Hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle

A technology of coal water slurry and entrained bed, which is applied in the field of coal gas and coal, can solve the problems that "double high" coal types cannot meet the requirements of slagging process and cannot be applied, and achieve the improvement of gasification reaction rate and carbon conversion rate, high carbon Conversion rate and cold gas efficiency, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments. .

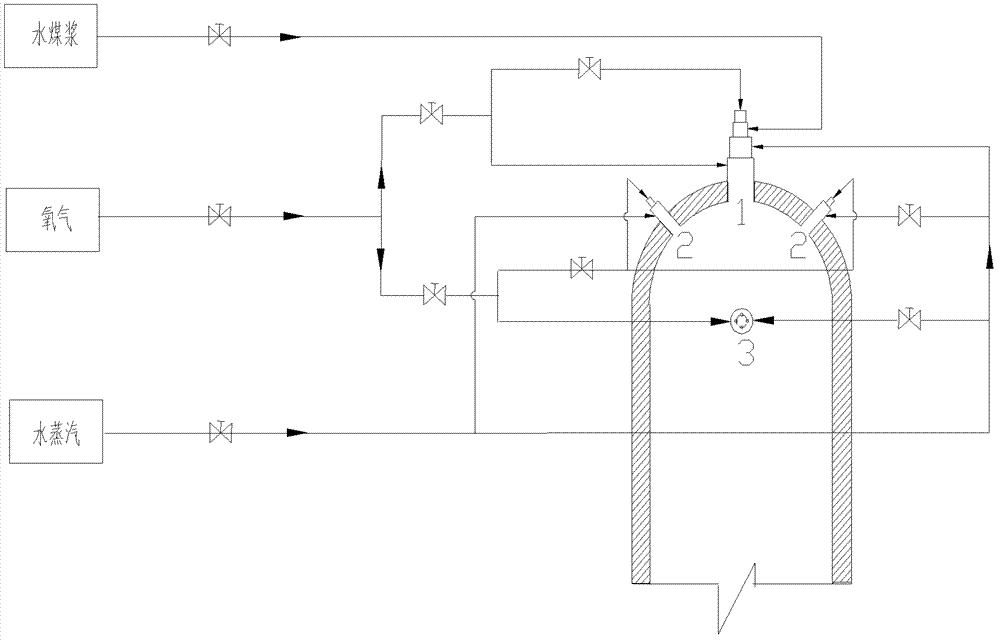

[0023] like figure 1 As shown, the staged oxygen supply and controllable flame coal-water slurry entrained bed combination nozzle of the present invention is installed on the gasifier, which includes a single main fuel nozzle 1, two water vapor nozzles 2 and two second-stage oxygen supply nozzles Nozzle 3 achieves the purpose of controlled flame dry slag removal through the comprehensive action of five nozzles.

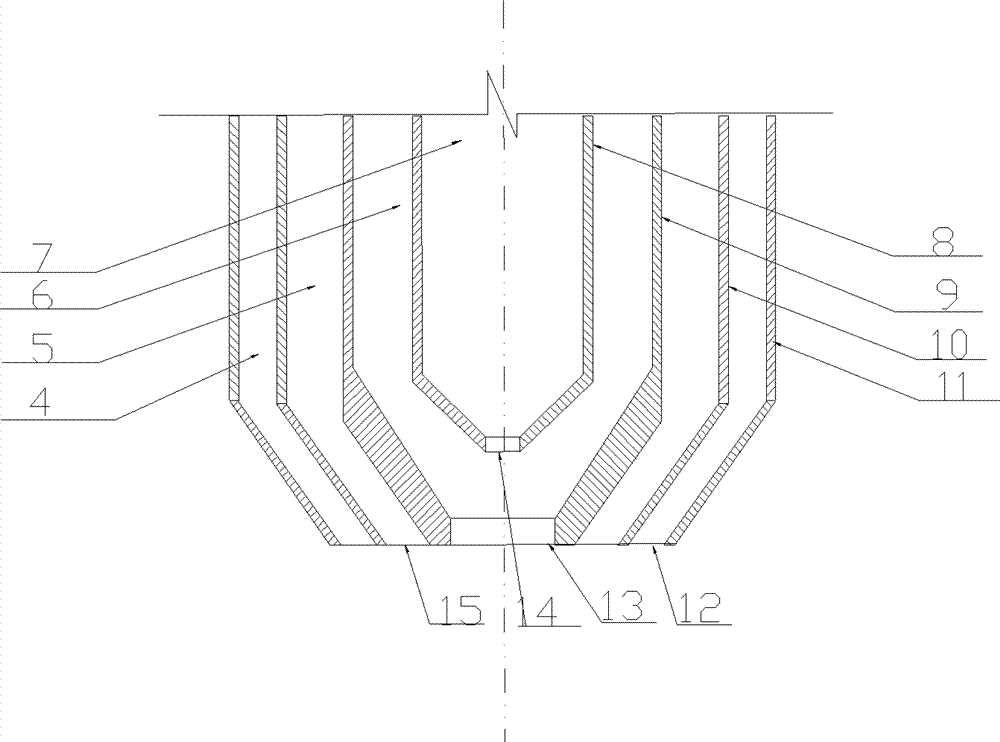

[0024] The main fuel nozzle 1 is located on the top of the gasifier, and its opening leads into the hearth of the gasifier. The axis of the main fuel nozzle 1 coincides with the vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com