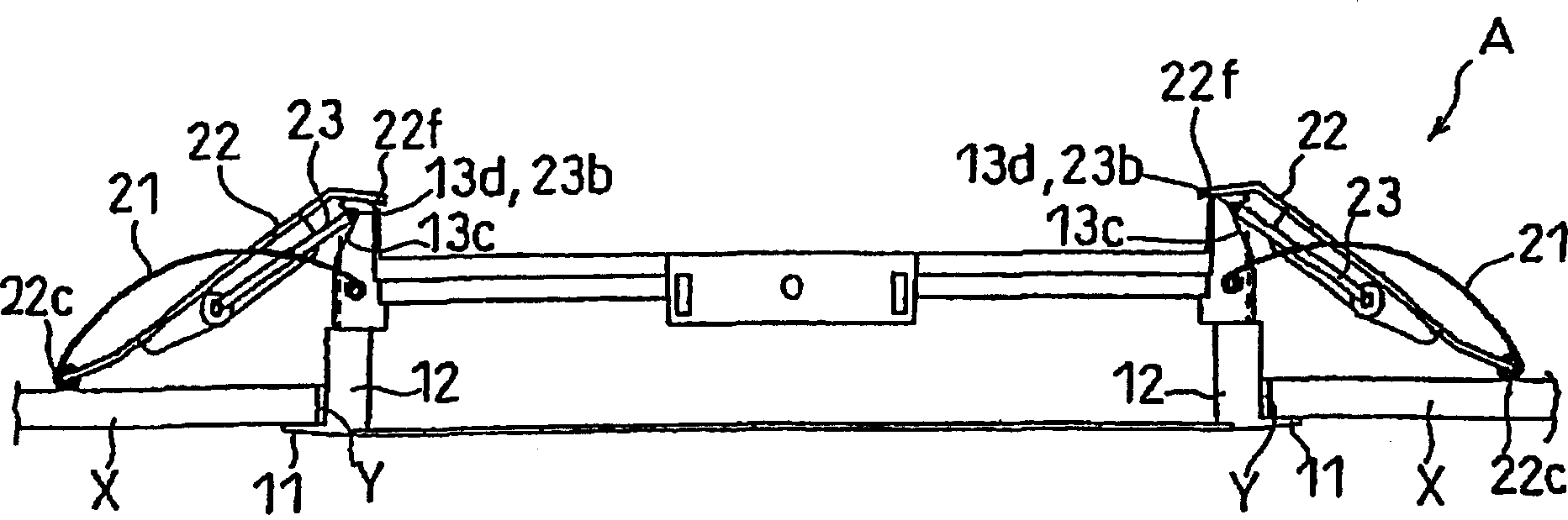

Fitting structure for built in type apparatus

The present invention is an installation structure for embedded appliances, which is used to accommodate and fix the installation frame of the installation appliance body in the installation hole formed on the ceiling, wall, etc., the installation frame has a frame frame embedded in the installation hole, formed The frame frame has a flange piece extending out of the mounting hole, and the support portion is connected to the mounting parts, and each mounting part is equipped with a leaf spring, an operating piece with an opening, One end is pivotally supported on the operating piece and the other end has a toggle lever with an engaging end, the leaf spring passes through the opening of the operating piece, one end is pivotally supported on a support shaft provided on the supporting portion, and the other end is pivotally supported on On the operation piece, after inserting the installation frame into the installation hole, abut one end of the operation piece against the inside of the top plate, wall, etc., and elastically deform the leaf spring to engage the engaging end with the claw of the support part of the installation frame part, whereby the mounting frame is lifted by the elastic force of the leaf spring.

