A Composite Inhibitor for Preventing Spontaneous Combustion of Coal Powder

A chemical inhibitor and spontaneous combustion technology, applied in fire prevention, dust prevention, safety devices, etc., can solve problems such as delaying coal spontaneous combustion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sodium dodecylsulfonate is made into a 0.1% aqueous solution, and the weight percent is 70% sodium dodecylsulfonate solution, and then 30% by weight of sodium percarbonate is dissolved in the above penetrant solution, After stirring evenly, component A is obtained;

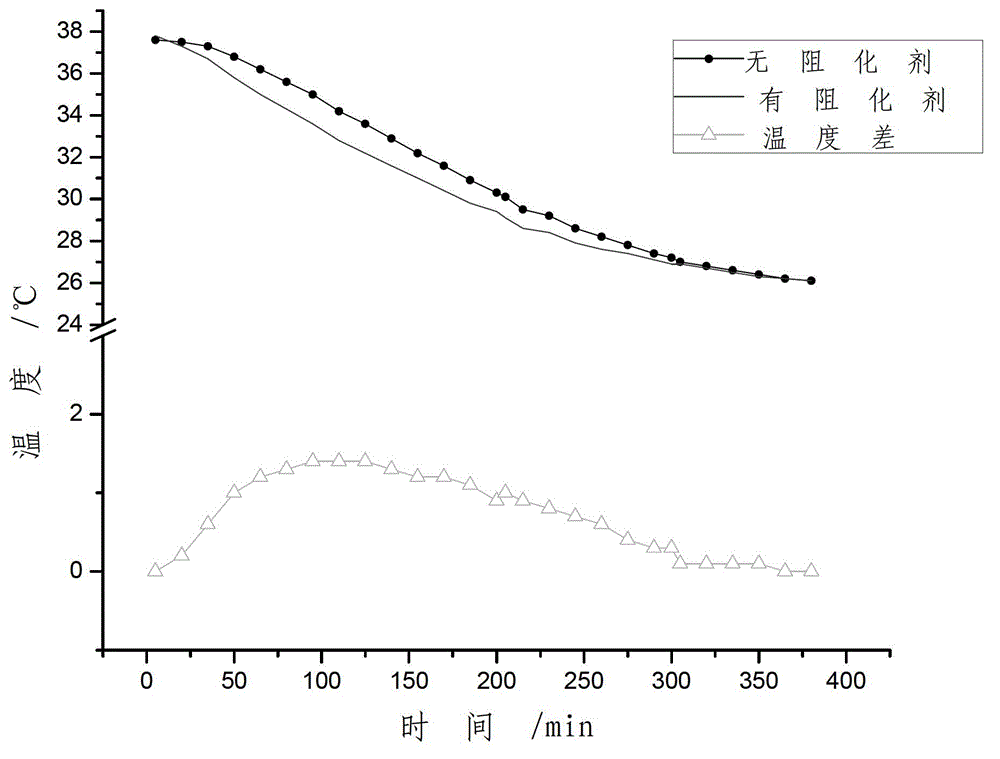

[0035] Then, the prepared sodium chloride of component A and component B was added to the pulverized coal at 40°C in a weight ratio of 1:1.5, and its temperature was monitored in real time and compared with the blank sample. Such as figure 1 As shown, the influence of the inhibitor on the pulverized coal temperature is obtained.

Embodiment 2

[0037] Make fatty alcohol polyoxyethylene ether into 0.3% aqueous solution, weigh 80% fatty alcohol polyoxyethylene ether solution by weight, and then dissolve 10% sodium persulfate and 10% potassium persulfate into the above-mentioned In the penetrant solution, after stirring evenly, component A is obtained;

