Aluminum rod feeding device

A technology for feeding devices and aluminum rods, which is applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of time-consuming and labor-intensive manual feeding, low production efficiency, and high furnace temperature, so as to reduce contact time and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

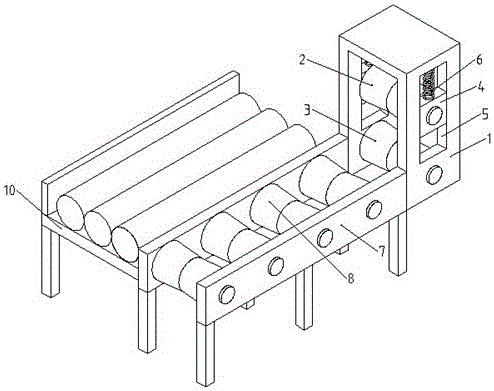

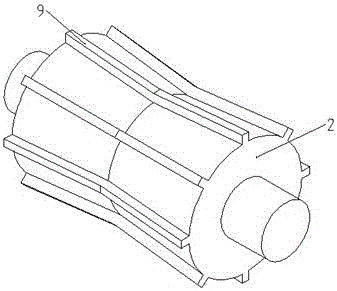

[0013] according to figure 1 with figure 2 To illustrate the specific embodiment of the present invention, it comprises the feed support 1 that is fixed in front of the feed inlet of heating furnace, is connected with upper feed roller 2 and lower feed roller 3 on the feed support 1, and upper feed roller 2 two sides shafts There is a sliding block 4 in the end sleeve, and there are chute 5 on the facade of both sides of the feeding bracket 1, and the sliding block 4 is inserted in the chute 5, and a spring 6 is connected to the top of the sliding block 4, and the spring 6 The other end of the feeder is connected to the upper part of the feeding bracket 1, and the upper feed roller 2 and the lower feed roller 3 are all connected to the motor.

[0014] The bottom of described feed support 1 is also connected with roller table 7, is connected with the roller 8 that is arranged in parallel with lower feed roller 3 on the roller table 7, and described roller 8 highest points and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com