Owner:ENDO LIGHTING CORP

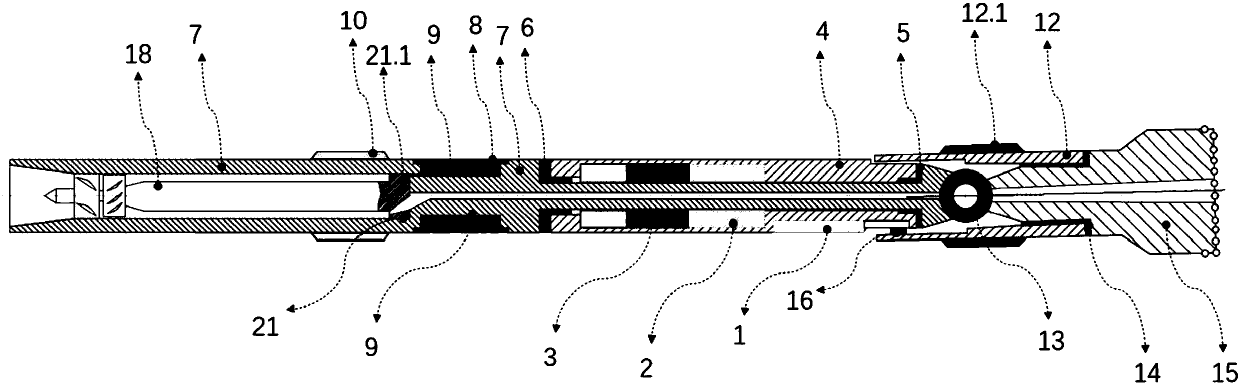

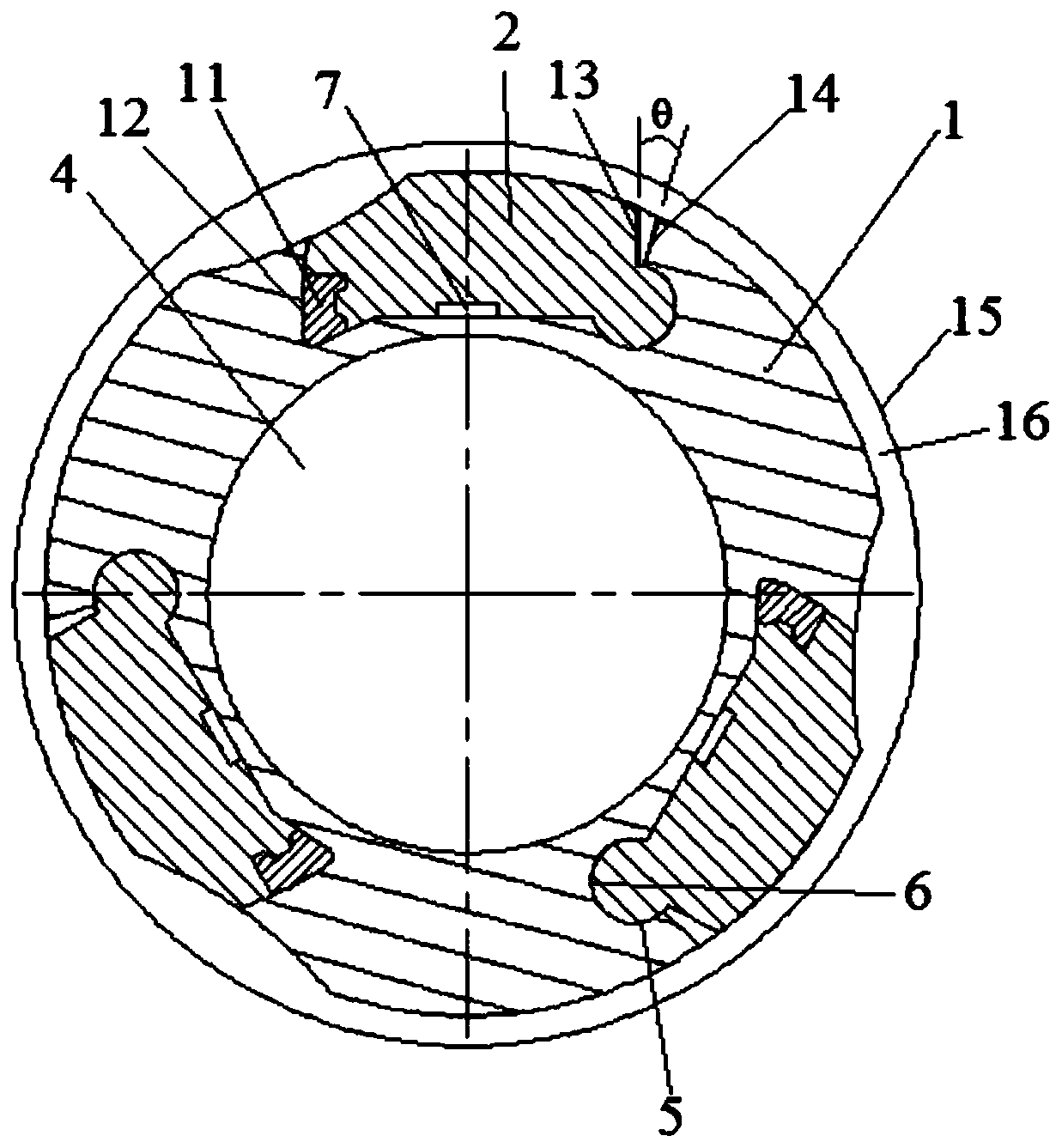

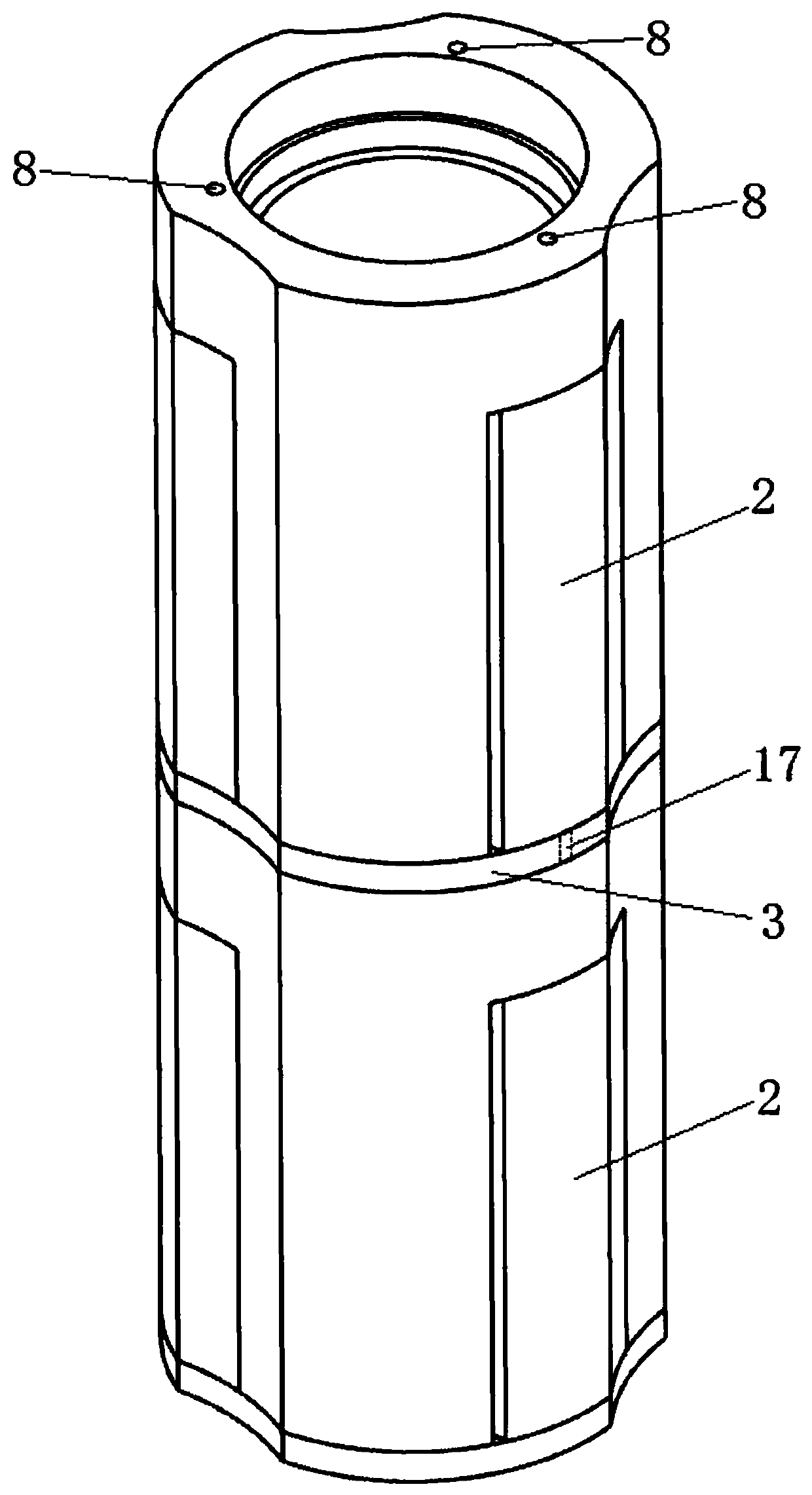

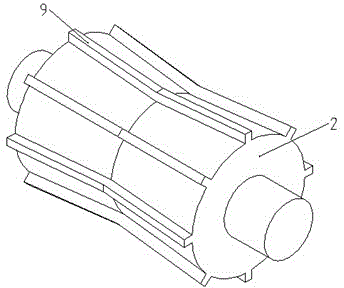

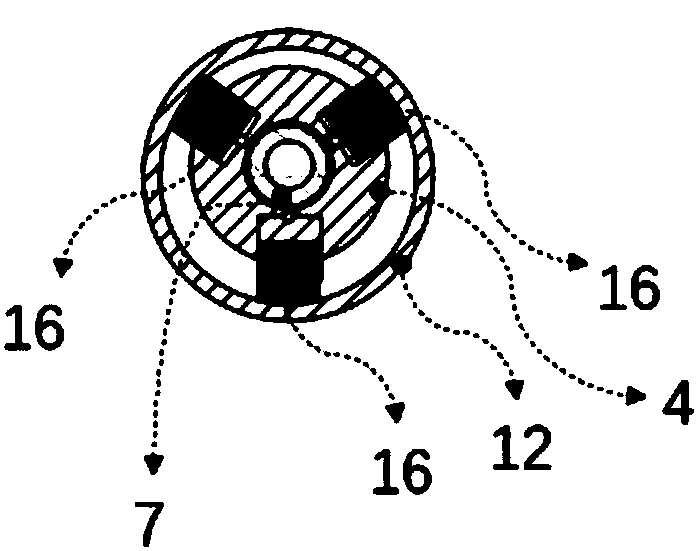

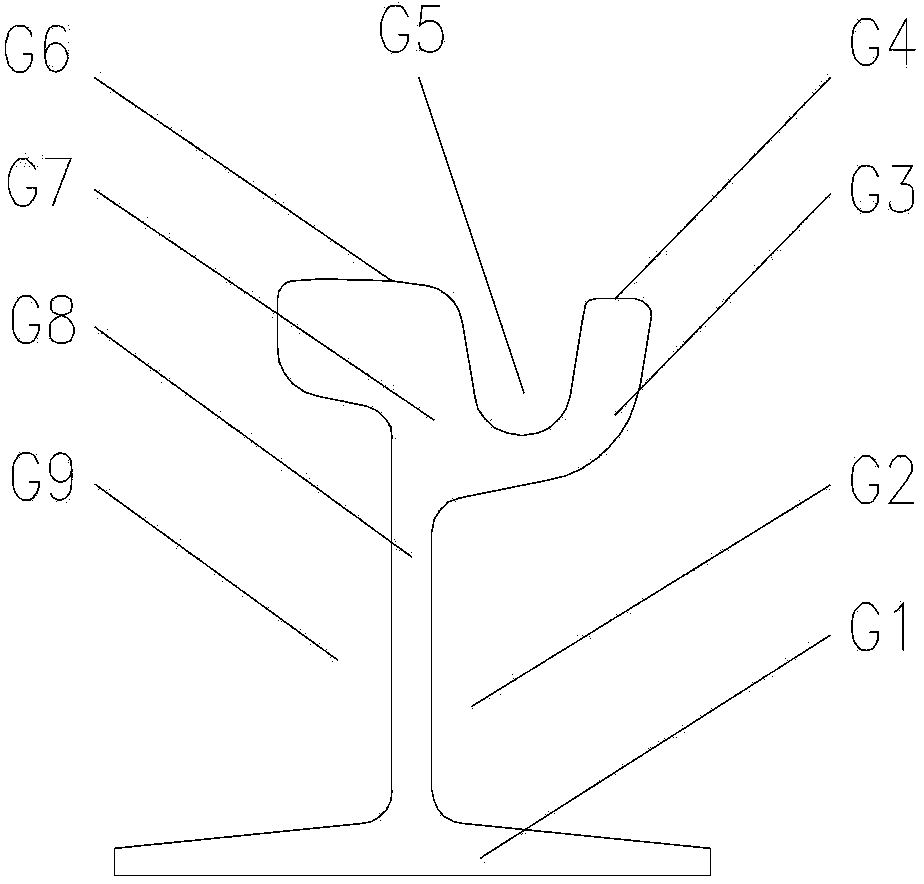

Small diameter coring type vertical drilling tool thrust actuator

PendingCN110219603ASmall space requirementImprove connection strengthEngine sealsDrilling rodsActuatorDrilling fluid

The invention discloses a small diameter coring type vertical drilling tool thrust actuator. The small diameter coring type vertical drilling tool thrust actuator comprises at least one thrust executing unit, wherein each thrust executing unit comprises an actuator body, pushing wing ribs and a lower end cover, a first through hole is coaxially formed in the centre of the actuator body, three mounting grooves are evenly formed in the outer circumference of the actuator body, and one pushing wing rib is installed in each of the mounting grooves; circular arc groove surfaces are arranged at oneends of the mounting grooves, circular arc cylinder surfaces are arranged at one ends of the pushing wing ribs, the circular arc cylinder surfaces are installed in the circular arc groove surfaces ina matched mode, grooves are formed in one surfaces of the pushing wing ribs, and the grooves are used as drilling fluid cavities; upper flow holes are formed in the upper part of the actuator body, flow discharge holes are formed in the lower end cover, the multiple thrust executing units are coaxially and successively connected upper and lower, and flow guide channels are formed in the thrust executing units. Coring operation can be carried out when drilling is carried out vertically.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Aluminum bar feeding device

InactiveCN104457278AReduce contact timeReduce labor intensityCharge manipulationHeating furnaceUltimate tensile strength

The invention discloses an aluminum bar feeding device which comprises a feeding support fixed in front of a feeding opening of a heating furnace. The feeding support is connected with an upper feeding roll and a lower feeding roll, sliding blocks are inserted into the two side shaft ends of the upper feeding roll in a sleeving mode, sliding grooves are formed in the two vertical side faces of the feeding support, the sliding blocks are inserted into and sleeved with the sliding grooves, the upper portions of the sliding blocks are connected with springs, the other ends of the springs are connected with the upper portion of the feeding support, and the upper feeding roll and the lower feeding roll are both connected with a motor. The aluminum bar feeding device has the advantages that through the feeding device, an aluminum bar can be automatically fed into the heating furnace, and does not need to be manually pushed, the contact time of workers and the heating furnace is shortened, and the labor intensity of workers is reduced.

