Patents

Literature

37 results about "Coal plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

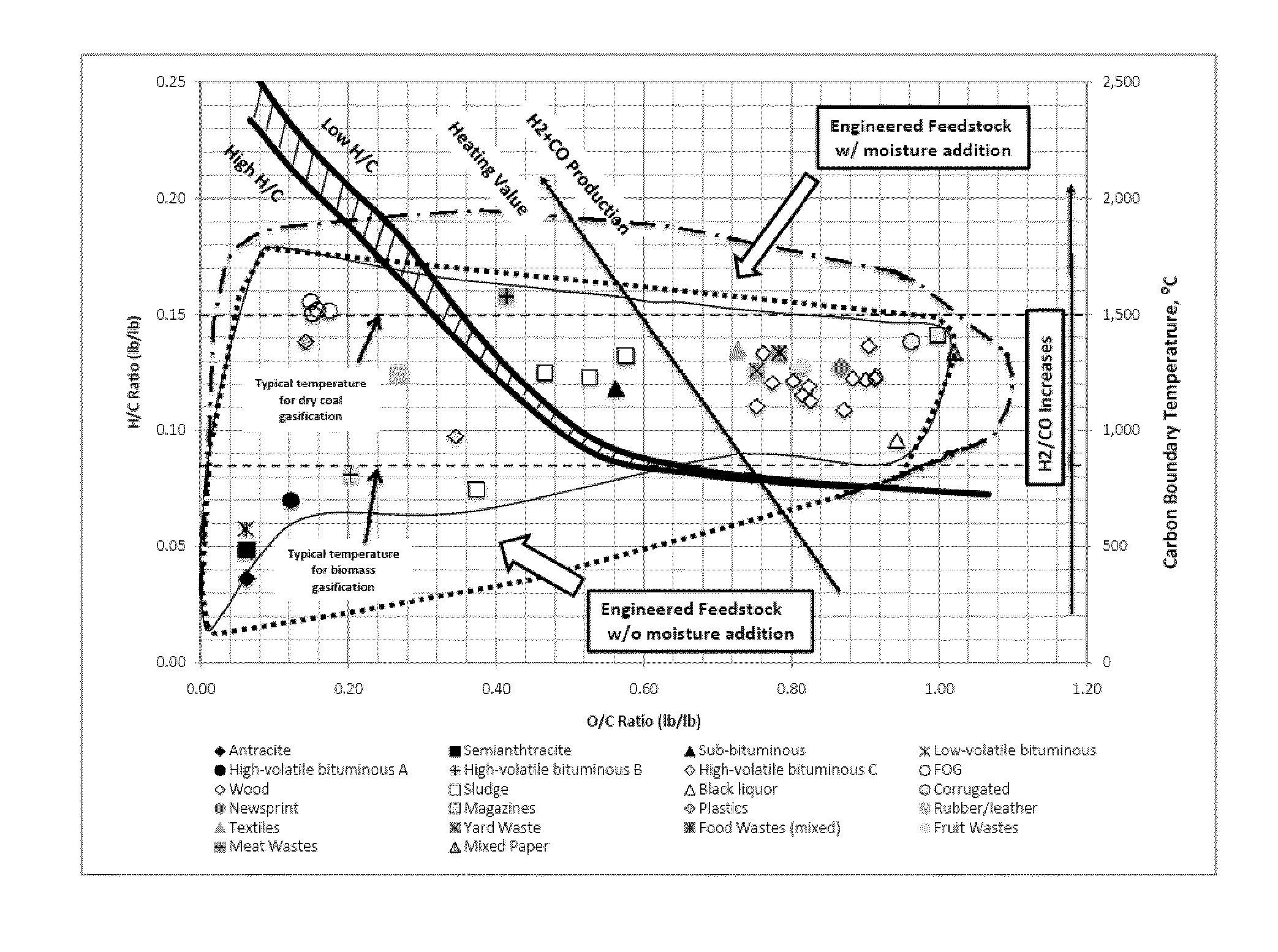

