Matrix for filling cast-in-situ concrete

A technology of concrete and carcass, applied to building materials, building components, floor slabs, etc., can solve the problem of igniting other objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

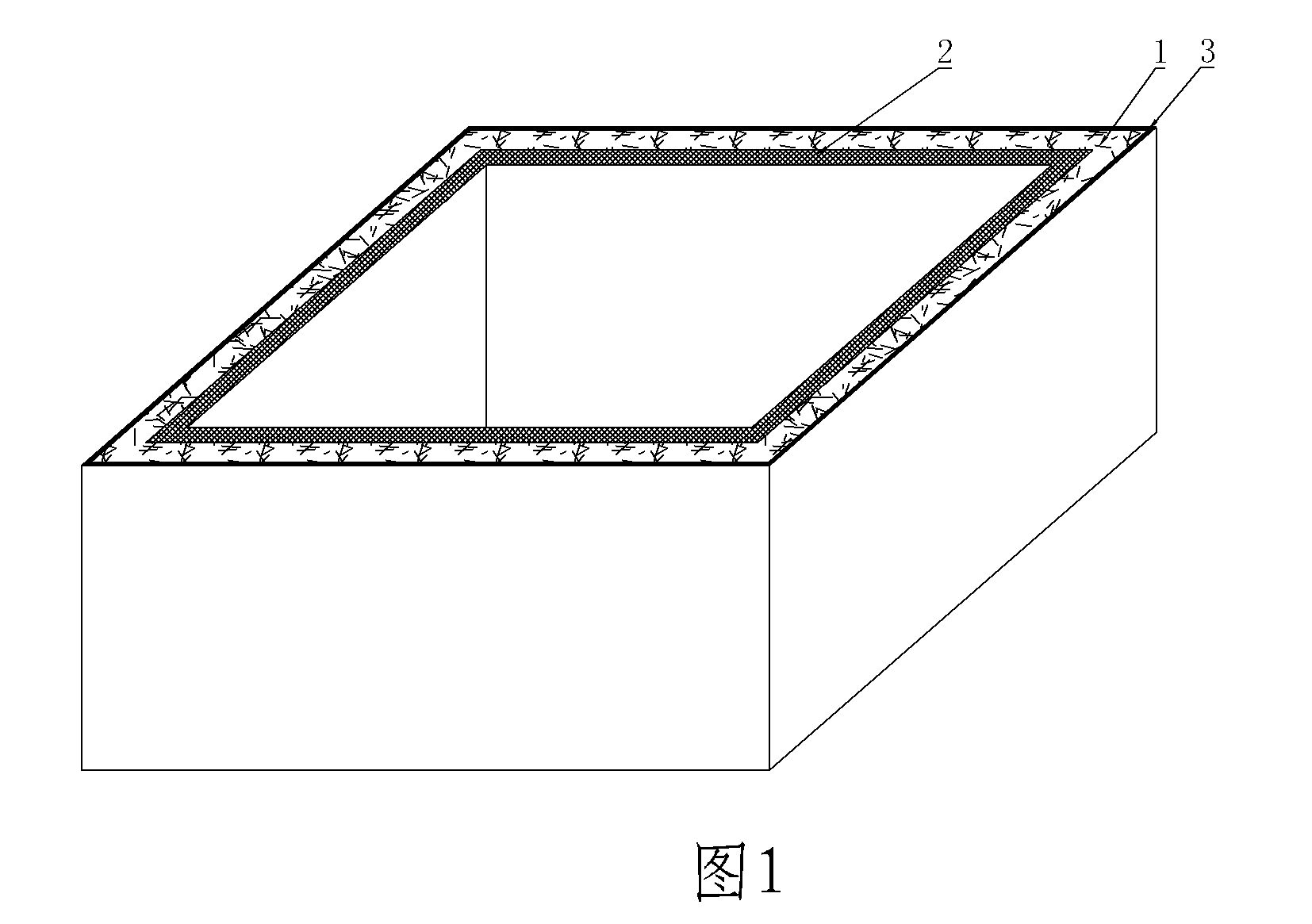

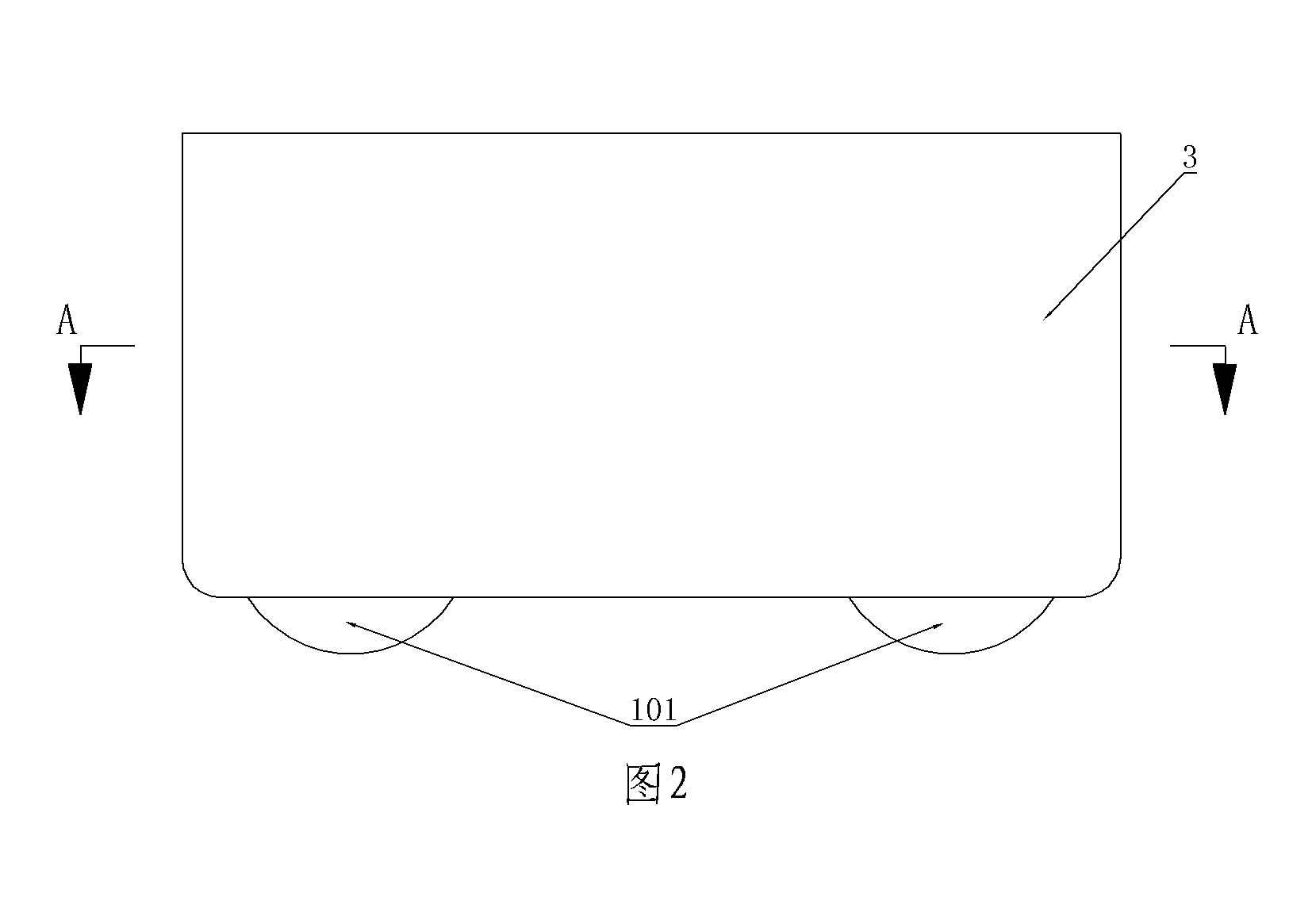

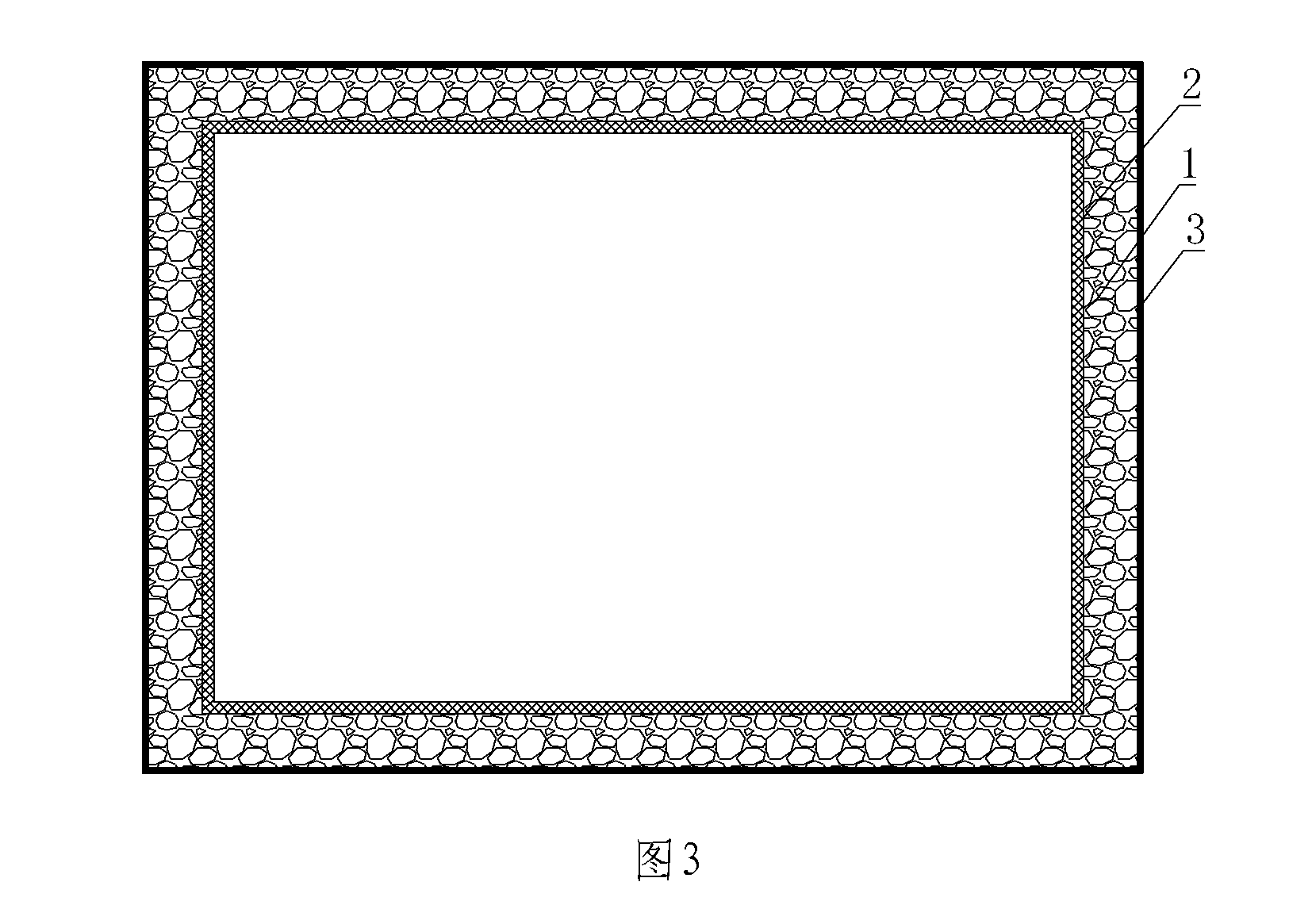

[0019] Embodiment 1 of the cast-in-place concrete filling matrix of the present invention: as Figure 1 to Figure 4 As shown, the cast-in-place concrete filling carcass is mainly composed of a carcass base 1 and an inflatable inner tank 2 in the carcass base 1, wherein the inner cavity of the carcass base 1 is a square inner cavity, and the corresponding inflatable inner tank 1 The shape is also square, and the inflatable liner 2 is directly embedded in the carcass base 1, so that the carcass base 1 can seal the inflatable liner 2 in it, that is, when the staff pours the carcass base 1, the The inflatable liner 2 and the carcass base 1 are integrally casted, and the material used for pouring the carcass base 1 is foamed concrete, so that the box body of the carcass base 1 is a spongy porous body composed of concrete entities and foam holes , and the outer surface of the carcass base 1 is provided with a waterproof layer 3 made of waterproof paint.

[0020] Among them, foamed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com