Owner:湖州宏鑫铝业有限公司

Bidirectional force-bearing slurry bearing device and rotating guiding tool utilizing same

ActiveCN108222833AExtend working lifeEasy maintenanceLinear bearingsDirectional drillingSlurryEngineering

The invention mainly belongs to the technical field of rotating guiding systems and particularly relates to a bidirectional force-bearing slurry bearing device and a rotating guiding tool utilizing the same. The bidirectional force-bearing slurry bearing device is arranged between non-rotating outer sleeves and a drill bit shaft on the lower portion of the rotating guiding tool and used for isolating rotating movement of the drill bit shaft so as to enable the non-rotating outer sleeves of the rotating guiding tool not to rotate in a relatively-large mode. Through the bidirectional force-bearing slurry bearing device, the non-rotating outer sleeves can be positioned in the radial direction and the biaxial direction and supported on the drill bit shaft, and accordingly the rotating guidingtool can work in bad slurry. The rotating guiding tool adopts the static internal pushing-abutting hinging type design; by hinging a non-rotating measurement and control body and a non-rotating execution mechanism body, the non-integral type structure is achieved; and a drilling tool is easily bent in a borehole, and thus bending stress to the upper portion of the guiding tool is small.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Magnetic head and its mfg. method

InactiveCN1480922AAvoid unevennessGuaranteed positional relationshipManufacture head surfaceManufacture unitary devices of plural headsEngineeringElectrical and Electronics engineering

In a magnetic head according to the present invention, a base is provided with at least one first positioning hole and a magnetic core half has a back portion which is disposed in the first positioning hole. In addition, the base is further provided with at least one first recess at the periphery of the first positioning hole and the base is partially deformed due to the first recess such that a portion of the base at the periphery of the first positioning hole is shifted to press the back portion of the magnetic core half against an inner side of the first positioning hole. Accordingly, the present invention provides a magnetic head in which the magnetic core half can be reliably fixed to the base and a method for manufacturing the magnetic head.

Owner:ALPS ALPINE CO LTD

Double flush clinch stud

Owner:PEM MANAGEMENT INC

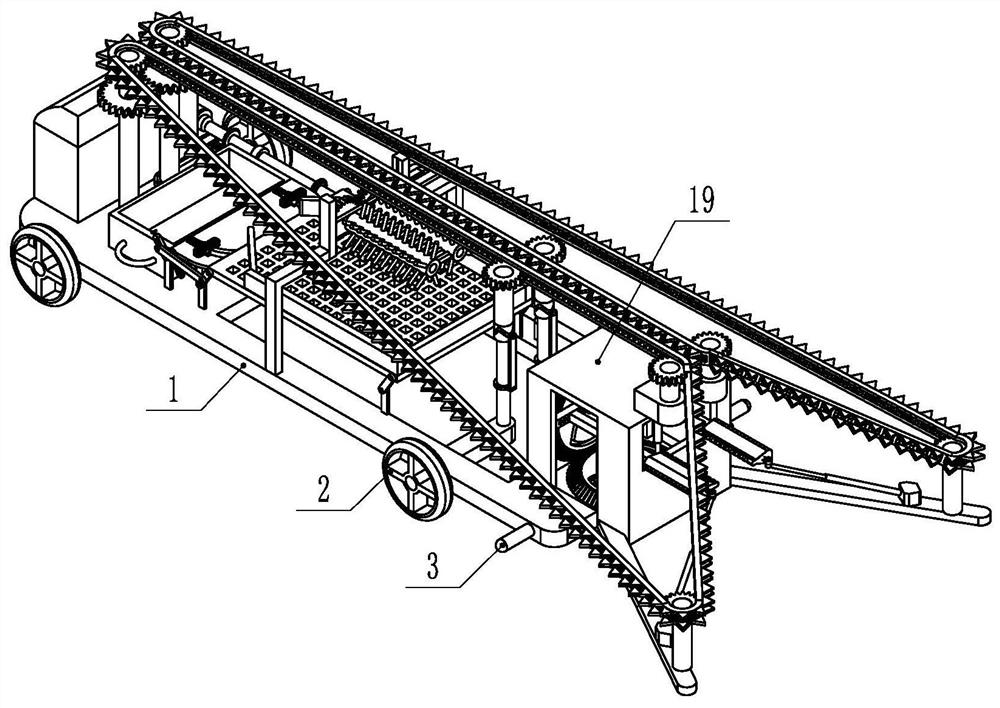

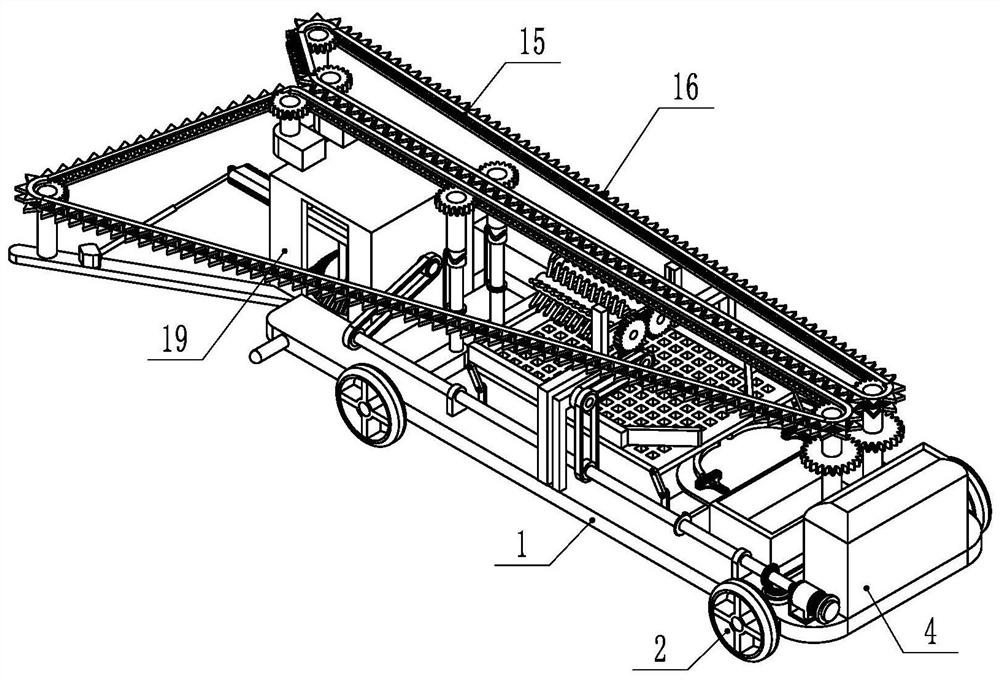

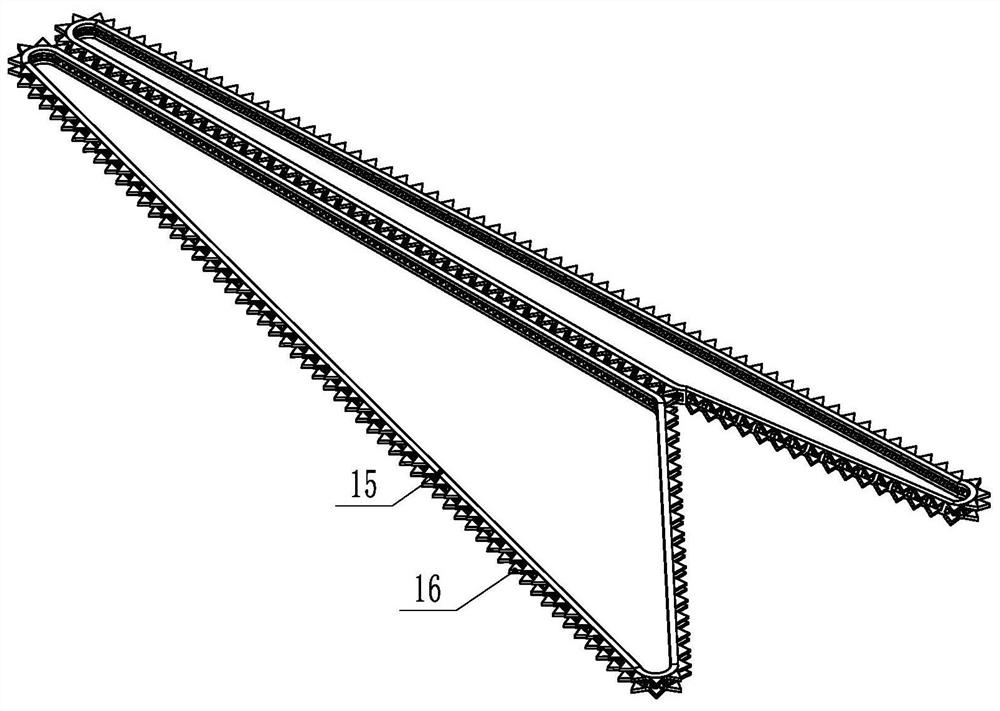

Peanut vine separating device for peanut harvesting

ActiveCN112449837AExtract comprehensivelySpeed up the efficiency of intermittent deliveryDigger harvestersThreshersEngineeringBiology

