Roller type cavity die extrusion molding method

An extrusion forming and roller technology, applied in the direction of metal extrusion, metal extrusion die, indenter/punch, etc., can solve the problem of inability to complete the transverse and longitudinal sections of the workpiece, increase the limit value of plastic deformation strength, and inability to extrude Extrusion of thin-walled plates, etc., to avoid accelerated wear by heat, prolong life, and be easy to extrude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

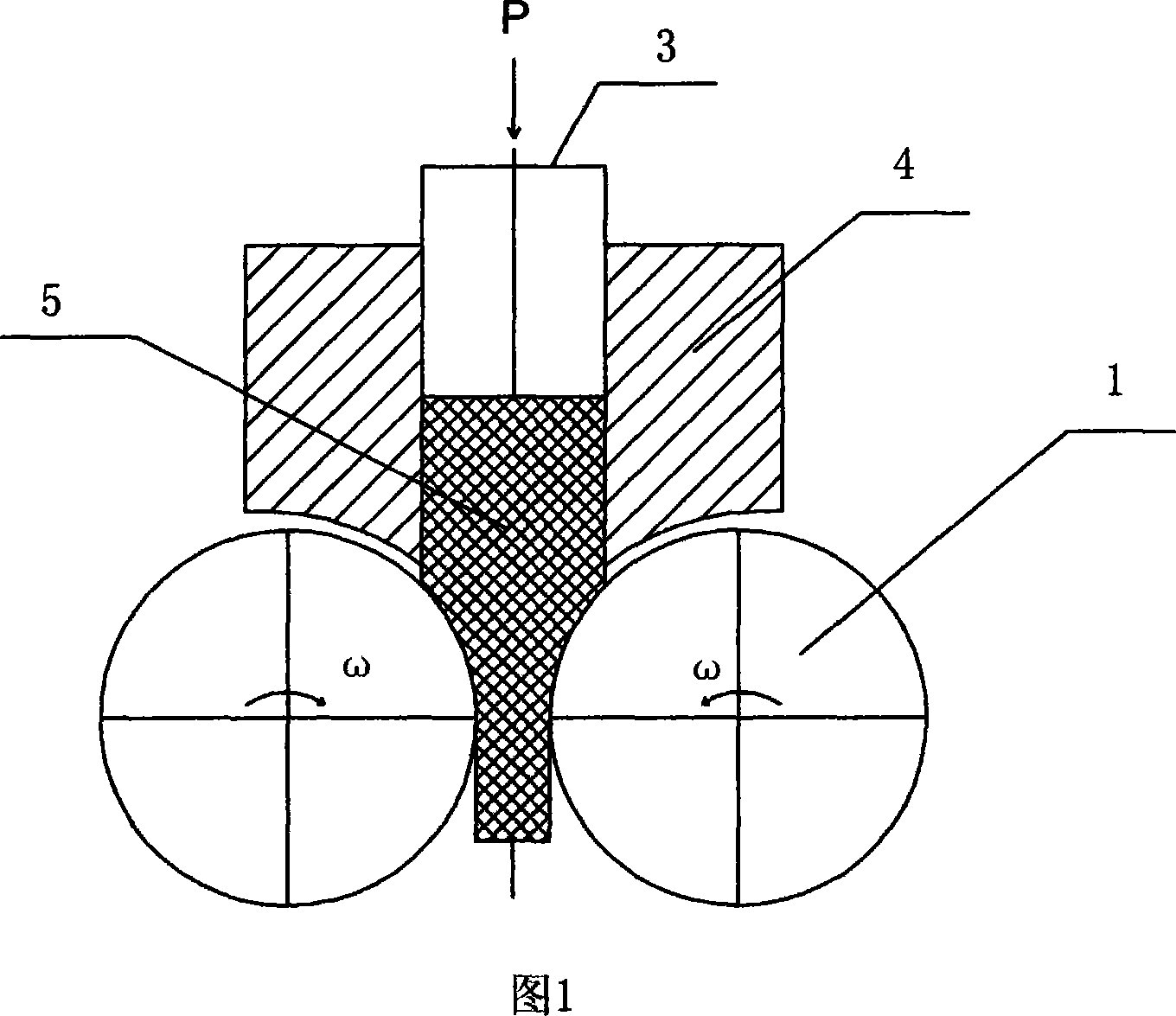

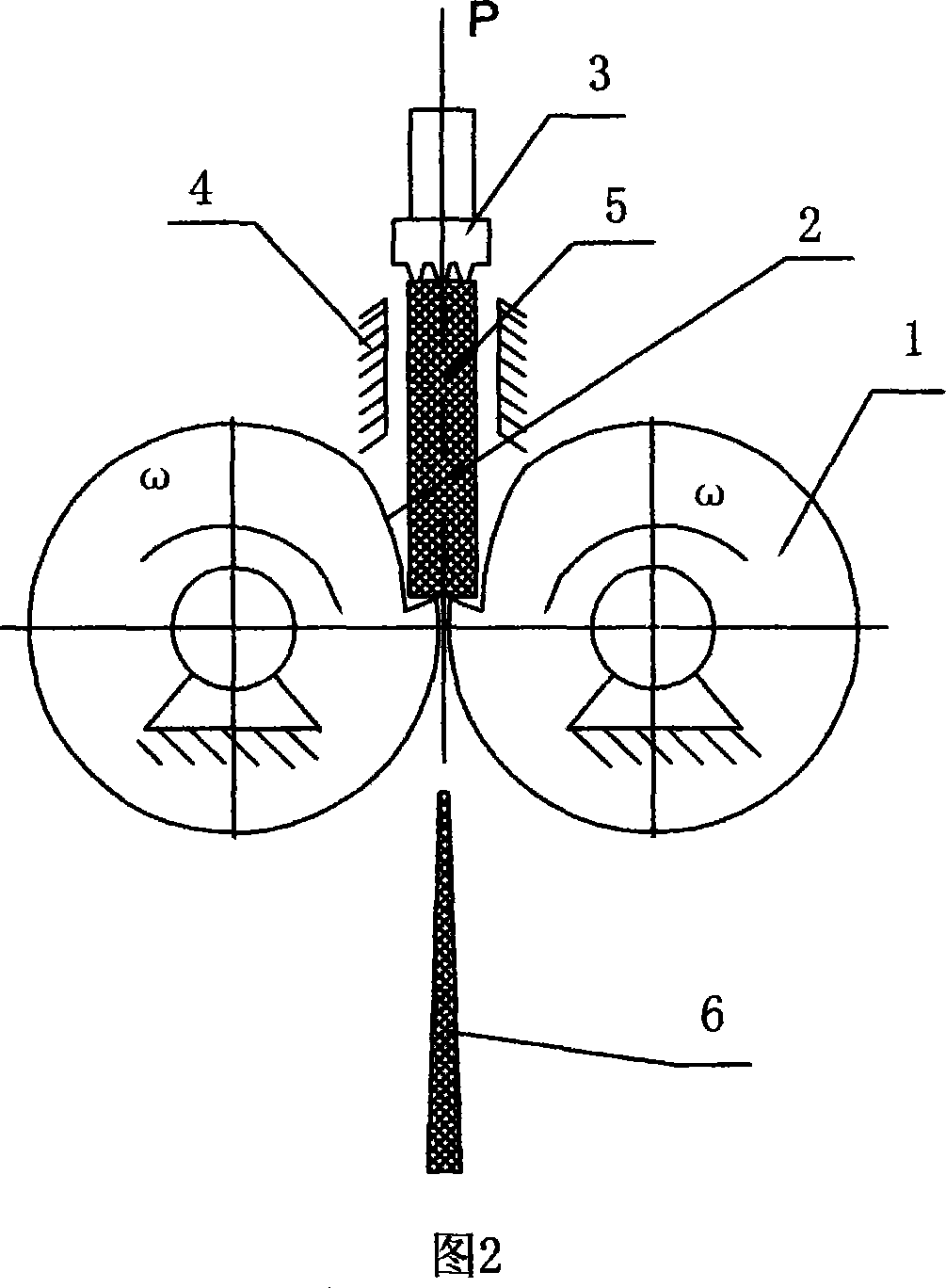

[0034] The present invention will be further described below in conjunction with the accompanying drawings. (Taking flat variable cross-section metal parts as an example)

