Patents

Literature

65results about How to "Fully burnt out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion-supporting, desulfurization and coal-saving additive used for boiler fire coal

InactiveCN101230301AHigh thermal efficiencyPrevent coking accidentsSolid fuelsFuel additivesCombustionPotassium dichromate

The invention provides a combustion-supporting desulfurating coal-saving additive which is used in the burning coal in boiler, the preparation of which is composed of 24-35 percent combustion improvers of methanol, aether, tween-80; 32-38 percent oxidants of potassium permanganate, potassium chlorate and potassium dichromate; 4-28 percent desulfurizer in which quicklime, potassium permanganate, potassium chlorate and potassium dichromate take part in; 18-22 percent anti-coking agent which contains potassium dichromate and quicklime; the rest is water, which complement the total volume of the additive to be 100 percent. The additive is prepared by adding water in the quicklime to produce lime cream; heating the water for acting as solution, after potassium permanganate, potassium chlorate and potassium dichromate are added into the solution and are stirred evenly; adding and mixing the methanol and tween-80 into the solution evenly, and then adding and mixing the lime cream into the solution evenly; finally adding and mixing the aether into the solution evenly; and preserving the heat for 1 hour. The invention can improve the desulfurization rate by 40 percent, improve the coal saving rate by 25 percent, and improve the thermal efficiency of the boiler by up to 5-10 percent; and can prevent the occurrence of boiler coking accident.

Owner:周兴泽

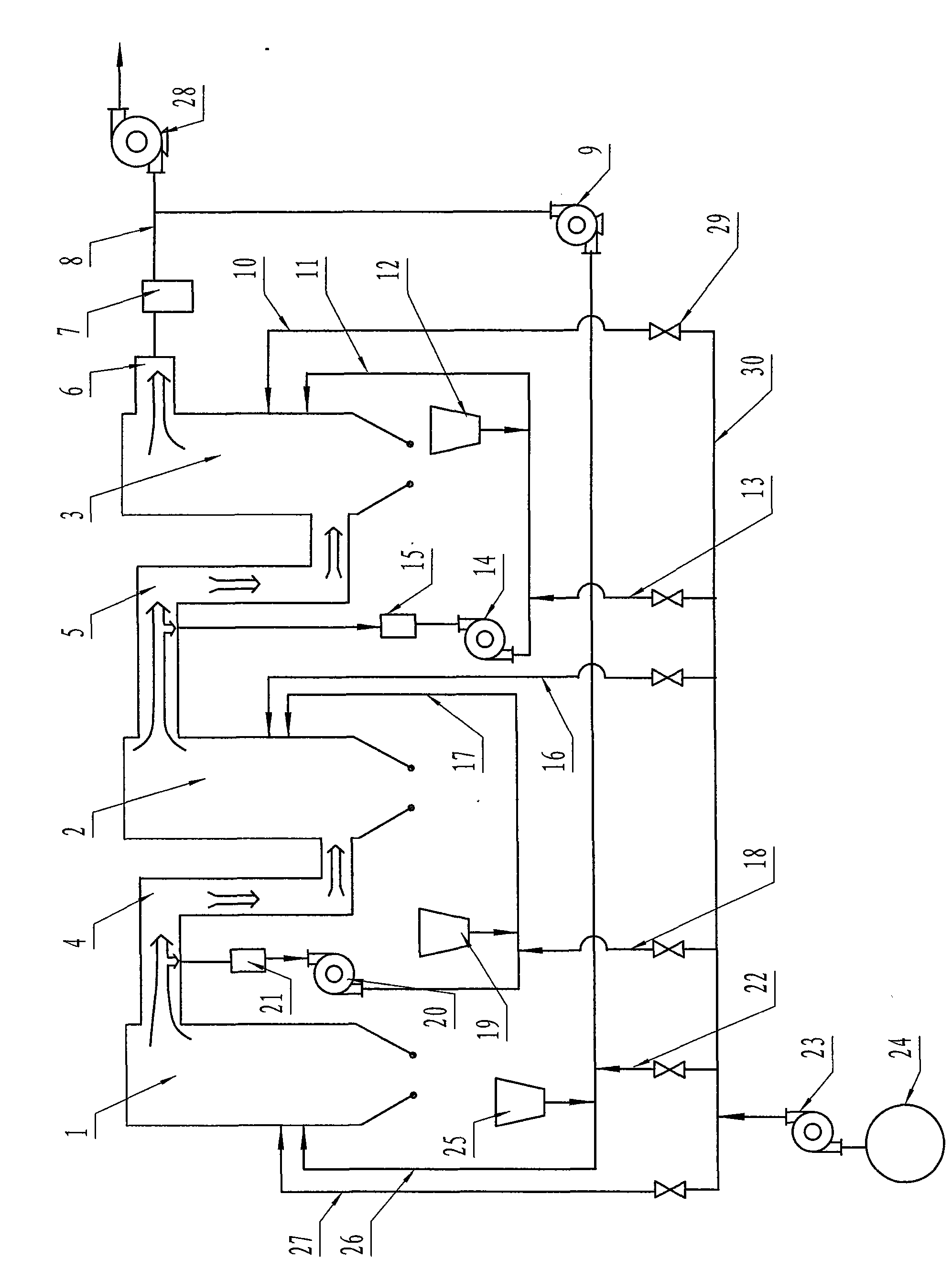

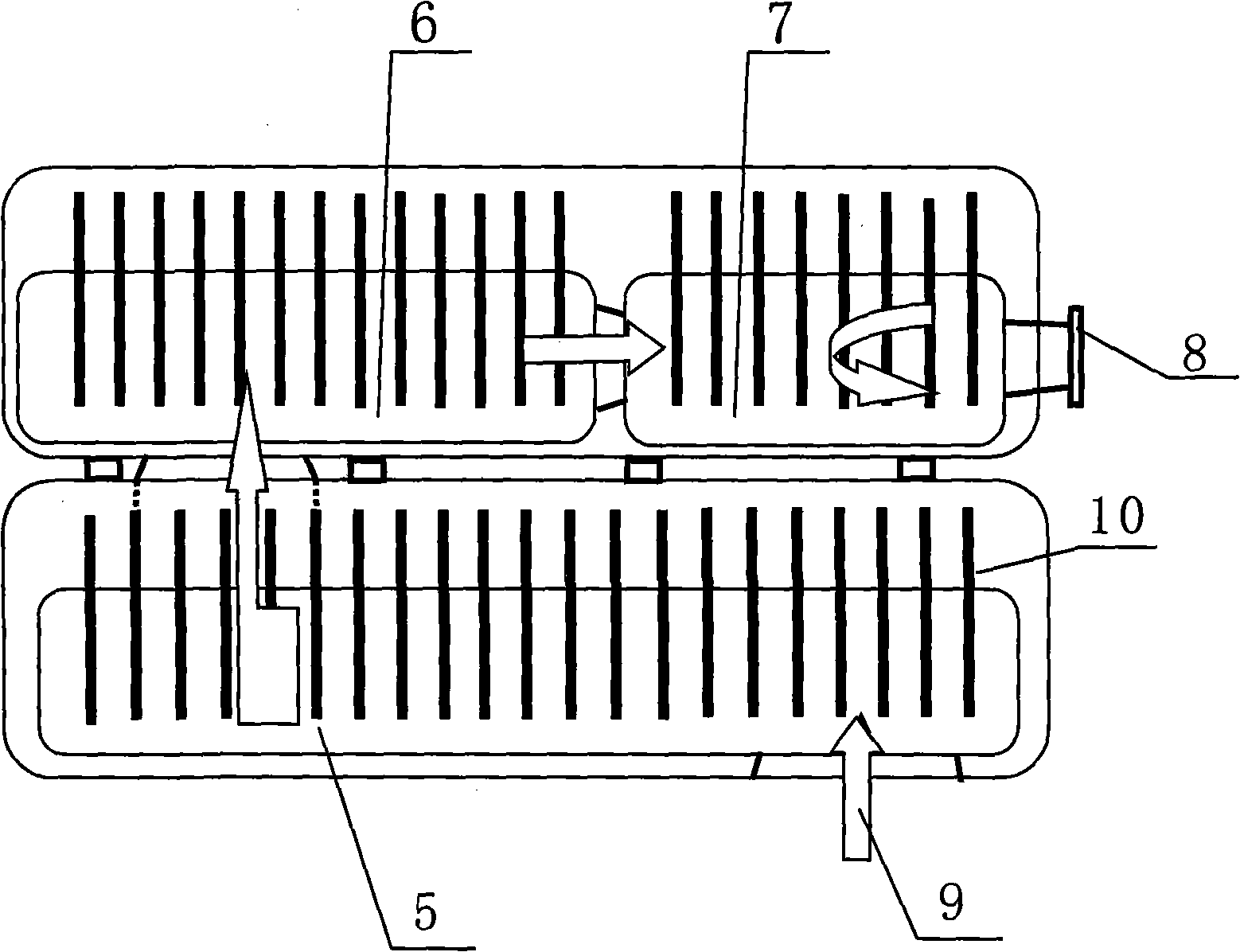

High oxygen concentration oxygen-enriched pulverized coal fractional combustion method and device therefor

InactiveCN101639227AReduce heating areaReduce power consumptionFuel supply regulationIndirect carbon-dioxide mitigationElectricityCombustion

The invention relates to a high oxygen concentration oxygen-enriched pulverized coal fractional combustion method and a device therefor. The invention has the technical scheme that a boiler type withthree stages of series connection hearths is adopted; when in combustion, the pulverized coal and oxygen are respectively put into the hearths for combustion according to the proportion in the combustion process; all recycling flue gas is pumped back into the first hearth and is blended with part of the oxygen filled in the first hearth for transmitting the pulverized coal for the first hearth; part of the flue gas generated by the first hearth is blended with part of the oxygen filled in the second hearth for transmitting the pulverized coal for the second hearth; and part of the flue gas generated by the second hearth is blended with part of the oxygen filled in the third hearth for transmitting the pulverized coal for the second hearth. The total concentration of O2 in the boiler reaches 70-80%; as the next stage of hearth adopts the flue gas generated by combustion of the previous hearth as dilute gas, the actual concentration of O2 in every stage of hearth is within the range of 30-40%. The quantity of the recycling flue gas is much less than that in the current oxygen-enriched combustion boiler, and the electricity consumption in the running of a flue gas circulation fan is obviously lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