A peanut vine separating device for peanut harvesting comprises a bottom plate, wherein chains inclining towards the lower end of the outer side of the front end are installed on the left side and theright side of the rear side of the upper end of the bottom plate correspondingly, tooth-shaped clamping plates capable of moving inwards and then moving upwards at the same time are installed at theleft end and the right end of the front side of the upper end of the bottom plate correspondingly. Special-shaped supporting plates are fixedly connected to the left side and the right side of the middle of the surface of the upper end of the bottom plate correspondingly, two fruit picking shafts which are matched with the chains and can move up and down while rotating are installed on the inner walls of the special-shaped supporting plates, leaking plates which are matched with the fruit picking shafts and can swing within a small range are installed in the middle of the surface of the upperend of the bottom plate, a containing plate matched with the leakage plates is fixedly connected to the middle of the rear side of the upper end surface of the bottom plate, and arc-shaped plates capable of moving backwards and swinging inwards are installed on the left side and the right side of the upper end surface of the containing plate correspondingly. By means of the tooth-shaped clamping plates which can move inwards and then move upwards at the same time, short peanut vines and obliquely-growing peanut vines can be pulled out upwards after being clamped.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE HENAN ACAD OF AGRI SCI

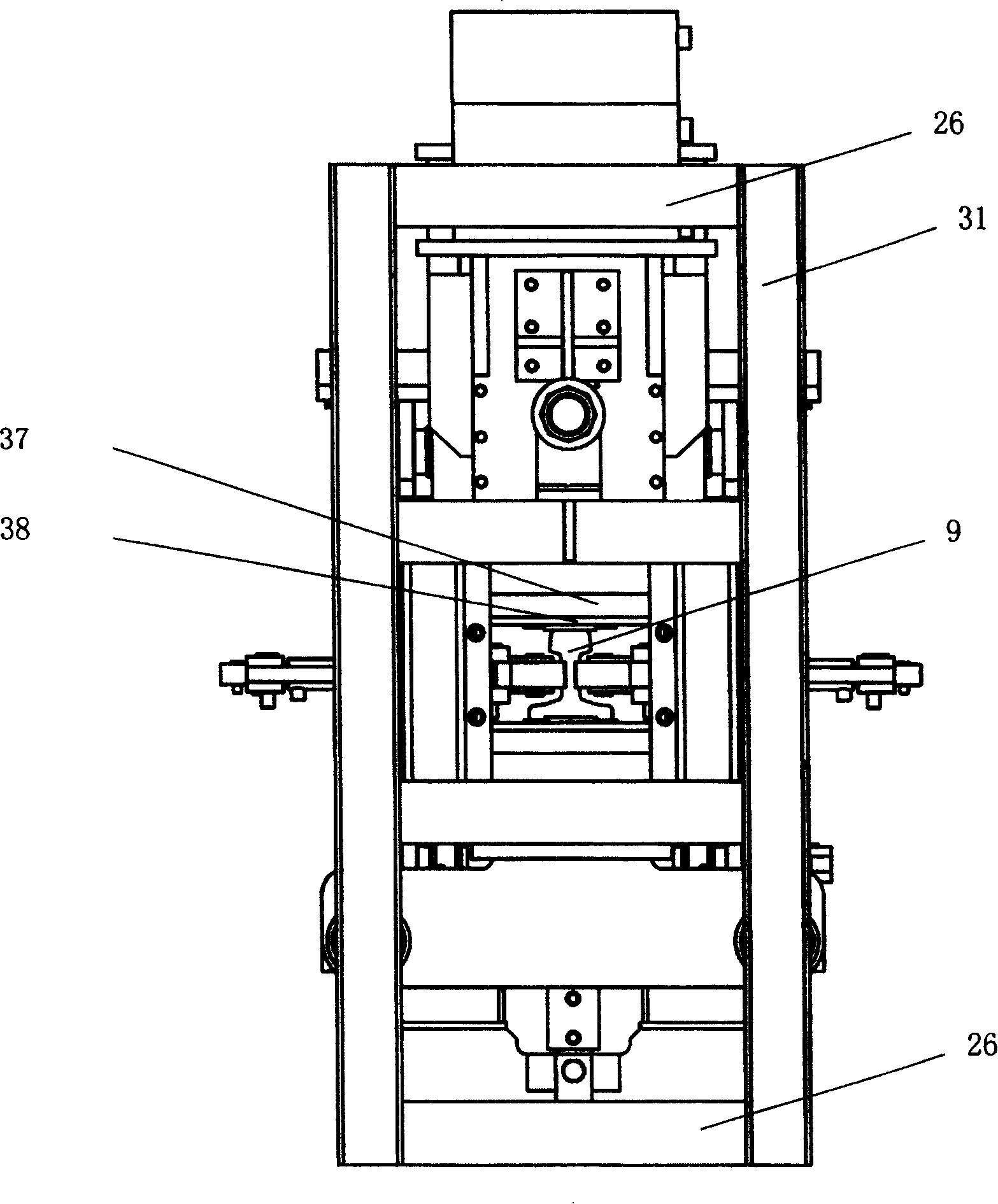

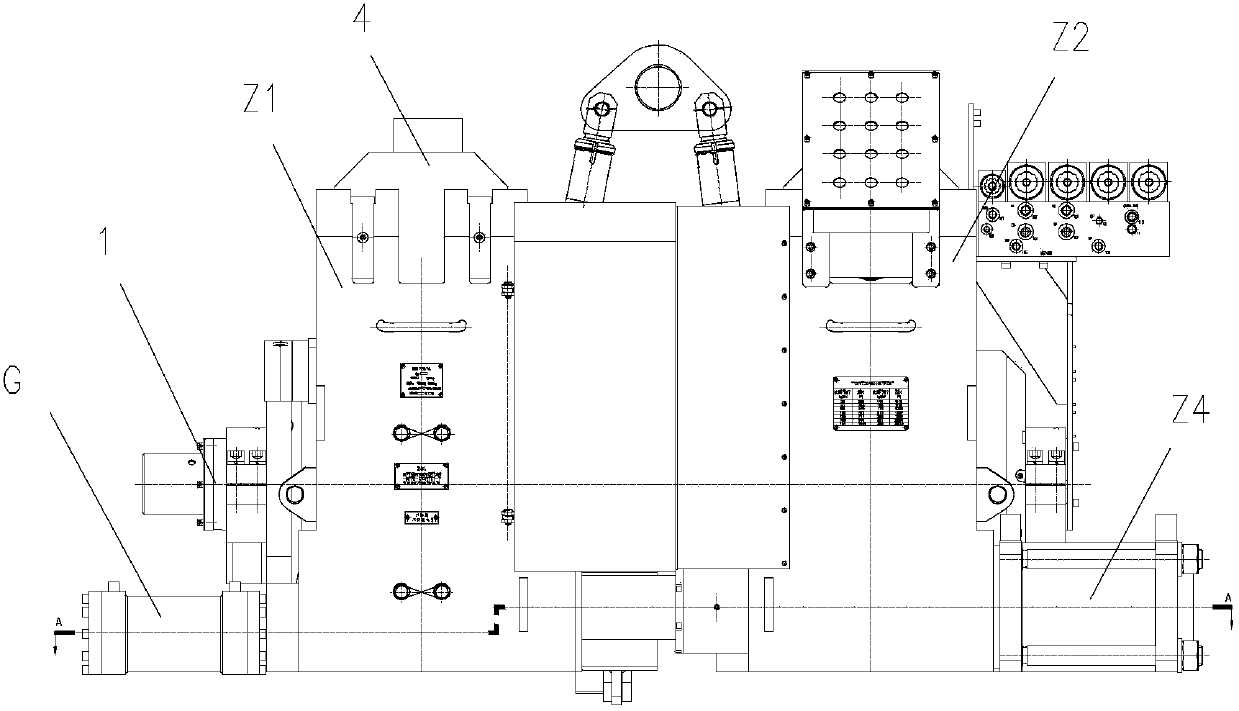

Channel steel rail flash welding machine

ActiveCN103388291AEliminate opening and closing interference and stagnationSimple structureRailway track constructionEngineeringAbnormal tissue growth

The invention relates to a channel steel rail flash welding machine, which belongs to the technical field of traffic facility construction. A front box body component and a back box body component of the machine are constructed by left and right clamp box bodies hinged onto a center shaft respectively; a tumor push knife is arranged at the inner end of the front box body component; a tumor push oil cylinder for driving the tumor push knife is arranged at the outer end of the front box body component; an upsetting oil cylinder for driving the front box body component and the back box body component to move oppositely are arranged on the outer side of the back box body component; the upper ends of the left and right clamp box bodies are hinged together with the two ends of a clamping oil cylinder which extends and contracts horizontally respectively; a hoisting shaft sleeve from the lower part of which positioning surfaces extend is sleeved on a central hinged shaft; the positioning surfaces are provided with parts contacted with the rail head treads and the rail lip treads of channel steel rails respectively; and the projection shapes of left and right jaws are at least partially matched with the shape of the rail waist slots of the channel steel rails respectively. According to the flash welding machine, welding of asymmetrical left and right channel steel rails can be completed without turning round and reversing, so that the labor intensity is lowered greatly, and the operation efficiency is increased remarkably.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Dry granulator

