Method for continuously producing large-particle spherical cobalt carbonate

A large particle, cobalt carbonate technology, applied in the direction of cobalt carbonate, etc., can solve the problems of affecting the particle size distribution and the continuous consistency of tapped density of the product, difficult to meet the large-scale production of large particle spherical cobalt carbonate, difficult to reduce production costs and other problems, To achieve the effect of friendly production environment, high sphericity and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Step 1: Making a suspension containing cobalt carbonate seeds with small particle size

[0088] ⑴ Prepare the solution

[0089] Take industrial grade cobalt chloride raw material, be mixed with 2.0mol / L cobalt chloride aqueous solution, be recorded as solution a;

[0090] Take technical grade sodium carbonate raw material, be mixed with 2.0mol / L sodium carbonate aqueous solution, be recorded as solution b;

[0091] ⑵Preparation of small particle size cobalt carbonate seed crystal reaction bottom liquid

[0092] Controlled by a metering pump, pump 20L of solution a prepared in step 1 (1) into a stainless steel reactor with an effective volume of 3000L, and add deionized water to the reactor to adjust to Co in the solution. 2+ The concentration of the concentration is 0.04mol / L, as the small particle size cobalt carbonate seed crystal reaction bottom liquid, the stirring blade of the reactor can be fully stirred to the small particle size cobalt carbonate seed crystal r...

Embodiment 2

[0121] Step 1 makes a suspension containing small particle size cobalt carbonate seeds

[0122] The production process is exactly the same as step 1 in Example 1;

[0123] step 2

[0124] ⑴Preparation of large particle spherical cobalt carbonate reaction bottom liquid

[0125] Manufacturing process is exactly the same as step 2 (1) in embodiment 1;

[0126] ⑵Make solution d

[0127] Manufacturing process is exactly the same as step 2 (2) in embodiment 1;

[0128] (3) Transfer part of the solution d

[0129] Use a centrifugal pump to transfer the 2200L solution d in the reaction kettle in step 2 (2) to a stainless steel airtight pressure filter washing machine, and leave the rest in the reaction kettle;

[0130] ⑷solid-liquid separation

[0131] Manufacturing process is exactly the same as step 2 (4) in embodiment 1;

[0132] ⑸ drying

[0133] Production process is exactly the same as step 2 (5) in embodiment 1, promptly makes the large particle cobalt carbonate powder ...

Embodiment 3

[0148] Step 1 makes a suspension containing small particle size cobalt carbonate seeds

[0149] The production process is exactly the same as step 1 in Example 1;

[0150] step 2

[0151] ⑴Preparation of large particle spherical cobalt carbonate reaction bottom liquid

[0152] Manufacturing process is exactly the same as step 2 (1) in embodiment 1;

[0153] ⑵Make solution d

[0154] Manufacturing process is exactly the same as step 2 (2) in embodiment 1;

[0155] (3) Transfer part of the solution d

[0156] Use a centrifugal pump to transfer the 2400L solution d in the reaction kettle in step 2 (2) to a stainless steel airtight pressure filter washing machine, and leave the rest in the reaction kettle;

[0157] ⑷solid-liquid separation

[0158] Manufacturing process is exactly the same as step 2 (4) in embodiment 1;

[0159] ⑸ drying

[0160] Production process is exactly the same as step 2 (5) in embodiment 1, promptly makes the large particle cobalt carbonate powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

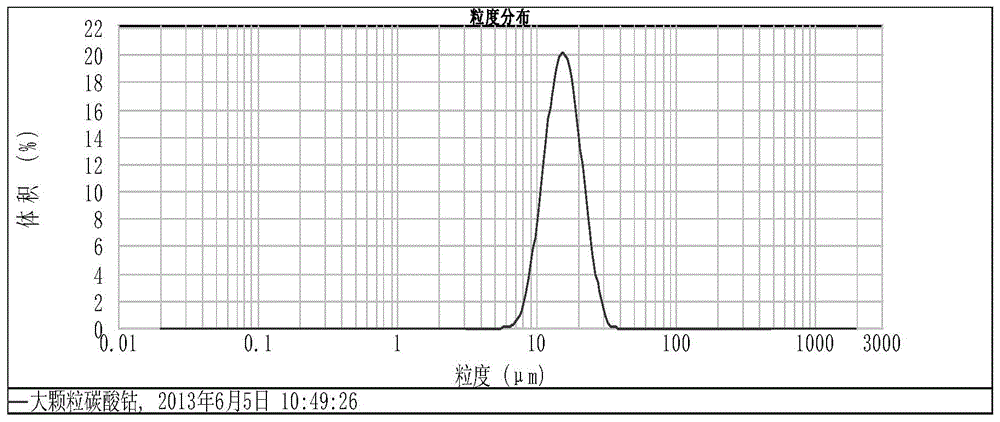

| Particle size distribution | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com