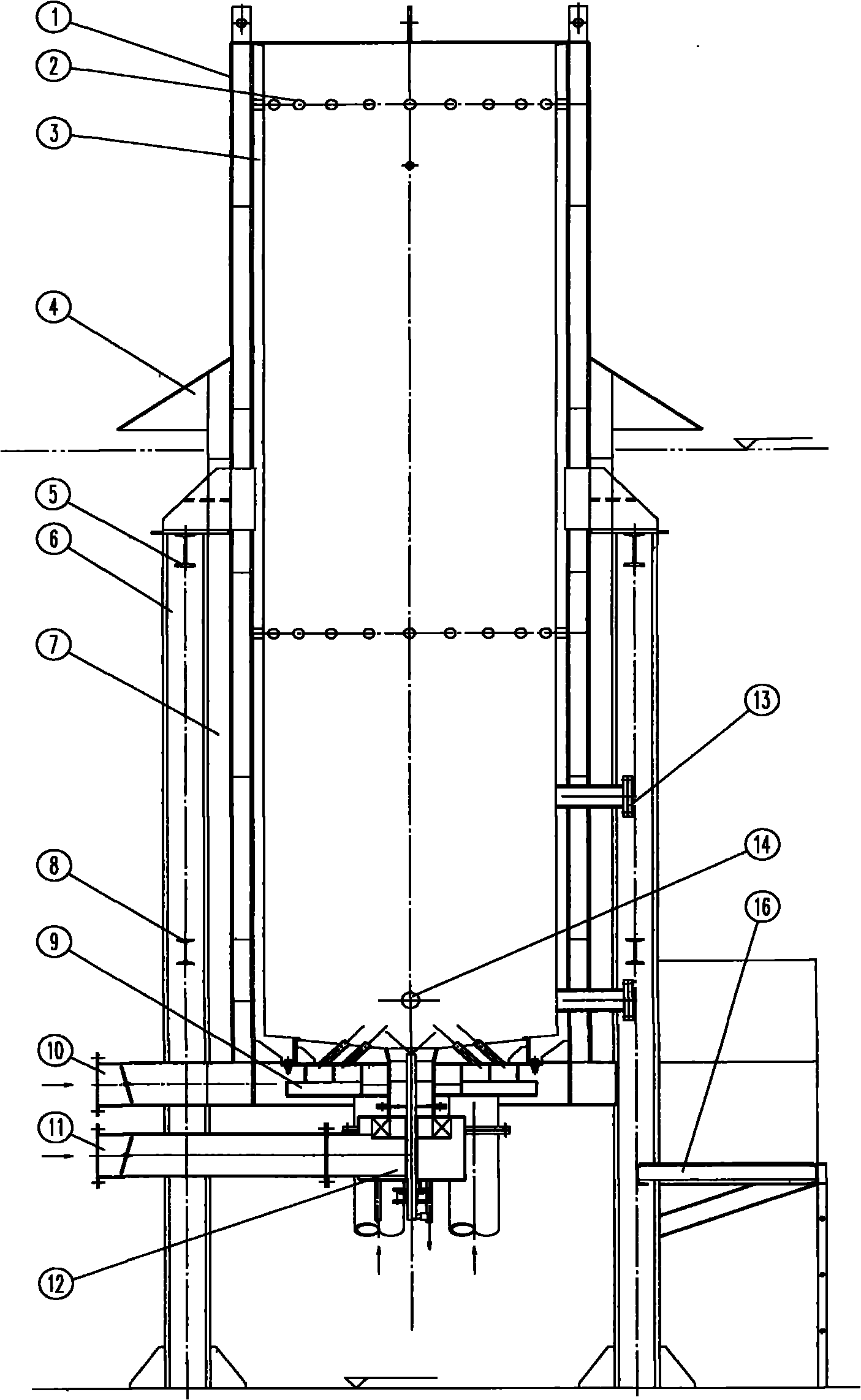

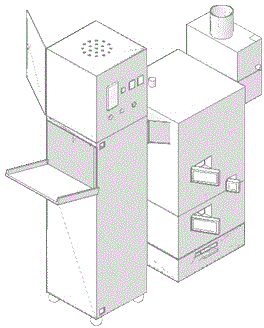

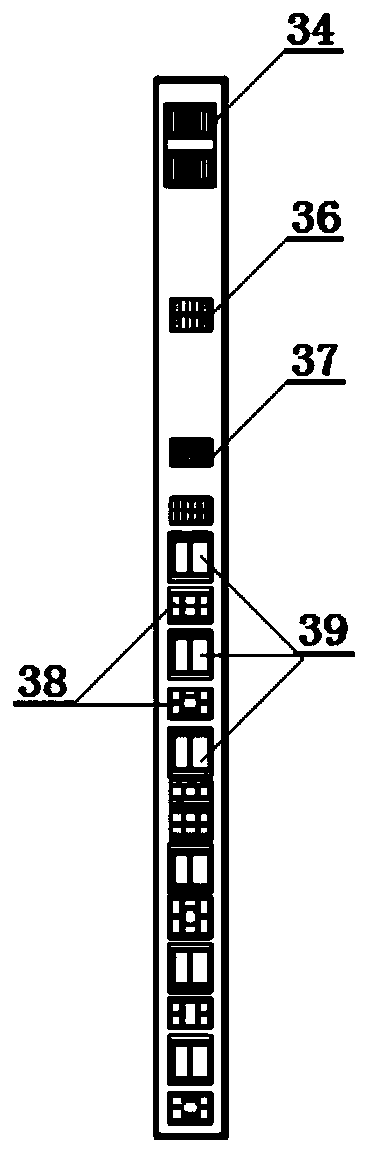

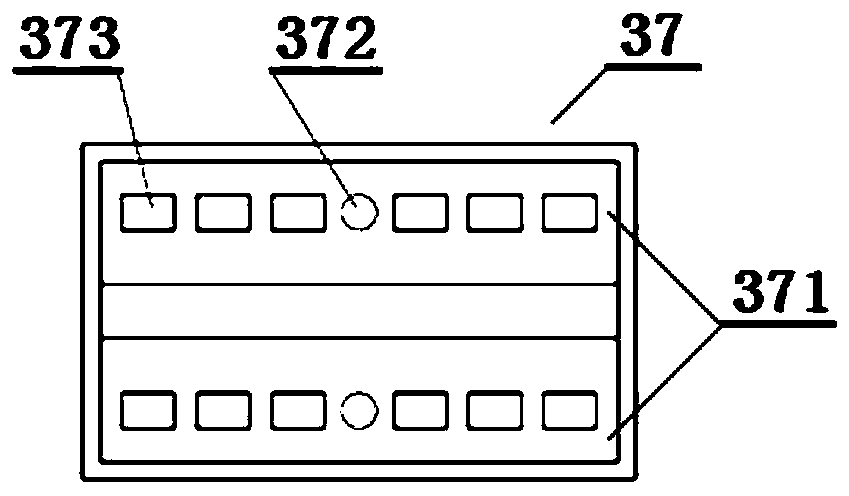

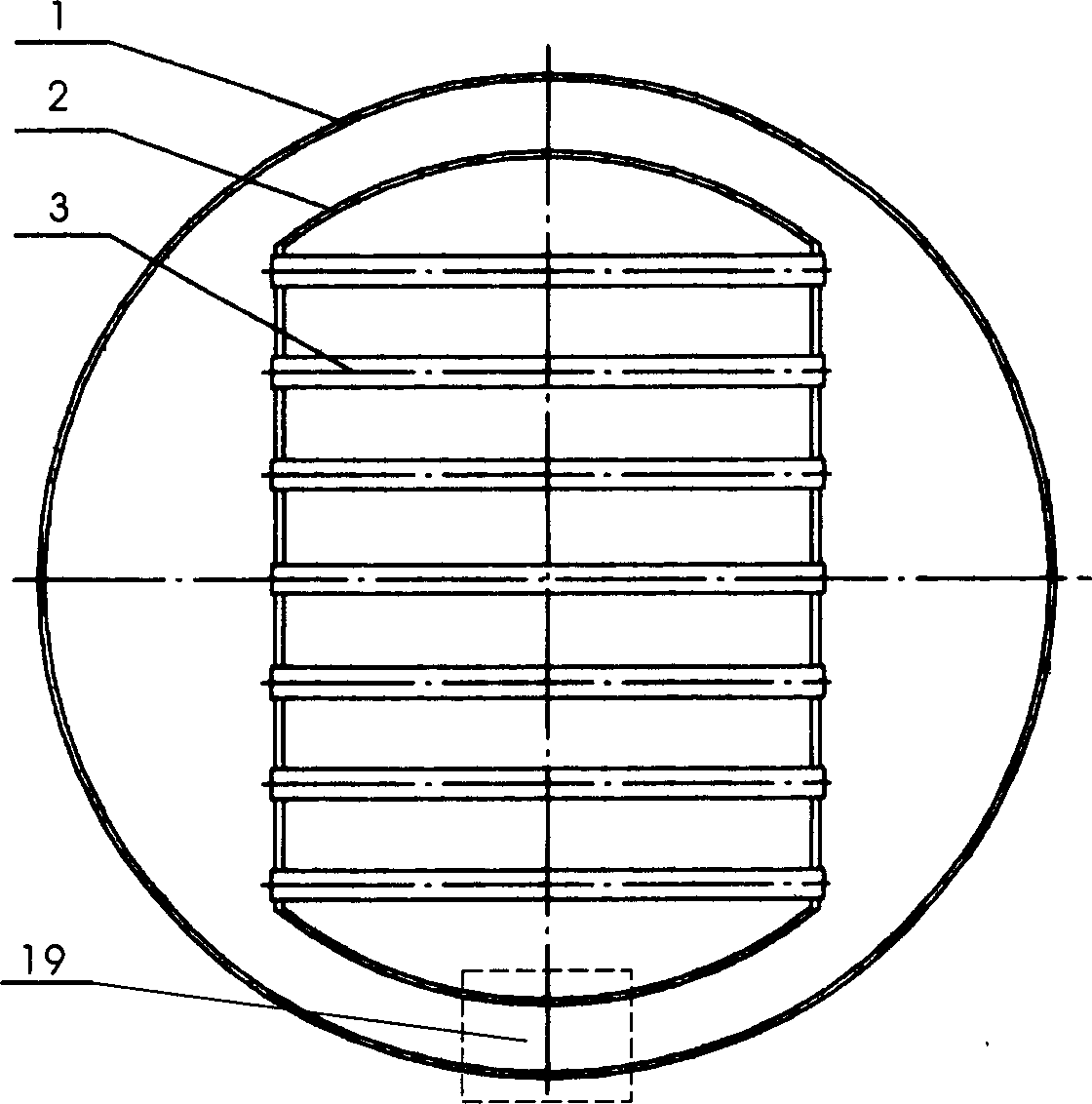

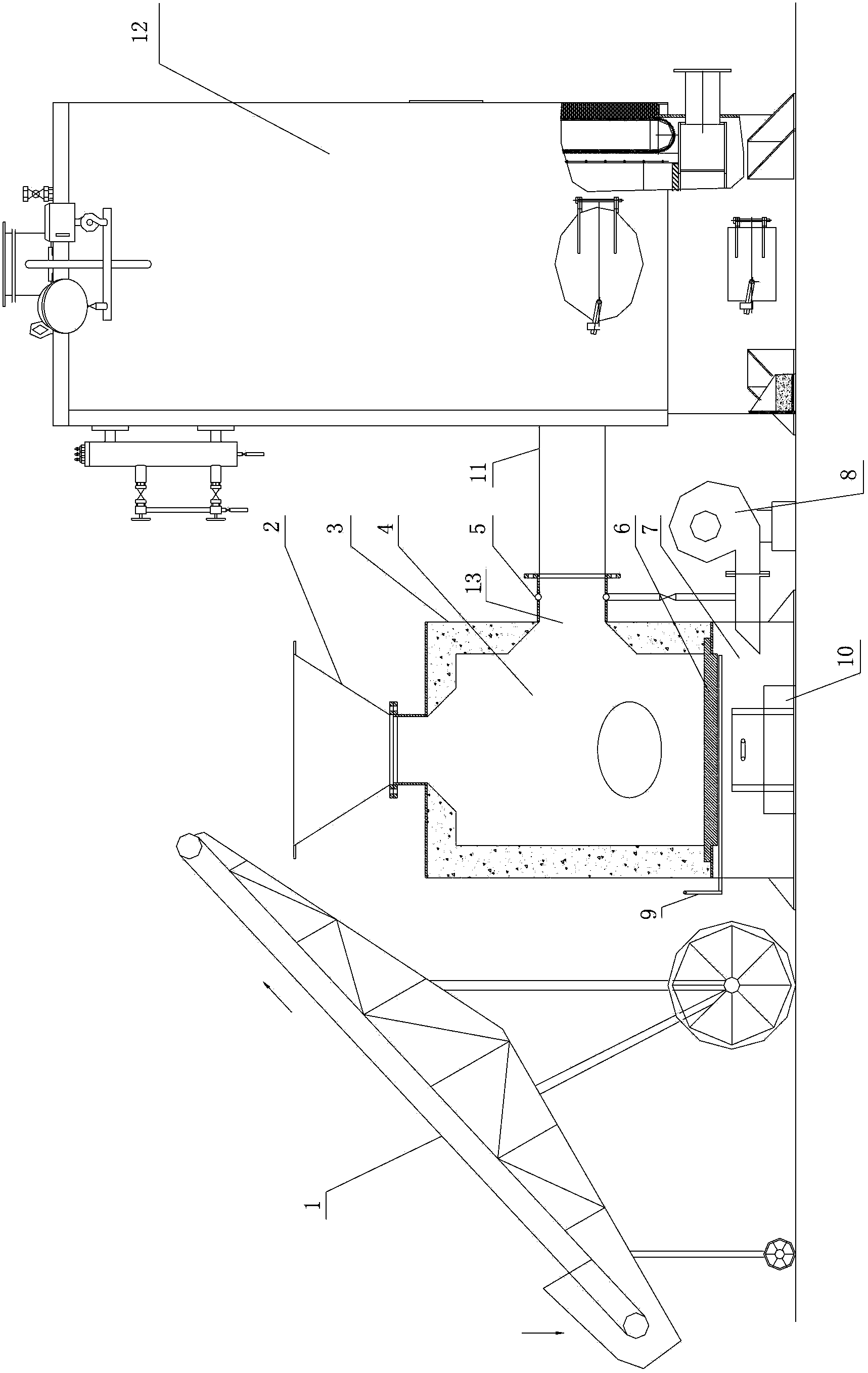

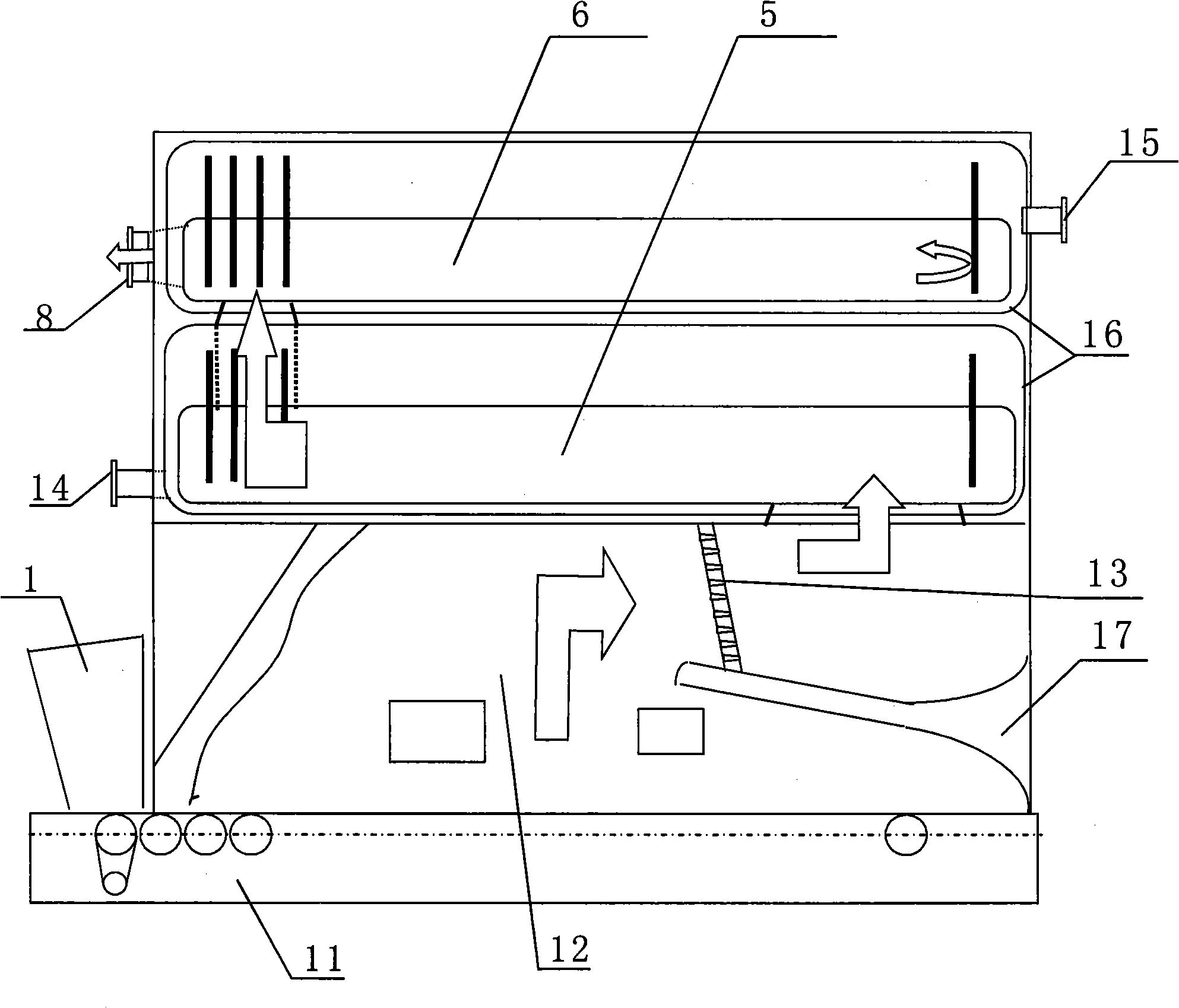

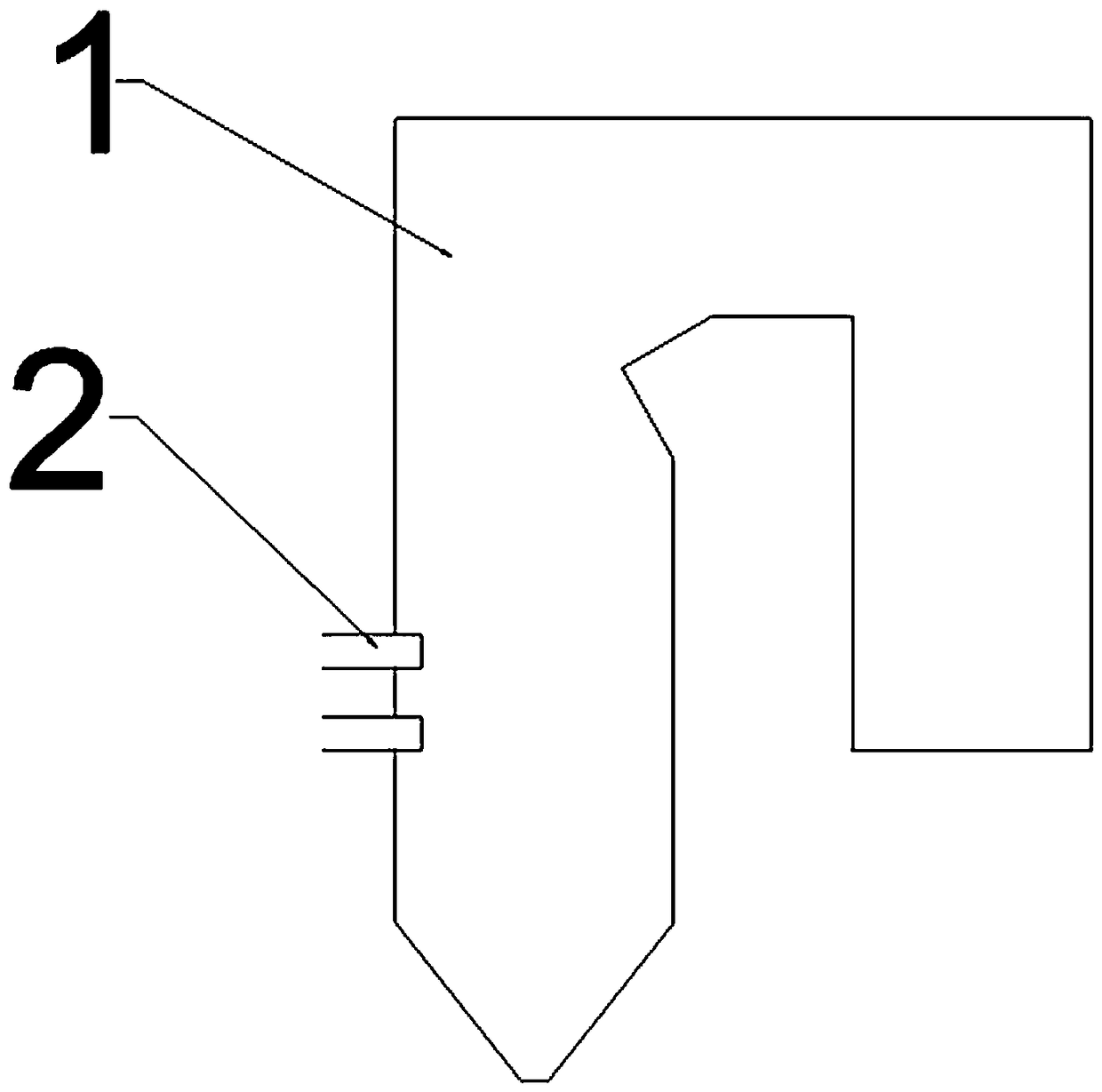

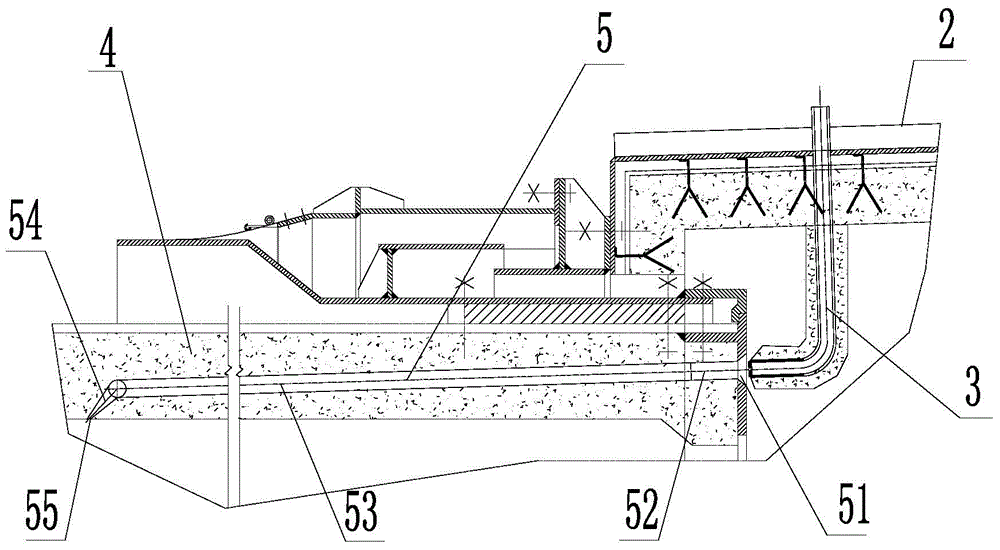

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

Steam boiler capable of achieving partial gasification combustion of coal

InactiveCN104864379AGuaranteed to catch fire in timeImprove adaptabilitySolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention relates to a steam boiler capable of achieving partial gasification combustion of coal. The steam boiler comprises a chain grate and a boiler body. The boiler body is located over the chain grate, a plurality of air chambers are arranged below the chain grate and sequentially arranged in the conveying direction of the chain grate, and the air chambers are located under a combustion chamber of the boiler body, wherein a steam spray pipe is arranged on the air chamber at the head end, a middle arch is further arranged in the combustion chamber, the combustion chamber is divided into a front combustion chamber body and a rear combustion chamber body through the middle arch, the front combustion chamber body is located over the air chamber at the head end, and the rear combustion chamber body is located over the rest of the air chambers. By means of the steam boiler, partial gasification combustion of the coal is achieved, the phenomenon of black smoke emitted from the boiler is avoided, and the carbon content of ash of the boiler can be reduced. Furthermore, the temperature of a coal layer can be reduced, and NOx can be reduced.

Owner:HARBIN HUASHI HAIDE TECH DEV +1

Garbage incinerator and incineration method

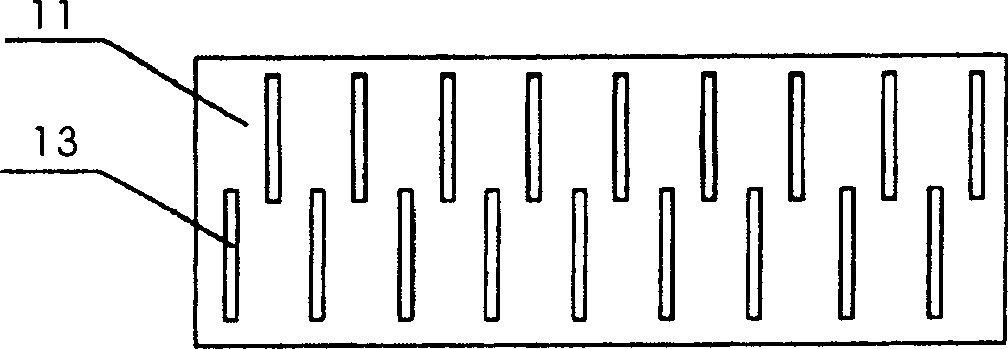

InactiveCN104566388ABurn evenlyFully burnt outIndirect carbon-dioxide mitigationAir/fuel supply for combustionReduction rateLitter

The invention relates to a garbage incinerator and an incineration method. The garbage incinerator comprises a plurality of grate plates and further comprises a plurality of independent air chambers located below the grate plates, each independent air chamber is provided with a primary air inlet pipe and an oxygen inlet pipe, and each oxygen inlet pipe is further provided with an electric air door for controlling oxygen inlet. Through regulating an independent oxygen supply unit, garbage can be uniformly burnt on the grate, the garbage is burnt out completely, and accordingly the garbage heat energy is completely used, the thermal reduction rate is lowered, and the grate plate protection is realized.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA +2

