Deicing method

A technology of heating section and time, which is applied in the field of deicing and aircraft deicing, can solve the problem that the electric power cannot be used in a wide range, and achieve the effect of efficient use of energy deicing technology, heat loss reduction, and small heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below.

[0023] A method of deicing comprising:

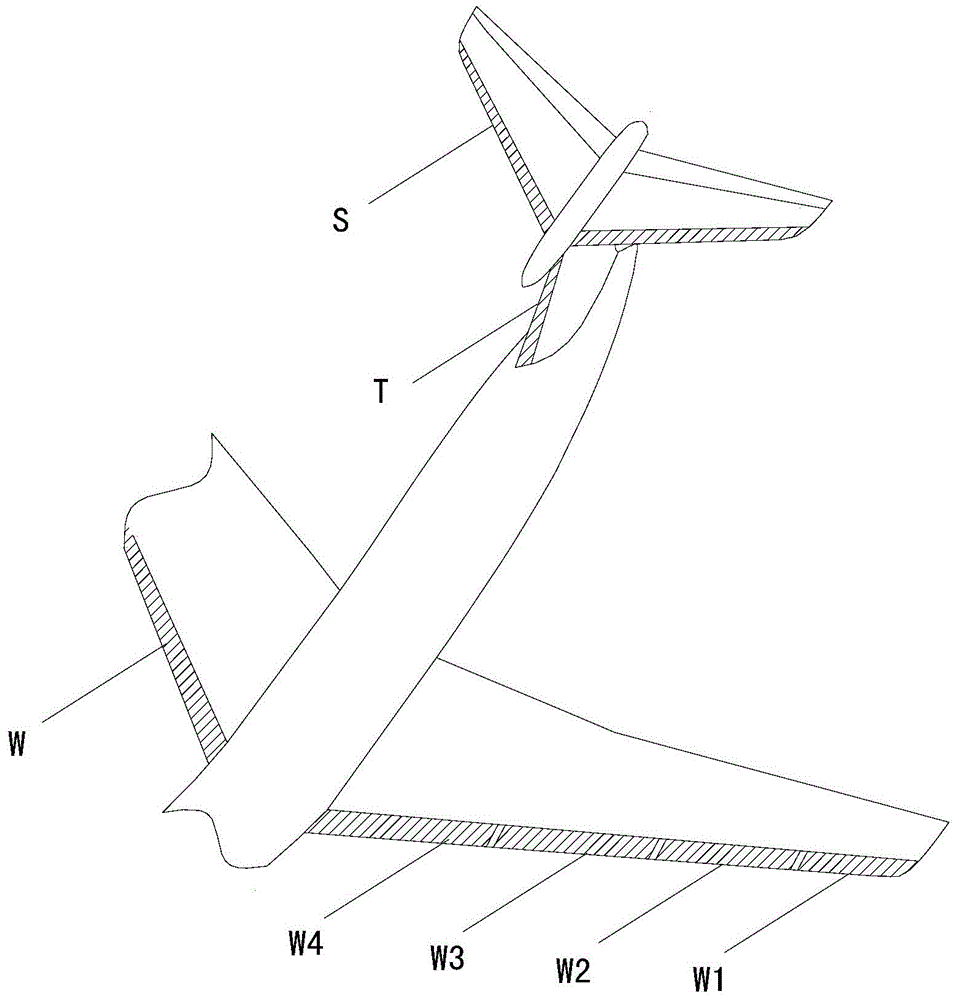

[0024] Step 1: Determine the protection range required by the tail, and calculate the deicing thermal load required for deicing the protection range;

