Patents

Literature

51results about How to "Reduce burning intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

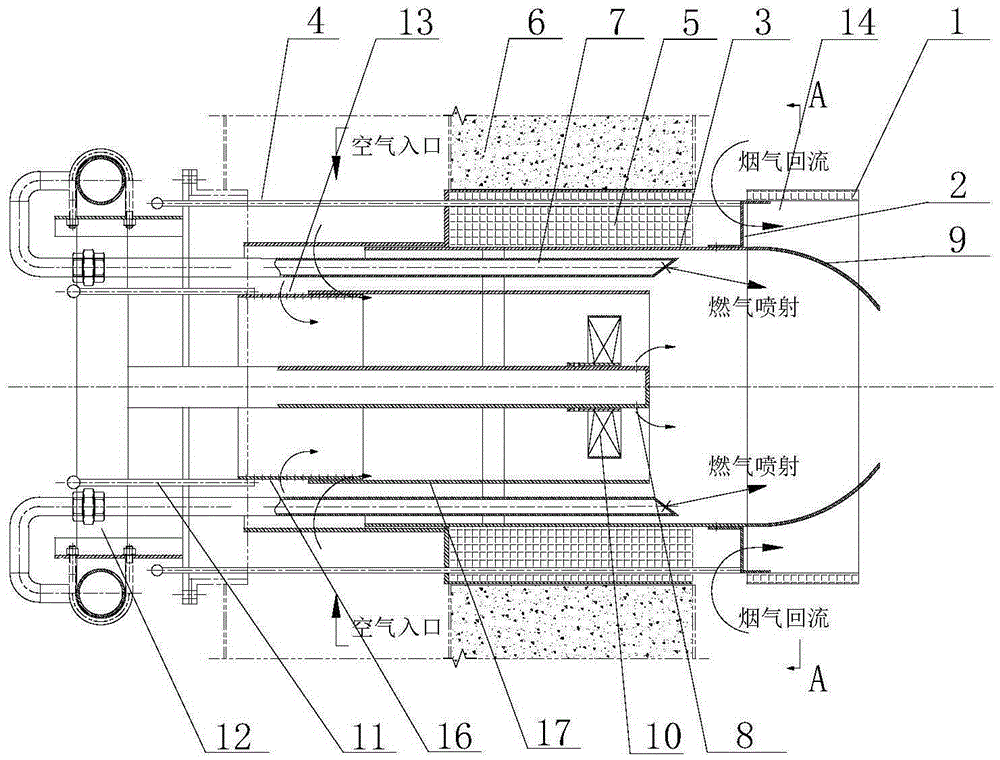

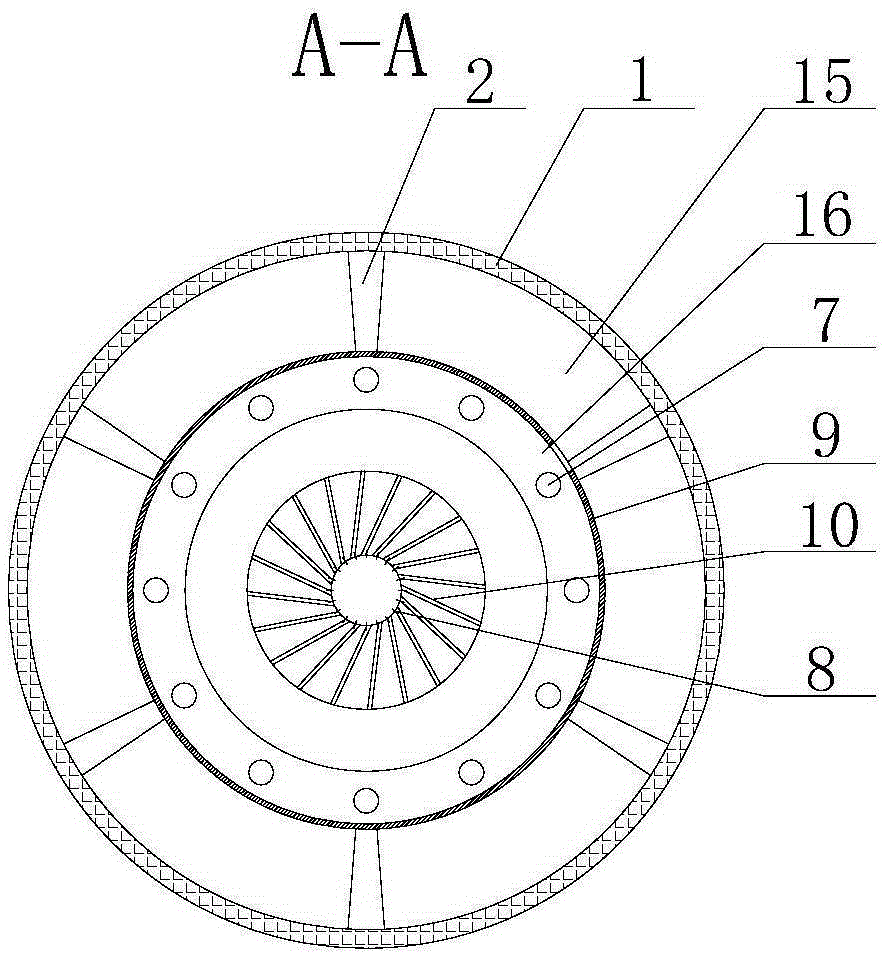

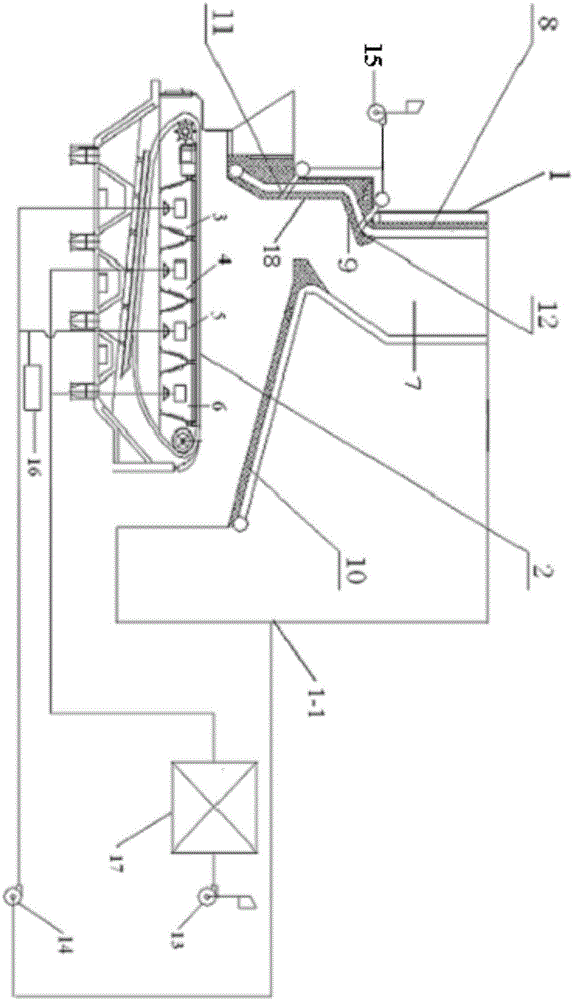

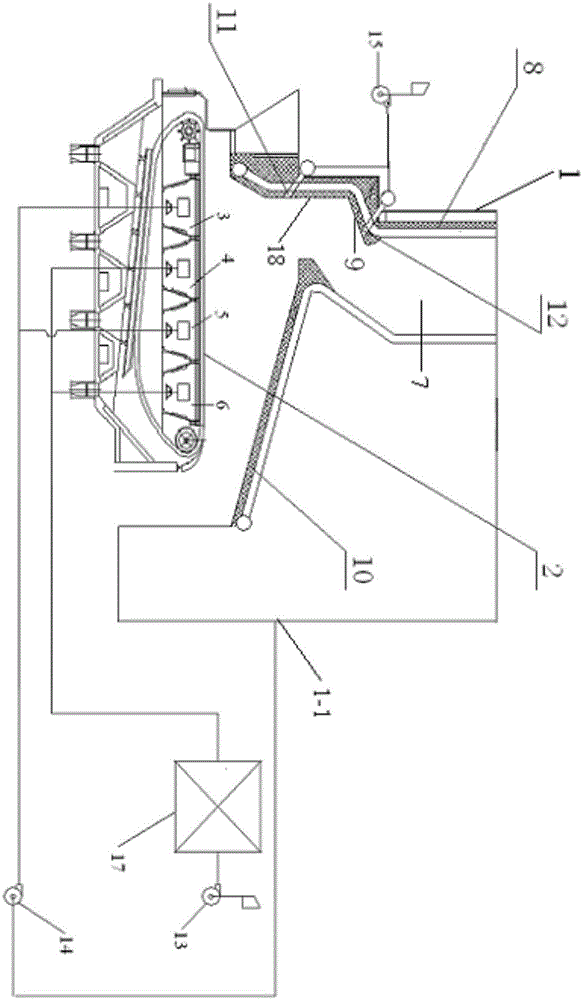

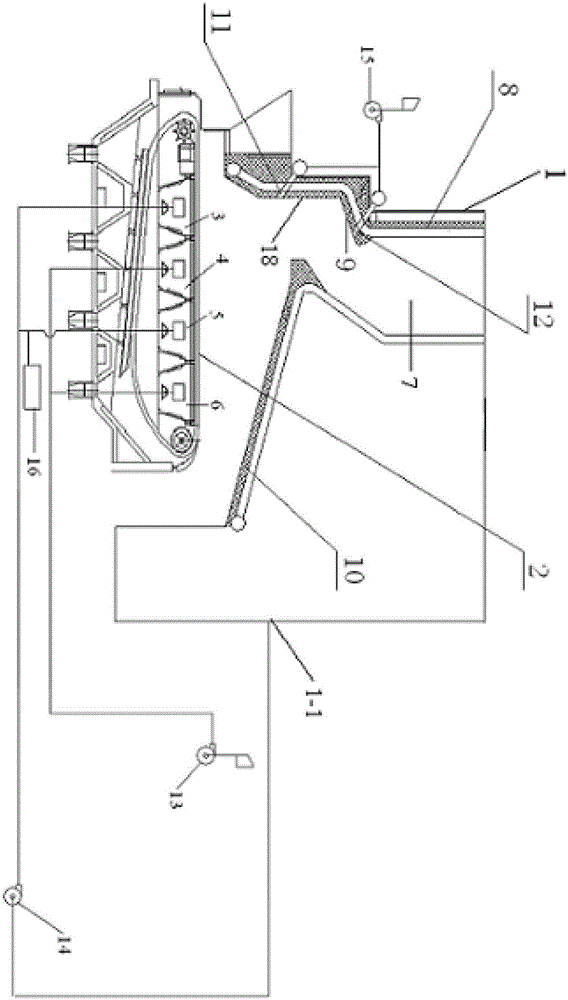

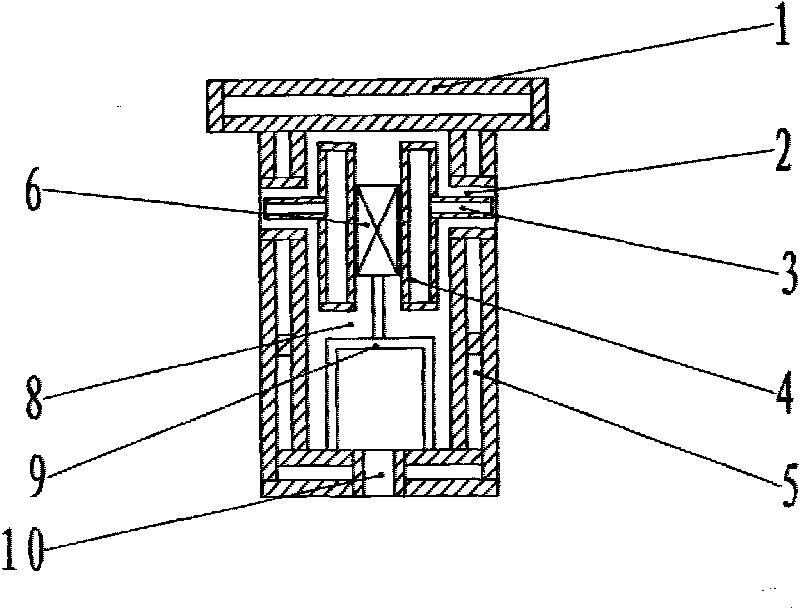

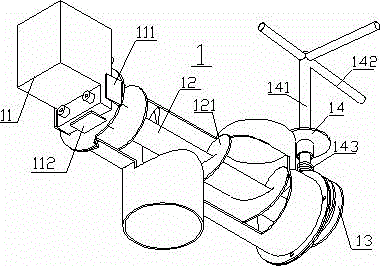

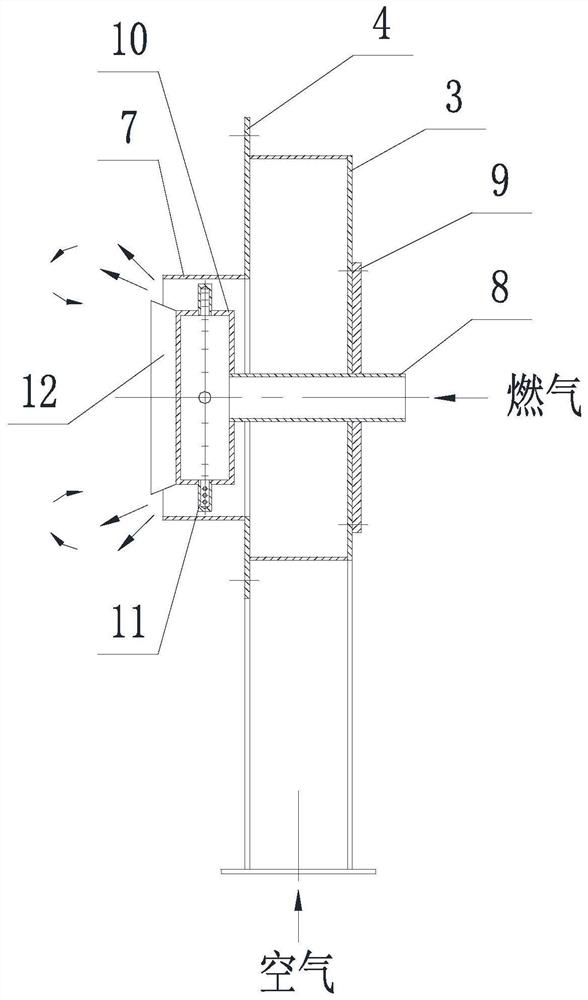

Smoke internal circulation low-nitrogen combustor

InactiveCN105299651ADilute oxygen concentrationExtended burn timeGaseous fuel burnerCombustorLow nitrogen

The invention discloses a smoke internal circulation low-nitrogen combustor which comprises an outer barrel. An inner barrel is arranged in the outer barrel. Main gas spray guns are arranged in a clearance between the outer barrel and the inner barrel. A center gas spray gun is arranged in the inner barrel. A mixed gas outlet flow guide shrinkage cover is fixedly connected with the end of the outer barrel and sleeved with a smoke backflow cover. The smoke backflow cover can slide front and back along the axis of the outer barrel. A smoke backflow channel is arranged between the mixed gas outlet flow guide shrinkage cover and the smoke backflow cover. According to the scheme, smoke in a hearth can flow into a flame area of a combustor outlet through the smoke backflow channel, and therefore the oxygen concentration in mixed gas is diluted, the combustion time of fuel is prolonged, the combustion strength is lowered, high-temperature areas are avoided, and finally the aim of reducing NOx emission is achieved. By means of the structure, no circulating smoke pipeline or circulating fan needs to be additionally arranged, and therefore the investment cost is low.

