Patents

Literature

172results about How to "Reduce heating area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

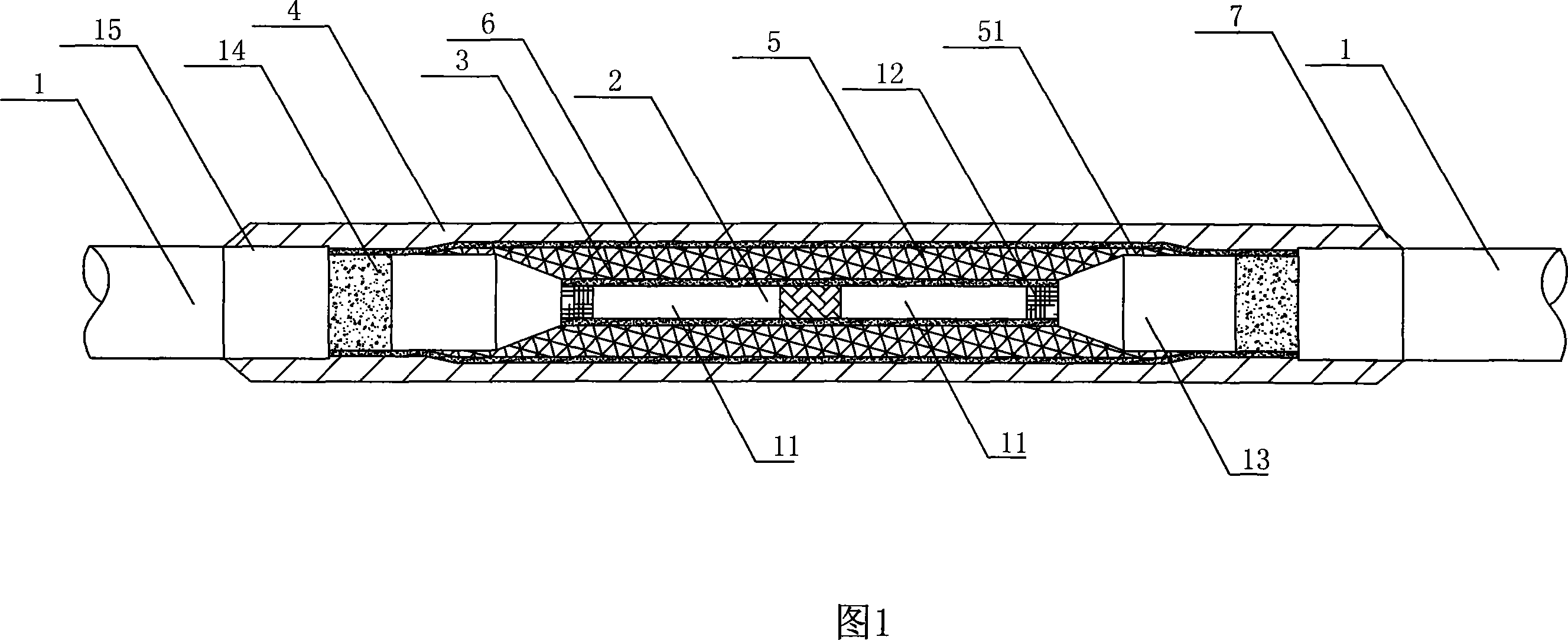

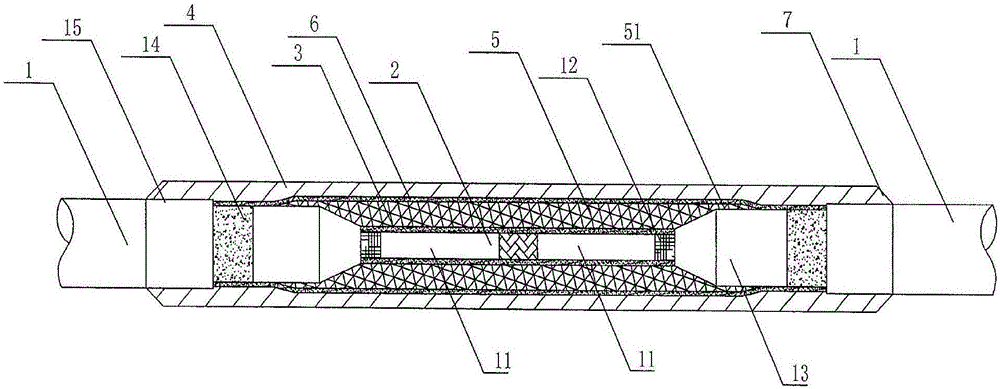

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

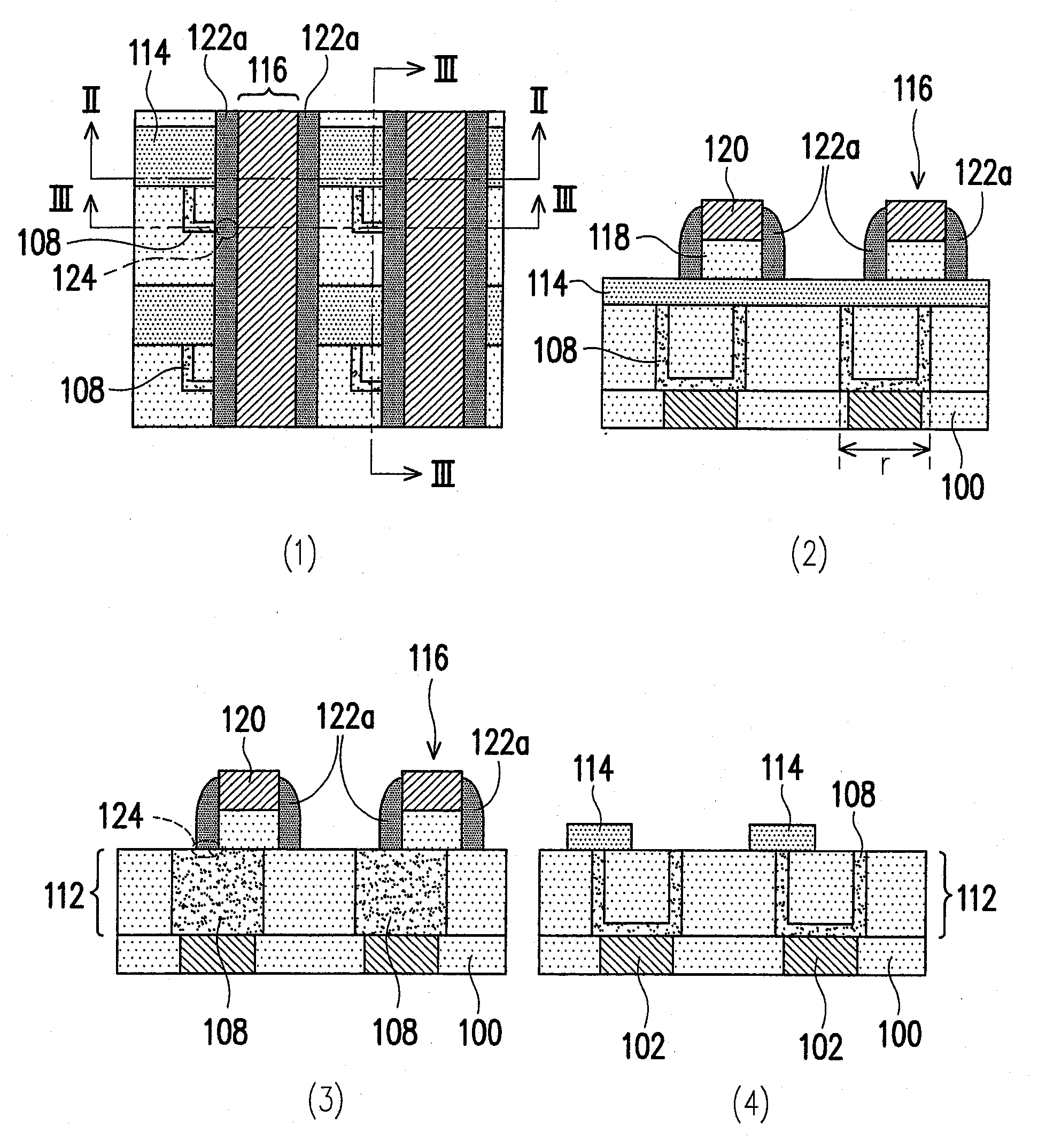

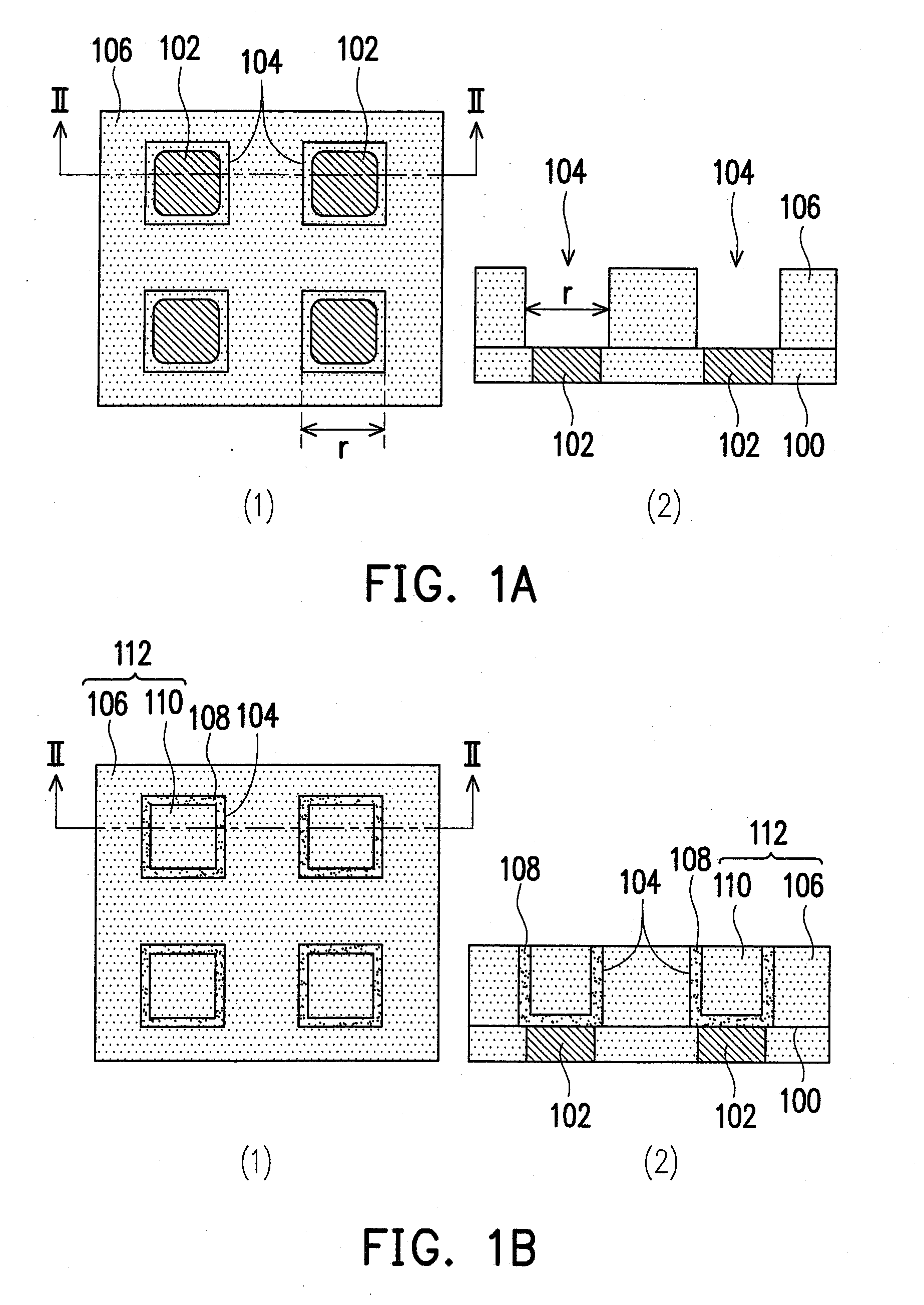

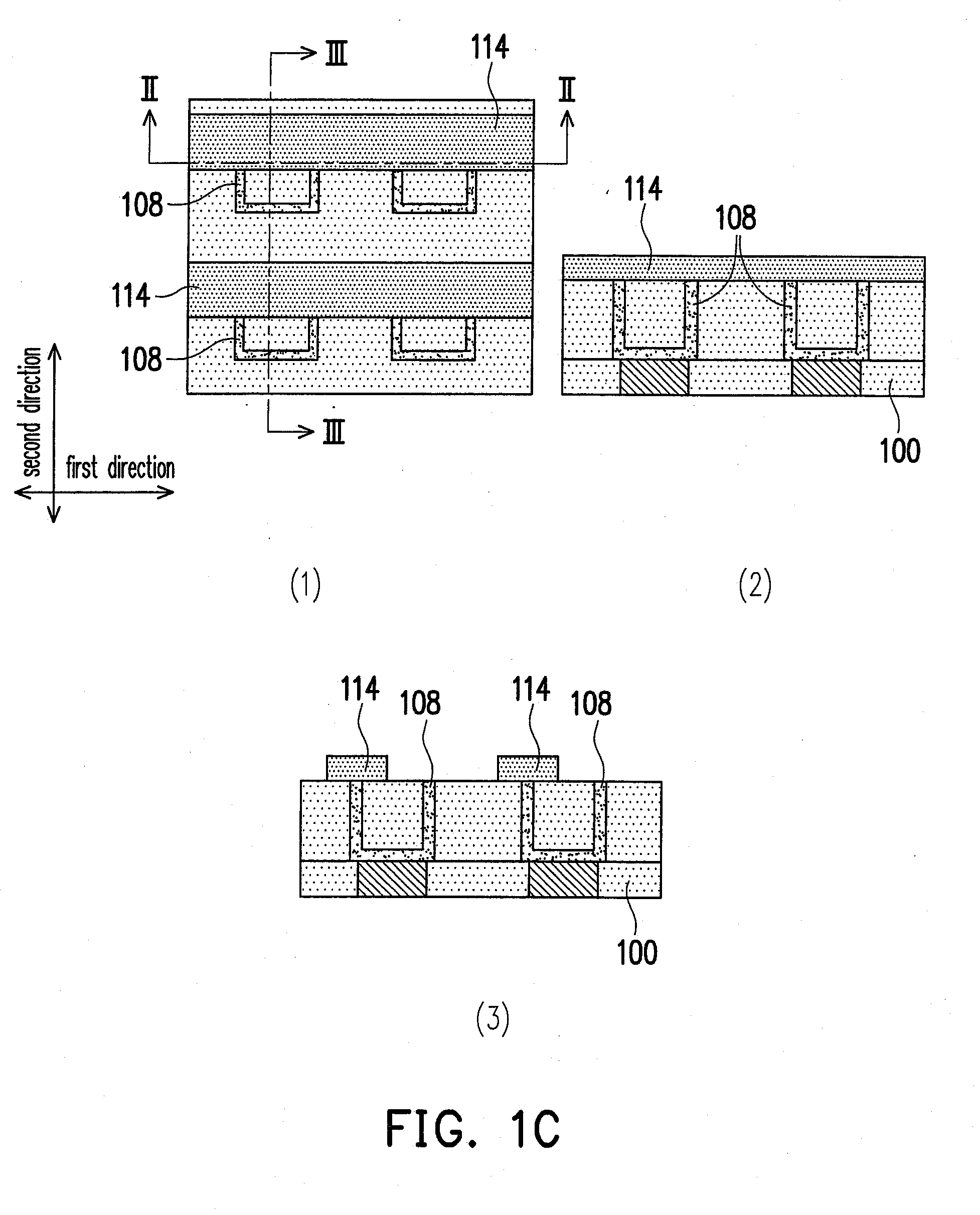

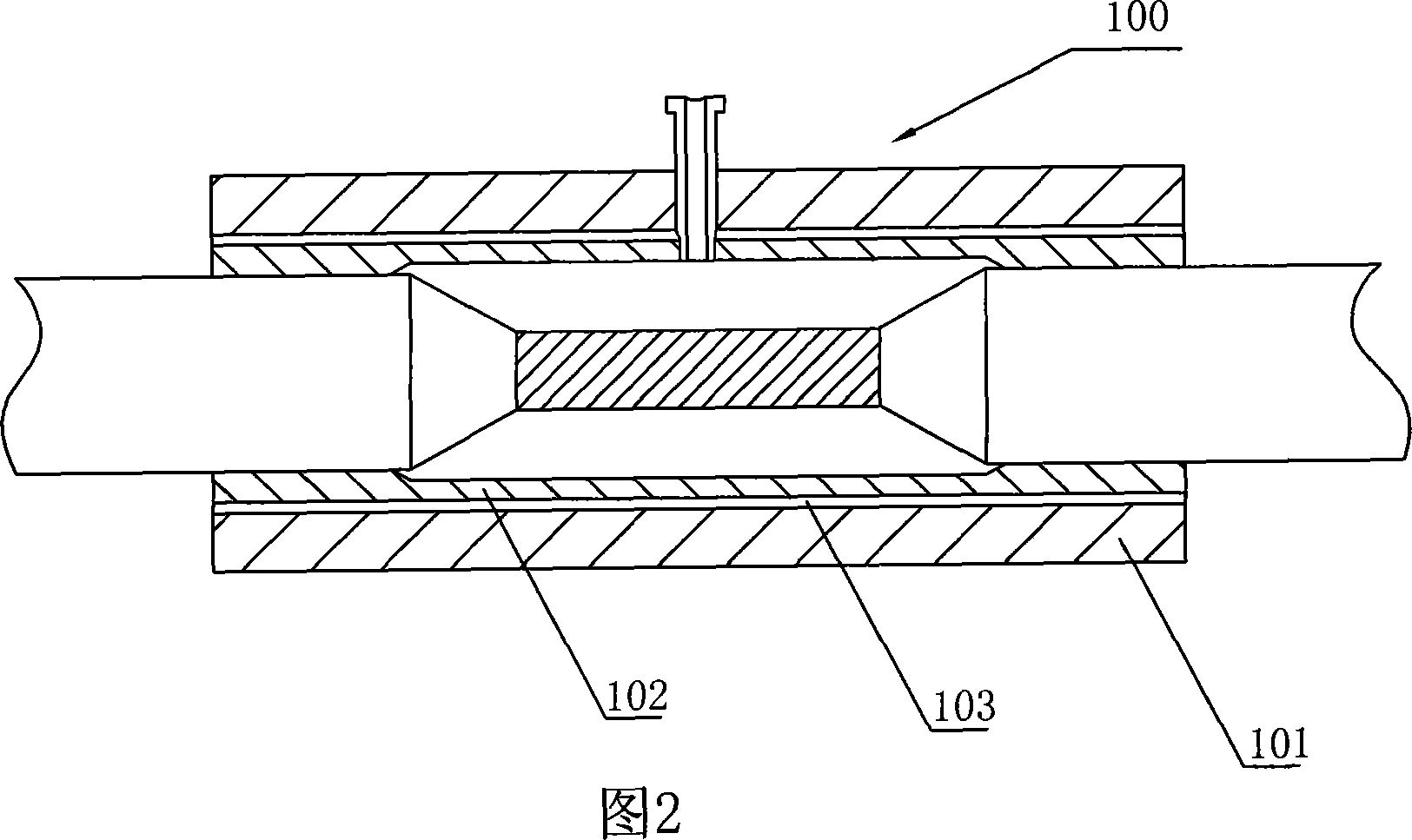

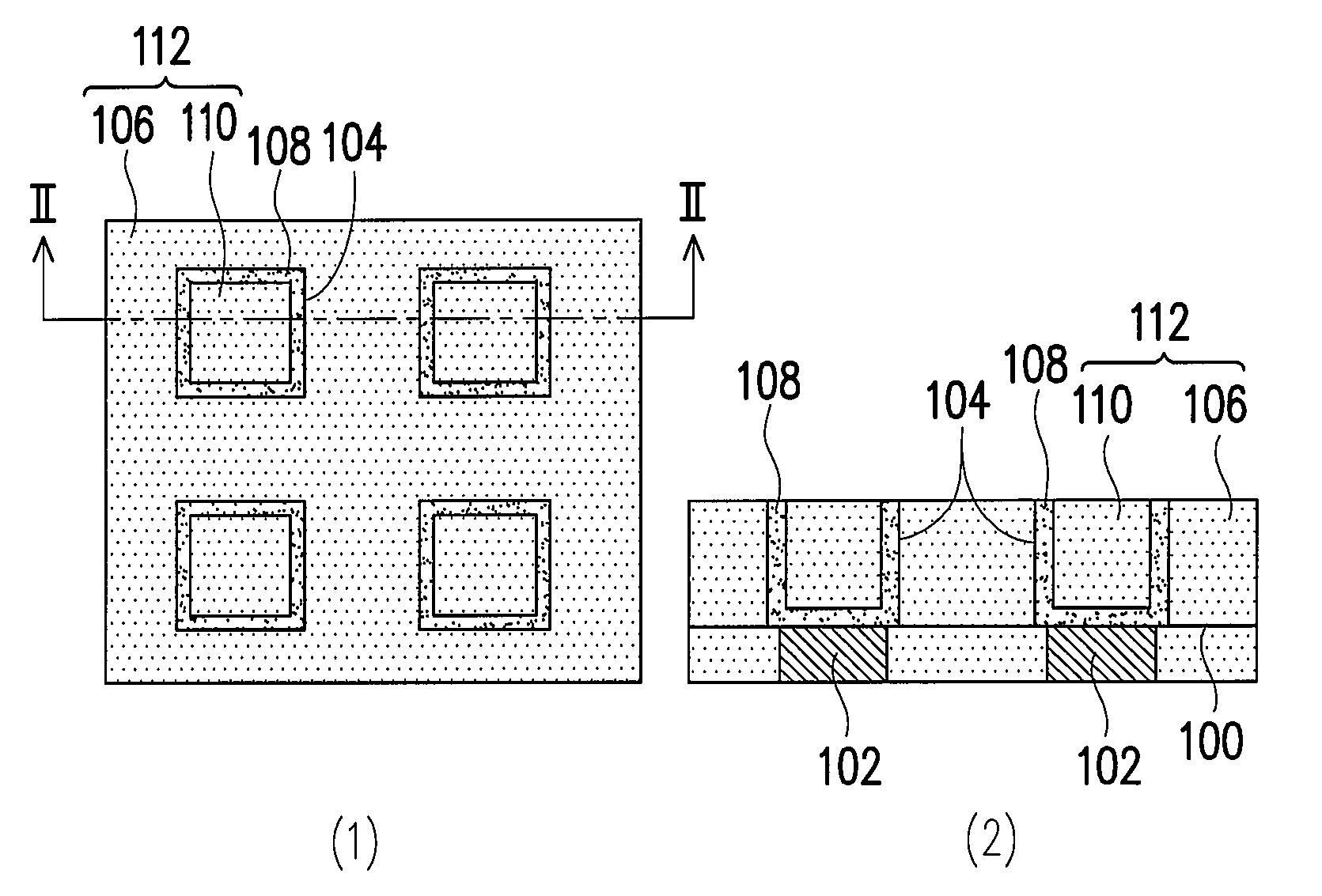

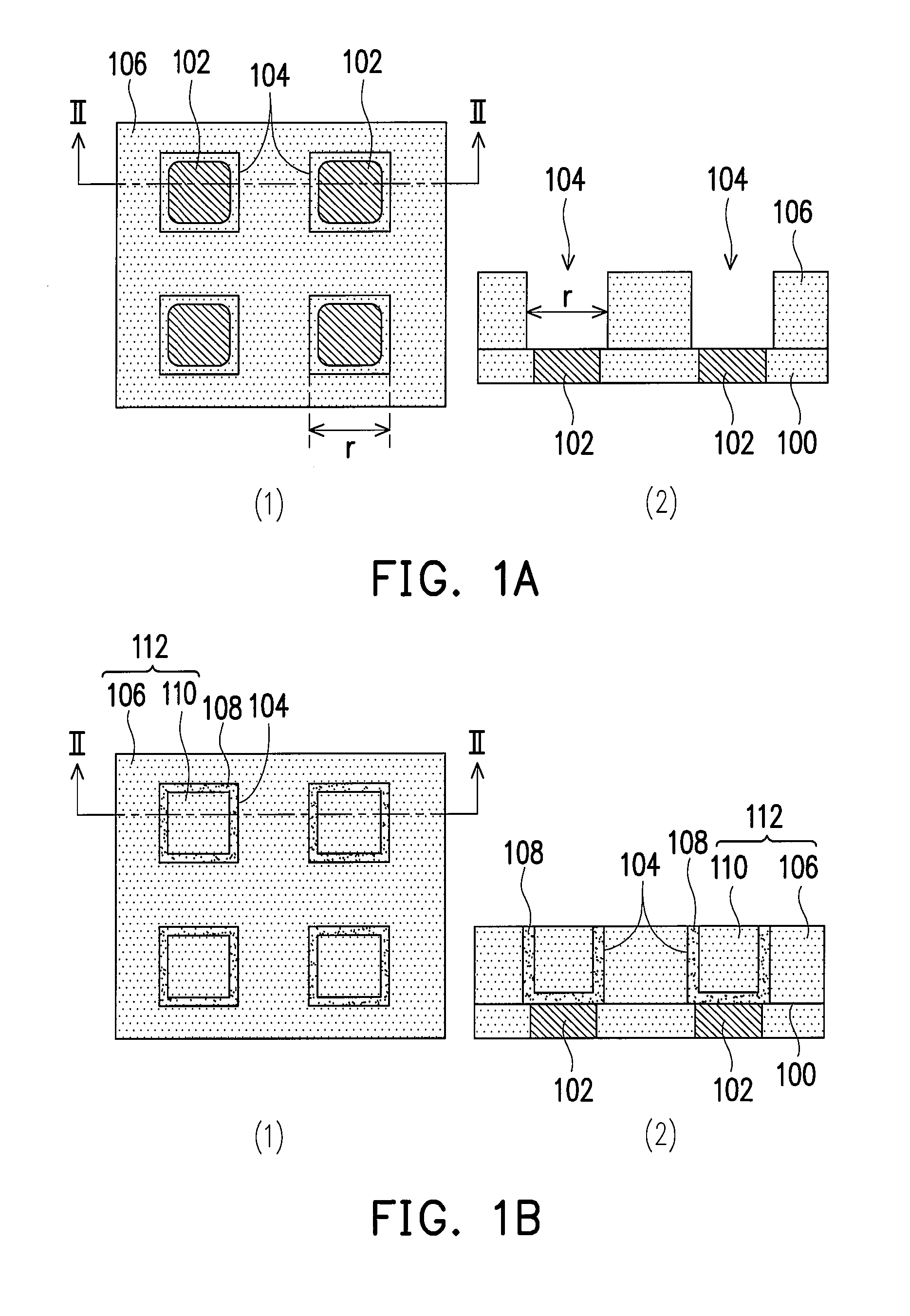

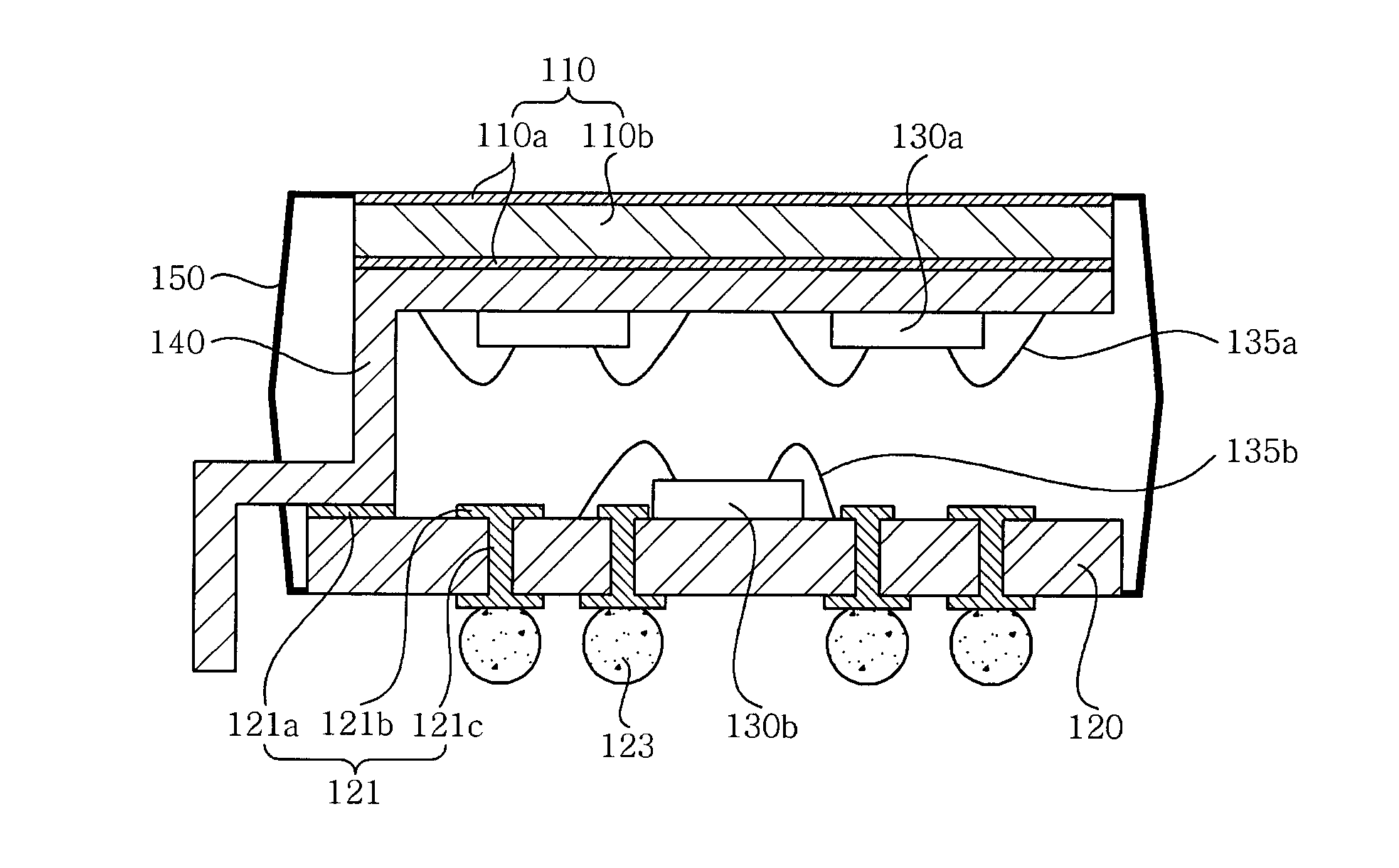

Semiconductor memory device, phase change memory device, and method of fabricating the same

