Small diameter coring type vertical drilling tool thrust actuator

An actuator and vertical drilling technology, which is applied to drilling equipment, directional drilling, and undisturbed core extraction devices, etc., can solve the problem that the center does not have enough space to install coring devices, restricts the development of deep geological drilling technology, and cannot realize vertical drilling while taking It saves space, meets the needs of vertical drilling operations, and has a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

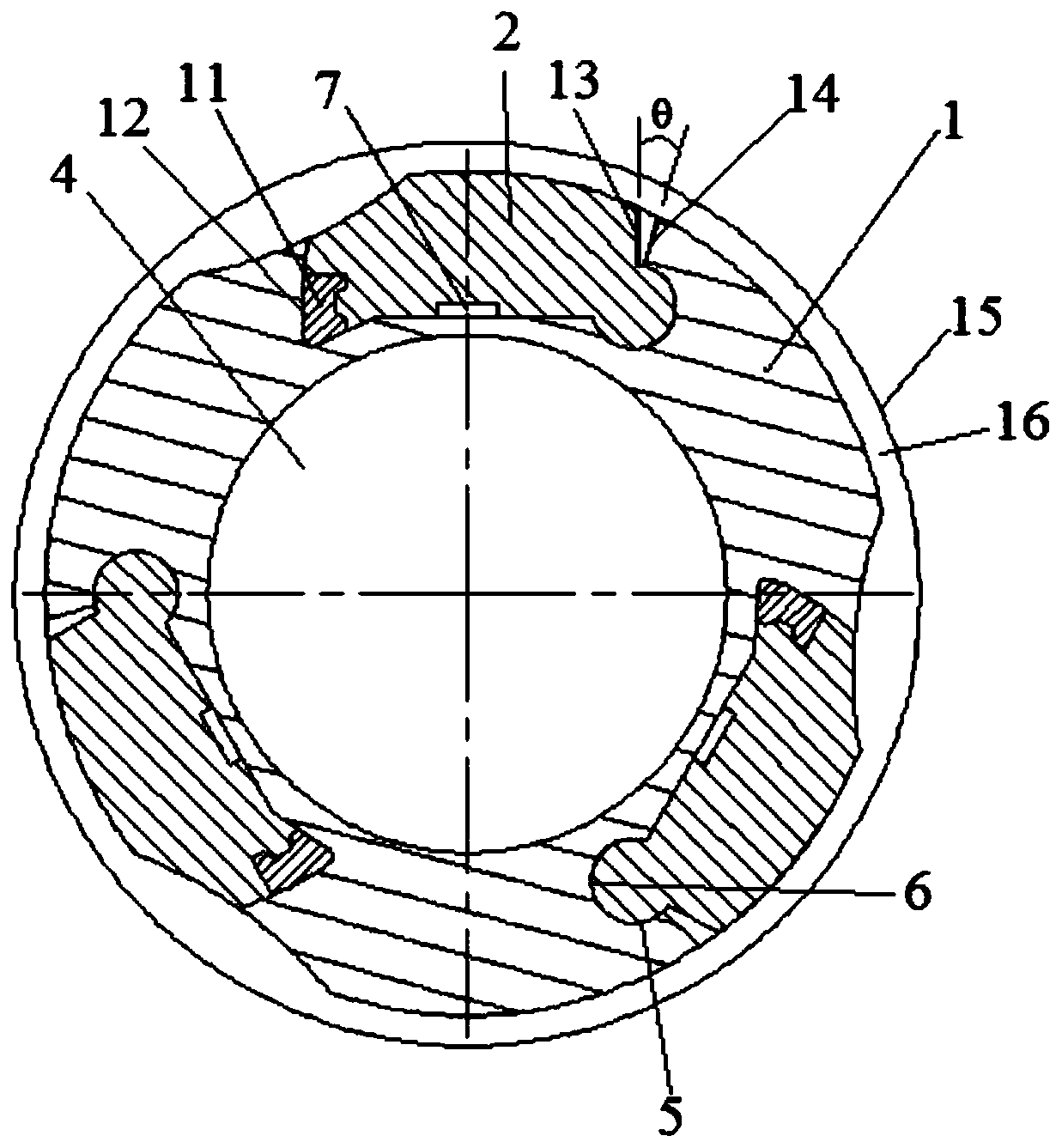

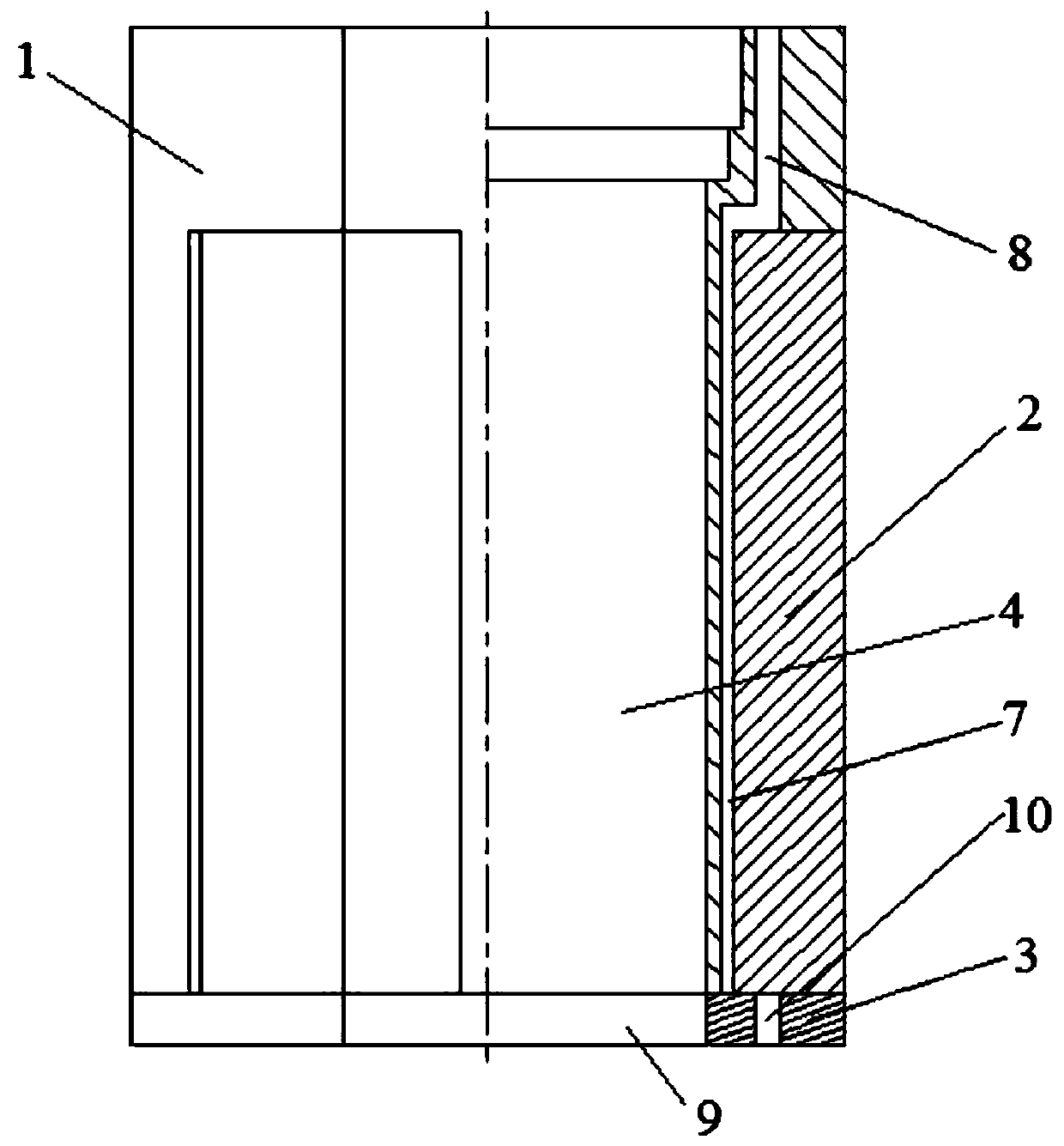

[0027] Such as Figure 1~2 As shown, this embodiment provides a small-diameter coring type vertical drilling tool thrust actuator, including a thrust actuator unit, the thrust actuator unit includes an actuator body 1, a push rib 2 and a lower end cover 3, the actuator body 1 The center is coaxially provided with a first through hole 4, the first through hole 4 is used to place the coring cylinder, and the outer circumference of the main body of the actuator 1 is evenly provided with three installation grooves, each installation groove is installed with a push rib 2, the installation One end of the groove is provided with an arc-shaped groove surface 5, and one end of the rib 2 is pushed against an arc-shaped cylinder 6, and the arc-shaped cylinder 6 is fitted in the arc-shaped groove surface 5, and the rib 2 can be pushed against the The axis of the arc-shaped cylindrical surface 6 rotates, and a groove 7 is provided on the side of the pushing rib 2 close to the first through...

