Molten salt energy storage-based ammonia boiler for real-time cracking of ammonia fuel through plasma

A technology of plasma and molten salt, which is applied to the combustion of block fuel and liquid fuel, the combustion of liquid fuel and gaseous fuel, the combustion of liquid fuel and powder fuel, etc. It can solve the problem of unstable combustion of ammonia fuel, Insufficient combustion and other problems, to achieve the effect of improving stability, improving combustion sufficiency, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

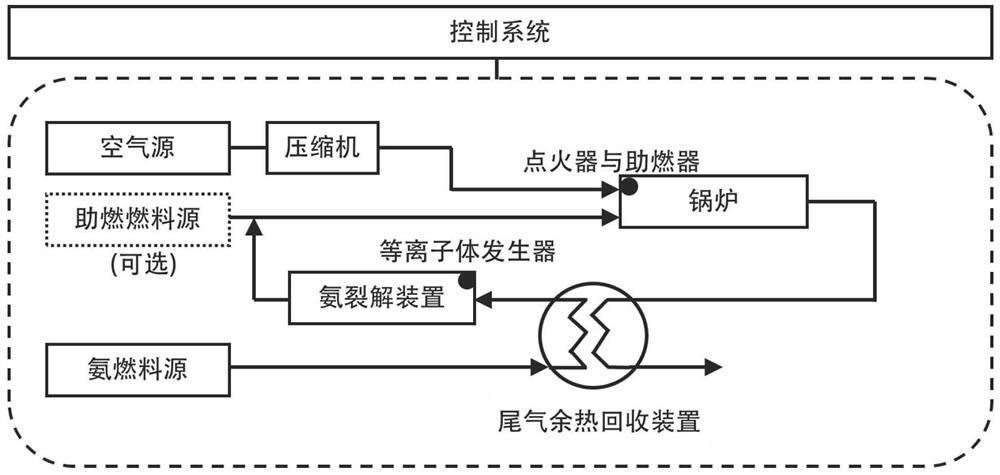

[0042] see Figure 1-7 As shown, the present invention is an ammonia boiler based on plasma real-time cracking of ammonia fuel based on molten salt energy storage. Wherein the ammonia decomposition box includes a plasma generator, a temperature sensor, a gas pressure sensor and a hydrogen component sensor; the plasma igniter includes an electric spark plasma generator; the plasma burner includes a microwave plasma generator; the plasma igniter and The plasma burner is installed in the combustion chamber of the ammonia boiler.

[0043] Before the ammonia fuel source is mixed with the air source, the ammonia fuel source is heated and decomposed online in real time by the ammonia decomposition box; after the liquid ammonia fuel is vaporized or the ammonia fuel enters the ammonia decomposition box in gaseous form, it is partially decomposed into ammonia and hydrogen online The mixed gas; the ammonia decomposition rate is controlled by the input power of the plasma generator, the de...