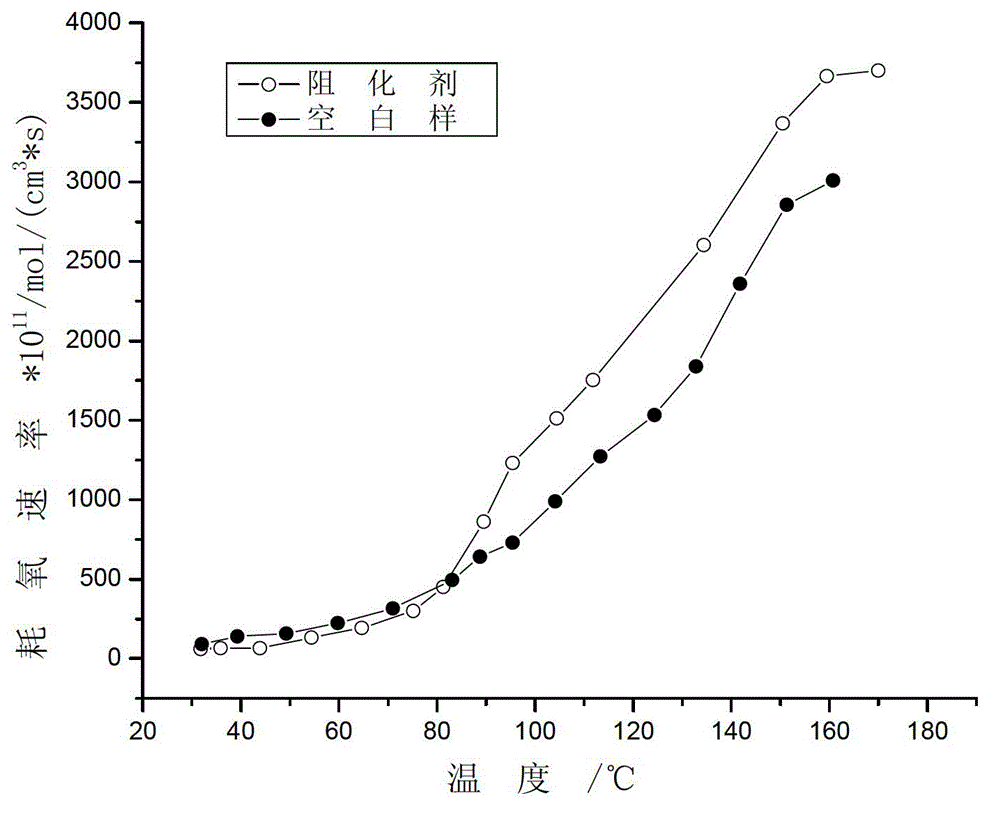

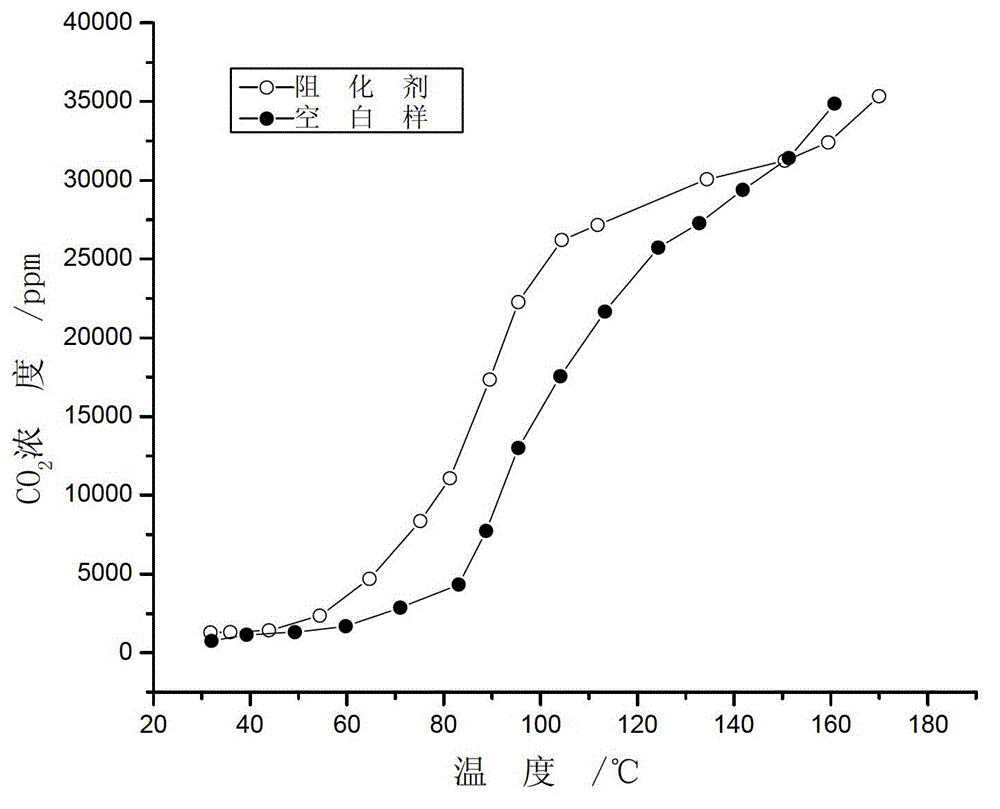

[0038] Then add the prepared ammonium chloride of component A and component B to the coal powder according to the weight ratio of 1:2.0, and place it on the XK type spontaneous combustion test bench to detect the gases in the process of spontaneous combustion in real time . As shown in Figure 2(a), Figure 2(b) and Figure 2(c).

Embodiment 3

[0040] Make dioctyl sodium dibutyrate sulfonate and sodium sulfamate into 0.2% aqueous solution, take by weight respectively 45% dioctyl sodium dibutyrate sulfonate and 45% sodium sulfamate aqueous solution, and then 5% by weight of percarbamide and 5% of ammonium persulfate are dissolved in the above-mentioned penetrant solution, and the component A is obtained after stirring evenly;

[0041] Then add the prepared A component and B component sodium bicarbonate and diammonium hydrogen phosphate to the coal powder according to the weight ratio of 1:3.0. The coal powder is packaged in an independent ton bag. The open-pit coal plant of Jiamao Coal Mine is stockpiling. Real-time monitoring of the central temperature of the bag coal to obtain the influence of the inhibitor on the temperature of the stored coal powder, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com