Double flush clinch stud

一种平面板、顶面的技术,应用在制造工具、机械设备、铆钉等方向,能够解决失效、旋转固定削弱等问题,达到高推出力、高齐平安装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

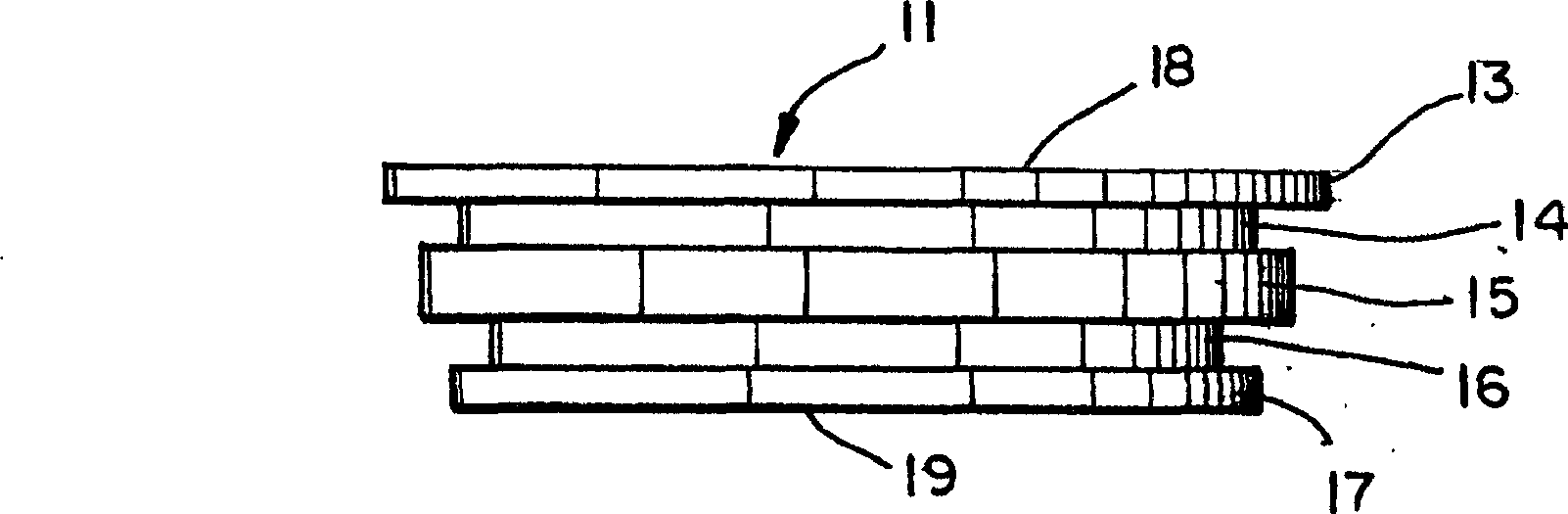

[0017] now refer to figure 1 , the present invention is a fixed type fastener having two pairs of displacers 13 and 15 and associated mutually coaxial adjacent undercuts 14 and 16, the diameter of the first pair 13 and 14 being larger than the other pair . The fastener terminates at the bottom via an end cap 17 . These formations are placed along the shank of the fastener between the top surface 18 and the bottom surface 19 of the end cap 17 .

