Station boiler anthracite powder combustion plant

An anthracite pulverized coal, combustion equipment technology, applied in the direction of combustion equipment, burners, combustion methods, etc., can solve the problems of short range, poor mixing in the later stage, and reduced boiler efficiency, and achieve improved boiler efficiency, simple structure, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

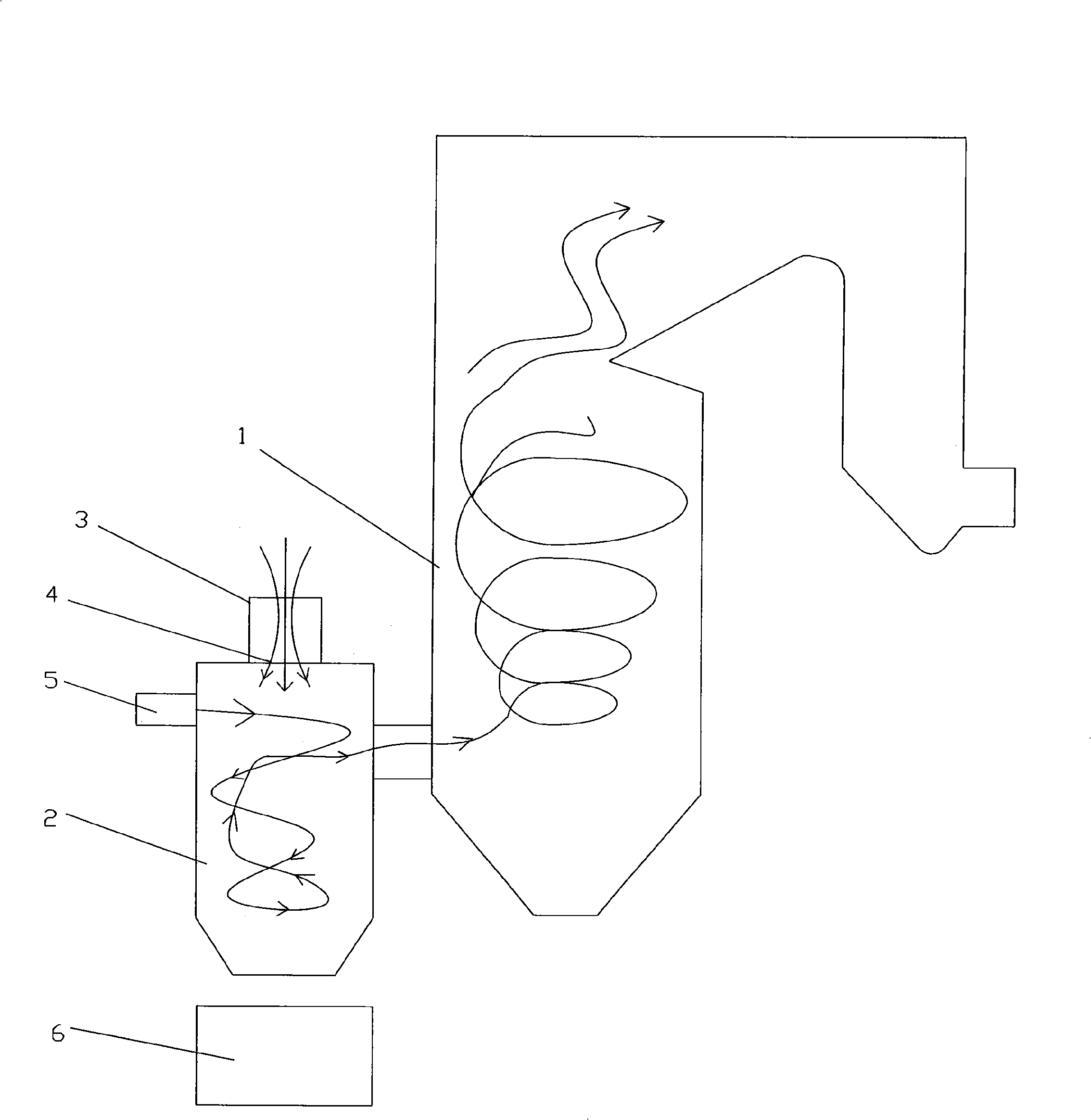

[0016] The structural representation of the power station boiler anthracite pulverized coal combustion equipment of the present invention is as follows figure 1 As shown, a boiler furnace 1 is included, wherein a cyclone combustion cylinder 2 is installed at the rear of the boiler furnace 1, and a spray gun 3 for spraying anthracite powder into the combustion chamber of the cyclone combustion cylinder 2 at a high speed is arranged above the cyclone combustion cylinder 2. The top of the combustion cylinder 2 is provided with a primary tangential air supply port 4 for feeding the air required for the combustion of anthracite coal.

[0017] In order to further ensure that the anthracite powder after ignition can be fully burned, the combustion chamber furnace wall of the cyclone combustion cylinder 2 is provided with a secondary tangential air supply port 5 for feeding the air required to ensure that the anthracite powder is fully combusted after ignition. The above-mentioned sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com