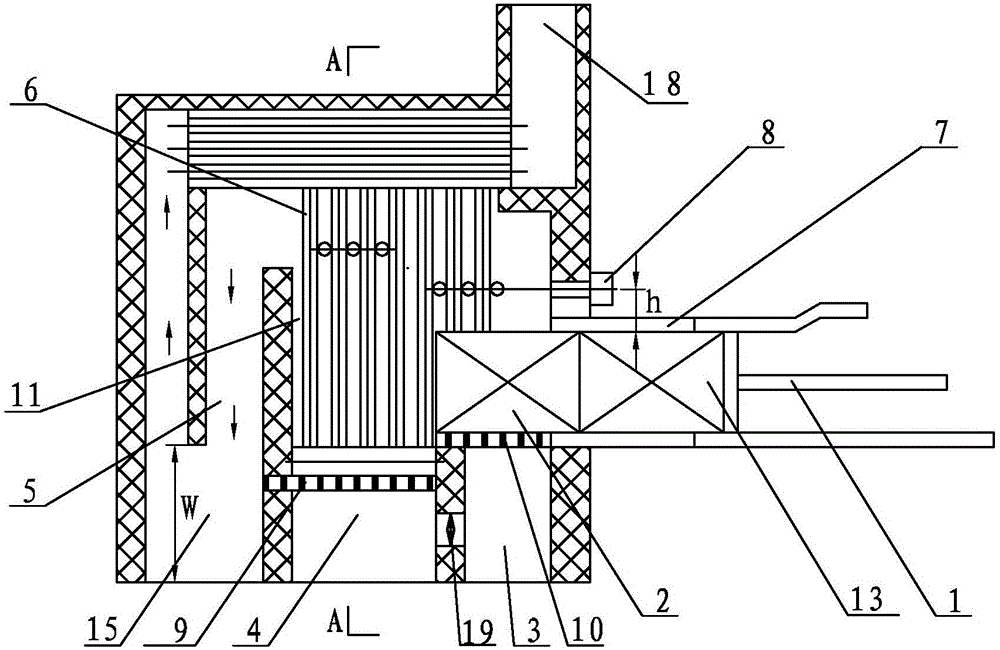

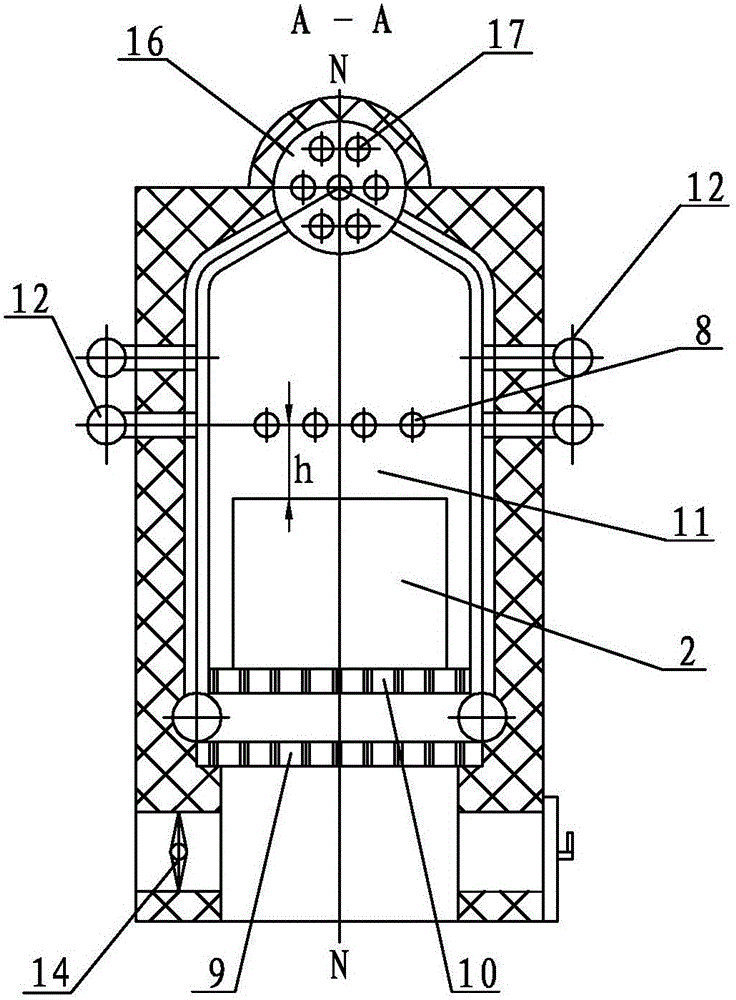

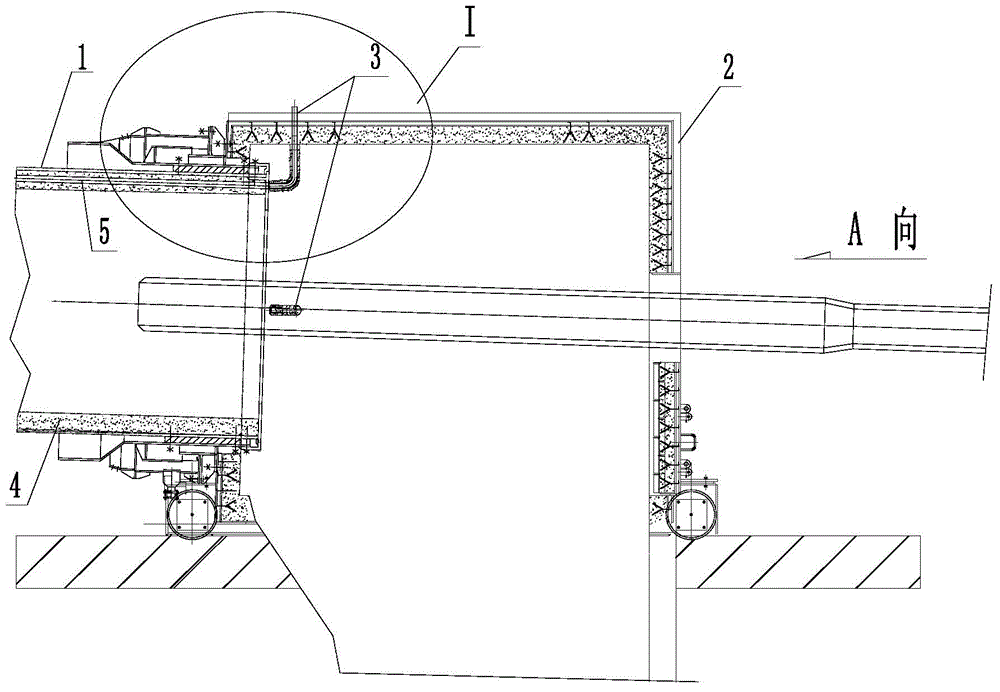

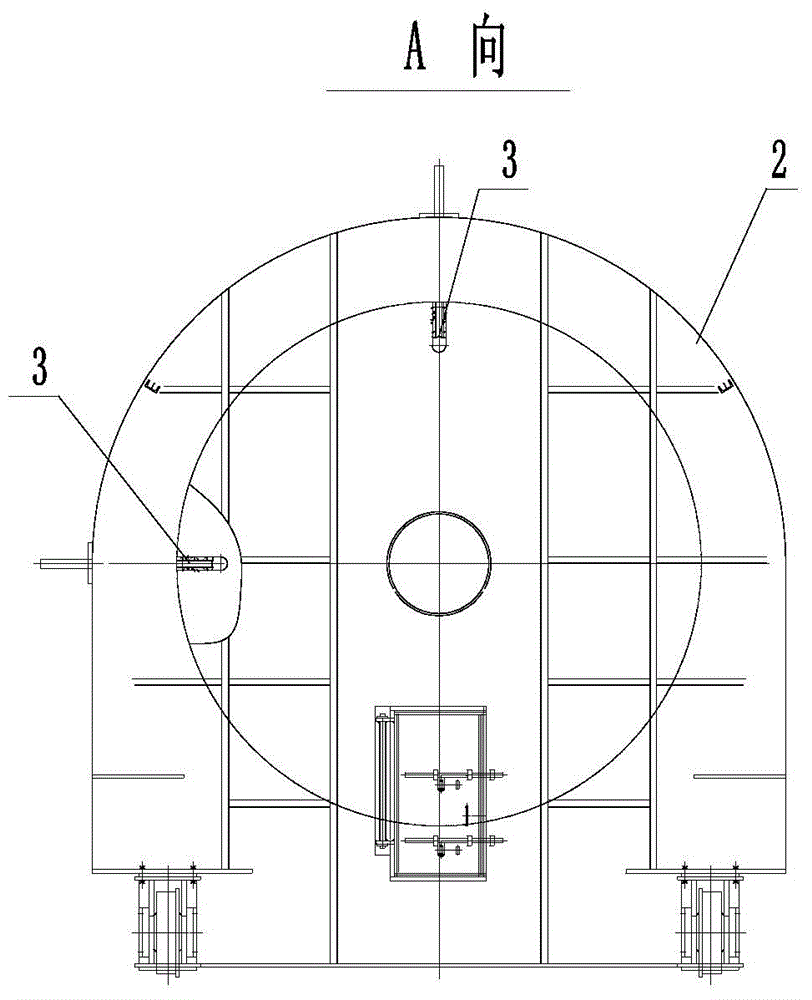

Coal-fired decoupling combustion apparatus and combustion method

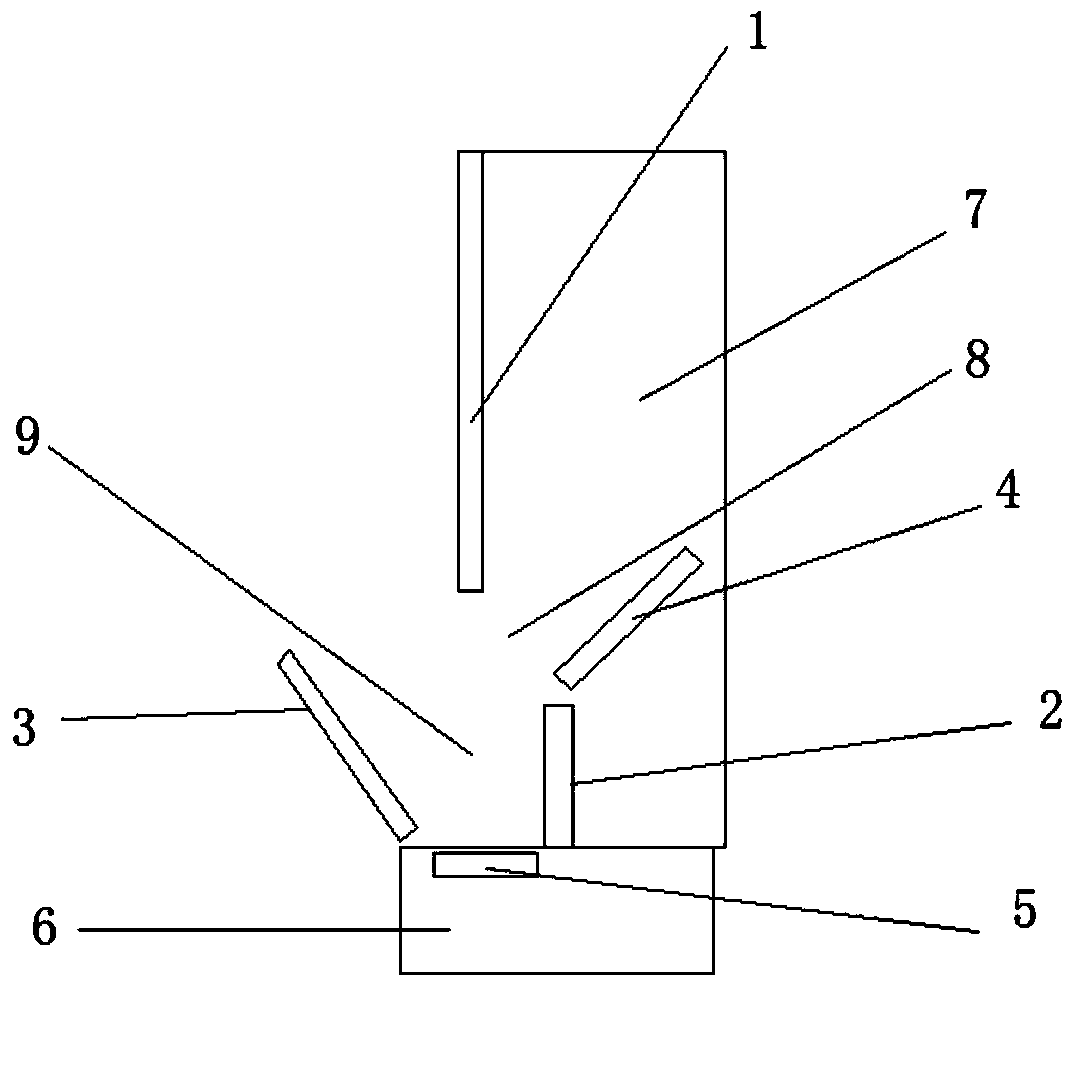

ActiveCN103471089AReduce harmful air leakageFully burnt outSolid fuel combustionIndirect carbon-dioxide mitigationCombustionStructural engineering

The invention belongs to the field of raw-coal combustion equipment, and particularly relates to a coal-fired decoupling combustion apparatus and a combustion method. The coal-fired decoupling combustion apparatus comprises a furnace and an air chamber (6) positioned below the furnace; the furnace comprises an upper partition wall (1), a first lower partition wall (2) and a second lower partition wall (3), the first lower condition wall (2) and the second lower partition wall (3) are respectively arranged below the inner lower side and the outer side of the upper partition wall (1), a first grate (4) is erected between the top of the inner first lower partition wall (2) and a side wall of the furnace, and a second grate (5) is arranged between the bottom of the first lower partition wall (2) and the bottom of the second lower partition wall (3); a gasification pyrolysis zone (7) and a semi-coke zone (8) are formed between space above the first grate (4) and the upper partition wall (1), and the semi-coke zone (8) is positioned below the gasification pyrolysis zone (7); a coke zone (9) is formed by the first lower partition wall (2) and the second lower partition wall (3). The coal-fired decoupling combustion apparatus and the combustion method have the advantages that a rate of harmful air leakage and an excess air coefficient can be reduced; the harmful air leakage in the semi-coke zone can be effectively reduced, and the capacity and the efficiency of a boiler can be guaranteed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Incinerator for processing pulping foul gas in paper mills

The invention relates to an incinerator for processing pulping foul gas in paper mills, belonging to machinery. The incinerator is composed of a cylinder burning system, a support structure, a fan, an air duct, a pipeline and a valve, wherein the cylinder is composed of an inner cylinder and an outer cylinder; an interlayer is formed between the inner cylinder and the outer cylinder; a flow guide plate is arranged in the interlayer and connected with the inner cylinder and the outer cylinder; the burning system is composed of a main burner and a foul gas burner; the main burner and the foul gas burner are connected to the bottom of the cylinder through flanges; the main burner is positioned at the center of the bottom of the cylinder; the spouts of the main burner are perpendicular to the foul gas burner and annularly arranged around the main burner; and the cylinder is perpendicularly fixed above an alkali recovery boiler by the support structure. The incinerator for processing foul gas has the advantages of reasonable structure, convenient use and operation, can be matched with the alkali recovery boiler, and can also be independently used for long-time service when the alkali recovery boiler stops working. The incinerator is suitable for processing pulping foul gas in paper mills by incineration, and can also be widely used for processing other similar harmful waste gases.

