Self pre-heating type high-speed burning nozzle and control method thereof.

A high-speed burner and preheater technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of high NOx emission value, flame instability, etc., to improve temperature uniformity, improve service life, and achieve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below.

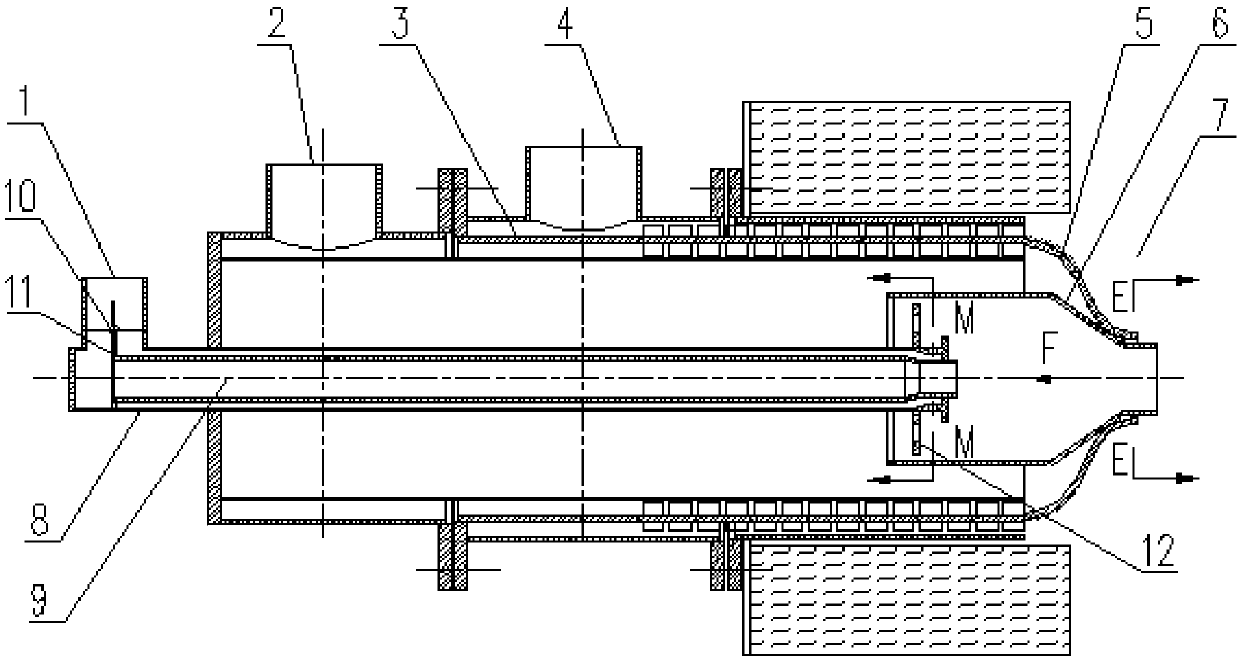

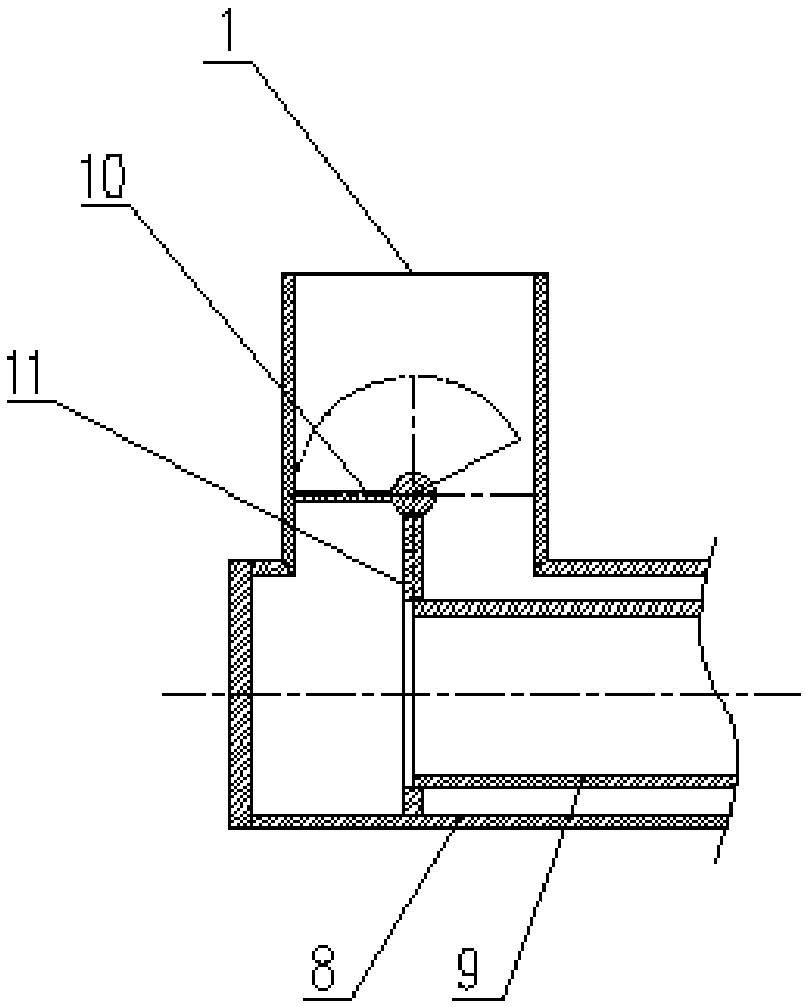

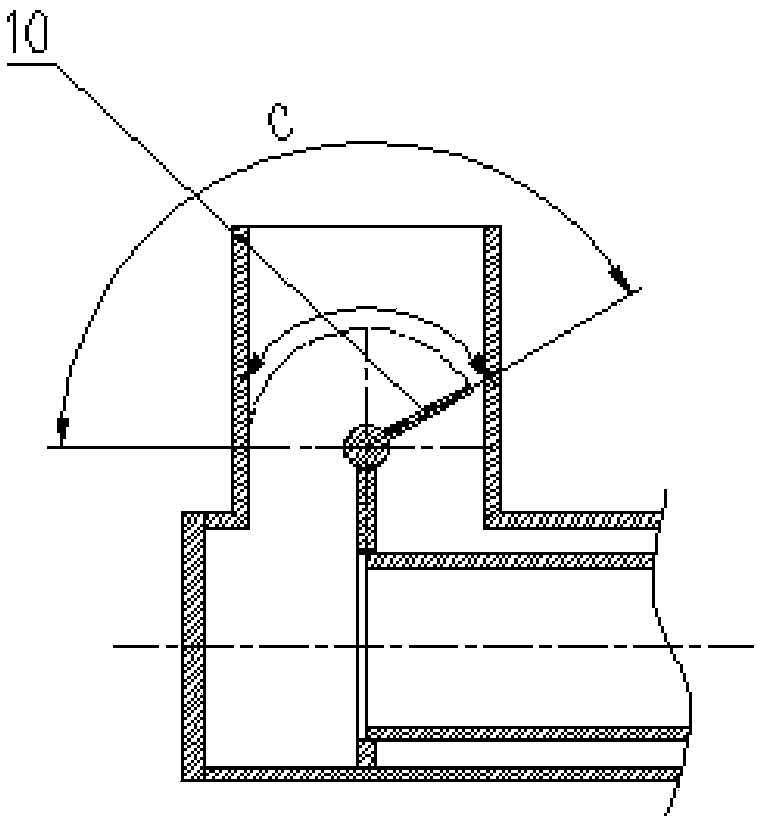

[0031] The reference signs in the accompanying drawings of the specification include:

[0032] Gas supply pipe 1, air supply pipe 2, preheater 3, exhaust pipe 4, flue gas deflector 5, combustion chamber 6, main combustion space 7, radial injection gas supply pipe 8, axial injection gas supply pipe 9. Gas regulating plate 10, partition plate 11, air distribution plate 12, circular baffle plate 13, radial gas nozzle 14, axial gas nozzle 15, air injection circular hole 16.

[0033] like figure 1 The self-preheating high-speed burner shown is, from left to right, the gas supply pipe 1, the air supply pipe 2 and the smoke exhaust pipe 4 installed on the burner shell, and the air supply pipe 2 and the smoke exhaust pipe 4 Separated preheater 3 , flue gas deflector 5 arranged on preheater 3 and close to main combustion space 7 , combustion chamber 6 and main combustion space 7 . The gas supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com