InactiveUS20070152205A1Increase fabrication yieldSimple to fabricateTransistorSemiconductor/solid-state device detailsSemiconductor memoryPhase-change memory

A phase change memory (PCM) device includes a substrate, bottom electrodes disposed in the substrate, a first dielectric layer disposed on the substrate, second dielectric layers, third dielectric layers, cup-shaped thermal electrodes, top electrodes, and PC material spacers. In the PCM device, each cup-shaped thermal electrode contacts with each bottom electrode. Second and third dielectric layers are disposed over the substrate in different directions, wherein each of the second and third dielectric layers covers a portion of the area surrounded by each cup-shaped thermal electrode, and the third dielectric layers overlay the second dielectric layers. The top electrodes are disposed on the third dielectric layers, wherein a plurality of stacked structure composed of the third dielectric layers and the top electrodes are formed thereon. The PC material spacers are formed on the sidewalls of each stacked structure and physically and electrically contact the cup-shaped thermal electrodes and the top electrodes.

Owner:IND TECH RES INST

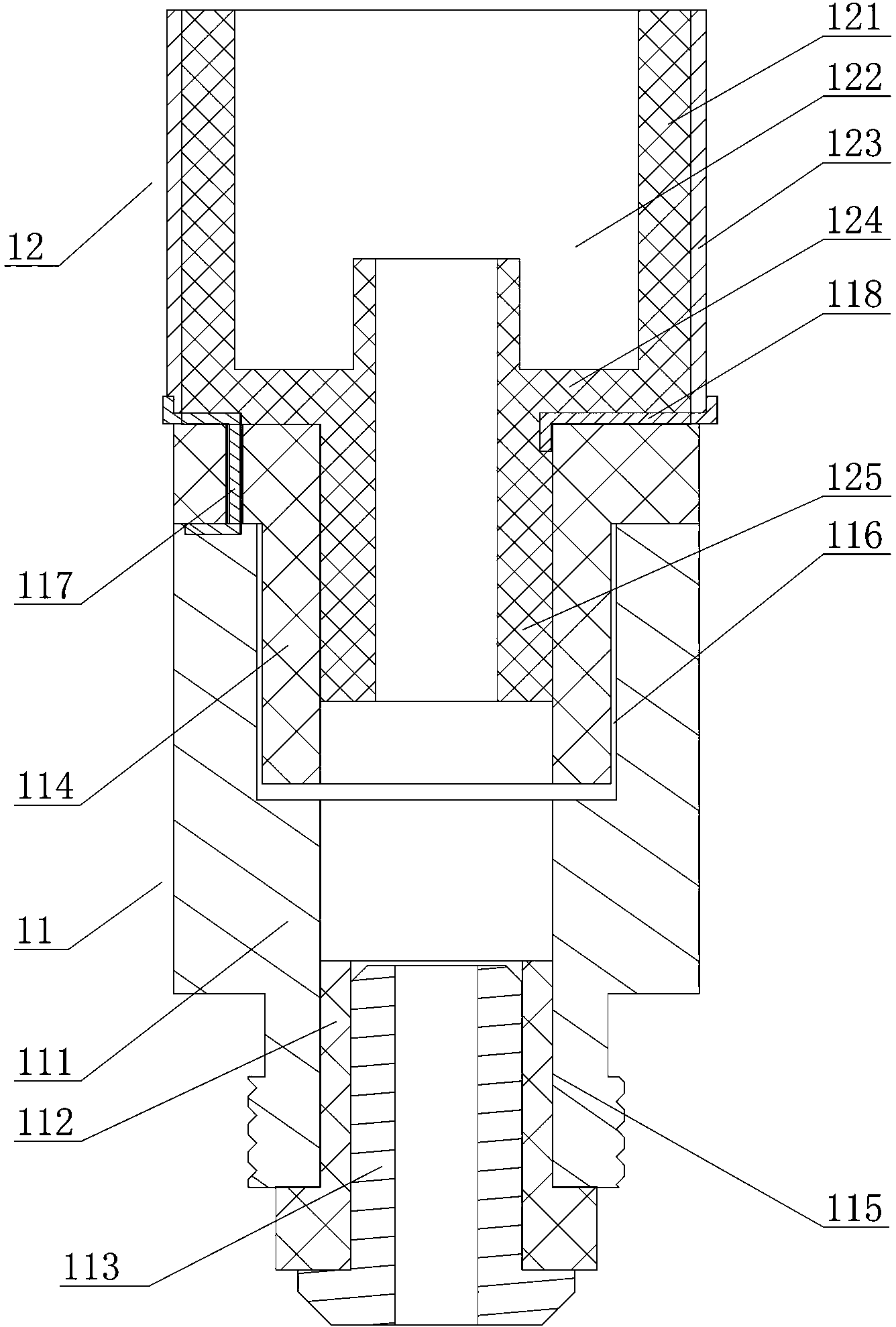

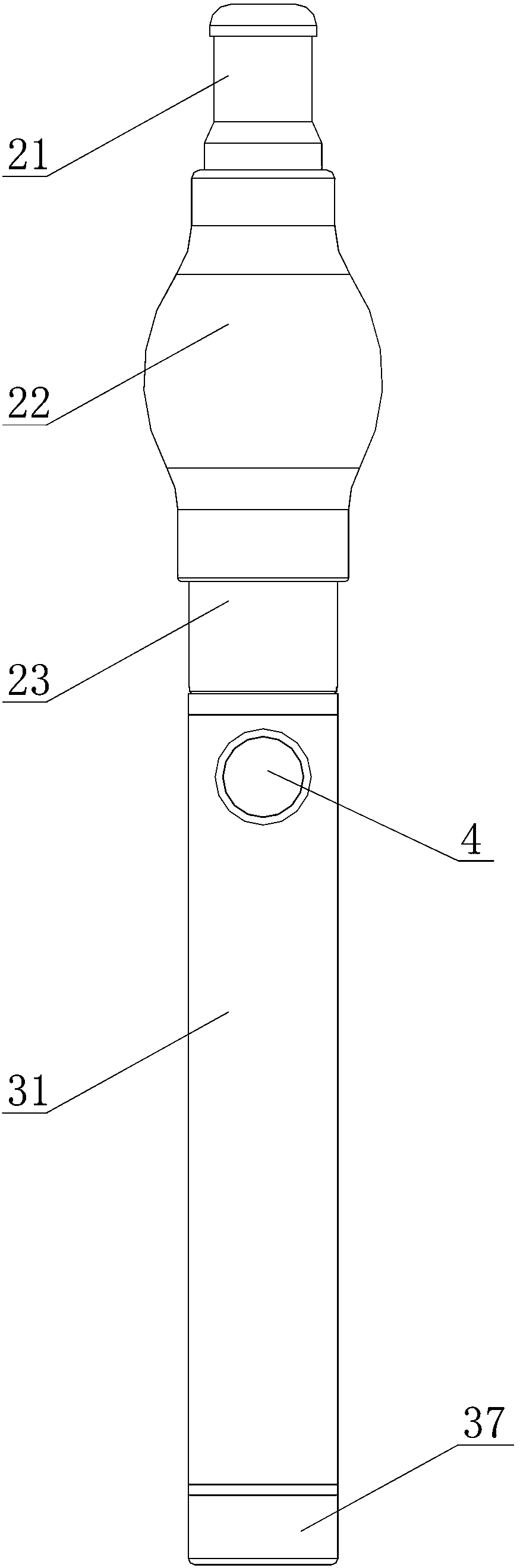

Surface heating type atomizer and electronic cigarette provided with same

The invention discloses a surface heating type atomizer and an electronic cigarette provided with same. The atomizer comprises a base and heating element, which are mutually connected; the heating element comprises a ceramic seat, an accommodating groove used for accommodating solid tobacco tar or paste is formed in the ceramic seat, a nano titanium metal heating material film is covered on the outer side of the ceramic seat; the electronic cigarette comprises an atomizer component and a cigarette rod component, which are mutually connected; the atomizer component comprises a cigarette holder, an atomizer tube, a first electrode connecting component and the atomizer, which are connected in sequence; the cigarette rod comprises a battery tube, as well as a second electrode connecting component, a battery and a control panel, which are arranged in the battery tube, the second electrode connecting component are connected with the battery through the control panel, a key switch connected with the control panel is arranged on the battery tube, and the first electrode connecting component and the second electrode connecting component are connected and conducted. The atomizer and the electronic cigarette provided with same have the advantages that the heating area is big, the atomization performance is good, the amount of the atomized oil smoke at a time is big, carbon deposition is avoided during the using process, the service life is long, and the atomizer and the electronic cigarette are energy-saving and environment-friendly.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

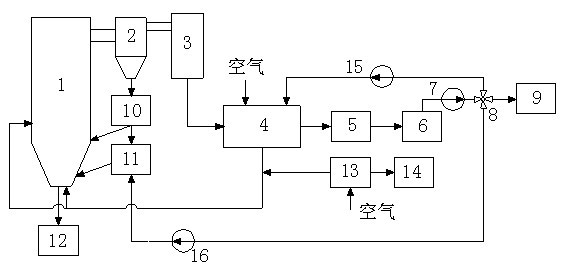

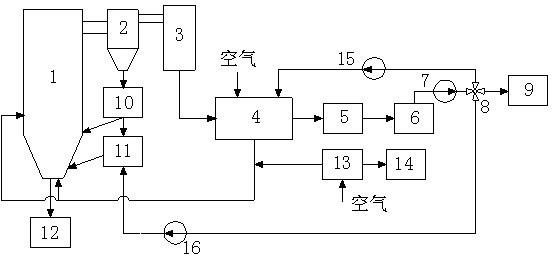

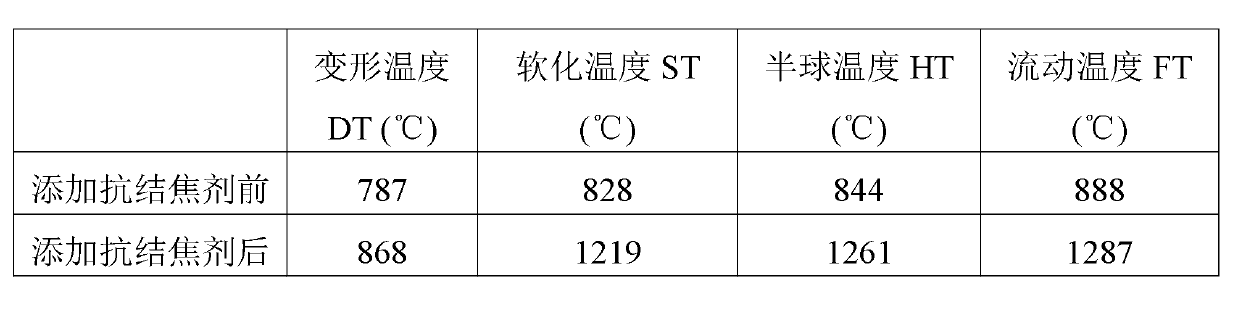

Coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and system

InactiveCN102425789ALow costZero pollution dischargeSolidificationFluidized bed combustionProcess engineeringPollution

The invention discloses a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction method and a coal-fired fluidized bed micro oxygen rich combustion CO2 emission reduction system for solving the problem of low-cost CO2 emission reduction of an industrialized coal-fired boiler. A micro oxygen rich combustion mode using mixed gas of air, oxygen and recycled smoke as a combustion aid is adopted, wherein the mixed gas contains about 25 percent of oxygen, 30 to 40 percent of recycled smoke and the balance of air; and in the micro oxygen rich combustion mode, the concentration of the CO2 gas in the generated smoke is 30 to 40 percent, and the CO2 in the smoke is removed by adopting a physical adsorption technology. The invention also provides a system device for implementing the method. By considering oxygen making cost, energy consumption and optimal comprehensive effect of separating CO2 by physical adsorption and combining the micro oxygen rich concept and the circulating fluidized bed combustion technology, desulfuration, denitration, decarburization and zero pollution emission at lower cost can be realized. The invention has the advantages of good economic efficiency, simple process, low energy consumption, high automation degree in operation process and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

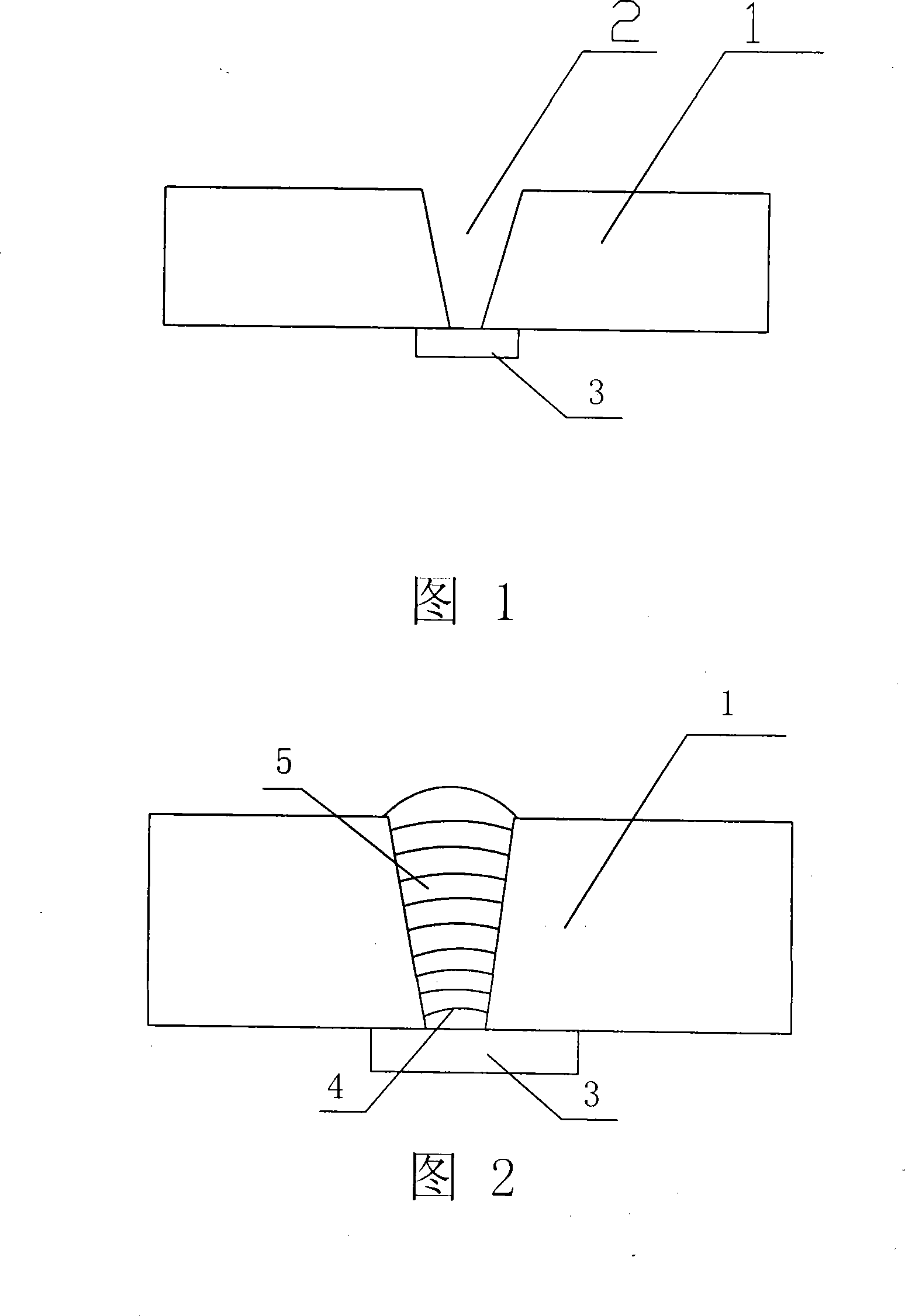

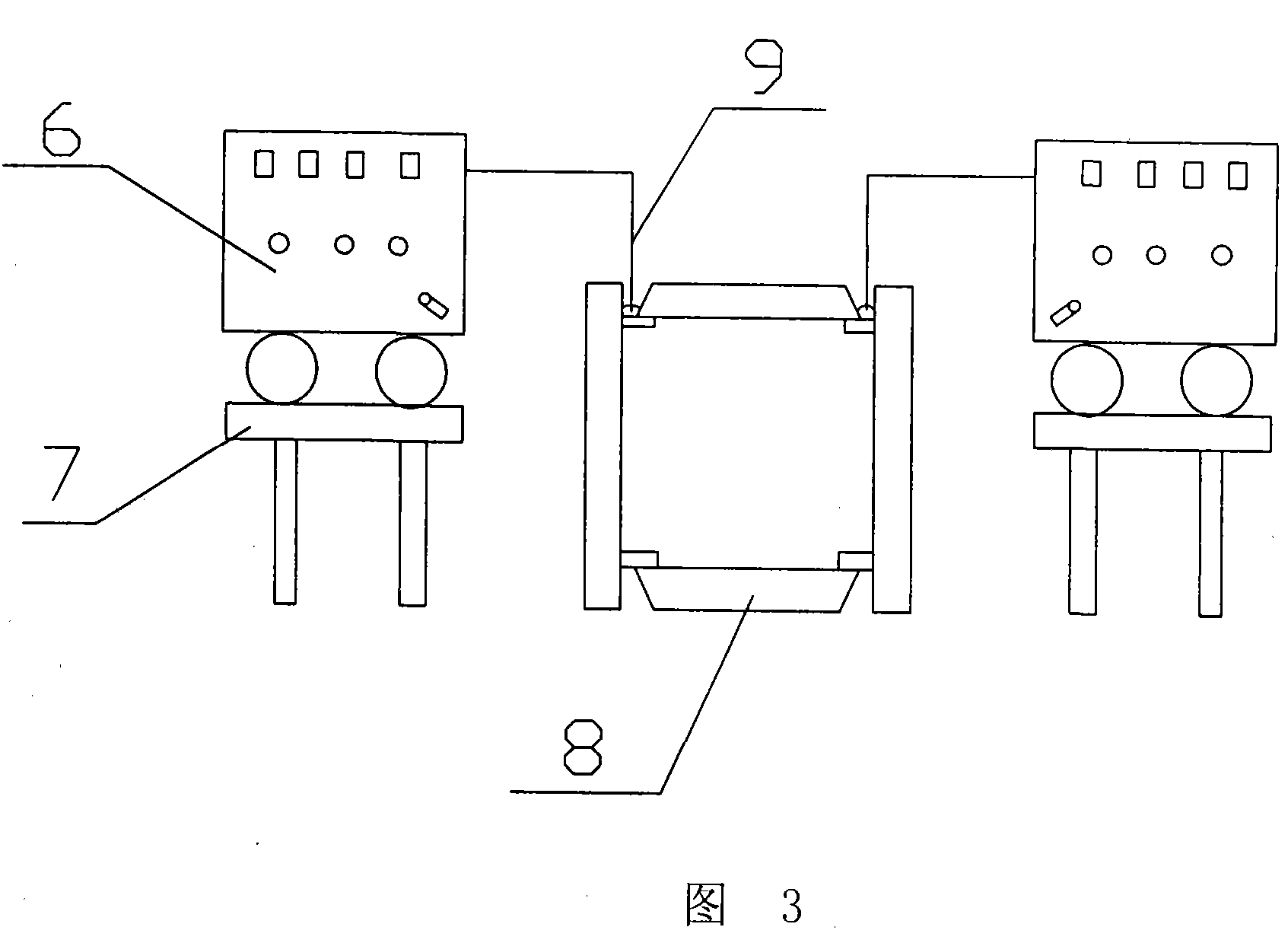

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

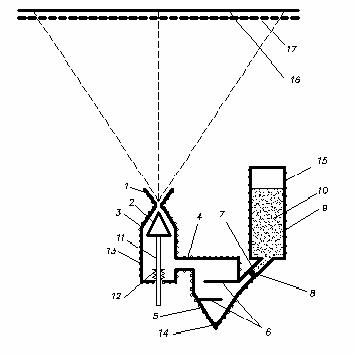

Vacuum evaporation system capable of controlling evaporating airflow distribution and components

ActiveCN102011096AImprove cleanlinessIncrease profitVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention relates to a vacuum evaporation system capable of controlling evaporating airflow distribution and components. The system comprises an evaporation gun, a high-temperature evaporation crucible and a storage tank filled with an evaporating material, wherein a nozzle with an upper conical surface and a lower conical surface is formed on the evaporation gun, and a movable airflow guidance plug is arranged inside the nozzle; a substrate to be evaporated is opposite to the front of the nozzle; the evaporation gun is connected with the high-temperature evaporation crucible which is provided with a cross baffle through a heat pipeline or a surge flask, and the other side of the crucible is connected with the storage tank through a pipeline which is provided with a feed valve; heating coils are arranged on the evaporation gun, the heat pipeline, the high-temperature evaporation crucible and the outer wall of the pipeline, and a heat coil is arranged on the outer wall of the storage tank as well; the evaporating material in the storage tank is delivered into the high-temperature evaporation crucible through the feed valve and the pipeline, so that the evaporating material to be evaporated is immediately turned to be vapor delivered to the evaporating gun; and the volume and the direction of the vapor can be controlled by changing the relative position of the airflow guidance plug and the nozzle, and the vapor is evaporated to the substrate to form an evaporating film, which is uniform and has set area and multiple components. The vacuum evaporation system has simple structure, can improve the utilization rate of the organic evaporating material, and can improve the production efficiency.