Owner:湖北盘古环保工程技术有限公司

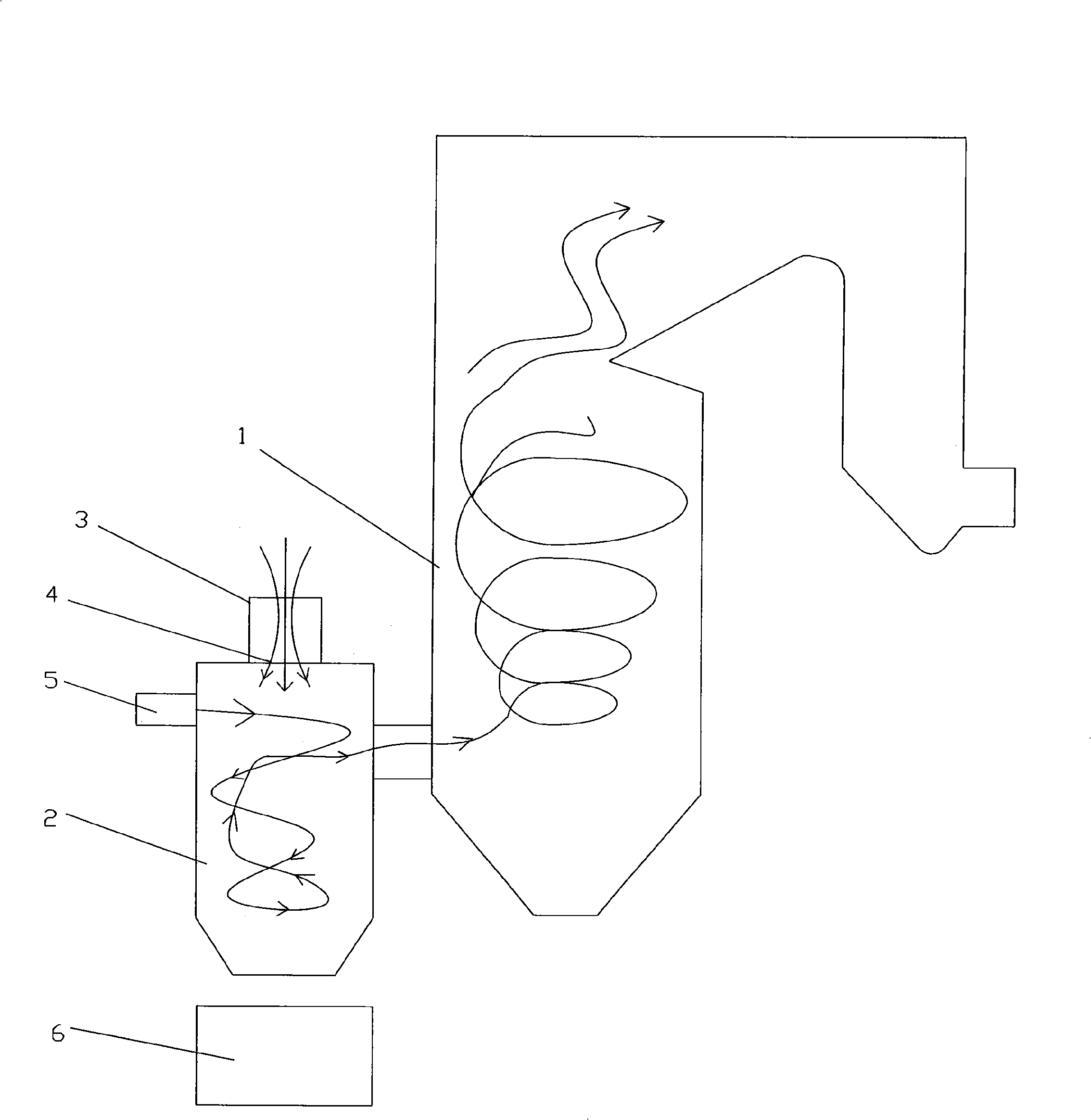

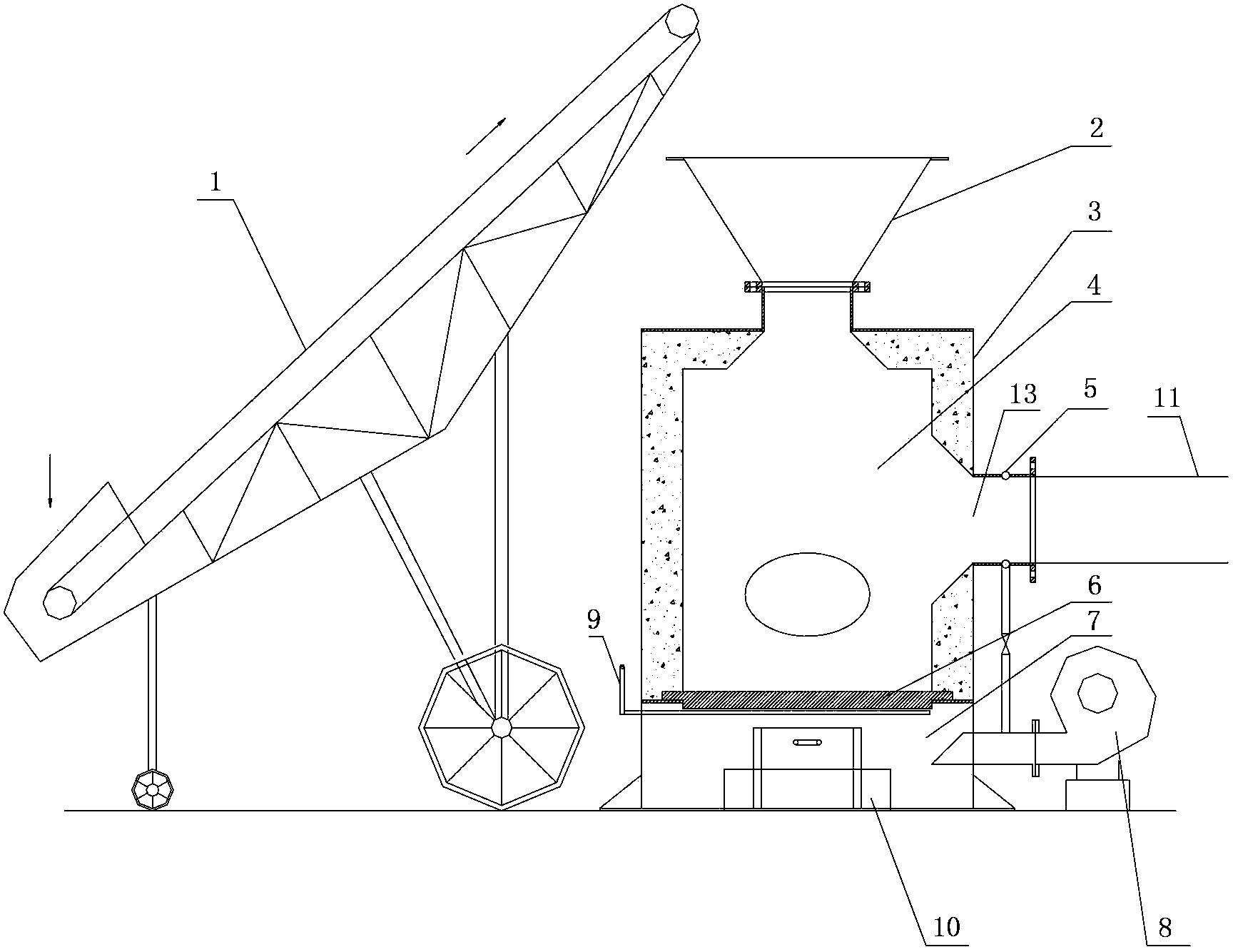

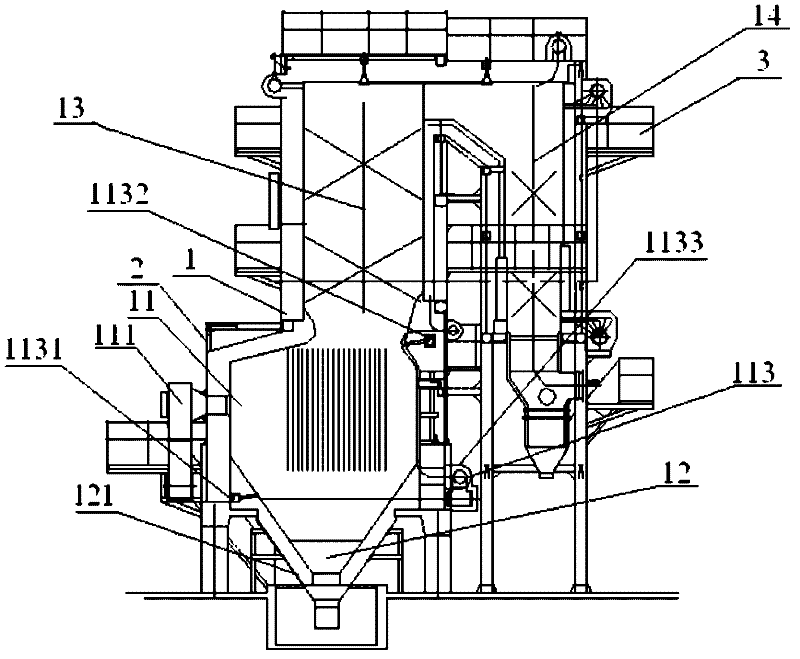

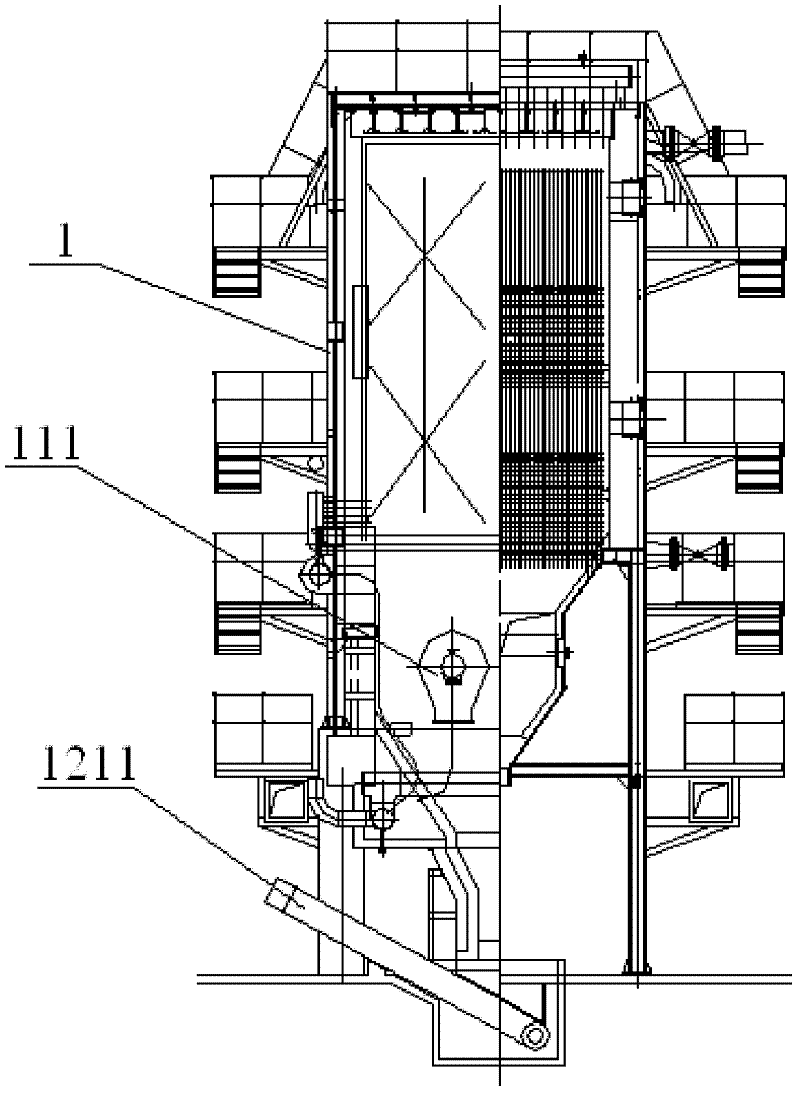

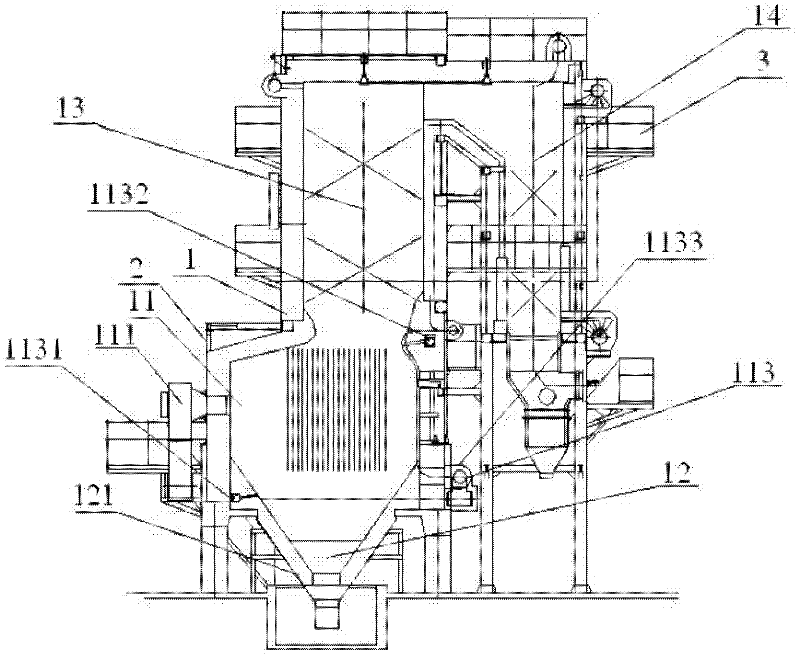

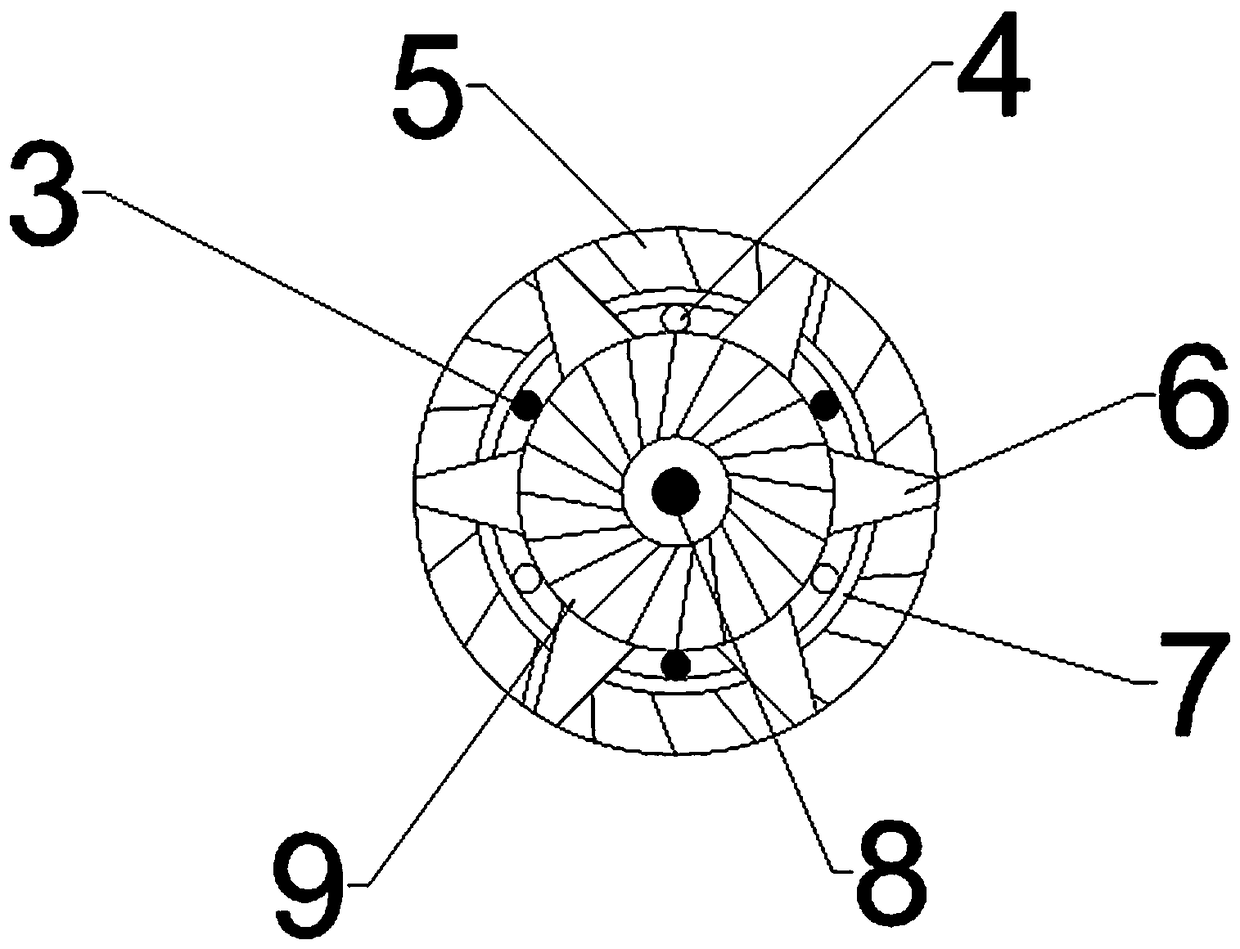

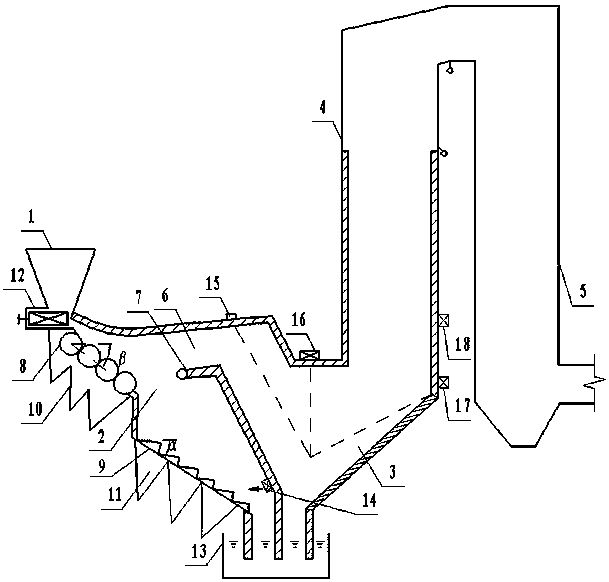

Station boiler anthracite powder combustion plant

InactiveCN101334162ACatch fire quicklyFully burnt outCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention relates to an anthracite powder combusting device of a utility boiler. The anthracite powder combusting device comprises a boiler furnace (1), wherein, a cyclone combustion tube (2) is installed at the rear part of the boiler furnace (1), a spraying gun inside a combusting chamber (3) through which the anthracite powder is rotated and sprayed into the cyclone combustion tube (2) at high speed is arranged at the upper part of the cyclone combustion tube (2), and a one-time tangential air supplying outlet (4) for feeding the required air of the anthracite powder is arranged above the cyclone combustion tube (2). A two-time tangential air supplying outlet (5) for feeding the air required to ensure the thorough combustion of the anthracite powder after firing is arranged on the furnace wall of the combusting chamber of the cyclone combustion tube (2). The anthracite powder combusting device adopts a structure of combined rotating flow type combustor and unidirectional flow type combustor, thus the advantages of the rotational flow type combustor and the unidirectional flow type combustor are integrated, and the anthracite powder can not only be rapidly ignited but also be sufficiently combusted, therefore, the efficiency of the boiler can be effectively enhanced. The anthracite powder combusting device has the advantages of reasonable design, simple structure and convenient operation, thereby being an anthracite powder combusting device of the utility boiler which can ensure the anthracite powder to be directly burnt out and has more remarkable social efficiency and economic efficiency.

Owner:GUANGDONG UNIV OF TECH

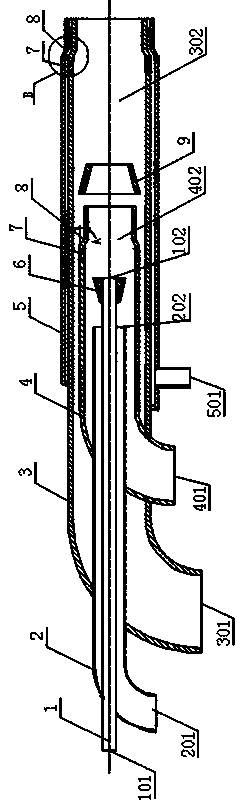

Self-stabilizing staged combustion pulverized coal burner

PendingCN108870385AStable supplyStable flow ratePulverulent fuel combustion burnersCombustionStaged combustion

The invention discloses a self-stabilizing staged combustion pulverized coal burner. The self-stabilizing staged combustion pulverized coal burner comprises, from inside to outside, a burning torch, aprimary pulverized coal air pipe, a burnout air distributing pipe, a secondary pulverized coal air pipe and a surrounding air pipe, wherein the burning torch and the primary pulverized coal air pipeare in sliding sleeve connection; the nozzle of the burning torch is provided with a burning oil nozzle and a choke plug; the outside of the air outlet section of the primary pulverized coal air pipeis connected in a sleeve mode with the burnout air distributing pipe; outside the primary pulverized coal air pipe and the burnout air distributing pipe is provided in a sleeve mode with the secondarypulverized coal air pipe; the outside of the secondary pulverized coal air pipe is connected in a sleeve mode with the surrounding air pipe; the front ends of the air outlets of the burnout air distributing pipe, the secondary pulverized coal air pipe and the surrounding air pipe are all provided with reducing joint sections. The self-stabilizing staged combustion pulverized coal burner is simplein structure, convenient and rapid to operate, high in economic practicability, energy-efficient and environmentally friendly, and can achieve graded control, two-stage combustion and oil-free combustion stabilization. Meanwhile, the self-stabilizing staged combustion pulverized coal burner is high in pulverized coal burnout rate, long in flame adjusting stroke, efficient and stable in boiler operation and good in popularization prospect.

Owner:贵州富燃环保科技有限公司

Household direct-fired heating appliance using compressed straw as fuel

ActiveCN104879785AStable feedingReduce frictional resistanceLighting and heating apparatusStove/ranges for heating waterCombustion chamberSmoke

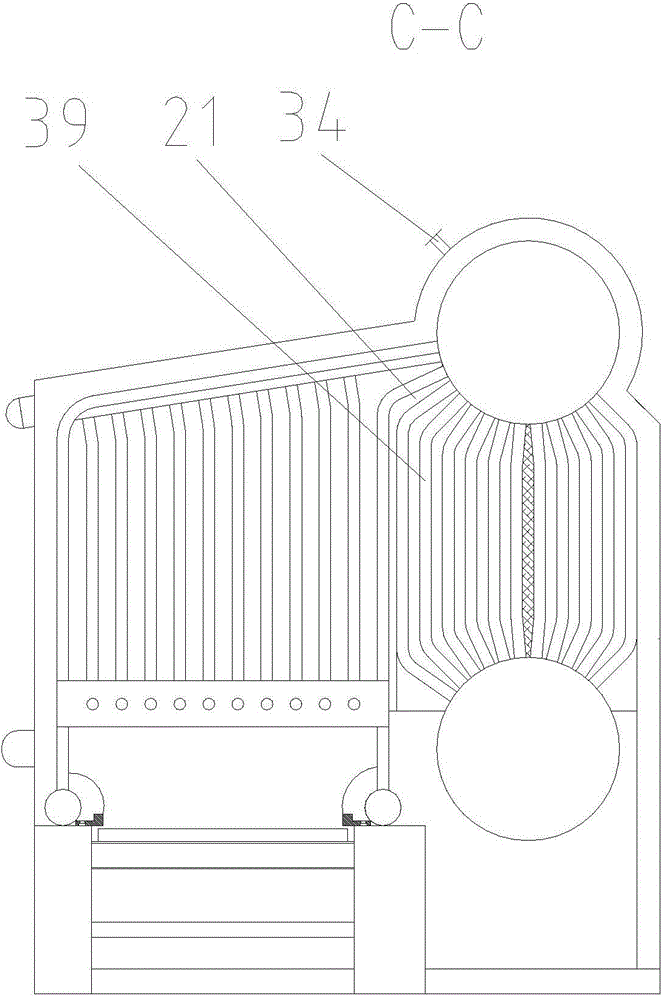

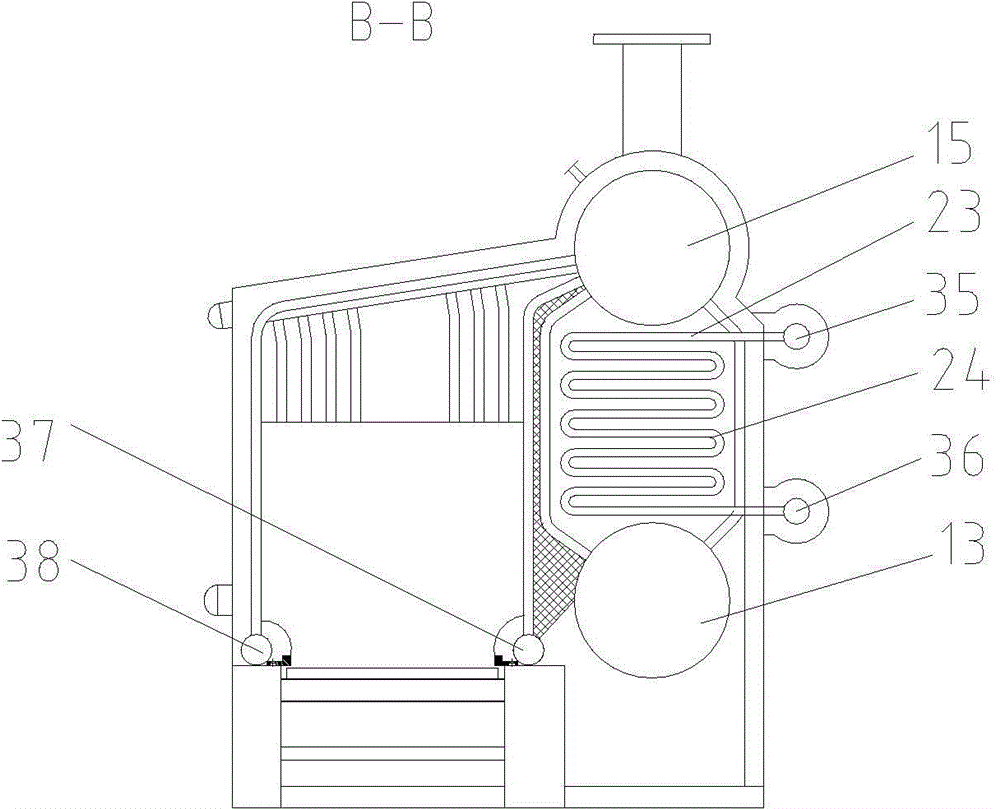

The invention relates to a household direct-fired heating appliance using compressed straw as fuel. The household direct-fired heating appliance comprises a heating furnace and an automatic feeder, which form an H-shaped structure and which are connected through a material pass. The upper structure of the heating furnace comprises the material pass, a smoke pass, a smoke window, a water jacket, a water-cooled grate, a convection bank, a balance tube, a water-cooled partition, an anti-radiation retainer, and a waste heat recovery water jacket. The lower structure of the heating furnace comprises a rocking grate, a combustion pass, a secondary air chamber, an insulation layer and an ash hopper. A combustion chamber comprises a main chamber and a secondary chamber. The automatic feeder comprises a speed control motor, a coupling, a screw, stirring blades, a tray, rollers, a limiting switch, a control circuit box, a motor box, and a fuel box. The automatic feeder can continuously and automatically convey the compressed straw for 12 hours; the compressed straw slips into the heating furnace through the material pass; the heating furnace combusts efficiently and stably. The household direct-fired heating appliance is high in combustion efficiency, low in pollutant emission, simple to operate, low in cost and widely applicable.

Owner:HEBEI UNIV OF TECH

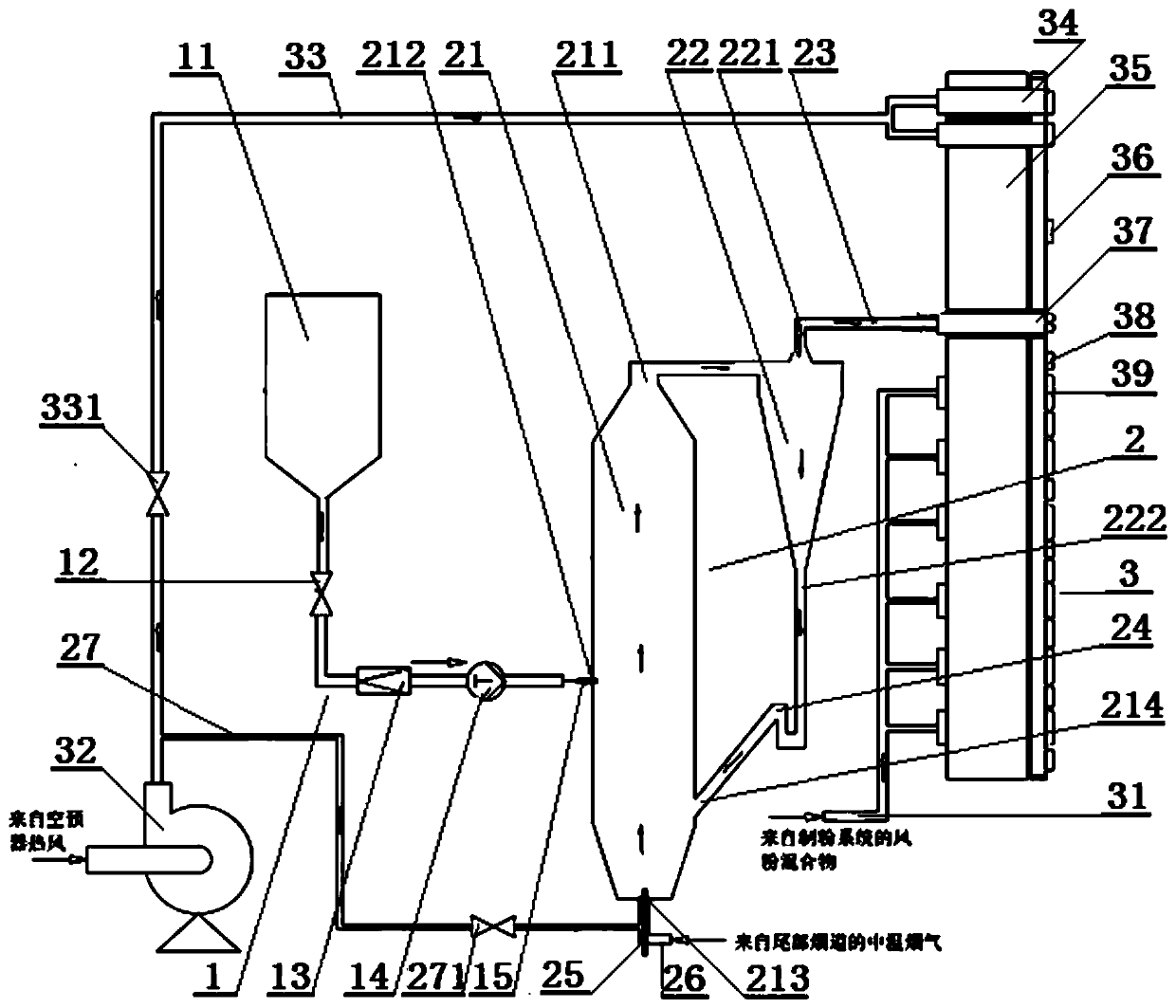

Composite reducing type low NOx emission device suitable for power station boiler

PendingCN111140865ACurb emissionsReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoal waterPower station

The invention relates to a composite reducing type low NOx emission device suitable for a power station boiler. The composite reducing type low NOx emission device comprises a coal water slurry generation mechanism, a coal water slurry pyrolytic reaction mechanism and a composite reducing type combustion device, wherein the coal water slurry generation mechanism has the function of treating coal powder into coal water slurry and is internally provided with a coal water slurry tank, the coal water slurry pyrolytic reaction mechanism has the function of pyrolysis generation of pyrolysis gas withreducing active components and is internally provided with a pyrolysis reactor and a cyclone separator, and the composite reducing type combustion device has the function of deeply reducing of NOx incombustion smoke. By adoption of high-speed separation air and the proper over fire air rate, the created oxygen content in the combustion area is smaller than 1%, the NOx generated low-oxygen area in combustion can be restrained, a composite spraying port is utilized for conveying pyrolysis gas generated through the coal water slurry pyrolytic reaction and internally containing reducing active components and ammonia into the area, the reducing reaction with NOx in smoke happens in the reducing atmosphere, the limitation of usage of a temperature window during NOx reducing through a conventional reducing agent is broken through, furnace interior efficient combustion and economical reducing are ensured, the NOx concentration in smoke is totally reduced, and NOx ultra-low emission of a coalpowder combustion furnace is achieved.