ActiveUS9827571B2Compact structureImprove sealingGranulation by pressingGrain treatmentsHardnessMaterials science

Owner:ZHEJIANG FUTURE MACHINERY

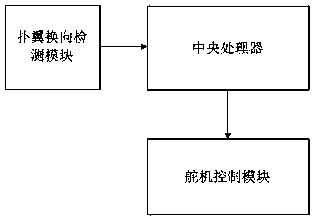

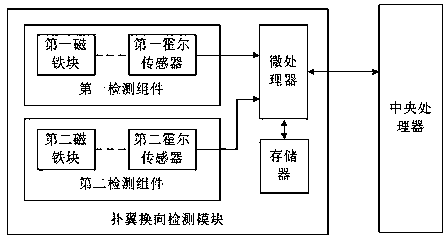

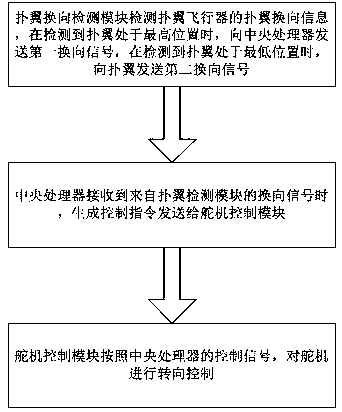

Steering gear control system and method of flapping wing aircraft vehicle

ActiveCN110027707AIncrease the projected areaIncrease motivationOrnithoptersFlapping wingControl system

The invention discloses a steering gear control system and method of a flapping wing aircraft vehicle. The steering gear control system includes a flapping wing reversing detecting module, a central processing unit and a steering gear control module, wherein the flapping wing reversing detecting module is used for detecting flapping wing reversing information of the flapping wing aircraft vehicle,and when a flapping wing is detected to locate in the lowest position and the highest position, and different reversing signals are sent to the central processing unit; according to the reversing signals from the flapping wing reversing detecting module, a steering gear rotating control instruction is generated by the central processing unit and transmitted to the steering gear control module; and the steering gear control module is used for controlling steering gear rotating of the flapping wing air craft vehicle according to the steering gear rotating control instruction of the central processing unit. According to the steering gear control system and method of the flapping wing aircraft vehicle, during flight of the flapping wing aircraft vehicle, negative lift force brought by upwardflapping the flapping wing is effectively lowered, and forward pushing force can be significantly increased.

Owner:MIANYANG KONGTIAN TECH CO LTD

Roller type cavity die extrusion molding method

InactiveCN100506415CHighlight substantiveSignificant technological progressExtrusion diesRams/plungersStressed stateStress reduction

The invention relates to a roller-type concave die extrusion forming method, which adopts a pair of rollers with a concave mold cavity opened on the circumferential surface of the two rollers, and is characterized in that a set of push rods and extrusion cylinders are used at the feed end. , the forming process of the blank is as follows: the blank is filled in the extrusion cylinder, the push rod exerts pressure on the end of the blank, and the blank is pushed to the roller-type die; the two rollers rotate actively at the same speed and in opposite directions, and the roller The frictional force of the wheels acting on both sides of the blank drives the blank to be sequentially extruded and deformed, and promotes the flow of metal, and the blank is extended in the feeding direction; the blank is discharged from the two rollers after being sequentially extruded. It improves the fluidity when the blank is deformed, improves the stress state, reduces the forming force, achieves the purpose of easy forming, reduces the bending and torsional stress of the mold, improves the life of the mold, and can be precisely formed.

Owner:ZHONGBEI UNIV

Lens cone bottom inner wall with flatting effect

The invention discloses a lens cone bottom inner wall with a flatting effect. Wavy decorative patterns are arranged on the lens cone bottom inner wall; and the decorative patterns are provided with wave crests and wave troughs. The lens cone bottom inner wall is simple to machine and low in cost, the lens cone bottom inner wall is designed to be provided with the wavy decorative patterns, the reflection direction of a light beam can be changed, the light beam is reflected in a dispersed state, and the energy of reflected light is greatly weakened, so that the purpose of eliminating stray lightis reached.

Owner:辽宁中蓝光电科技有限公司

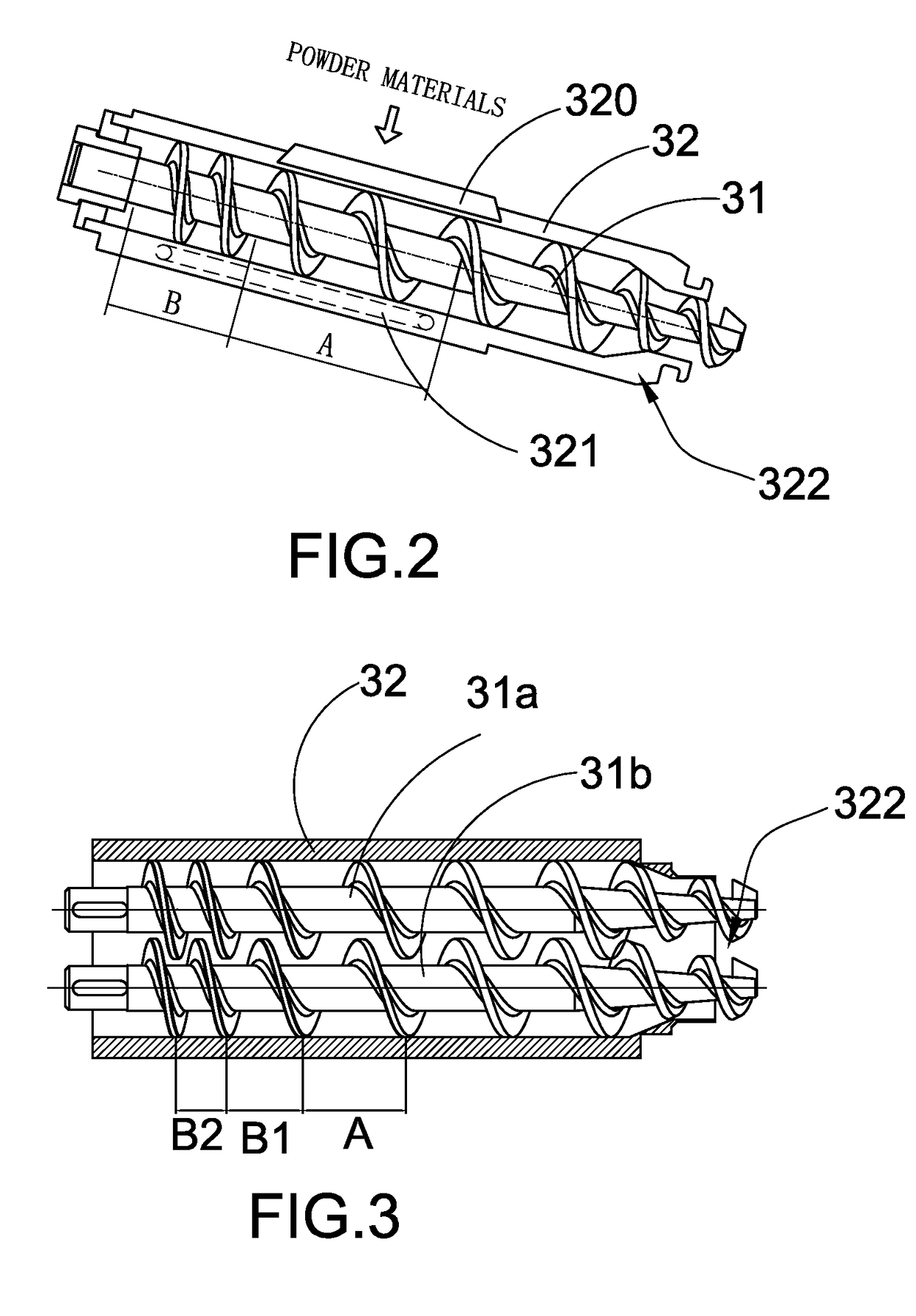

Rapid screw feeding equipment

InactiveCN111646124AIncrease delivery rateReduce cloggingPackagingConveyor partsElectric machineDrive motor

The invention relates to the technical field of feeding equipment, in particular to rapid screw feeding equipment. The rapid screw feeding equipment comprises a rack and a feeding pipe mounted on therack. A discharge port is formed in one end of the feeding pipe, a feed hopper is arranged in the middle of the feeding pipe, a drive motor is arranged on the other side of the feeding pipe, the drivemotor is connected with a rotary shaft through a shaft, the rotary shaft is slidingly embedded into the inner side of the feeding pipe, the rack is fixedly provided with a rectangular sliding rod, the rectangular sliding rod is slidingly provided with a fixing frame, the drive motor is fixedly arranged on the fixing frame, an electric push rod is arranged on the lower side of the fixing frame, the fixing frame is connected with the rack through the electric push rod, one end of the feeding pipe is connected with a connecting pipe, the other end of the connecting pipe is connected with a telescopic pipe, the drive motor is arranged on the fixing frame, the electric push rod of the drive motor can push the fixing frame to move left and right, thus, the rotary shaft connected with the motordrives a screw to move in the feeding pipe, and the screw generates thrust forwards while carrying out spiral conveying.