Owner:SHANGHAI UNIV

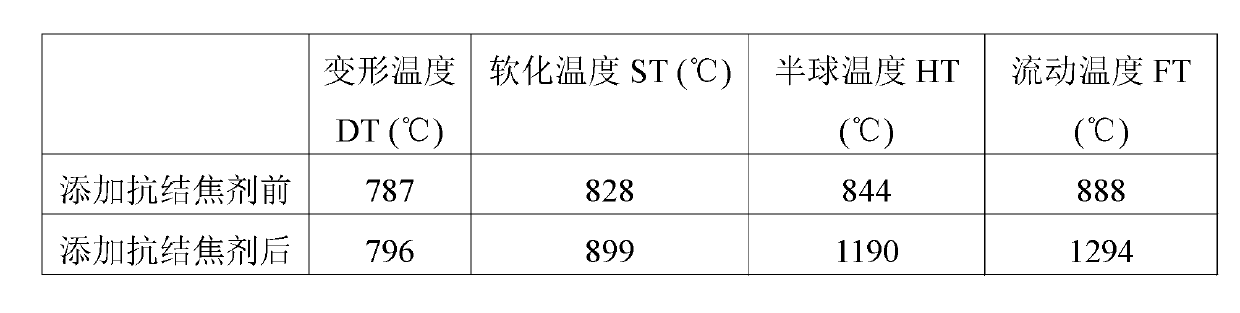

Industrial residue boiler anti-coking agent and application method thereof

InactiveCN103013617ARaise the ash melting temperatureAlleviate coking and slagging in the furnaceSolid fuelsFuel additivesPulverised fuel ashEngineering

The invention discloses an industrial residue boiler anti-coking agent and an application method thereof, belonging to the technical field of anti-coking additives. The industrial residue boiler anti-coking agent comprises the following components in percentage by mass: 30-60% of kaolin, 30-60% of CaO and 10-20% of fly ash. When in use, the industrial residue boiler anti-coking agent, accounting for 1-2% of the total mass of the industrial residue fuel, is added to the industrial residue fuel and evenly mixed. The industrial residue boiler anti-coking agent disclosed by the invention has high porosity, and the surface micropores have adsorbability; the industrial residue boiler anti-coking agent is simple to use, and the addition amount is only 1-2% of the total weight of the fuel, so that the invention does not influence the combustion characteristics of the fuel and the normal operation of the boiler, and does not need to modify the existing combustion equipment, thereby greatly lowering the investment cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

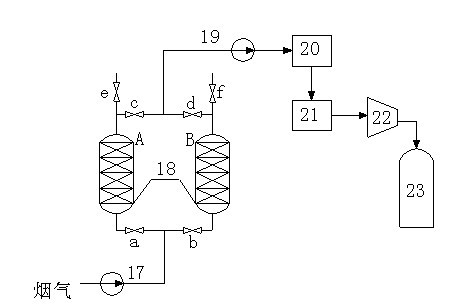

High oxygen concentration oxygen-enriched pulverized coal fractional combustion method and device therefor

InactiveCN101639227AReduce heating areaReduce power consumptionFuel supply regulationIndirect carbon-dioxide mitigationElectricityCombustion

The invention relates to a high oxygen concentration oxygen-enriched pulverized coal fractional combustion method and a device therefor. The invention has the technical scheme that a boiler type withthree stages of series connection hearths is adopted; when in combustion, the pulverized coal and oxygen are respectively put into the hearths for combustion according to the proportion in the combustion process; all recycling flue gas is pumped back into the first hearth and is blended with part of the oxygen filled in the first hearth for transmitting the pulverized coal for the first hearth; part of the flue gas generated by the first hearth is blended with part of the oxygen filled in the second hearth for transmitting the pulverized coal for the second hearth; and part of the flue gas generated by the second hearth is blended with part of the oxygen filled in the third hearth for transmitting the pulverized coal for the second hearth. The total concentration of O2 in the boiler reaches 70-80%; as the next stage of hearth adopts the flue gas generated by combustion of the previous hearth as dilute gas, the actual concentration of O2 in every stage of hearth is within the range of 30-40%. The quantity of the recycling flue gas is much less than that in the current oxygen-enriched combustion boiler, and the electricity consumption in the running of a flue gas circulation fan is obviously lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

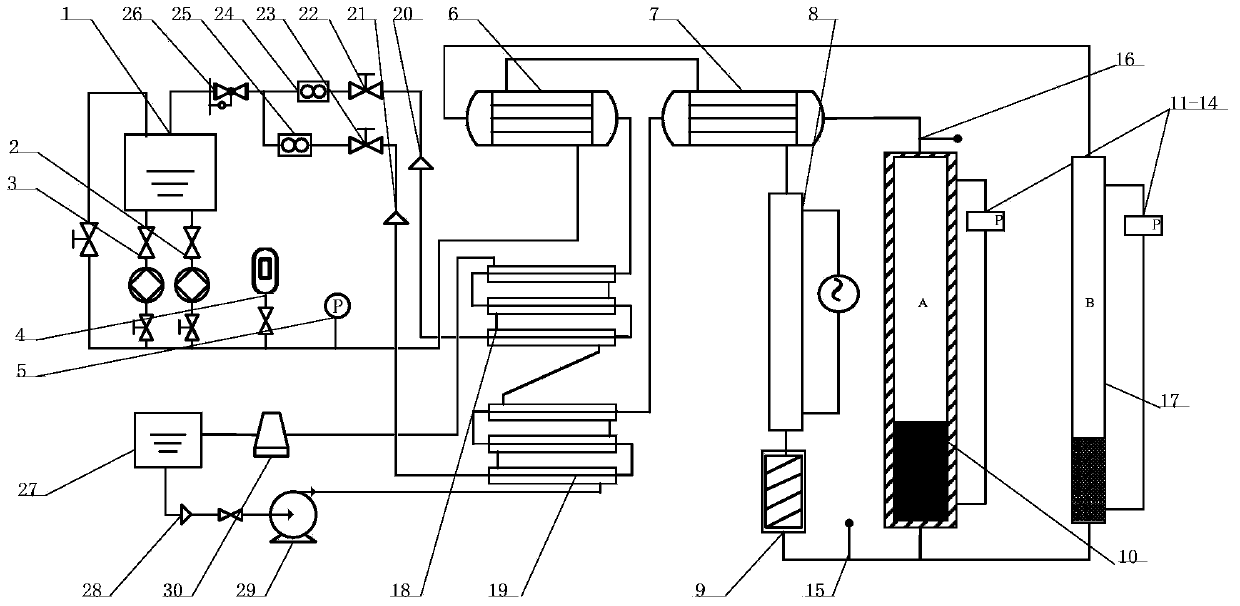

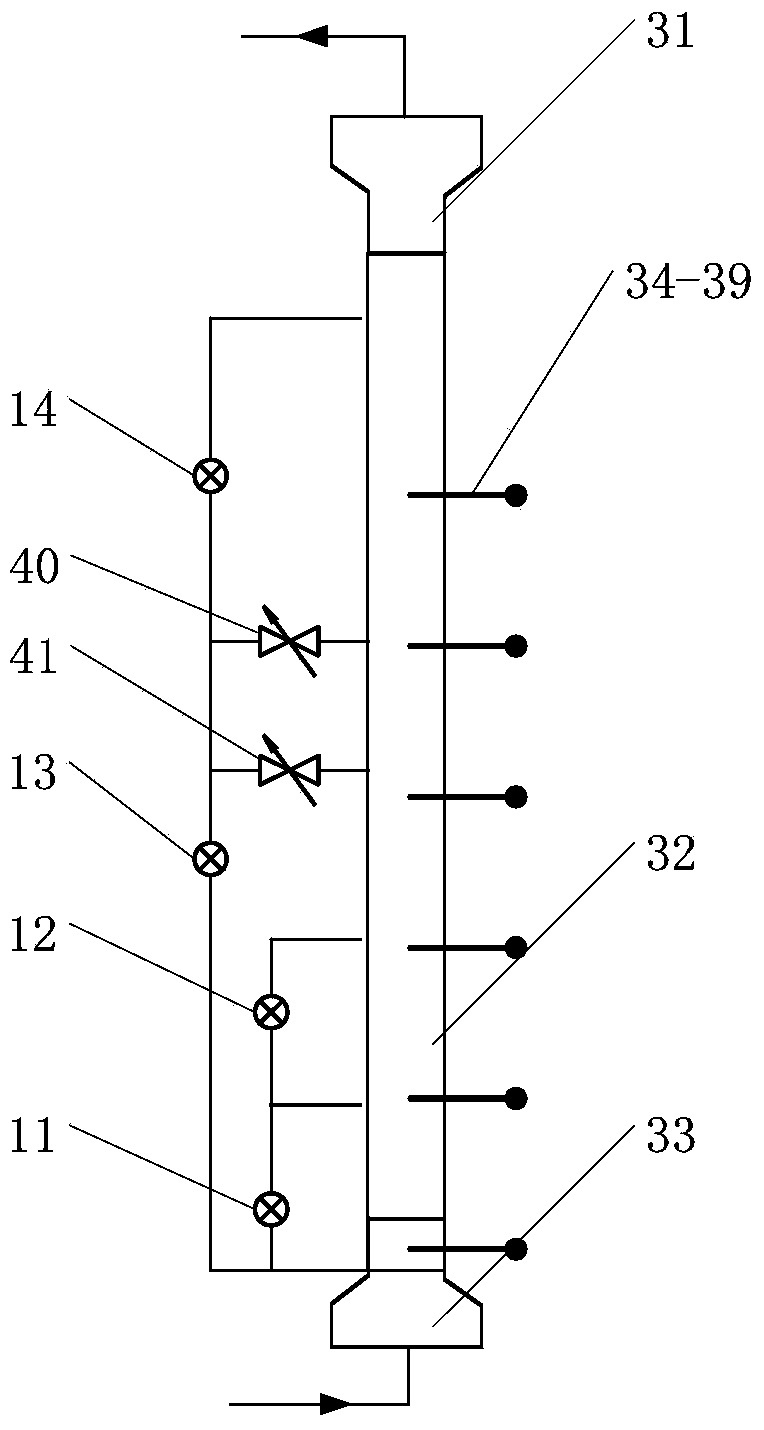

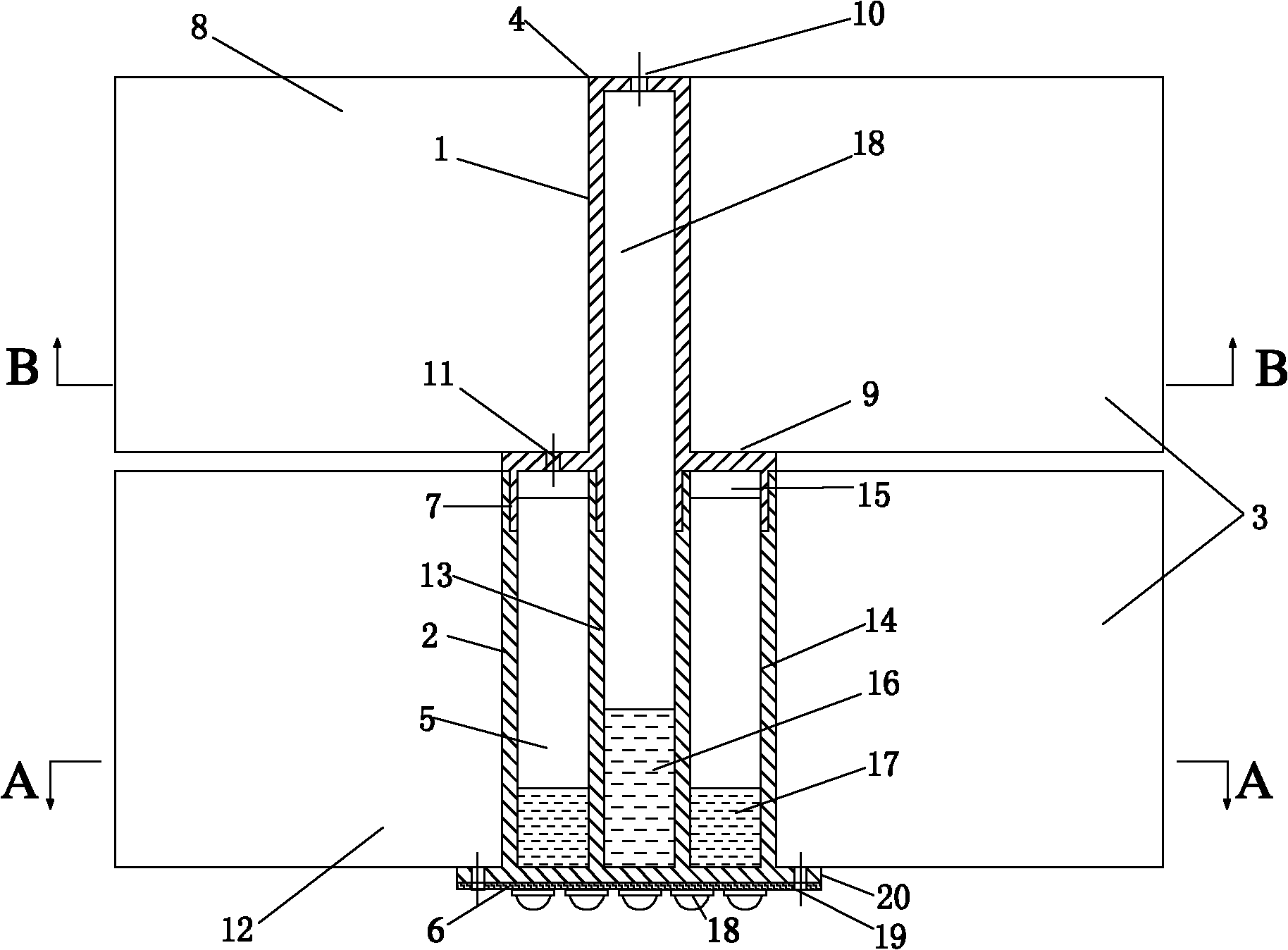

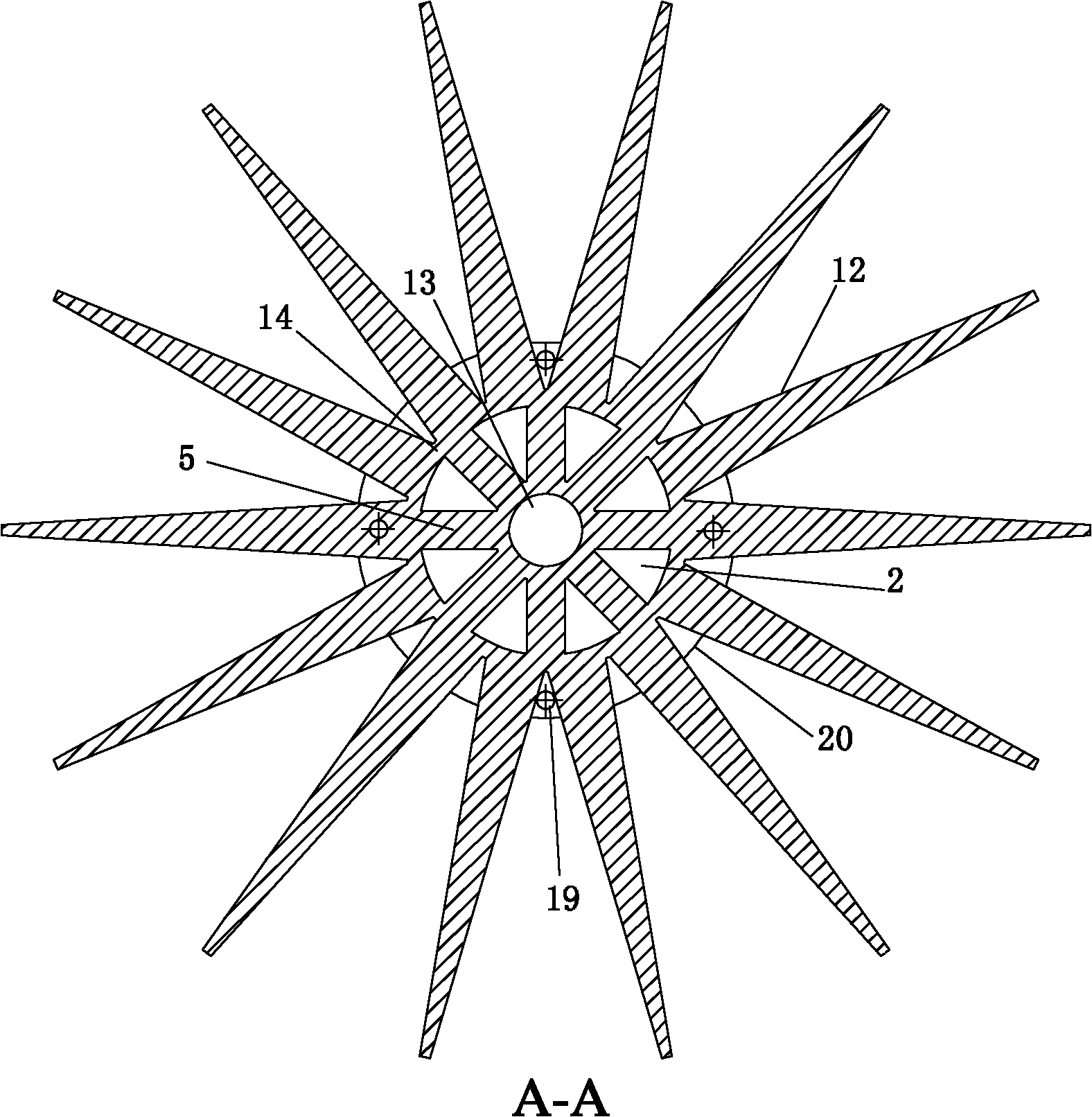

Device for testing supercritical water fluidized bed two-phase flow and heat-transfer characteristic

ActiveCN103630327AStructural solutionSolve measurement difficultiesHydrodynamic testingSimultaneous control of multiple variablesTemperature controlCooling tower

The invention discloses a device for testing the supercritical water fluidized bed two-phase flow and the heat-transfer characteristic. The device consists of a main circulation system and an auxiliary circulation system, wherein the main circulation system comprises a first water tank; the first water tank is connected with a pulse damper by two plunger pumps connected in parallel; the first water tank is also connected with two reverse-flow regenerators in series; a cold fluid outlet of the second reverse-flow regenerator is connected with a preheater; a spiral pipe heater is respectively connected with a fluidized bed test section A and a fluidized bed test section B; the fluidized bed test section A and the fluidized bed test section B are respectively connected with hot fluid inlets of the two reverse-flow regenerators; two hot fluid outlets are respectively connected with a counterbalance valve after passing by reverse-flow coolers, filters, flow regulating valves and mass flowmeters in sequence; temperature control thermocouples are arranged on an outlet and an inlet of the test section A and the test section B; differential pressure pickups and temperature thermocouples are arranged in the sections; the auxiliary circulation system comprises a second water tank; the second water tank is connected with two reverse-flow coolers by a circulation cooling water pump in series; the second reverse-flow cooler reflows to the second water tank by a cooling tower.

Owner:XI AN JIAOTONG UNIV

Gravity type flat heat pipe radiator for cooling LED

InactiveCN101893220AIncrease cooling areaSimple and cheap to manufacturePoint-like light sourceLighting heating/cooling arrangementsAgricultural engineeringHeat pipe

The invention relates to a gravity type flat heat pipe radiator for cooling an LED in the technical field of LEDs. The gravity type flat heat pipe radiator comprises a central radiating pipe, a combined radiating pipe, radiating fins, a cover plate and a straight rib, wherein the central radiating pipe is fixedly connected with the combined radiating pipe; the combined radiating pipe is fixedly connected with a substrate of the LED; the cover plate is fixedly arranged on the top of the combined radiating pipe; a plurality of radiating fins are fixedly arranged on upper and lower sides of the cover plate and are respectively connected with the externals of the central radiating pipe and the combined radiating pipe; and the straight rib is radially arranged in the combined radiating pipe and is connected with the radiating fins. The gravity type flat heat pipe radiator is a novel high-power LED radiator with the advantages of large radiating area, high radiating efficiency, good starting performance, light weight, good temperature uniformity, compact structure and convenient processing.

Owner:SHANGHAI JIAO TONG UNIV

Method for producing coated granule phytase

InactiveCN1775067AImprove thermal stabilityImprove stabilityHydrolasesAccessory food factorsPhytaseMetallurgy

The production method of coated granular phytase includes the following steps: uniformly mixing phytase and stabilizing agent, slowly adding fully-dissolved binder at the same time of shearing materials, stirring, cutting, kneading and granulating in the granulating machine to obtain granular material, boiling and drying, then using spray method to coat the granular phytase and screening so as to obtain the invented spherical coated granular phytase.

Owner:南宁瑞致生物工程有限公司

Additive inhibiting biomass boiler coking and using method thereof

ActiveCN105238494AWill not affect normal operationDoes not affect combustion characteristicsBiofuelsSolid fuelsChemical reactionSlag

The invention discloses an additive inhibiting biomass boiler coking. The additive is prepared from, by mass, 35-65% of kaolin, 30-60% of CaO and 5-35% of Mg(OH)2. When the additive is used, the addition proportion accounts for 0.5-2% of the total mass of biomass fuel. The additive can be directly mixed with biomass uniformly, then enters a combustion furnace by means of a feeding system of the boiler, and can be sprayed into a hearth uniformly along with an air inlet system, use is easy, and operation is easy. The additive has large porosity, the reaction area of the additive and the biomass fuel can be increased, pores in the surface of the additive have adsorption performance, alkali metal such as K and Na can be adsorbed to the surface of the additive effectively, the chemical reaction is carried out so that a high-melting-point substance can be generated, and ash deposition and slag bonding of the heated face are reduced; the amount of the adopted additive is small, efficiency is high, the coking resistant effect is remarkable, and the ash fusion point of the biomass can be remarkably increased.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

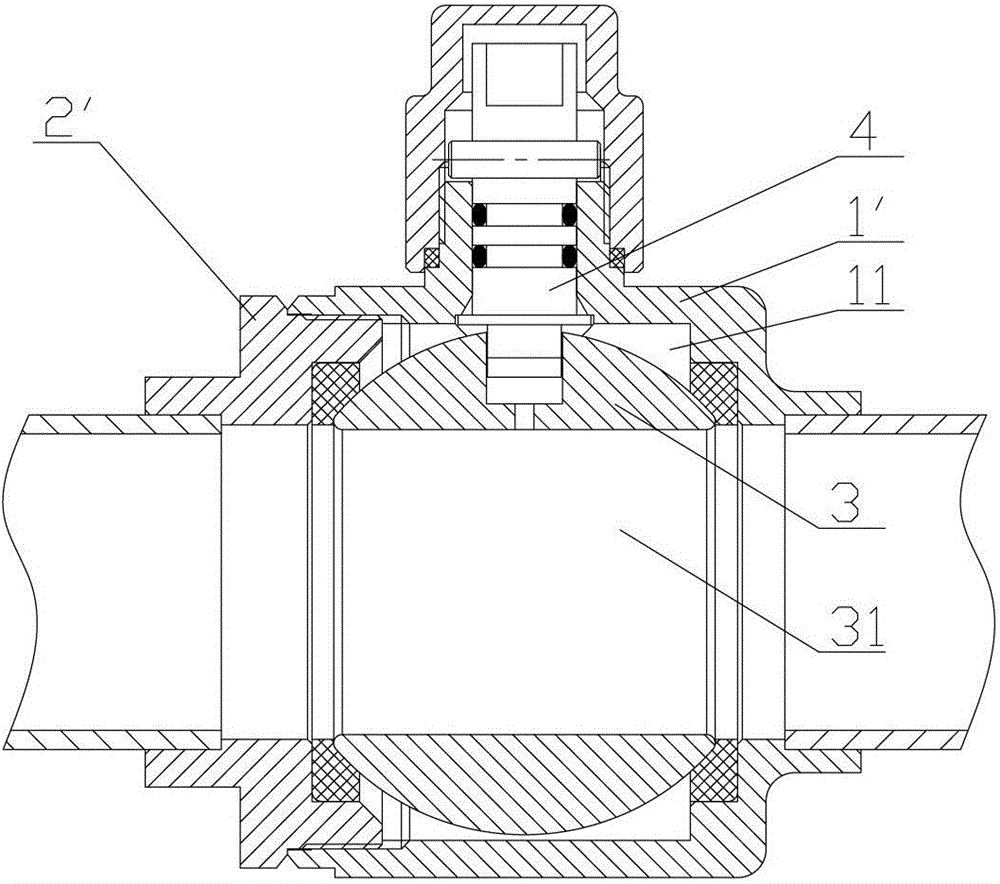

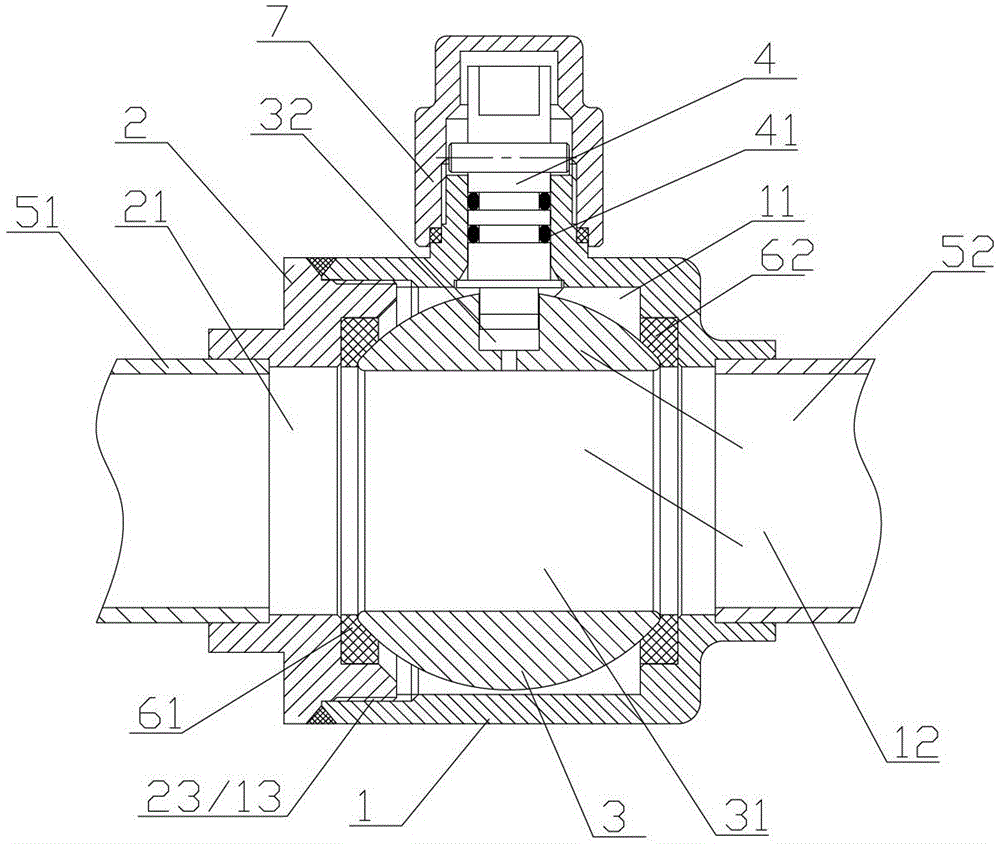

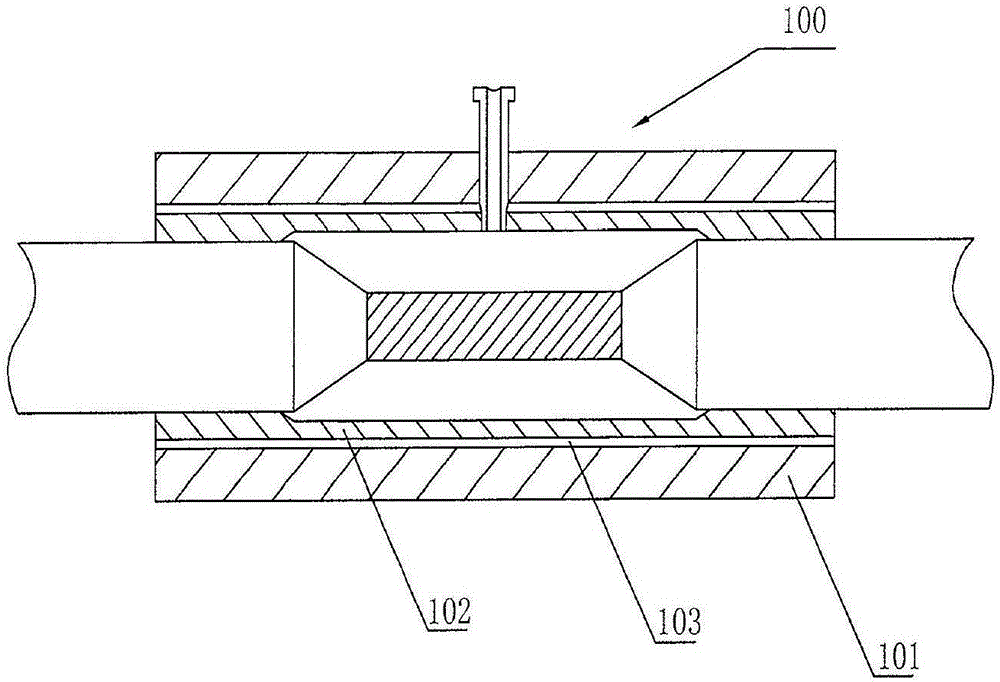

Ball valve and combination method thereof

InactiveCN104033616AAffect the opening and closing performanceHigh densityPlug valvesMetal working apparatusEngineeringMaterials processing