Embodiment 2

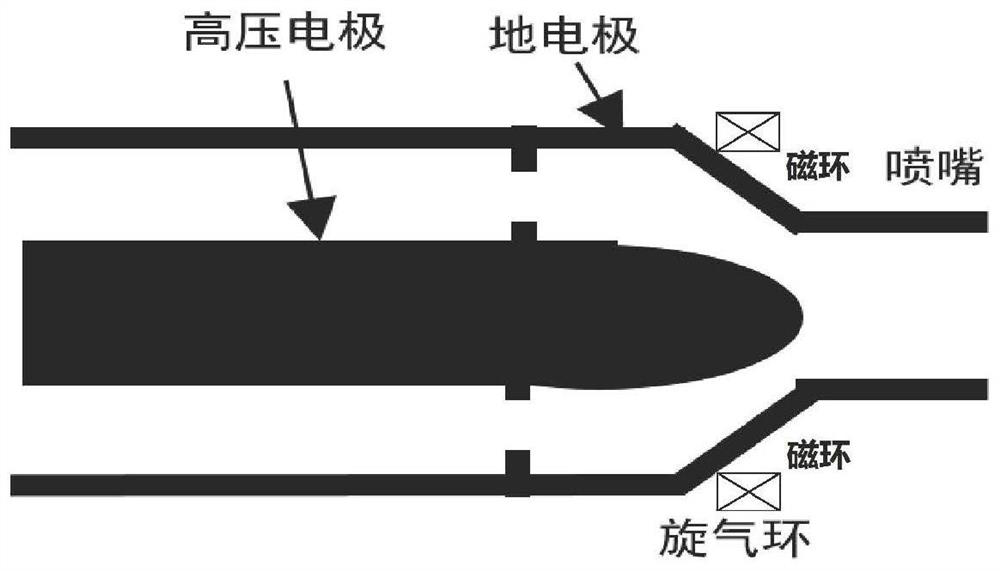

[0049] Such as figure 2 As shown, the plasma generator adopts a sliding arc plasma generator, and the overall structure of the sliding arc plasma generator adopts a coaxial structure;

[0050] The sliding arc plasma generator in the ammonia decomposition box includes a high voltage electrode, a cyclone ring, a ground electrode and a nozzle; the high voltage electrode is a rod-shaped structure, the ground electrode is a tapered tubular structure, and the nozzle is a conical structure; the high voltage electrode, the ground electrode and The three nozzles are coaxially fixed in space; the high-voltage electrode and the nozzle are fixedly connected to the ground electrode respectively. And there is a shrinking device on the nozzle.

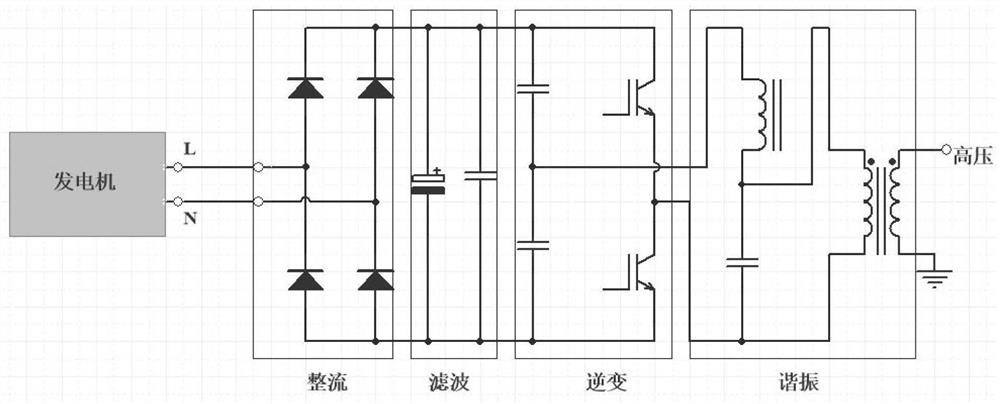

[0051] The principle block diagram of the sliding arc plasma power supply is as follows: image 3 As shown, the power supply of the sliding arc plasma power supply is provided by the mains or the generator. The power supply includes a rectifier ci...

Embodiment 3

[0056] The tail gas treatment process of ammonia boiler is as follows: Figure 7 As shown, the tail gas produced by the ammonia boiler is first passed into ammonia water to remove the acid gas CO 2 and NO 2 , subsequently configured to detect NO x Concentration of NO x Sensors and NH 3 concentration of NH 3 sensor, if the concentration of ammonia is high, the exhaust gas is introduced into line A to purify NO through a selective catalytic reduction catalyst (zeolite or vanadium catalyst containing Fe ions and the main components are Si, O, Al, etc.) x , the treated one contains a higher concentration of NH 3 The exhaust gas is introduced into the ammonia boiler for reuse, and part of the purified NH 3 Pass through ammonia water to keep the concentration of ammonia water at the optimal value for absorbing acid gas; if the concentration of ammonia is low, enter line B equipped with a suitable catalyst to pass NH 3 +NO x →N 2 +H 2 O reaction to NH 3 and NO x Purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com