T-shaped burning beam

A technology for burning beams and beam bodies, which is applied to burners, lighting and heating equipment, etc., can solve problems such as increasing equipment investment and maintenance costs, easily burning out the burner port, and affecting normal production, saving equipment investment and maintenance. cost, improve product quality, reduce and avoid the effect of local over-burning or burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

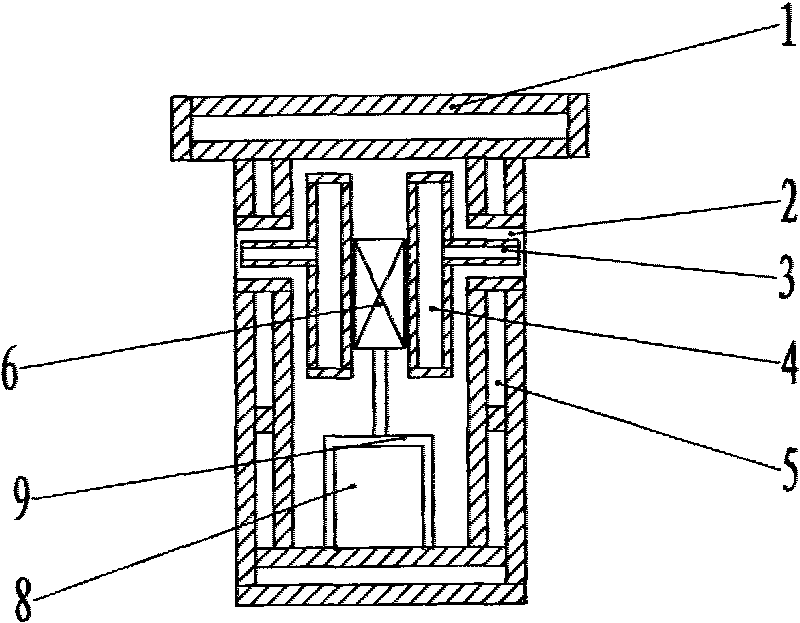

Embodiment 1

[0017] The "T"-shaped combustion beam of the present invention is composed of a beam body 1. The beam body is provided with a fuel pipeline 4 and an air passage 8. Both sides of the beam body are provided with burners 2, 10 burners on each side. A type of fuel nozzle 3 and an air outlet, the fuel nozzle 3 extends into the burner port, and the fuel pipeline is connected to the fuel nozzle. The air outlet is the gap around the fuel nozzle and communicates with the air passage. There are two fuel pipelines in the beam body, and the fuel pipelines are of rectangular box-like structure. The two fuel pipelines are fixedly installed in the air channel by fixing pieces 6, and the fixing pieces are supported by brackets 9. Each fuel pipeline is connected to the air passage. The fuel nozzle of the same side burner, the fuel nozzle is inserted into the burner port. Between the inner wall and the outer wall of the combustion beam, there is a cavity 5 through which a cooling medium circul...

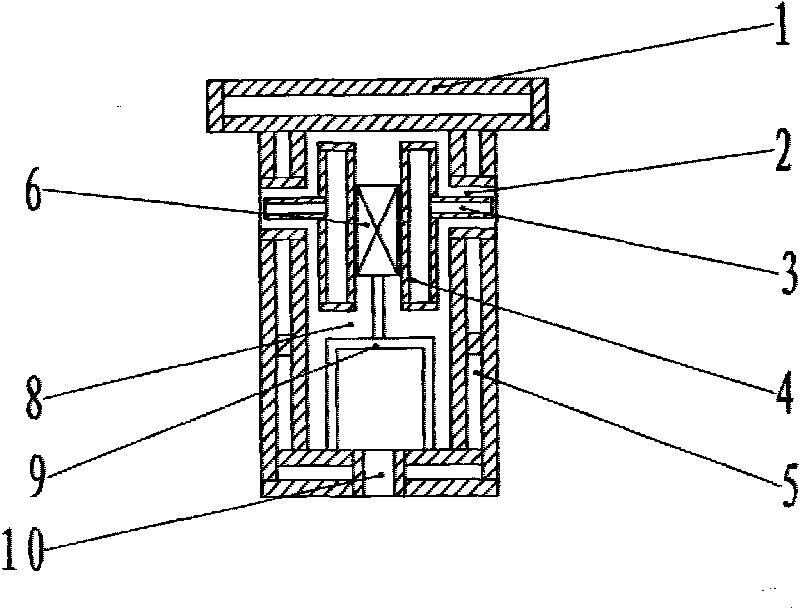

Embodiment 2

[0020] Another solution of the present invention is as figure 2 As shown, the lower part of the beam body is provided with 10 air nozzles 10 , and the air passages are connected to the air outlet of the burner 2 and the air nozzles 10 . The two fuel pipelines are fixedly installed in the air passage with fixing pieces 6 , and the fixing pieces are supported by brackets 9 . Other structures are the same as those of Embodiment 1.

[0021] The supplementary combustion-supporting air ejected from the air nozzles 10 at the lower part of the combustion beam disperses and flows upward under the suction action of the upper suction beam in the kiln body, and continues to burn with the incompletely burned fuel. In order to reduce the intensity of fuel combustion at the burner outlet and improve the uniformity of calcined products.

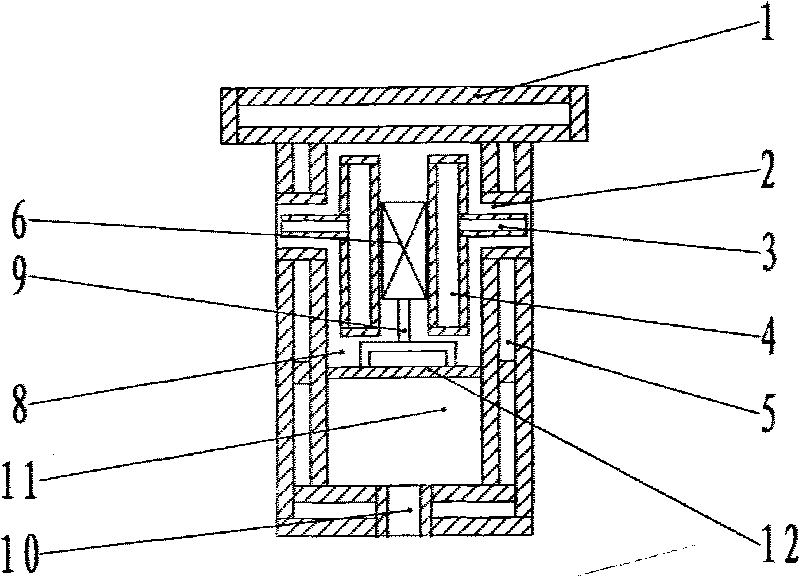

Embodiment 3

[0023] Another embodiment of the present invention is as follows image 3 As shown, the lower part of the beam body is provided with 10 air nozzles 10 , and the beam body is divided into upper and lower air passages 8 and 11 by a partition 12 . The fuel line 4 passes through the upper air passage 8 and communicates with the air outlet of the burner, and the lower air passage 11 communicates with the air nozzle 10 . Other structures are the same as those of Embodiment 1.

[0024] The supplementary combustion-supporting air ejected from the air nozzles 10 at the lower part of the combustion beam disperses and flows upward under the suction action of the upper suction beam in the kiln body, and continues to burn with the incompletely burned fuel. The pressure entering the upper air passage 8 is controlled to be lower than the pressure of the lower air passage 11, so that the amount of air ejected from the burner is lower than the theoretical value required for combustion, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com