Owner:SHANGHAI JIAO TONG UNIV

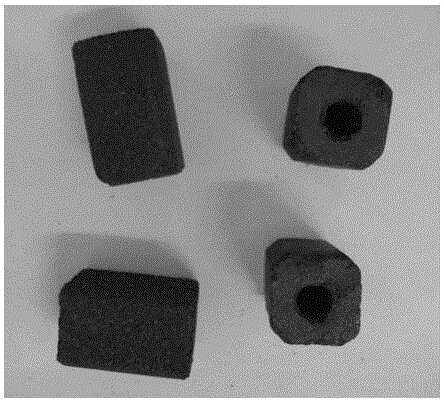

Coal-quality machine-made charcoal preparation method

InactiveCN106318504AReduce manufacturing costExtensive sources of raw materialsBiofuelsSolid fuelsBrown coalChemistry

The invention belongs to the technical field of machine-made charcoal and relates to a coal-quality machine-made charcoal preparation method. The method includes: crushing brown coal and biomass charcoal into 0.1-2mm of brown coal particles and biomass charcoal particles respectively; charring the 0.1-2mm of brown coal particles at 600-800 DEG C for 4-8h under a condition of air isolation, and cooling to the room temperature to obtain carbides; well mixing the carbides, the biomass particles and adhesives according to a mass ratio of 60-95:0-35:2-5, adding water, and well mixing to obtain mixed materials, wherein moisture in the mixed materials is controlled to be 10-15% of the mass of the mixed materials; subjecting the obtained mixed materials to compression moulding under a pressure of 0.5-1MPa, and drying at 100-200 DEG C to obtain coal-quality machine-made charcoal. The coal-quality machine-made charcoal prepared according to the method is low in cost, environment friendly and excellent in combustion performance.

Owner:KUNMING UNIV OF SCI & TECH

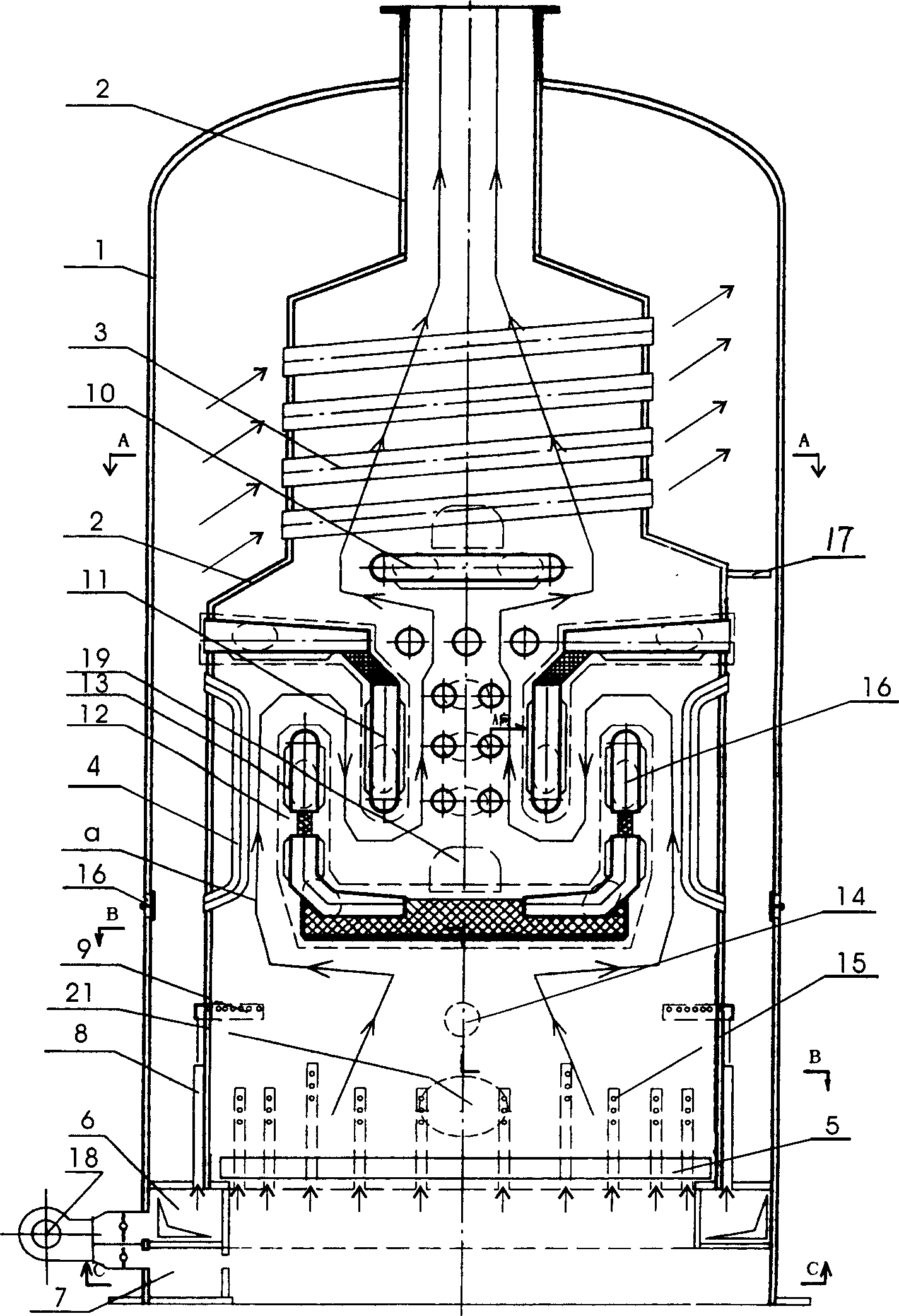

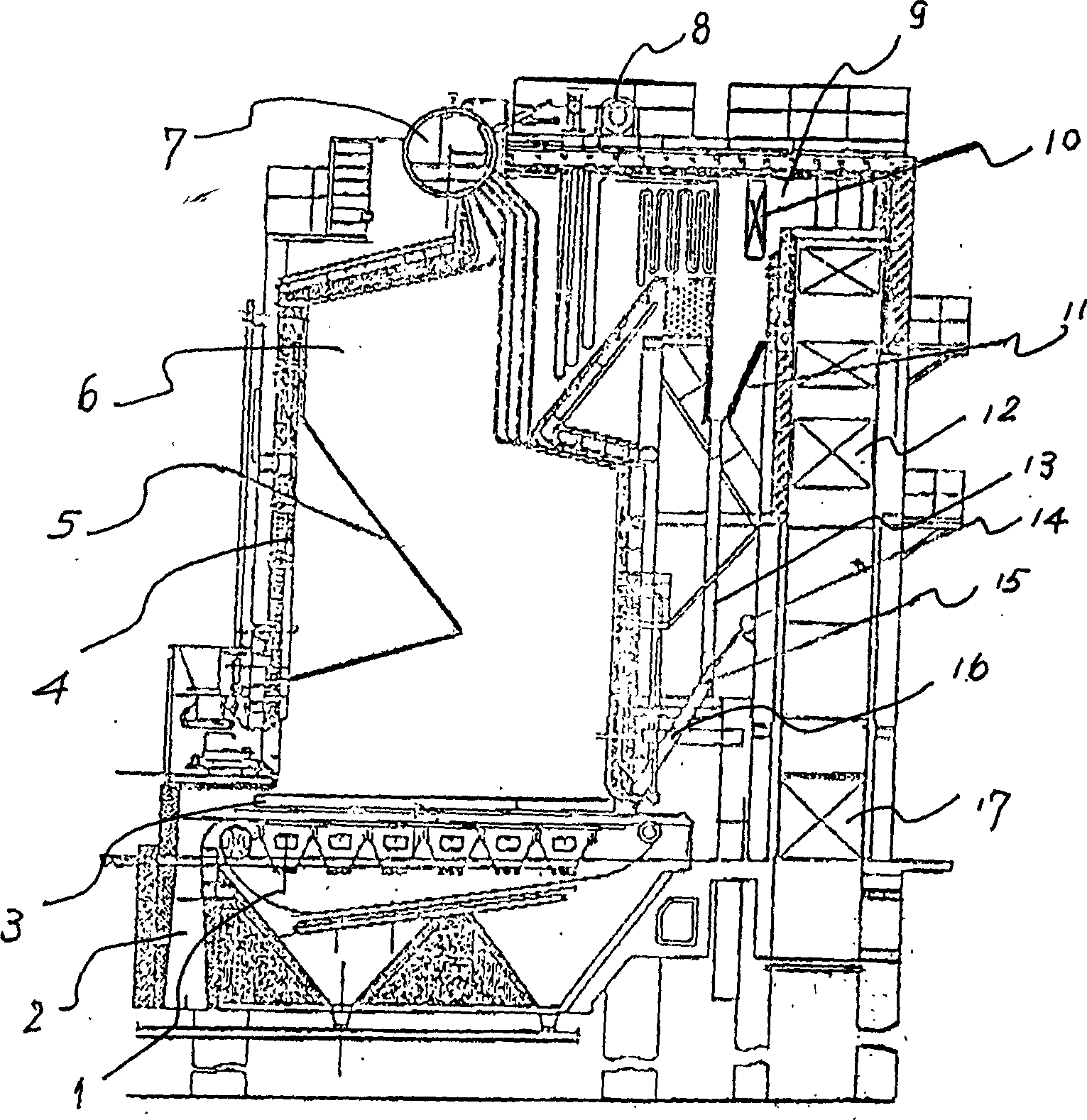

Three return stroke half fire coal, fuel oil and gas-fired smokeless boiler

InactiveCN1670431AEasy to manufactureMaintain stiffnessSolid fuel combustionWater heatersDust controlEngineering

This invention relates to a three return travel half coal, oil and gas fuel smokelessness boiler. It includes boiler external cylinder, inner bag shell, multiple horizontal siphonal areas, water cold wall pipe, and combination furnace arch and fire grate. Its feature is that annular secondary air bellows and arched first air bellows are fixed under fire grate, the secondary air bellow is interconnected to vertical quadric air manifold set along furnace outer wall, semilunar horizontal air pipe is set under arched high temperature fume outlet at both sides of furnace. The combination furnace arch is consisted by yi form up furnace arch, inverse L form middle arch and concave down arch. The three arches are all formed by combination of horizontal cleet water cover and vertical cleet water cover and plugging cleet water cover connecting through fire bricks, and malpositioned in inner bag shell, three return travel flue is formed under up furnace arch. Both sides of up parts of inner bag shell shrink entad to form two segment special form barrel of vertical upright faces. Up part horizontal pipe is put up between two vertical upright faces. Bituminous coal smokelessness burning technique and inner furnace smoke prevention and dust control technique is formed by the boiler in this invention and air distribution burning technique and multifunction furnace arch structure. Coal cleanliness burning smokelessness boiler is formed by the combination of bituminous coal smokelessness burning technique and three return half coal process. Its heat efficiency is high when running longtime, energy saving effect is great, discharging of polluting matter is low, and the oil and gas fuel boiler is achieved.

Owner:畲顺元

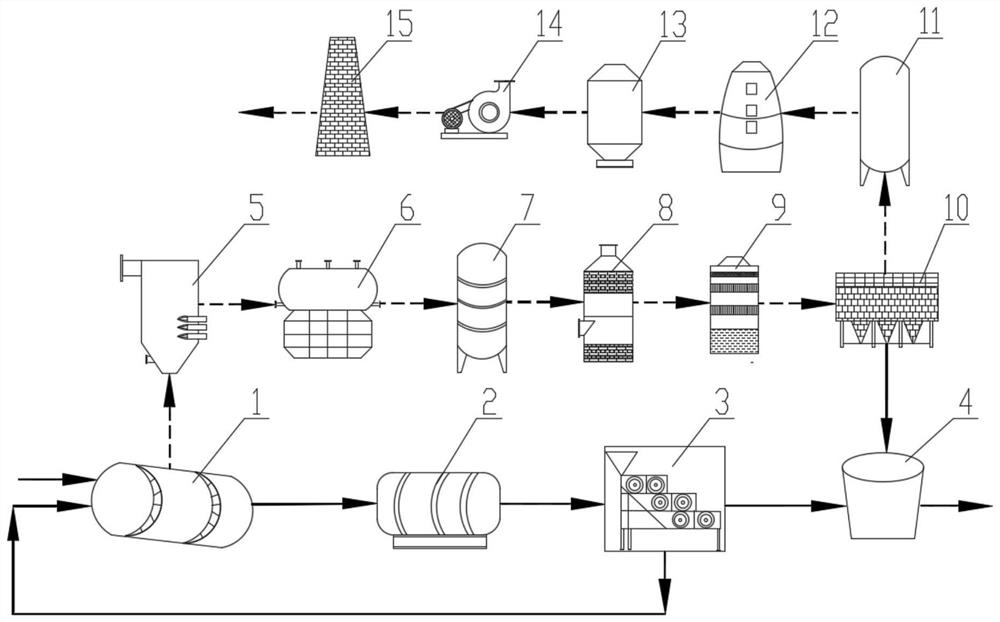

Method for treating hazardous waste by utilizing oxygen carrier to assist combustion in rotary kiln

The invention discloses a method for treating hazardous waste by utilizing an oxygen carrier to assist combustion in a rotary kiln. The method comprises the following steps that the oxygen carrier andthe hazardous waste are reasonably matched and then added into a main combustion chamber of the rotary kiln, the uniformity of oxygen distribution in the main combustion chamber is improved accordingto the oxygen absorption and release characteristics and the catalytic performance of the oxygen carrier, the hazardous waste and oxygen are fully mixed in time and space, the combustion efficiency is improved, and generation and emission of harmful gases in the main combustion chamber are reduced; ash slag which contains the oxygen carrier and is discharged from the rotary kiln passes through aslag cooler and then enters a separation device, the oxygen carrier is separated from the ash slag and then conveyed to the rotary kiln, and cyclic utilization of the oxygen carrier is achieved; and the ash slag is conveyed out for melting treatment. By means of the method, sufficient combustion and complete combustion of the hazardous waste are promoted, the uniformity of oxygen and temperature distribution in the main combustion chamber is improved, and the problems that according to an existing rotary kiln incineration technology, the flue gas emission concentration is unstable and exceedsthe standard frequently are solved.

Owner:SOUTHEAST UNIV

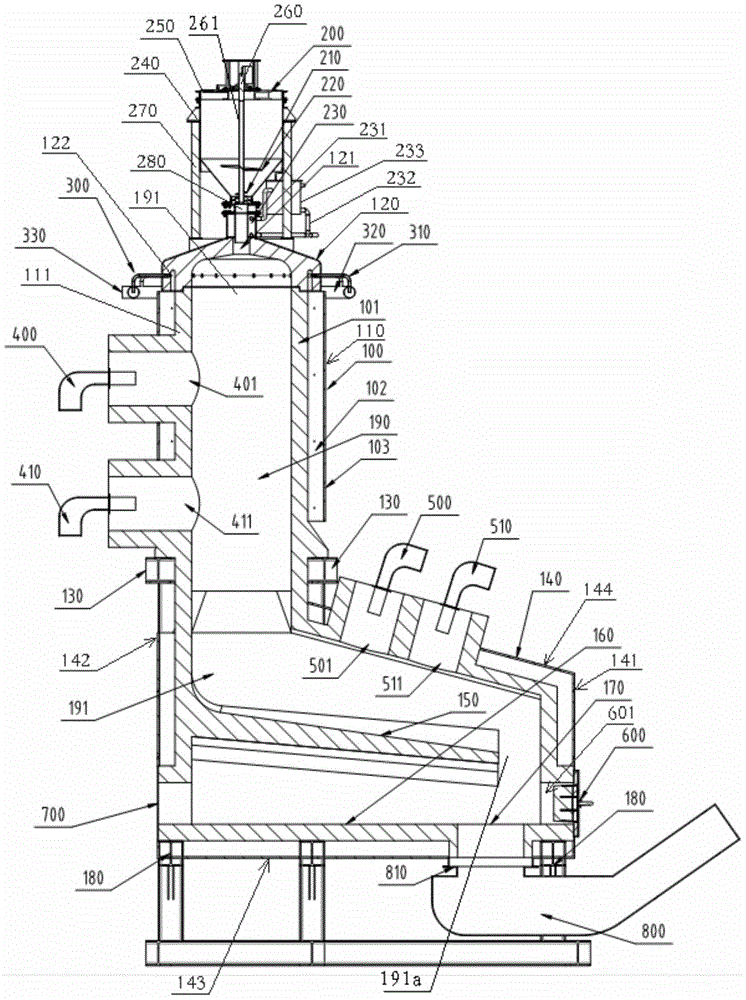

Heat storage ash melting device

The invention discloses a heat storage ash melting device, comprising a furnace body; the upper half part of the furnace body is a cylindrical upright furnace body; the lower half part of the furnace body is a box furnace body; the whole box furnace body is in a structural mode with a higher rear part and a lower front part. A cylindrical upright hearth is arranged in the cylindrical upright furnace body, a retracing horizontal hearth is arranged in the box furnace body; a heat storage ash melting bed is arranged in the retracing horizontal hearth; a furnace top cover is arranged above the cylindrical upright furnace body; a feeder and an oxygen supply device are arranged on the furnace top cover; two furnace starting combustion supporting burners are arranged at the rear wall of the cylindrical upright furnace body; two temperature control burners are arranged on a furnace arch of the box furnace body; a round cork furnace door and a fume outlet are arranged on the front wall and rear wall of the box furnace body respectively; a slag discharge port is formed in the furnace bottom of the box furnace body and is jointed with a water cooling slag extractor. The heat storage ash melting device is an ash melting technology with high adaptive capacity, good operation benefits and capability of ensuring ash melting quality.