Owner:郭毅义

Garage vehicle carrying plate butt-joint device

A garage vehicle carrying plate butt-joint device is used for butt joint with a vehicle carrying plate for bearing a vehicle and comprises a frame mechanism, a butt-joint driving assembly and a pulling assembly, wherein the butt-joint driving assembly is installed on the frame mechanism and can drive the pulling assembly to move among an initial position, a butt joint position and a working position. The vehicle carrying plate for bearing the vehicle is provided with a butt -joint portion at the bottom, when a vehicle is located at the position where the vehicle is to be carried, the pulling assembly moves to the butt-joint position from the initial position so as to be in butt joint with the butt-joint portion and then moves to the working position, the pulling assembly can pull the vehicle carrying plate to the conveying device in the process of moving from the butt-joint position to the working position.

Owner:中集物联科技有限公司 +3

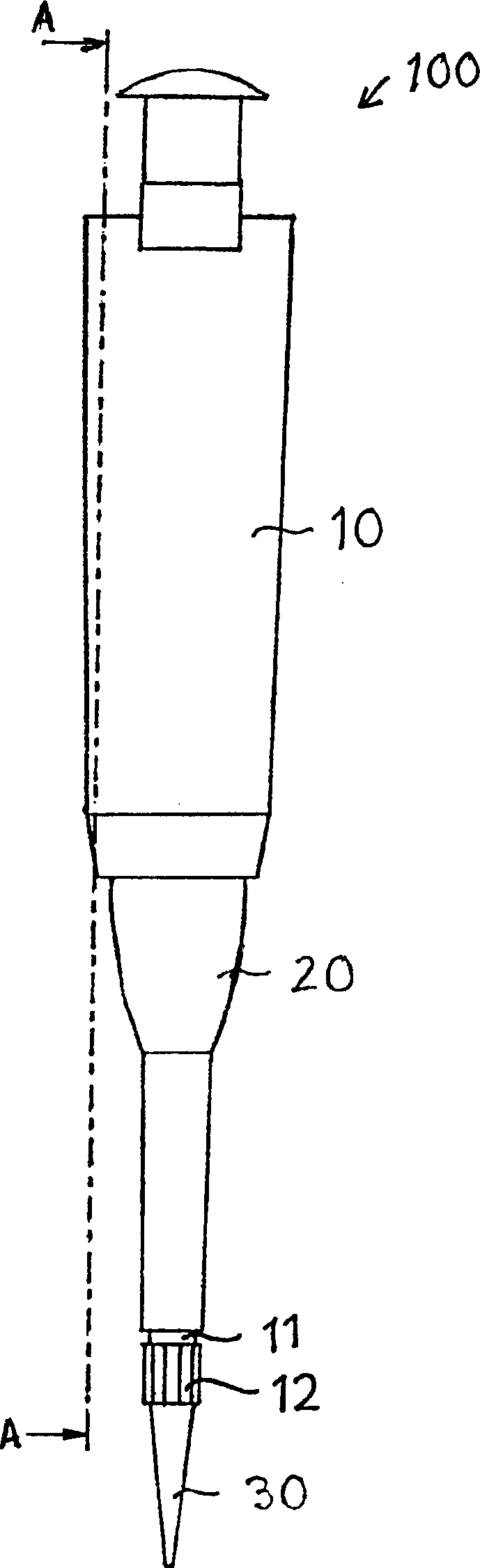

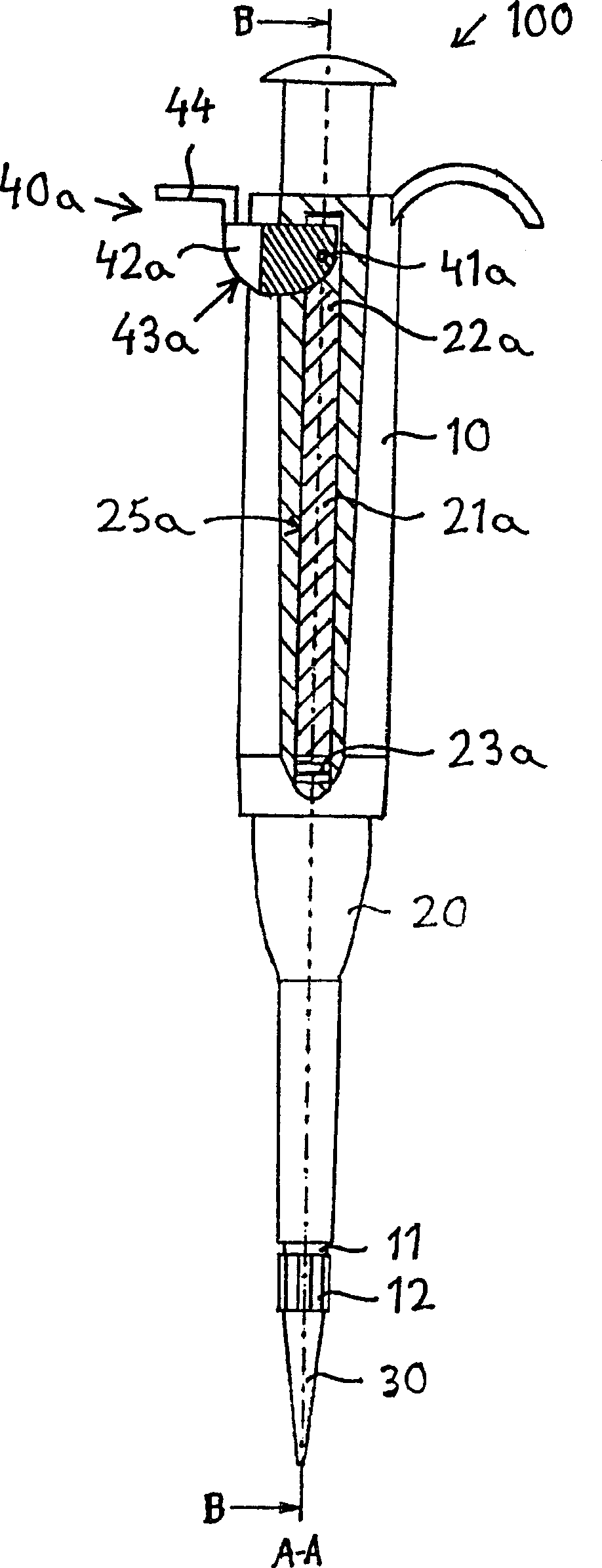

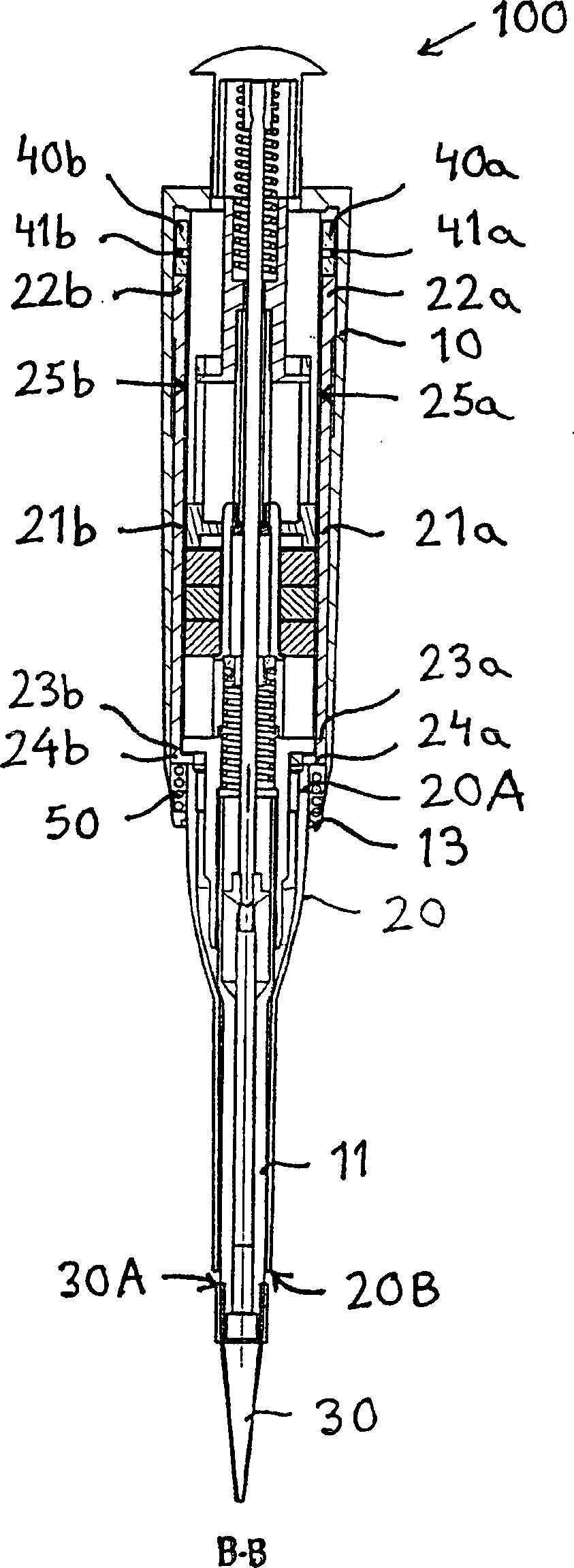

Pipette device

A pipette device comprises a body with a tip having a distal end suitable for mounting a disposable pipette prong thereon through a compact grating and cooperation mode; a tip ejecting unit used for performing a shift between the distal end of the disposable pipette prong and the upper end of the body along the longitudinal axis direction of the pipette device; and at least one actuator located at the upper end of the body and interacting with the ejecting unit to complete the shift of the tip ejecting unit along the longitudinal axis direction of the pipette device. Said at least one actuator comprises a tappet element connected with the body using a connection point and having a tappet surface with at least one part is vaulted, wherein said tappet surface is suitable for contact with the upper side of the ejecting unit to move the ejecting unit in the direction of the longitudinal axis of the pipette arrangement to eject the disposable tip from the distal end.