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

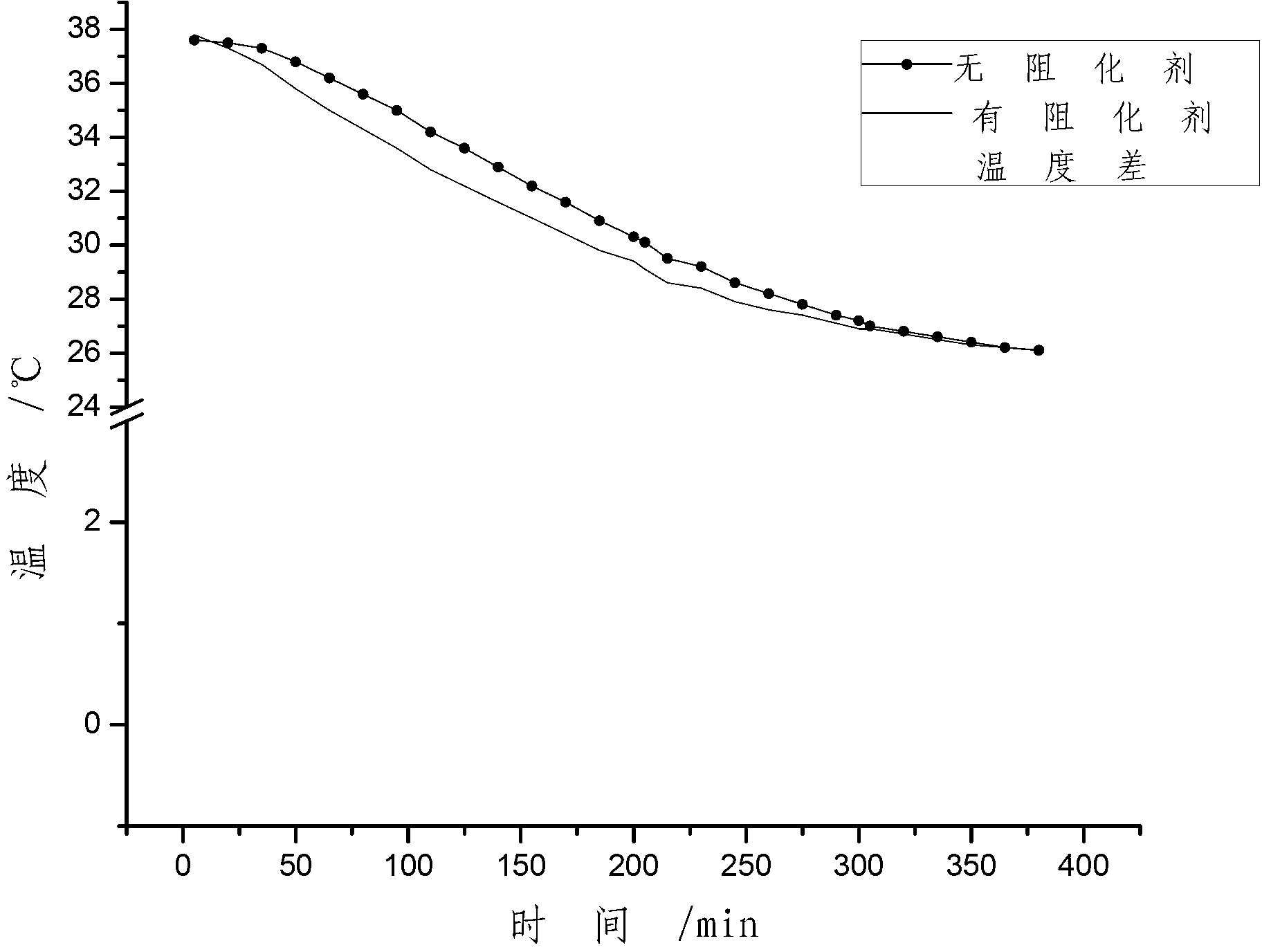

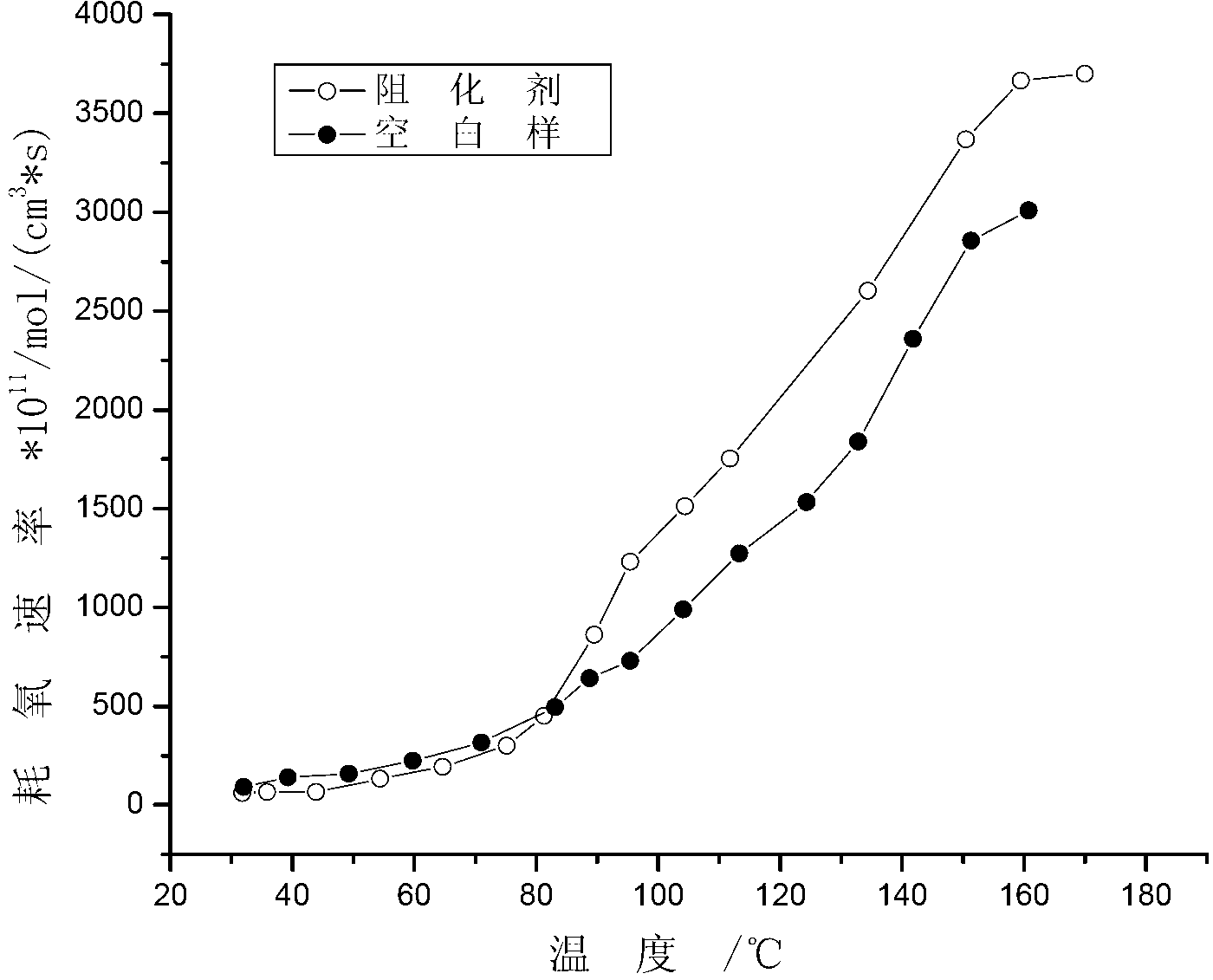

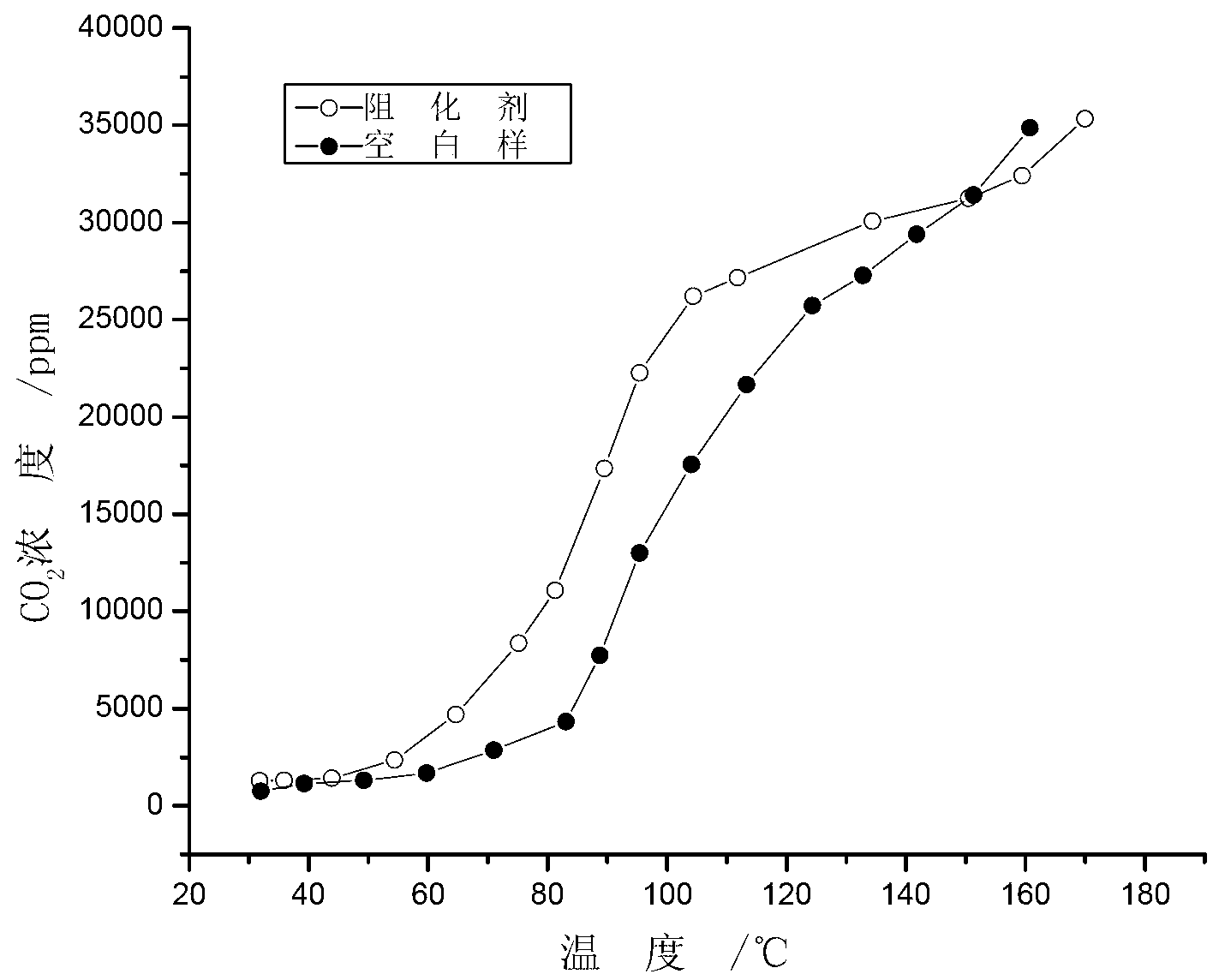

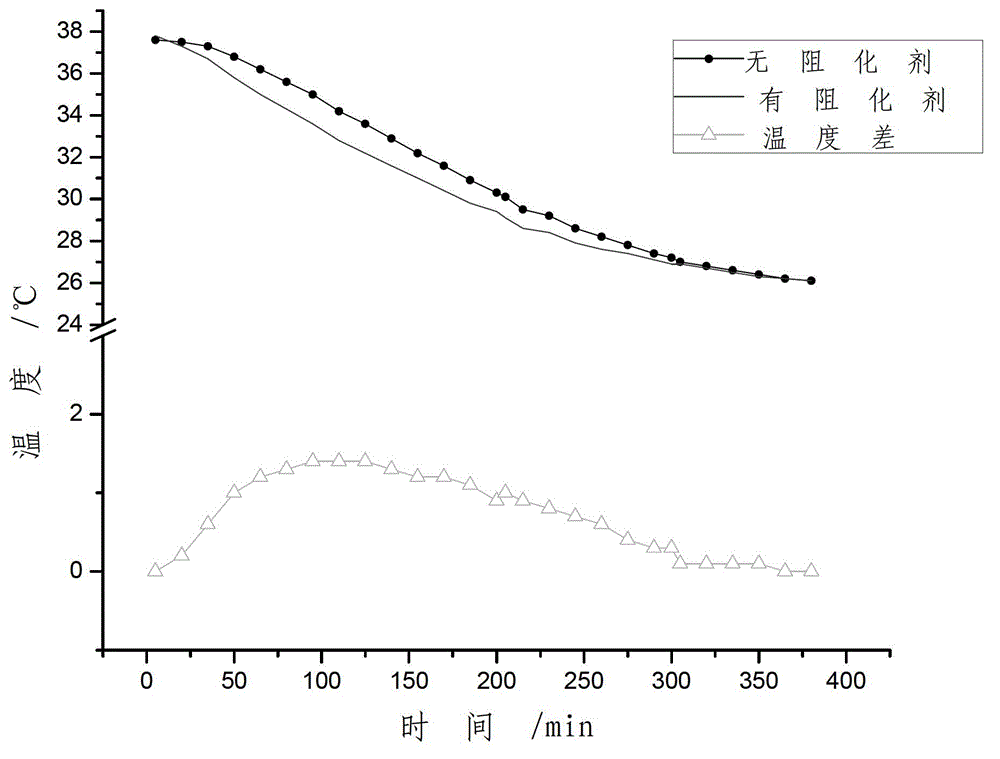

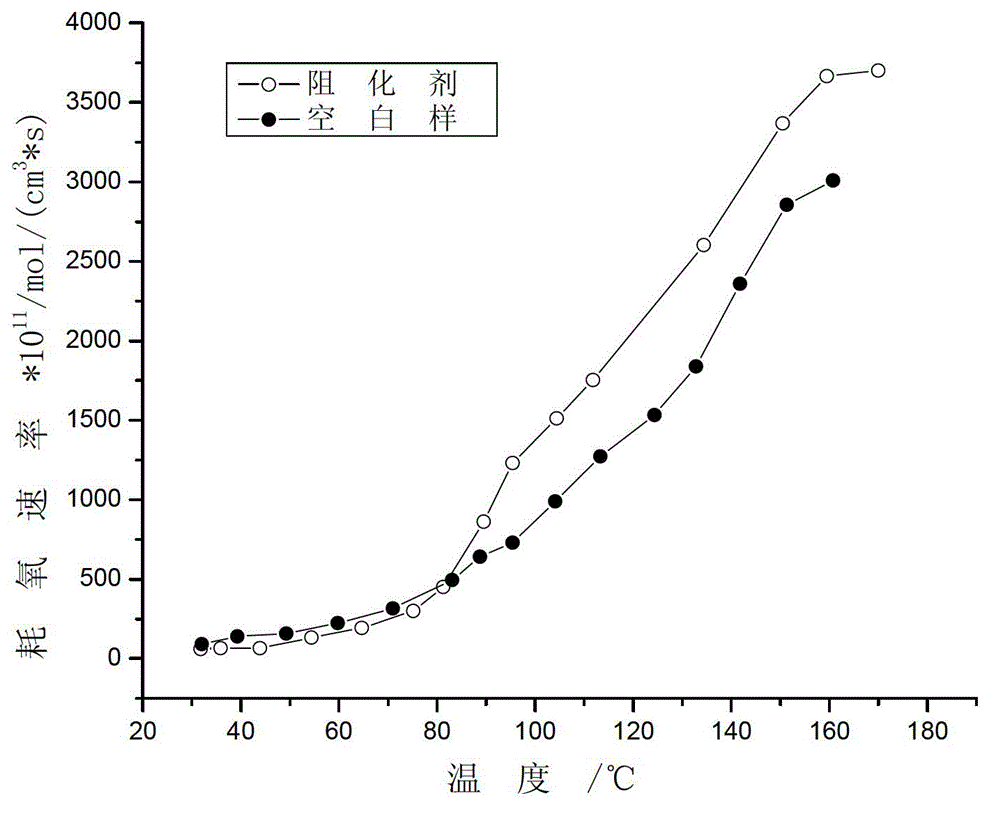

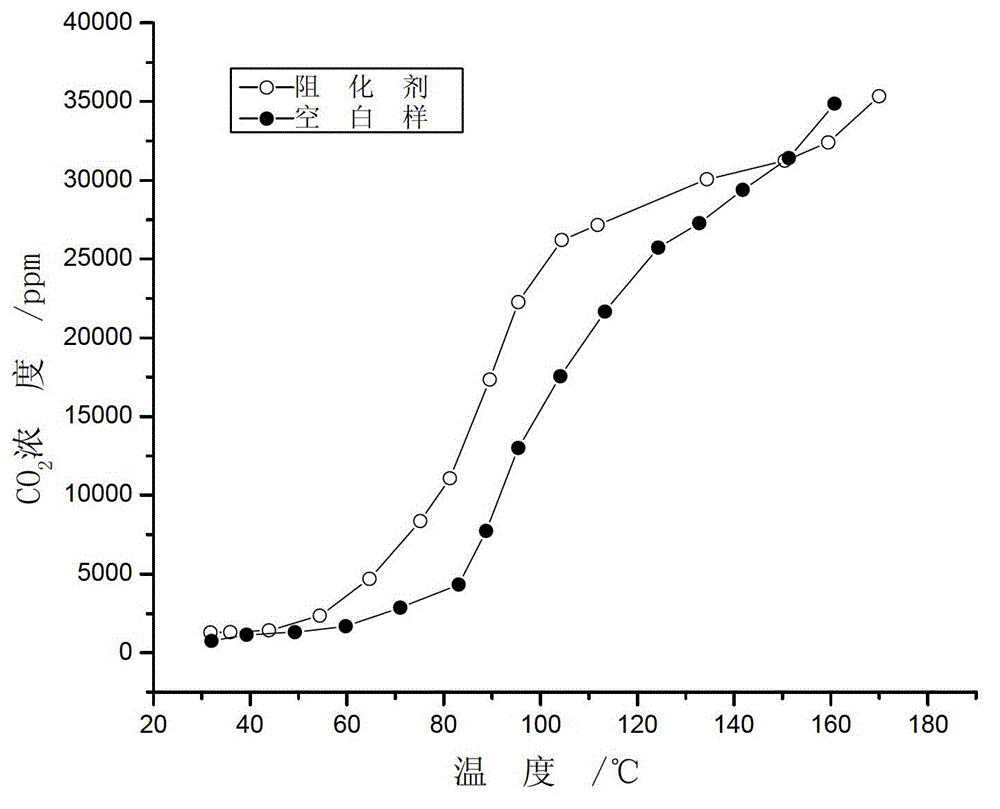

Compound stopping agent for preventing pulverized coal from spontaneous combustion

InactiveCN103306710AReduce reactivityReduce generationDust removalFire preventionInorganic saltsSpontaneous combustion

The invention discloses a compound stopping agent for preventing pulverized coal from spontaneous combustion and a preparation method of the compound stopping agent. The compound stopping agent mainly comprises a component A and a component B, wherein the component A comprises 70%-90% of a penetrant and 10%-30% of peroxide; the component B comprises inorganic salt. The component A and the component B are mixed at a weight ratio of 1:(1.5-3) and used as the compound stopping agent. The preparation method comprises steps as follows: firstly, the penetrant is prepared into an aqueous solution, then the peroxide is dissolved in the penetrant, and the mixture is stirred, so that the component A of the stopping agent is obtained; the component A is matched with the inorganic salt of the component B for use. The compound stopping agent has the characteristics of low cost and non-toxic. During the use, the component A and the component B of the stopping agent are jointly and uniformly added to the pulverized coal, the operation is simple, the stopping effect is excellent, and the compound stopping agent has a wide application prospect.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

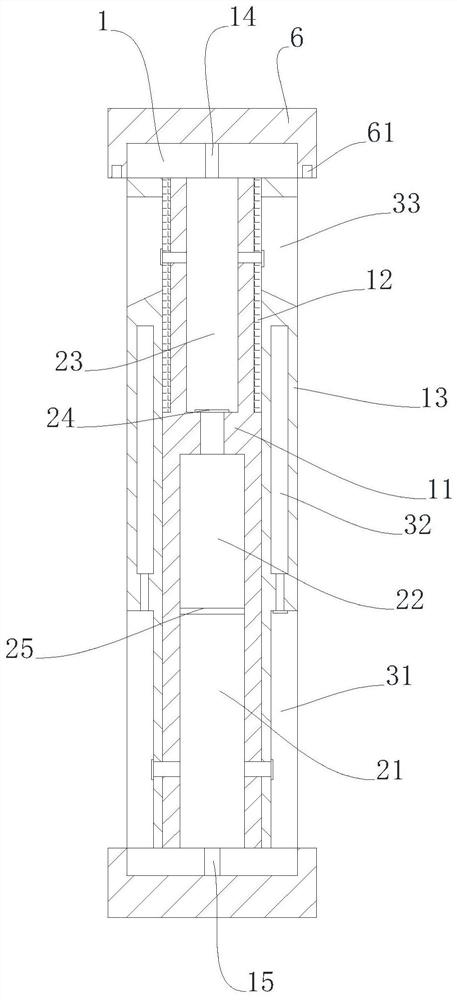

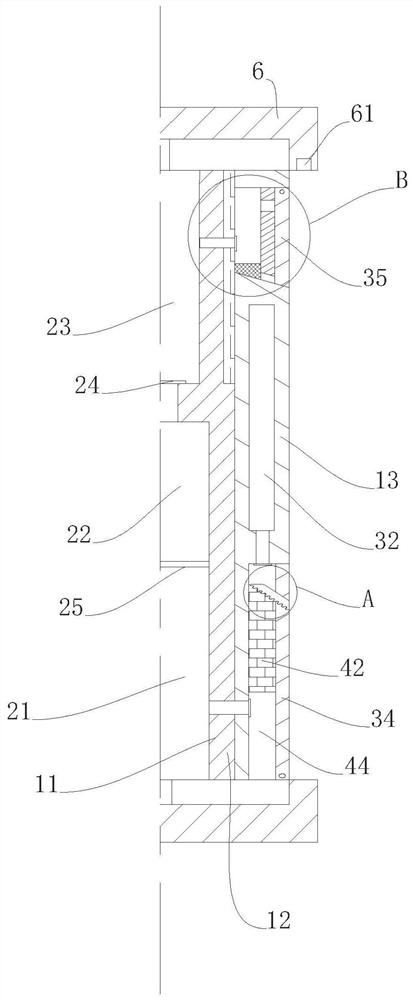

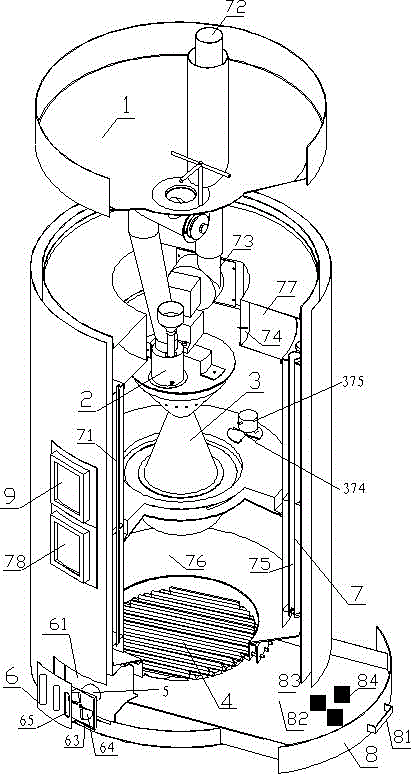

Anti-slagging biomass cascade conversion combustion device

ActiveCN106594713APrevent slaggingThermochemical conversion achievedSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention provides an anti-slagging biomass cascade conversion combustion device and relates to a biomass combustion device. The anti-slagging biomass cascade conversion combustion device aims at solving the technical problem that slagging happens easily when straw is combusted through an existing chain furnace. The anti-slagging biomass cascade conversion combustion device is composed of a chain furnace, a steam generator, an air blower, a high-temperature induced draft fan and an air preheater. A secondary air nozzle is arranged on the front wall below a front arch. An overfire air nozzle is arranged on the front arch. A circulating flue gas chamber communicates with a flue opening in the tail of the chain furnace through the high-temperature induced draft fan. A weak primary air chamber communicates with the air blower through the air preheater. A steam-circulating flue gas chamber communicates with the steam generator and the high-temperature induced draft fan. A strong primary air chamber communicates with the air blower through the air preheater. The secondary air nozzle communicates with the air blower. The overfire air nozzle communicates with the air blower. The anti-slagging biomass cascade conversion combustion device effectively solves the problem of slagging of biomass combustion chain grates.