The invention discloses a ball valve and a combination method thereof. The ball valve comprises a valve seat (2) with a first port end (21), a valve body (1) with a second port end (12), a ball valve element (3) and a valve rod (4), the valve seat (2) and the valve body (1) are fixedly connected to form a valve cavity (11), the ball valve element (3) is arranged in the valve cavity (11), and the valve rod (4) adjusts the valve element. The ball valve is characterized in that the valve seat (2) and the valve body (1) are subjected to casting forming respectively by stainless steel materials, and fixedly welded by laser. The combination method of the ball valve includes that (A10) the valve seat is processed by the stainless steel materials through a casting method; (A20) the valve body is processed by the stainless steel materials through the casting method; (A30) the valve element (3) is processed and formed by the stainless steel materials or a copper material; (A40) the valve seat (2) is fixedly connected with the valve body (1) through a laser welding process. By means of the combination method, materials of the valve body or the valve seat can not be deformed after heated, and thereby, opening and closing performances of the valve can not be affected.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

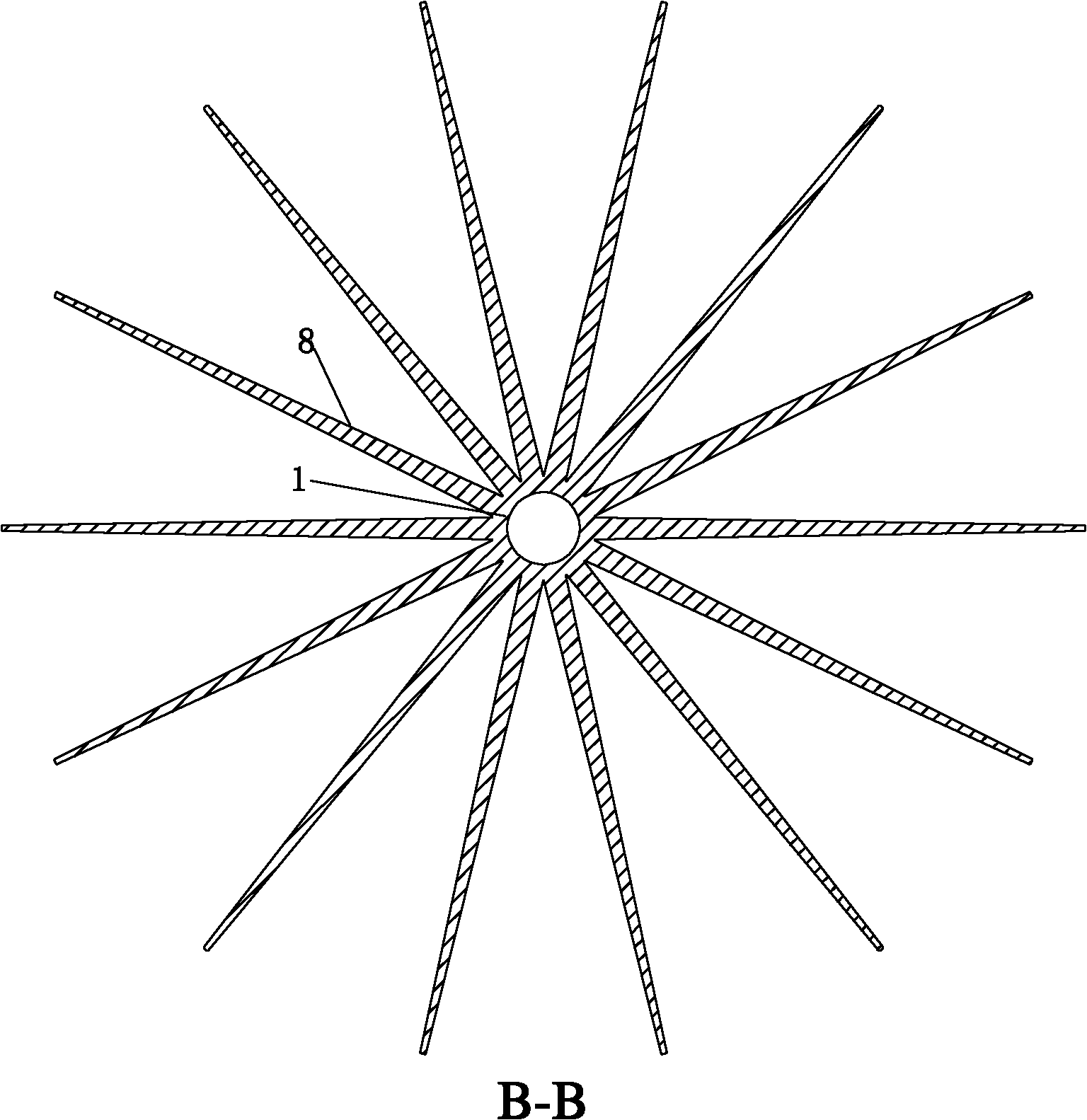

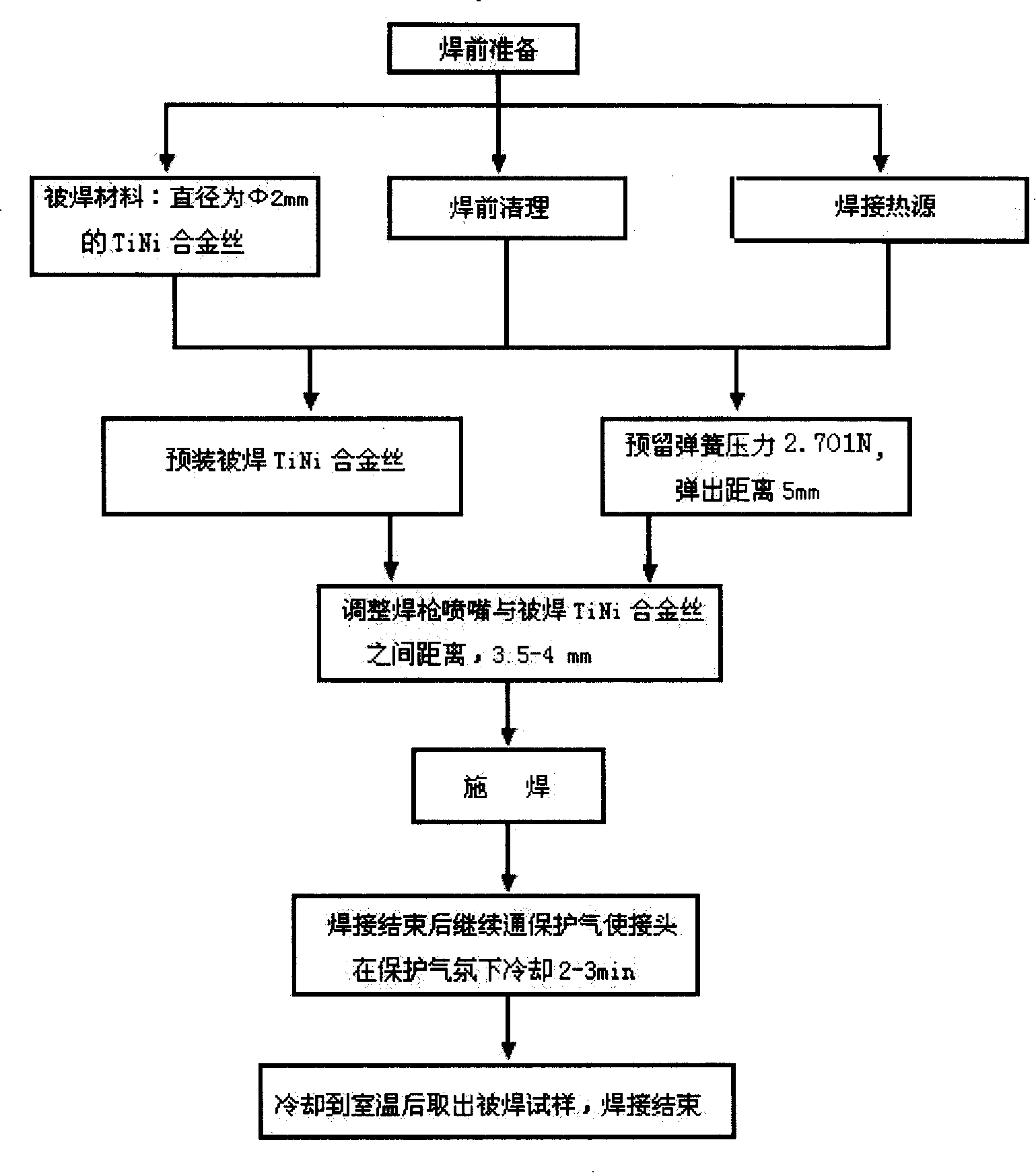

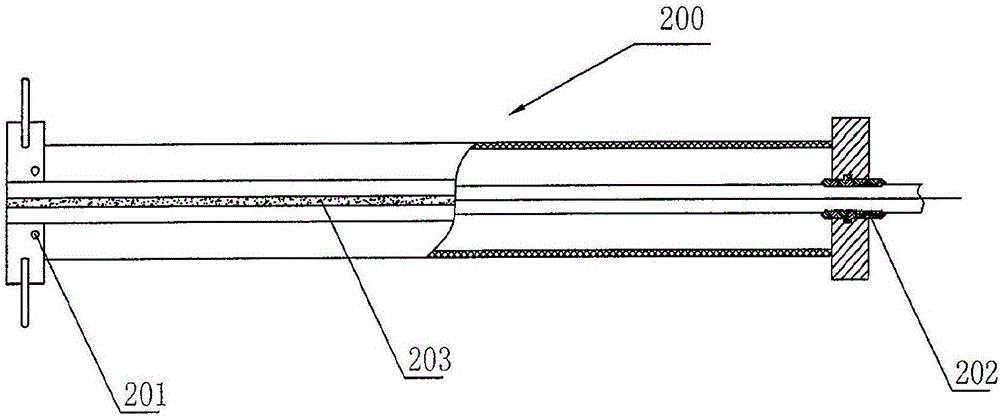

High energy beam current welding press welding process and special clamp

InactiveCN101204760AShorten connection timeReduce heating areaWelding/cutting auxillary devicesAuxillary welding devicesMetalWelding joint

The invention discloses a TiNi shape memory alloy melting and connecting technology, in particular to a high-energy beam welding press welding technology and a specific clamp. The invention adopts a high-energy density beam flow as a welding implementing heat source with the advantages of centralized and straight voltaic arc energy and high voltaic arc penetration factor, thus shortening the whole connecting time, decreasing the heating surface area and reducing heat input to the most extent, eliminating the heat effect area and effectively improving the crassitude problem of the welding line structure. The specific tooling and fixture adopted by the invention can squeeze the melt welding line metal out completely by utilizing a pretightening force when an alloy wire joint part is melt, thus keeping the crystal grains of the welding joint to be approach to a parent metal and no generation of new phases, the welding line welded with a joint to be plump and a smooth transition to acquire a joint basically formed by uniform parent metal and ensuring the tensile-strength and memory function of the material after being welded; the invention has the advantages of simple technology, reasonable design on the clamp and convenient use. The invention can be widely used in a TiNi shape memory alloy melting and connecting technology.

Owner:南京理工大学张家港工程院有限公司

Anti-deformation method of steel plate tailor welding cross column

InactiveCN102275033AReduce heating areaGuaranteed verticalityArc welding apparatusSheet steelAgricultural engineering

The invention relates to a method for anti-deformation of steel plate tailor welding cross columns. The edge plates are assembled into H-shaped steel by tailor welding, and then submerged arc welding is carried out, and then assembled and formed, and finally the connection points of the remaining connection parts are cut off. The invention provides a cross column that can prevent the deformation of the tailor-welded cross column, and can accurately correspond to the connecting hole of the beam, so that the installation is smoother.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Rice dehumidification equipment

InactiveCN113357889AEvenly heatedEasy to dehumidify and drySievingScreeningAgricultural scienceAgricultural engineering

The invention provides rice dehumidification equipment. The rice dehumidification equipment comprises a processing barrel and an airing mechanism, wherein a material guiding area and a material turning area which are arranged up and down are arranged in the processing cylinder, and a moving plate and a driving mechanism used for driving the moving plate to move back and forth in the material guiding area and the material turning area are arranged in the processing cylinder. The rice dehumidifying equipment provided in the invention can scatter caked rice, so that the rice is uniformly heated; the rice at the bottom can be turned to the uppermost part, so that people can conveniently dry and dehumidify; the rice can be uniformly turned and stirred through turning claws, so that the rice can be better dried and heated; the dried rice can be discharged through a screen, and the situation that the heated area of the caked rice is reduced and the dehumidification efficiency is reduced due to the fact that the dried rice is mixed with the caked rice is prevented; and through the arrangement of a conveyor, the screened rice is guided into the conveyor and then is uniformly dried through a roller, so that the situation that the dehumidification of the rice does not reach the standards is prevented.

Owner:宿松县佳兴米业有限公司

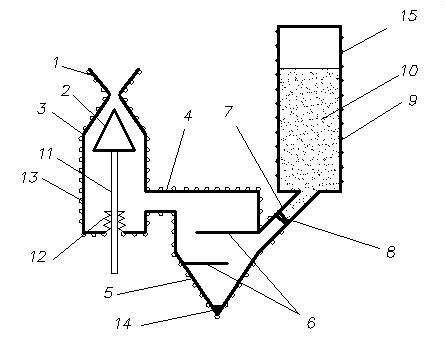

Preparation method of crosslinked polyethylene cable connector

InactiveCN106374397AElectrical performance improvements and enhancementsEliminate void defectsApparatus for joining/termination cablesAnti stressEngineering

The invention relates to a cable connector, in particular to a preparation method of a crosslinked polyethylene cable connector. The preparation method comprises the following steps: firstly, peeling and cutting insulating layers at two ends of a cable so that a core of the cable is exposed; secondly, cutting the crosslinked insulating layers on two sides of the connector to be conical; thirdly, setting an anti-stress cone at the end of the cable, and fixing the treated cable to two ends of an insulating forming die, wherein the insulating forming die comprises a metal outer die and an elastic lining die, an elastic die expansion gap is formed between the metal outer die and the elastic lining die, and the temperature of an inner cavity of the insulating forming die is raised to be 120 DEG C; fourthly, after performing cleaning drying treatment on the surface of the insulating layer, setting an outer semi-conducting layer in combination with an outer shielding layer reserved section of the cable; and fifthly, wrapping a metal belt on the surface of the outer semi-conducting layer in a gap manner, using an oxyhydrogen flame to firmly weld two ends of the metal belt and the outer surface of a lead protective tube so as to form a metal projective sleeve tube, and then using the oxyhydrogen flame to trim welding surfaces at two ends of the metal protective sleeve tube so as to form a slope connecting section.

Owner:重庆三峡电线电缆科技股份有限公司

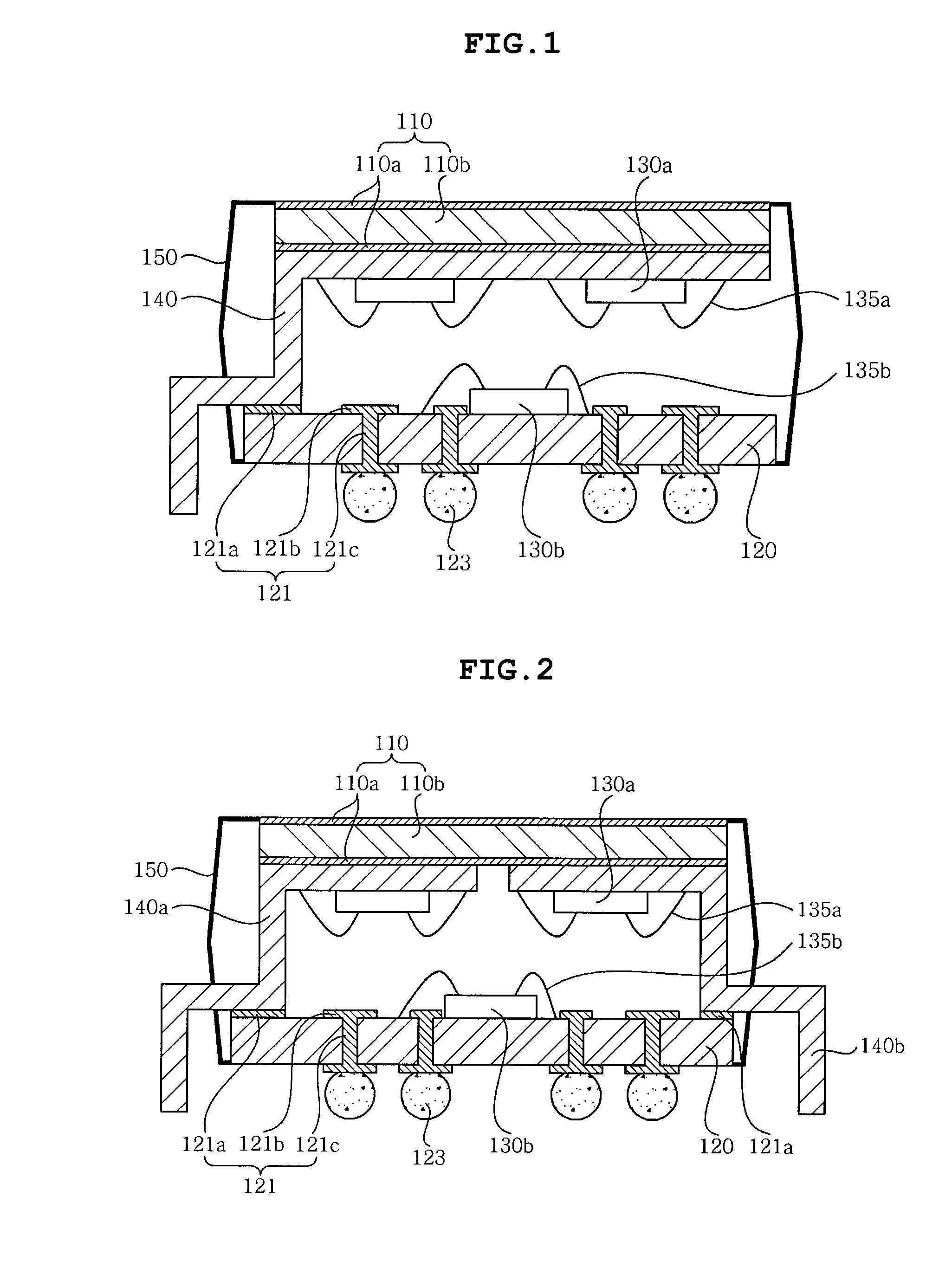

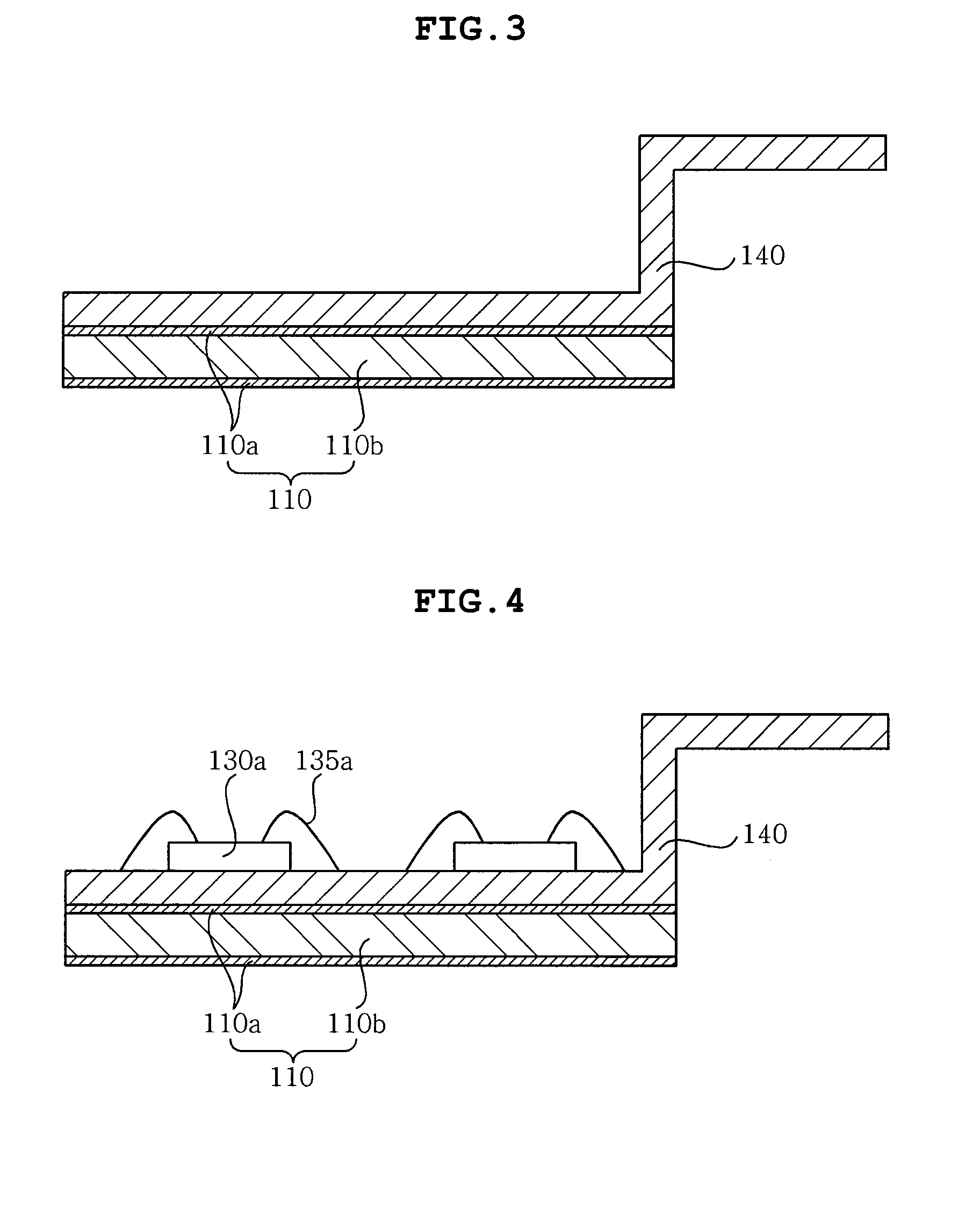

Power module package and method for manufacturing the same

InactiveUS20130009290A1Cost reductionLow production costSemiconductor/solid-state device detailsSolid-state devicesExternal connectionEngineering

Disclosed herein is a power module package including: a first substrate; a second substrate having a pad for connection to the first substrate formed on one side or both sides of one surface thereof and having external connection terminals for connection to the outside formed on the other surface thereof; and a lead frame having one end bonded to the first substrate and the other end bonded to the pad of the second substrate to thereby vertically connect the first and second substrates to each other.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