Owner:SARTORIUS BIOHIT LIQUID HANDLING

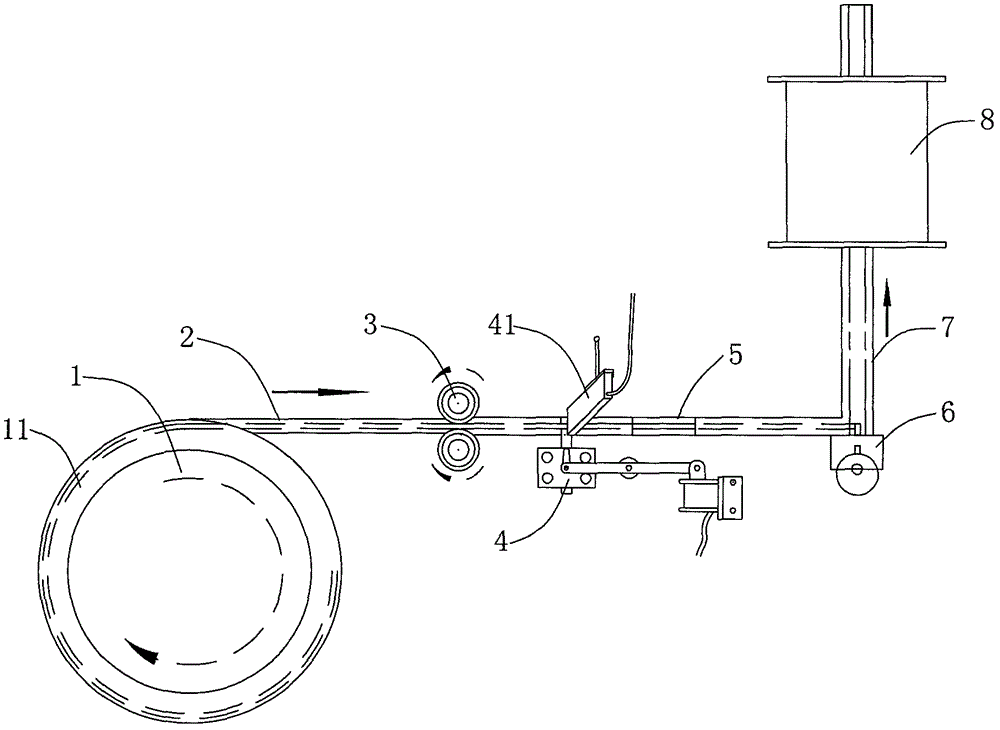

Equipment for automatically piling up and magnetizing blocky magnetic materials

InactiveCN102360712BIncrease push forceTo achieve the work needs of magnetizationMagnetic bodiesInductances/transformers/magnets manufactureMagnetizationEngineering

The invention provides equipment for automatically piling up and magnetizing blocky magnetic materials. The equipment comprises a vibration disc; the inner wall of the vibration disc is provided with a spiral type conveying channel and the outlet end of the spiral type conveying channel is connected with a vibration disc output rail. A work piece pushing mechanism is arranged on the vibration disc output rail, an ejection opening is arranged at one side of the vibration disc output rail and an ejection mechanism is arranged at the other side of the vibration disc output rail. A photoelectric detection inductive switch is arranged above the ejection opening, and the photoelectric detection inductive switch is electrically connected with the ejection mechanism and is used for driving a workpiece which is ejected by the ejection mechanism. A work piece leaning device is connected to the rear side of the ejection opening and an output rail of the work piece leaning device is connected with a work piece stacking and conveying rail and an elastic ejecting and stacking mechanism. The equipment provided by the invention is rational in structure design, small in energy consumption and lowin noise and can be used for identifying magnetic product work pieces in the same direction and conveying and stacking the magnetic product work pieces at a high speed, so that the full automation, the high efficiency and 100% of saturated magnetization are realized, the manual work is avoided and the work efficiency is improved.

Owner:于洁 +1

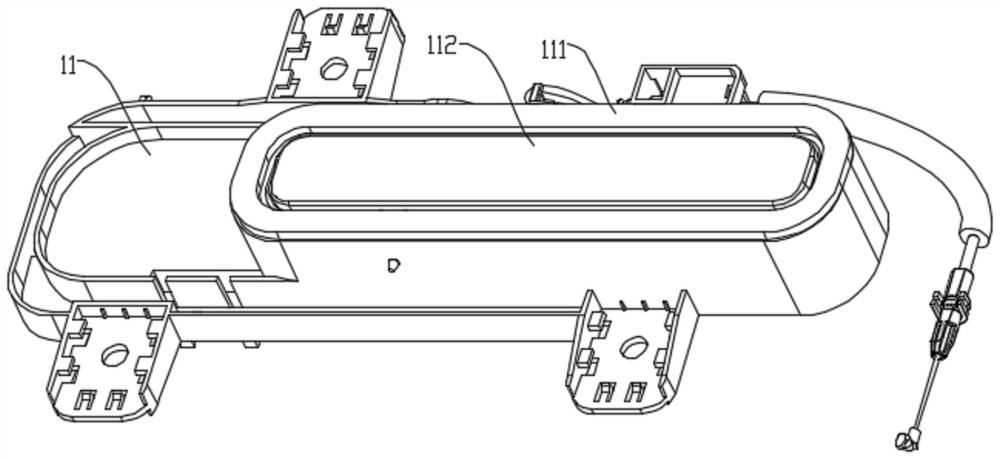

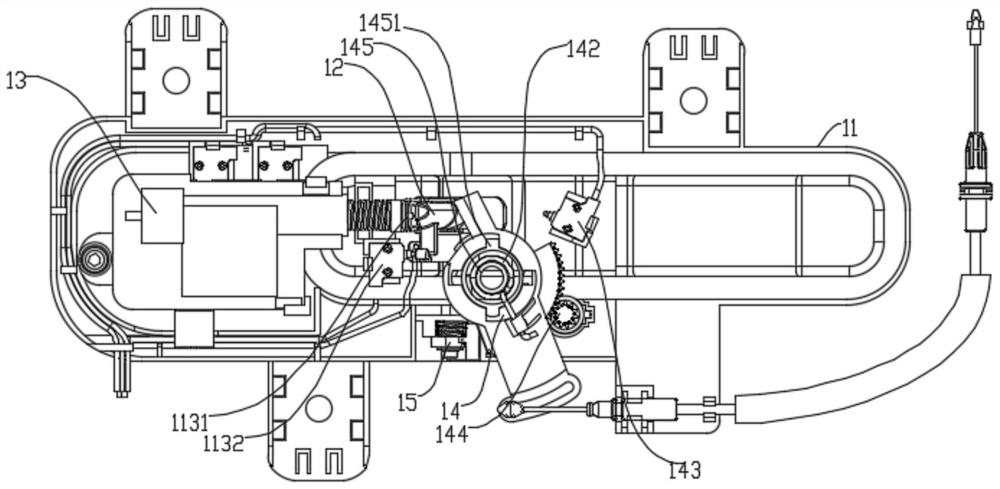

Overturning type electric handle

PendingCN112252866AHigh precisionImprove reliabilityLock parts movement dampingNoise-prevention/anti-rattling lockingEngineeringStructural engineering

The invention discloses an overturning type electric handle which comprises a handle base, a overturning handle assembly rotationally connected with the handle base, an actuator and a swing arm structure. The actuator and the swing arm structure are installed on the inner side of the handle base. The overturning handle assembly includes an initial horizontal posture, a down-pressing triggering in-place posture, a welcoming position posture and a door opening in-place posture. The actuator is used for providing driving force for the handle overturning assembly to transit from a downward-pressing in-place triggering posture to a welcoming position posture, and the swing arm structure is used for providing driving force for the handle overturning assembly to achieve transition from the door opening in-place posture to the initial horizontal posture. The actuator comprises a driving sliding rod and a driving mechanism, the driving mechanism is used for driving the driving sliding rod to dotelescopic movement, the telescopic movement direction of the driving sliding rod is defined as the X axis, and the actuator further comprises a plurality of position switches arranged on one side ofthe driving sliding rod in the X axis direction. The invention provides the down-pressing triggering overturning type electric handle which is simple and reliable in structure.