Owner:HARBIN INST OF TECH

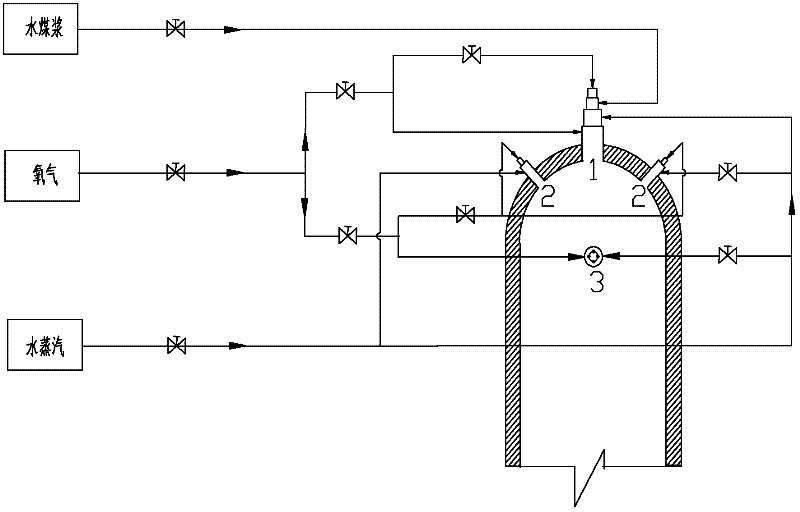

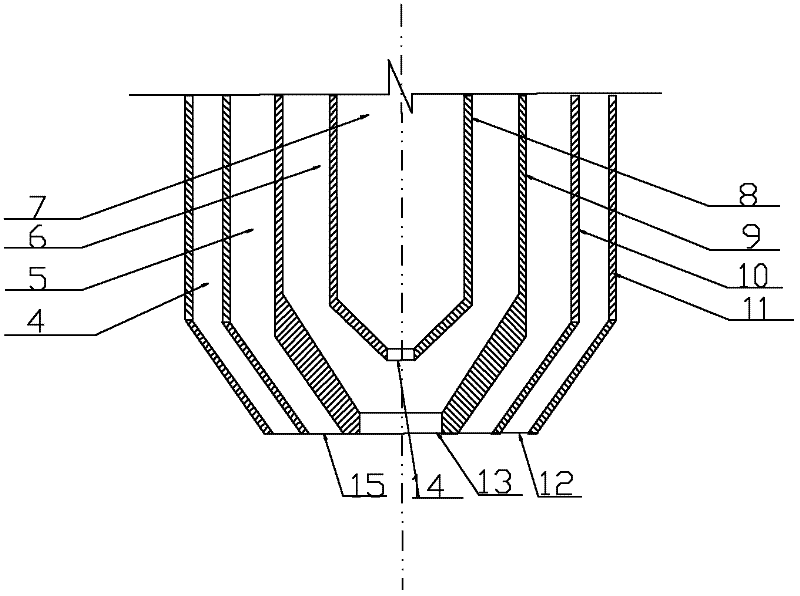

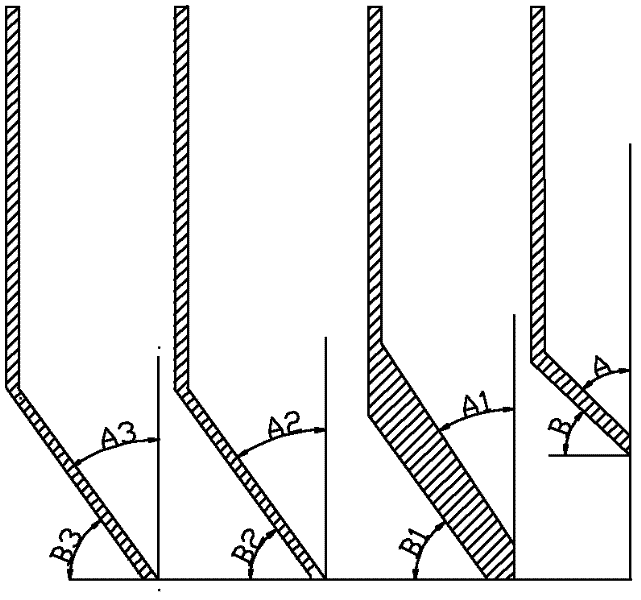

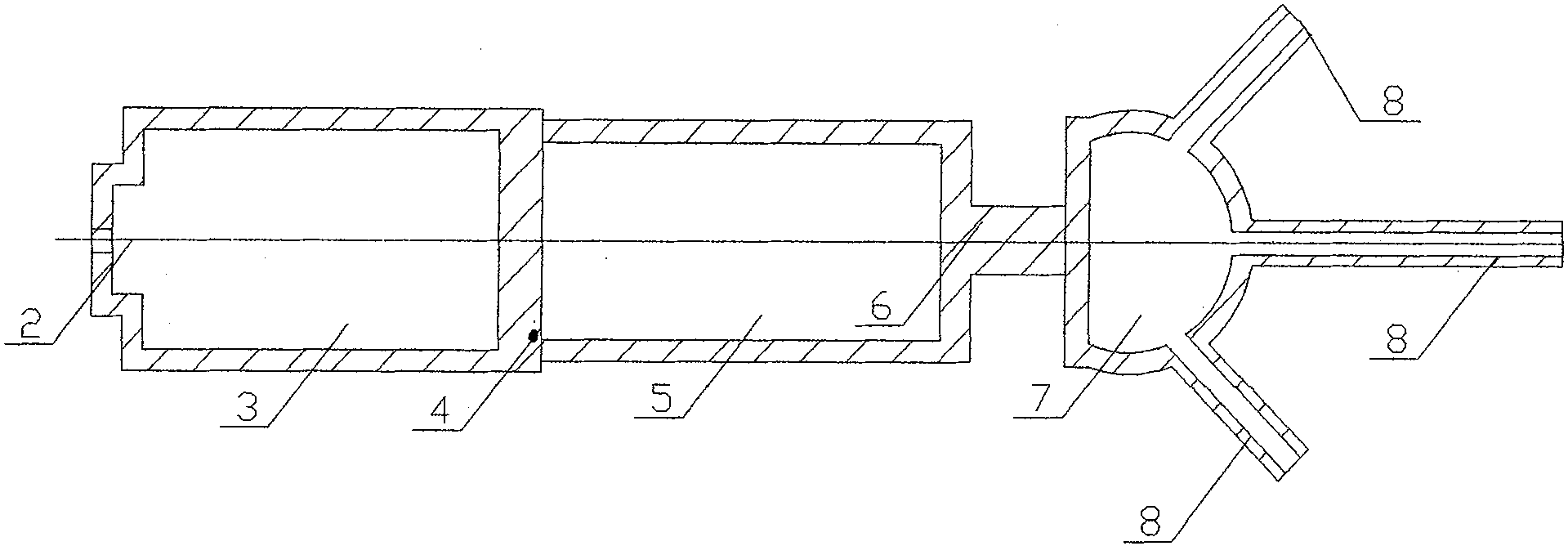

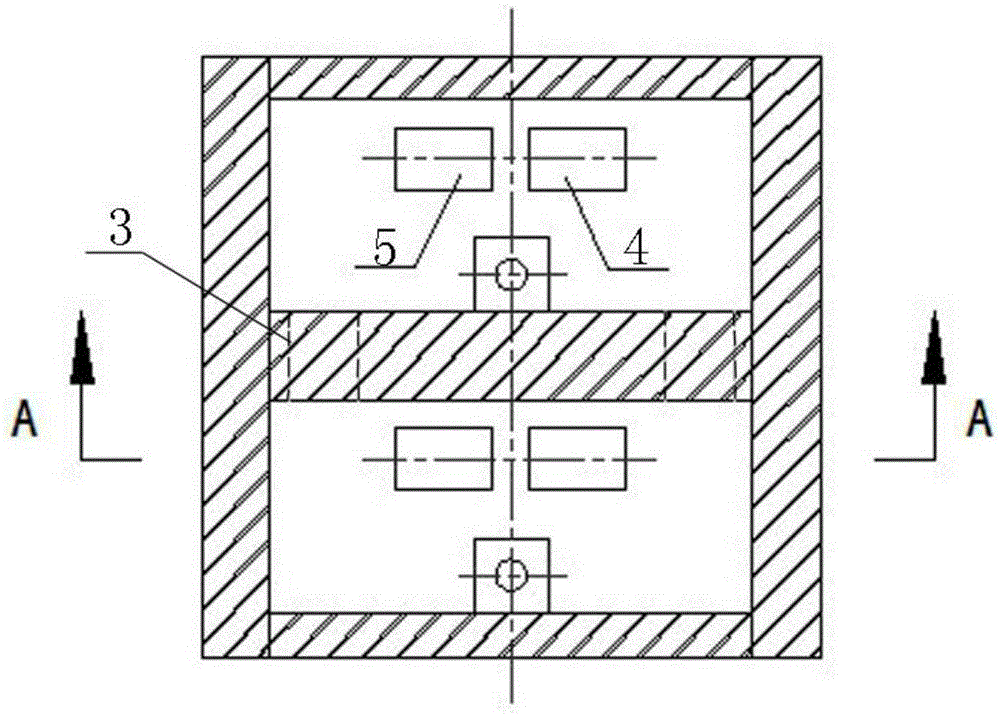

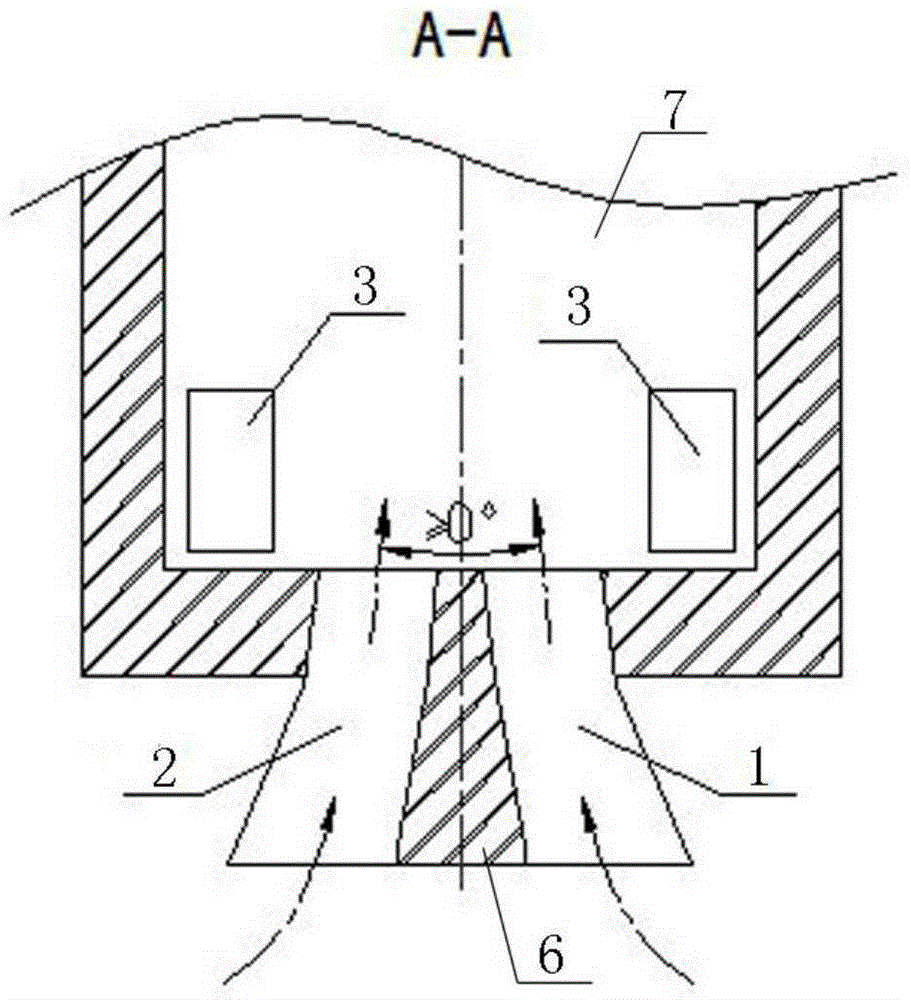

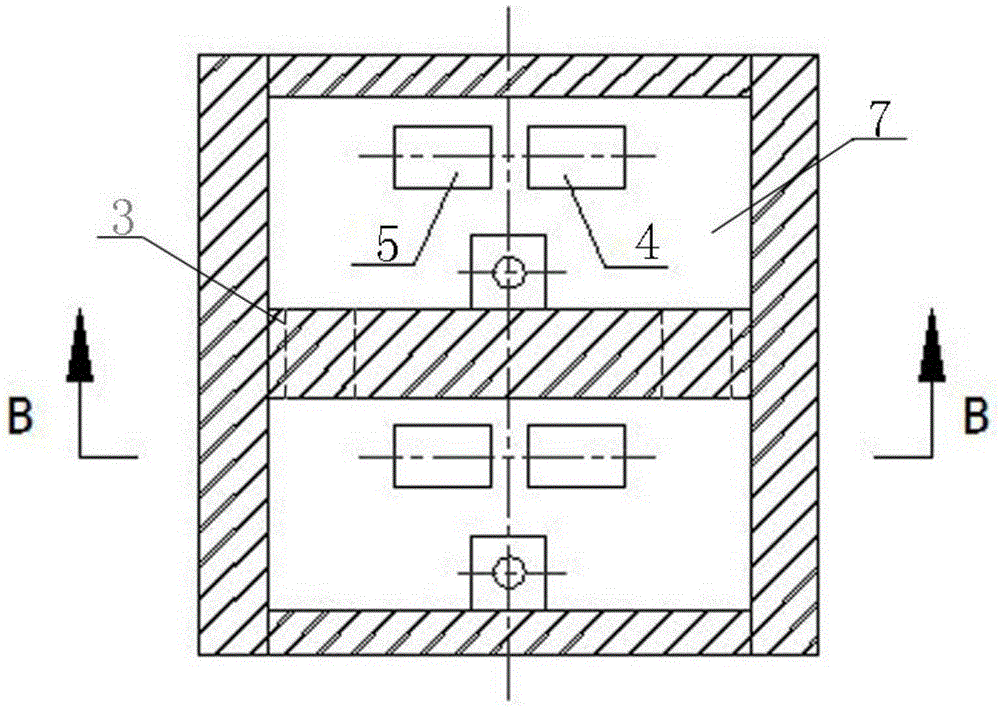

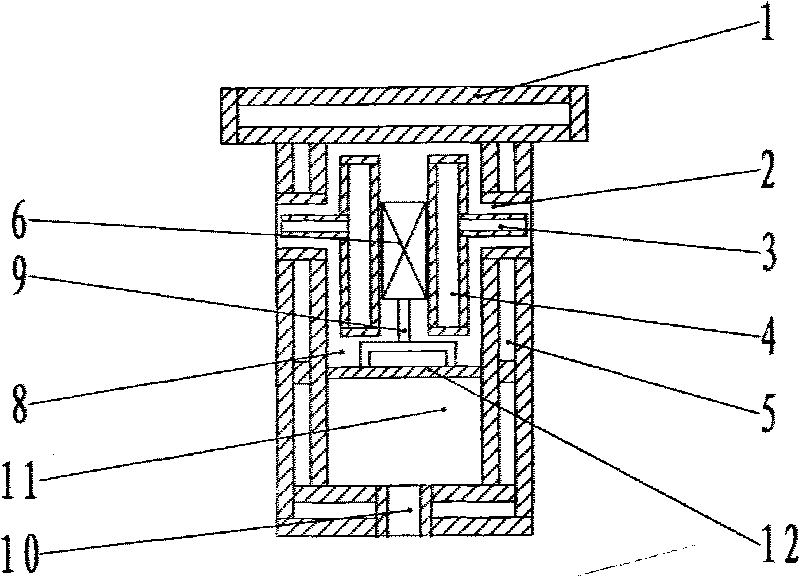

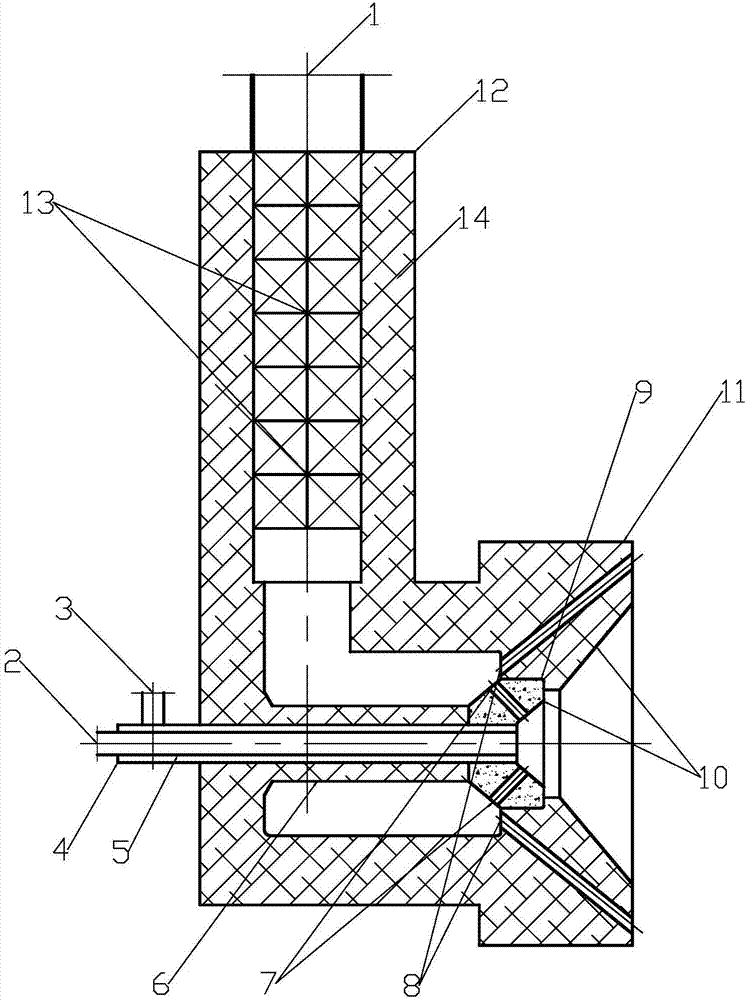

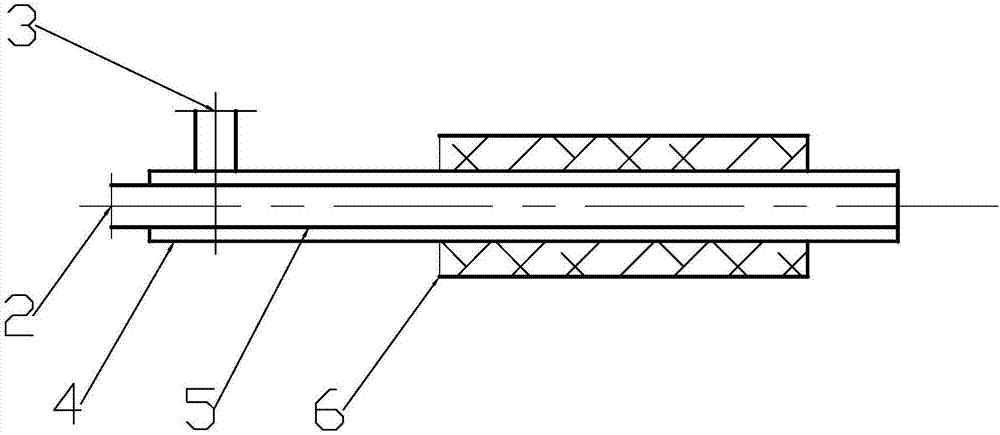

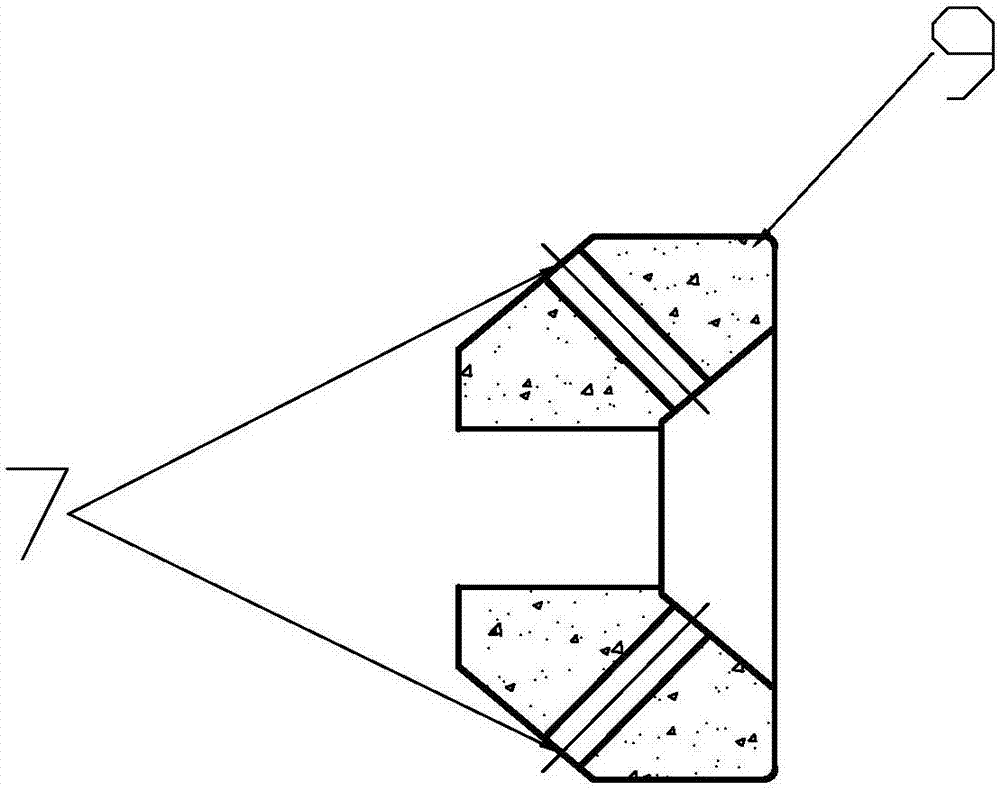

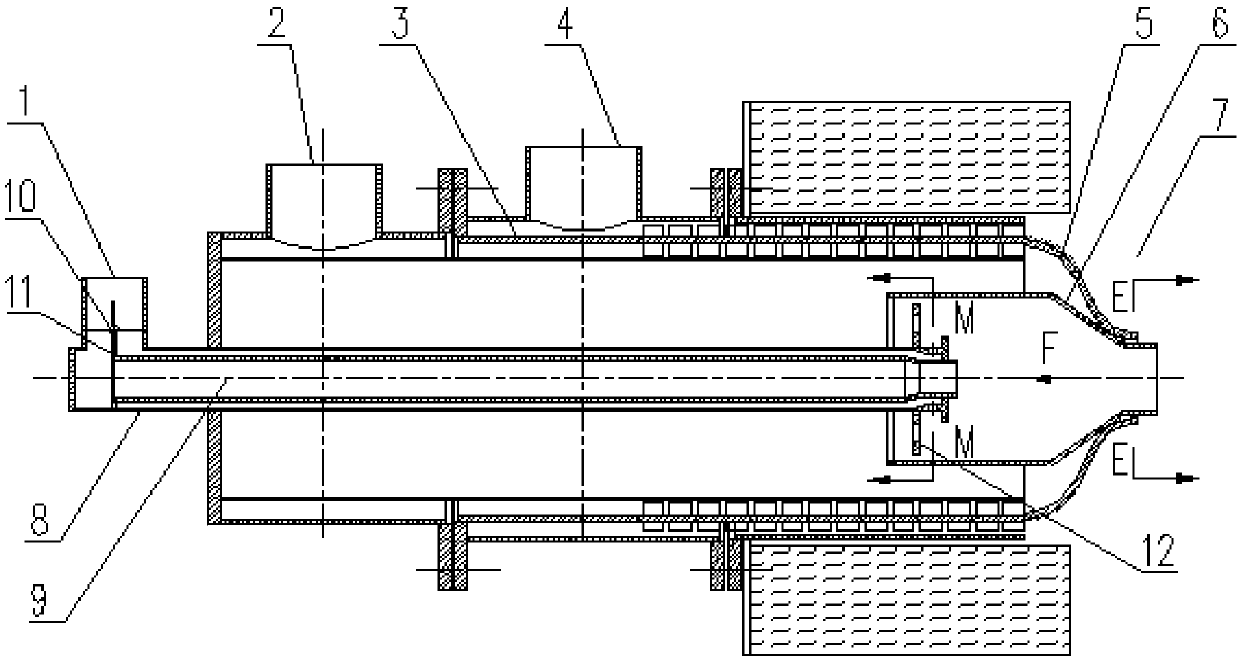

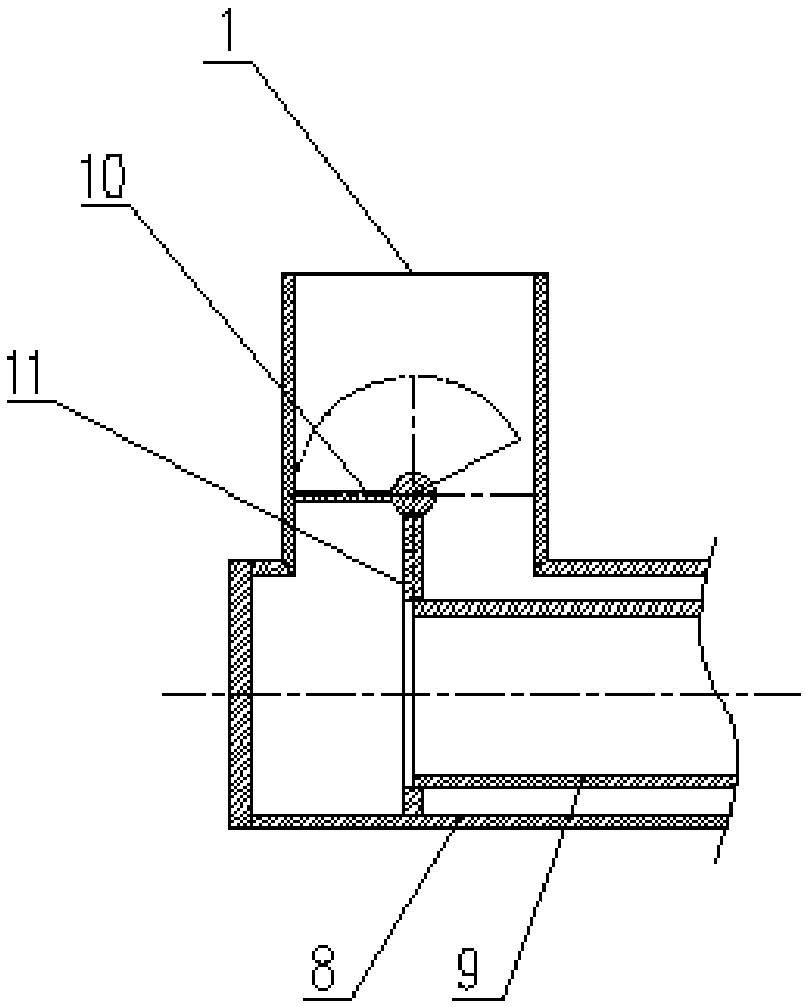

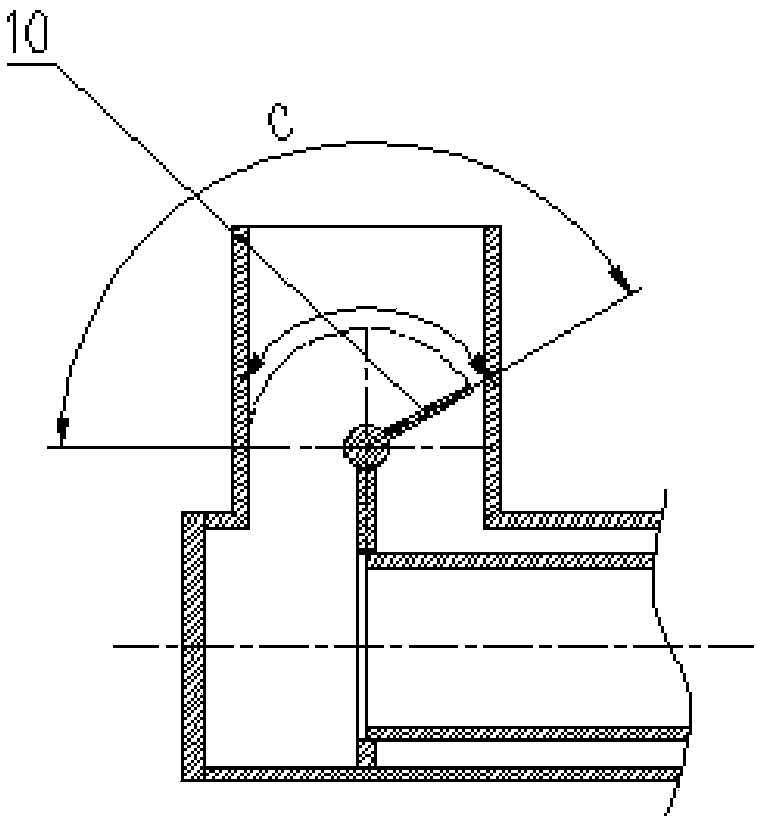

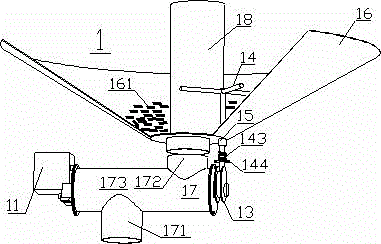

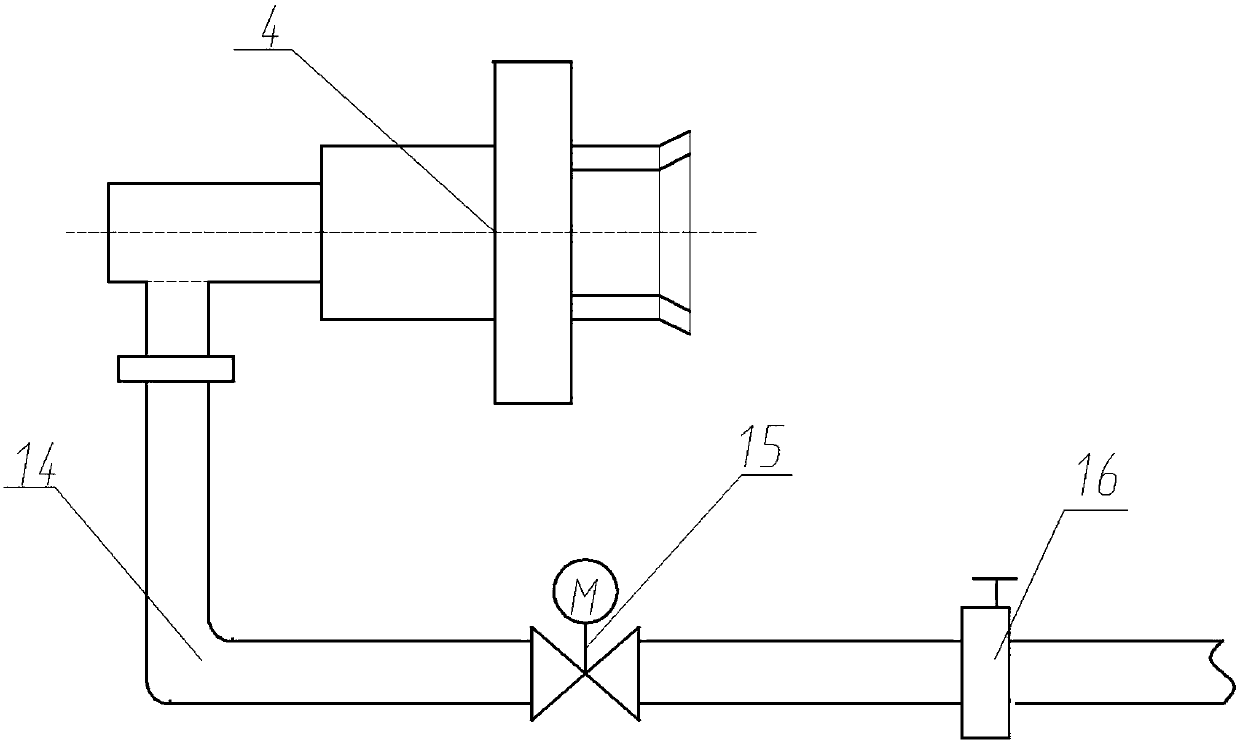

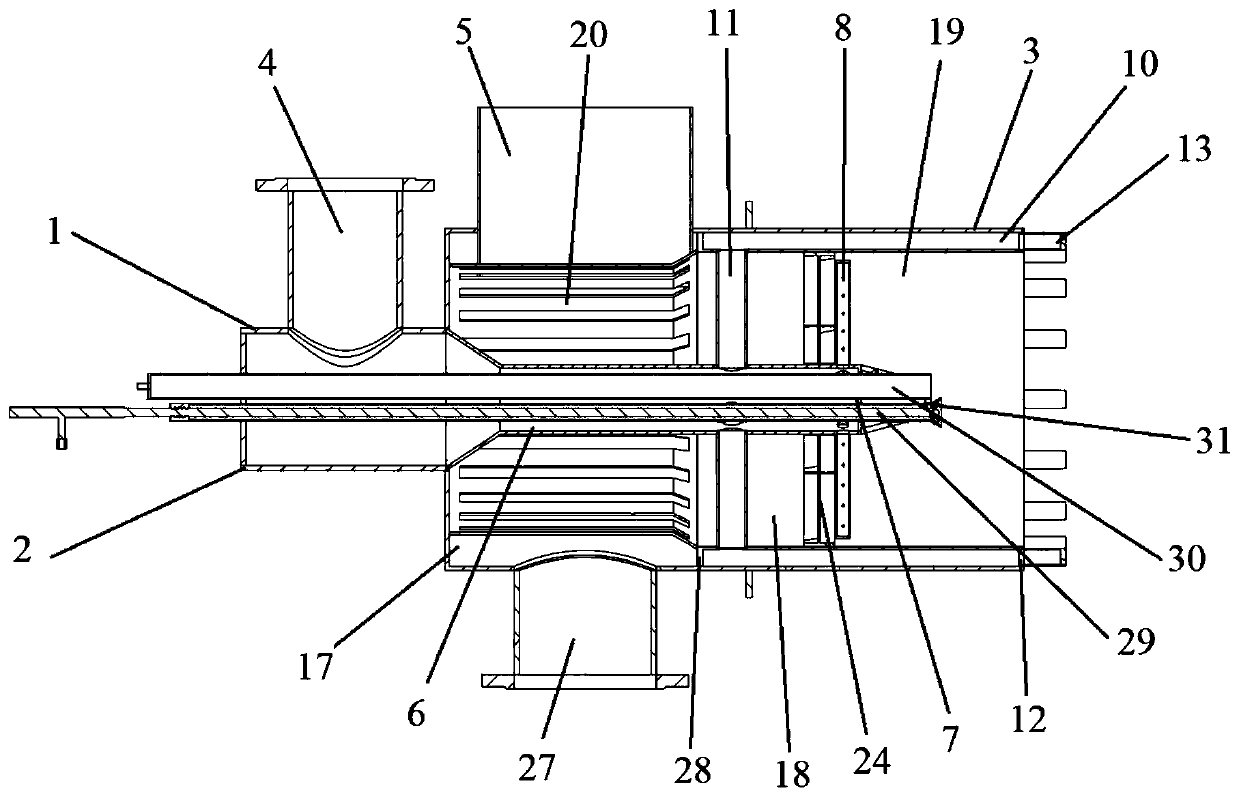

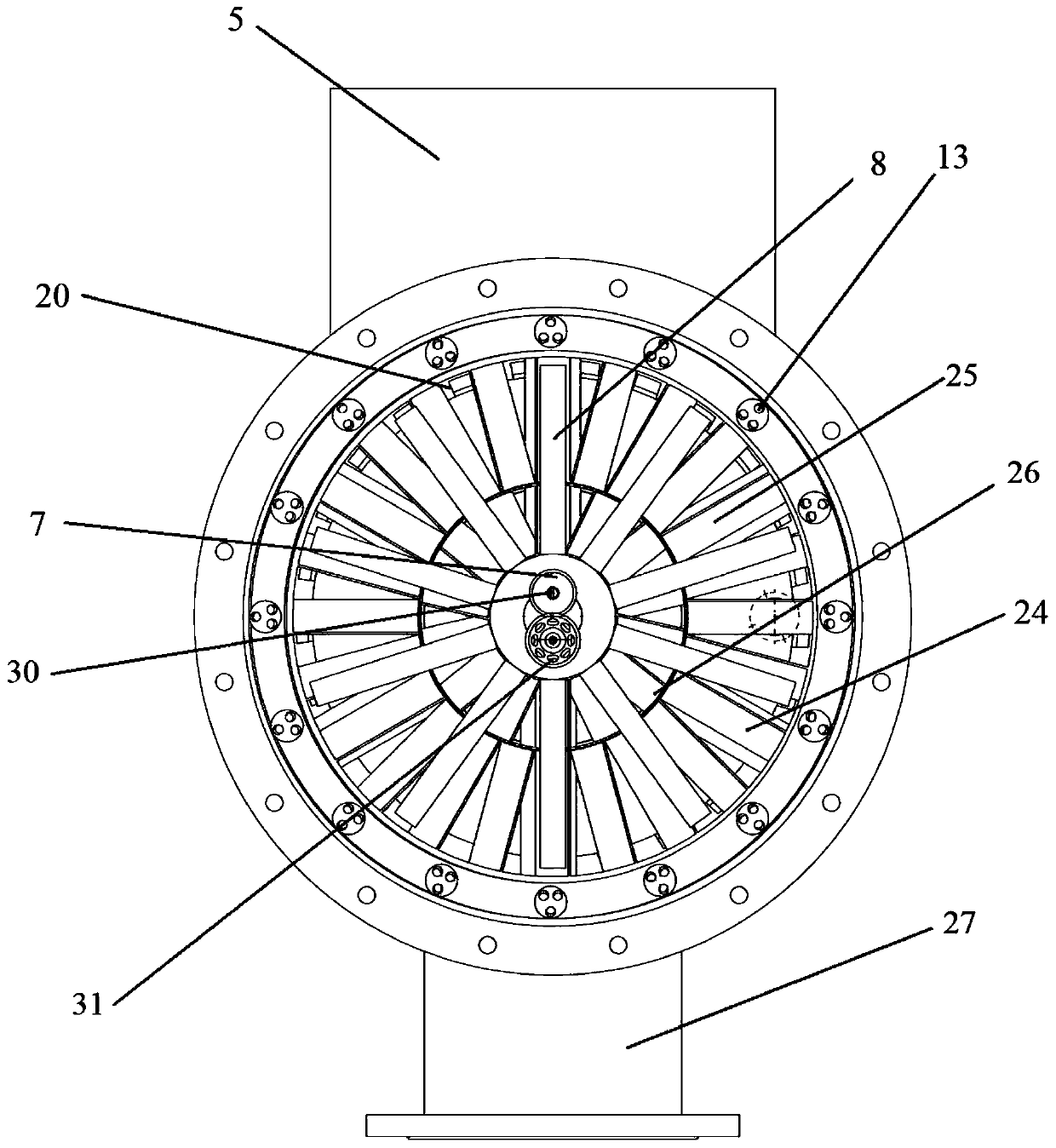

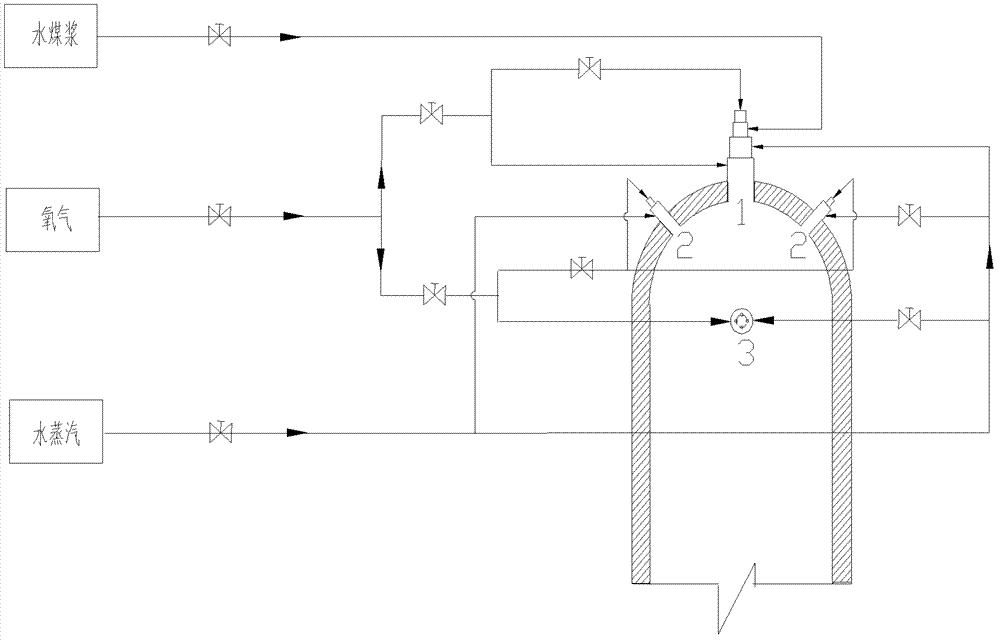

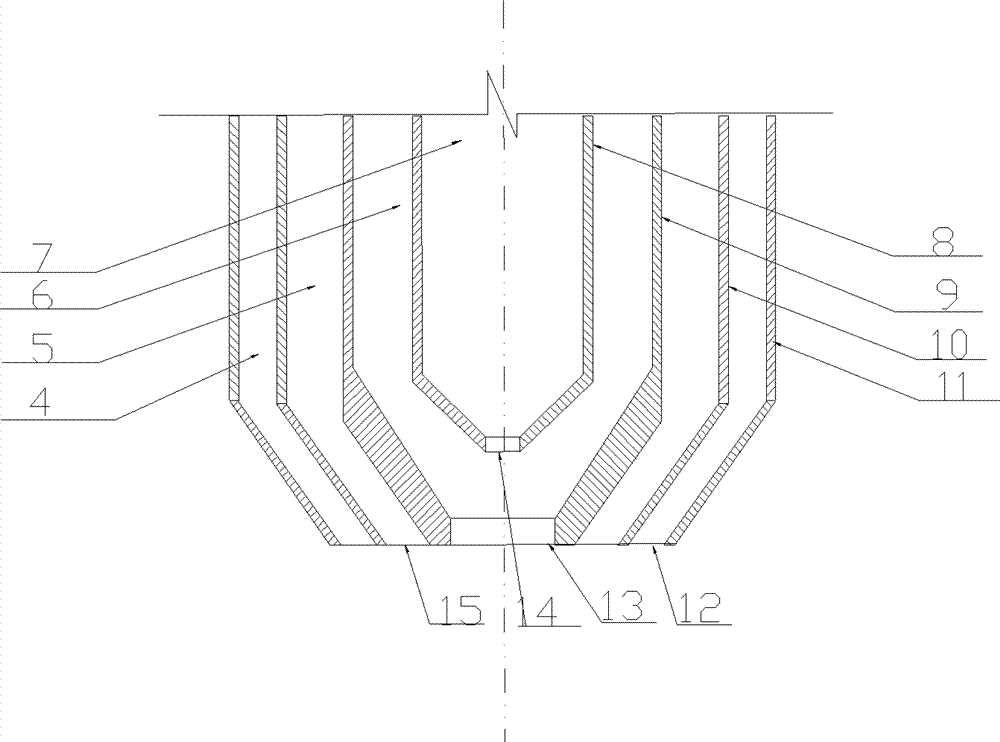

Hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle

InactiveCN102492477AReduce burning intensityLower flame temperatureLiquid spraying apparatusCombined combustion mitigationSlagReaction rate

The invention relates to a hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle which is arranged on a gasification furnace. The hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle comprises a main fuel nozzle which is arranged at the top of a furnace, two steam nozzles which are arranged at the two sides of a furnace arch and two oxygen supply nozzles which are horizontally arranged in a hedging manner, wherein the nozzles are respectively connected with a coal water slurry source, an oxygen source and a steam source, and the openings of the nozzles lead into a hearth of the gasification furnace. According to the invention, an advanced temperature control technology combining a grading oxygen supply temperature control technology and a steam temperature control technology is adopted, combustion intensity and flame temperature in the furnace are effectively reduced, and the aim that ash at the outlet of the gasification chamber is non-fused solid slag; meanwhile, gasification reaction rate and carbon conversion rate are improved, thus gasification solid deslagging on a 'double high' coal type large-scale pressurization entrained bed in China is realized, and the hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle provided by the invention is especially applicable to industrial application of a high-ash (25-27%) and high-ash-fusing-point (FT is more than 1400 DEG C) coal type large-scale gasification device in China.