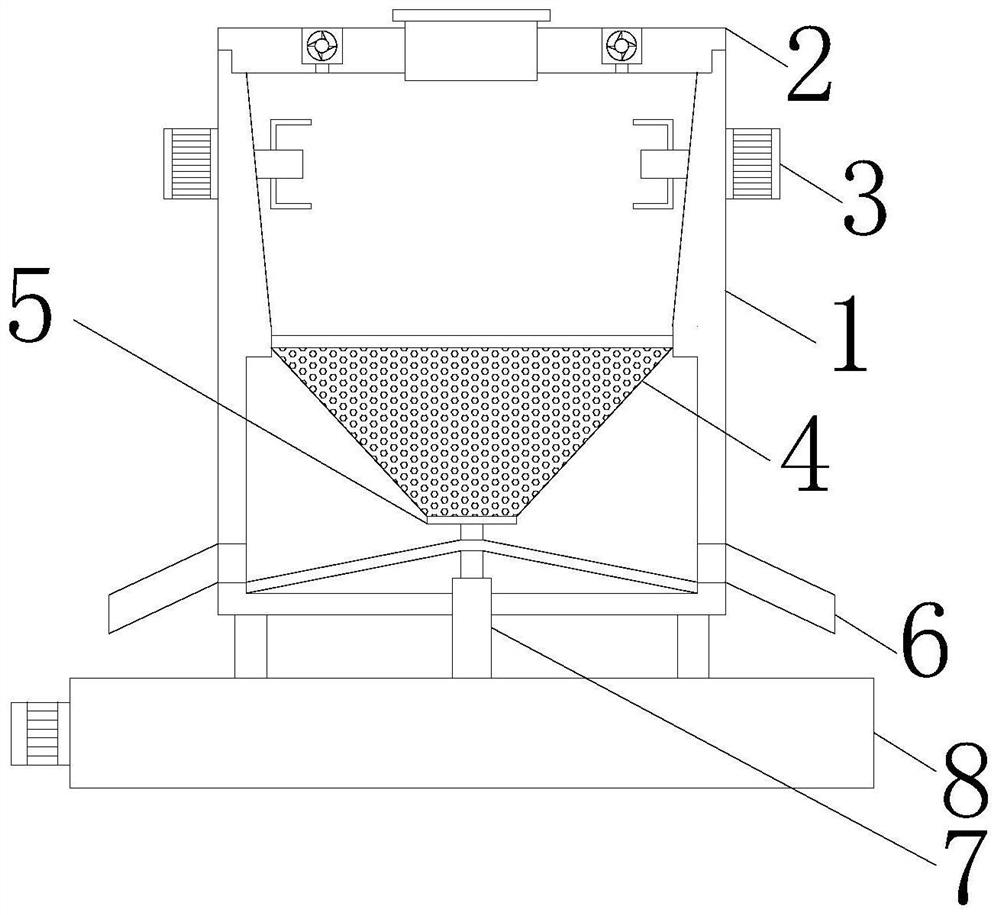

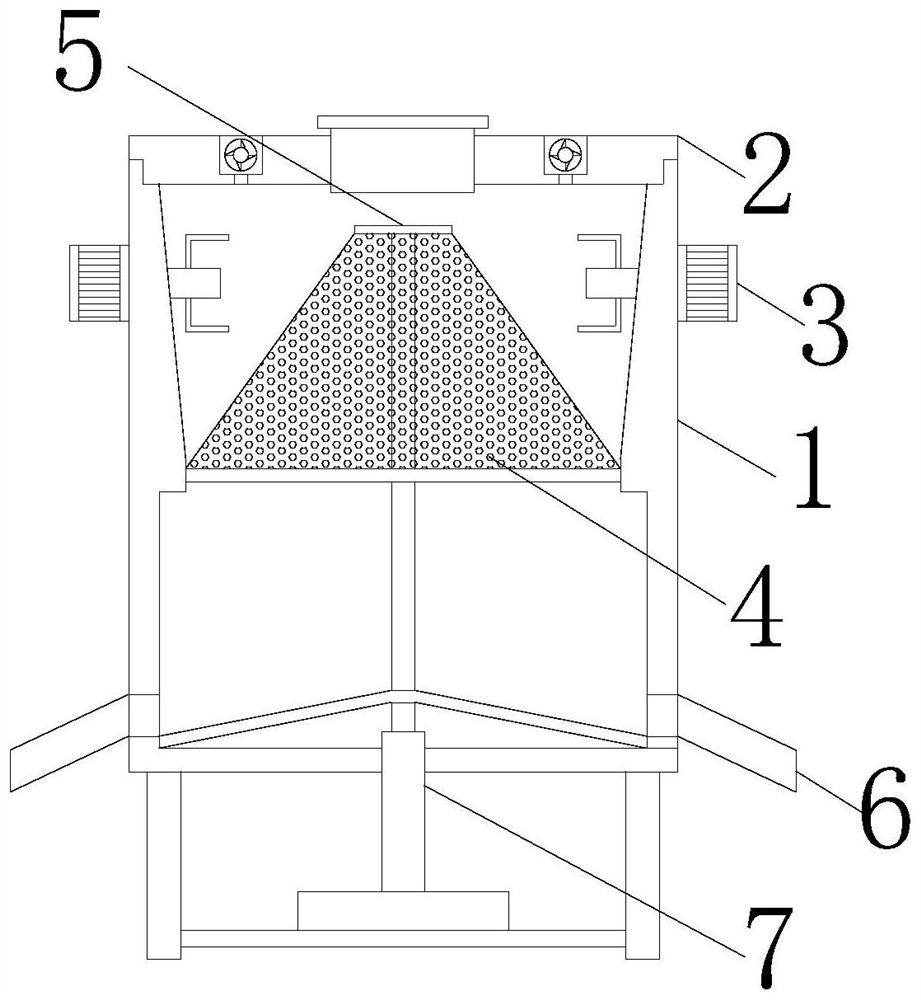

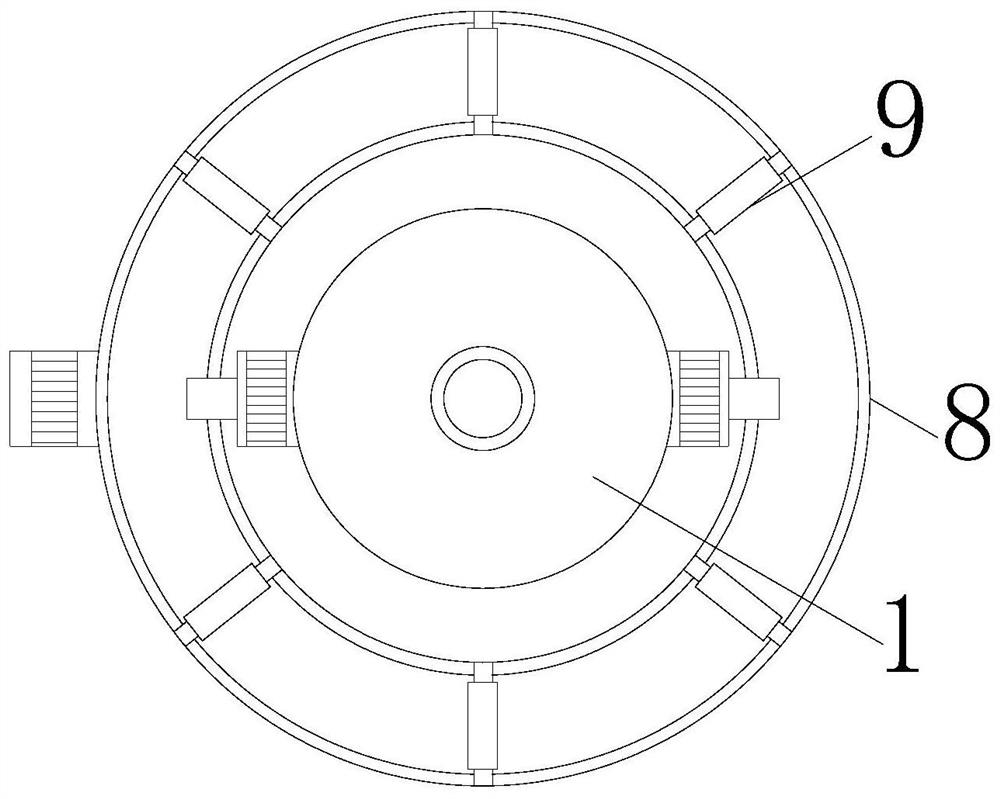

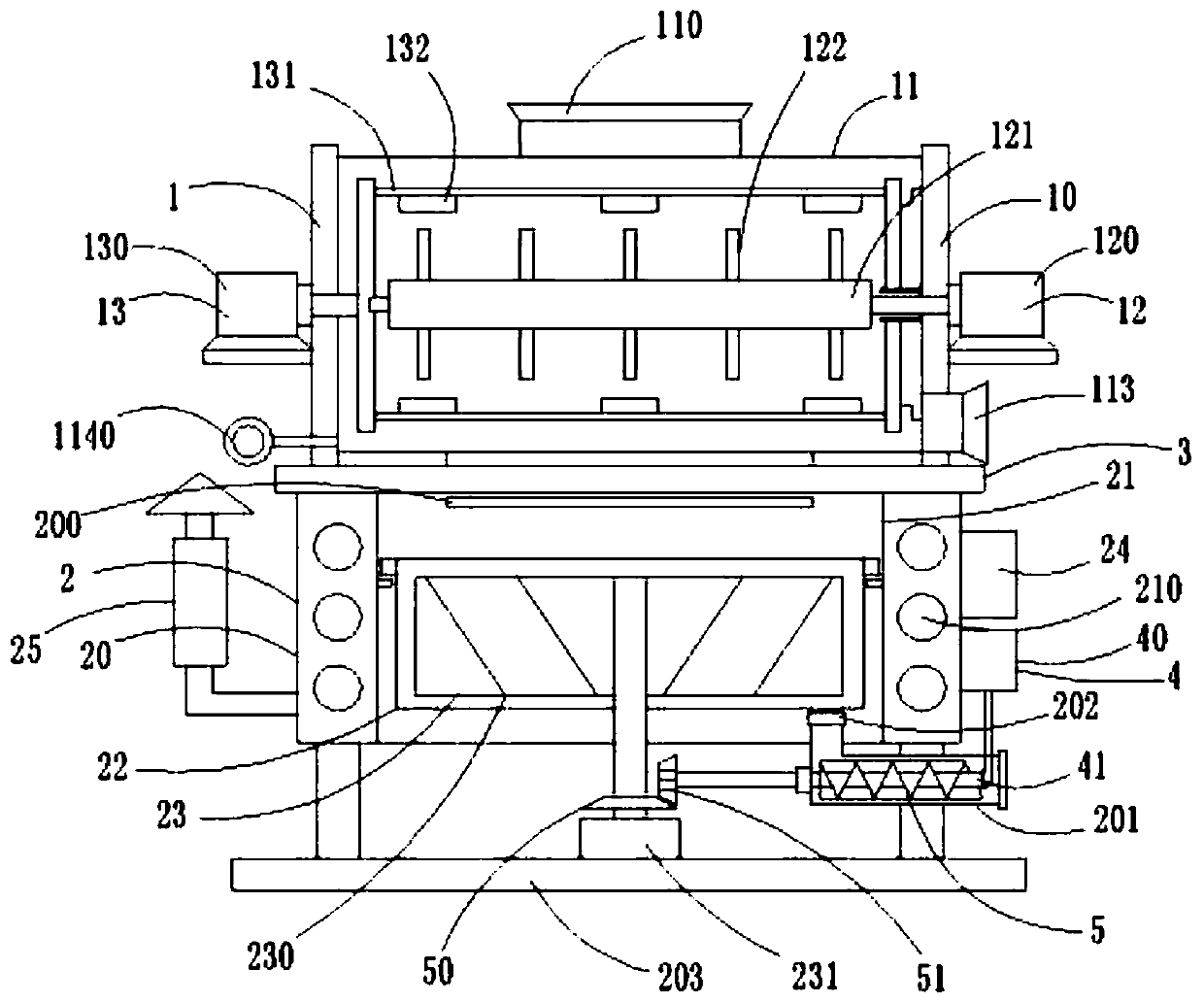

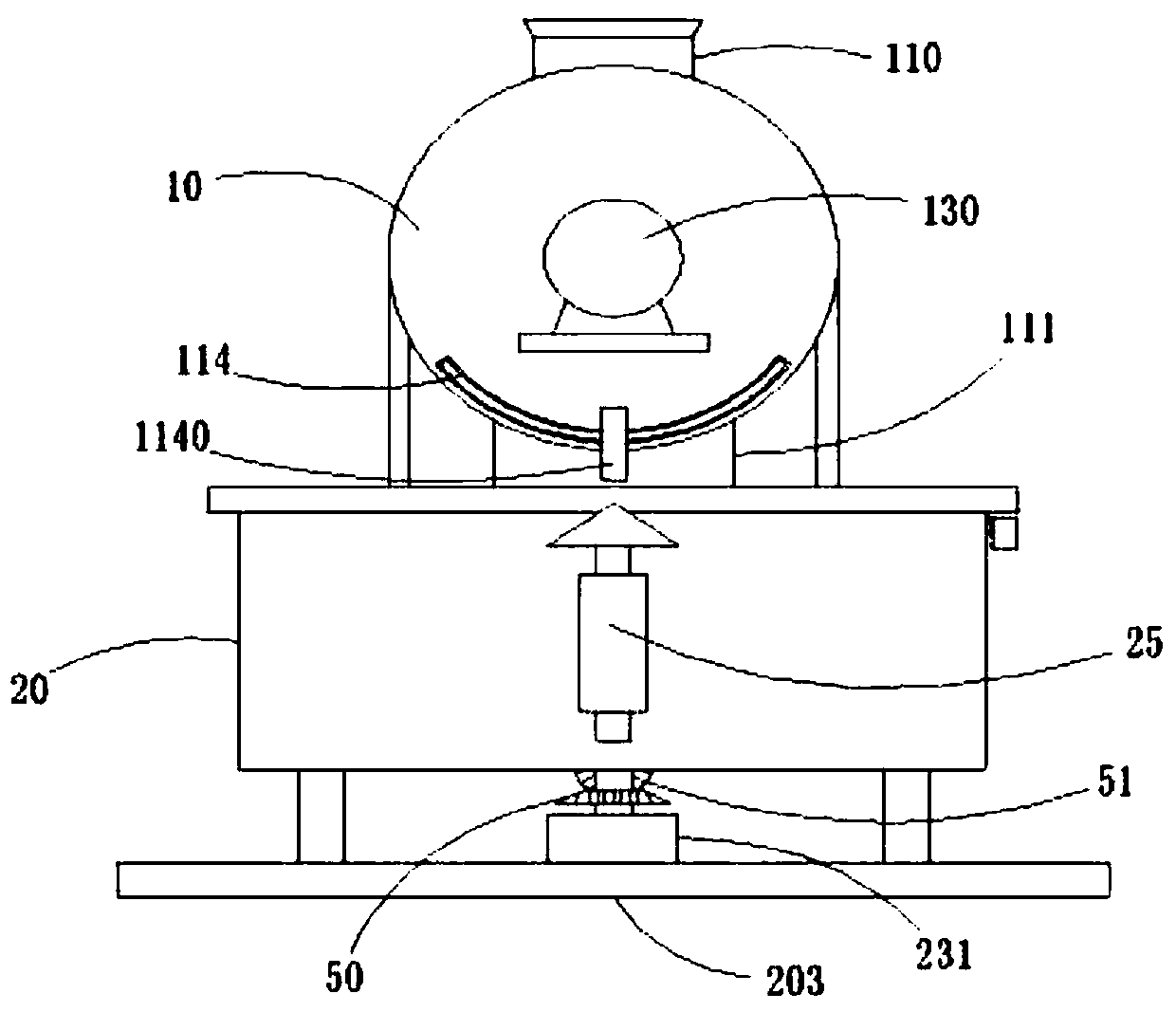

Integrated device for persistent organic contaminated soil remediation treatment

ActiveCN110280578AReduce metal contentImprove qualityContaminated soil reclamationEngineeringElectric control

The invention discloses an integrated device for persistent organic contaminated soil remediation treatment. The device comprises a soil pretreatment device, a soil thermal desorption device, a fixing plate, a bacteria solution delivery device and an electric control box; the soil pretreatment device is arranged at the upper end of the fixing plate, the soil pretreatment device is used for performing crushing and impurity removing on soil, late thermal desorption treatment is facilitated, the soil thermal desorption device is arranged at the lower end of the fixing plate and used for performing thermal desorption treatment on persistent organic pollutants, the organic pollutants in the soil are volatilized, and finally treatment is conducted through a flue gas combustion cylinder, and the bacteria solution delivery device is used for adding the composite bacteria solution into the treated soil, and the electric control box is used for controlling operation of the device. The device is reasonable in structural design, high in treatment efficiency, small in secondary pollution and suitable for mass promotion.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

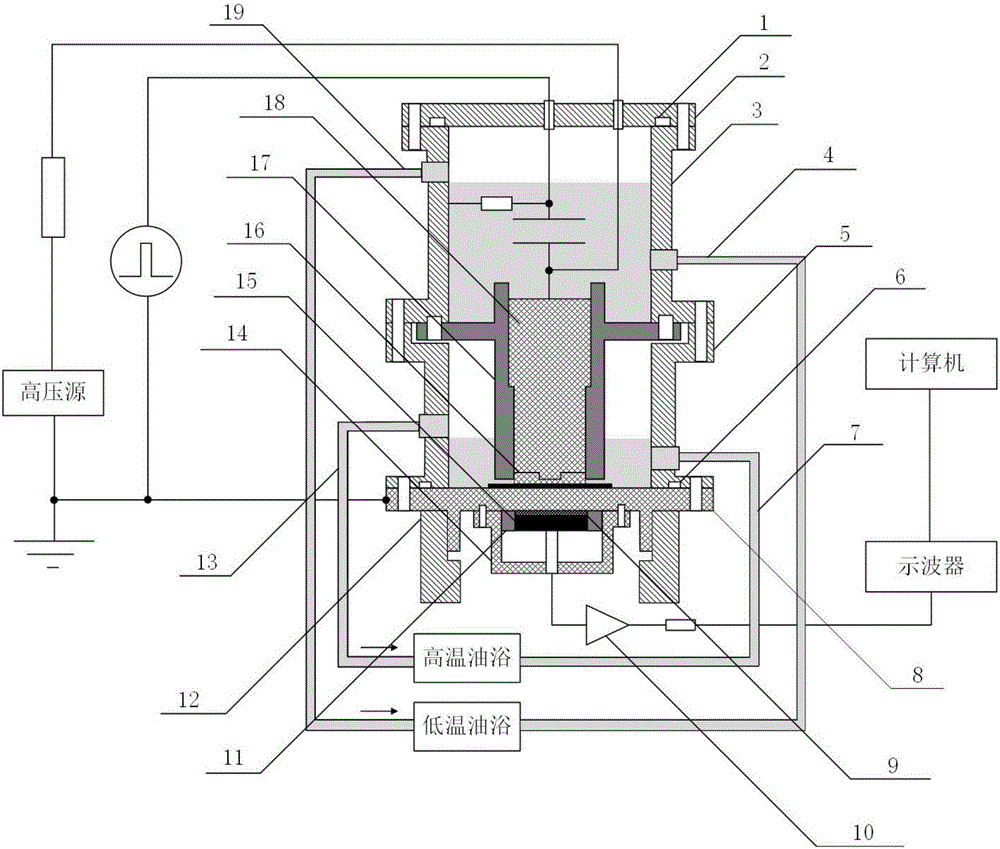

High-temperature anti-jamming space charge measuring device and method

ActiveCN106771683AGuaranteed Dielectric StrengthEliminate partial dischargeElectrical measurementsPolyvinylidene fluoridePhysics

A high-temperature anti-jamming space charge measuring device and method are provided; the device is composed of a pulse coupling circuit unit, an electrode test unit, and an acoustic pulse sensor unit; the electrode test unit heats a sample to different temperatures through high-temperature oil bath; the pulse coupling circuit unit isolates the heating effect of the electrode test unit through normal-temperature oil batch circulation; the acoustic pulse sensor unit is made of polyvinylidene fluoride-trifluoroethylene or lithium niobate crystal material. The method comprises the steps of 1) selecting a test required sensor material as test temperature requires; 2) placing a sample in the measuring device; 3) adjusting a normal-temperature and heating oil bath circulation system; 4) setting the temperature of the heating oil bath circulation system, and running space charge test when the temperature sensor reaches a set value and stabilizes. The high-temperature anti-jamming space charge measuring device and method have the advantages that the heating effect of the electrode test unit upon the pulse coupling circuit unit can be eliminated effectively, shielding effect is good, and space charge can be accurately measured under high temperature and high field strength.

Owner:XI AN JIAOTONG UNIV

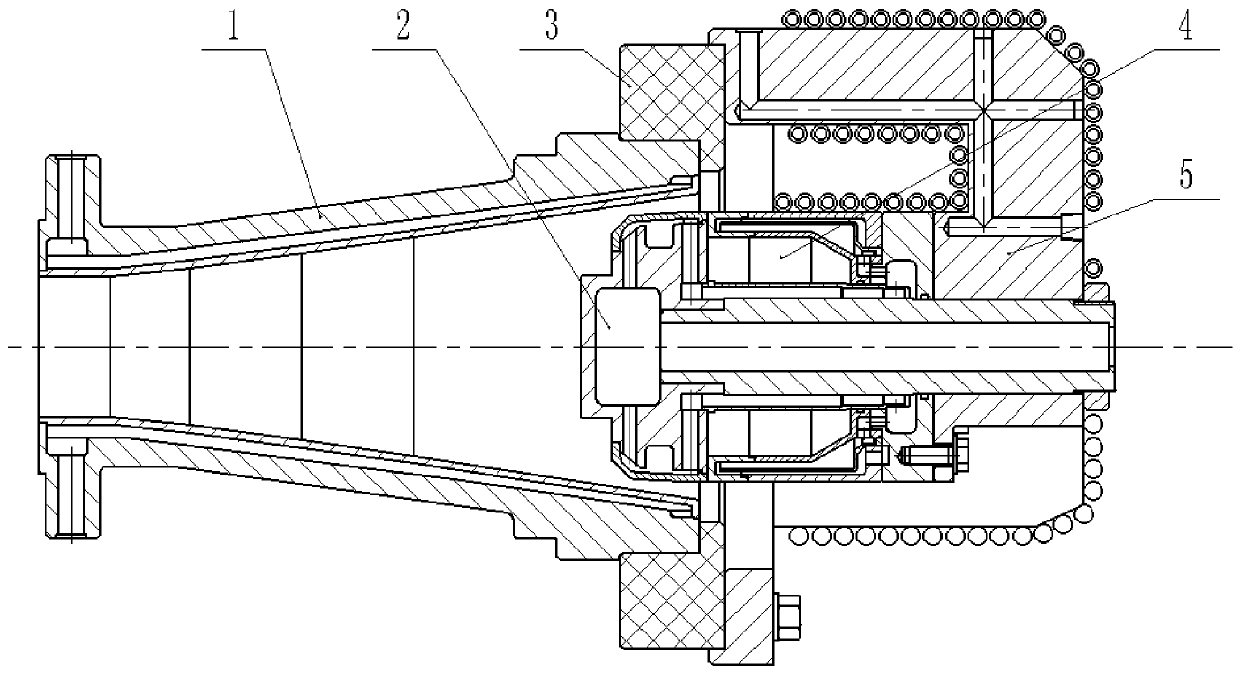

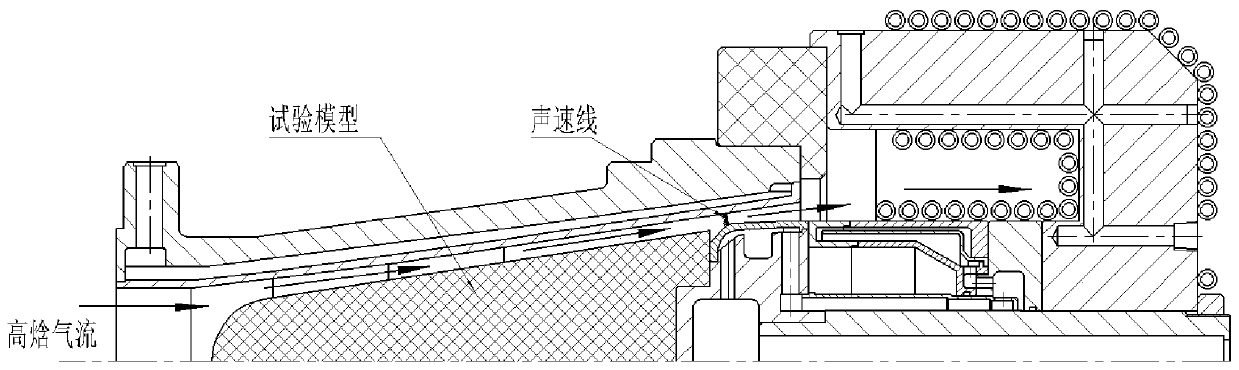

Subsonic-speed ladle cover ablation test device under high-entropy condition

PendingCN110712764AEnsure ablationReduce heating areaAircraft components testingEngineeringStructural engineering

The invention discloses a subsonic-speed ladle cover ablation test device under high-entropy condition. The device comprises a ladle cover spraying pipe, a throat way support rod, a transfer flange, atransfer section and a model bracket. The ladle cover spraying pipe and the model bracket are fixed on the transfer flange. The throat way support rod is connected with the model bracket by the transfer section; and a throat way part of the throat way support rod is positioned in the ladle cover spraying pipe. The overlap with the center axis of the ladle cover spraying pipe is guaranteed throughconnection between the throat way support rod and the transfer section. During testing, a test model is mounted on the throat way support rod, an annular channel between the outer surface of the testmodel and the inner surface of the ladle cover spraying pipe is a high-entropy airflow channel, and the flowing of air currents in the ladle cover spraying pipe is subsonic-speed flowing. The devicecan be applied to aerospace pneumatic thermal protection ground simulation tests in high-entropy airflow state.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