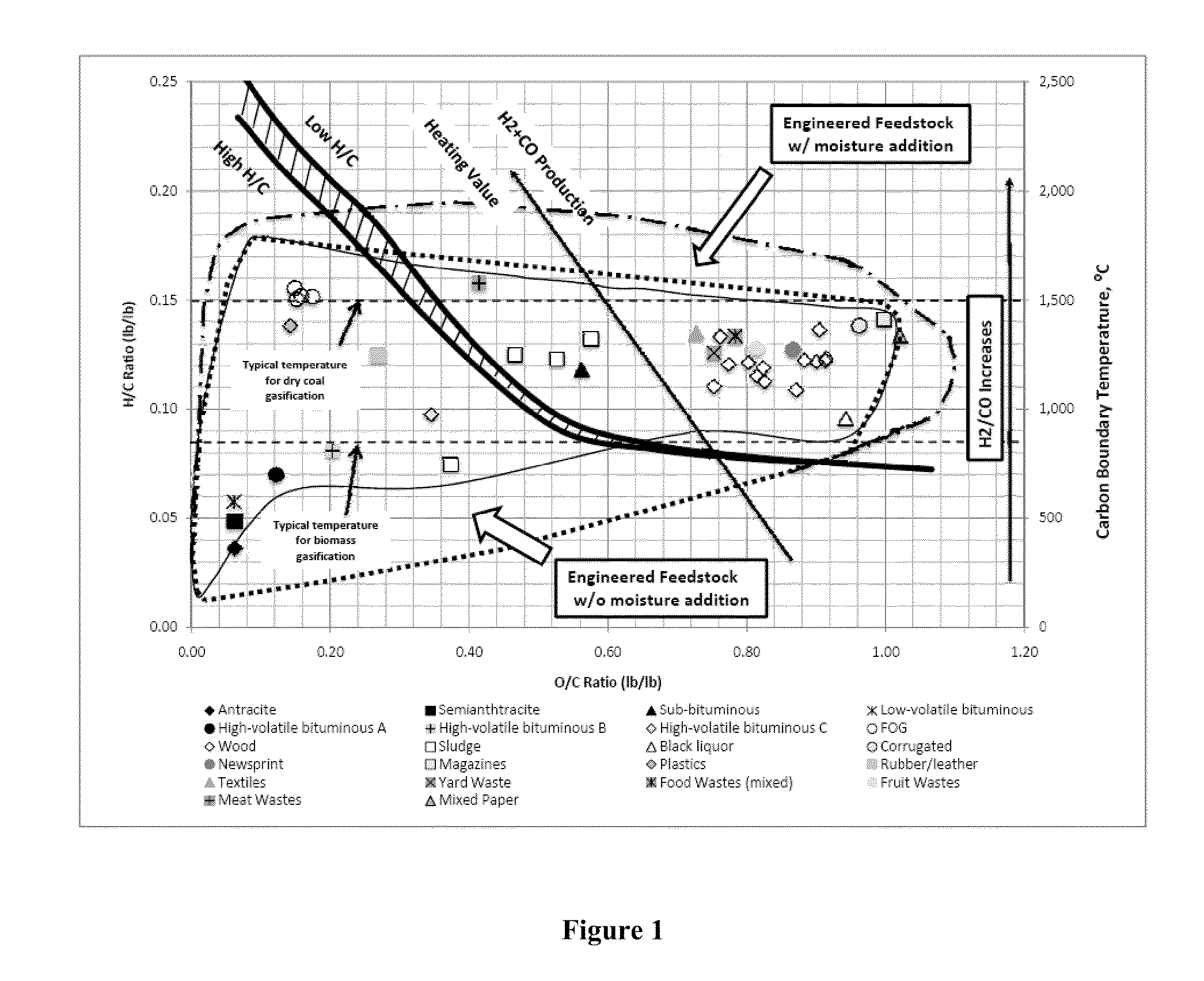

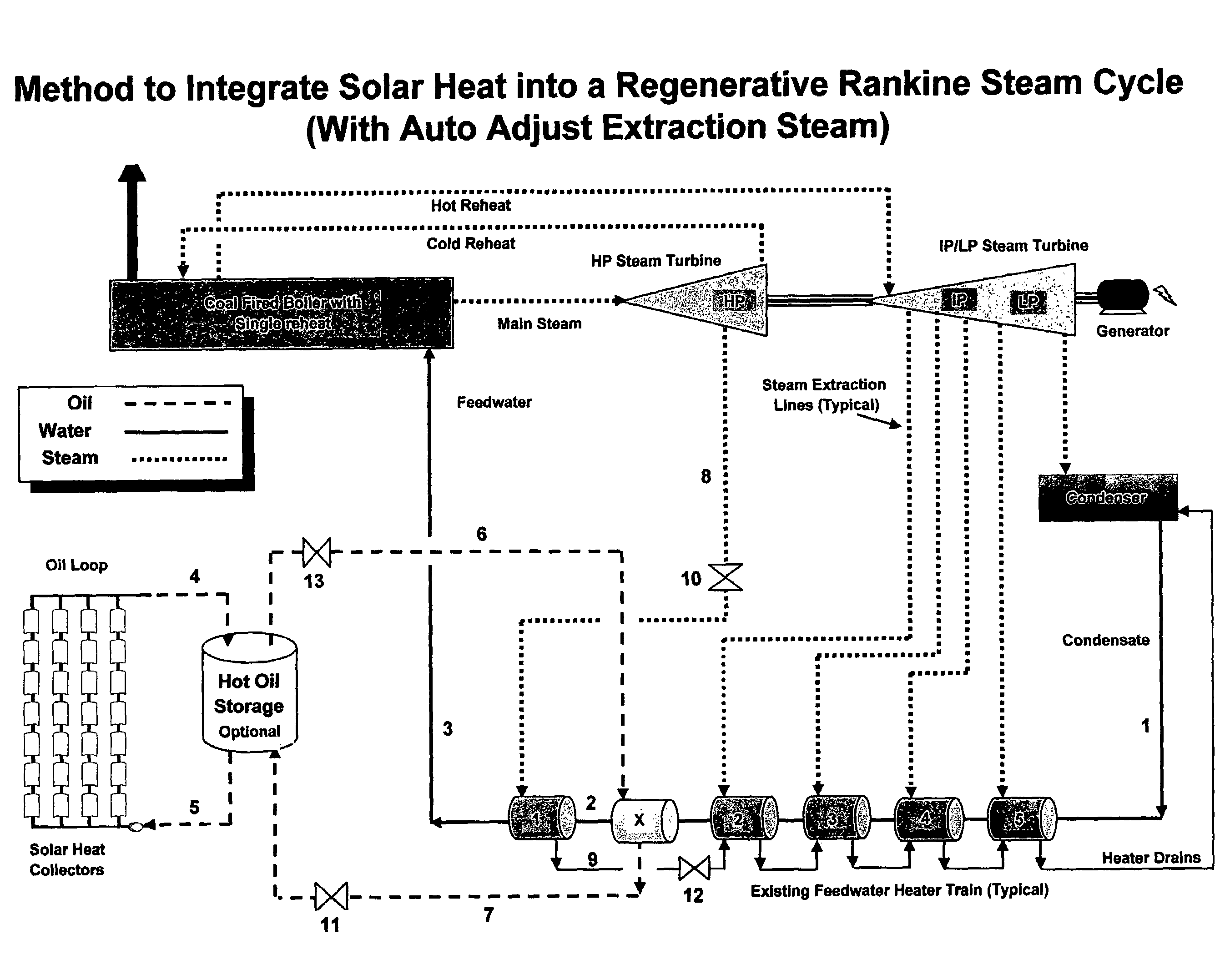

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS20100031560A1Reduce harm to the environmentQuality improvementMechanical working/deformationBiofuelsEngineeringCoal fired