Owner:SHANGHAI JIAO TONG UNIV

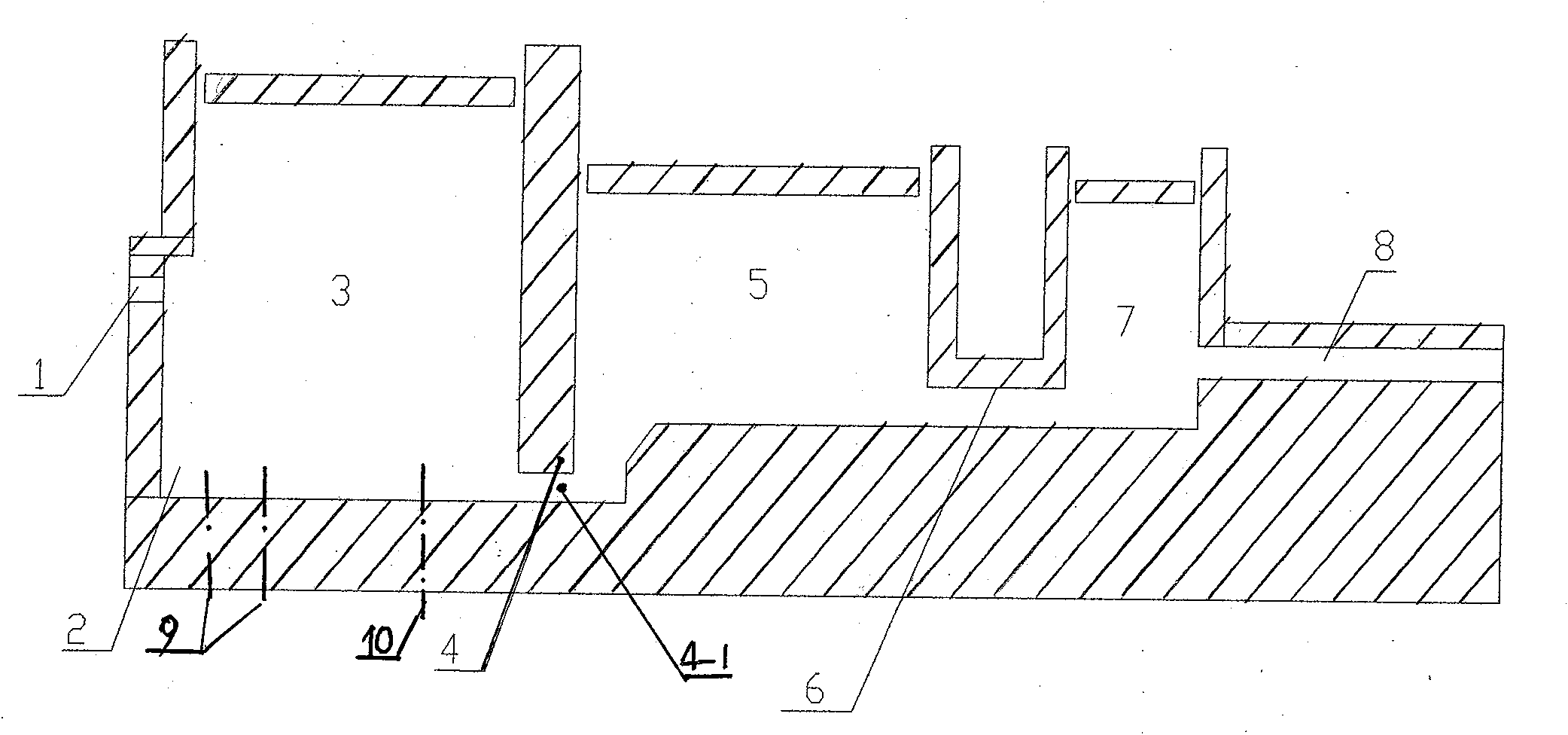

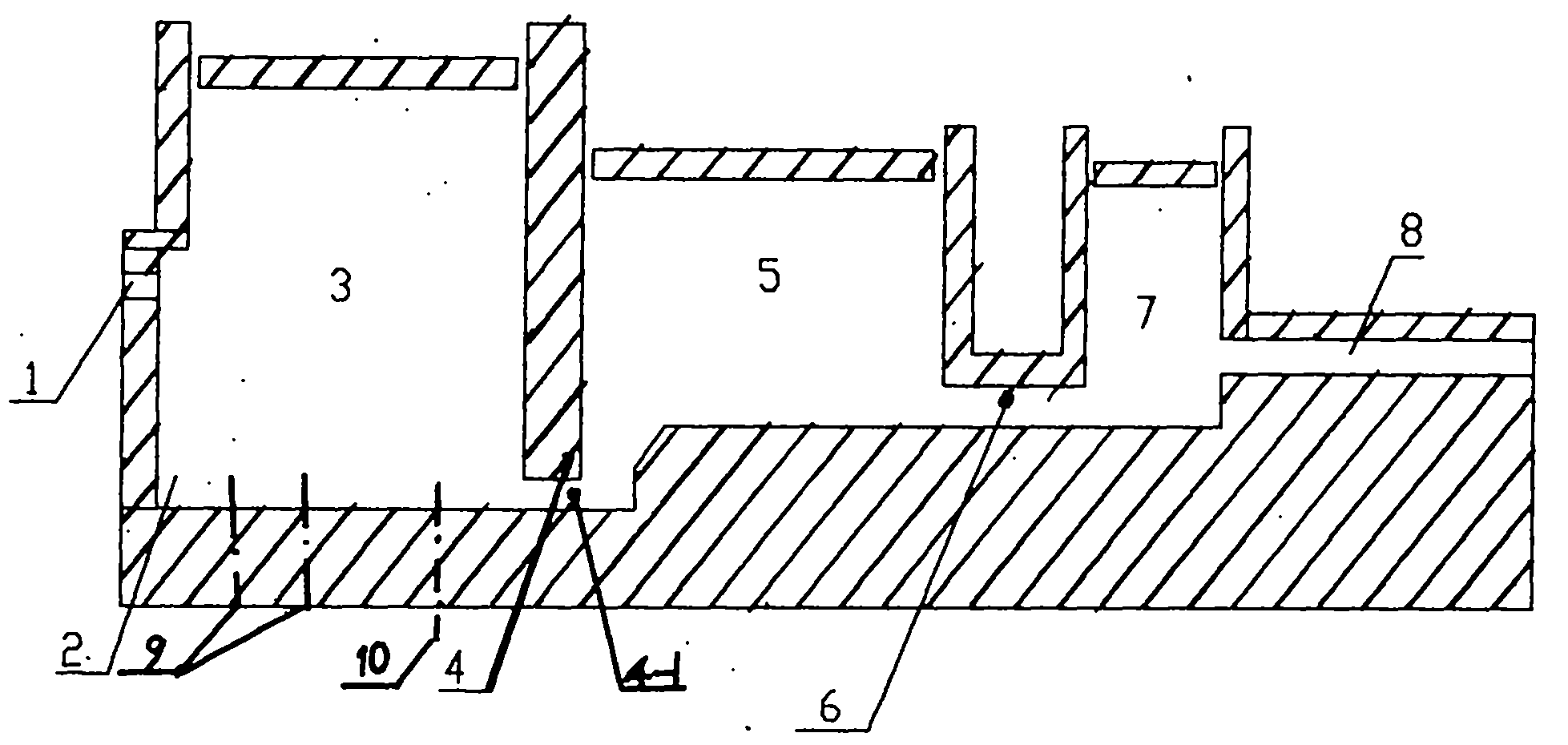

Glass tank for melting high-boron low-alkali or alkali-free glass

InactiveCN101880120AEasy to manageTimely managementTank furnacesGlass productionMelting tankAlkali free

The invention relates to a glass tank for melting high-boron low-alkali or alkali-free glass and manufacturing a TFT-LED glass substrate. The glass tank comprises a heating system matched with the glass tank and is characterized in that: the internal structure of the glass tank comprises a pre-melting tank with a feed inlet, a cross flame melting tank connected with the pre-melting tank, a cross flame clarification tank communicated with the cross flame melting tank through a lower passage of a flow-limiting diaphragm wall, and a cross flame work pool communicated with the cross flame clarification tank through a pipeline; and a forming passage for delivering molten glass is formed on the cross flame work pool. The glass tank reasonably utilizes energy; and the generated molten glass has the advantages of quick temperature rise, uniformity and high defoaming efficiency.

Owner:TUNGHSU GRP

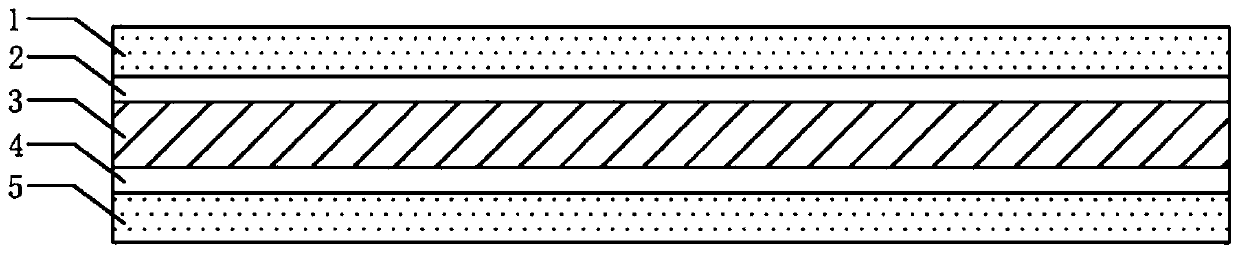

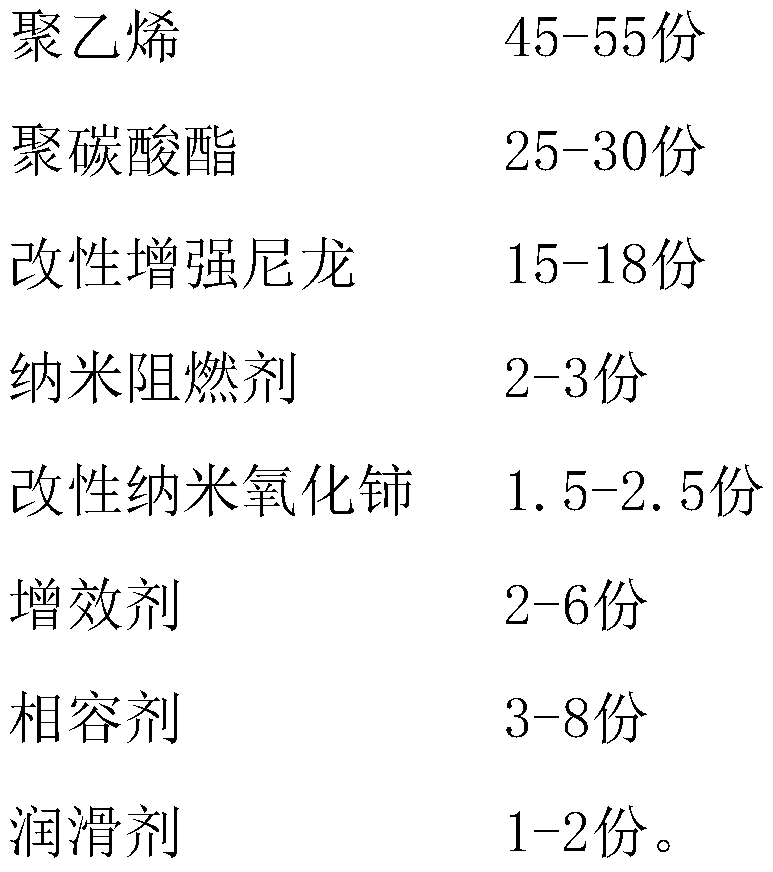

Fireproof aluminium-plastic panel containing nanometer flame retardant and core material special for fireproof aluminium-plastic panel containing nanometer flame retardant

InactiveCN110157072AGood compatibilityGood dispersionSynthetic resin layered productsMetal layered productsDispersityInjection moulding

The invention relates to the technical field of aluminium-plastic panels, in particular to a fireproof aluminium-plastic panel containing a nanometer flame retardant and a core material special for the fireproof aluminium-plastic panel containing the nanometer flame retardant. The core material comprises the following raw materials in parts by weight: 45-55 parts of polyethylene, 25-30 parts of polycarbonate, 15-18 parts of modified enhanced nylon, 2-3 parts of the nanometer flame retardant, 1.5-2.5 parts of modified nanometer cerium oxide, 2-6 parts of a synergist, 3-8 parts of a compatilizerand 1-2 parts of a lubricant. The core material has excellent flame-retardant and fireproof performance, the mobility is high, a core layer can be easily produced through extrusion molding and injection molding, and the core layer produced by using the core material is high in strength and excellent in hardness, resists bending, is not liable to deform, and is excellent in weather resistance; andby adopting the nanometer flame retardant, through combined action of the nanometer flame retardant and the synergist, the core material can have the excellent flame retardant and fireproof performance, and not only can the synergist have an flame-retardant effect, but also a powder state of the synergist can promote the dispersity of materials, so that the rheological property of the core material in the subsequent technologies is improved.

Owner:东莞华尔泰装饰材料有限公司

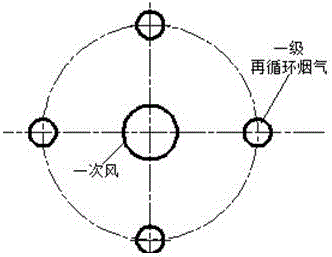

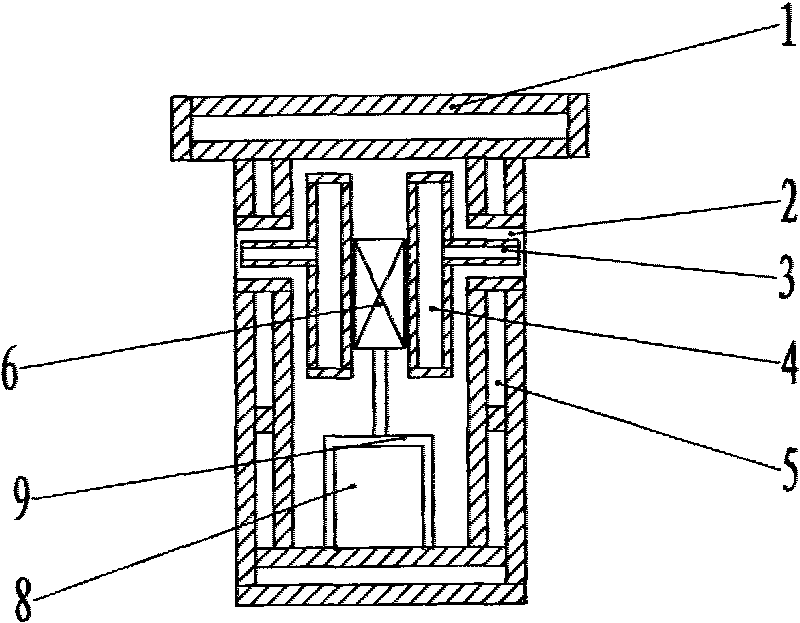

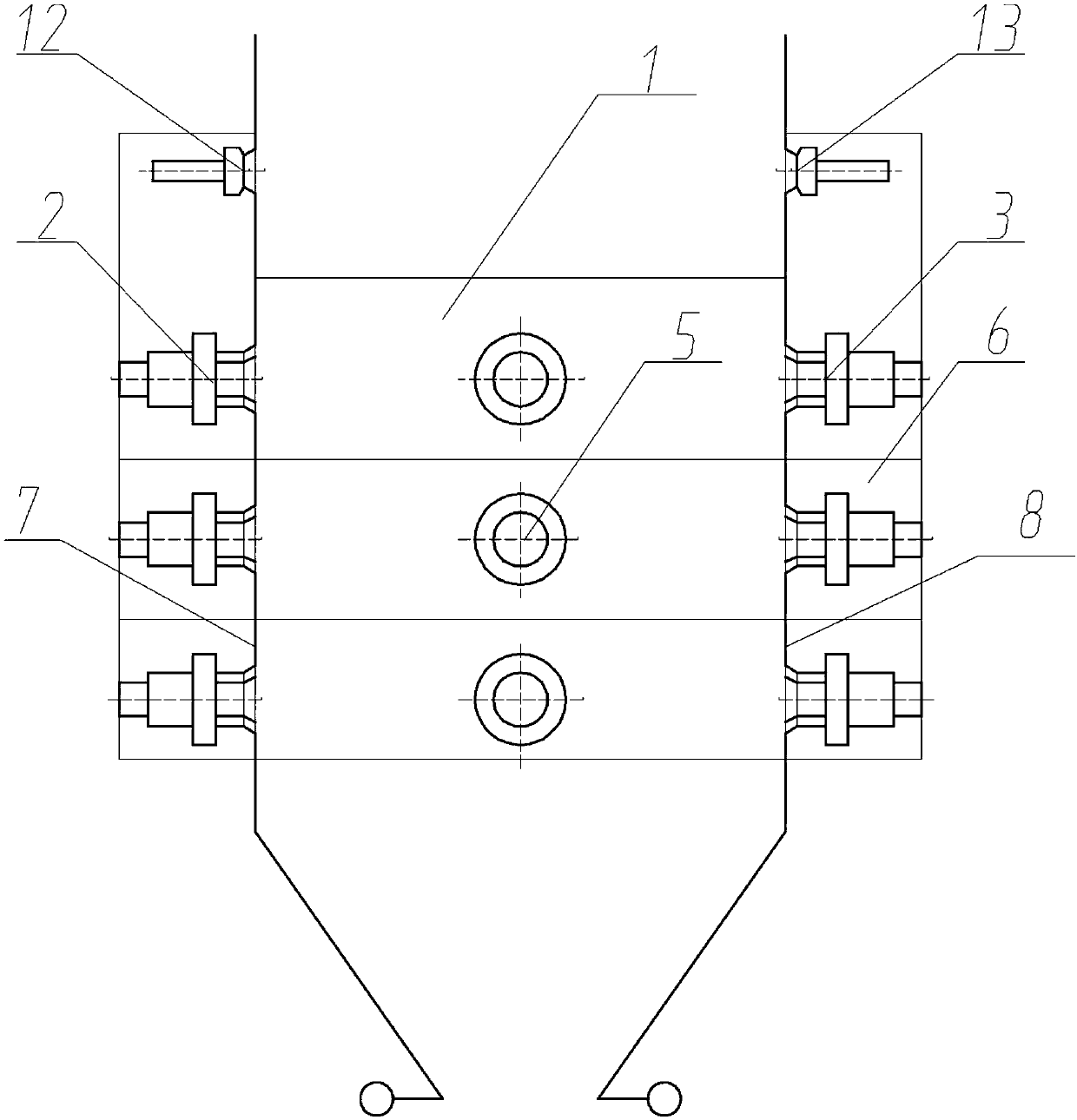

Low-nitrogen combustion device for fluidized bed boiler

ActiveCN106642090AImprove temperature distribution uniformityReduce burning intensityFluidized bed combustionStaged combustionFlue gasCoupling

The invention relates to a low-nitrogen combustion device for a fluidized bed boiler. According to the principle of oxynitride generation, through coupling of air staging and recycled flue gas staging technologies, a combustion area with three stages of the strong reducing property, the weak reducing property and oxidability is formed in the height direction of a hearth, meanwhile, the combustion intensity of a dense-phase area of the hearth is remarkably alleviated, the combustion temperature of the dense-phase area of the hearth is controlled, the distribution uniformity of the overall temperature of the hearth is improved, and generation of temperature type oxynitride is restrained; and meanwhile, generation of fuel type oxynitride is greatly lowered, and generated oxynitride can be restored into nitrogen.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