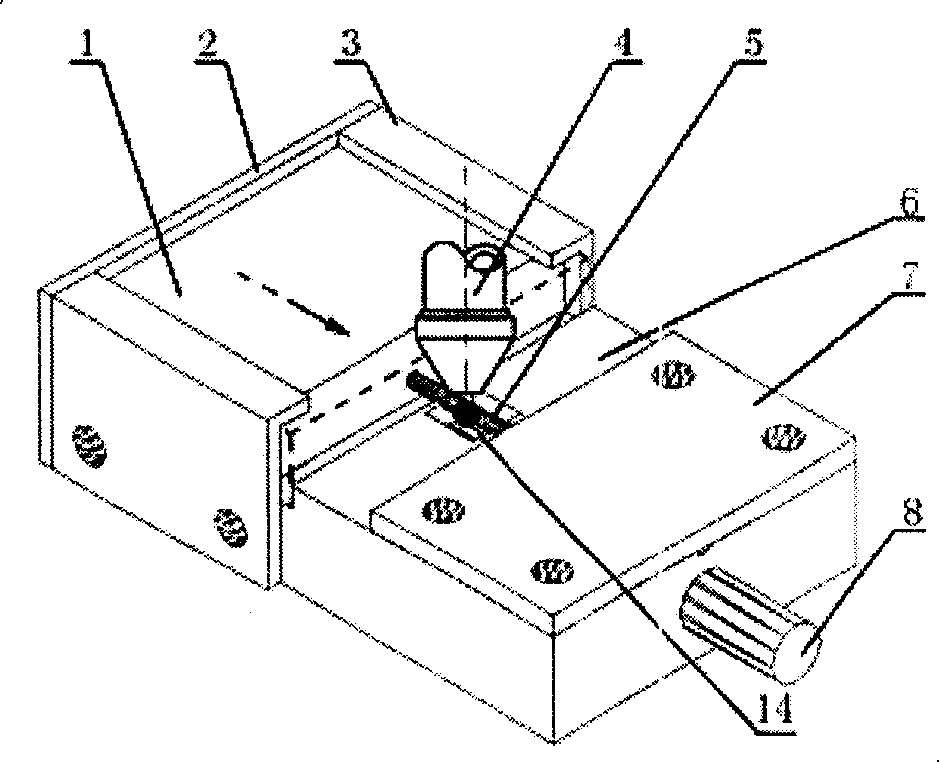

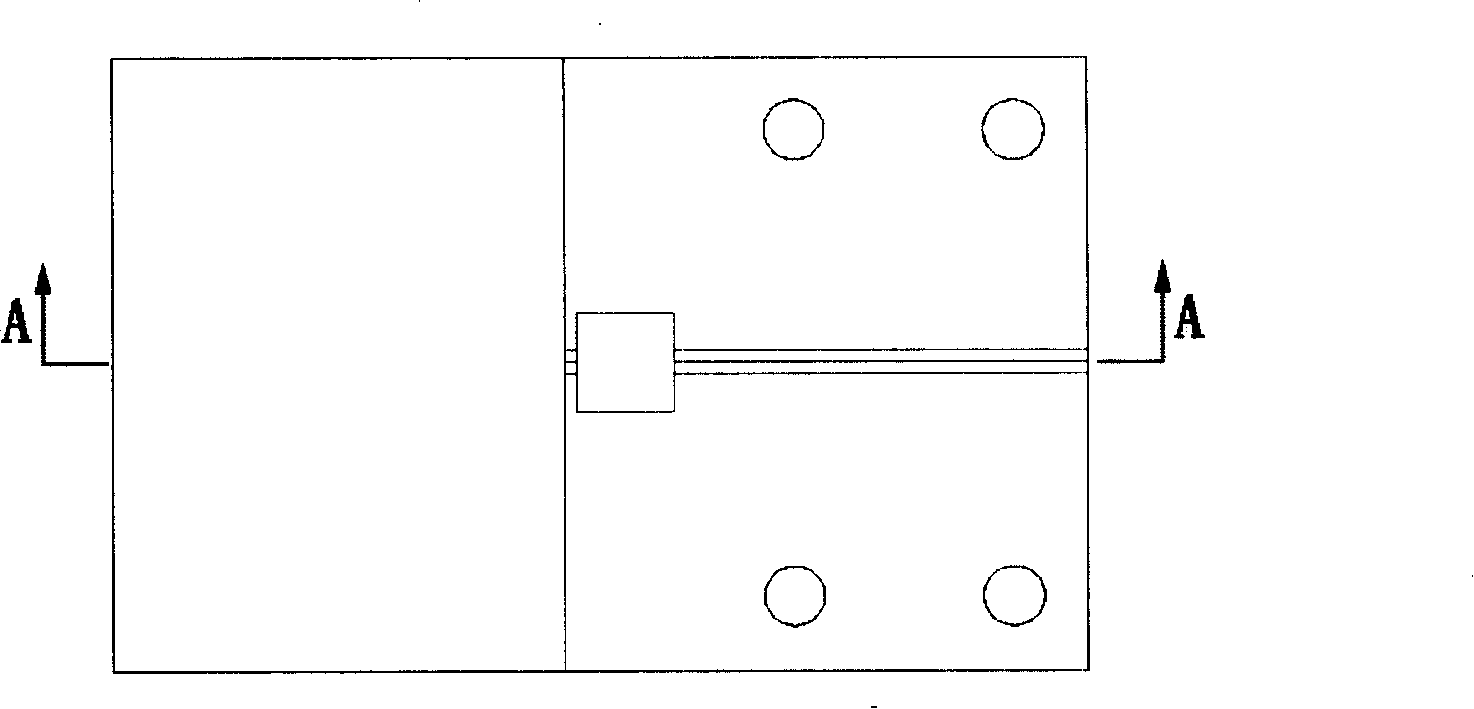

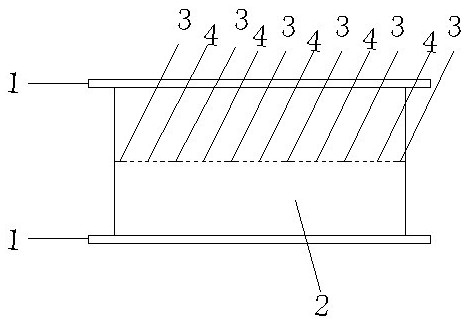

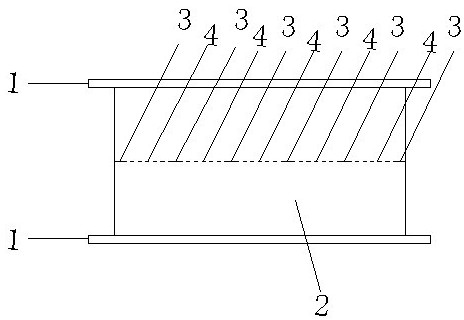

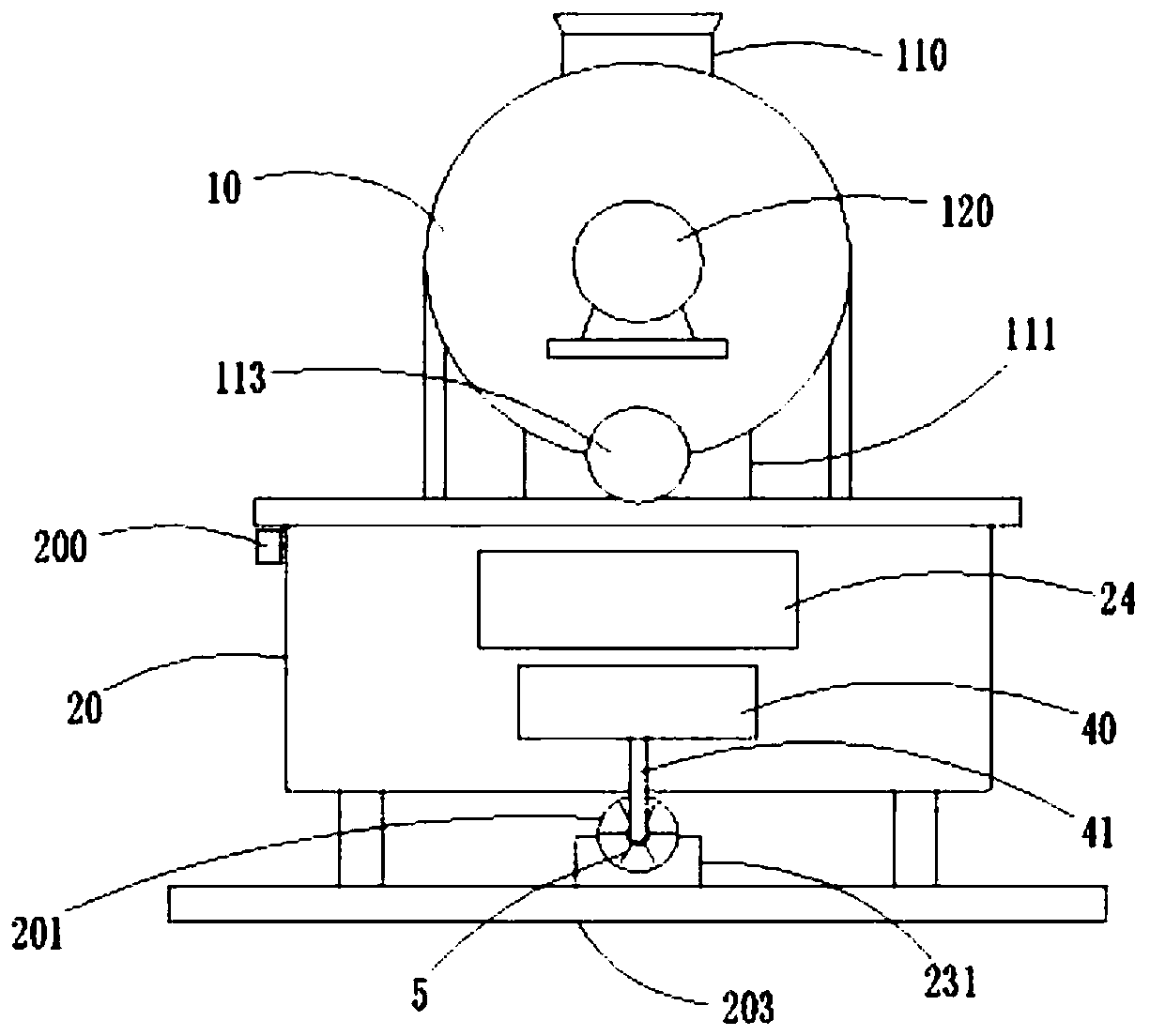

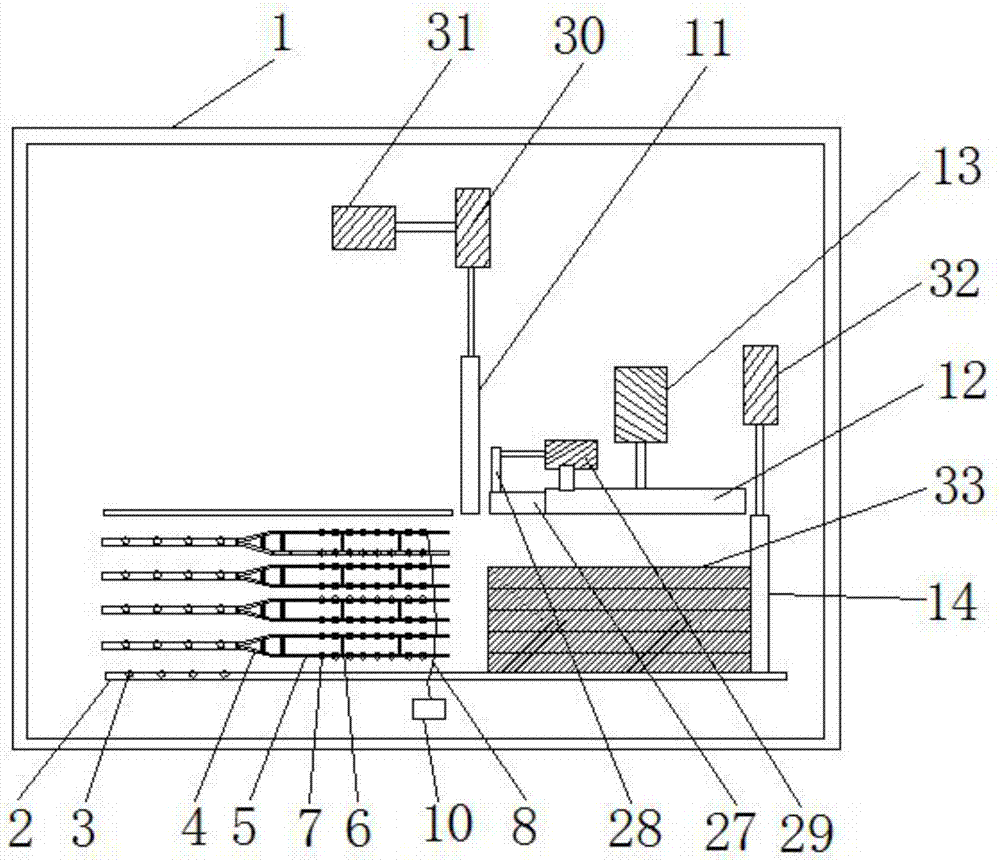

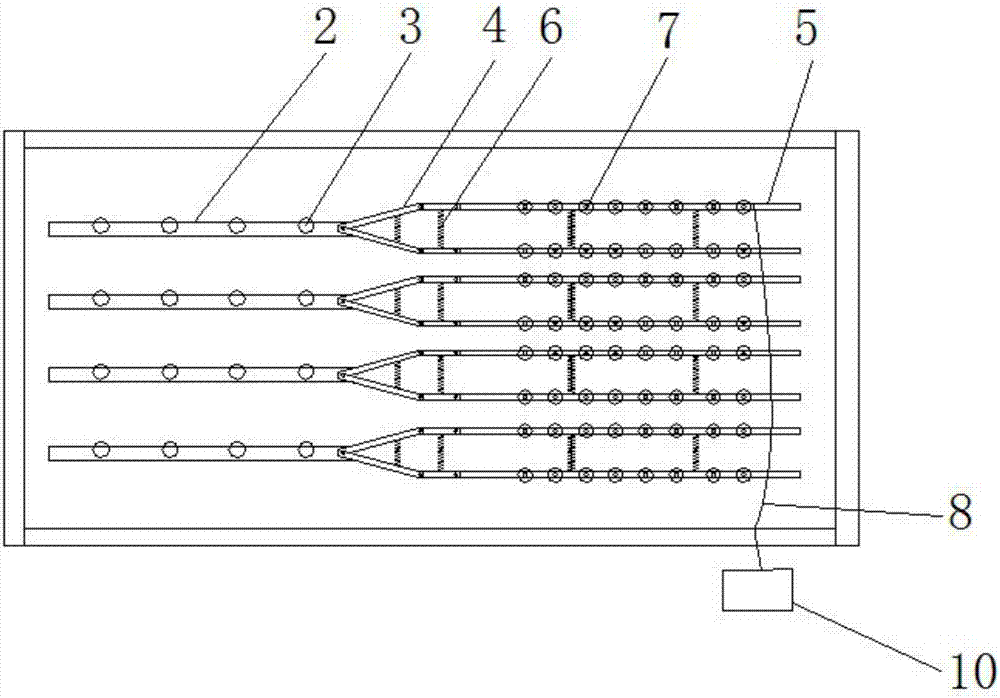

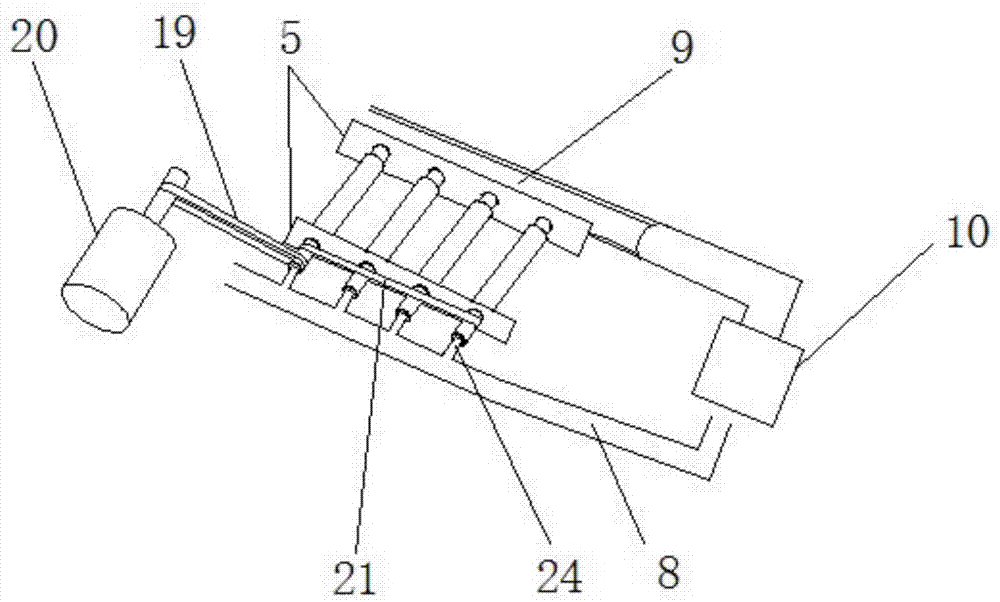

Bonding and hot-pressing integrated machine for wood plates

InactiveCN107283555AAvoid deformationIncrease profitPlywood pressesVeneer pressesHydraulic cylinderEngineering

The invention discloses a bonding and hot-pressing integrated machine for wood plates. The bonding and hot-pressing integrated machine comprises a machine frame (1); feeding plates (2) are arranged in the machine frame (1); conveying rollers (3) are arranged on the feeding plates (2); guide frames (4) are connected to the feeding plates (2); one end of each guide frame (4) is connected with two roller frames (5); springs (6) are connected between two corresponding roller frames (5); gluing rollers (7) are arranged on the roller frames (5) and are connected with gluing pipes (8) and recovery grooves (9); one ends of the gluing pipes (8) are connected with a glue tank (10); one ends of the roller frames (5) are connected with a front baffle (11); one end of the front baffle (11) is connected with an electric heating plate (12); the upper end of the electric heating plate (12) is connected with a hydraulic cylinder (13); and a rear baffle (14) is arranged at one end of the electric heating plate(12). The bonding and hot-pressing integrated machine has the advantages that the efficiency can be improved, the utilization rate can be increased, the bonding strength can be enhanced, the splicing effect can be improved, the application range is wide, and the gluing uniformity is good.

Owner:湖州南浔亨力木制品厂

Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof

ActiveCN111058116AEasy to prepareEasy to operateArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsEngineeringBiology

The invention discloses a skin-core type poly(lactic acid) (PLA) / poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and a preparation method thereof, and belongs to the field of high polymer materials. The preparation method of the skin-core type PLA / PHBV composite fiber specifically includes the steps: 1, respectively drying the raw material PLA in a skin layer and a raw material PHBV in a core layer, wherein moisture content of the PLA and the PHBV is not more than 200 ppm; and 2, weighing the raw materials PLA and PHBV obtained in the step 1 according to a composite spinning ratio to perform compositely spinning, melting spinning, cross air blowing, applying oil, winding, online stretching, and thermoforming to obtain the skin-core type PLA / PHBV composite fiber, wherein the number of holes in a spinning plate used during a spinning process is 24-144. The material prepared according to the method is high in breaking strength, and can be applied to the fields of medical materials, agricultural textile, disposable goods and package materials.

Owner:JIANGNAN UNIV

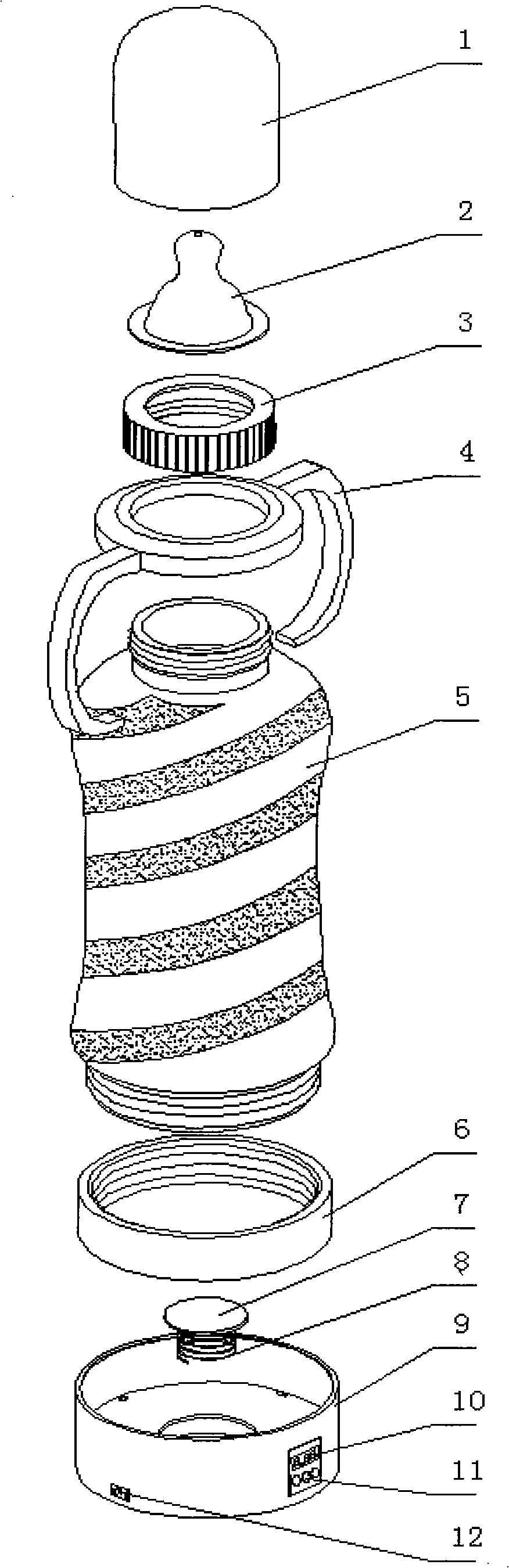

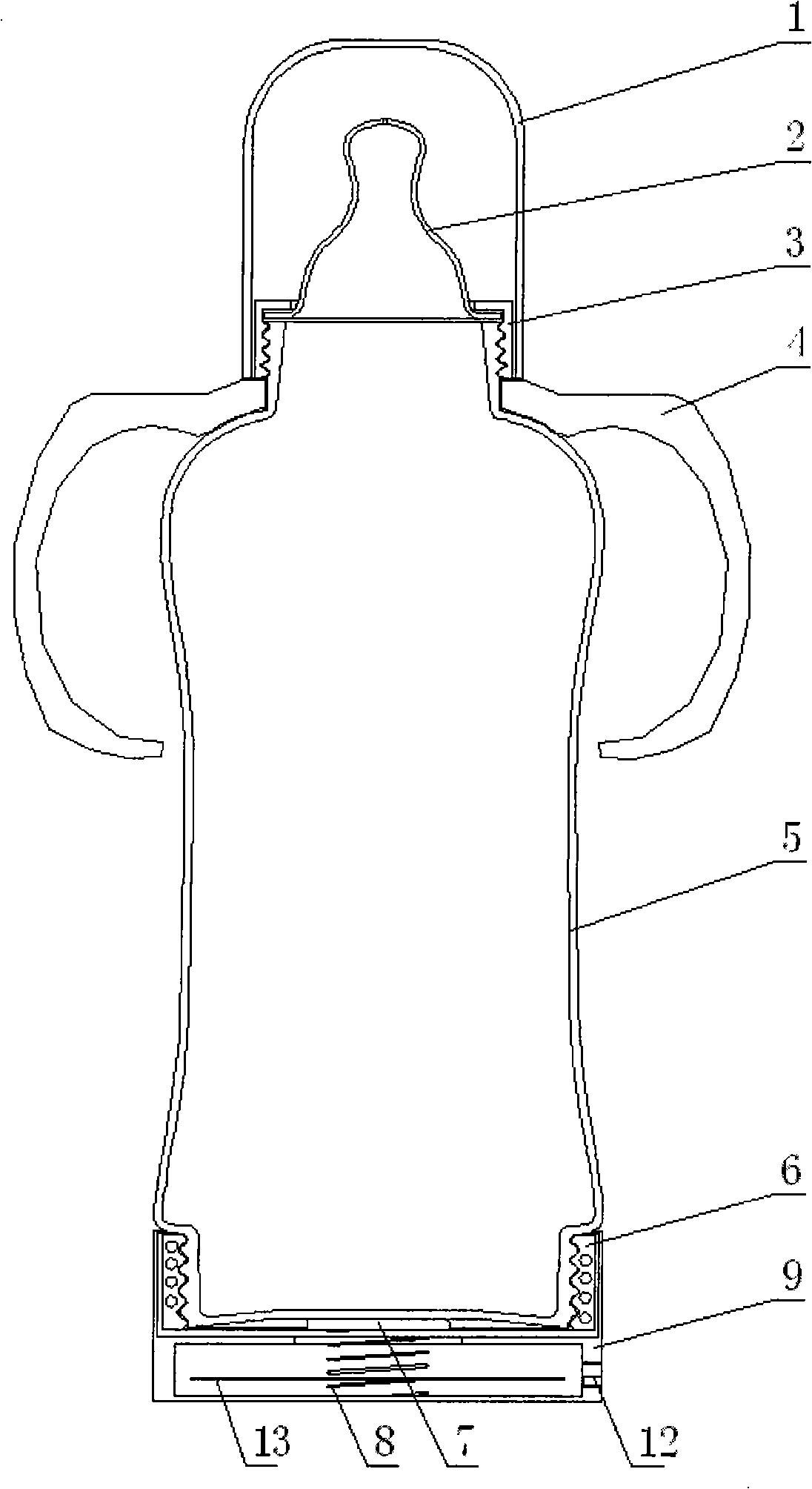

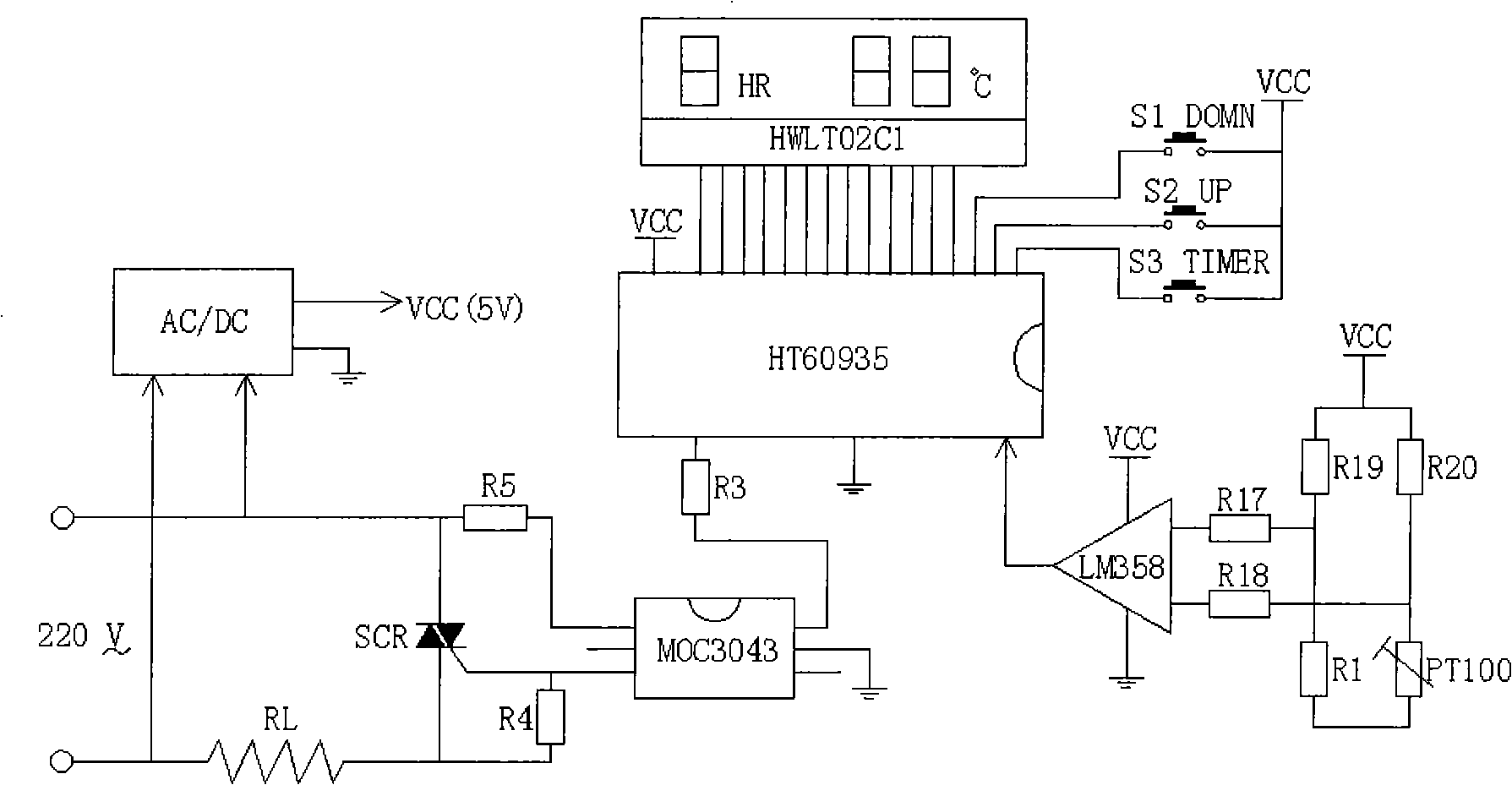

Thermal insulation nursing bottle

InactiveCN101268987AReduce volumeReduce weightElectric heatingFeeding-bottlesKey pressingLiquid-crystal display

The invention discloses a heat preservation nursing bottle which belongs to nursling articles for daily use, the heat preservation nursing bottle comprises a nipple, a bottle cap and a bottle body; an attemperator is arranged at the lower part of the bottle body and includes a base, and a ring-shaped heater which is tightly contacted with the bottle body is fixed at the upper part of the base; the center of the base is fixed with a temperature sensor which props against the bottom of the bottle body by a spring; the side of the base is provided with a mains jack, a liquid crystal display device and a control keystoke, and a control circuit board that adopts a microprocessor as the core is arranged inside the lower part of the base. The heat preservation nursing bottle can accurately regulate the temperature of the milk and the timing time by the keystoke, and the reserved holding temperature, the current temperature of the milk and the time can be displayed on the liquid crystal display device; at the same time, the heat preservation nursing bottle has the advantages of small volume, light weight, low price and strong performance, etc.