Owner:上海煜工环保科技有限公司

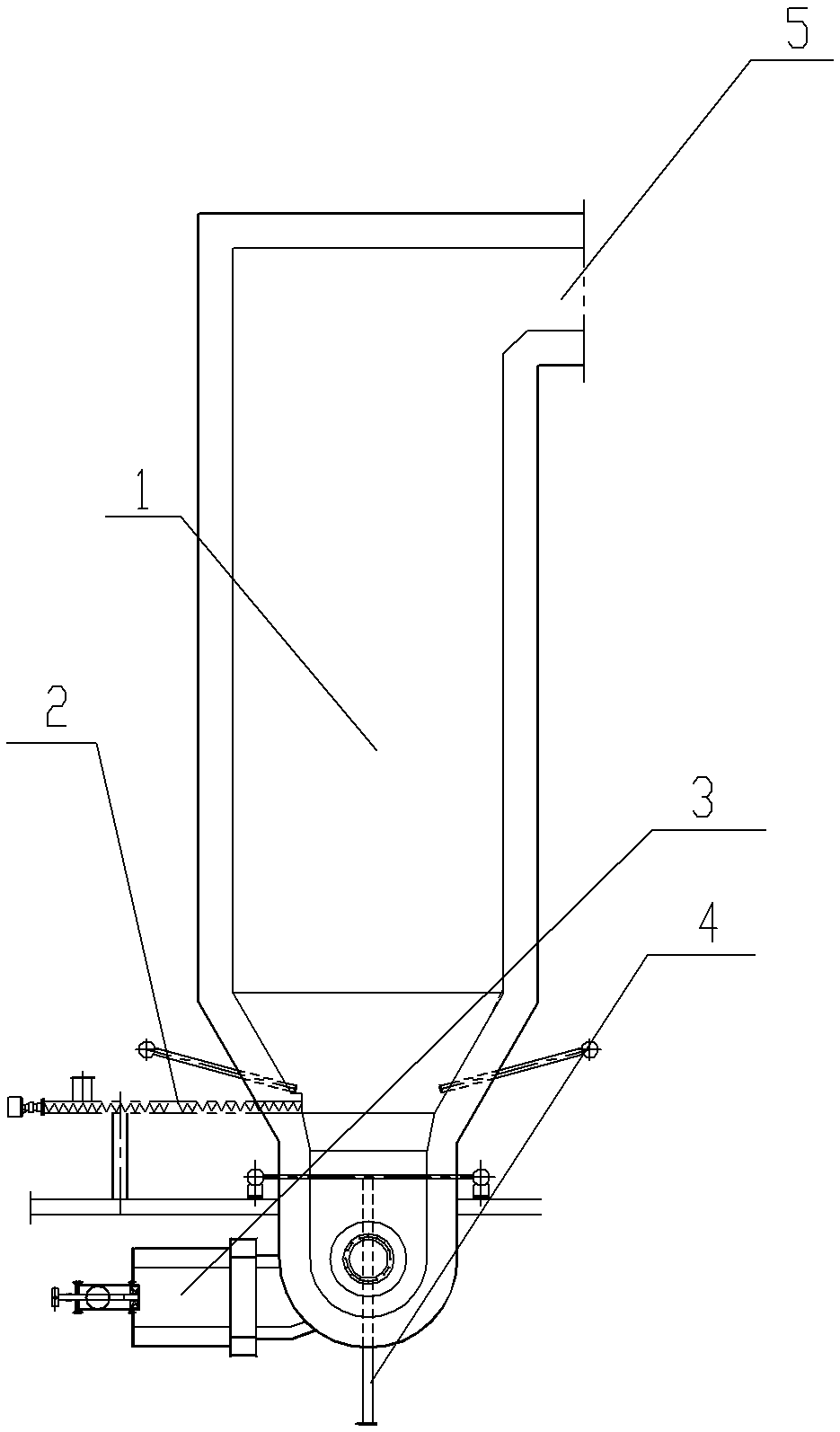

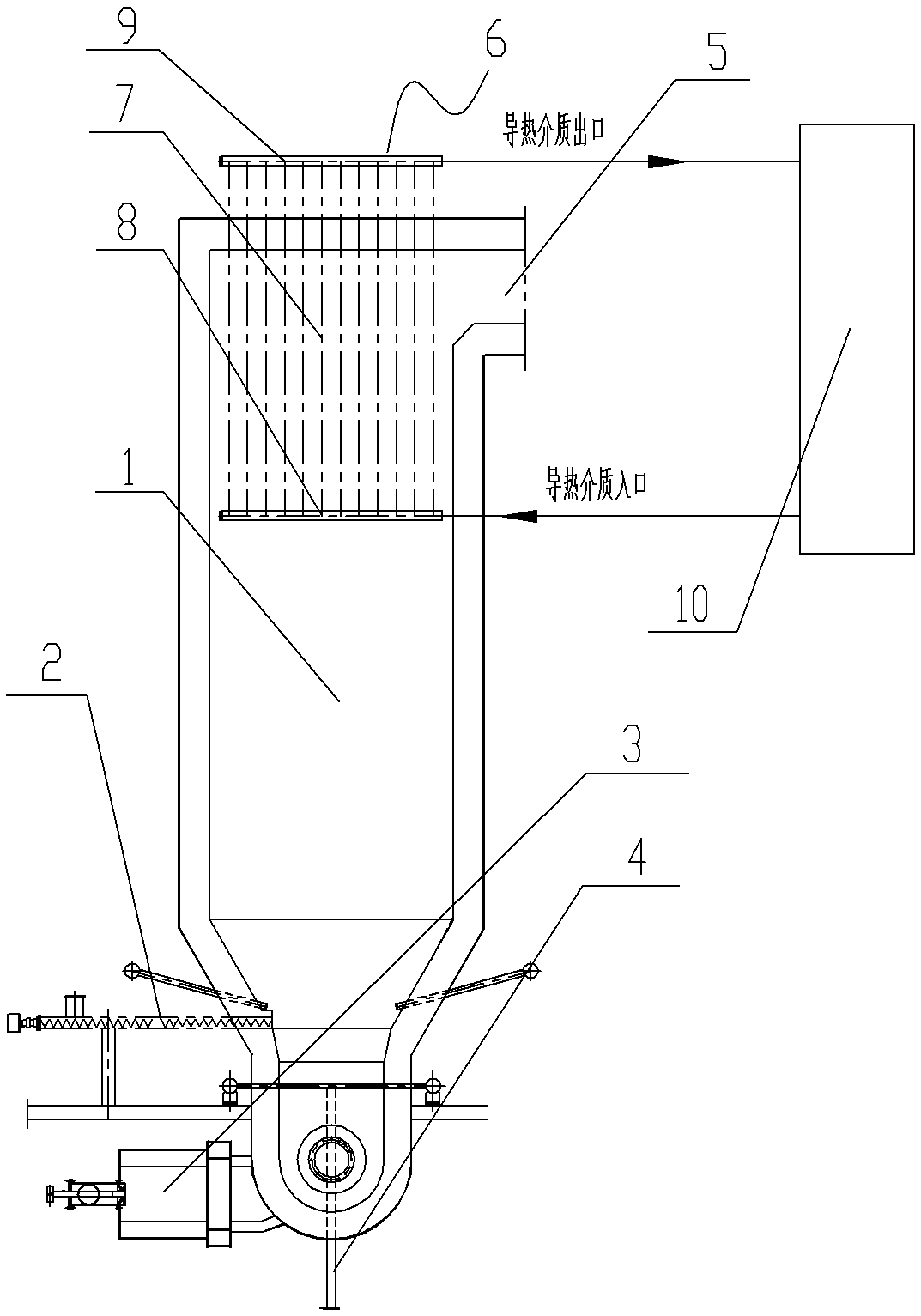

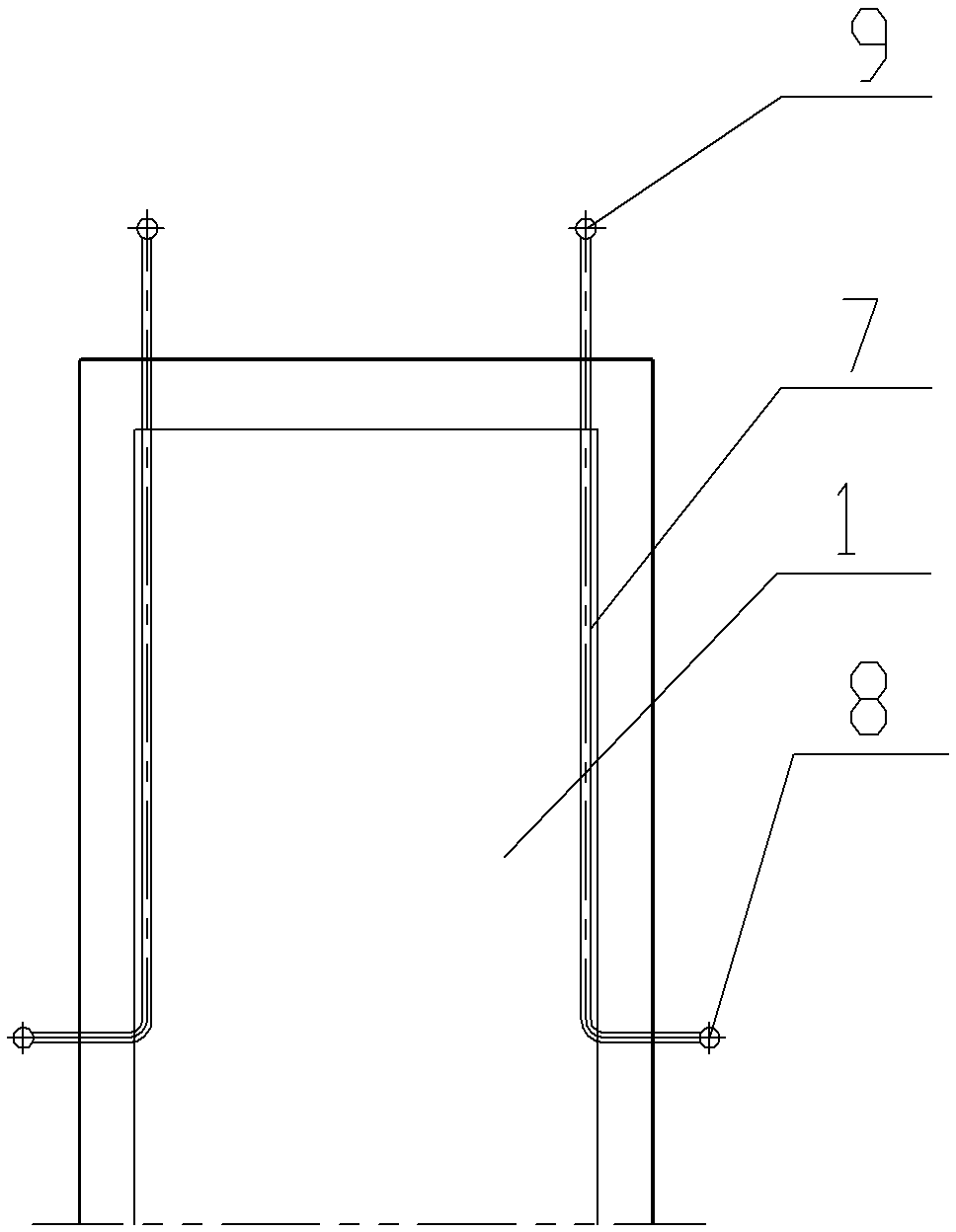

Sludge incinerator structure

PendingCN107796004AFully burnt outReduce generationIncinerator apparatusThermal insulationHeat conducting

The invention relates to the technical field of sludge incineration, in particular to a sludge incinerator structure, which is simple in structure, low in cost and excellent in cooling effect, and guarantees the combustion effect. The sludge incinerator structure comprises a thermal insulation hearth; the lower end of the thermal insulation hearth is connected with a sludge feeding mechanism, an under-bed ignition device and a slag discharge pipe; and the side surface of the upper end of the thermal insulation hearth is provided with a high-temperature flue gas outlet. The sludge incinerator structure is characterized in that a heat conducting device is arranged in the part, at the high-temperature flue gas outlet, of the thermal insulation hearth; the heat conducting device comprises heatconducting pipes; one end of each heat conducting pipe penetrates through the side wall of the thermal insulation heath and is connected with a heat conducting medium inlet pipe; and the other end ofeach heat conducting pipe penetrates through the top of the thermal insulation hearth is connected with a heat conducting medium outlet pipe.

Owner:WUXI HUAGUANG BOILER

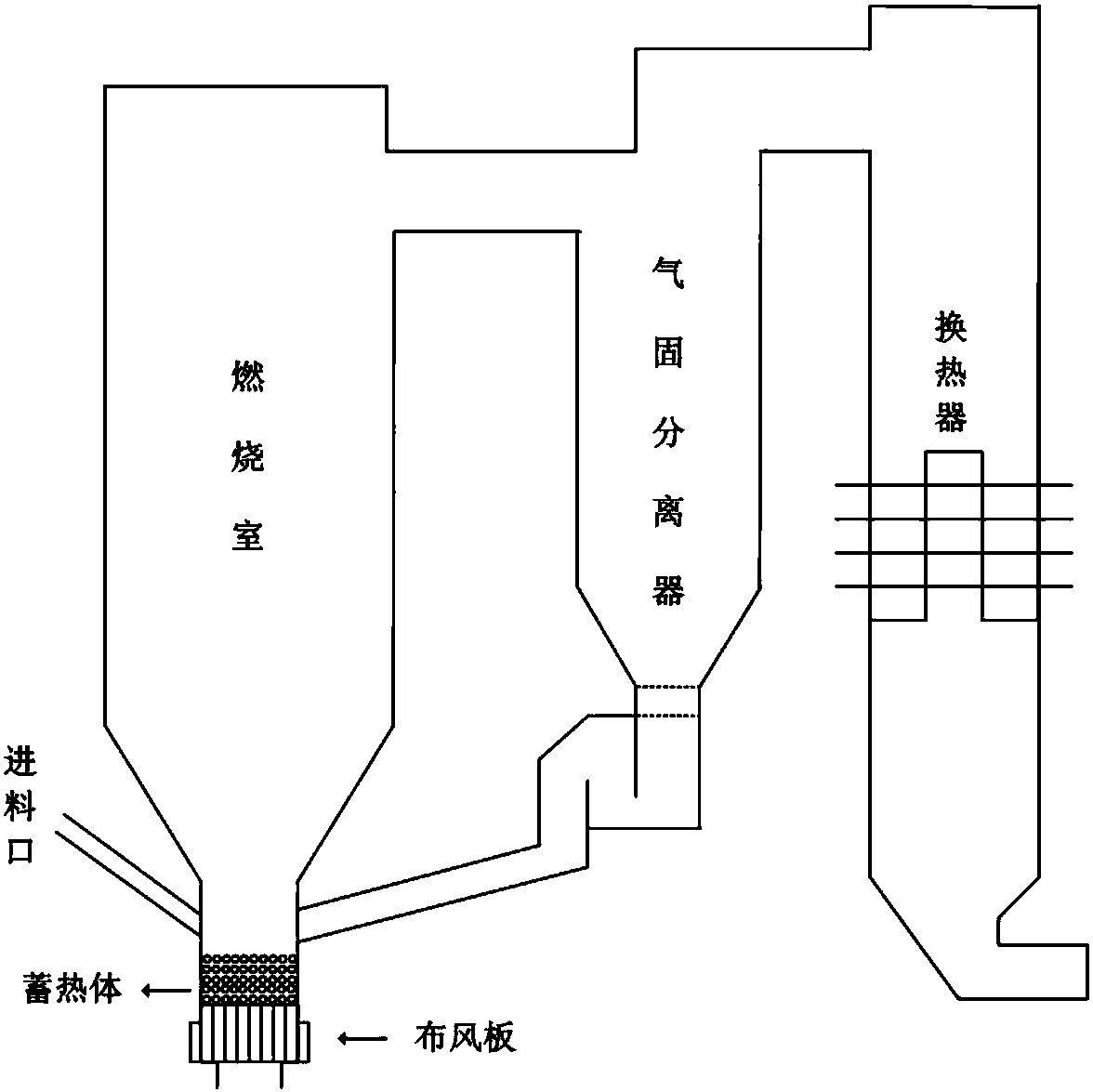

Method for promoting stable burning of biomass fuel and used for burning of fluidized bed

InactiveCN108800113ANot meltNon-condensingFluidized bed combustionApparatus for fluidised bed combustionAir preheaterEngineering

In biomass fluidized burning, a heat storage body needs to be added because the ash content of the biomass fuel is low, and the burnout residue is not enough to form a bed material. The fluidized windis difficult to control, and the burning is unstable due to the fact that accumulation density of a current heat storage body is far from that of the biomass, the back end equipment of a boiler is caused to be sticky to dust and worn, or the rear of the boiler is clogged and coking. According to a method for full burning of the biomass fluidization, by using an inorganic porous and lightweight natural or man-made materials resistant to high temperature as the heat storage body, the accumulation density of the heat storage body is 200-1500 Kg / m3, similar to the biomass raw materials, the heatstorage body is laid on a furnace wind arraying plate, through the air blowing of an air blower, the fluidized and stable burning with the biomass is achieved, and the problems that dust sticking of awater flow bundle, a superheater, an economizer, an air preheater due to the biomass fuel blended within the smoke as well as the blockage and coking caused by the local high temperature at the bottom of the boiler can be avoided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

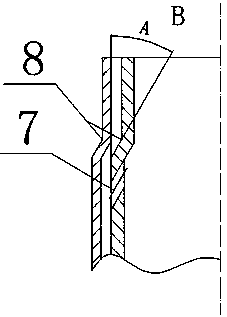

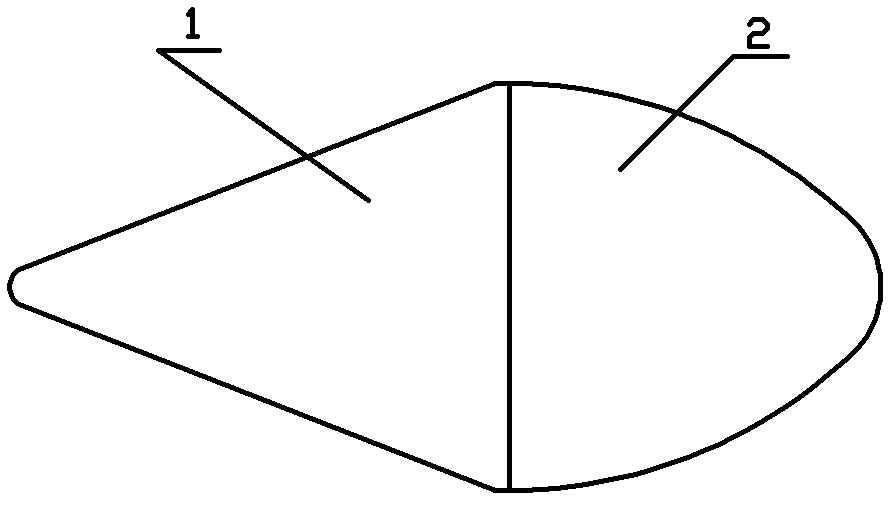

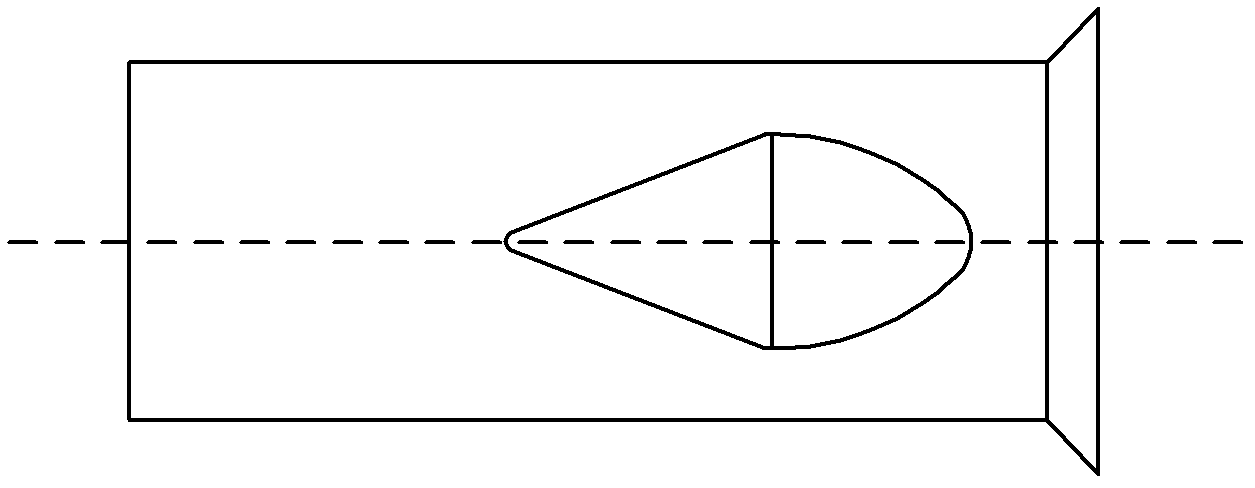

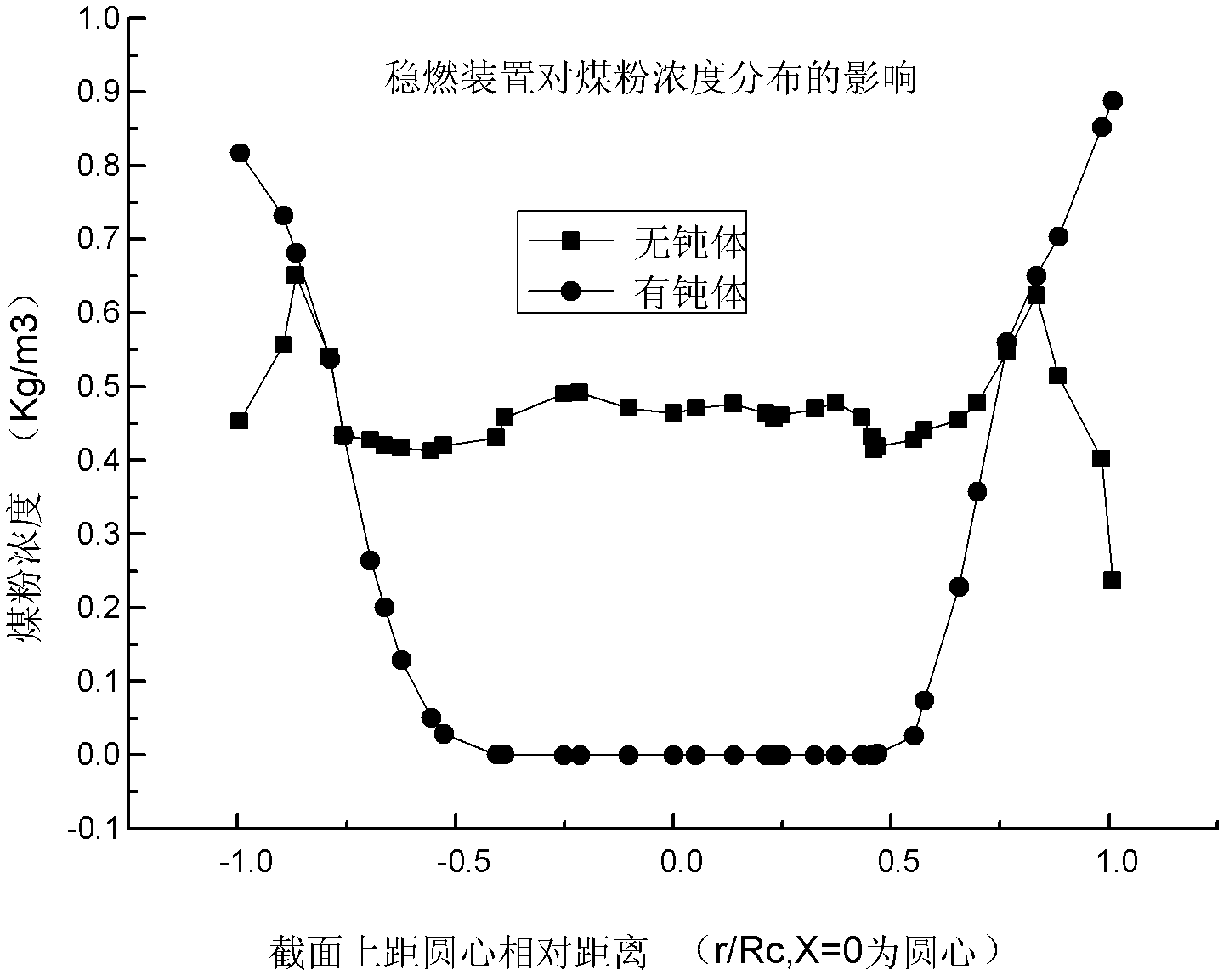

Low-oxynitride and low-load stable combustion device of turbulent combustor

InactiveCN102322636AImprove adaptabilityCatch fire quicklyPulverulent fuel combustion burnersEngineeringCoal particle

The invention belongs to the technical field of turbulent combustors of power plants, and in particular relates to a low-oxynitride and low-load stable combustion device of a turbulent combustor. The stable combustion device comprises two parts, namely, a ramming member and a vortex suppression member, wherein the ramming member is in a conoid structure, and the vortex suppression member is a streamlined structure body formed by two circular-arc surfaces. The stable combustion device is arranged near an outlet of a primary air pipe of the turbulent combustor; and when pulverized coal airflow passes through the stable combustion device, pulverized coal particles are gathered towards an outer ring of the primary air pipe, therefore the pulverized coal concentration is improved, the generation amount of NOx is effectively reduced, ignition heat is reduced, and timely ignition and stable combustion of the pulverized coal airflow under the conditions of low load and combustion of fault coal are facilitated. In addition, by means of the vortex suppression member of the stable combustion device, vortexes at the tail part of the stable combustion device can be effectively prevented from being formed, and the combustor can be prevented from slag-bonding, coking and burning-out.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Gasified and cracked peat combustion furnace

ActiveCN103383109ASolve the whereabouts problemNo pollution in the processIncinerator apparatusCombustionFlue gas

Owner:句容市华联特种设备制造有限公司

Novel water-coal-slurry fired organic heat carrier boiler

ActiveCN102455057AReduce settlementReduce cokingStorage heatersIndirect carbon-dioxide mitigationBottom ashAir preheater

The invention discloses a novel water-coal-slurry fired organic heat carrier boiler, which comprises a boiler foundation, a boiler wall, a boiler body, an outer guard plate, a steel frame and a platform ladder, wherein the boiler body comprises a hearth, an ash outlet system of a cold ash hopper, an oil cooling system, a convection bank, a smoke duct and an air pre-heater; the hearth is encircled by a front wall, a left wall, a right wall and a rear wall; a cyclone burner is arranged on the front wall of the hearth, the distance among the cyclone burner, the hearth and the upper edge of the cold ash hopper is greater than the width of the flame airflow of the cyclone burner, and the distribution of the cyclone burner is matched with the shape of the hearth; the hearth is provided with a lower hearth secondary air device; and hearth ash blowing devices are respectively arranged on the left wall, the right wall and the rear wall of the hearth. The water-coal-slurry fired organic heat carrier boiler has the advantages that: the boiler bottom ash of a combustion chamber is greatly reduced, the bottom of the boiler is difficult to coke, and the mechanical incomplete burning heat loss of the boiler is reduced; and the water-coal-slurry is burnt more stably in the boiler and fired more quickly, and the burn-off rate of the water-coal-slurry is greatly improved.

