High oxygen concentration oxygen-enriched pulverized coal fractional combustion method and device therefor

A technology of oxygen-enriched pulverized coal and graded combustion, which is applied in the direction of combustion methods, combustion control, and fuel supply adjustment, and can solve problems such as spontaneous combustion of pulverized coal, high oxygen concentration, deflagration, etc., and achieve the goal of reducing power consumption and heating area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

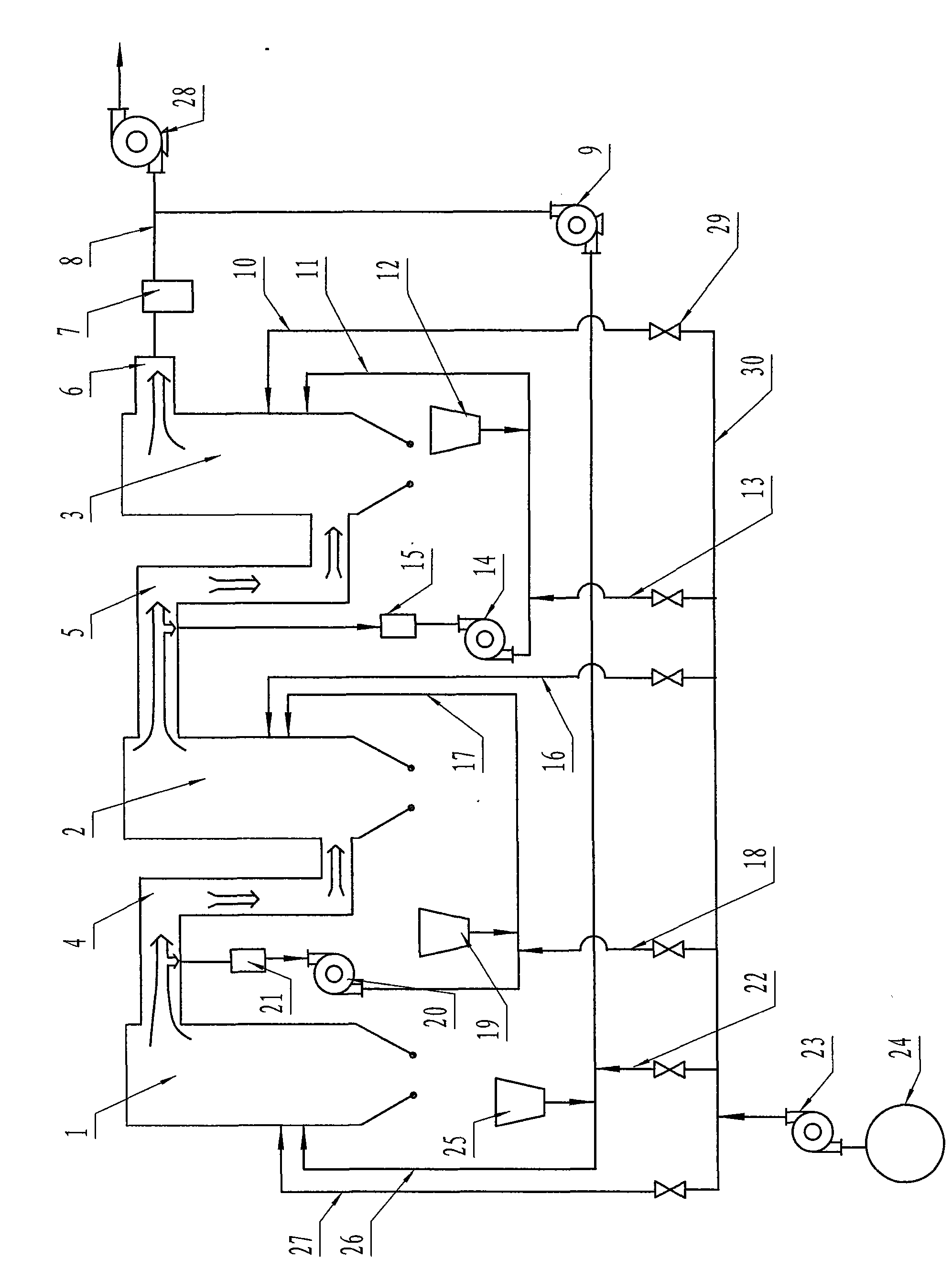

Image

Examples

Embodiment 1

[0019] Embodiment 1: coal burning is calculated by Fuxin coal, and the composition analysis of coal is: C ar =48.3%, H ar = 3.3%, O ar =8.6%, N ar =0.8%S ar = 1.0%, A ar = 23%, M ar = 15%, Q net,ar =18645 (kJ / kg), V daf = 41%. Taking the coal consumption of the boiler as 100t / h as an example, taking seconds as the unit of time, 27.78kg / s of coal is burned per second. In order to ensure the complete combustion of pulverized coal, the excess O 2 coefficient is 1.05, then O 2 30.09m 3 / s. O in the combustion gas 2 Concentration is 80%, need to circulate flue gas 7.52m 3 / s, the combustion process produces a total flue gas volume of 48.27m 3 / s, the recycled flue gas accounts for 15.58% of the total flue gas. The above volumes are standard state volumes. The specific plan is:

[0020] Total pulverized coal and total O 2 15%, 28% and 57% of the furnace are put into the first, second and third furnace respectively. That is to say, the amount of coal burned in the ...

Embodiment 2

[0024] Embodiment 2: coal burning is calculated by Yangquan anthracite, and the composition analysis of coal is: C ar = 68.9%, H ar =2.9%, O ar = 2.4%, N ar = 1% S ar = 0.8%, A ar =19%, M ar = 5%, Q net,ar =26400(kJ / kg), V daf = 9%. Taking the coal consumption of the boiler as 100t / h as an example, taking seconds as the unit of time, 27.78kg / s of coal is burned per second. In order to ensure the complete combustion of pulverized coal, the excess O 2 coefficient is 1.05, then O 2 41.87m 3 / s. O in the combustion gas 2 Concentration is 75%, need to circulate flue gas 13.95m 3 / s, the total flue gas produced during the combustion process is 55.83m 3 / s, the recycled flue gas accounts for 22.9% of the total flue gas. The above volumes are standard state volumes. The specific plan is:

[0025] Total pulverized coal and total O 2 20%, 33% and 47% of the furnace are put into the first, second and third furnace respectively. That is, the coal consumption of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com