Owner:赵永生

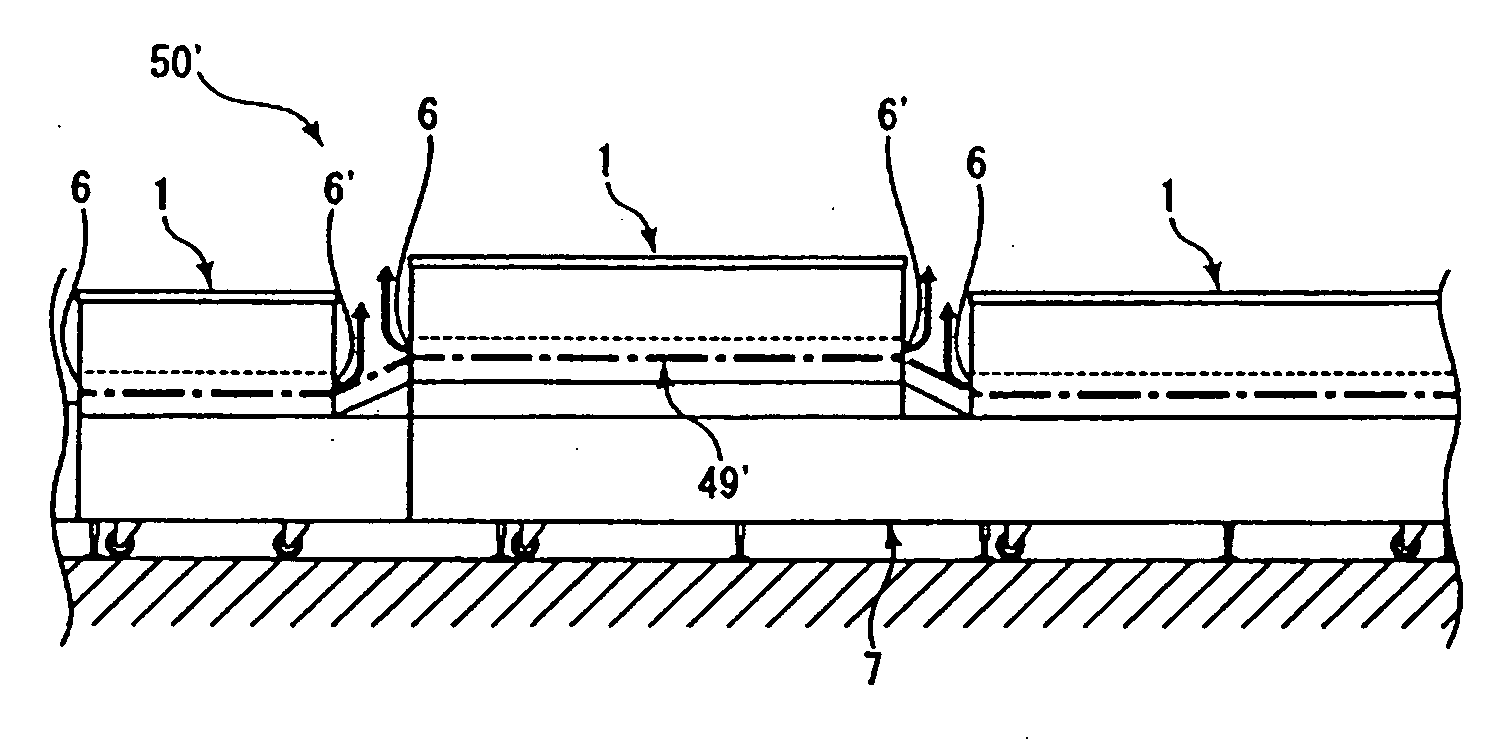

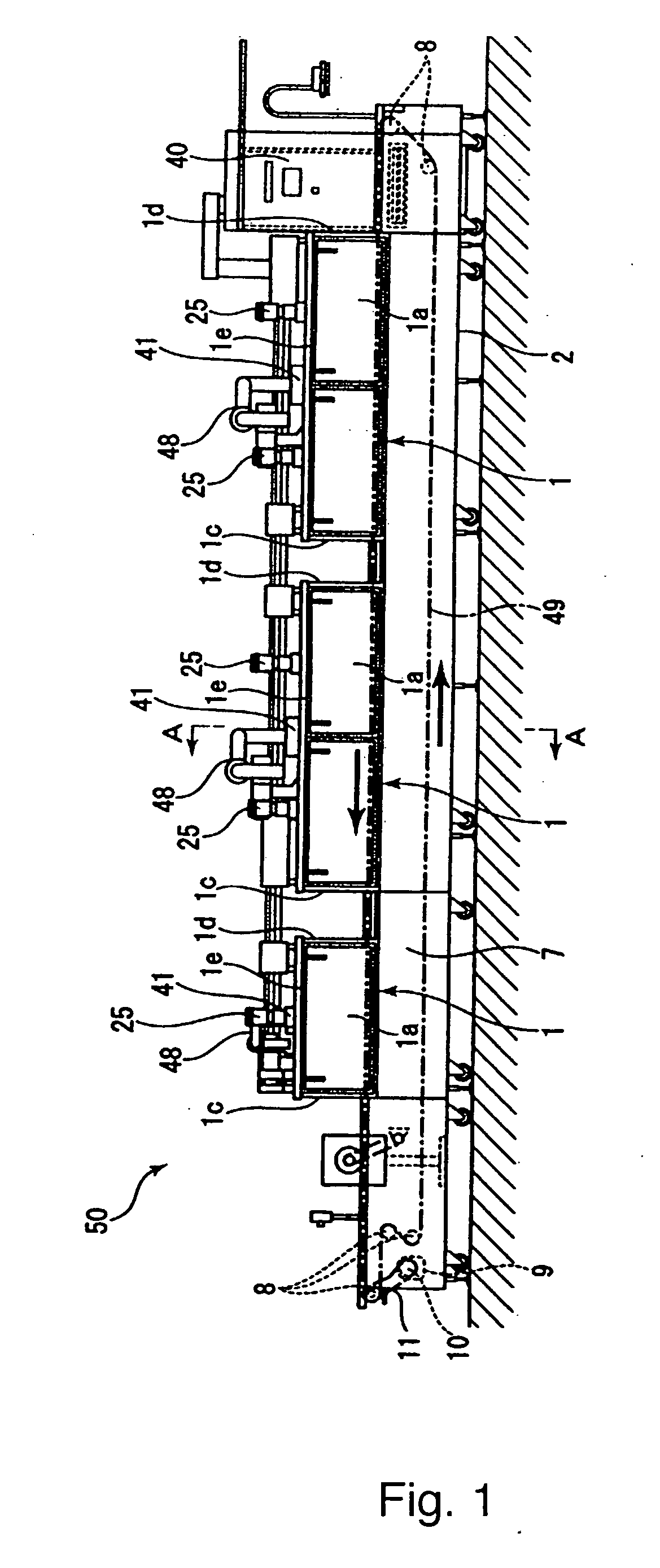

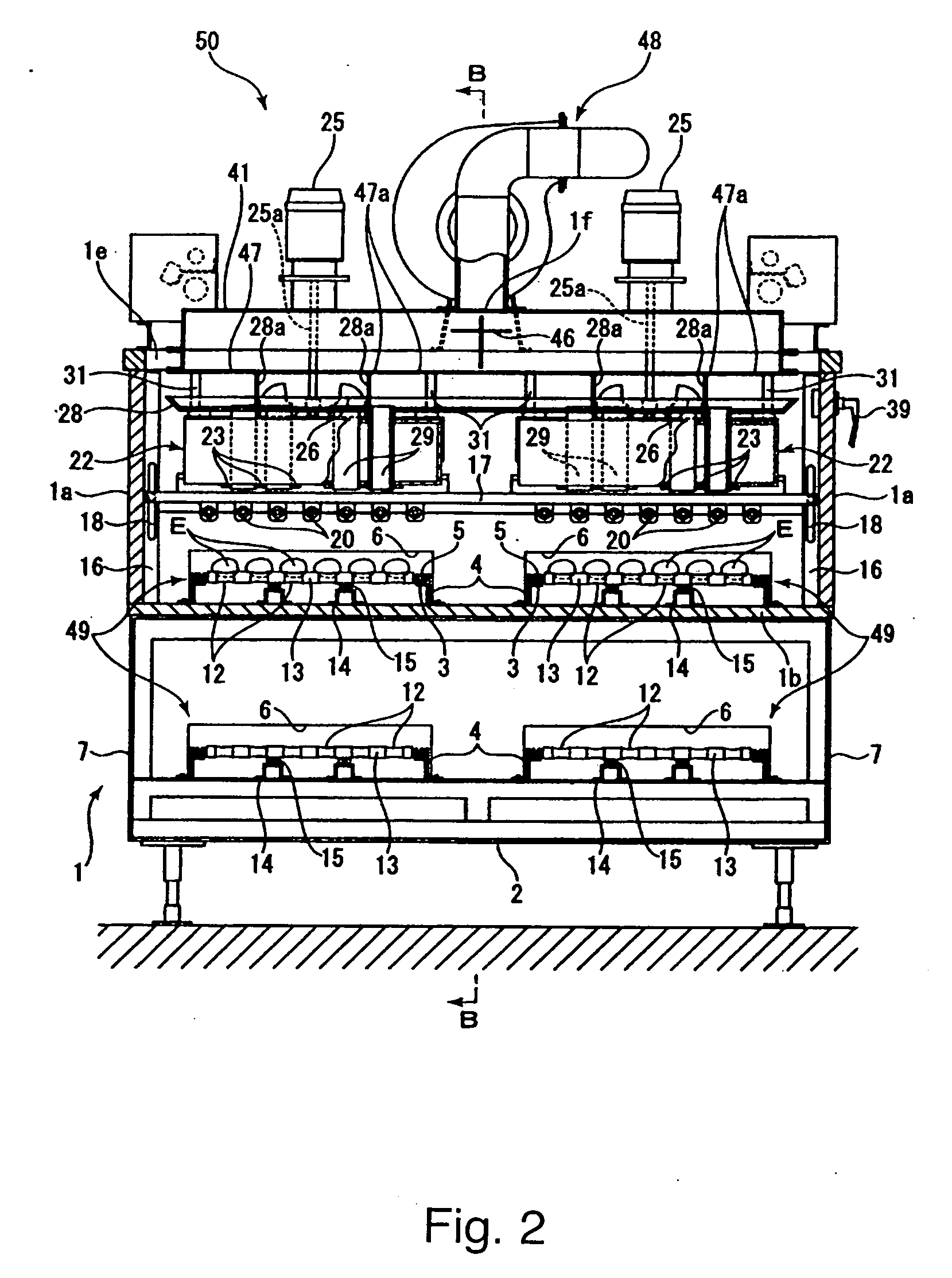

Apparatus for Cooking Food

InactiveUS20090120304A1Reduce the temperatureReduce heating areaAir-treating devicesCooking vesselsEngineeringAir blower

An apparatus for cooking food capable of quickly regulating the temperature in a housing and not causing uneven heating of food in the housing in the temperature regulation. The apparatus (50) has a housing (1) having a heater (20) in it and provided at a predetermined place in a conveyance route formed by a conveyor (49). The apparatus (50) heats food (E) to be heated by causing it to be conveyed and pass in the housing (1). An air supply opening (1f) is formed in a predetermined place of the housing (1), an air blower (48) is connected to the air supply opening (1f), and outside air can be supplied to the inside of the housing (1) by the air blower (48) via the air supply opening (1f). When the outside air is supplied from the air supply opening (1f), the air in the housing (1) is discharged from an entrance / exit (6, 6′) for the food (E) formed in the housing (1).

Owner:ISHINO SEISAKUSHOKK

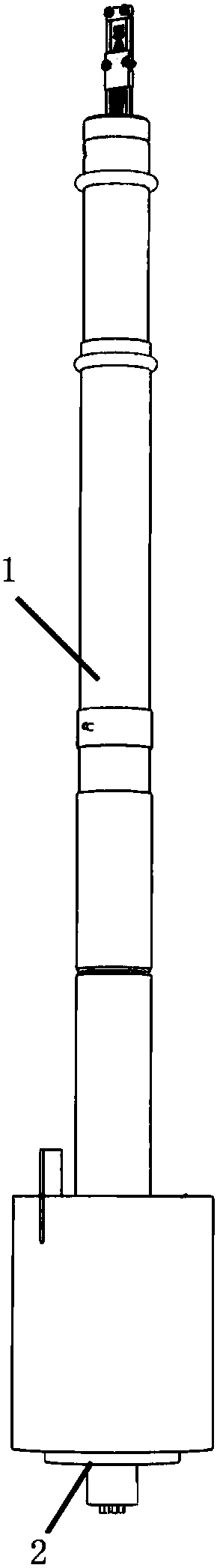

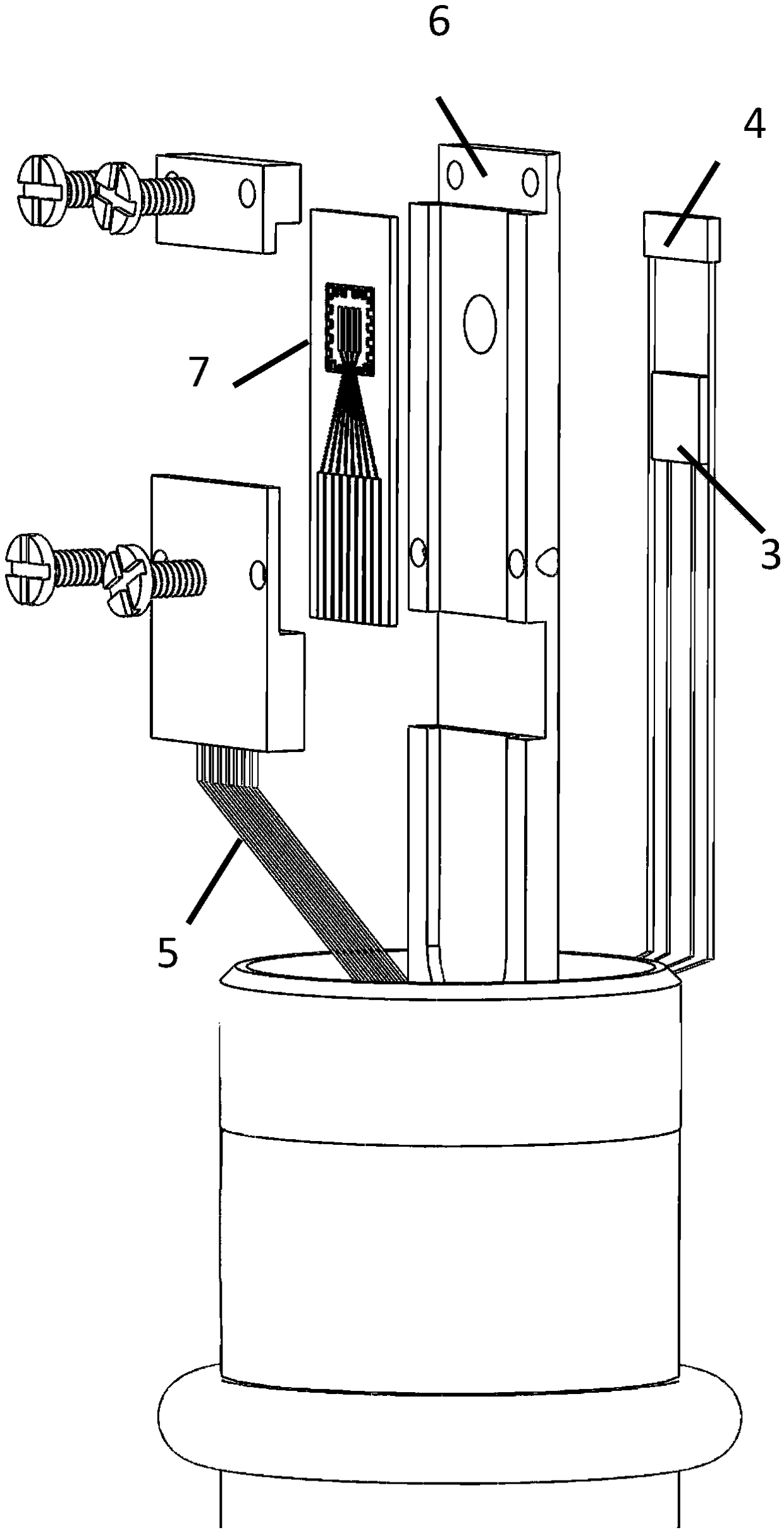

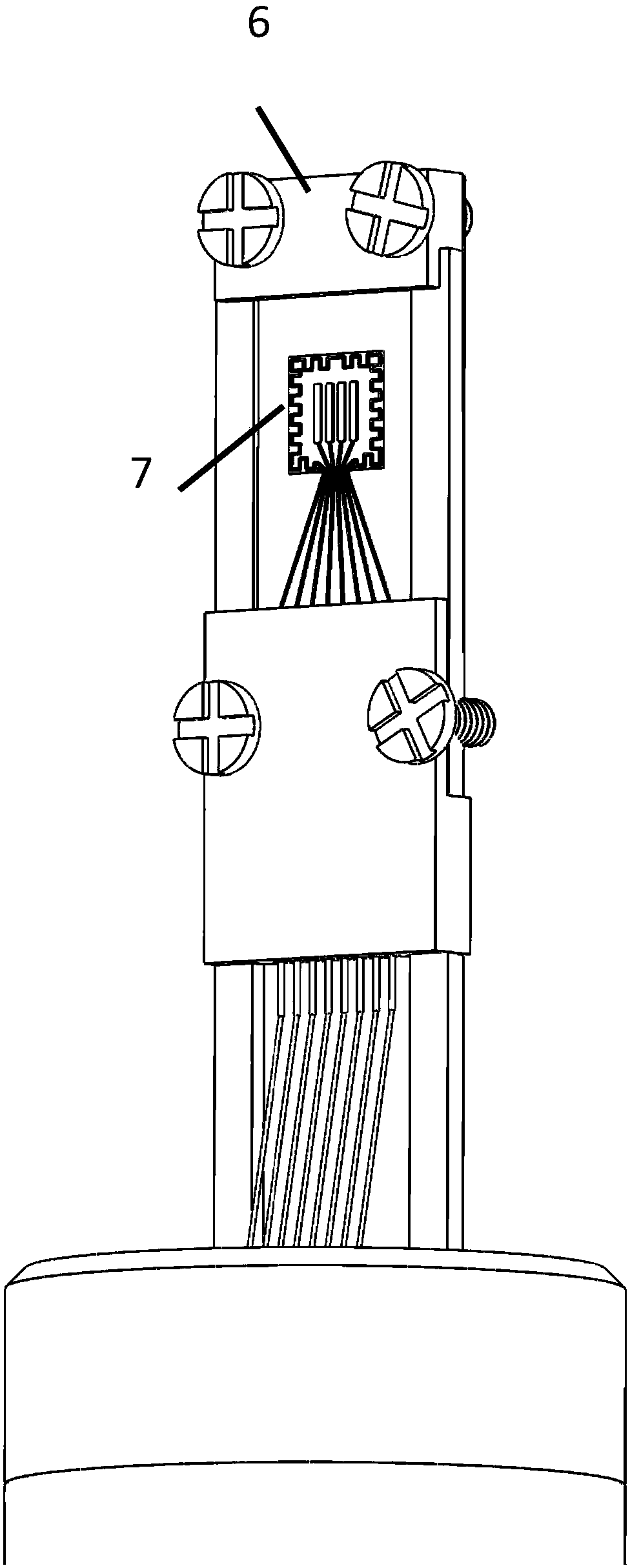

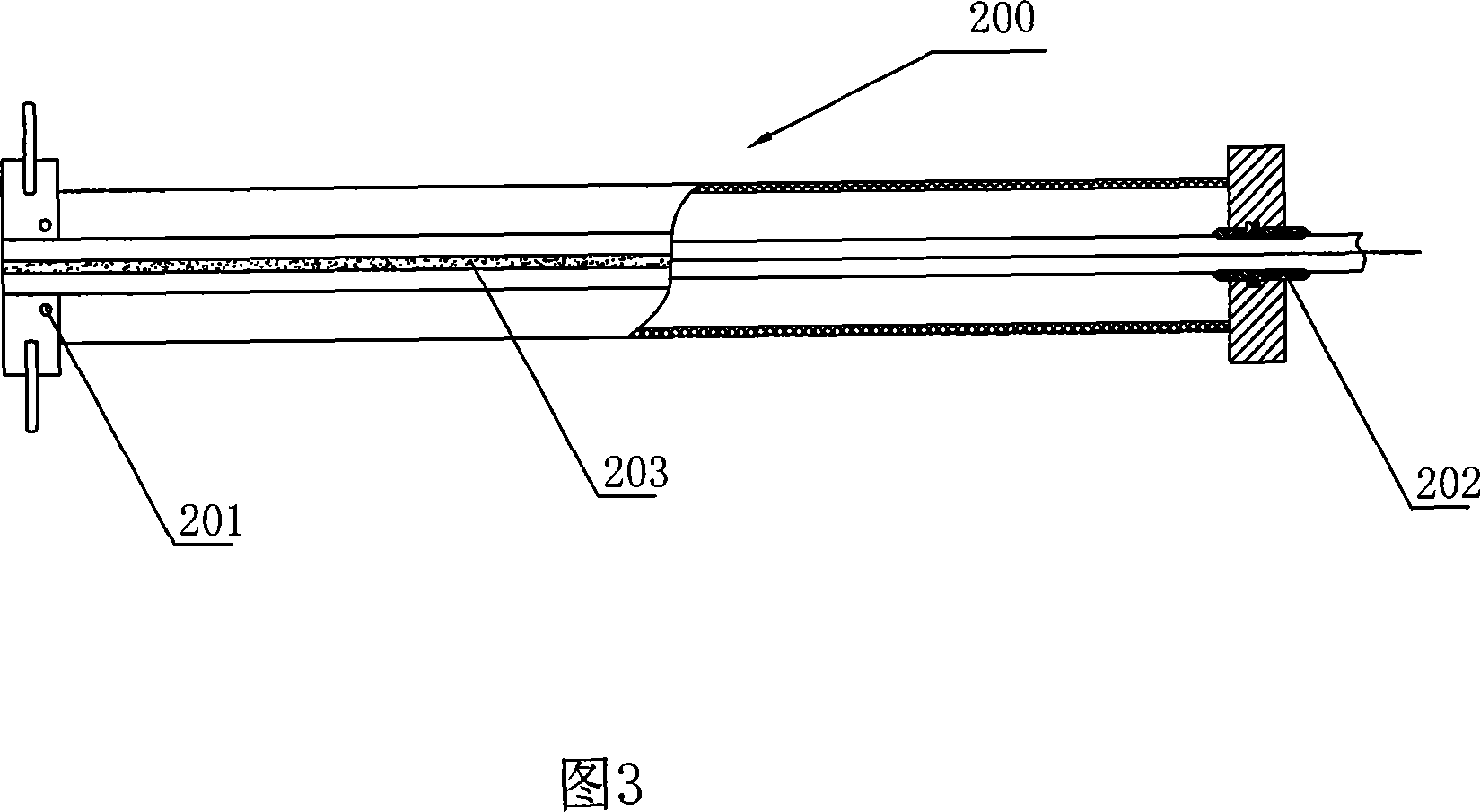

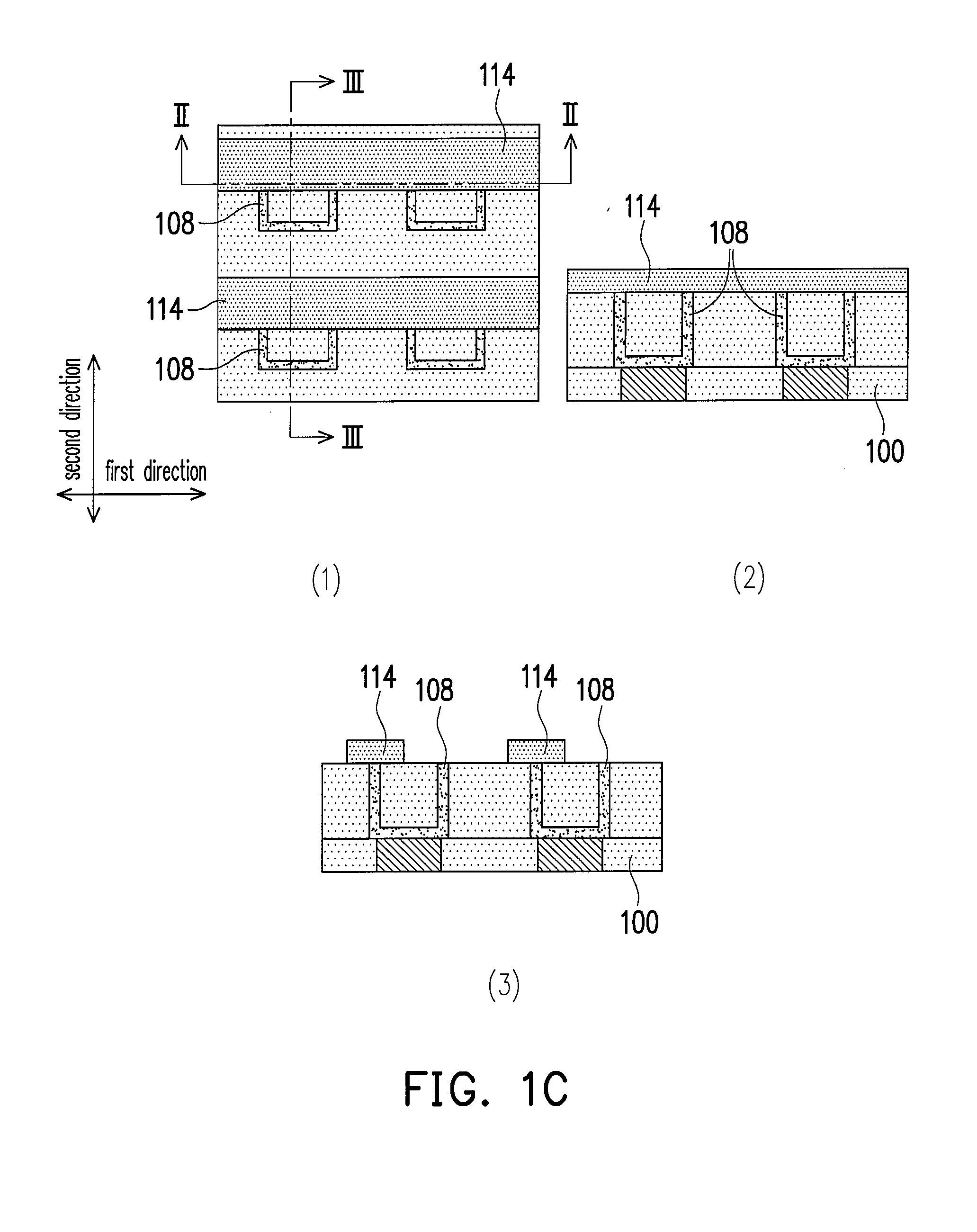

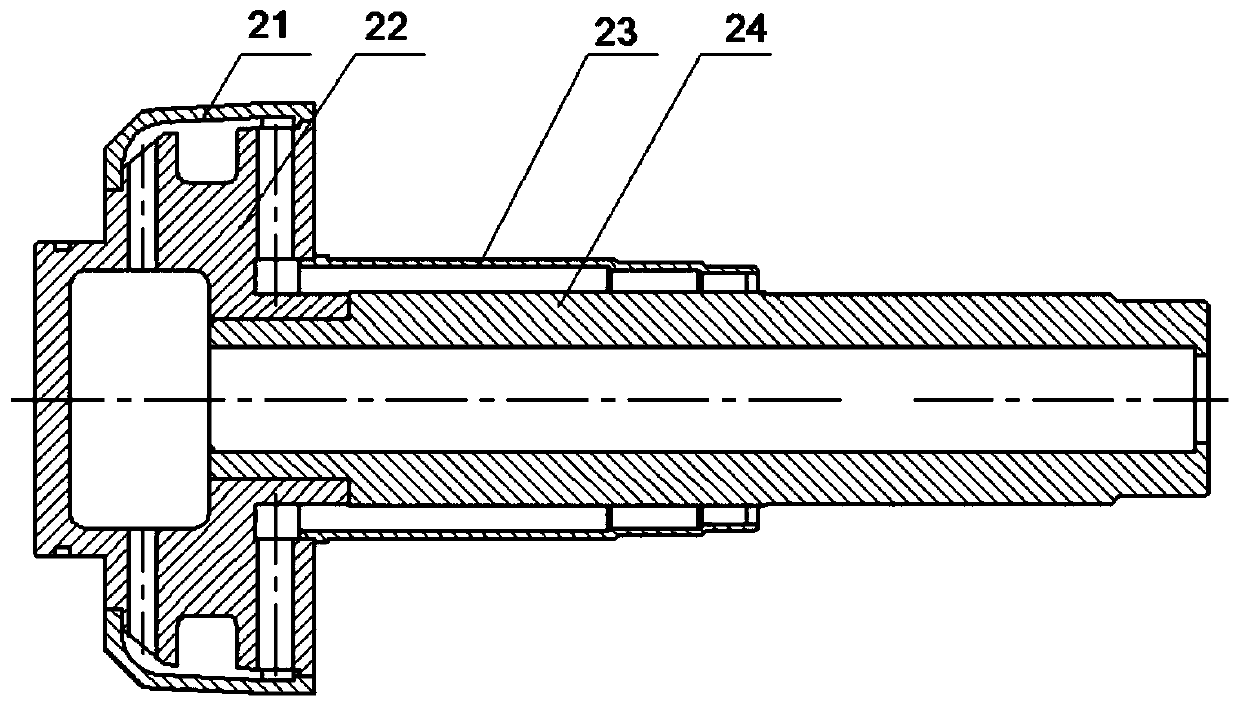

In-situ electrical sample rod system for transmission electron microscope

PendingCN108198740AMonitoring heating temperatureMonitor heating rateElectric discharge tubesChemical reactionDimension measurement

