Ultra-low load combustion device suitable for wall type rotational flow opposed firing boiler

A technology of opposing combustion and combustion devices, which is applied in the direction of using various fuel combustion, combustion types, combustion equipment, etc., can solve the problems of reduced load operation, etc., and achieve the effects of low load stability, low heat capacity, and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

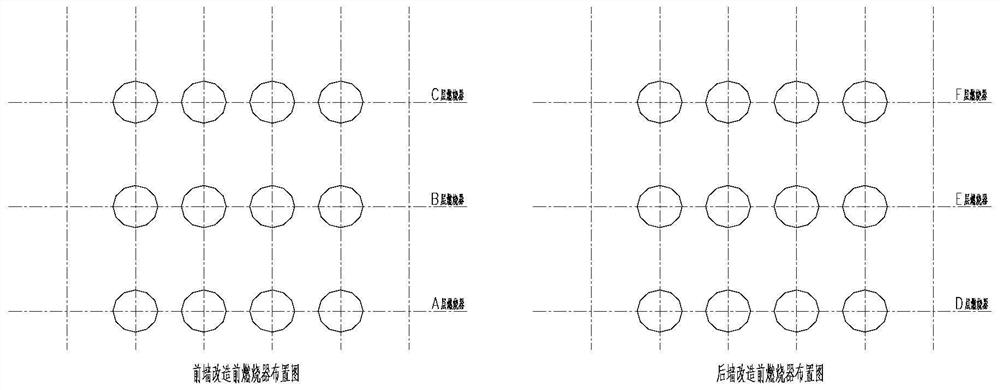

[0030] Renovate the wall-type swirling counter-fired boiler, add a layer of low-capacity pulverized coal burners (G and H) above the original uppermost layer of burners on the front and rear walls, and arrange the low-capacity pulverized coal burners on each layer The number is the same as the number of original burner arrangements on each floor. The layout position of the low-capacity pulverized coal burner is the same as that of the burner in the longitudinal direction; figure 2 (taking 4 main burners on each floor as an example) as shown.

[0031] The small-capacity pulverized coal feeding device is equipped with corresponding coal incoming, cold and hot air systems, and the low-capacity pulverized coal burner is equipped with an air box air duct and a water-cooled wall.

[0032] Wherein, the small-capacity pulverized coal feeding device communicates with the low-capacity pulverized coal burner. When the number of small-capacity pulverized coal feeding devices is 1 set, ...

Embodiment 2

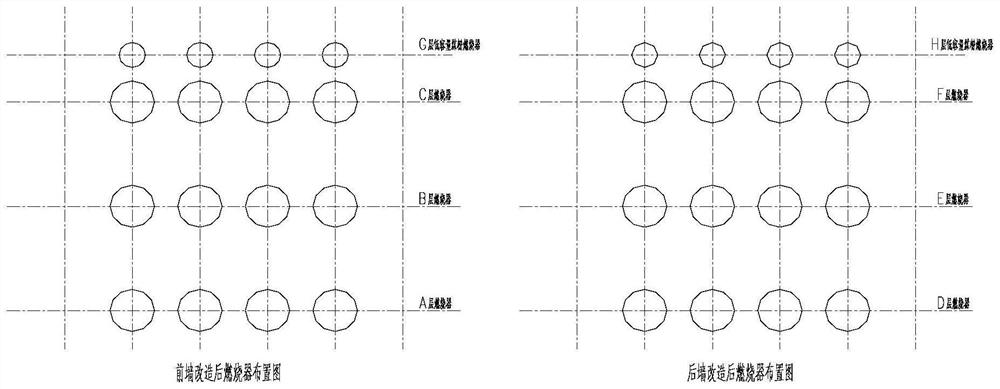

[0035] Renovate the wall-type swirling counter-combustion boiler, add a layer of low-capacity pulverized coal burners (G and H) above the original uppermost layer of burners on the front and rear walls, and the number of original burners on each layer is N , the number of low-capacity pulverized coal burners in each layer is N-2; the layout position of low-capacity pulverized coal burners is the same as that of the burners in the longitudinal direction. The arrangement of burners and low-capacity pulverized coal burners after transformation is as follows: image 3 (taking 4 main burners on each floor as an example) as shown.

[0036] The small-capacity pulverized coal feeding device is equipped with corresponding coal incoming, cold and hot air systems, and the low-capacity pulverized coal burner is equipped with an air box air duct and a water-cooled wall.

[0037] Wherein, the small-capacity pulverized coal feeding device communicates with the low-capacity pulverized coal b...

Embodiment 3

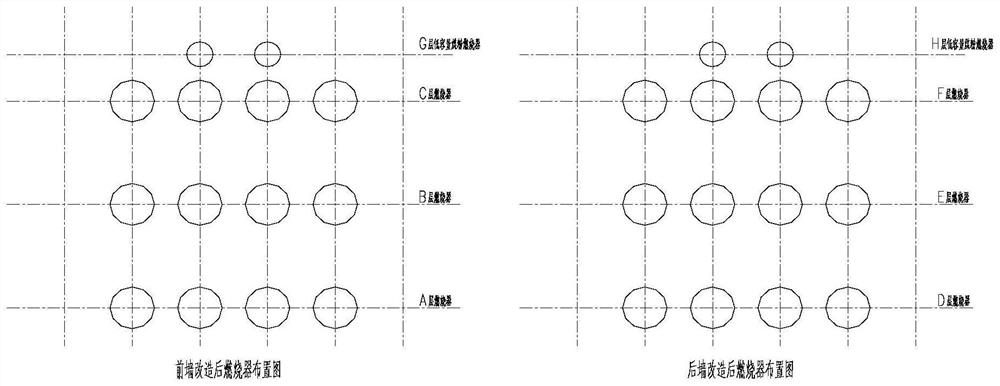

[0040] Renovate the wall-type swirling counter-combustion boiler, add a layer of low-capacity pulverized coal burners (G and H) above the original uppermost layer of burners on the front and rear walls, and the number of original burners on each layer is N , the number of low-capacity pulverized coal burners on each floor is N-1; the layout of low-capacity pulverized coal burners is vertically staggered with the burner layout. The arrangement of burners and low-capacity pulverized coal burners after transformation is as follows: Figure 4 (taking 4 main burners on each floor as an example) as shown.

[0041] The small-capacity pulverized coal feeding device is equipped with corresponding coal incoming, cold and hot air systems, and the low-capacity pulverized coal burner is equipped with an air box air duct and a water-cooled wall.

[0042] Wherein, the small-capacity pulverized coal feeding device communicates with the low-capacity pulverized coal burner. When the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com