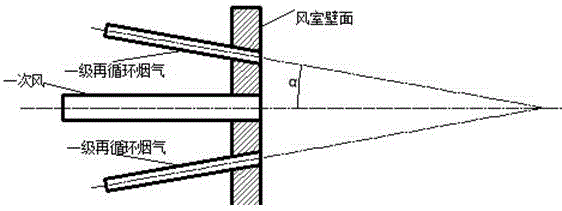

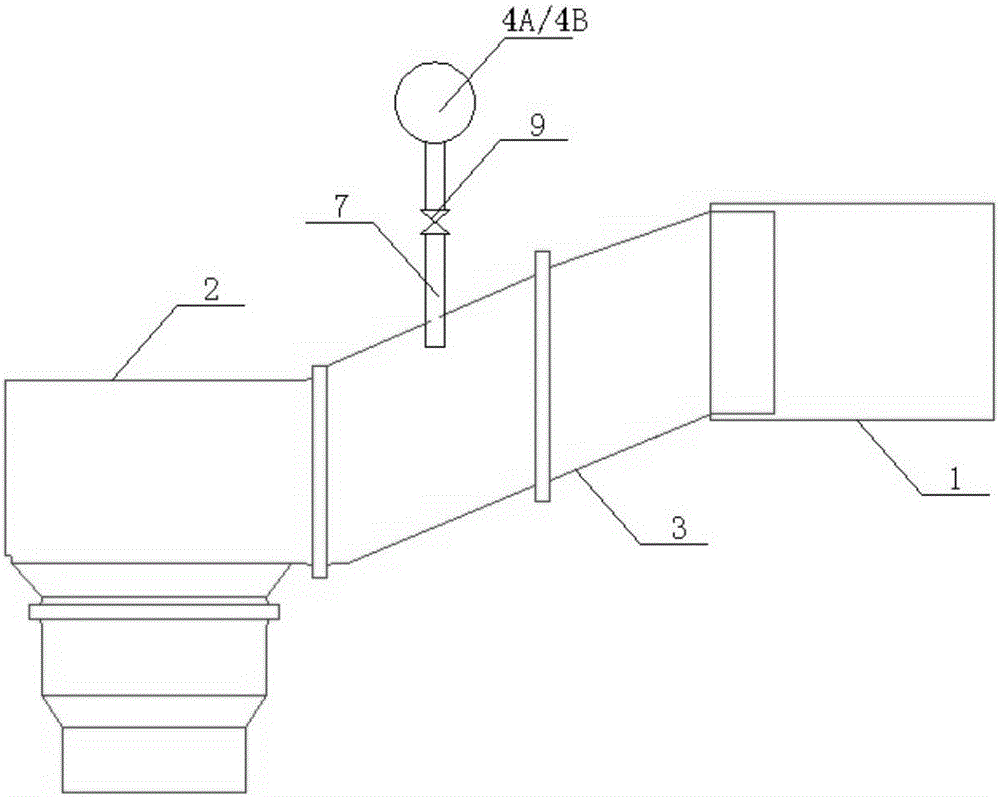

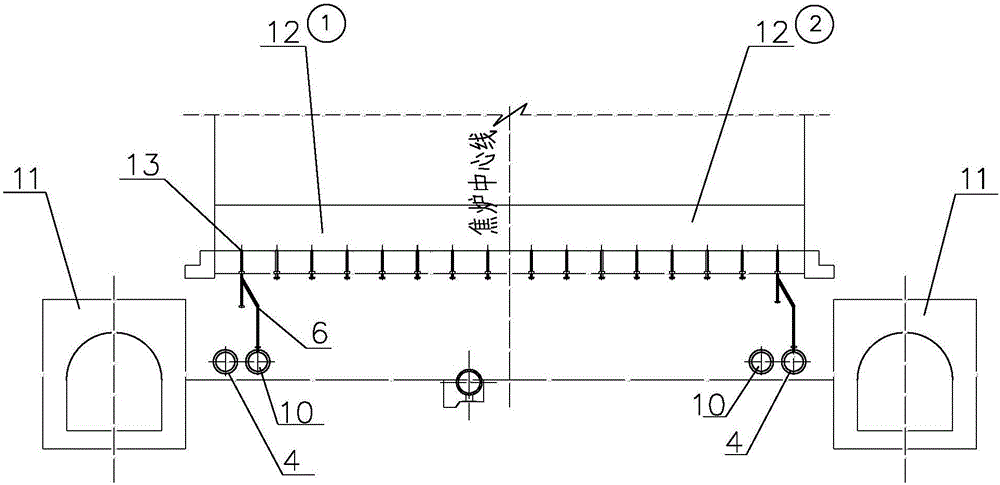

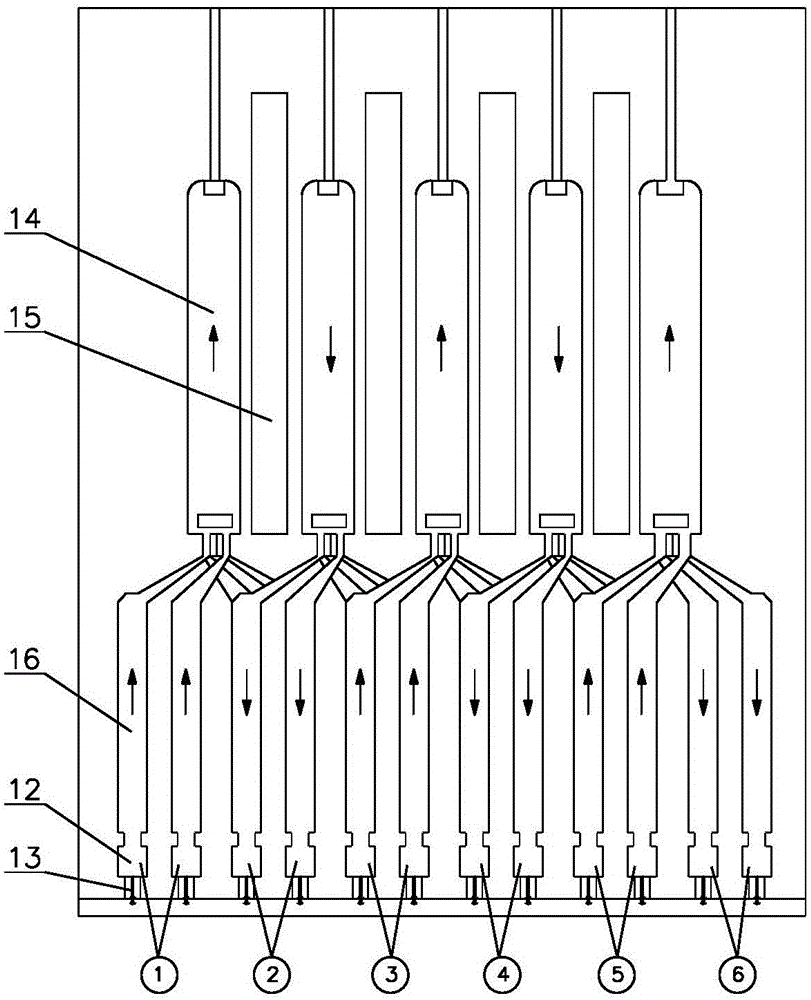

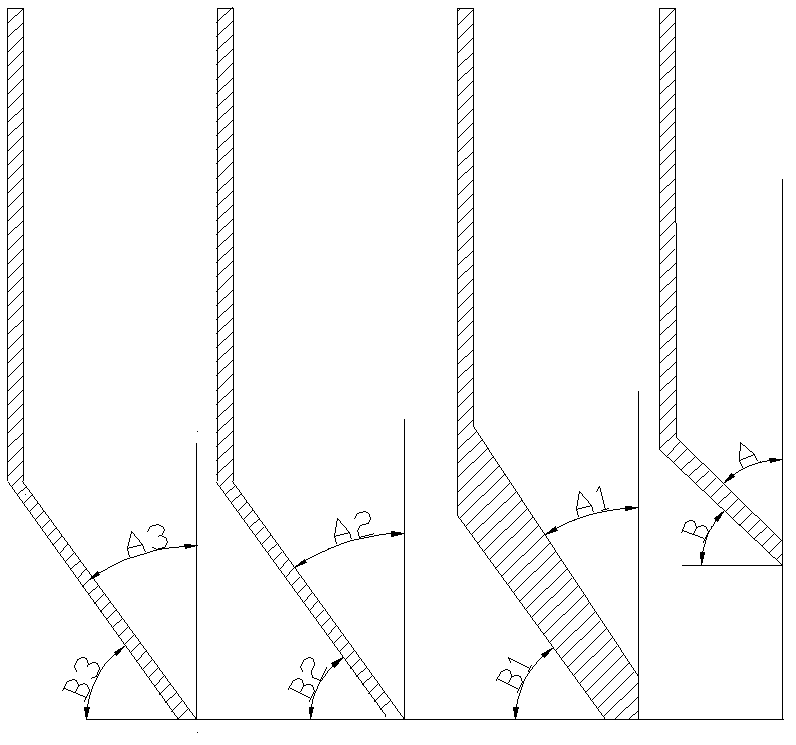

Method and vertical flue bottom structure for reducing production of nitrogen oxides by coke oven

InactiveCN105349158AReduced burning intensityLower combustion temperatureCombustible gas coke oven heatingFlueNitrogen oxides

The invention relates to a method and a structure for reducing production of nitrogen oxides by a coke oven. A combustible gas passage in front of a combustible gas inlet and a combustion-supporting gas passage in front of a combustion-supporting gas inlet are respectively arranged obliquely toward the outer sides, and the included angle between the center lines of the two passages is not smaller than 3 degrees. The trends of the combustible gas passage and the combustion-supporting gas passage in a chute area are changed, so that a combustible gas and a combustion-supporting gas respectively enter a vertical flue in opposite directs, are blended with circulation waste gas at the bottom of the vertical flue, and then burn, accordingly, the concentrations of the combustible gas and oxygen are reduced, the combustion intensity is weakened and the combustion temperature is lowered; the blending point of the combustible gas and the combustion-supporting gas which enter the vertical flue is moved upwards, so that the high heating uniformity of the vertical flue is improved, and the production of nitrogen oxides during combustion in the vertical flue is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

T-shaped burning beam

The invention provides a T-shaped burning beam, which consists of a beam body. Fuel pipelines and an air channel are arranged in the beam body; two sides of the beam body are provided with burner nozzles, and each side comprises 5 to 20 burner nozzles; each burner nozzle comprises a lengthened fuel nozzle and an air outlet; and the air outlet is a gap around the fuel nozzle. Two fuel pipelines are fixedly arranged in the air channel by fixing elements, and each fuel pipeline is connected with the burner nozzles on the same side. The two fuel pipelines are arranged respectively; and the fuel nozzles are lengthened fuel nozzles and are inserted in burner nozzle mouths so that the fuel is burnt outside the burner nozzles, the flame is far away from the beam body wall, the burner nozzle mouths and a T-shaped head of the burning beam are prevented from being burnt out, the equipment investment and the maintenance cost are saved, and the service life of the burning beam is prolonged.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadway

InactiveCN106499431AEliminate the risk of explosionAvoid self-heatingDust removalFire preventionSpontaneous combustionKerosene

The invention particularly relates to a nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadways, and solves the problem of difficult fire prevention in the goafs during tunneling. The nitrogen injection fireproofing method for adjacent goafs during tunneling along empty roadways comprises the following steps: determining nitrogen injection flow in the goafs and the time of the nitrogen injection, and starting the nitrogen injection if the following conditions meet anyone of the conditions including the temperature of the goafs over 26 DEG C or daily temperature rise of 1 DEG C; the water temperature of the goafs exceeding 26 DEG C; local parts of the workplace giving signs of fire, such as tar or kerosene odor; preburying nitrogen injection pipelines using a cross bedding method, with the step distance of 40 m, and cycling until the workplace is tunneled. The method applies the nitrogen injection fireproofing method to the fire prevention and control of the goafs during tunneling, not only eliminates the danger of gas explosion, reduces the effect of air leakage, plays the role of cooling, but prevents the self-heating and the spontaneous combustion of coal and reduces burning strength.

Owner:DATONG COAL MINE GRP

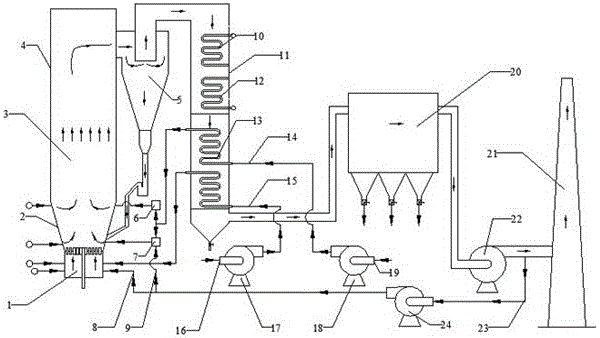

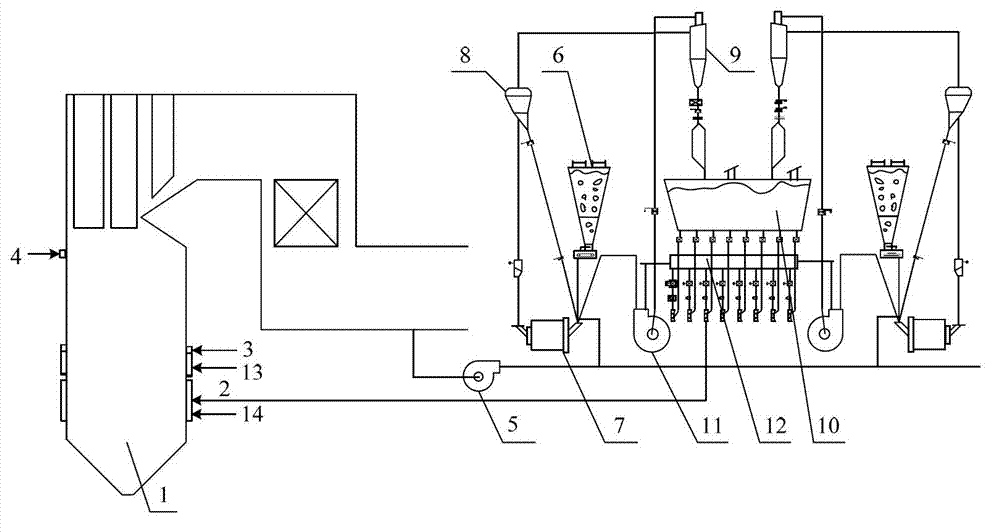

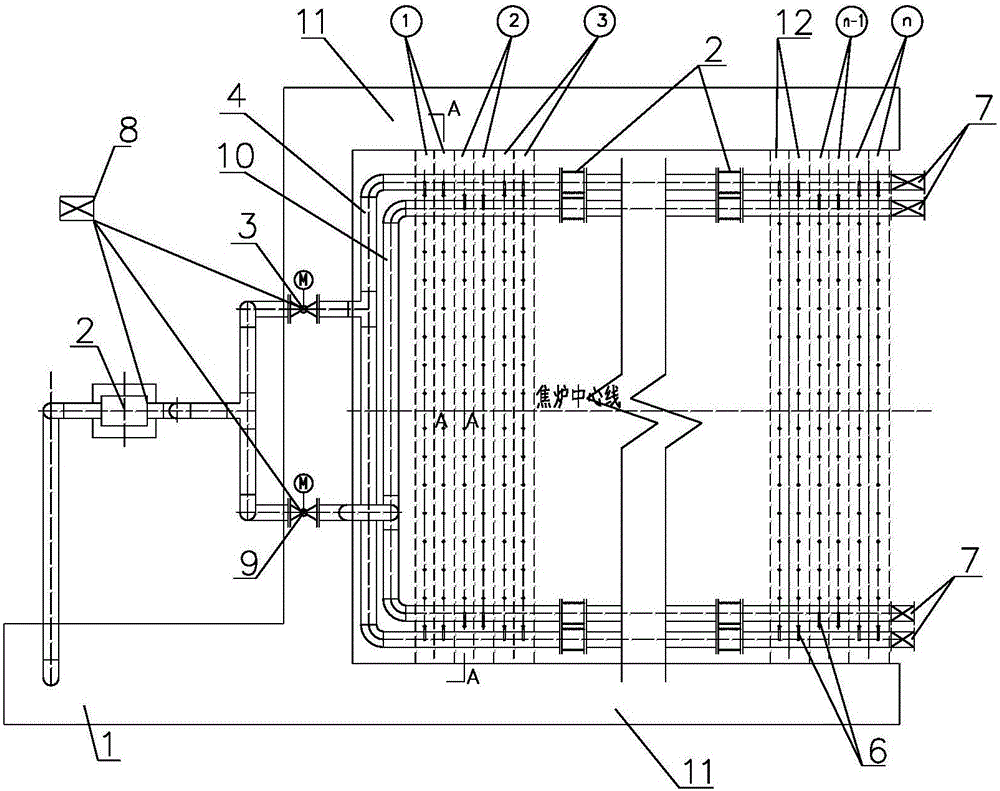

Multi-coal-type adaptive type low-NOx burning system

ActiveCN103206716AEmission reductionSuppress generationLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationCombustion systemBoiler slag

Provided is a multi-coal-type adaptive type low-NOx burning system. Boiler smoke in a boiler tail smoke channel is delivered into an inlet of a coal pulverizing system through a boiler smoke fan and a corresponding pipe, exhaust gas in the coal pulverizing system can enter a primary-air bellows through a corresponding pipe system to participate in pulverized coal delivery, simultaneously the primary-air bellows can be connected with an angle adjustable type high-speed over fire air (OFA) nozzle on the upper portion of a boiler, and a part of hot primary air of a high pressure head is utilized as high speed OFA to be delivered into a boiler cavity. The system can reduce burning strength of the pulverized coal in the boiler and the temperature level of a main burning area by means of the smoke recirculation burning, can achieve the effect that the pulverized coal is burned in grading mode along the air depth in the height direction of the boiler by means of the angle adjustable type high speed OFA, screen bottom air and the like, improves adapting capability to the pulverized coal, restrains generation of NOx, prevents boiler slag bonding, and ensures operation safety and economy of the boiler.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

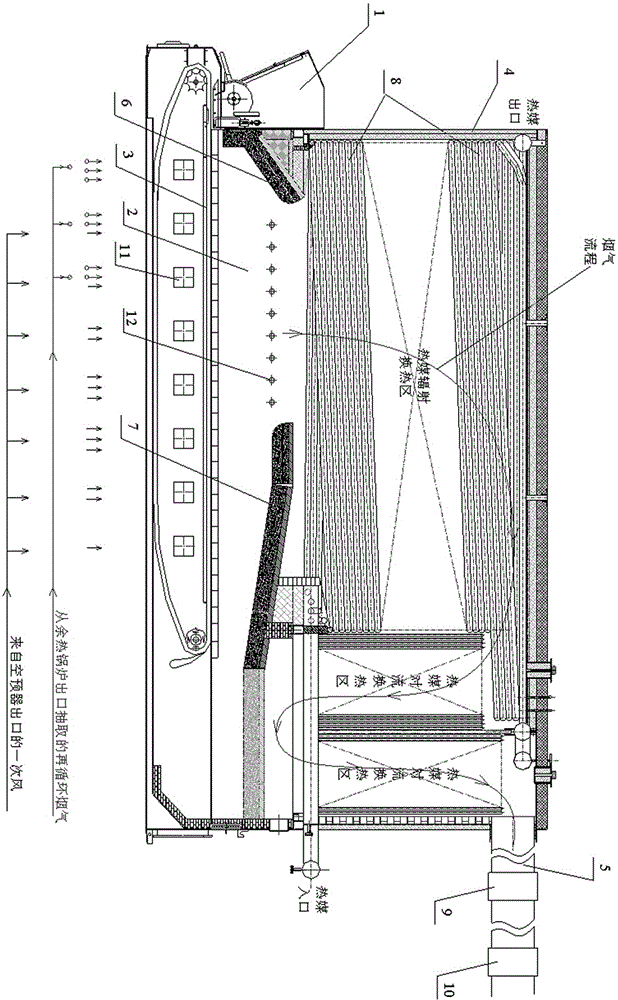

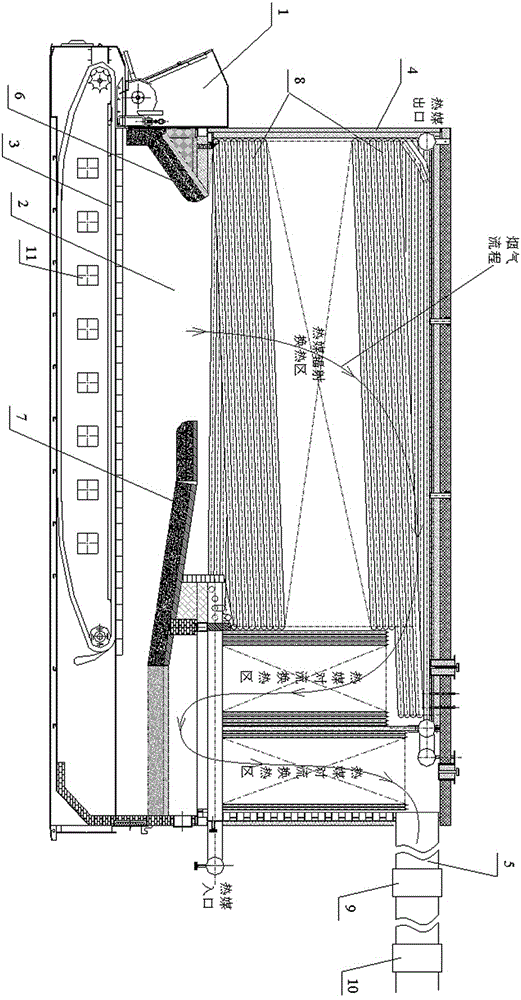

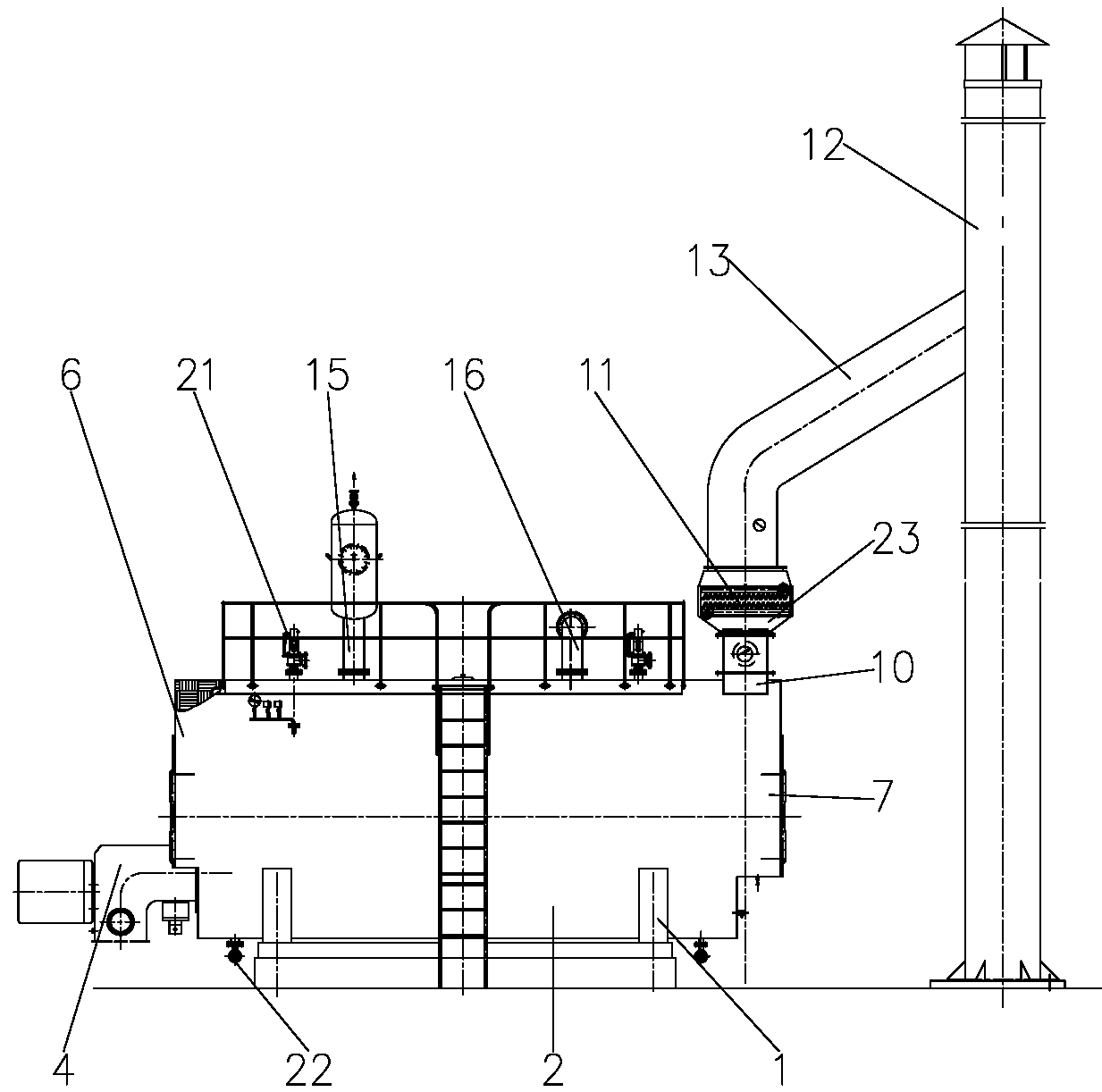

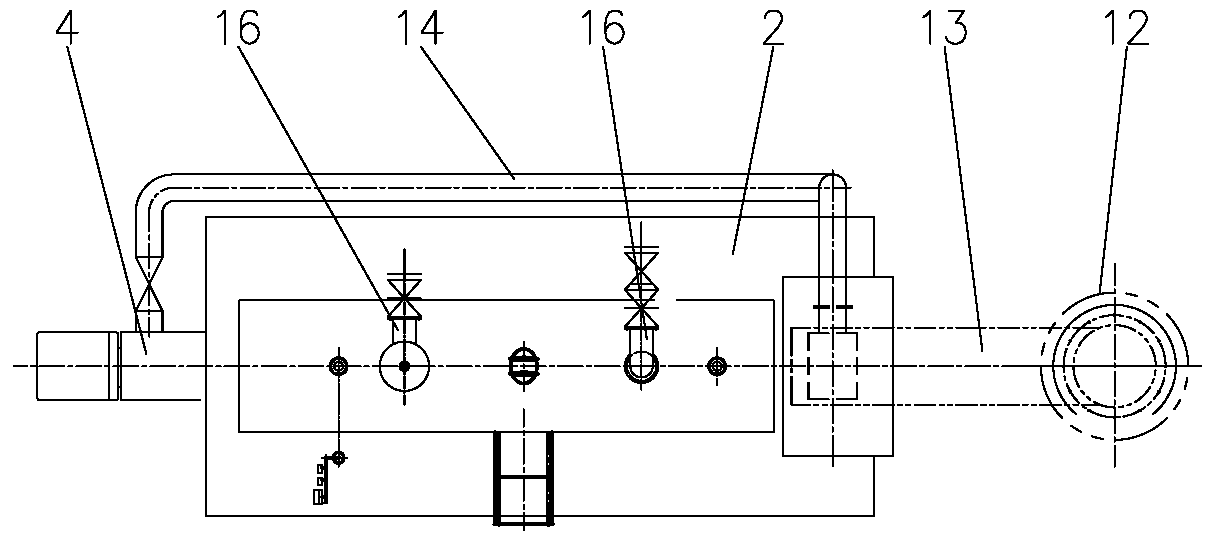

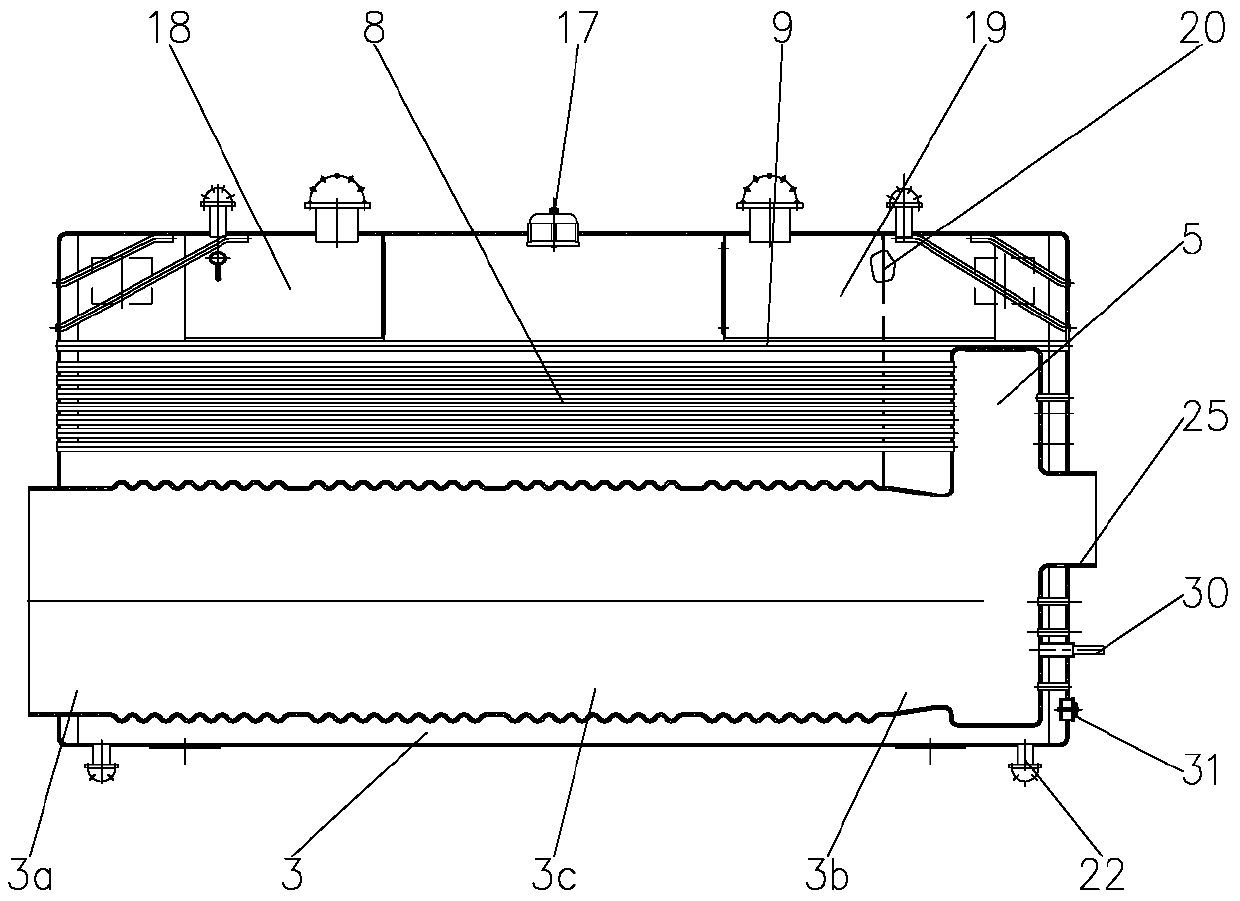

Horizontal type chain grate heat medium heater capable of coupling side wall staging air and flue gas recirculation

ActiveCN104792007AReduce generationLower combustion temperatureStorage heatersAir preheaterCombustion chamber

The invention discloses a horizontal type chain grate heat medium heater capable of coupling side wall staging air and smoke recirculation. The horizontal type chain grate heat medium heater is composed of a scraper coal feeder, a combustion chamber, a chain grate, a horizontal type heater body and a rear smoke channel. According to the horizontal type chain grate heat medium heater, staging air is distributed on the two side walls of the horizontal type chain grate heat medium heater, and meanwhile primary air is supplied in sections under the grate to build the staging combustion conditions in the heater; smoke is extracted from the position, between a waste heat boiler and an air preheater, of the rear smoke channel and fed into multiple primary chambers located on the front portion of the chain grate to organize smoke recycling. Accordingly, on one hand, the retention time of coal particles in the heater in a combustion state of being far away from the stoichiometric ratio is prolonged; on the other hand, in a coal seam combustion area, the oxygen concentration is diluted, the combustion temperature is lowered, the combustion intensity is weakened, therefore, the combustion process is delayed, and finally the low NOx combustion in the coal-fired horizontal type chain grate heat medium heater is achieved.

