Method and vertical flue bottom structure for reducing production of nitrogen oxides by coke oven

A technology of nitrogen oxides and bottom structure, which is used in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problems of high nitrogen oxide emissions, sufficient mixing of circulating exhaust gas, and high combustion temperature in coke ovens. , to achieve the effect of weakening combustion intensity, reducing pollution and reducing combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

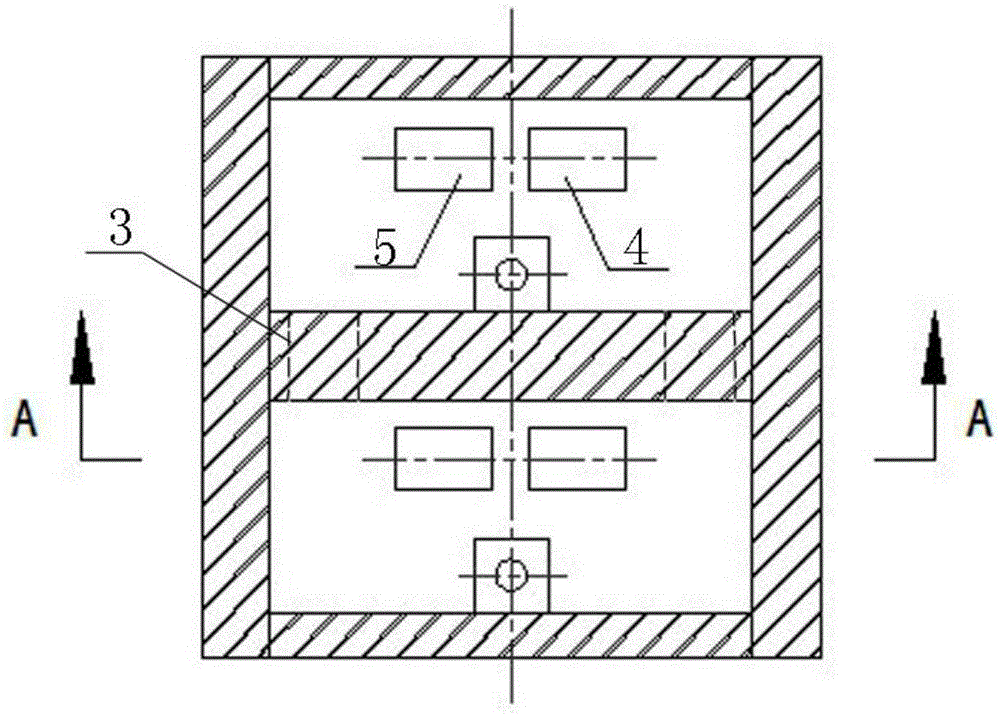

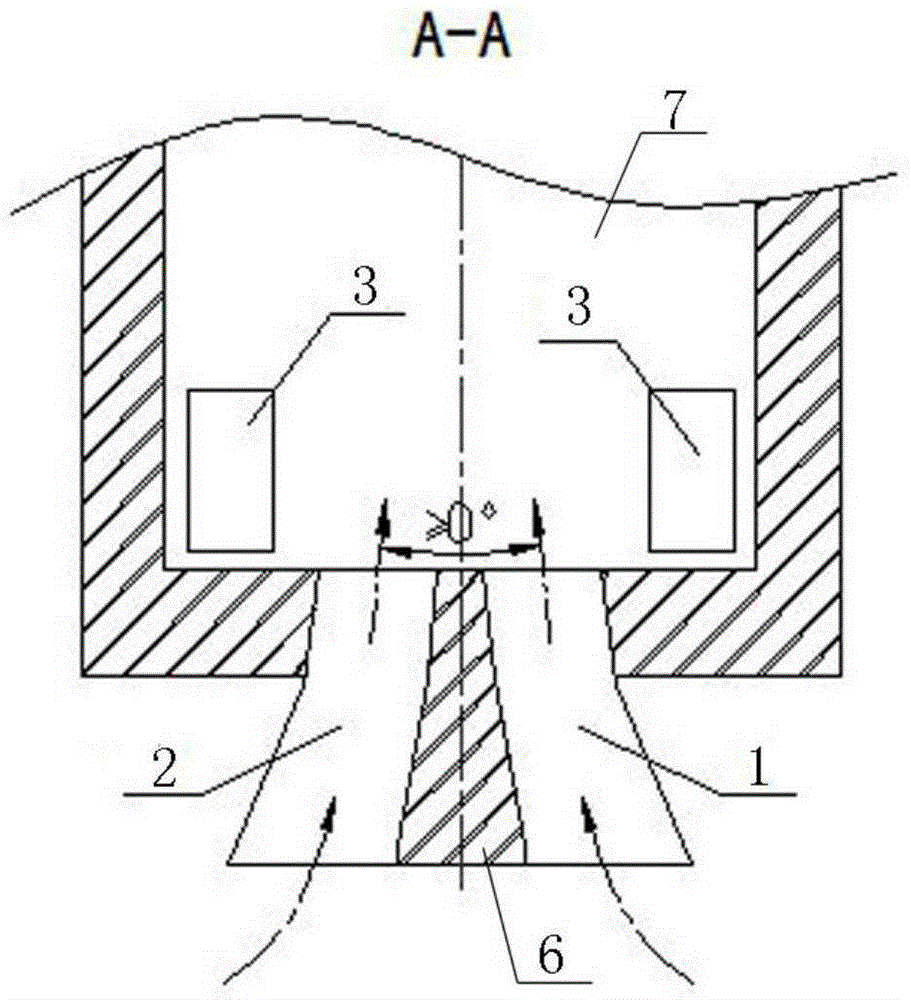

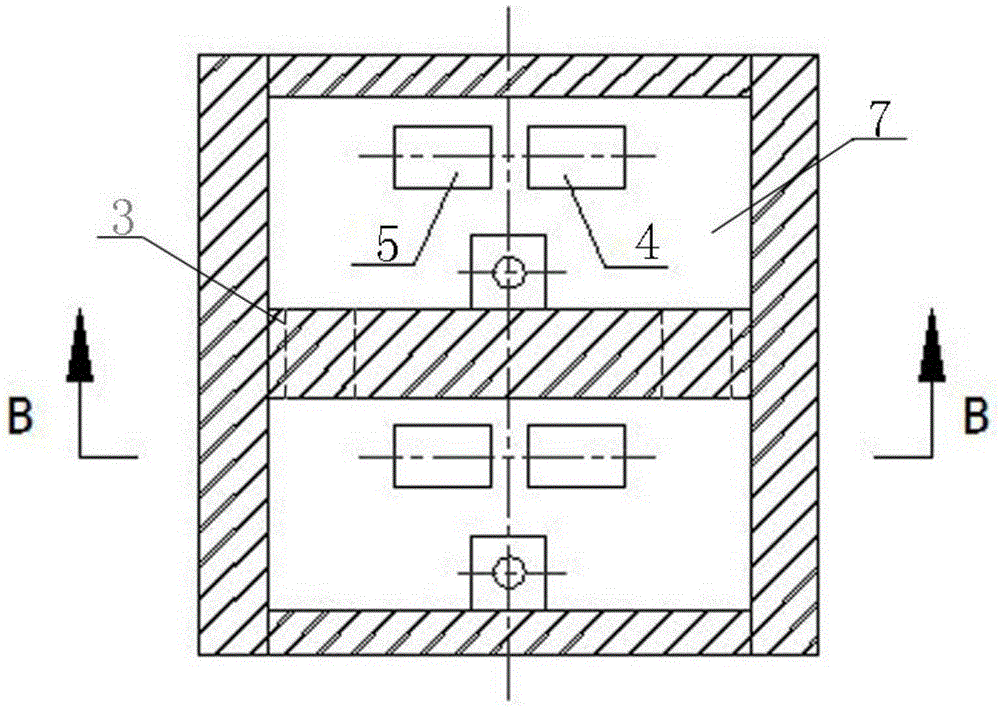

[0020] See Figure 3-Figure 4 , is a structural schematic view of the bottom of the fireway and the chute area of the present invention. A method for reducing the formation of nitrogen oxides in coke ovens according to the present invention, by changing the direction of the combustible gas channel 1 and the combustion-supporting gas channel 2 in the chute area 6, the combustible gas and the combustion-supporting gas respectively enter the standing fire along the direction away from each other. In the channel 7, the combustible gas and combustion-supporting gas are mixed with the circulating waste gas at the bottom of the standing fire channel 7 before burning to reduce the concentration of combustible gas and oxygen, weaken the combustion intensity, and reduce the combustion temperature; the combustible gas and combustion-supporting gas enter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com