The invention relates to the field of in-situ measurement and research of a transmission electron microscope accessory and a low-dimensional material, and in particular to an in-situ electrical samplerod system for a transmission electron microscope. The system comprises a high-vacuum round airtight connector, a hollow sample rod framework, a wire, a ceramic heating sheet, a thermosensitive resistor, a temperature control unit and a heating chip, wherein the high-vacuum round airtight connector is used for conducting an electrical signal, a surface of the hollow sample rod framework is insulated, the wire is arranged in the sample rod framework, the thermosensitive resistor and the ceramic heating sheet are integrated with a miniature sample table, are connected with the round airtight connector and an external circuit unit by the wire and are used for monitoring a heating temperature, a heating rate and temperature stability of the miniature sample table, and the heating chip is placed on the miniature sample table and can be used for controlling a temperature of a sample micro region. By the system, the atomic dimension measurement and research of macro performance of the material in a vacuum environment and under heating and electrical field conditions is achieved to the greatest extent, and the system is widely used for researching high-temperature phase change, electricalproperty, thermoelectric performance, chemical reaction and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

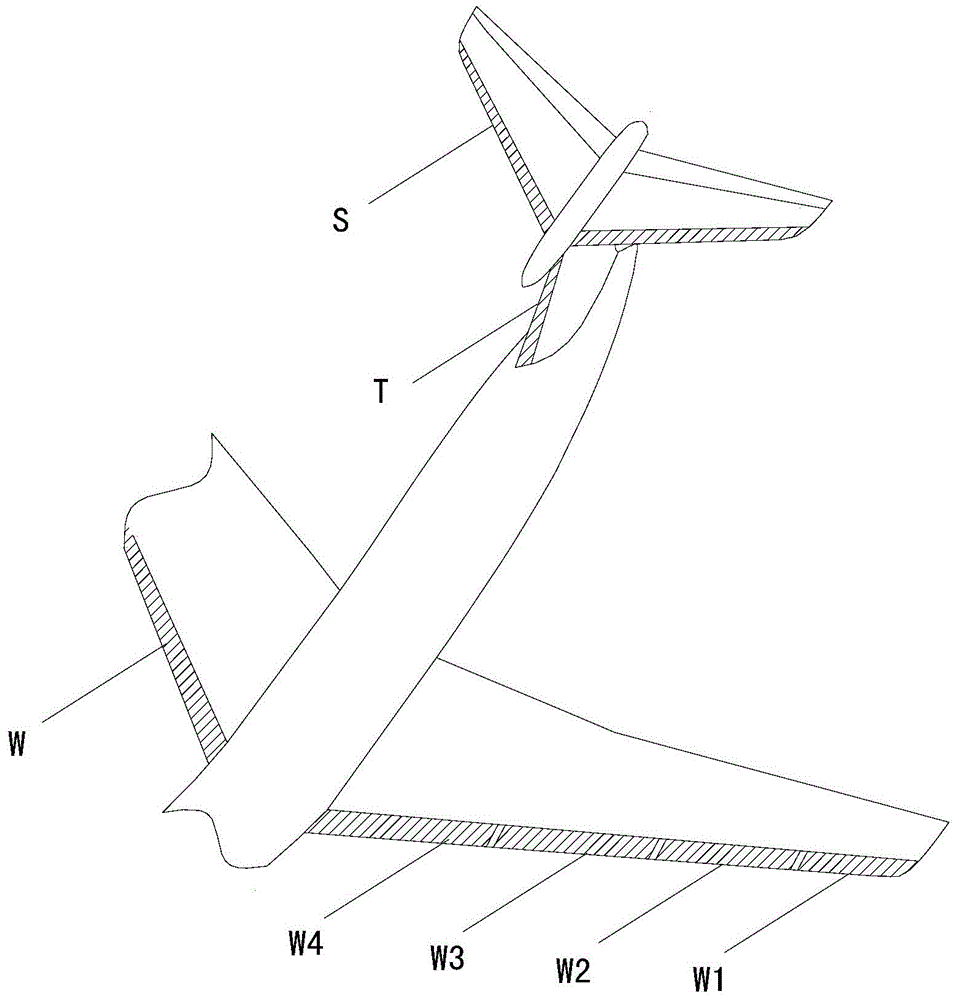

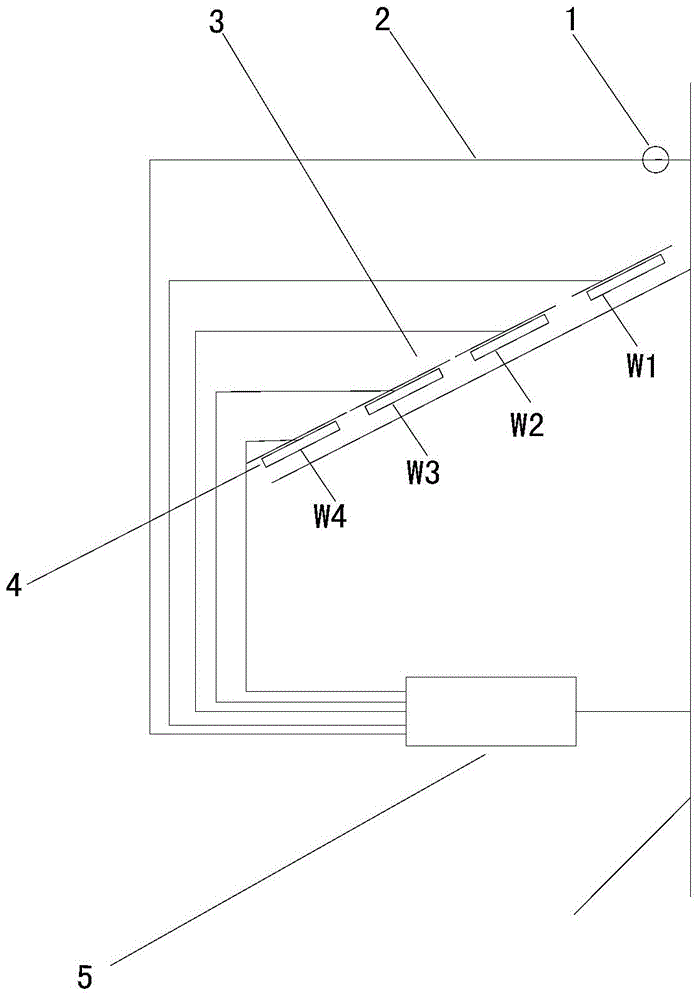

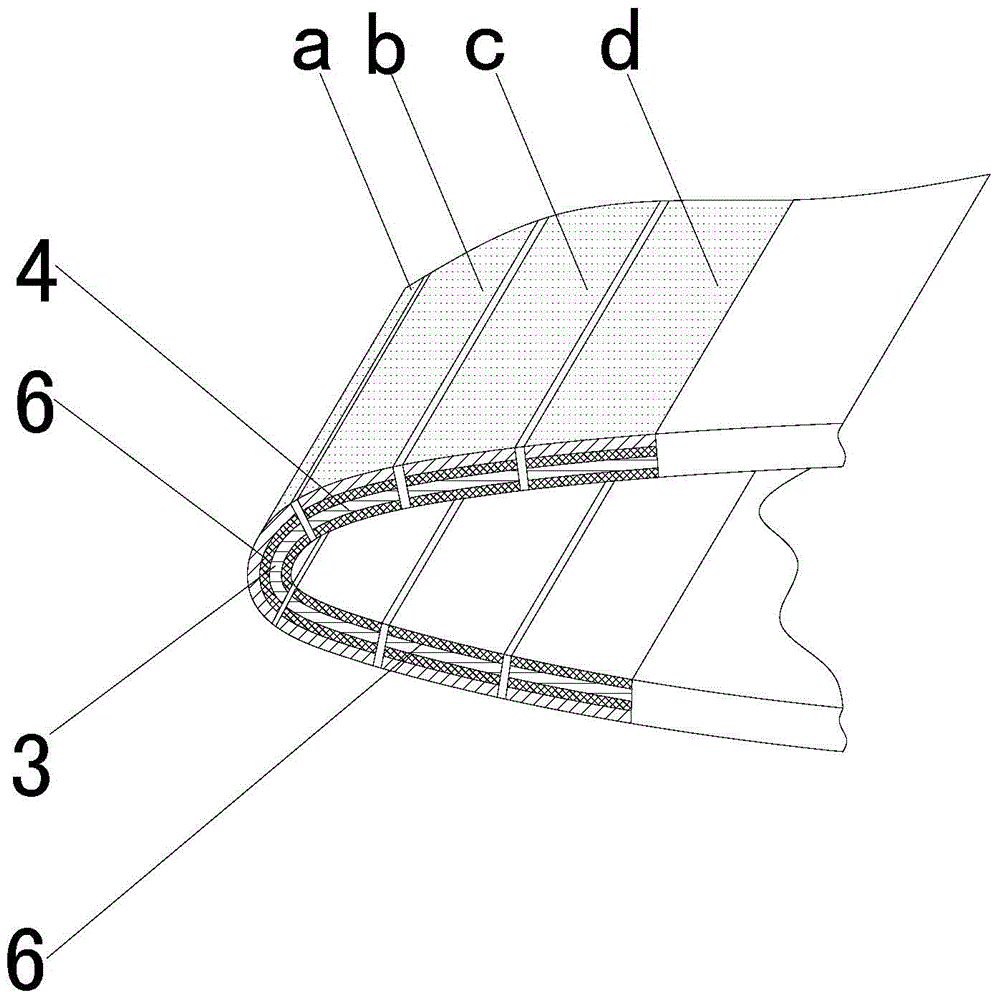

Deicing method

The invention belongs to the field of aircraft deicing, and provides a deicing method, which can save power consumption by deicing. Including: Step 1: Determine the protection range required by the tail, and calculate the deicing thermal load required for deicing the protection range; Step 2: Divide the tail into several heating sections according to the deicing thermal load required by the tail; Step 3: Calculate the freezing time for each heating section to reach the deicing thickness; Step 4: Determine the deicing time for each heating section according to the deicing thickness and heating power.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Method of fabricating phase change memory device

InactiveUS20090269910A1Reduce heating areaHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryPhase-change material

In a method of fabricating a phase change memory (PCM) device, a substrate having bottom electrodes formed therein is provided. A first dielectric layer having cup-shaped thermal electrodes is formed over the substrate. Second dielectric layers are formed on the substrate. Stacked structures are formed on the substrate. A PC material film is formed over the substrate and covers the stacked structures and the second dielectric layers. The PC material film is anisotropically etched to form PC material spacers on sidewalls of the stacked structures, and each of the PC material spacers physically and electrically contacts each of the cup-shaped thermal electrodes and top electrodes. The PC material spacers include phase change material. The PC material spacers are over-etched to remove the PC material film on the sidewalls of the second dielectric layers.

Owner:IND TECH RES INST

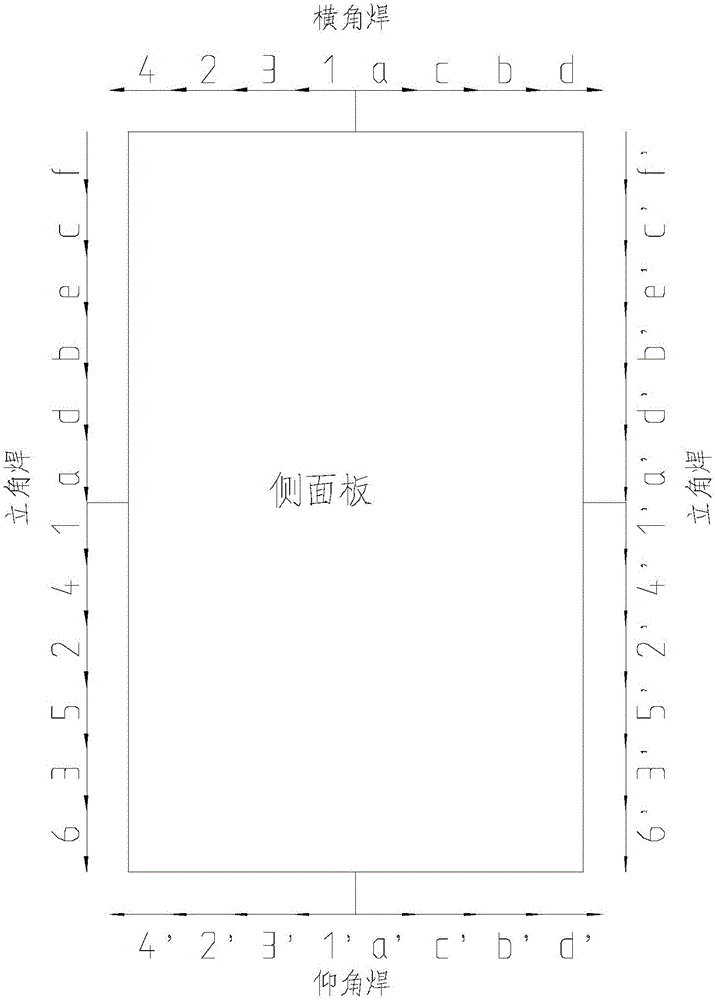

Chemical module panel laying and welding method

ActiveCN106141471AReduce welding distortionUniform weld patternWelding apparatusQuality by DesignChemical engineering

The invention discloses a chemical module panel laying and welding method. The chemical module panel laying and welding method comprises the following steps of (A) dividing a frame of a chemical module into sub planes; (B) splicing, shaping and blasting sand to subpanels; (C) preparing before the panels are laid; (D) laying the panels: laying the top panel, the bottom panel and the side panel; (E) welding the panels: welding the top panel, the bottom panel and the side panel; and (F) inspecting and accepting the whole chemical module. According to the panel laying and welding method, the bottlenecks of unstable quality and difficulty in meeting design quality requirements in the prior art are overcome, the module panel welded by using the panel laying and welding method has the advantages of attractive appearance, no irregularity and stable laying and welding quality, and the panel laying and welding method has a wide popularization vale in the field of chemical module panel laying and welding construction.

Owner:江苏利柏特股份有限公司

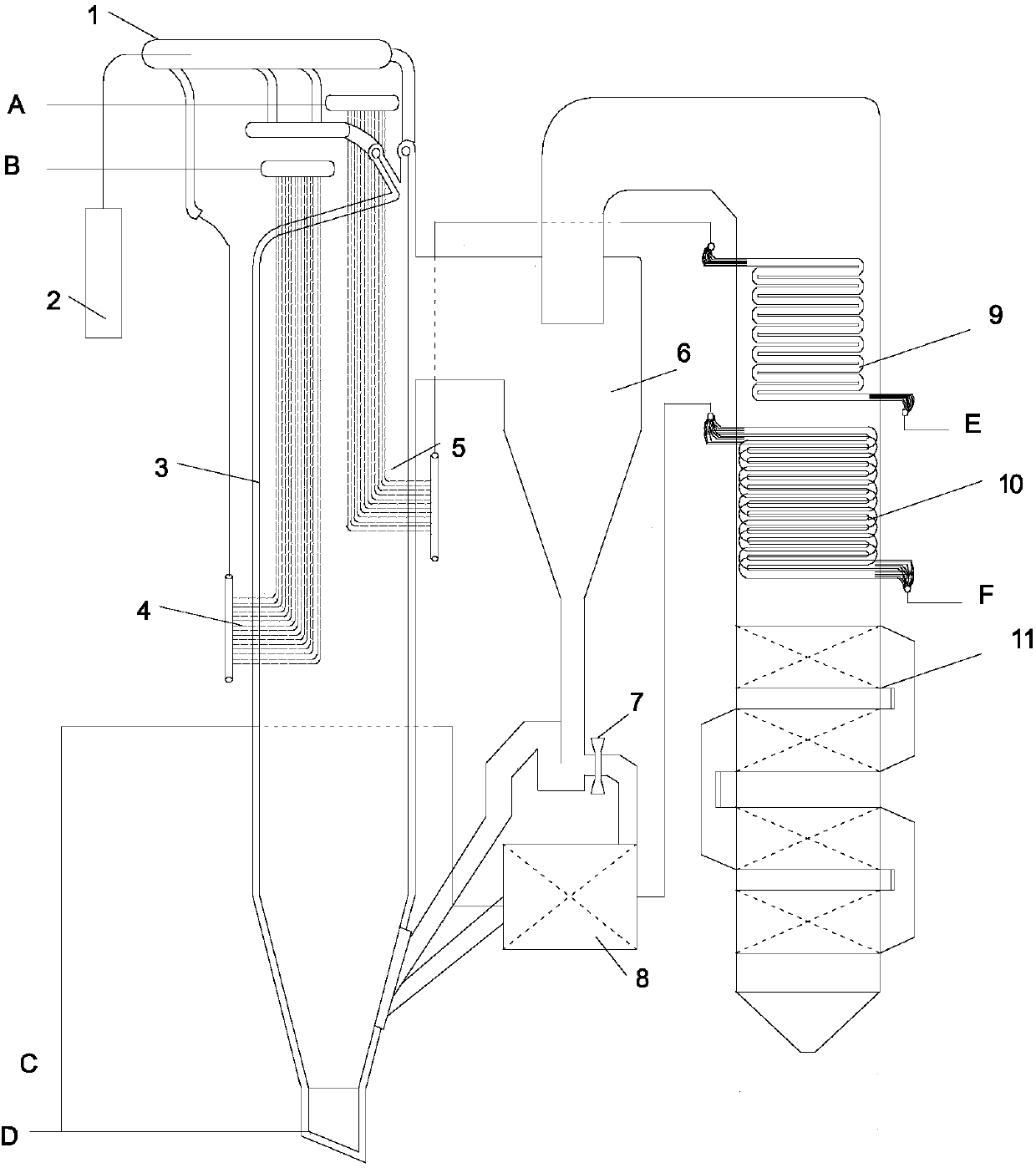

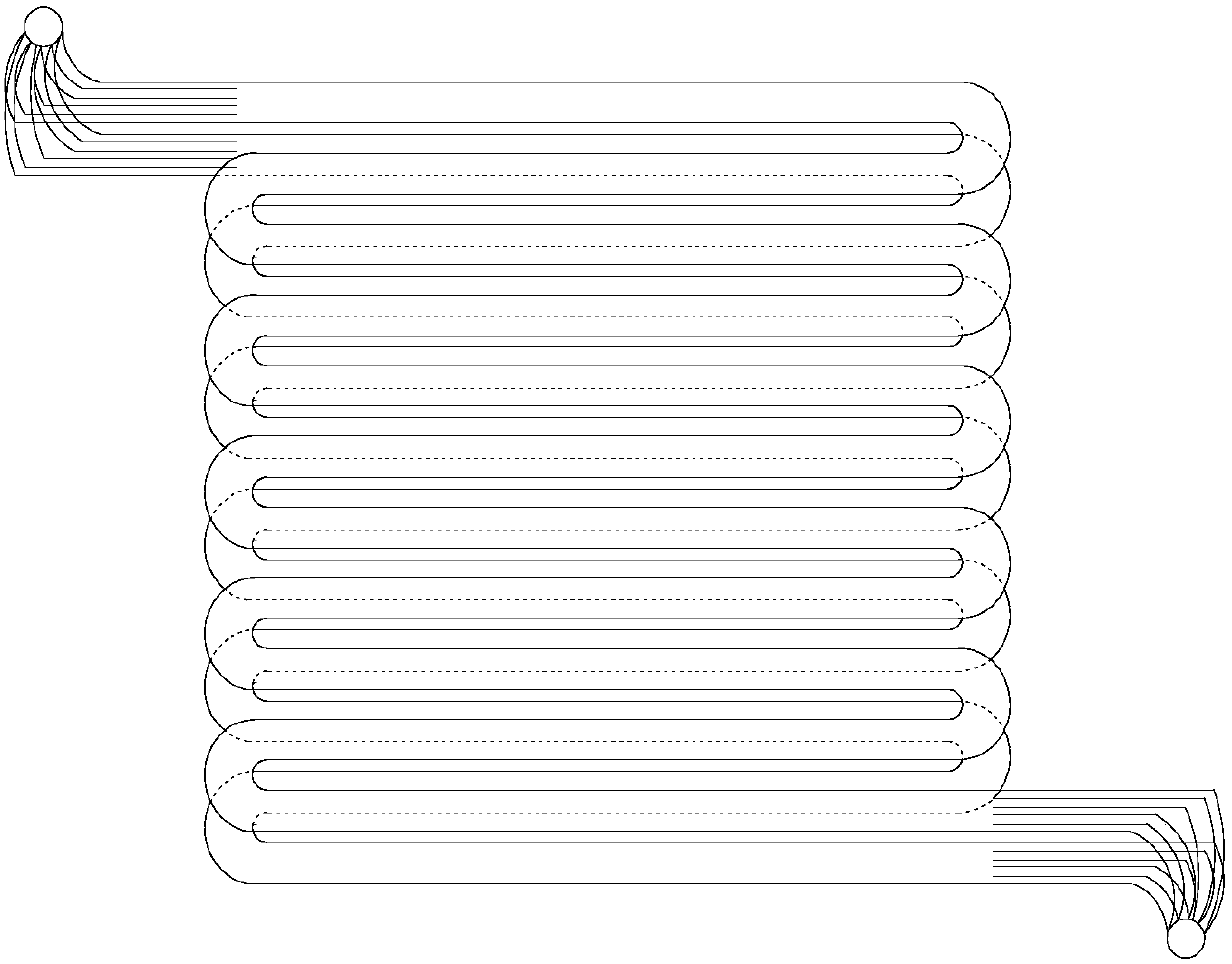

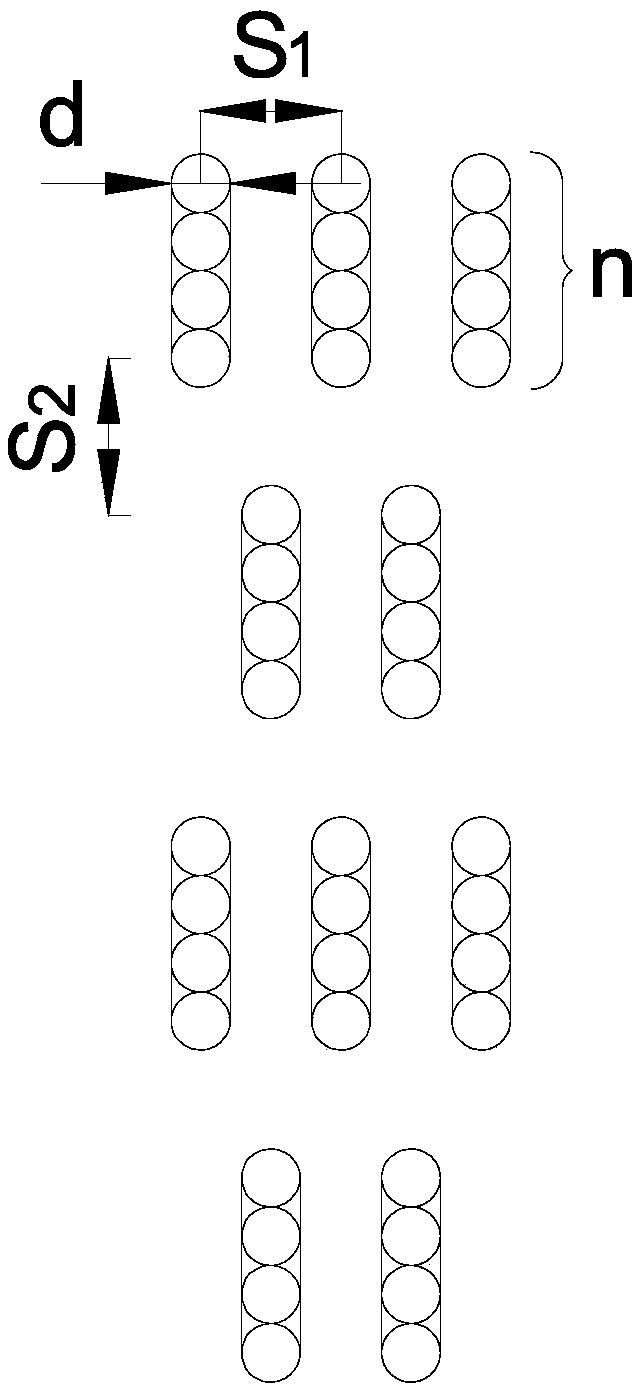

Supercritical carbon dioxide circulating fluidized bed coal fired boiler and power generation system driven by same

ActiveCN107906498AIncrease energy densitySmall initial economic investmentSteam engine plantsSteam superheatersEngineeringEconomizer

The invention discloses a supercritical carbon dioxide circulating fluidized bed coal fired boiler. Supercritical carbon dioxide is adopted to replace steam in an existing circulating fluidized bed boiler to serve as a working medium for absorbing heat and acting, and the heat absorption process of the working medium comprises the steps of one-time flow division and one-time re-heating. The heating face of the working medium of the supercritical carbon dioxide circulating fluidized bed boiler comprises a carbon dioxide cold wall screen type heater and a high temperature reheater which are arranged in a hearth. An externally arranged a superior economizer treating dust as a heat source is arranged on a material recycling device section between an outlet of a separator and the hearth in parallel. A heating face in a rear smoke channel in the flowing direction of smoke comprises a low temperature reheater and a subordinate economizer. The invention further discloses a power generation system driven by the supercritical carbon dioxide circulating fluidized bed coal fired boiler to generate power. The supercritical carbon dioxide circulating fluidized bed coal fired boiler enhances smoke heat transmission of a high temperature section of the reheater, and meanwhile relieves heat demanded pressure of the rear smoke channel, the emission amount of pollutants can be effectively reduced, the smoke emission temperature can be effectively decreased, and the boiler efficiency is improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000061.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000071.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000072.png)