Subsonic-speed ladle cover ablation test device under high-entropy condition

A kind of ablation test and subsonic technology, which is applied in the direction of aircraft component testing, etc., can solve the problems that cannot meet the test requirements, and achieve the effects of improving survivability, reducing cooling water flow, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail in conjunction with the accompanying drawings and specific implementation.

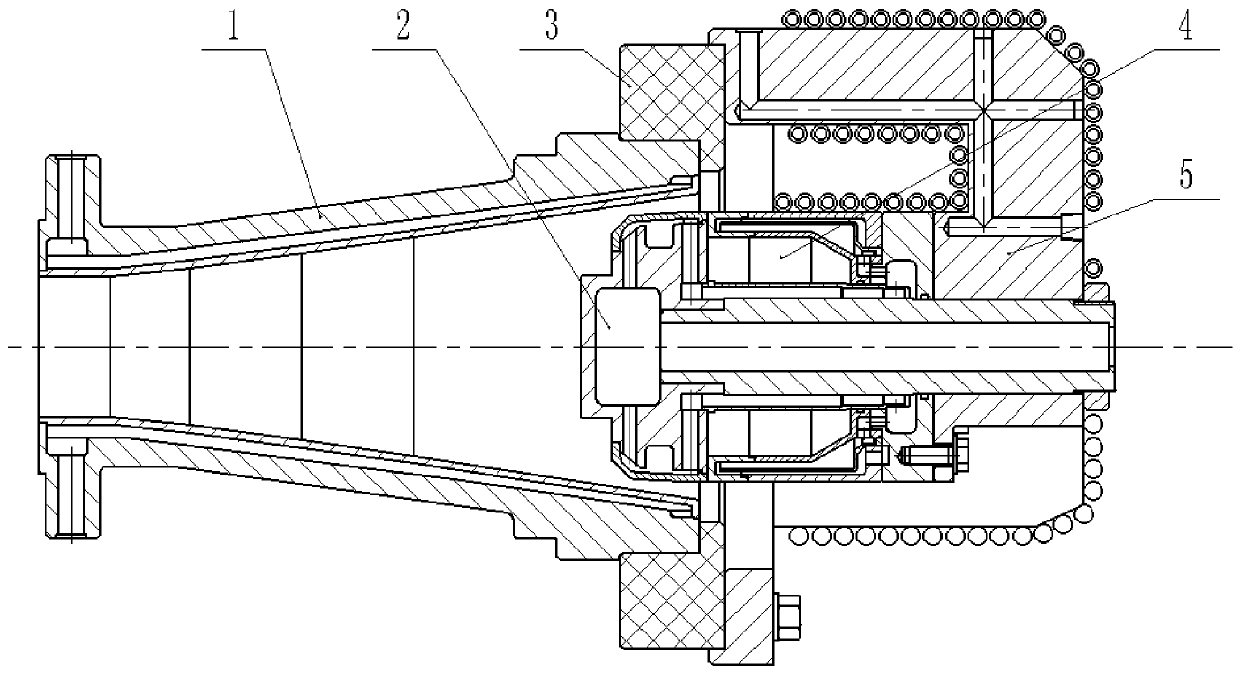

[0044] The invention provides a subsonic envelope ablation test device for high enthalpy conditions, such as figure 1 As shown, it includes a shroud nozzle 1 , a throat strut 2 , an adapter section 4 and a model bracket 5 . in:

[0045] The covering nozzle 1 and the model bracket 5 are fixed on the adapter flange 3 . The throat strut 2 is installed on the model bracket 5 through the transition section 4, the connection between the throat strut 2 and the transition section 4 is guaranteed to coincide with the central axis of the envelope nozzle 1, the throat part of the throat strut 2 Located inside the envelope nozzle 1.

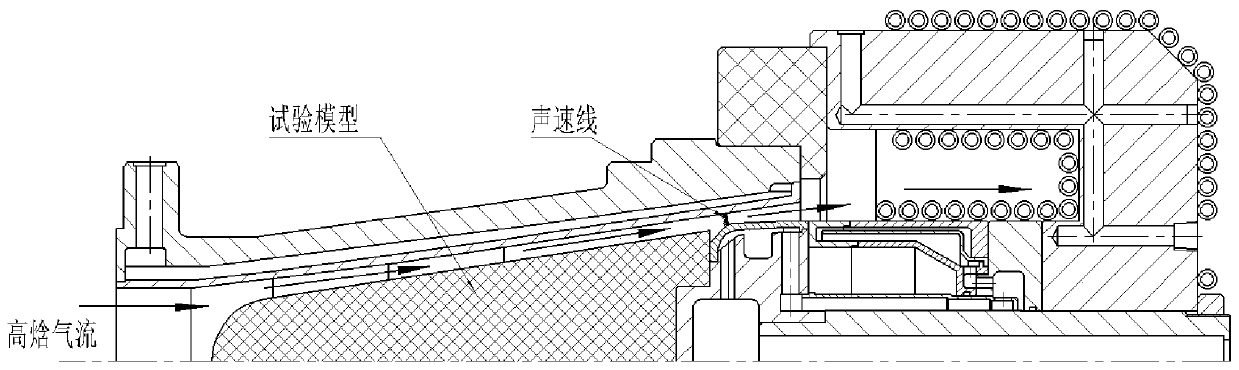

[0046] Specifically, such as figure 2 As shown, when the test is carried out, the test model is installed on the throat strut 2, and the annular channel between the outer surface of the test model and the inner surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com