Owner:江苏宇澄环境工程设备有限公司

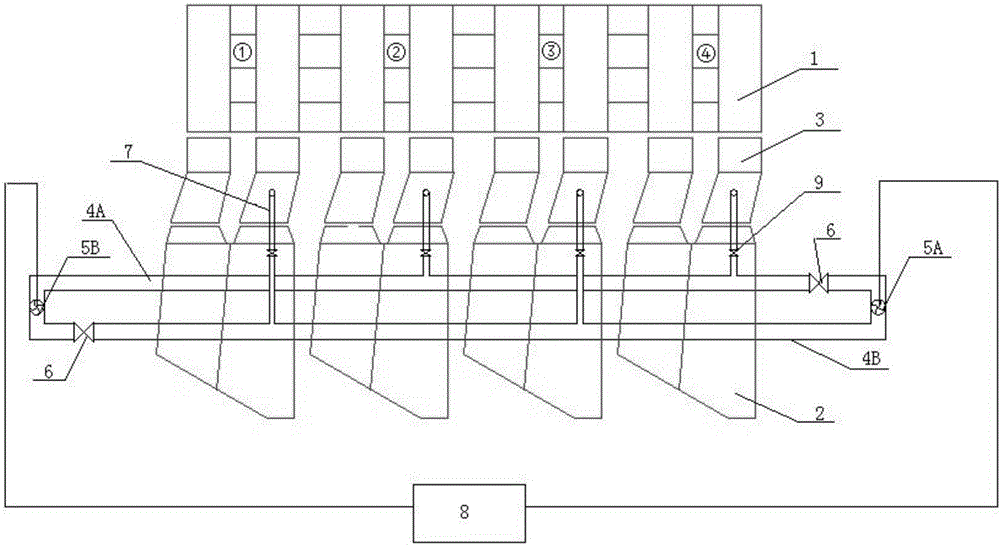

Method and system for reducing nitric oxide in coke-oven exhaust gas

InactiveCN105885877AIncrease exhaust gas circulationReduce burning intensityCombustible gas coke oven heatingAutomatic controlAutomotive engineering

The invention relates to a method and system for reducing a nitric oxide in a coke-oven exhaust gas. When a coke-oven heating system executes reversing operation, a descending exhaust gas is led out from a small flue with downdraft through an exhaust gas branch pipe; and the dropping exhaust gas is merged into exhaust gas main pipes and is introduced into the small flue with updraft through the exhaust gas branch pipe. Particularly, the exhaust gas branch pipe is led out from a two-fork part of exchanging a shutter / faucet; the exhaust gas branch pipe is connected with the exhaust gas main pipe I or the exhaust gas main pipe II according to the arranged order at interval; two ends of the exhaust gas main pipe I and two ends of the exhaust gas main pipe II are communicated to form an annular exhaust gas channel; a speed-regulating fan and a main pipe control valve are arranged on the exhaust gas main pipe I and the exhaust gas main pipe II respectively; and the speed-regulating fan is connected with the coke-oven control system and is linked with a reversing actuation mechanism of the coke-oven heating system respectively. By the method and the system, the exhaust gas circulating amount of a coke oven can be increased; the combustion strength is reduced; the content of the nitric oxide in the coke-oven exhaust gas is reduced; the system is simple in structure, low in investment, fast acting and convenient to adjust; and automatic control can be achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Coke oven heating method capable of lowering concentration of nitrogen oxides in waste gas

InactiveCN106010587AIncrease exhaust gas circulationReduce nitrogen oxide contentCombustible gas coke oven heatingNitrogen oxidesAutomatic control

The invention relates to a coke oven heating method capable of reducing the concentration of nitrogen oxides in waste gas. A waste gas main pipe A and a waste gas main pipe B are respectively buried at the bottom of both sides of a small flue of the coke oven. The flue is connected, and the other end is respectively connected to the small coke oven flue with different airflow directions through the cleaning hole; At the same time, the small flue of the coke oven changes from downdraft to updraft; at this time, the high-temperature exhaust gas extracted from the main flue of the coke oven enters the updraft corresponding to the small flue of the coke oven through the exhaust gas main pipe B and the cleaning hole. The present invention can reduce the combustion intensity of coal gas and achieve the purpose of reducing the nitrogen oxide content in the coke oven exhaust gas by extracting the flue waste gas in the coke oven main flue and mixing it into the rising airflow heated by the coke oven; The device has the advantages of simple structure, low investment, convenient adjustment and automatic control.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

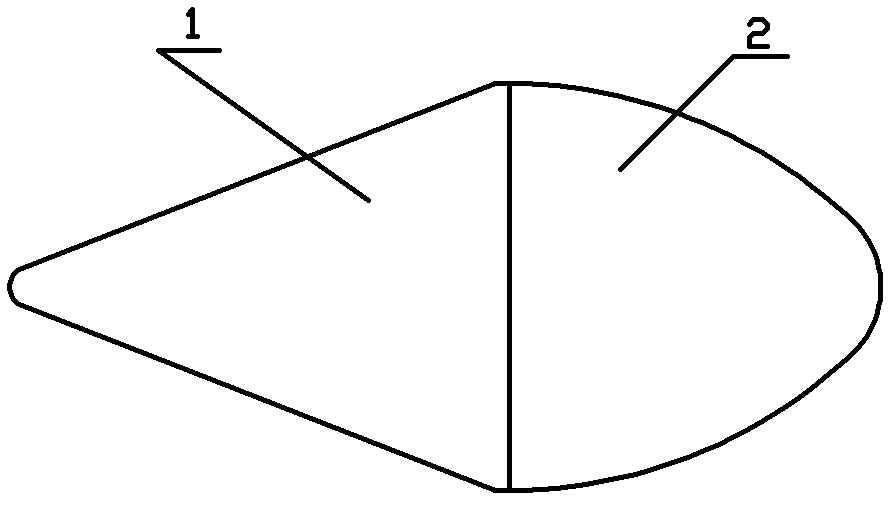

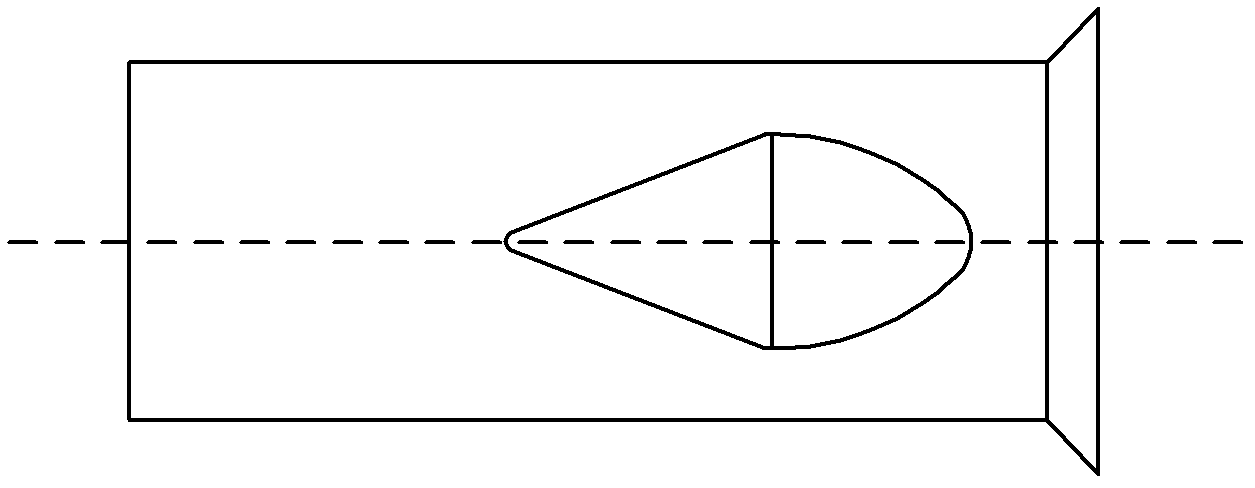

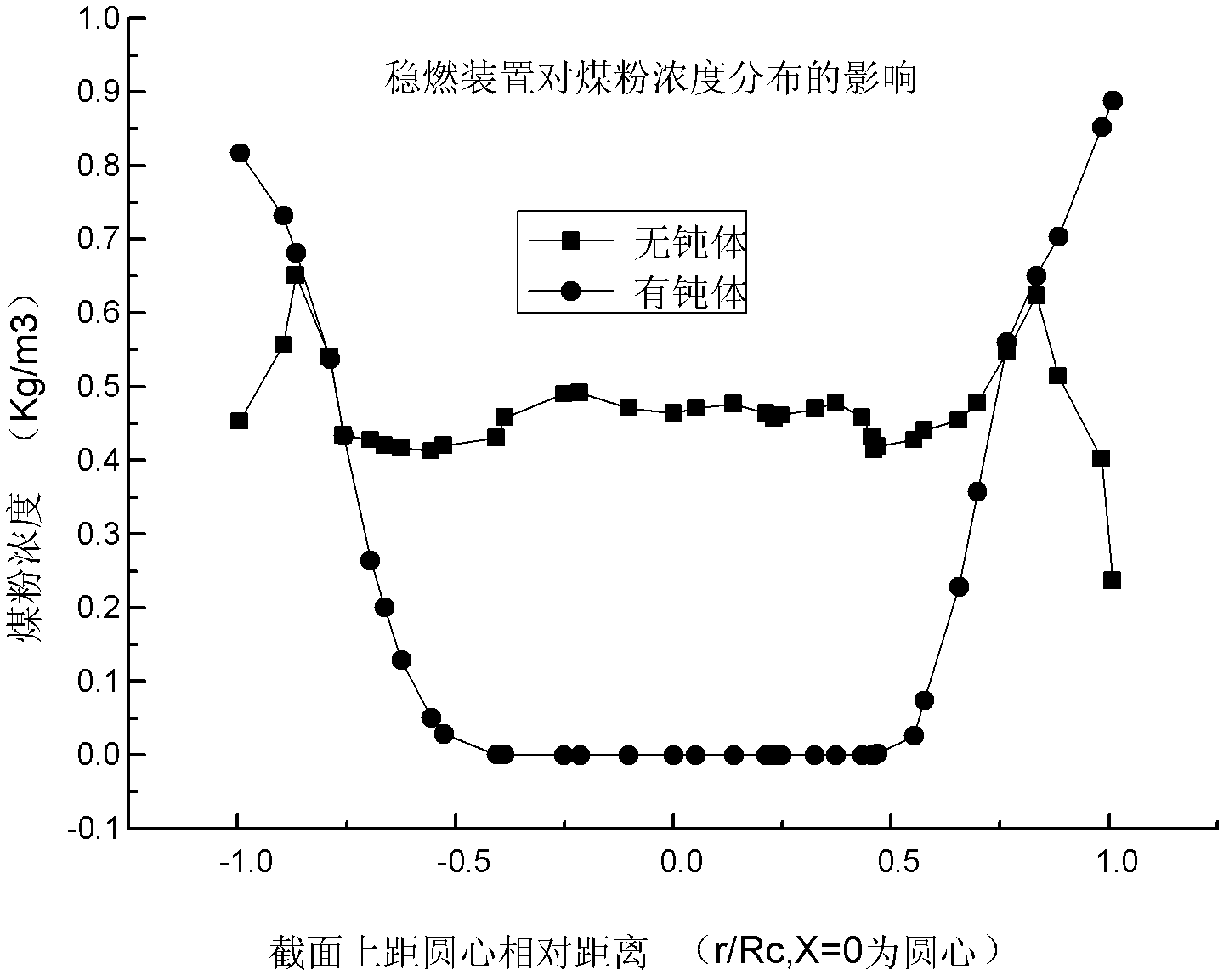

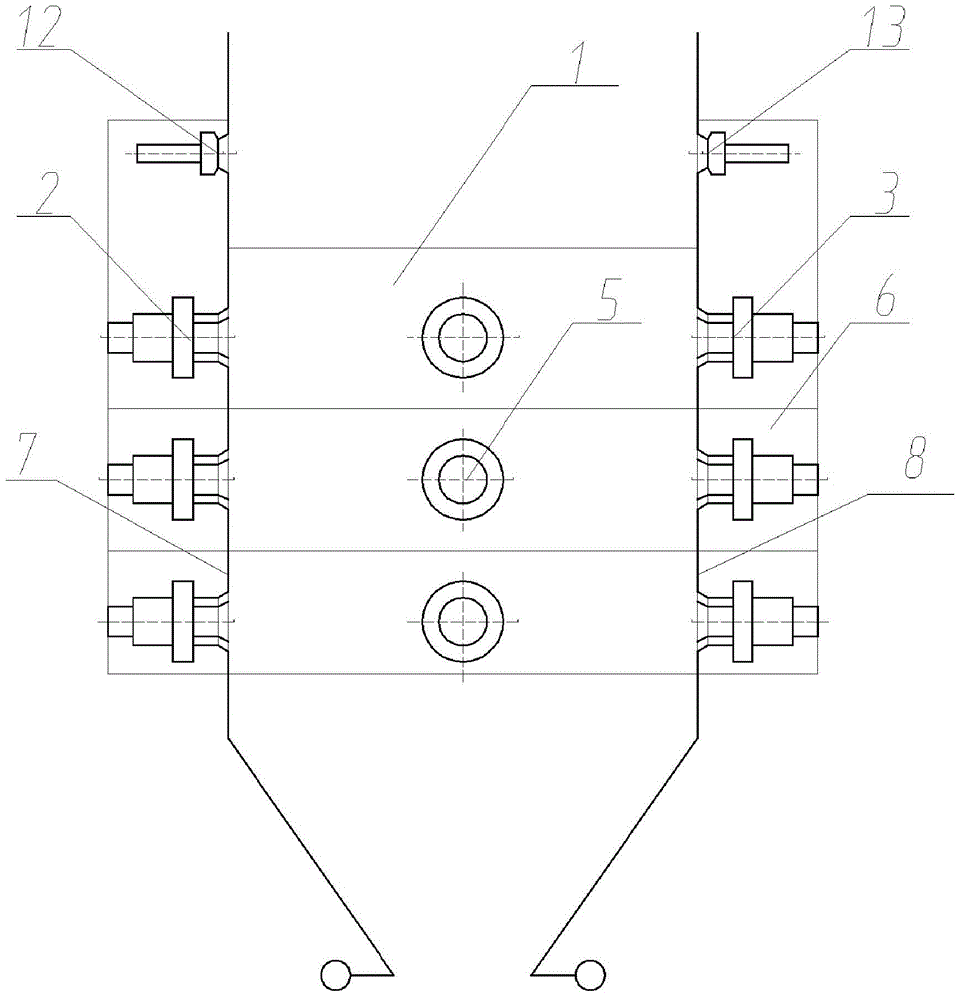

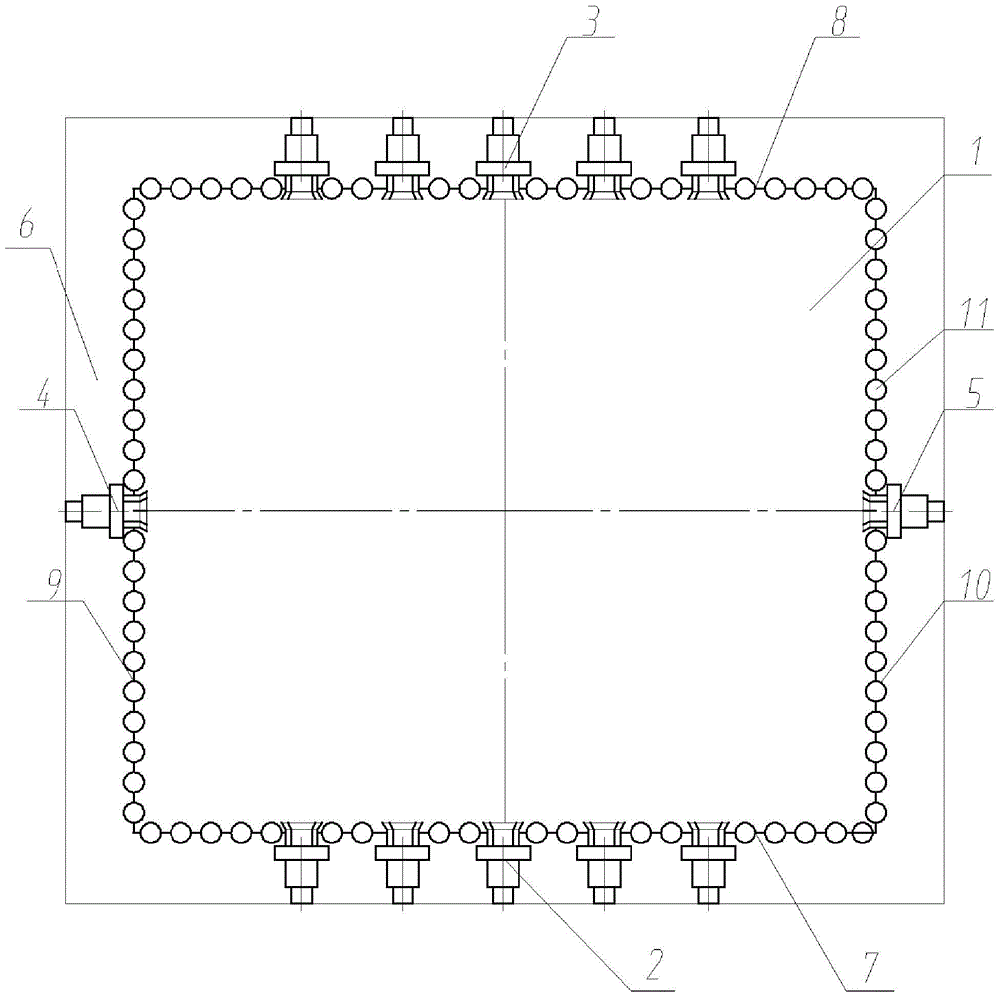

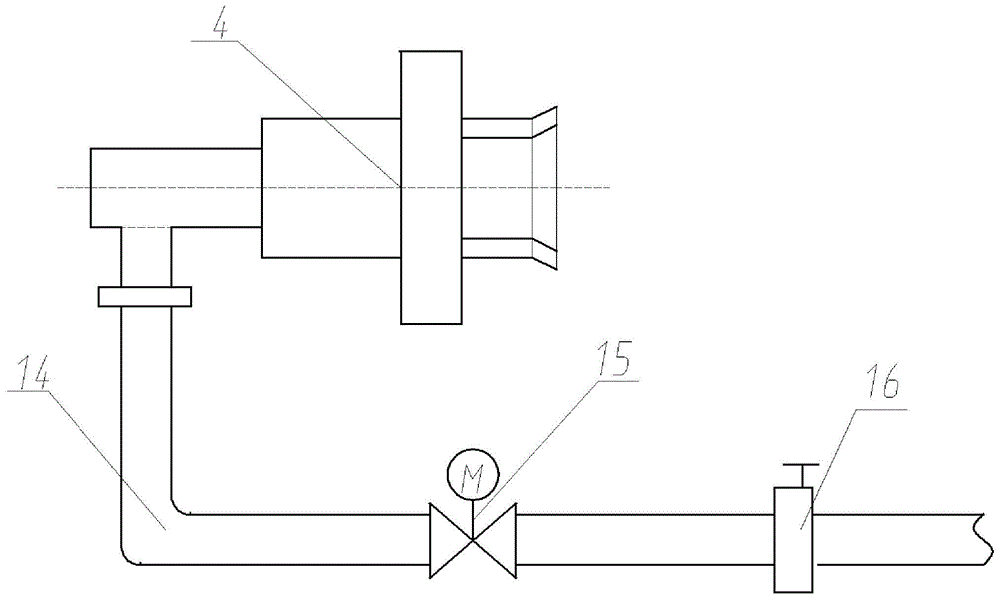

Low-oxynitride and low-load stable combustion device of turbulent combustor

InactiveCN102322636AImprove adaptabilityCatch fire quicklyPulverulent fuel combustion burnersEngineeringCoal particle

The invention belongs to the technical field of turbulent combustors of power plants, and in particular relates to a low-oxynitride and low-load stable combustion device of a turbulent combustor. The stable combustion device comprises two parts, namely, a ramming member and a vortex suppression member, wherein the ramming member is in a conoid structure, and the vortex suppression member is a streamlined structure body formed by two circular-arc surfaces. The stable combustion device is arranged near an outlet of a primary air pipe of the turbulent combustor; and when pulverized coal airflow passes through the stable combustion device, pulverized coal particles are gathered towards an outer ring of the primary air pipe, therefore the pulverized coal concentration is improved, the generation amount of NOx is effectively reduced, ignition heat is reduced, and timely ignition and stable combustion of the pulverized coal airflow under the conditions of low load and combustion of fault coal are facilitated. In addition, by means of the vortex suppression member of the stable combustion device, vortexes at the tail part of the stable combustion device can be effectively prevented from being formed, and the combustor can be prevented from slag-bonding, coking and burning-out.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

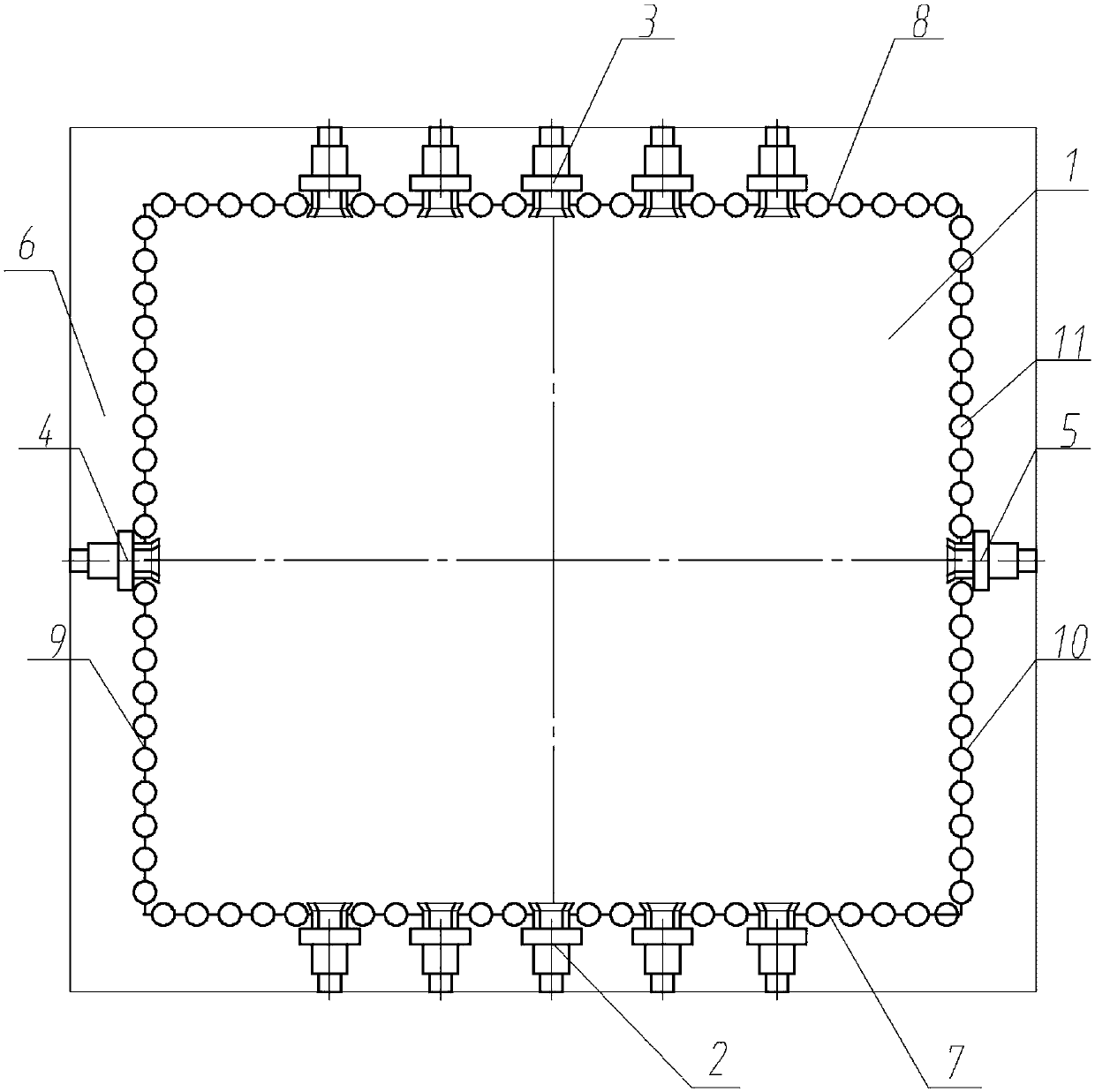

Opposed firing structure of boiler

ActiveCN104595891AIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorStructural engineering

The invention discloses an opposed firing structure of a boiler. The opposed firing structure comprises a hearth, wherein the hearth is formed by enclosing of a boiler left-side wall, a boiler right-side wall, a boiler front wall and a boiler rear wall; left-side wall burners are distributed on the middle line of the boiler left-side wall along the height direction of the hearth; right-side wall burners are distributed on the middle line of the boiler right-side wall along the height direction of the hearth; a plurality of rows of front-wall burners are distributed on the boiler front wall; a plurality of rows of rear-wall burners are distributed on the boiler rear wall; and the peripheries of the boiler left-side wall, the boiler right-side wall, the boiler front wall and the boiler rear wall are provided with bellows for providing secondary air and over-fired air for the hearth. The opposed firing structure disclosed by the invention has the advantage that on the basis of not influencing the original coal-powder burning mode, the problem of corrosion caused by high temperature of water cooling walls of the side walls is thoroughly solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

