Flash welding machine for fixed steel rail

A flash welding machine, fixed technology, applied in the direction of welding equipment, welding equipment, resistance welding equipment, etc., can solve the problem of high power and quality requirements of electrical components, adverse effects of rail joint straightness, and complex circuits of high-voltage parts, etc. problem, to achieve the effect of improving the quality of pushing convex, improving the overall rigidity and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with the embodiment shown in accompanying drawing:

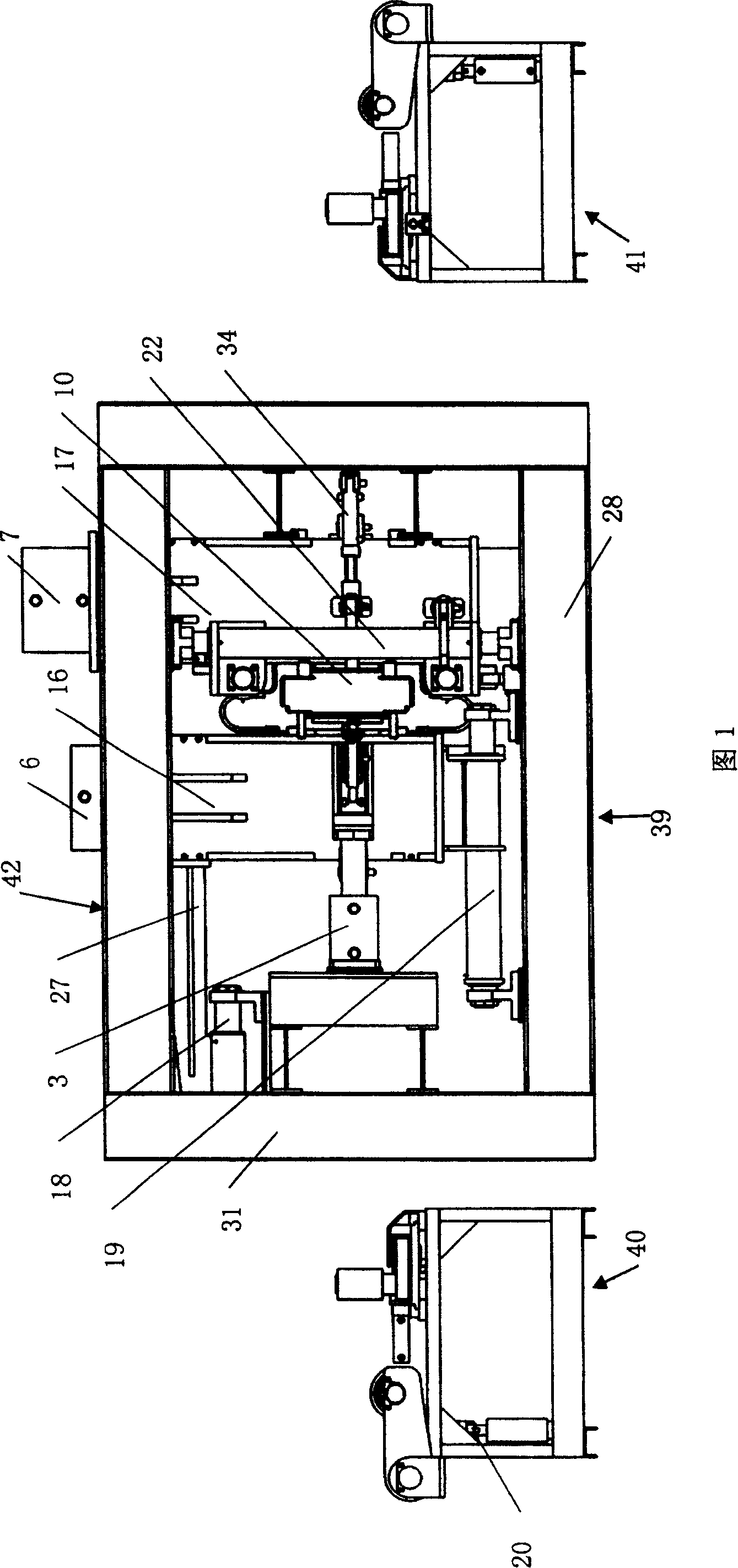

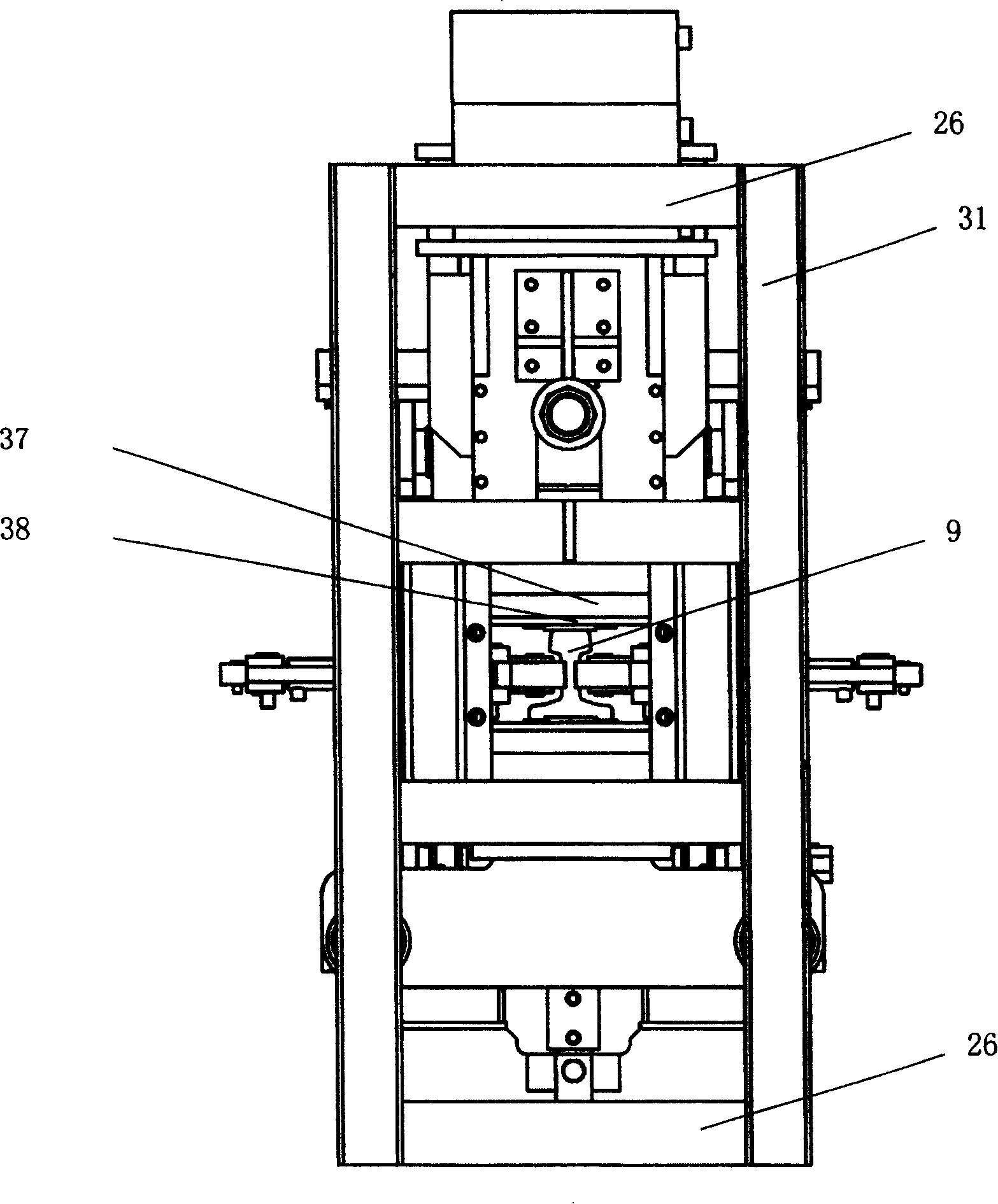

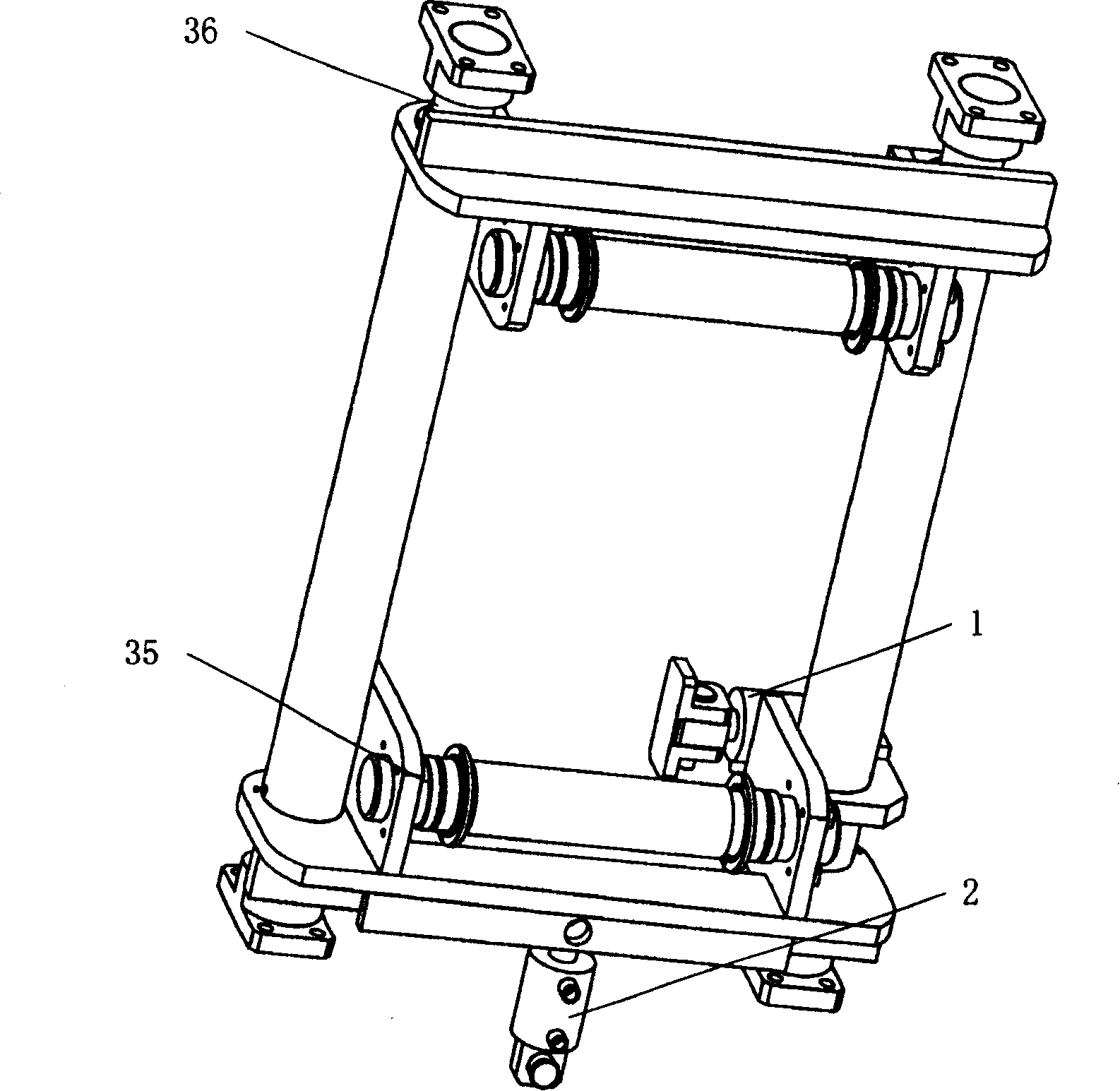

[0029] Figure 1- Figure 5 As shown, the fixed rail flash welder of the present invention includes a main frame 39 of a frame structure and two primary counter rail frames 40, 41 ( FIG. 1 ) independent of the main frame 39 . The frame of fixed rail flash welding machine main frame 39 adopts frame structure, and frame 42 is made up of four longitudinal beams 28, four end beams 26 and four vertical beams 31. Inside the frame 42 there are a moving frame 16, a static frame 17 and a centering frame 22. The upper ends of the moving frame 16 and the static frame 17 are respectively connected to the rail clamping oil cylinder 6 of the moving frame and the rail clamping oil cylinder 7 of the static frame, and the lower end of the piston of the rail clamping oil cylinder 7 of the static frame is connected to the transformer cover 37, and the rail electrode 38 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com