Owner:ZHEJIANG XIANCHUANG ENERGY TECH CO LTD

Boiler with back-burning coal spreader

InactiveCN1453522ARaise the combustion temperatureImprove burnout rateWater heatersLump/pulverulent fuel feeder/distributionSlagEngineering

The present invention is energy-saving environment-protecting boiler with back-burning coal spreader. It includes air chamber, slag hole, fire grate, front wall, hearth, vapor bubble, overheater, steering chamber, coal economizer and air preheater; and it features the hearth with one inside furnace arch, the steering chamber with separator and the material backing unit below the separator. The furnace arch has the functions of raising the burning temperature inside the hearth, capturing partial flyash particles and increasing the disturbance inside the furnace. The separator has the functions of separating out unburnt carbon containing flyash and feeding it to fire grate for burning via back of furnace. The present invention has the advantages of high burning temperature, high burningefficiency and less pollution.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

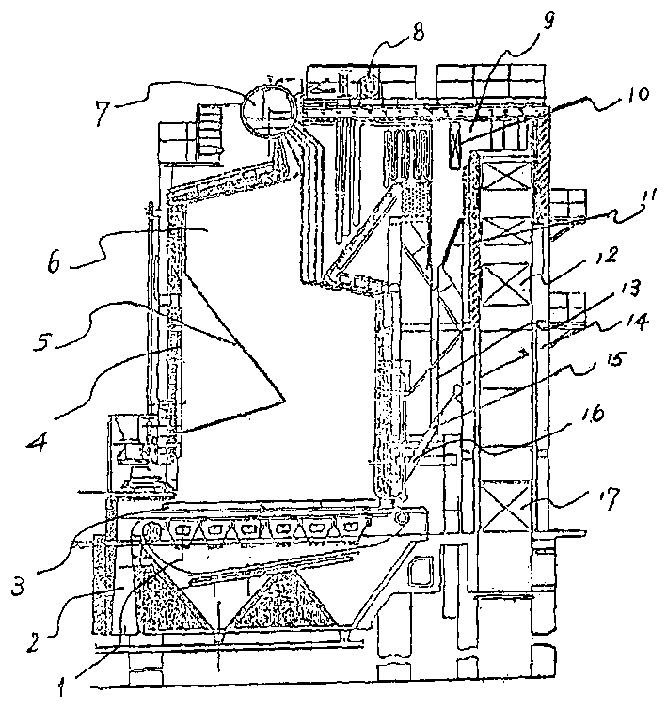

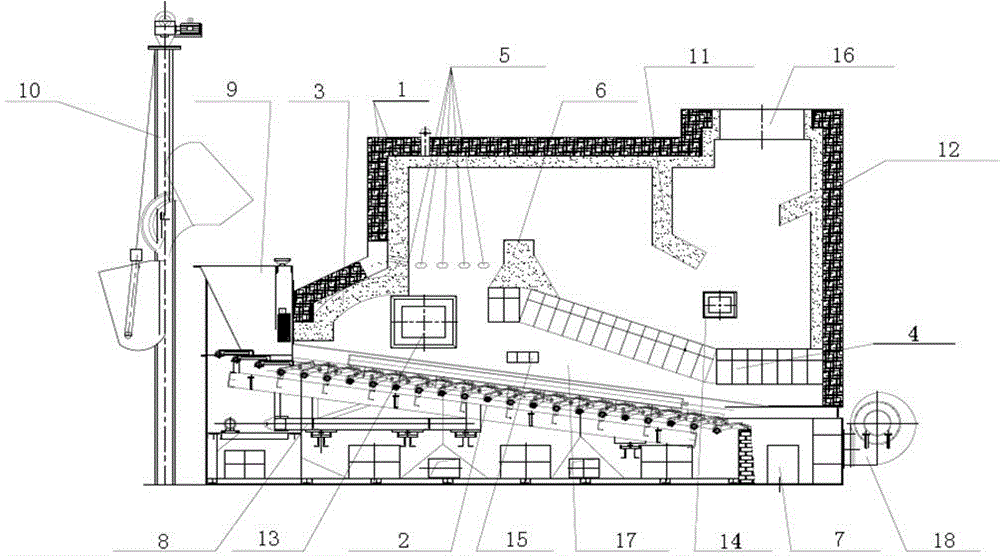

High-efficiency micro-discharging fire coal hot water boiler

InactiveCN101256025ABurn fullyFully burnt outSolid fuel combustionWater heatersCombustion chamberEngineering

The invention relates to a high efficiency micro-discharge coal-fired hot water boiler. A smokeless chimney is installed with a low smoke discharging temperature, high thermal efficiency, a quick temperature elevating speed and high combustion efficiency. Since the chimney is smokeless, discharging indicators tend towards zero, so that effects of little burn, little discharge, scientific control, environmental protection and energy saving are implemented. The inventive boiler comprises a boiler body, one side of the boiler body is connected to a coal feeder, and the other side of the boiler body is connected to a fume channel waste heat recovery system which is connected to a desulfurization dust removing system. The boiler body comprises a combustion chamber, a chain grate is disposed under the combustion chamber, a main internal furnace and an accessorial internal furnace both of which are used as internal furnaces and communicate with each other are disposed above the combustion chamber sequentially, a water inlet is disposed on the main internal furnace, a hot water outlet and a smoke discharging pore are disposed on the accessorial internal furnace, and a fire averaging plate connected with a boiler crown is disposed in the combustion chamber. Heat transfer steel tubes are disposed in the main internal furnace and the accessorial internal furnace, a set of heat transfer steel tubes used as fire path one is disposed in the main internal furnace, and two sets of heat transfer steel tubes used as fire path two and fire path three respectively are disposed in the accessorial internal furnace.

Owner:陇县永安热力工程有限公司

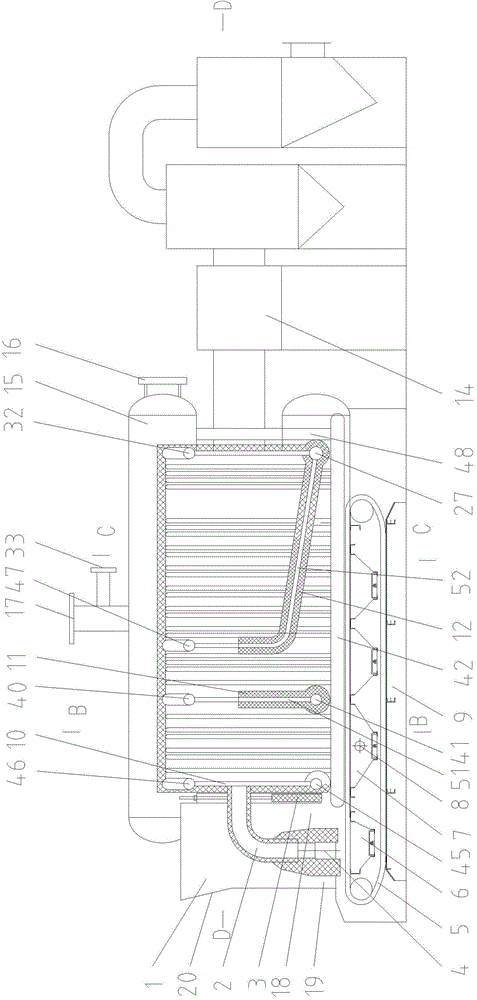

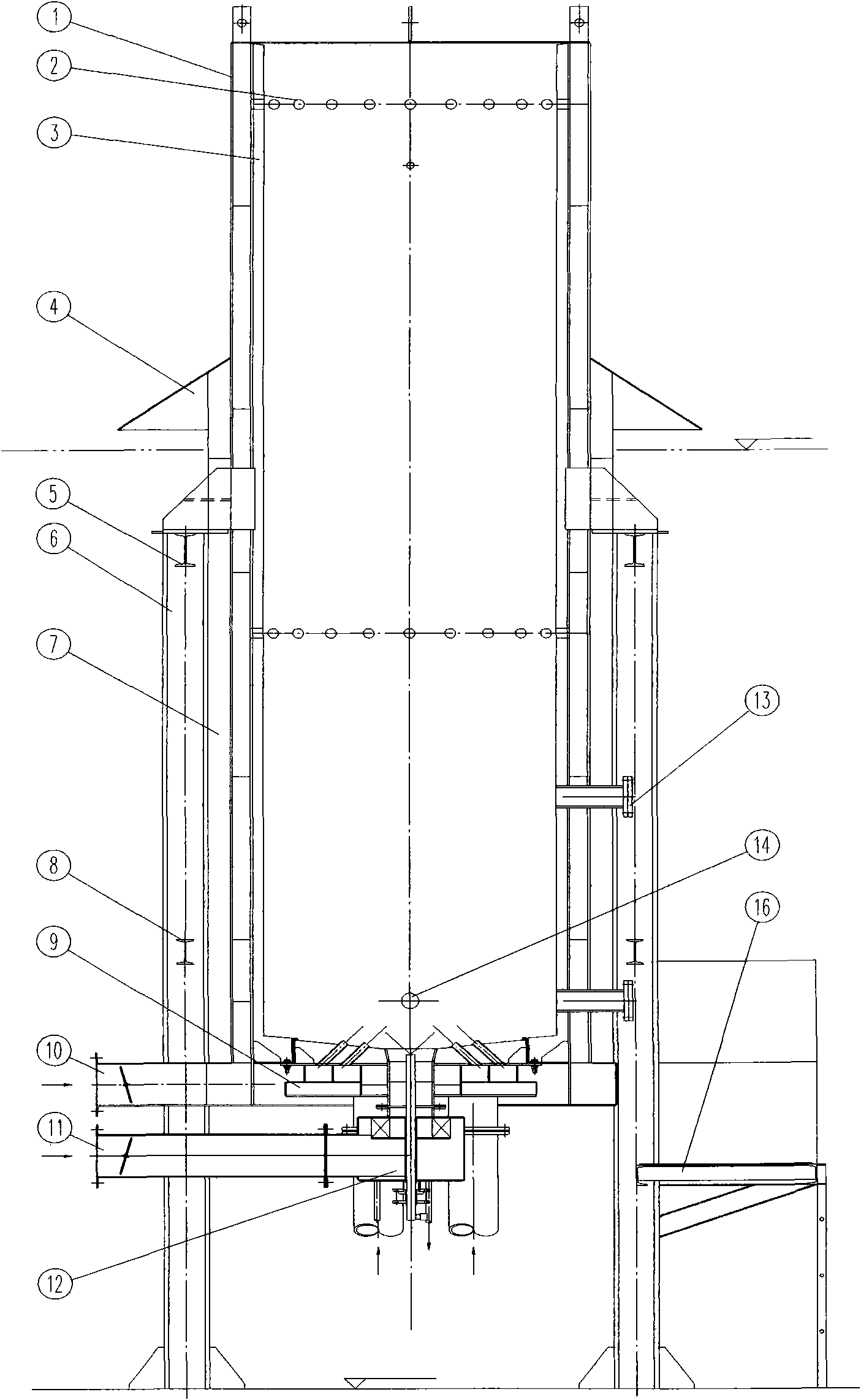

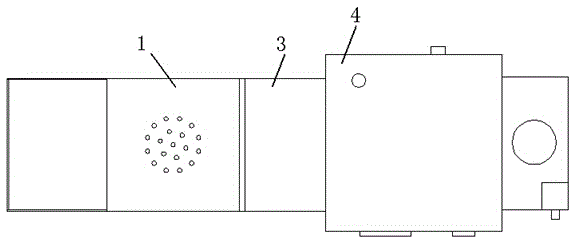

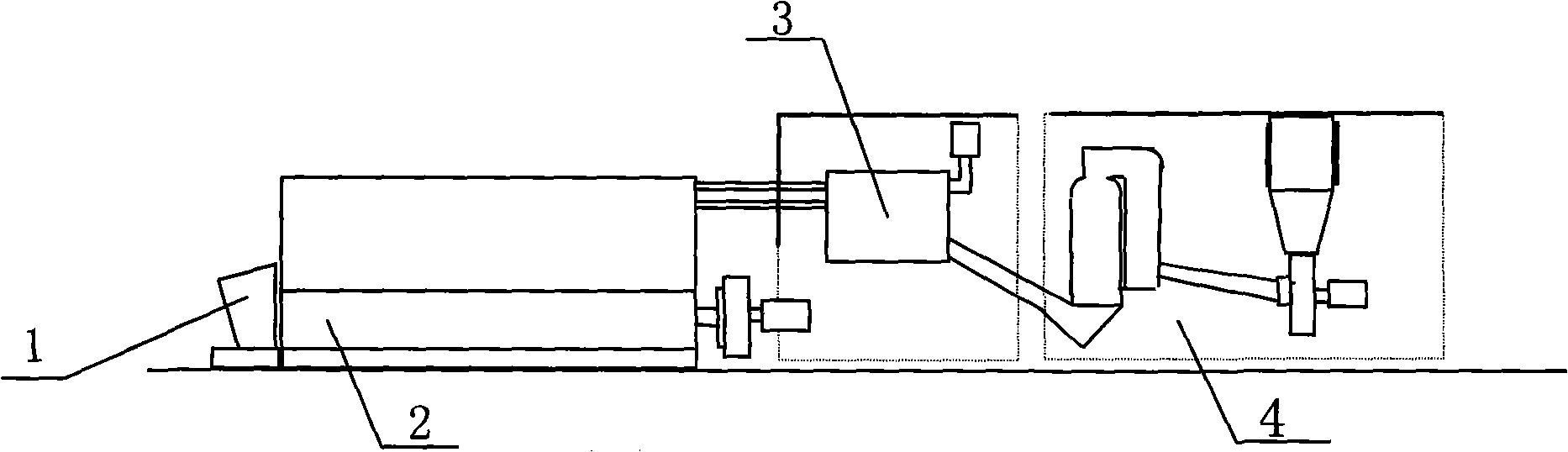

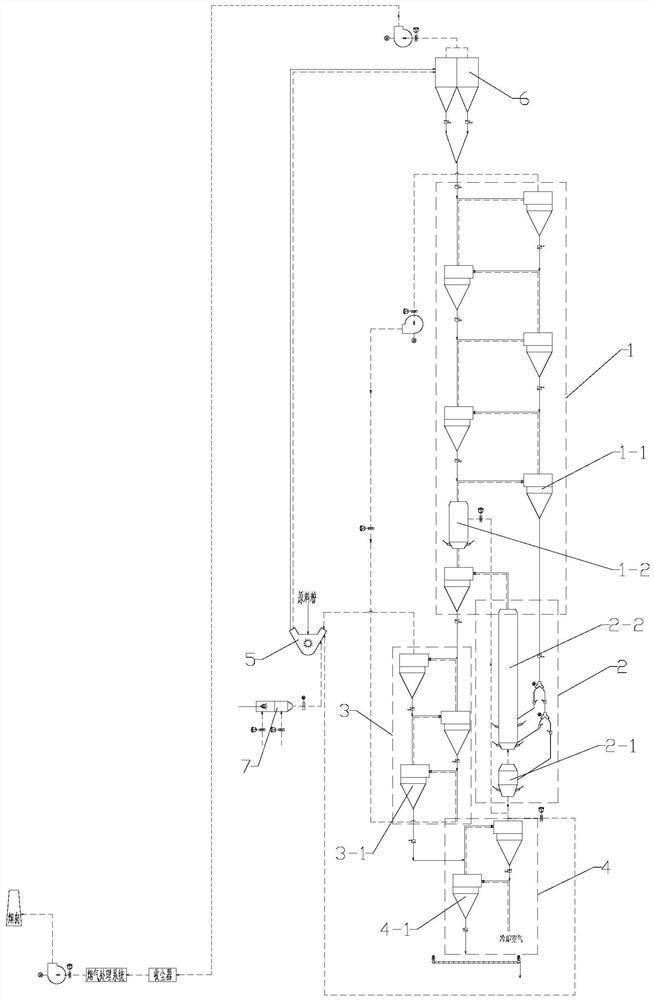

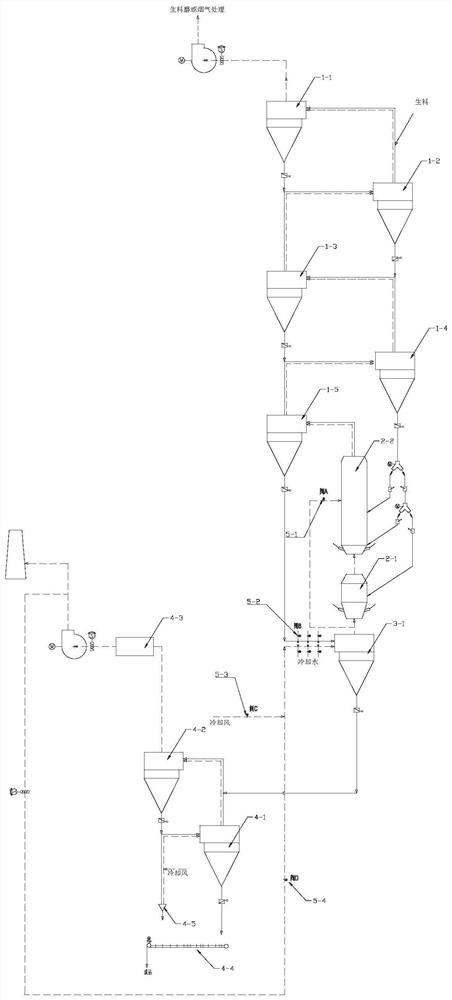

Preparation system and preparation method of high-activity metakaolin finished product with controllable color

PendingCN113816390AReduce concentrationReduce difficultyPreheating chargesSilicon compoundsMetallurgyKaolin clay

The invention discloses a preparation system and a preparation method of a high-activity metakaolin finished product with controllable color. The preparation system comprises a suspension preheating system, a calcining furnace system, a first cooling system and a second cooling system, the calcining furnace system comprises a preheating furnace and a modification furnace, a top outlet of the preheating furnace is connected with a bottom inlet of the modification furnace, and a reduction area is arranged in the modification furnace; an oxidizing furnace system is arranged between an air outlet of a lowermost-stage cyclone preheater and an inlet of a penultimate-stage cyclone preheater of the suspension preheating system, and an oxidizing area is arranged in an oxidizing furnace; and a discharge port of the lowermost-stage cyclone preheater is connected with a material inlet of the first cooling system, the oxygen concentration of a cooling medium of the first cooling system is 4% or less, the first cooling system is used for cooling materials to 200-350 DEG C, and a material outlet of the first cooling system is connected with a material inlet of the second cooling system. The metakaolin which meets the color control requirement can be produced, and the problems that a preparation system is high in energy consumption and small in processing capacity, and the product quality is difficult to control are solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Reciprocating type exhaust gas pyrolysis furnace

InactiveCN104819458AGood for running costsReduce consumptionByproduct vaporizationCasings/liningsBrickCombustion chamber

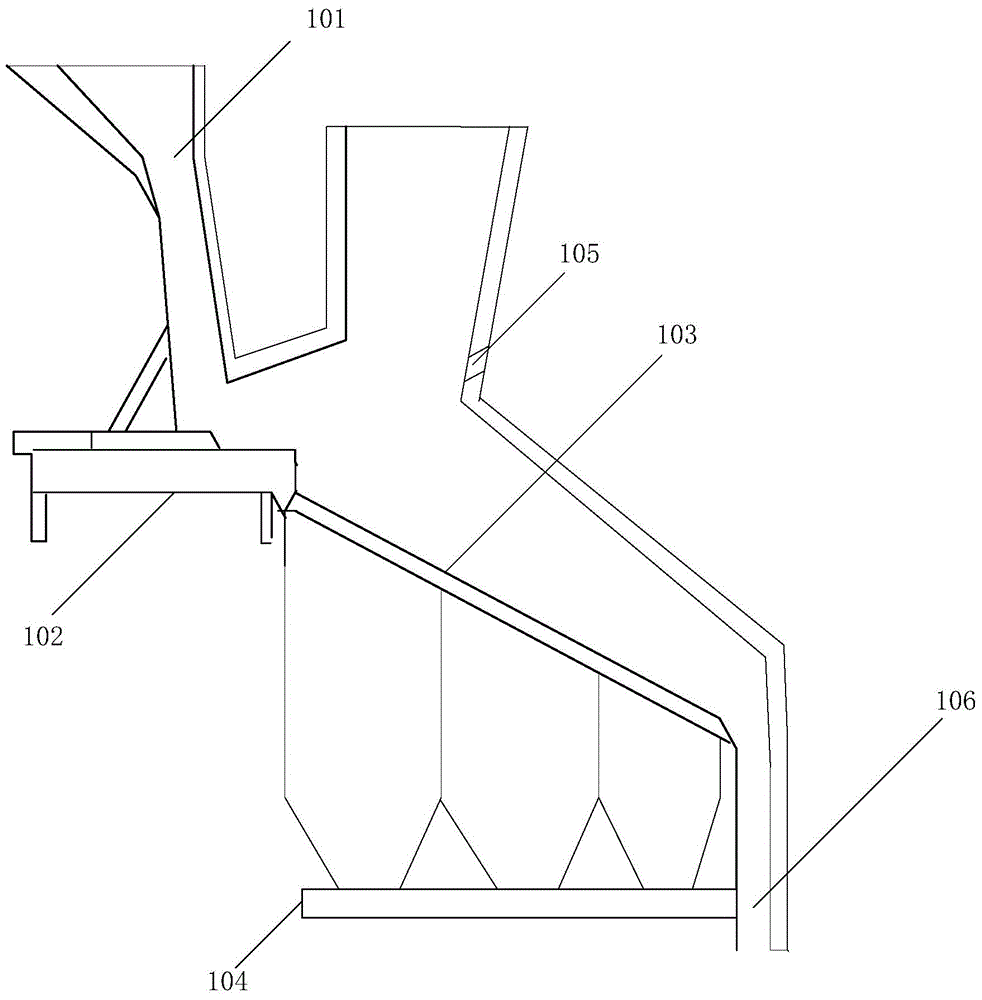

The invention discloses a reciprocating type exhaust gas pyrolysis furnace. The furnace comprises a furnace wall housing forming a hearth combustion chamber, the bottom of the hearth combustion chamber is inclinedly provided with a reciprocating type fire grate and a fire grate power mechanism for driving the reciprocating type fire grate, an inner side front end and an inner side rear end of the furnace wall housing are respectively provided with a front furnace arch and a rear furnace arch, the front furnace arch and the rear furnace arch are located above the reciprocating type fire grate, multiple C-shaped exhaust gas injection pipes are arranged between the front furnace arch and the rear furnace arch, the top of the furnace wall housing is provided with a high-temperature flue gas outlet, the bottom of the furnace wall housing is provided with a slag outlet, the rear furnace arch is prepared from arch bricks by bricklaying, and a fireproof concrete layer is casted on the surface of the rear furnace arch. The reciprocating type exhaust gas pyrolysis furnace has a low operation cost and can fully burn or decompose combustible gas such as fire coal and CO and poisonous and harmful substances in the hearth combustion chamber.

