Frequency conversion and automatically controlled dual-purpose boiler with built-in precombustion chamber using coal water slurry or oil as fuel

A pre-combustion chamber and water-burning technology, applied in the direction of using a variety of fuel combustion, burners, combustion methods, etc., can solve the problems of low control level, poor heat resistance, wear resistance and rigidity of nozzles, and heating system accidents. Achieve the effect of complete configuration, strong integration and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

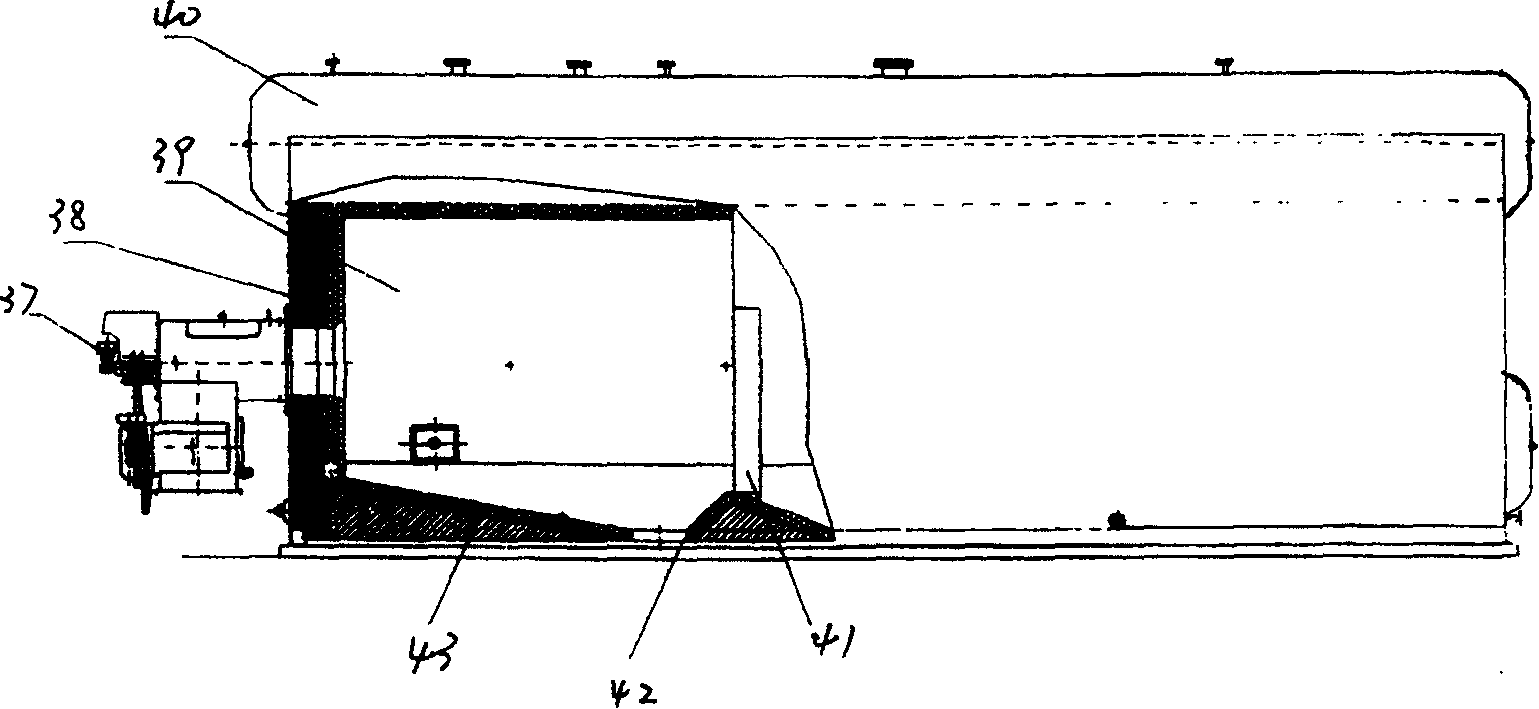

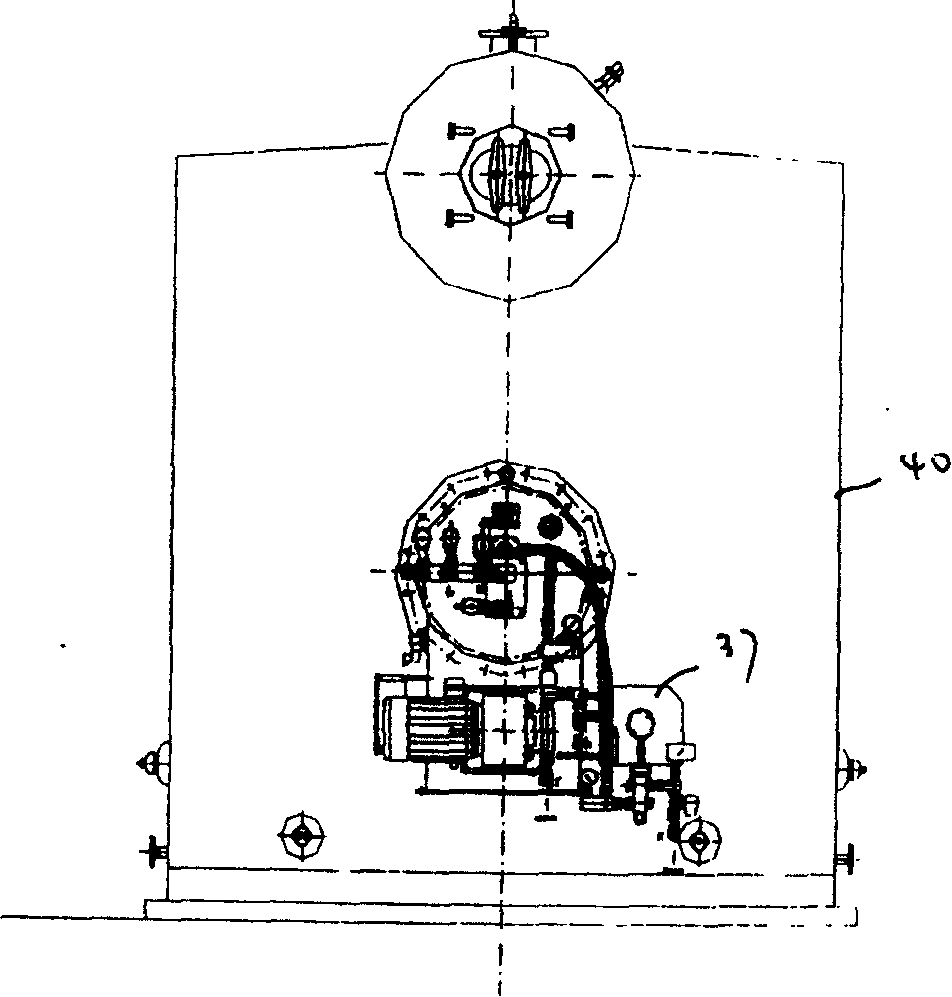

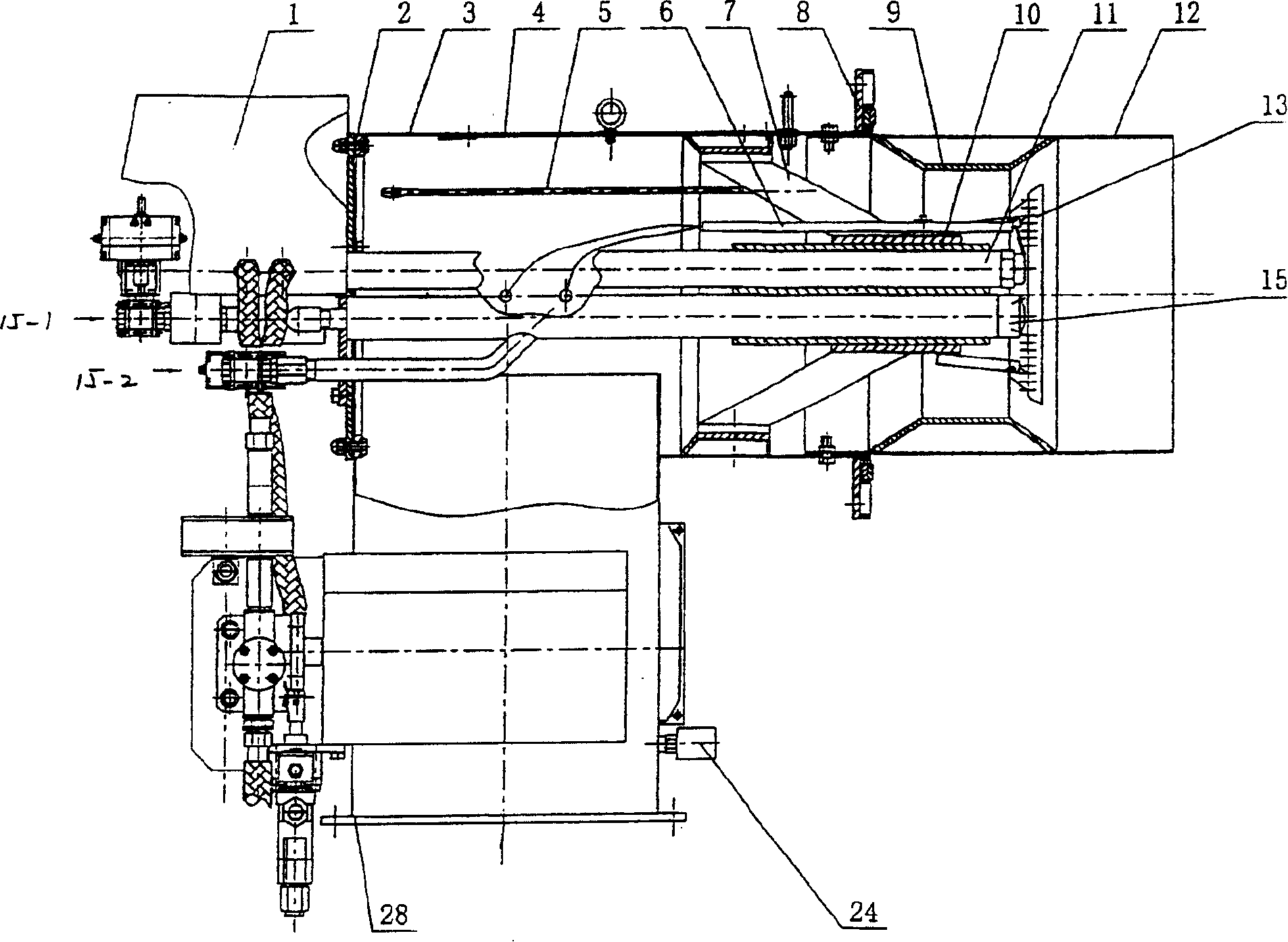

[0049] like Figure 1-2 , The invention is a dual-purpose boiler with a built-in pre-combustion chamber for automatic control of combustion of coal-water slurry and oil. It is mainly composed of a boiler body 40, a burner 37 and a pre-combustion chamber 39. The burner 37 is connected to the front wall 38 of the boiler body 40 . The pre-combustion chamber 39 is designed integrally with the boiler body 40 , is built in the front portion of the boiler furnace, and is integrated with the front wall 38 of the boiler body 40 . The pins are reasonably arranged on the water-cooled wall, and the high-temperature-resistant and anti-penetration refractory material 43 is integrally poured to prevent the coking and fusion of the combustion chamber and prolong the service life of the combustion chamber. Set a certain width and height on both sides of the pre-combustion chamber outlet. The fire wall 41 makes the pre-combustion chamber form a semi-open space, so that the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com