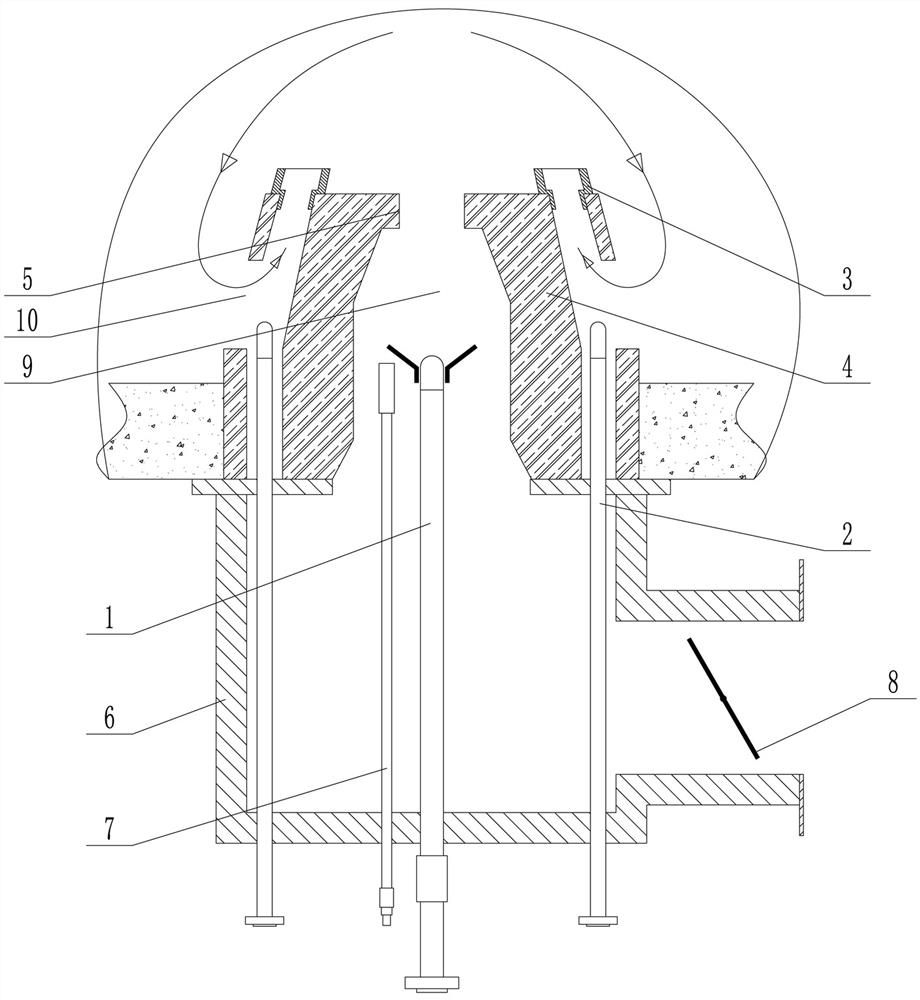

Novel heat accumulating type flat flame burner

PendingCN107420898ALower combustion temperatureReduce generationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberAir volume

The invention discloses a novel heat accumulating type flat flame burner comprising a hollow burner shell internally provided with a heat accumulating body, a flat flame burner brick, an air inlet, an ignition burner body, a burner core and an air-fuel mixing head. A flat flame combustor of a horn-shaped gradually-wider structure is arranged at one end of the flat flame burner brick. The air-fuel mixing head is provided with primary air channels which are distributed along the outer edge of a gas pipe circumferentially and are gathered together towards the direction of a burning pipe shaft core. The flat flame burner brick is provided with secondary air channels which are distributed along the outer edge of the flat flame combustor circumferentially, are scattered radially and evenly from the burner shell to the direction of a hearth, and correspond to the horn-shaped gradually-wider structure of the flat flame combustor. The primary combustion-supporting air volume accounts for about 30%-50% of the total volume, and the secondary combustion-supporting air volume accounts for 50%-70% of the total volume. According to the novel heat accumulating type flat flame burner, special air staged rotational flow technology is adopted, the condition that flame forms a flat flame shape is not influenced, meanwhile, the oxygen content during burning is diluted, the burning temperature of the flame is lowered, and thermal NOx generated during burning is reduced greatly.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

A Composite Inhibitor for Preventing Spontaneous Combustion of Coal Powder

InactiveCN103306710BReduce reactivityReduce generationDust removalFire preventionSpontaneous combustionInorganic salts

The invention discloses a compound stopping agent for preventing pulverized coal from spontaneous combustion and a preparation method of the compound stopping agent. The compound stopping agent mainly comprises a component A and a component B, wherein the component A comprises 70%-90% of a penetrant and 10%-30% of peroxide; the component B comprises inorganic salt. The component A and the component B are mixed at a weight ratio of 1:(1.5-3) and used as the compound stopping agent. The preparation method comprises steps as follows: firstly, the penetrant is prepared into an aqueous solution, then the peroxide is dissolved in the penetrant, and the mixture is stirred, so that the component A of the stopping agent is obtained; the component A is matched with the inorganic salt of the component B for use. The compound stopping agent has the characteristics of low cost and non-toxic. During the use, the component A and the component B of the stopping agent are jointly and uniformly added to the pulverized coal, the operation is simple, the stopping effect is excellent, and the compound stopping agent has a wide application prospect.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP +1

Efficient flame-retardant smoke-isolating fireproof door

The invention discloses an efficient flame-retardant smoke-isolation fireproof door. The efficient flame-retardant smoke-isolation fireproof door comprises a fireproof door body, the fireproof door body comprises a fireproof core plate, a fireproof outer plate is arranged outside the fireproof core plate, a gas storage cavity and a liquid storage cavity which are isolated through a first isolationfilm are sequentially distributed in the fireproof core plate from bottom to top, the gas storage cavity is filled with inert gas, and the liquid storage cavity is filled with cooling liquid; a gas outlet groove, an evaporation cavity and a liquid outlet groove are sequentially formed in the fireproof outer plate from bottom to top, the gas outlet groove communicates with the gas storage cavity,a first sealing plate is arranged in the gas outlet groove, the liquid outlet groove communicates with the liquid storage cavity, a second sealing plate is arranged in the liquid outlet groove, the evaporation cavity is located on the outer sides of the gas storage cavity and the liquid storage cavity and communicates with the gas outlet groove, and evaporation liquid is arranged in the evaporation cavity. The efficient flame-retardant smoke-isolation fireproof door has the characteristics that smoke dust is effectively blocked, the temperature and the fire behavior of the fireproof door are reduced, and help to escape personnel is enhanced.

Owner:浙江振元安防科技有限公司

Self pre-heating type high-speed burning nozzle and control method thereof.

PendingCN109654496AAchieve stabilityStable combustionIndirect carbon-dioxide mitigationGaseous fuel burnerGas conditioningProcess engineering

The invention belongs to the field of combustors and relates to a self pre-heating type high-speed burning nozzle and a control method thereof. A fuel gas supplying pipe is provided with a radial jetting fuel gas supplying pipe and an axial jetting fuel gas supplying pipe; through a fuel gas adjusting plate arranged at a fuel gas supplying pipe inlet position, the proportion of fuel jet in the radial direction and fuel jet in the axial direction is automatically adjusted; a combustion chamber penetrates through the middle of a flue gas flow guiding device; after air pass through a pre-heater,part of the air directly flows into a main combustion space from a gap between the combustion chamber and the flue gas flow guiding device, and remaining air flows into the combustion chamber and is sprayed into the main combustion space when reacting with fuel gas; and the gap between the combustion chamber and the flue gas flow guiding device is increased along with rising of the temperature. According to the self pre-heating type high-speed burning nozzle and the control method thereof, due to the fact that the pre-heater expands due to heating, the position of the flue gas flow guiding device is adjusted, and the air grading proportion is controlled; meanwhile, the fuel grading proportion is correspondingly adjusted, flame stability under the medium and low temperature state can be effectively guaranteed, the flame length under the high temperature state can also be automatically lengthened in a pulling manner, the flame local high temperature is controlled, temperature uniformityis improved, and NOx emission is lowered.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Environment-friendly energy-saving boiler

The invention provides an environment-friendly energy-saving boiler. The environment-friendly energy-saving boiler comprises a chassis, a boiler body is fixedly installed on the chassis, and the boiler body is internally provided with a boiler furnace and a reversal chamber which is located at the rear end of the boiler furnace; a combustion engine is arranged at the portion, corresponding to theboiler furnace, of the front end of the boiler body, the front end of the boiler body is further provided with a front smoke box, and the rear end of the boiler body is provided with a rear smoke box;and a first smoke tube group is arranged between the reversal chamber and the front smoke box, a second smoke tube group is arranged between the front smoke box and the rear smoke box, and a chimneybase which communicates with the rear smoke box is arranged on the rear smoke box. The environment-friendly energy-saving boiler is characterized in that an energy-saving condenser is installed on thechimney base and provided with a connecting smoke flue which is connected with a chimney; a smoke recirculating tube is arranged between the chimney base and the energy-saving condenser, the other end of the smoke recirculating tube is connected with an air inlet of the combustion engine, the volume of smoke, sucked into the combustion engine, in the smoke recirculating tube accounts for 10%-16%that of the smoke exhausted in the chimney base, and the volume heat load of the boiler furnace ranges from 850 KW / m<3> to 1,050 KW / m<3>. Not only can the using requirement be met, but also the environment-friendly energy-saving boiler is more energy-saving and environment-friendly compared with an existing hot-water boiler.

Owner:CHONGQING ZHONGGUO ENERGY TECH

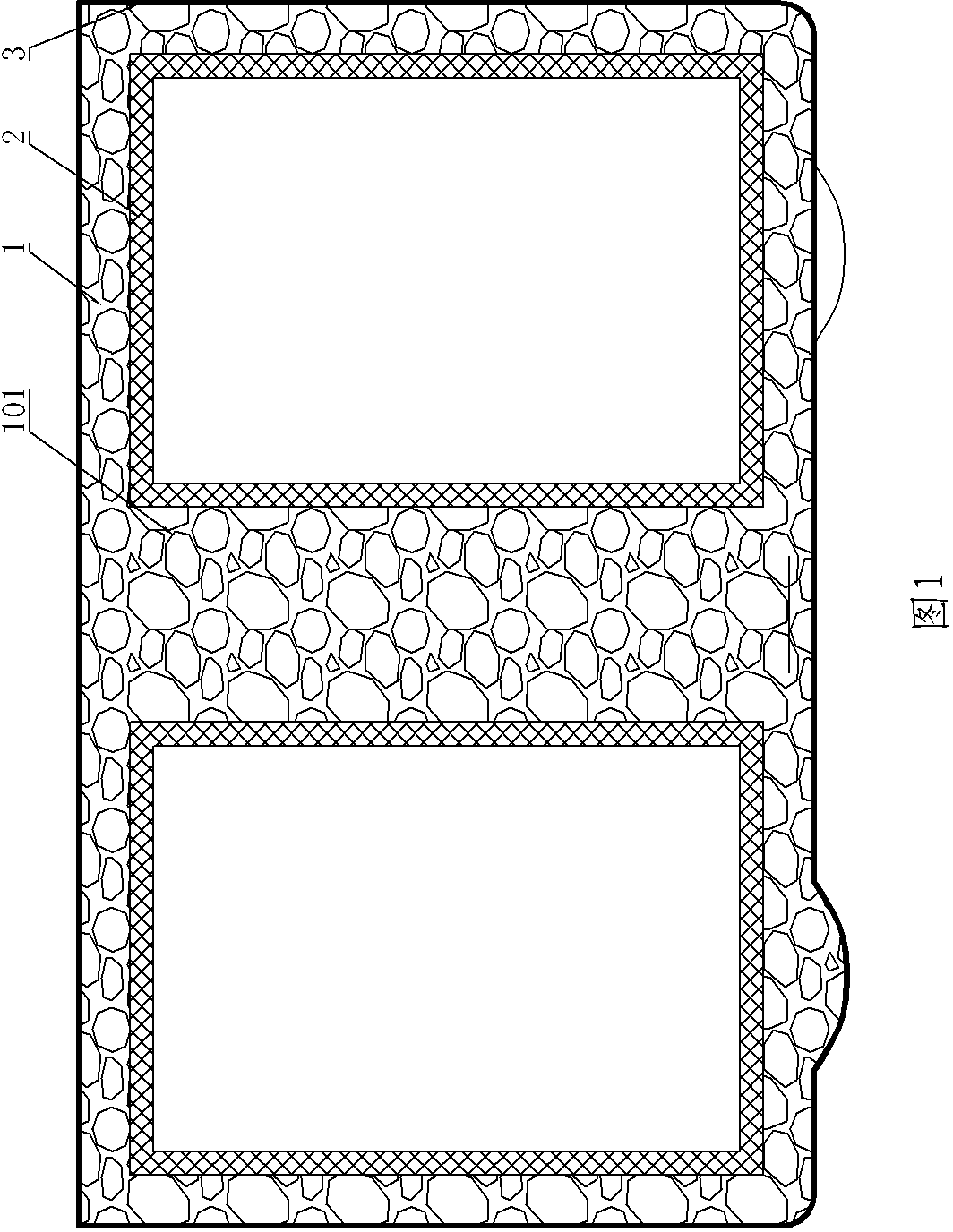

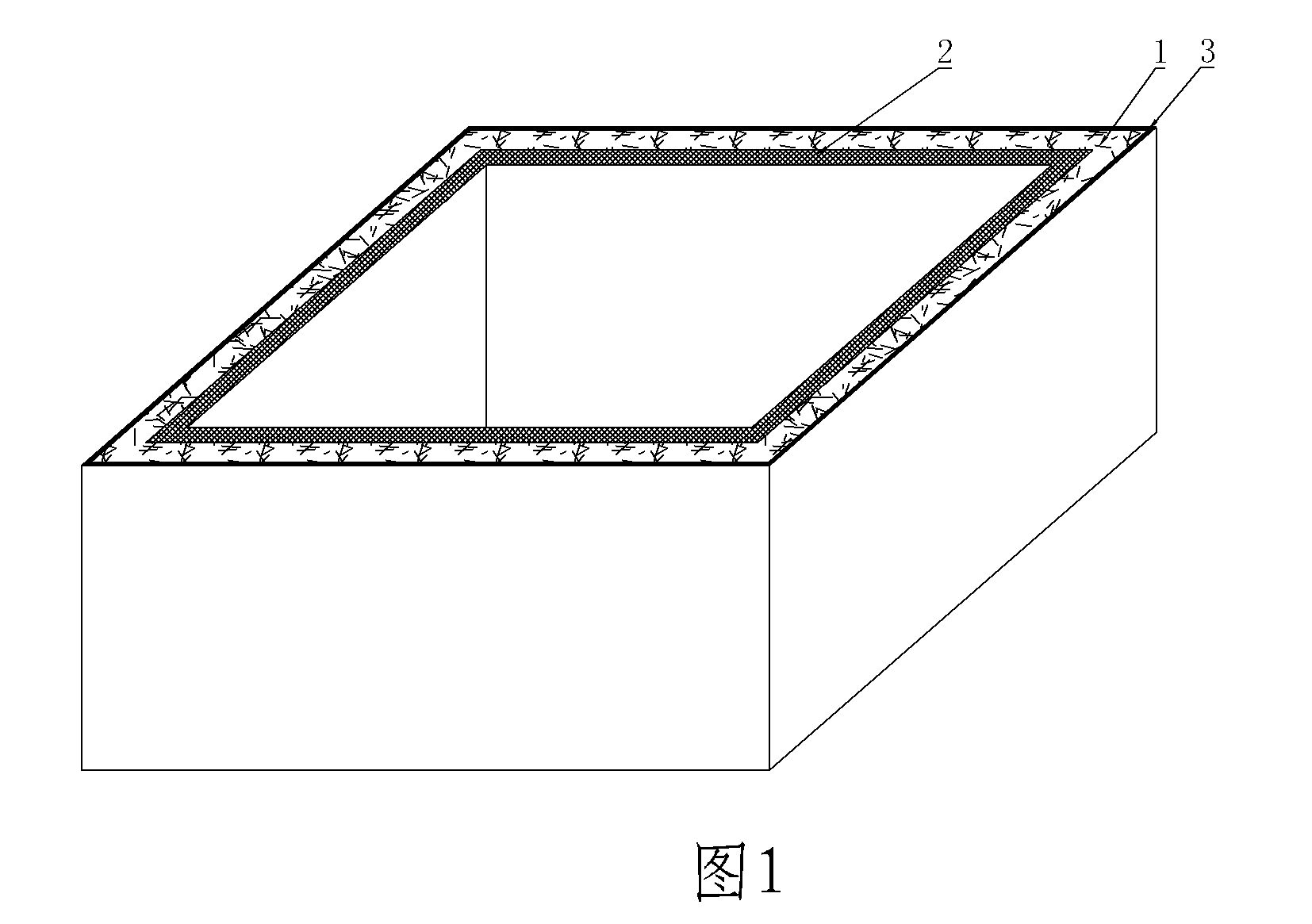

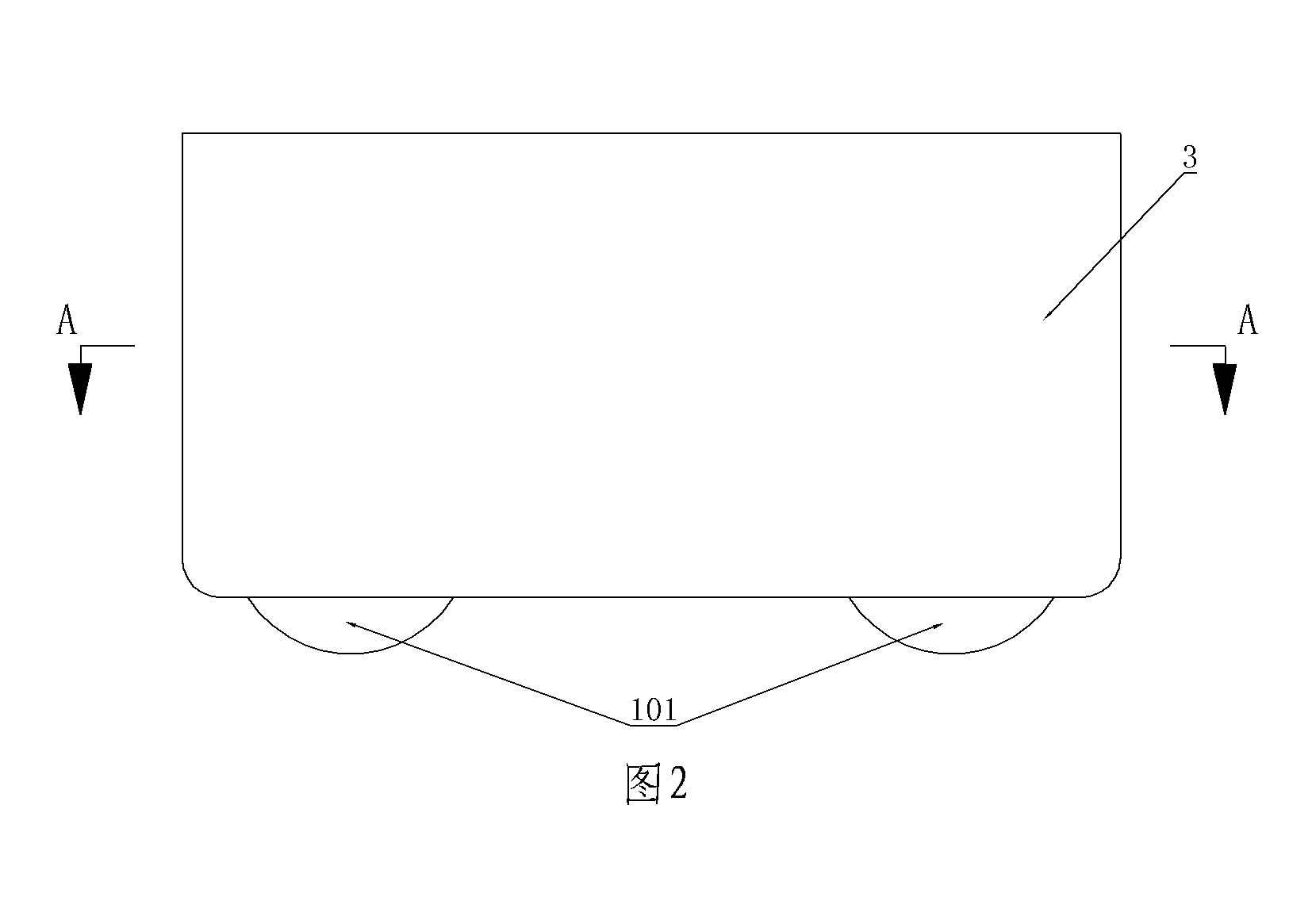

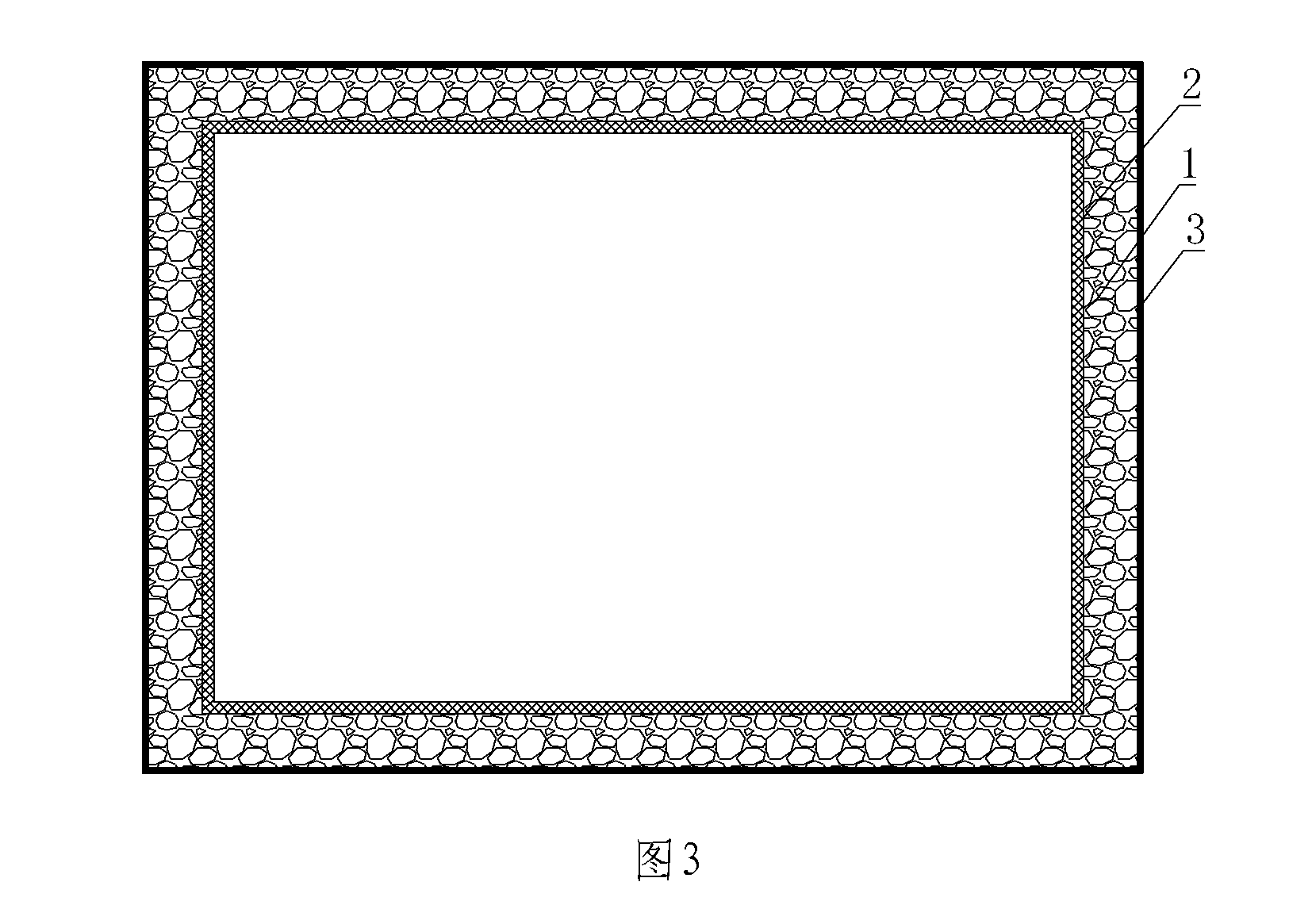

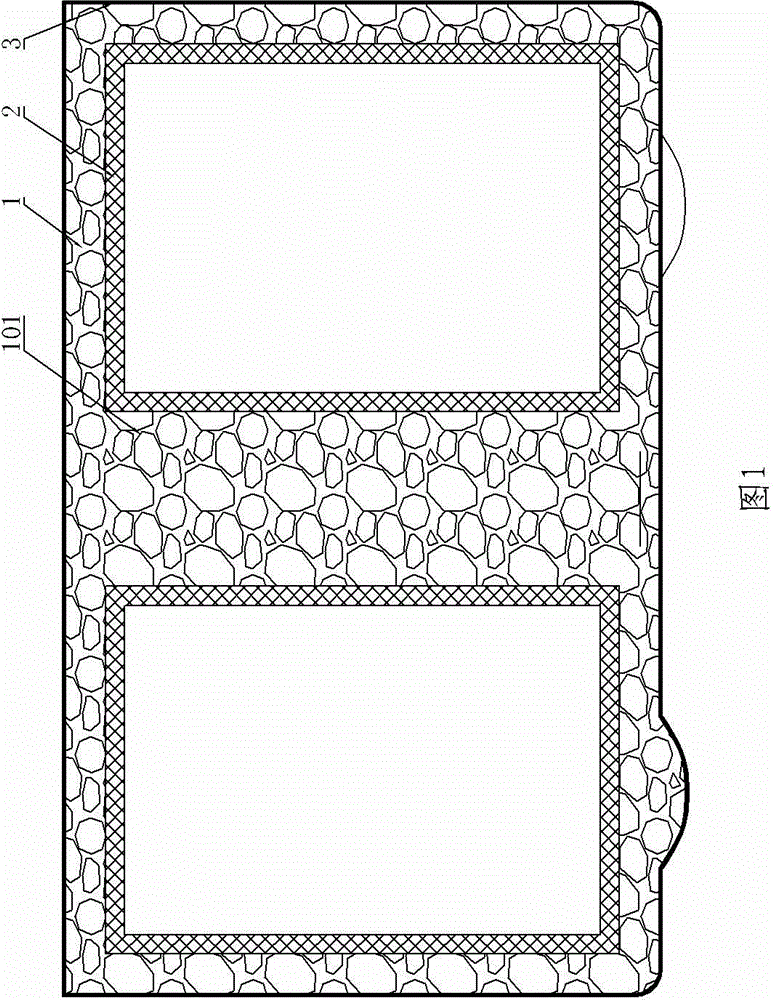

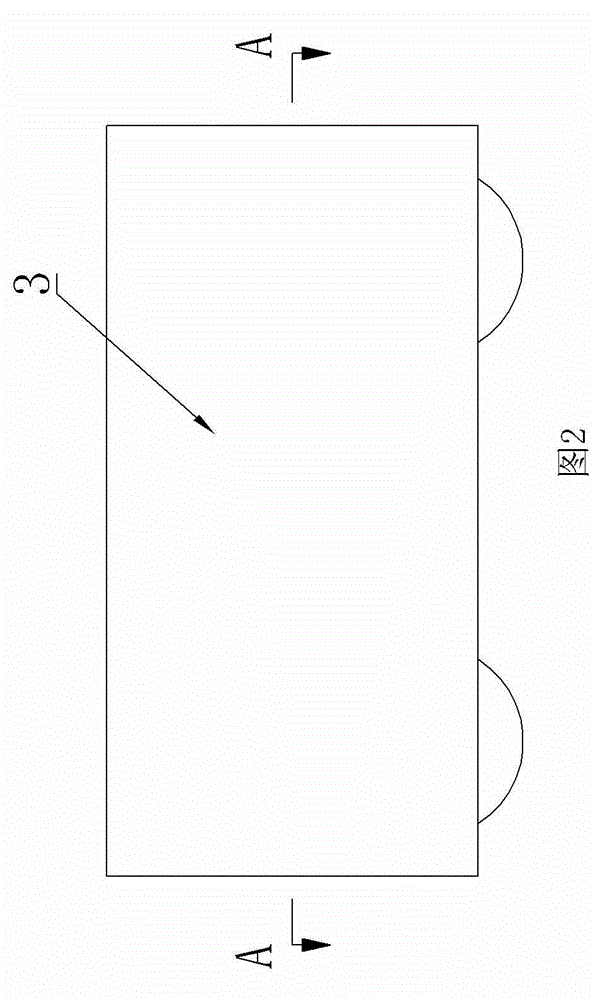

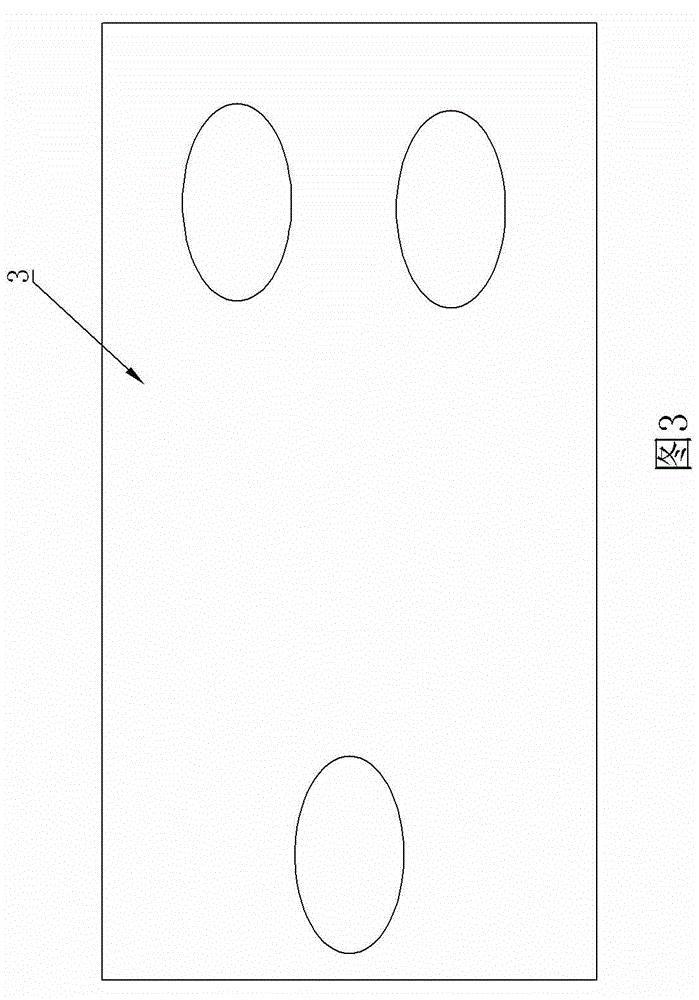

Cast-in-place concrete filling tire body

InactiveCN102912913AImprove support strengthStable supportConstruction materialFloorsUltimate tensile strengthOpen fire