Owner:陆骏

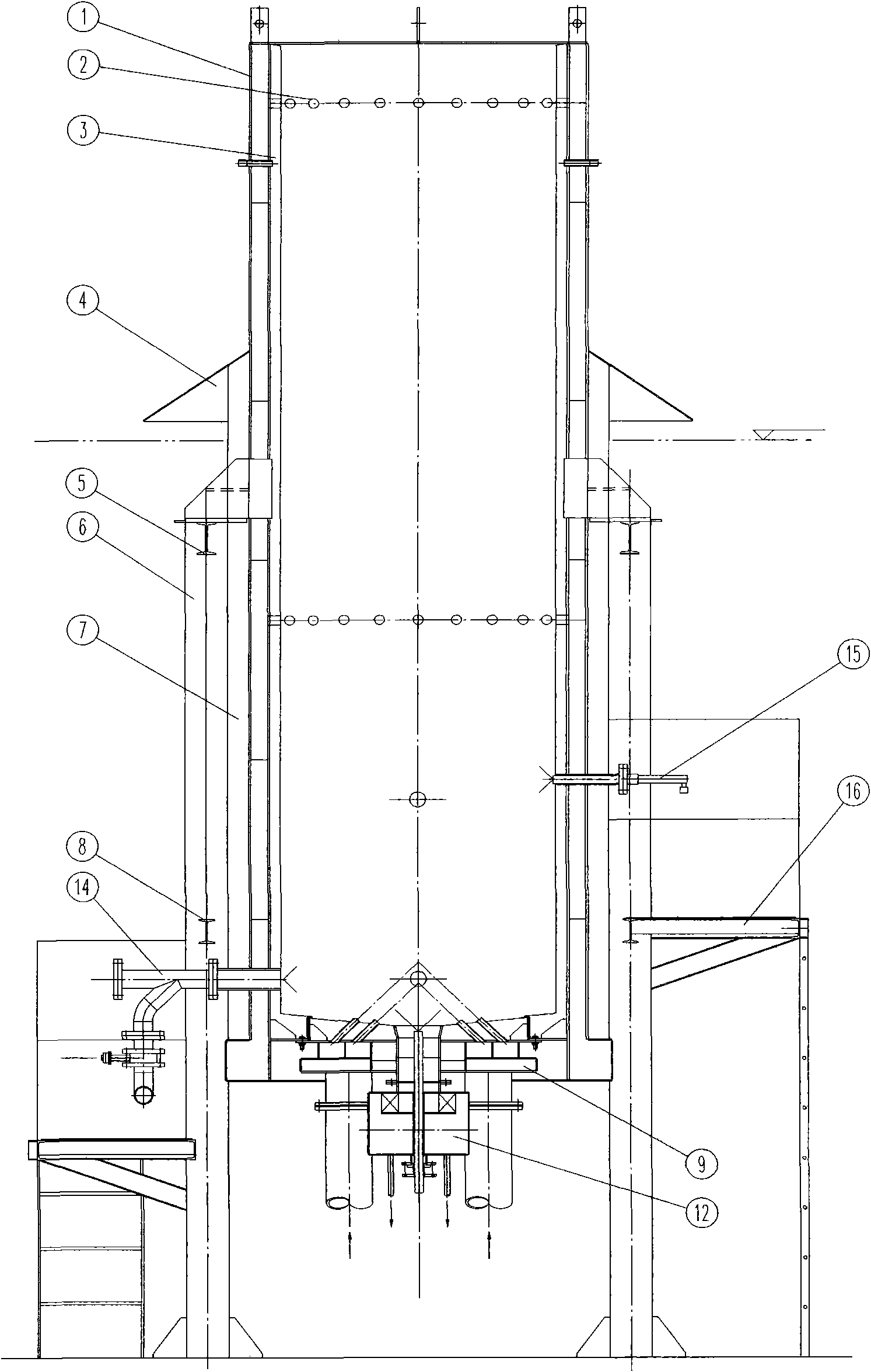

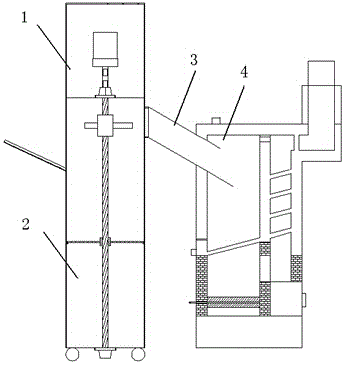

Flexibly-adjustable high-activity metakaolin preparation system and method

ActiveCN112939002AFully burnt outAchieve recyclingFurnace typesFurnace coolingKaolin clayProcess engineering

The invention belongs to the field of high-activity metakaolin preparation, and particularly relates to a flexibly-adjustable high-activity metakaolin preparation system and method. The flexibly-adjustable high-activity metakaolin preparation system comprises a suspension preheating system, wherein the suspension preheating system comprises multiple stages of cyclone preheaters, raw powder is subjected to preheating and gas-solid separation in the cyclone preheaters, and the raw powder having been subjected to multiple times of heat exchange and gas-solid separation enters a calcining furnace system from the penultimate-stage cyclone preheater of the suspension preheating system. According to the flexibly-adjustable high-activity metakaolin preparation system and method, the requirements of different industries for the color of a finished metakaolin product are fully considered, high-activity metakaolin is produced, and meanwhile the problems that a conventional metakaolin preparation system is high in energy consumption, small in processing capacity, difficult in product quality control and the like are solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

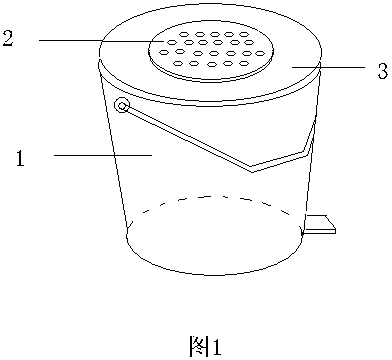

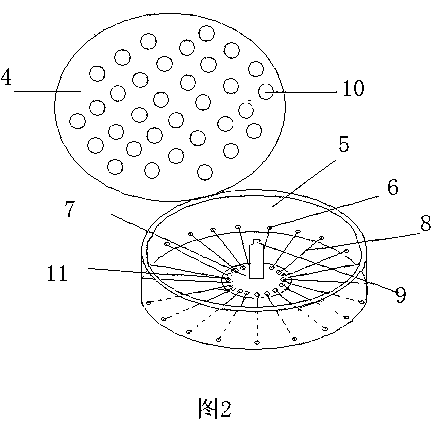

Safety type large-capacity mosquito-repellent incense barrel

The invention discloses a safety type large-capacity mosquito-repellent incense barrel which comprises a pedal type dustbin and a bottomless mosquito-repellent incense case. The safety type large-capacity mosquito-repellent incense barrel is skilled in design, simple in structure and easy to realize, and prevents mosquito-repellent incenses from being exposed to cause scalding and fire when the mosquito-repellent incenses combust in the bottomless mosquito-repellent incense case; and the mosquito-repellent incenses combust in a suspending mode so as to be fully combusted, after the mosquito-repellent incenses combust, ash falls in the pedal type dustbin, thus the safety type large-capacity mosquito-repellent incense barrel is clean and environment-friendly. In addition, the pedal type dustbin is larger in ash storage capacity, and thus the time interval of clearing the ash is greatly prolonged, and another application of the pedal type dustbin is developed.

Owner:张人益

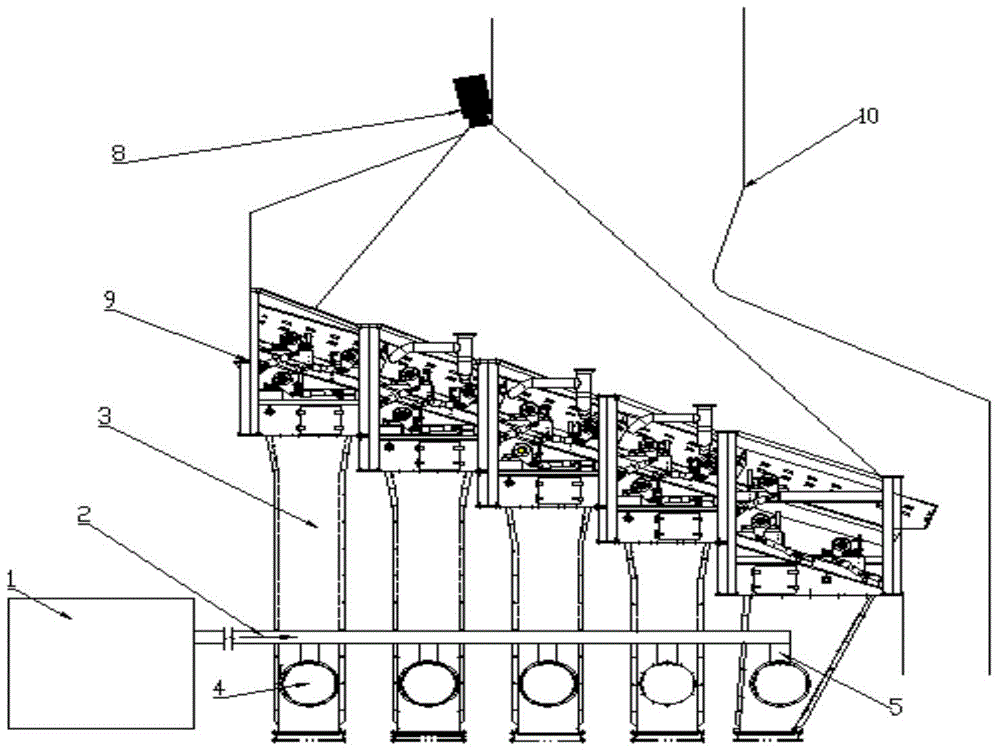

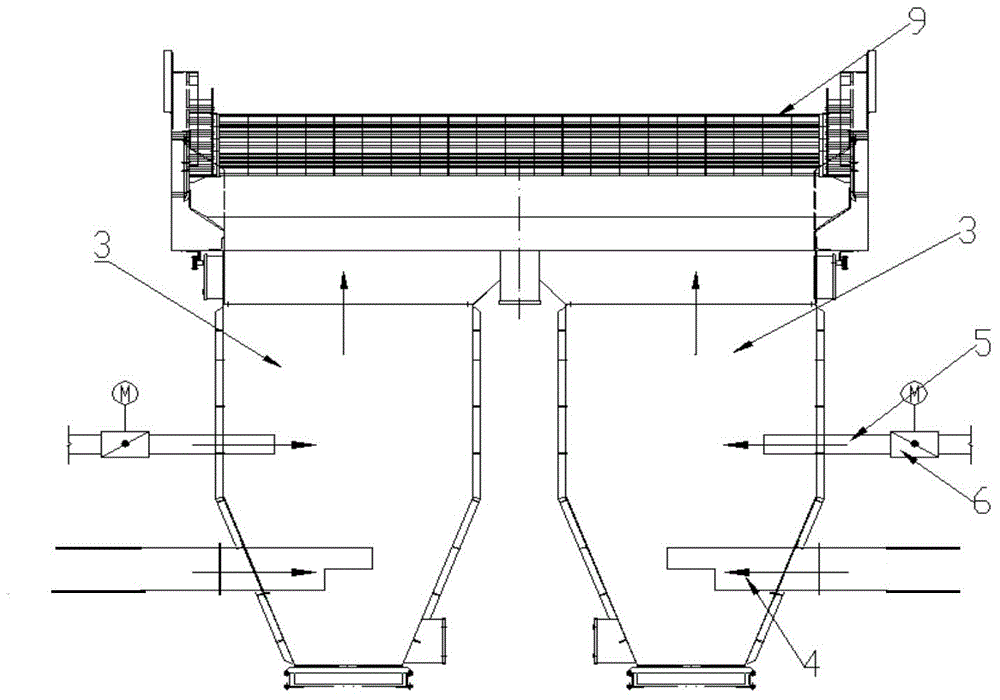

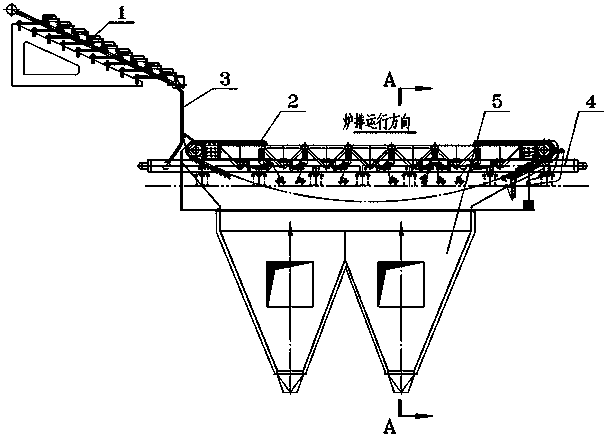

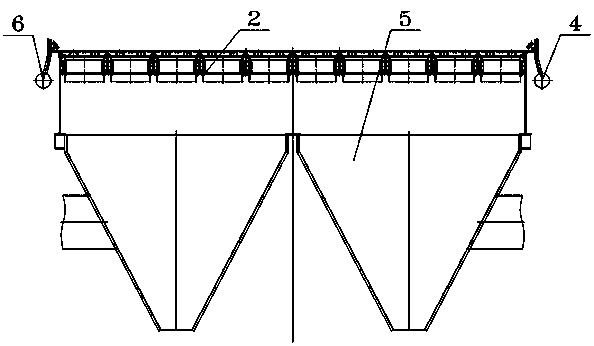

Composite grate combustion equipment

The invention discloses composite grate combustion equipment and relates to the technical field of biomass fuel boilers. Bilateral sides of a grate of the composite grate combustion equipment are respectively provided with water cooling headers; the grate is formed by a reciprocating grate at the front section and a catenary chain tensioning type chain grate at the rear section; the reciprocating grate which is inclined downward along the movement direction of fuel is higher than the catenary chain tensioning type chain grate. The fuel is fed into the inclined type reciprocating grate through a feeder to be preheated and dried and then is driven by the reciprocating grate to move in a downward roll mode step by step and a rolling falling effect through the height difference at a stair position of the two grates is achieved, the time for staying in the air of the fuel is prolonged, the fuel permeability is increased, and the fuel and the combustion-supporting oxygen are fully mixed. The inclined reciprocating grate plays a role in preheating and drying and the catenary chain tensioning type chain grate plays a role in discharging and burning out. According to the composite grate combustion equipment, when various biomass fuel and high-moisture fuel are combusted, the height difference between the two grates are utilized, fuel combustion is facilitated, the combustion is full, the burn-off rate of the fuel is greatly improved, and the combustion efficiency of the equipment is improved.

Owner:JINAN BOILER GRP

Low-nitrogen burner boiler

The invention relates to a low-nitrogen burner boiler, and belongs to the technical field of combustion boilers. According to the low-nitrogen burner boiler, pulverized coal is sprayed out through a pulverized coal spray gun and a central pulverized coal spray gun, and a higher axial speed airflow is generated, so that mixing of central air and central coal is improved; a secondary air turbine swirls into a hearth at the periphery to ensure that air and unburned particles in combustion products are fully mixed; wrapped swirling air is formed outside a flow pattern of central swirling air, so that excessive air is provided for the peripheral coal, and the combustion time of the air and the coal is increased through swirling; the swirling air at the outermost side is adopted to help to formhigh-temperature flue gas backflow inside the hearth at the root of flame; at the same time, a well aerodynamic field is organized, timely ignition and full burnout are carried out as well as prevention of producing of coking is carried out, and NOx emission is minimized. The low-nitrogen burner boiler ensures the safe operation of a machine set, the economic efficiency of the machine set is improved, and wide application prospects in the aspects of energy conservation, emission reduction, boiler efficiency improvement and the like are achieved.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Secondary air oxygen-enrichment pulse combustion gas spraying device and method of rotary kiln

ActiveCN104613752ABurn fullyFully burnt outRotary drum furnacesIndirect carbon-dioxide mitigationButt jointPollution

The invention relates to a secondary air oxygen-enrichment pulse combustion gas spraying device and method of a rotary kiln. The device comprises a plurality of oxygen-enrichment spray guns which are fixed to a kiln hood of the rotary kiln. The end, corresponding to the oxygen-enrichment spray guns, of the portion, located in a cooling zone, of a kiln lining is provided with air inlets of an oxygen-enrichment secondary air channel. Outlets of the oxygen-enrichment secondary air channel are formed in the inner wall of the portion, located in a firing zone, of the kiln lining. The kiln lining and the oxygen-enrichment secondary air channel are formed by pouring refractory castable integrally. The method comprises the steps that when the oxygen-enrichment spray guns and the oxygen-enrichment secondary air channel coincide, valves are opened to spray gas, and when the oxygen-enrichment spray guns are moved away from the oxygen-enrichment secondary air channel, the valves are closed, gun spraying is stopped, and then the oxygen-enrichment pulse combustion pulse process is completed. Compared with the prior art, the secondary air oxygen-enrichment pulse combustion gas spraying device and method of the rotary kiln have the advantages that through butt joint between the oxygen-enrichment spray guns and the oxygen-enrichment secondary air channel in the rotating process of the rotary kiln, oxygen-enriched air is supplied to the firing zone for after-combustion, the flow of the oxygen-enriched air is controllable, air supply is even, the oxygen-enriched air entering the kiln is fully preheated so that the combustion efficiency can be further improved, and the purposes of utilizing waste heat, eliminating pollution, saving energy and reducing emission are achieved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Combination fire grate vaporization incinerator

PendingCN108343968AReduce heat intensityEmission reductionIncinerator apparatusCombustion chamberFlue gas

The invention discloses a combination fire grate vaporization incinerator. The combination fire grate vaporization incinerator comprises a hopper, a vaporizing chamber, a combustion chamber and a tailportion flue. Two sides of the vaporizing chamber are arranged obliquely and a slag-falling channel is formed by contracting the bottom of the two sides of the vaporizing chamber, and a water seal tank is formed in the bottom end of the slag-falling channel. The vaporizing chamber is internally provided with a middle arch which is arranged obliquely, and the vaporizing chamber is divided into a vaporizing area provided with a communicating vaporizing air channel on the upper portion and a vaporizing combustion area. The combustion chamber is arranged above the vaporizing combustion area. A combination fire grate is arranged on an inclined side of the vaporizing area, the starting end of the combination fire grate is located below the hopper, and the tail end of the combination fire grateis connected with the slag-falling channel. The combination fire grate at least comprises a first-stage fire grate and a second-stage fire grate which are arranged in a ladder mode. The top of the vaporizing combustion area and the combustion chamber are arranged in a shape like a Chinese character 'ao', the extending section of the vaporizing air channel and the combustion chamber are separatelylocated at platforms at two sides of the Chinese character 'ao', and the concave part of the top of the vaporizing combustion area forms a side baffle wall of the vaporizing air channel. The combination fire grate vaporization incinerator is subjected to vaporizing first and then burnt and two stage combustion, and has the advantages of wide fuel adaptability and good initial emission of flue gas.

Owner:BEIJING ONE A HI TECH ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com