Overhead-valve combustion chamber of two-stroke gasoline direction injection engine

A technology of in-cylinder direct injection and overhead valves, applied in combustion engines, internal combustion piston engines, cylinders, etc., can solve unfavorable fuel atomization and fragmentation, evaporation and diffusion of stratified mixed gas, difficult control of ignition and combustion phases, and knocking and high pressure rise rate to achieve the effects of easy atomization and evaporation, miniaturization and high injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring to the accompanying drawings and specific examples, the combustion chamber of the overhead valve two-stroke direct-injection gasoline engine provided by the present invention will be described in detail according to the working sequence of scavenging, mixed gas organization and combustion in a single cycle of the engine.

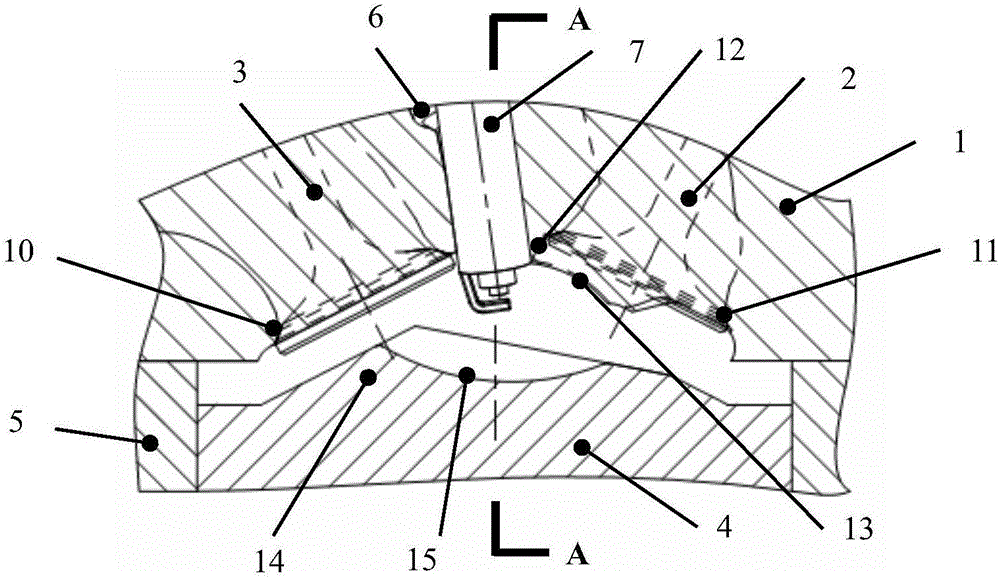

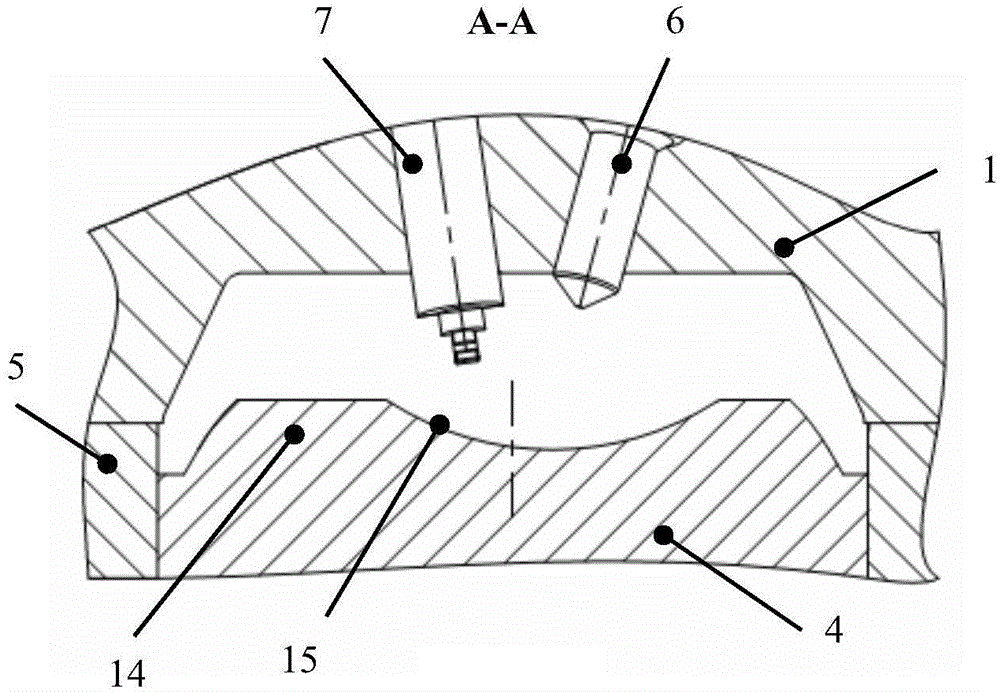

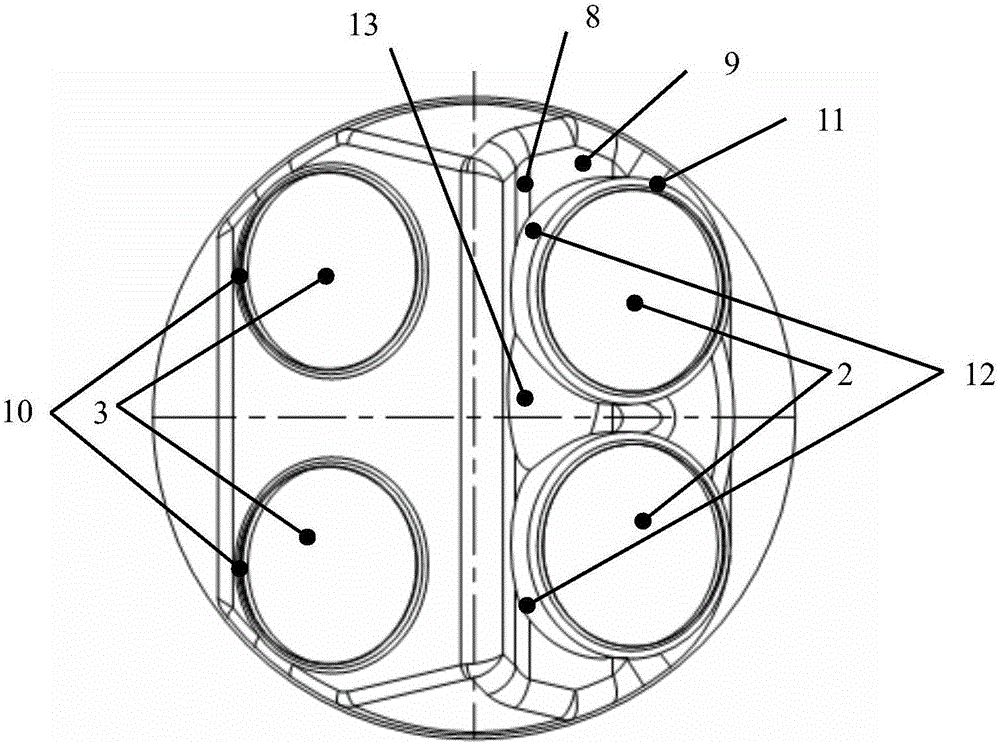

[0027] Fig. 1 (a) and Fig. 1 (b) have shown the longitudinal structure sectional view and the A-A section sectional view of the combustion chamber of direct injection gasoline engine in the overhead valve two-stroke cylinder that the present invention provides respectively, and wherein, section A-A is through cylinder center line and with Section perpendicular to the longitudinal section in Figure 1(a). As shown in Fig. 1 (a) and Fig. 1 (b), the direct injection gasoline engine combustion chamber in the overhead valve two-stroke cylinder provided by the present invention is cylinder head 1, intake valve 2 and exhaust valve 3, piston 4, cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com