Owner:SHANGHAI JIAMU AUTO PARTS CO LTD

Aluminum rod feeding device

InactiveCN104457278BReduce contact timeReduce labor intensityCharge manipulationEngineeringHeating furnace

The invention discloses an aluminum bar feeding device which comprises a feeding support fixed in front of a feeding opening of a heating furnace. The feeding support is connected with an upper feeding roll and a lower feeding roll, sliding blocks are inserted into the two side shaft ends of the upper feeding roll in a sleeving mode, sliding grooves are formed in the two vertical side faces of the feeding support, the sliding blocks are inserted into and sleeved with the sliding grooves, the upper portions of the sliding blocks are connected with springs, the other ends of the springs are connected with the upper portion of the feeding support, and the upper feeding roll and the lower feeding roll are both connected with a motor. The aluminum bar feeding device has the advantages that through the feeding device, an aluminum bar can be automatically fed into the heating furnace, and does not need to be manually pushed, the contact time of workers and the heating furnace is shortened, and the labor intensity of workers is reduced.

Owner:湖州宏鑫铝业有限公司

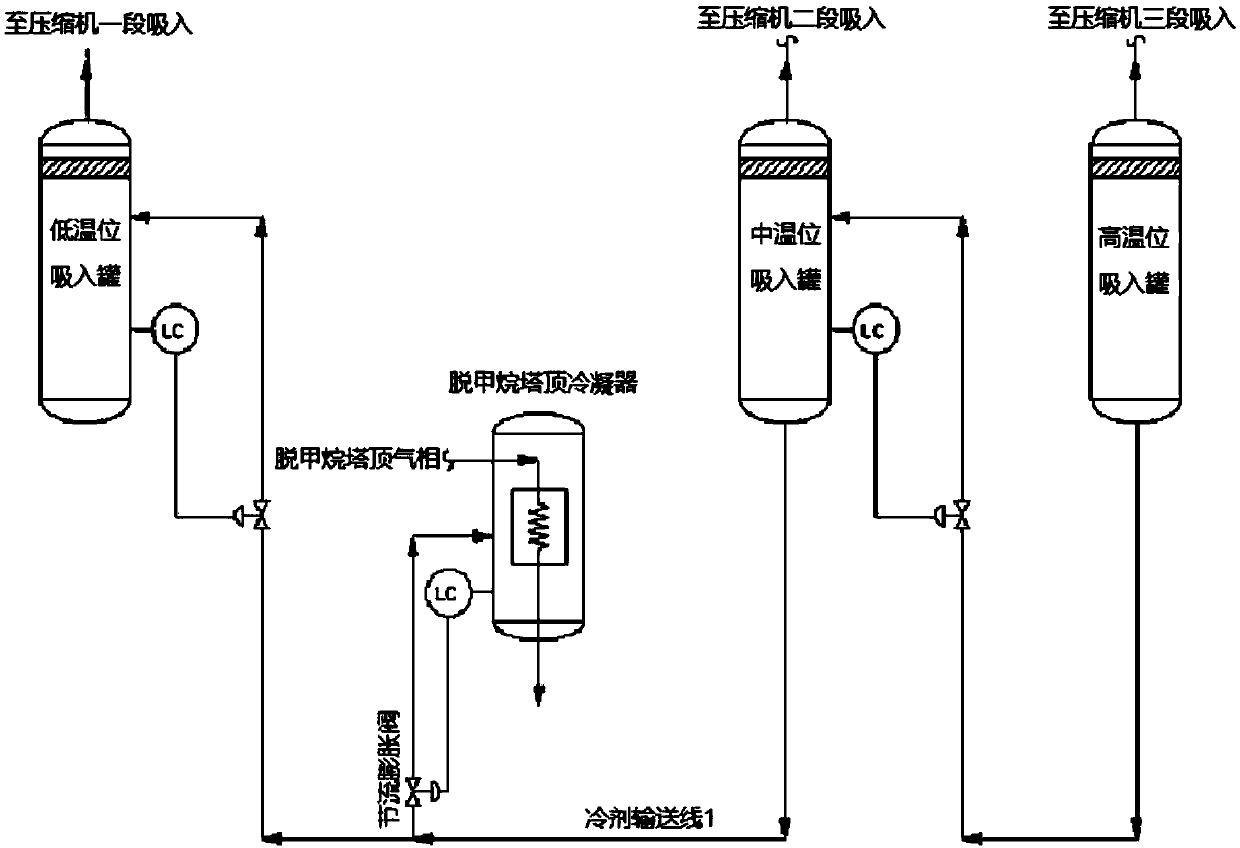

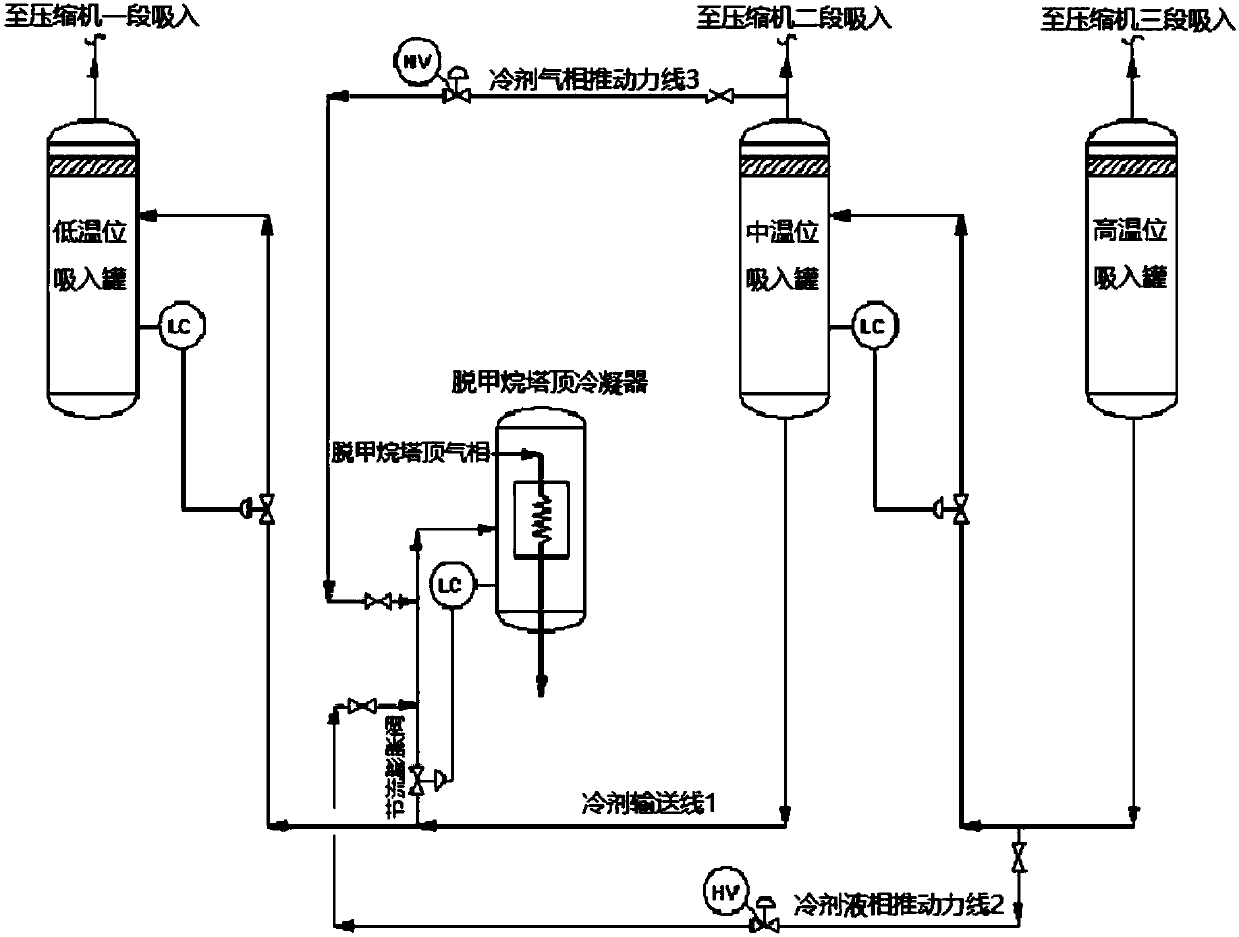

A device and a method for improving start-up operation of a demethanizer of an ethylene device

ActiveCN109867579AIncrease push forceStable operationHydrocarbon purification/separationHydrocarbonsRefrigerantEngineering

The invention belongs to the field of ethylene production devices, and relates to a device and a method for improving start-up operation of a demethanizer of an ethylene device. The refrigerant conveying device comprises a medium-temperature suction tank, a high-temperature suction tank, a refrigerant pipeline and a refrigerant liquid-phase pushing force pipeline, the tank bottom of the medium-temperature suction tank is connected to a demethanizer overhead condenser through the refrigerant pipeline, and the tank bottom of the high-temperature suction tank is connected to the refrigerant pipeline through the refrigerant liquid-phase pushing force pipeline. By utilizing the ethylene refrigerant pipeline additionally arranged in front of the demethanizer overhead condenser, the pushing forceof the ethylene refrigerant of the demethanizer is increased, so that the operation of the demethanizer is stable, the loss of ethylene at the top of the demethanizer is reduced, and column top and bottom products of the demethanizer are qualified.

Owner:SINOPEC ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com