Low-oxynitride and low-load stable combustion device of turbulent combustor

A low nitrogen oxide, swirl burner technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve the problem of incomplete combustion of pulverized coal particles, affecting the ignition and stable combustion of pulverized coal, and the probability of impact It can achieve the effect of good adaptability of coal, easy processing and installation, and prolonging the life of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a low-nitrogen oxide low-load stable combustion device for a swirl burner. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

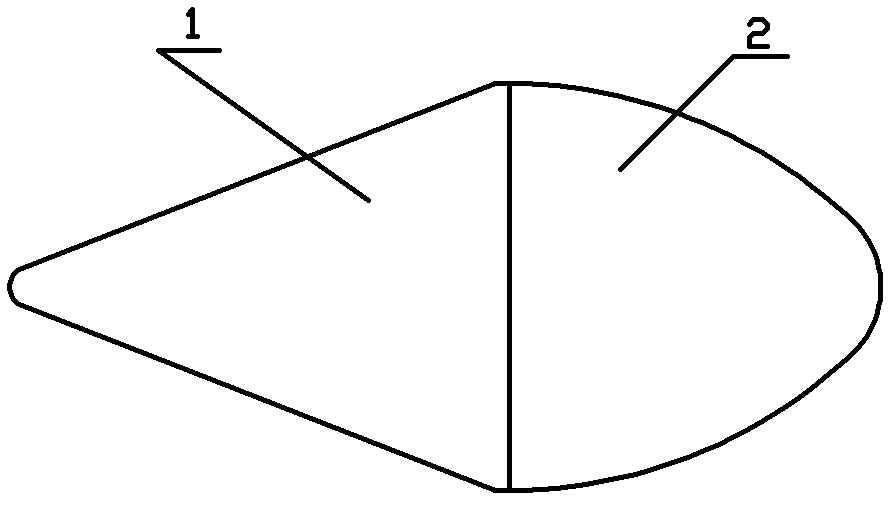

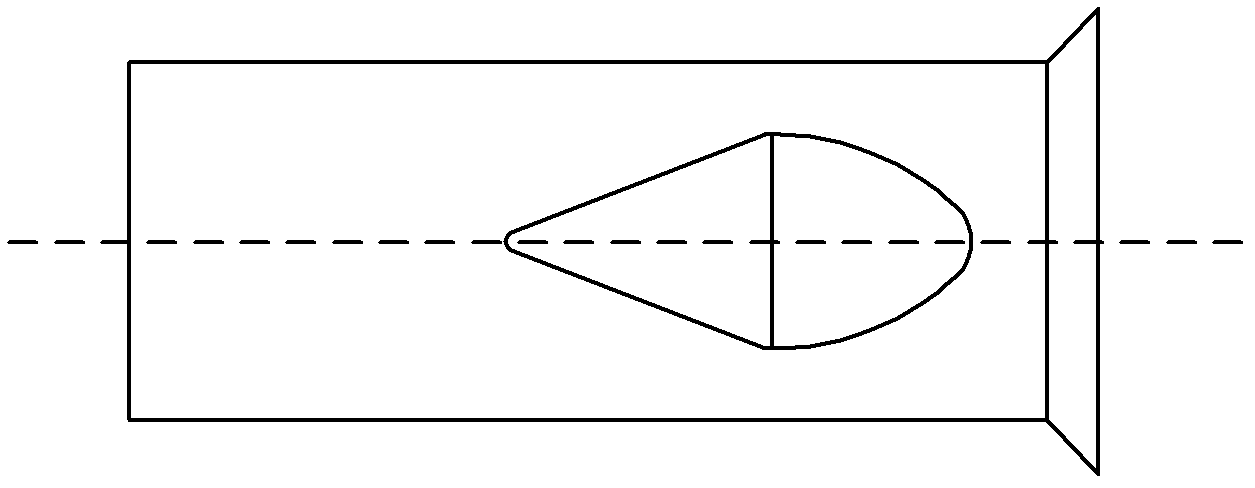

[0031] Such as figure 1 As shown, the combustion stabilizing device is horizontally installed in the primary air duct and consists of two parts. The first part is the impact part, which is in the shape of a cone. A streamlined structure composed of intersecting parts; the impact part and the vortex elimination part share the bottom surface; the radius R of the cone is (0.3-0.6) Rc, the cone angle α is 10°-30°, and the radius R of the front end chamfering arc 0 is (0.01~0.04)Rc; the arc radius r of the arc generatrix is (1.3~1.8)Rc, and the radius r of the sphere is 0 is (0.25~0.35) Rc, the central angle β is 60°~85°; the distance between the end of the combustion stabilization device and the outlet of the primary air duct is (0.1~0.2)Rc,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com