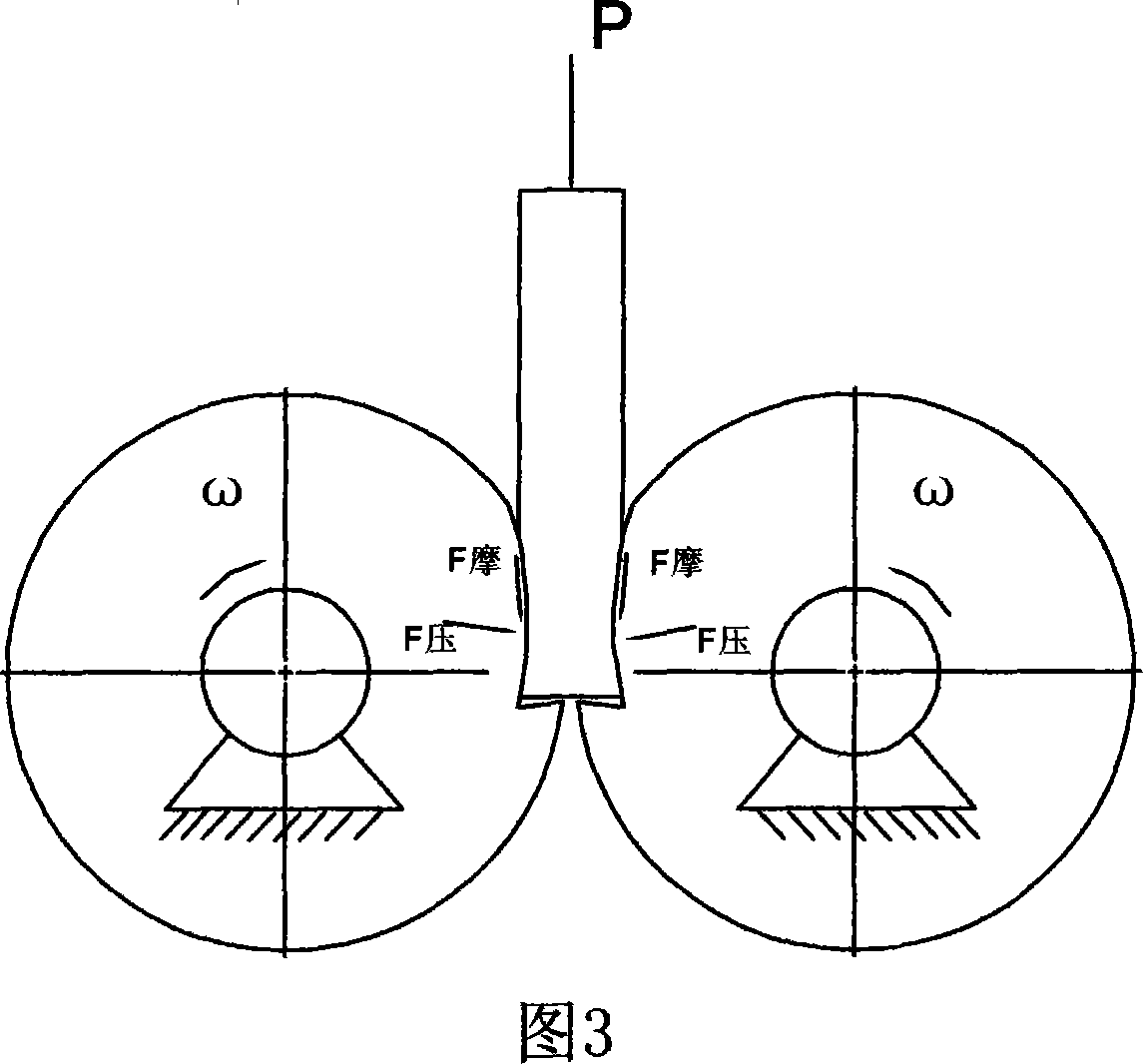

[0035] As shown in FIG. 1 , it is a basic schematic diagram of roller extrusion forming, and in FIG. 2 , it is a schematic diagram of a roller extrusion die extrusion method of the present invention. A roller-type concave die extrusion forming method adopts a pair of rollers 1, the cavity 2 of the concave mold is opened on the circumferential surface of the two rollers along the axial direction, and at the same time, there are pushing rods 3 and extrusion rods at the entrance of the roller blank. Press cylinder 4, the forming process of its blank is:

[0036] (1) The blank 5 is filled in the extrusion cylinder, and the push rod exerts a thrust P on one end of the blank, and the blank is pressed and pushed, and at the same time plays a role of alignment, and the end of the push rod is perpendicular to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com