The invention relates to a cast-in-place concrete filling tire body. The cast-in-place concrete filling tire body comprises a base body of the tire body and an annular inflation liner which is embedded into the base body of the tire body and is fixedly sealed in the bas body of the tire body. According to the cast-in-place concrete filling tire body, a supporting body is added in a box body of the base body of the tire body to improve the support between the top surface and the bottom surface of the base body of the tire body, and the annular inflation liner is embedded into the base body of the tire body and is capable of supporting each circumferential wall of the base body of the tire body, so that the whole supporting strength of the tire body is higher; once the inflation liner is directly contacted with open fire, the wall of the inflation liner can be burnt, therefore, the burning strength of the inflation liner is low, and the burning time of the inflation liner is short, and furthermore, the problem of the prior art that other objects can be ignited when fillers in the cast-in-place concrete filling tire body are burnt can be solved.

Owner:周立成

A two-stage combustion device and combustion method for biomass briquette fuel

ActiveCN104296127BIncrease the circulation areaEnhanced radiation heat transferSolid fuel combustionCombustion regulationPollutant emissionsPulp and paper industry

The invention discloses a two-section type combustion device and method for biomass briquettes. The combustion device comprises a feeding device and is characterized in that a heat exchange body is arranged on the lower side of the feeding device, a top combustion device and a bottom combustion device are arranged in the heat exchange body, a hearth is arranged between the bottom combustion device and the top combustion device, an ash device is arranged on the lower side of the bottom combustion device, an ignition device is arranged on the upper side of the top combustion device, a top air inflow device is arranged at the bottom of the top combustion device, a bottom air inflow device is arranged at the bottom of the heat exchange body, and a smoke exhaust device is arranged at the upper portion of the heat exchange body. According to the two-section type combustion device and method, continuous and stable feeding can be achieved, agglomeration is avoided, the excess air coefficient and pollutant discharge are low, and the automation degree is high.

Owner:SHANDONG JIANZHU UNIV

Opposed firing boiler

InactiveCN110617473AIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

The invention discloses an opposed firing boiler. The opposed firing boiler comprises a hearth surrounded by a boiler left-side wall, a boiler right-side wall, a boiler front wall and a boiler rear wall. A left-side wall burner is arranged on the center line of the boiler left-side wall in the height direction of the hearth, a right-side burner is arranged on the center line of the boiler right-side wall in the height direction of the hearth, several front wall burners are arranged on the boiler front wall, and several rear wall burners are arranged on the boiler rear wall; and a bellow for providing secondary air and over-fire air for the hearth is arranged at the peripheries of the boiler left-side wall, the boiler right-side wall, the boiler front wall and the boiler rear wall. According to the structure of the opposed firing boiler, on the basis that an original pulverized coal firing mode is not influenced, the problem of high temperature corrosion to side wall water cooling wallsis thoroughly solved.

Owner:XIAN ANT PETROLEUM TECH

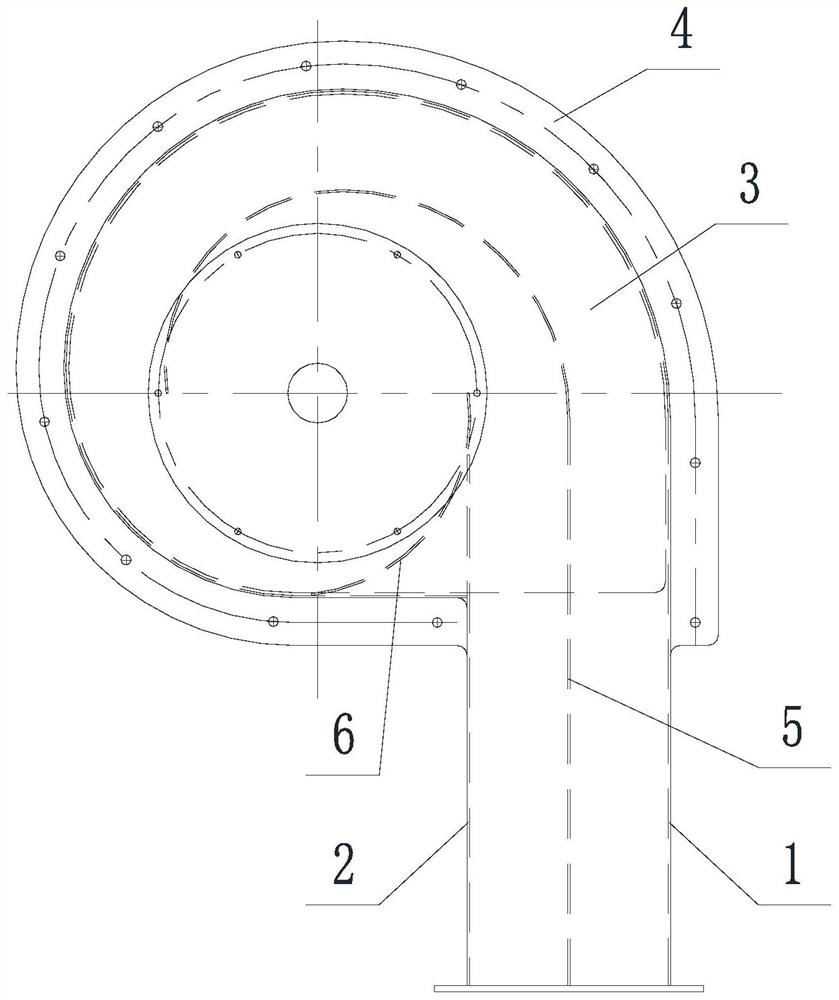

Hollow conical rotational flow flame low-nitrogen gas burner

ActiveCN112815311ASuppress generationReduce burning intensityGaseous fuel burnerEngineeringNitrogen gas

A hollow conical rotational flow flame low-nitrogen gas burner comprises a volute unit and a burning head unit. The volute unit comprises an air inlet and an air outlet, the air inlet is formed in the head of the volute unit, the air outlet is formed in the side face of the volute unit, and a throat ring is arranged at the air outlet. The burning head unit comprises a distributor, nozzles and a cone frustum, the distributor is installed in the throat ring, a mixing area is formed between the circumferential face of the distributor and the inner wall of the throat ring, the distributor is provided with an inner cavity, and the inner side end face of the distributor communicates with a gas inlet. Each nozzle is provided with an opening end and a gas outlet, the multiple nozzles are evenly distributed and installed on the circumferential face of the distributor, the opening ends communicate with the inner cavity, a gas cavity is formed between the opening ends and the closed ends, and the gas outlets communicate with the gas cavity and are arranged towards an opening of the throat ring. The small end face of the cone frustum is connected with the outer side end face of the distributor, the large end face of the cone frustum is arranged outwards, a hollow conical rotational flow flame area is formed between the large end face and the opening of the throat ring, and a smoke backflow area is formed by a hollow inner cavity of the cone frustum.

Owner:浙江南方锅炉有限公司

Low-NOx low-CO efficient energy-saving combustor

PendingCN113864774AReduce generationReduce leakageIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberCombustor

The invention discloses a low-NOx low-CO efficient energy-saving combustor. The low-NOx low-CO efficient energy-saving combustor comprises a combustor shell. A combustion chamber body is mounted at the top end of the combustor shell. An inner cavity of the combustion chamber body is a combustion chamber. A combustor closing opening is formed in the top end of the combustion chamber body. A secondary nozzle with a flow guide pipe is arranged outside the top end of the combustion chamber. Fuel gas sprayed out of a main gun is mixed with air entering the combustion chamber at a high speed, and therefore low-temperature oxygen-enriched main flames are formed in the combustion chamber, and generation of NOx and CO is reduced. The fuel gas sprayed out of each combustor auxiliary gun can draw smoke into the secondary nozzle with the flow guide pipe from the position of a smoke backflow channel, and then the smoke is sprayed into the main flames through the secondary nozzle with the flow guide pipe to be combusted. Due to the fact that a large amount of smoke is contained, the combustion intensity is reduced, generation of NOx is reduced, the fuel gas leaked into the smoke of the combustion chamber is reduced, and formation of CO is reduced.

Owner:LUOYANG LEBANG PETROCHEM EQUIP

Low-nitrogen combustor

PendingCN109973994ARaise the combustion temperatureReduce NO

<sub>x</sub>Burner ignition devicsGaseous fuel burnerCombustorLow nitrogen

The invention provides a low-nitrogen combustor which comprises a shell. The shell is formed by coaxially connecting a fuel section and a combustion section, the outer wall of the fuel section is vertically connected with a fuel gas connecting pipe, a combustion-supporting air connecting pipe is vertically connected on the outer wall of the combustion section, and the combustion section further comprises a fuel gas channel communicating with the fuel section. The low-nitrogen combustor further comprises an ignition device and a primary fuel gas branch pipeline, the primary fuel gas branch pipeline communicates with the fuel gas channel, a primary fuel nozzle is formed in the primary fuel branch pipeline, the inner side of the combustion section is also connected with a secondary fuel gas annular gap channel and a secondary fuel gas branch pipeline, and one end of the secondary fuel gas annular gap is provided with a plurality of secondary fuel spray pipes. The structure of fuel classification and flue gas internal circulation is adopted, and the combustion-supporting air vertically collides with the air flow sprayed by the primary fuel nozzle and is ignited by a pilot burner. At anoutlet of the combustor, secondary fuel is sprayed out to be added into combustion, high-speed airflow or flame forms local negative pressure, and a low-temperature rich combustion area is formed, sothat NOx is reduced.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle

InactiveCN102492477BReduce burning intensityLower flame temperatureLiquid spraying apparatusCombined combustion mitigationSlagReaction rate

The invention relates to a hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle which is arranged on a gasification furnace. The hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle comprises a main fuel nozzle which is arranged at the top of a furnace, two steam nozzles which are arranged at the two sides of a furnace arch and two oxygen supply nozzles which are horizontally arranged in a hedging manner, wherein the nozzles are respectively connected with a coal water slurry source, an oxygen source and a steam source, and the openings of the nozzles lead into a hearth of the gasification furnace. According to the invention, an advanced temperature control technology combining a grading oxygen supply temperature control technology and a steam temperature control technology is adopted, combustion intensity and flame temperature in the furnace are effectively reduced, and the aim that ash at the outlet of the gasification chamber is non-fused solid slag; meanwhile, gasification reaction rate and carbon conversion rate are improved, thus gasification solid deslagging on a 'double high' coal type large-scale pressurization entrained bed in China is realized, and the hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle provided by the invention is especially applicable to industrial application of a high-ash (25-27%) and high-ash-fusing-point (FT is more than 1400 DEG C) coal type large-scale gasification device in China.

Owner:SHANGHAI JIAOTONG UNIV

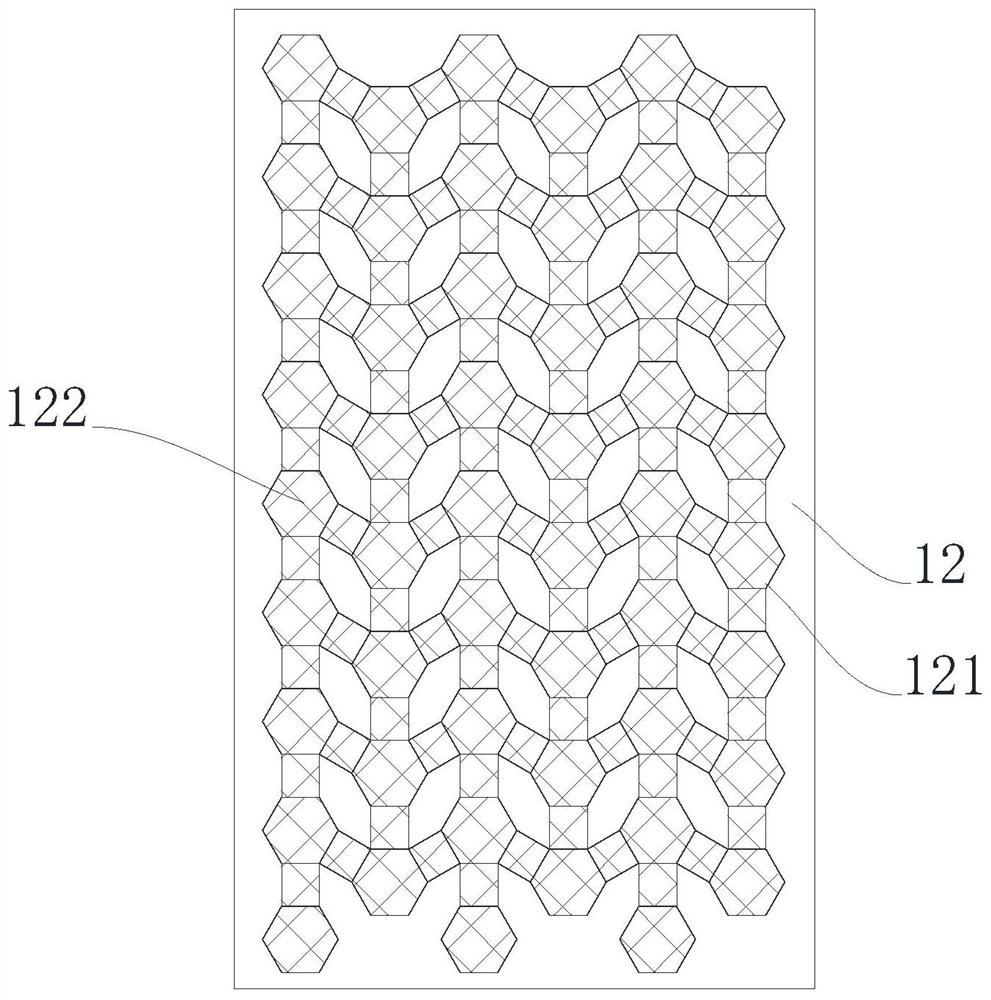

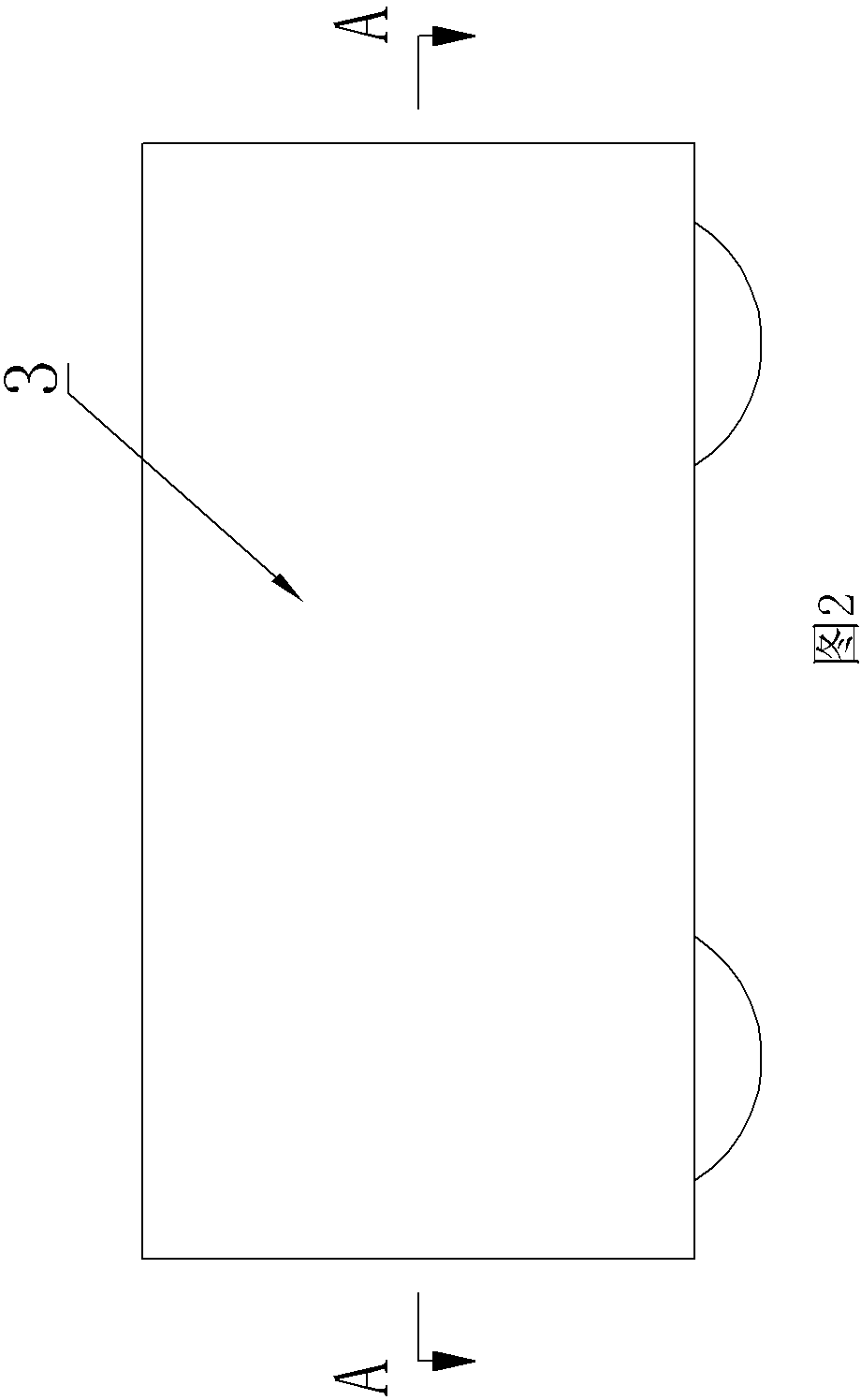

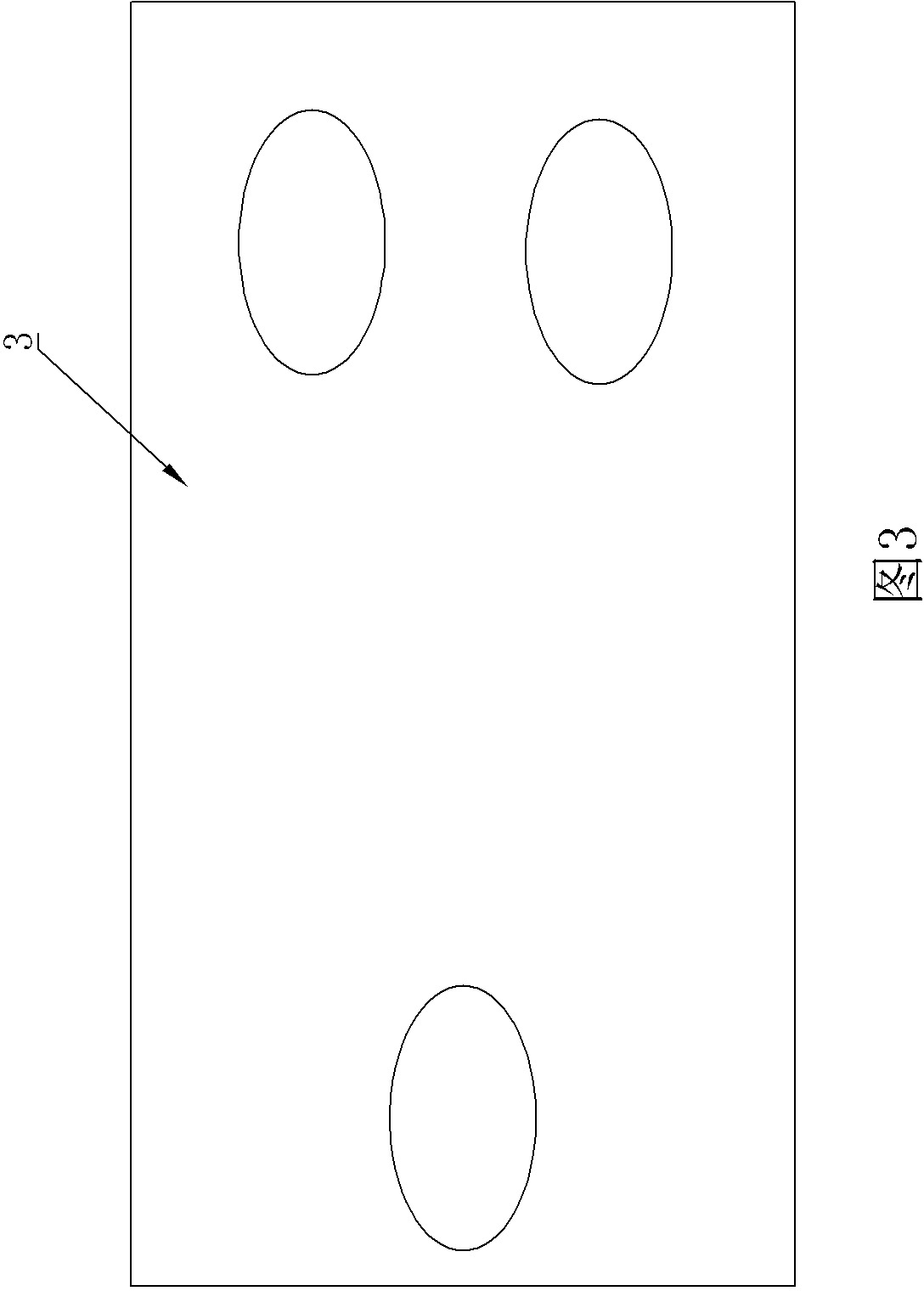

Matrix for filling cast-in-situ concrete

InactiveCN102912912AAvoid the problem that the surrounding wall is sunken inwardReduce burning intensityConstruction materialFloorsEngineeringUltimate tensile strength

The invention relates to a matrix for filling cast-in-situ concrete. The matrix comprises a matrix base body and an aerating liner embedded in the matrix base body; and the aerating liner is fixedly sealed in the matrix base body. The inner part of the matrix base body is internally provided with the aerating liner, and the aerating liner is directly embedded in the matrix base body. In use, the aerating liner can play the role of supporting the peripheral wall of the matrix from the inner part of the matrix, therefore, the problem that the peripheral wall of the matrix is sunken inwards in use is avoided; a shell of the aerating liner can be only burned when the aerating liner is directly contacted with open fire, so that the burning intensity of the aerating liner is low, the burning time is relatively short, and further, the problem that in the prior art, a filler in the matrix for filling the cast-in-situ concrete can ignite the other matters in the process of burning is solved.

Owner:周立成

A kind of cast-in-place concrete filled matrix

InactiveCN102912913BImprove support strengthStable supportConstruction materialFloorsEngineeringUltimate tensile strength

The invention relates to a cast-in-place concrete filling tire body. The cast-in-place concrete filling tire body comprises a base body of the tire body and an annular inflation liner which is embedded into the base body of the tire body and is fixedly sealed in the bas body of the tire body. According to the cast-in-place concrete filling tire body, a supporting body is added in a box body of the base body of the tire body to improve the support between the top surface and the bottom surface of the base body of the tire body, and the annular inflation liner is embedded into the base body of the tire body and is capable of supporting each circumferential wall of the base body of the tire body, so that the whole supporting strength of the tire body is higher; once the inflation liner is directly contacted with open fire, the wall of the inflation liner can be burnt, therefore, the burning strength of the inflation liner is low, and the burning time of the inflation liner is short, and furthermore, the problem of the prior art that other objects can be ignited when fillers in the cast-in-place concrete filling tire body are burnt can be solved.

Owner:周立成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com