Anti-deformation method of steel plate tailor welding cross column

A cross-column, anti-deformation technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the difficulty of on-site installation, the difficulty of matching the connection hole group between the cross-column and the beam, and the difficulty of accurate tailor-welded dimensions. grasp etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

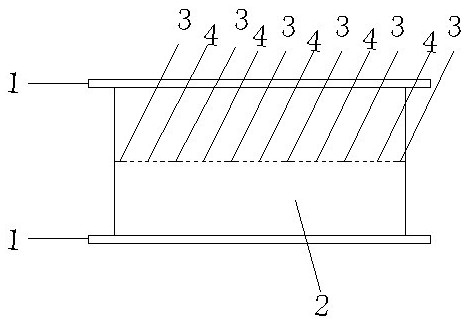

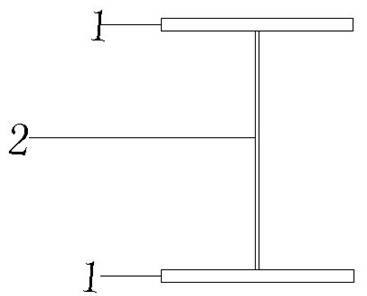

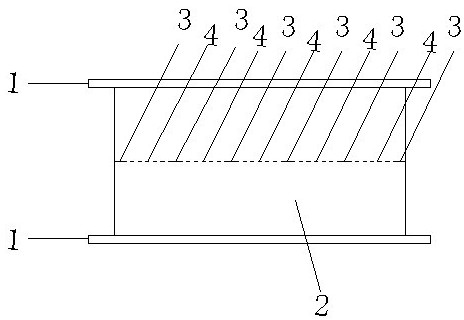

[0014] see figure 1 , 2 shown.

[0015] Cut the H-shaped steel web (2) to be cut along the center line by 500mm to form the cut area (4), keep the connection at 100mm to form the connection area (3), cut it at 500mm, and connect at 100mm. In such a cycle, the processed web (2) and the two flange plates (1) are tailor-welded to form an H-shaped steel, and then welded by submerged arc welding, then assembled and formed, and finally the 100mm connection area (3) is cut off In this way, the cut H-shaped steel becomes two symmetrical T-shaped steels, and the heating area is greatly reduced, so that the verticality, twist and straightness can be effectively guaranteed. The assembled cross column fully meets the design requirements, the welding current of the cross column must not exceed 300A, the voltage is 35-38V, and the welding sequence is diagonal, circular, and alternate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com