Embodiment 2

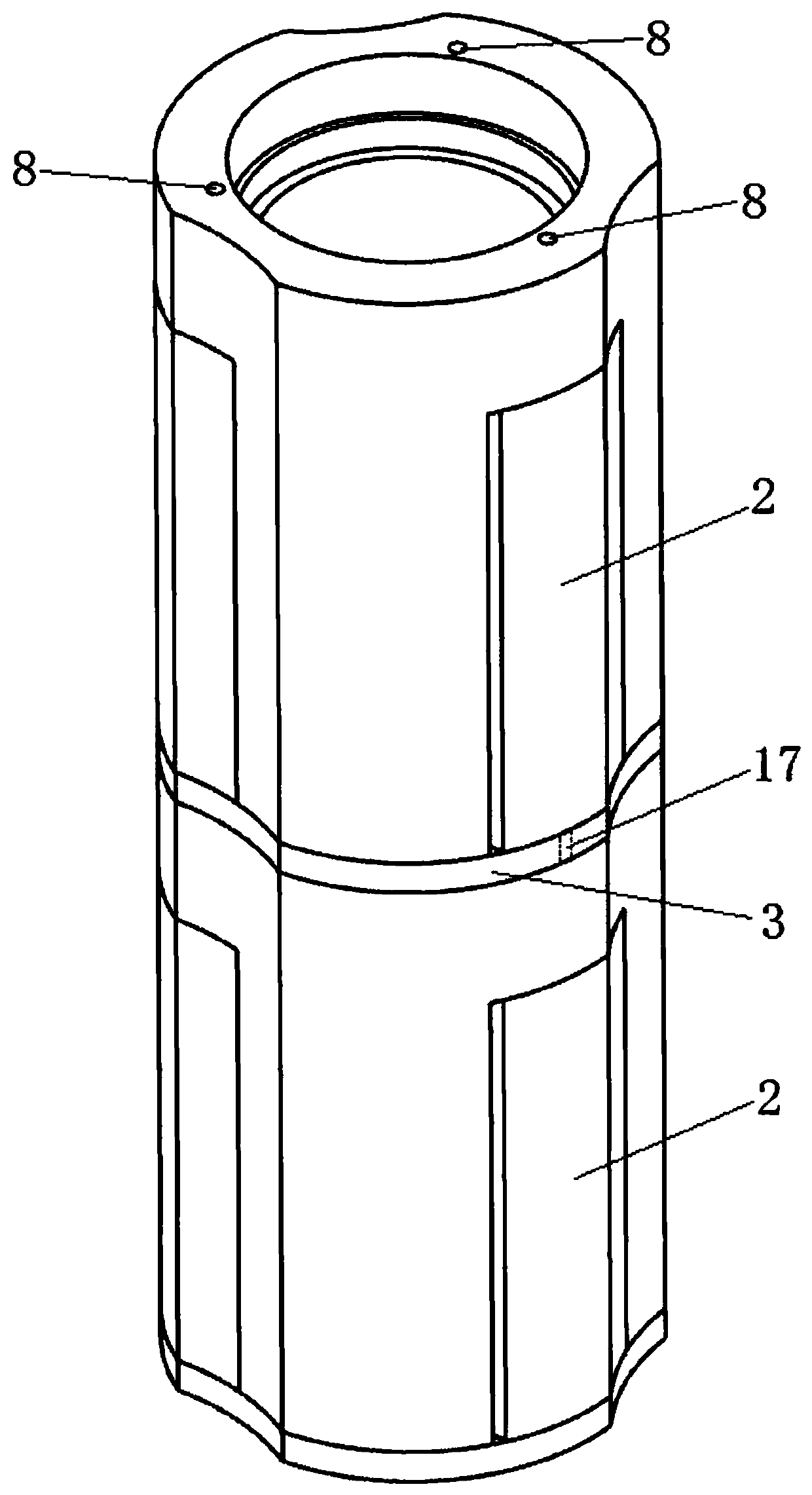

[0038] Such as image 3 As shown, this embodiment provides a small-diameter coring type vertical drilling tool thrust actuator, including two thrust actuators in Embodiment 1, and the two thrust actuators are coaxially connected up and down and are respectively the first thrust actuator and the first thrust actuator. The second thrust implementing unit, the pushing rib 2 of the first thrust implementing unit and the pushing rib 2 of the second thrust implementing unit are collinear in the vertical direction.

[0039] In this embodiment, the diversion passage 17 is arranged on the lower end cover 3 of the first thrust execution unit, and the upper and lower ends of the diversion passage 17 are respectively connected with the drilling fluid chamber in the first thrust execution unit and the second thrust execution unit. The upper flow hole 8 in the first thrust execution unit is connected, and the drilling fluid passes through the upper flow hole 8, the drilling fluid chamber an...

Embodiment 3

[0041] Such as Figure 4 As shown, this embodiment provides a small-diameter coring type vertical drilling tool thrust actuator, including two thrust actuators in Embodiment 1, and the two thrust actuators are connected up and down coaxially and are respectively the first thrust actuator and the first thrust actuator. The second thrust implementing unit, the pushing rib 2 of the first thrust implementing unit and the pushing rib 2 of the second thrust implementing unit are not collinear in the vertical direction.

[0042] In this embodiment, the diversion channel 17 is arranged on the actuator main body 1 and the lower end cover 3 in the first thrust actuator unit, the diversion channel 17 runs through the actuator body 1 and the lower end cover 3 up and down, and the lower end of the diversion channel 17 It communicates with the upflow hole 8 in the second thrust execution unit, and the drilling fluid passes through the guide channel 17 in the first thrust execution unit, inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com