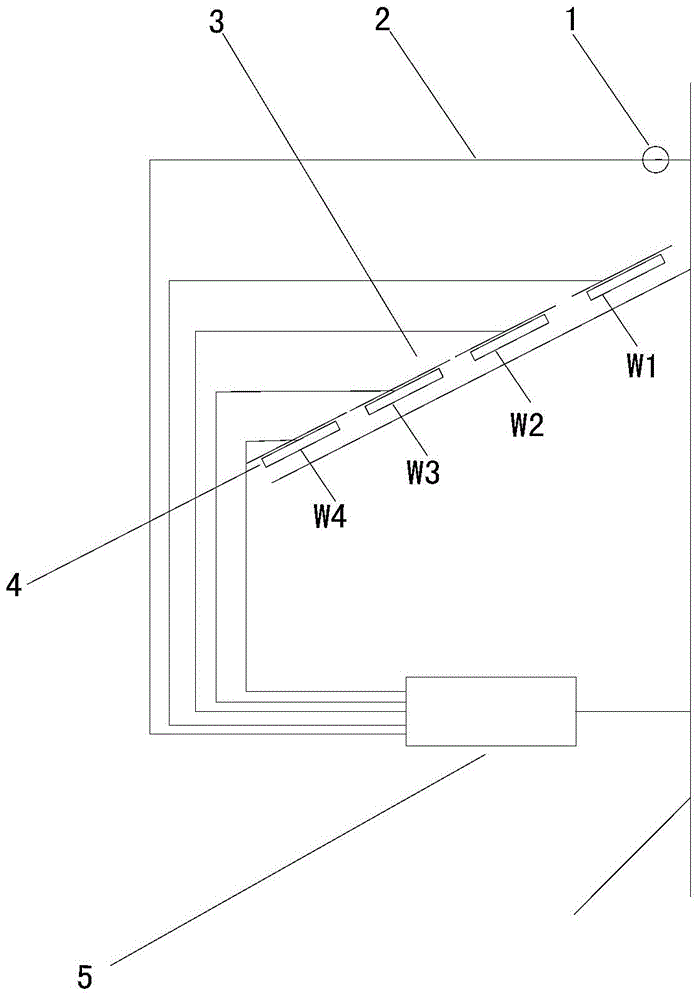

[0025] Step 2: Divide the empennage into several heating sections according to the deicing thermal load required by the empennage;

[0026] Step 3: Calculate the freezing time for each heating section to reach the deicing thickness;

[0027] Step 4: Determine the deicing time of each heating segment according to the deicing thickness and heating power.

[0028] Further, step 4 includes:

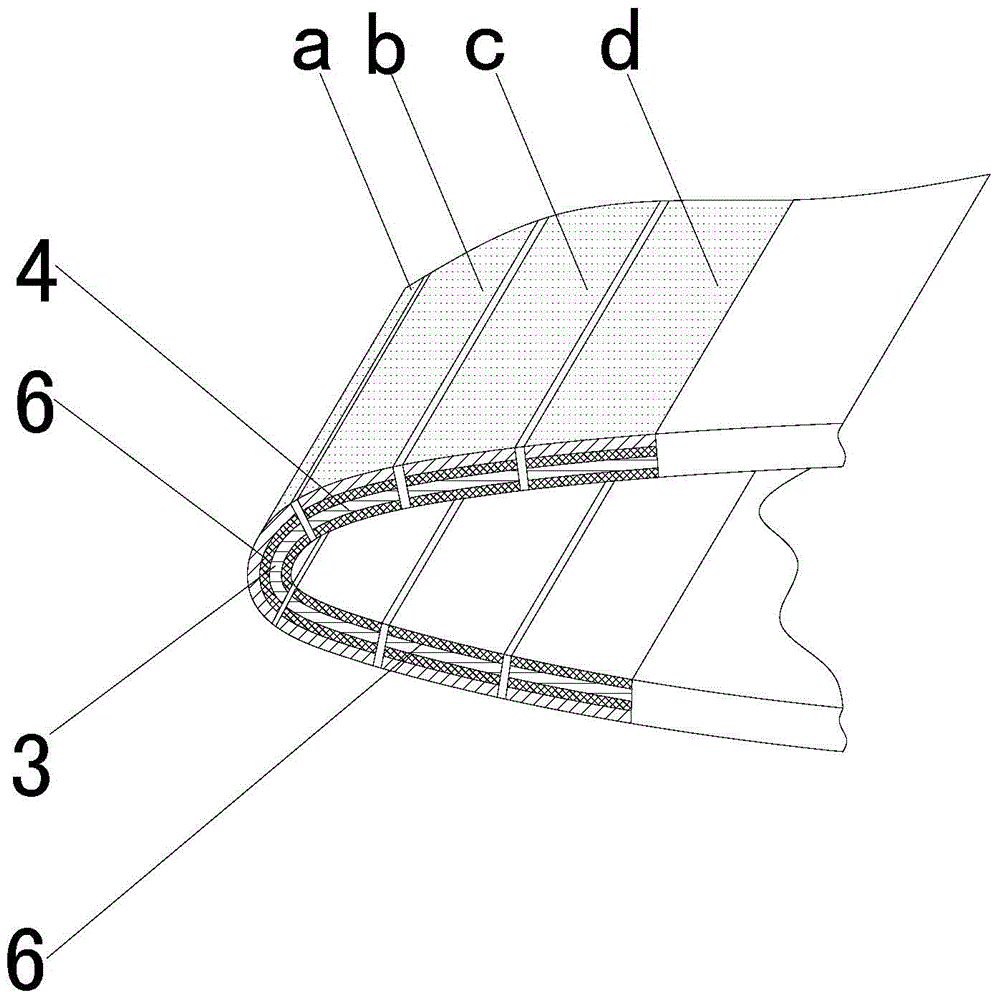

[0029] Step 41: dividing the heating area in each heating section according to the impact characteristics of water droplets;

[0030] Step 42: During the deicing time of the heating section, continuously heat the stagnation point region of the leading edge of the heating section, and perform periodic pulse electric heating on other heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com