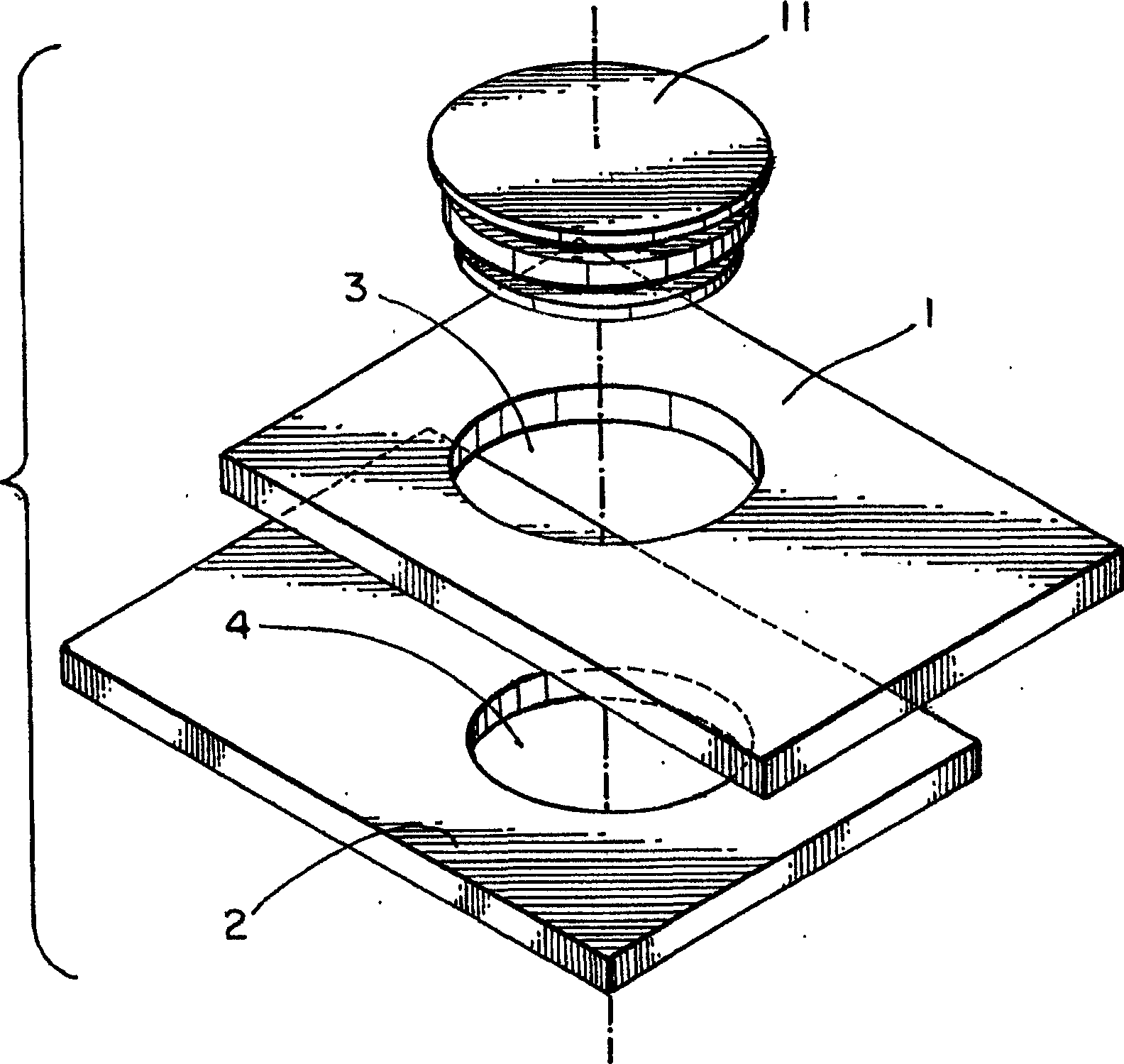

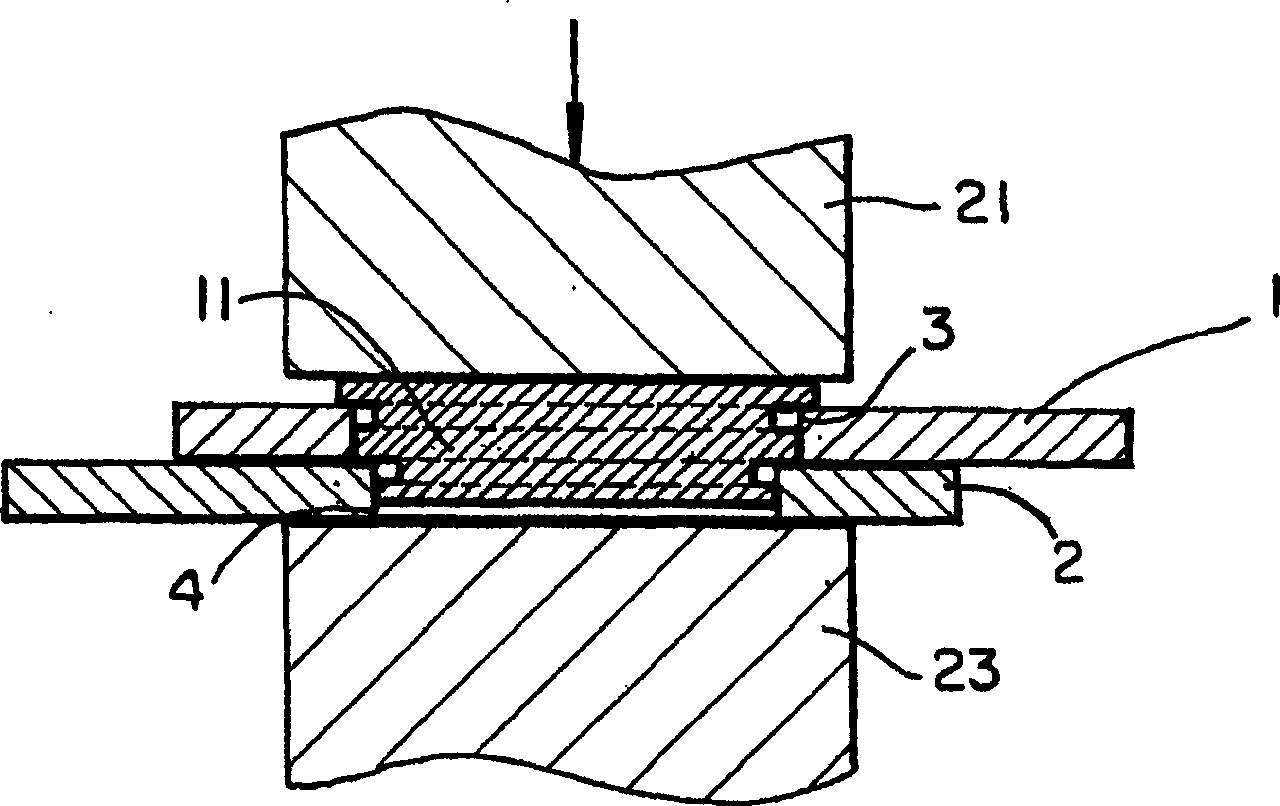

[0018] like figure 2 As shown in , the two boards 1, 2 are held in alignment by the fixed connector of the invention, which is forcibly applied from above. Panels 1 and 2 are shown separately in this figure for illustrative purposes only. The top and second plates comprise aligned holes 3 and 4 having different diameters corresponding to the diameters of the respective displacers and undercuts of the connectors. The diameter of the hole 3 in the top plate is larger than the diameter of the hole 4 in the second plate, allowing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com