A device and a method for improving start-up operation of a demethanizer of an ethylene device

A demethanizer and conveying device technology, applied in the field of ethylene production equipment, can solve the problems of high temperature at the top of the demethanizer and insufficient cooling capacity of process materials, etc., and achieve the effect of increasing the pushing force, reducing losses and stabilizing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

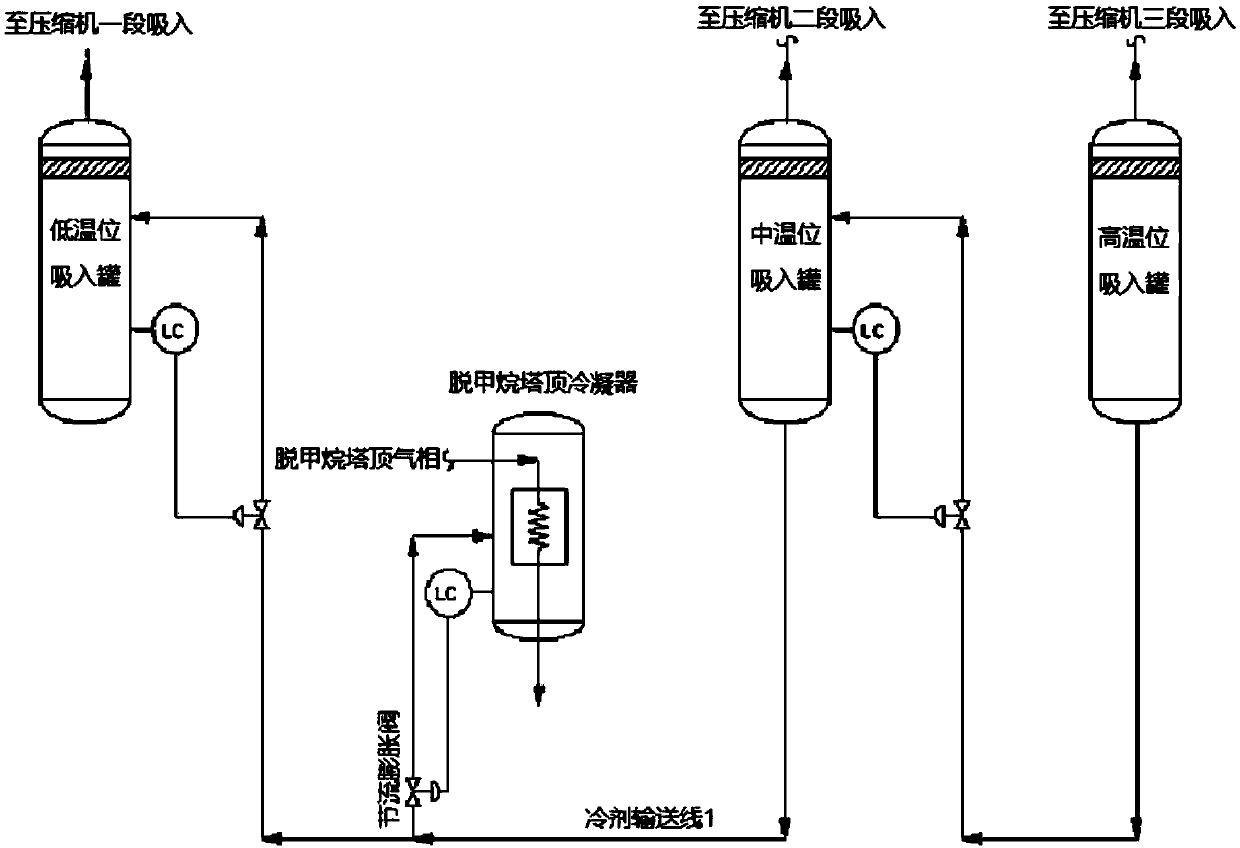

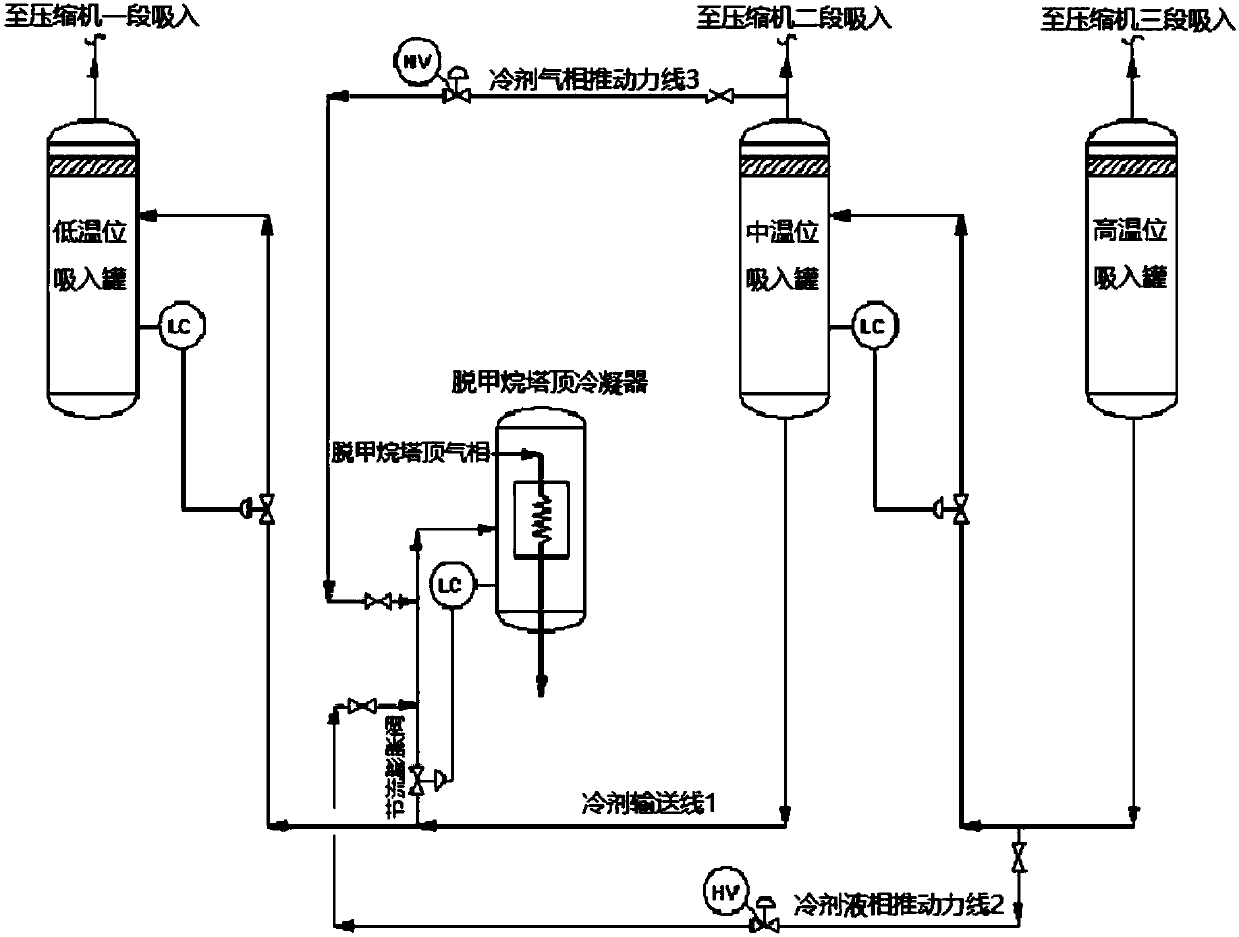

[0024] In this embodiment, the process flow diagram of the refrigerant delivery device used for the start-up of the demethanizer of the ethylene plant is as follows figure 2 shown.

[0025] The refrigerant delivery device includes a medium-temperature suction tank, a high-temperature suction tank, a refrigerant delivery line, a refrigerant liquid-phase driving force line and a refrigerant gas-phase driving force line, and the bottom of the medium-temperature suction tank passes through the refrigerant delivery line Connected to the demethanizer overhead condenser, the tank bottom of the high-temperature suction tank is connected to the refrigerant delivery line through the refrigerant liquid-phase driving force line, and the tank top of the medium-temperature suction tank is connected to the refrigerant gas-phase driving force line through the refrigerant gas phase. agent delivery line; the refrigerant delivery line is provided with a throttling expansion valve, and the refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com