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

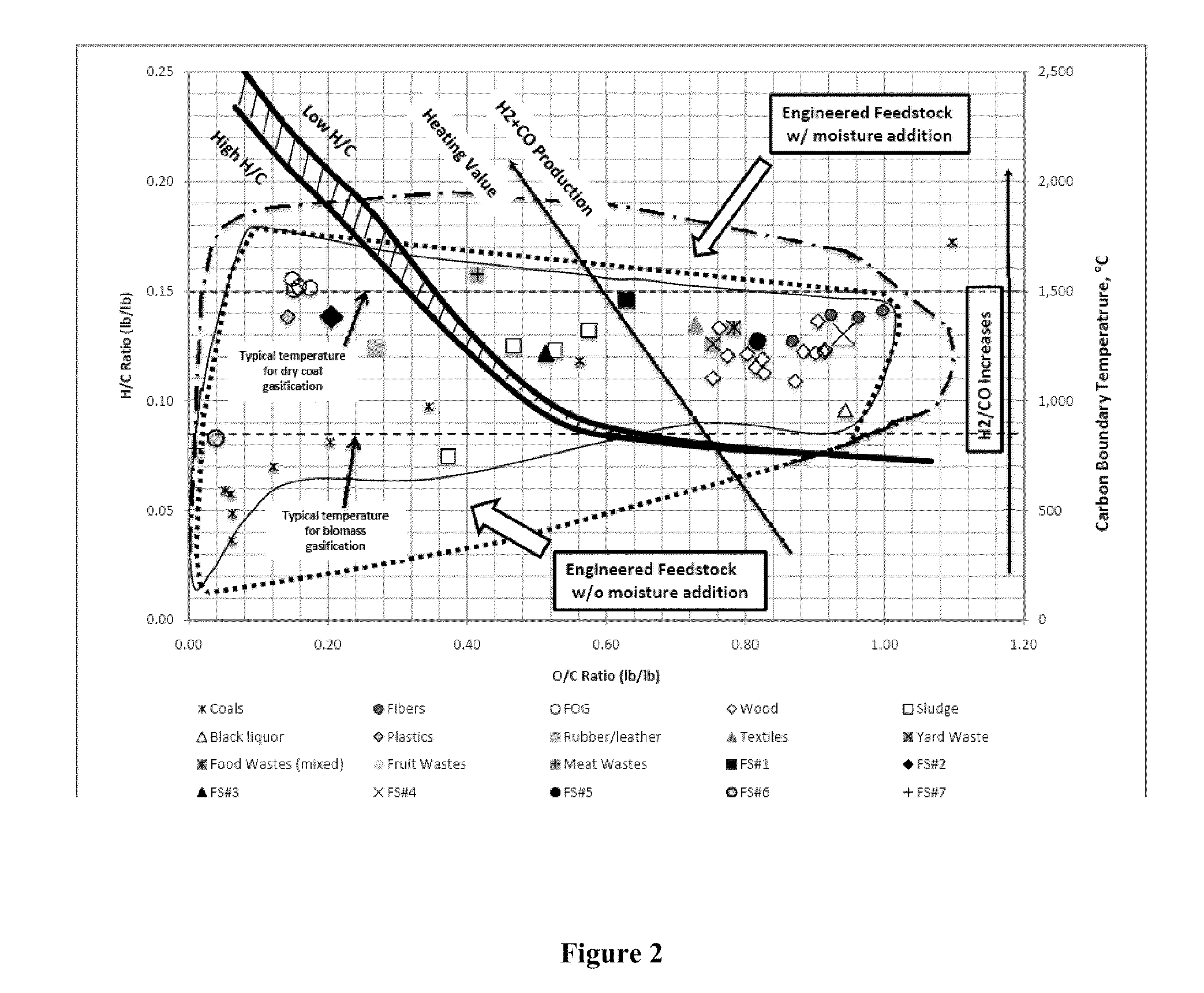

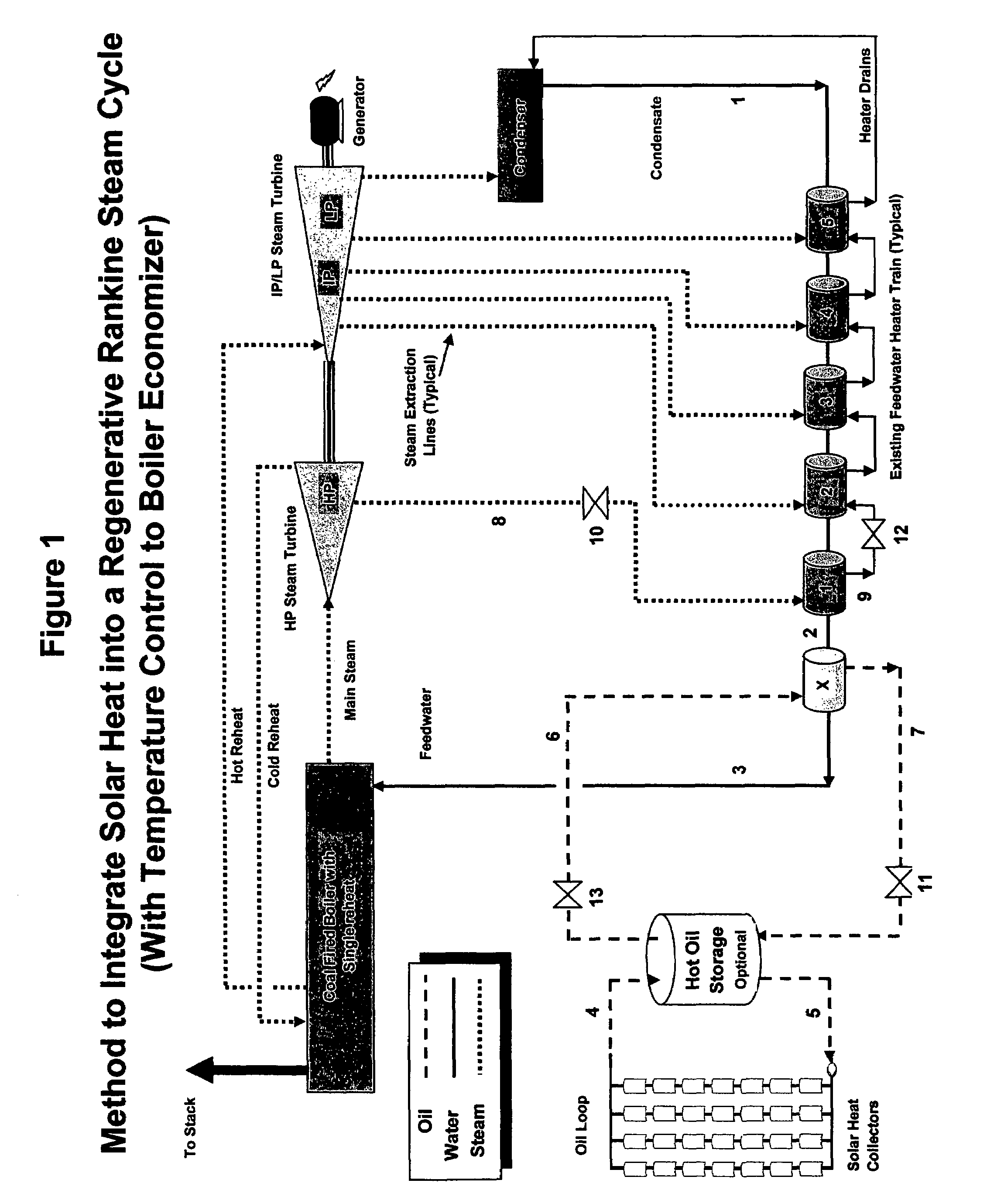

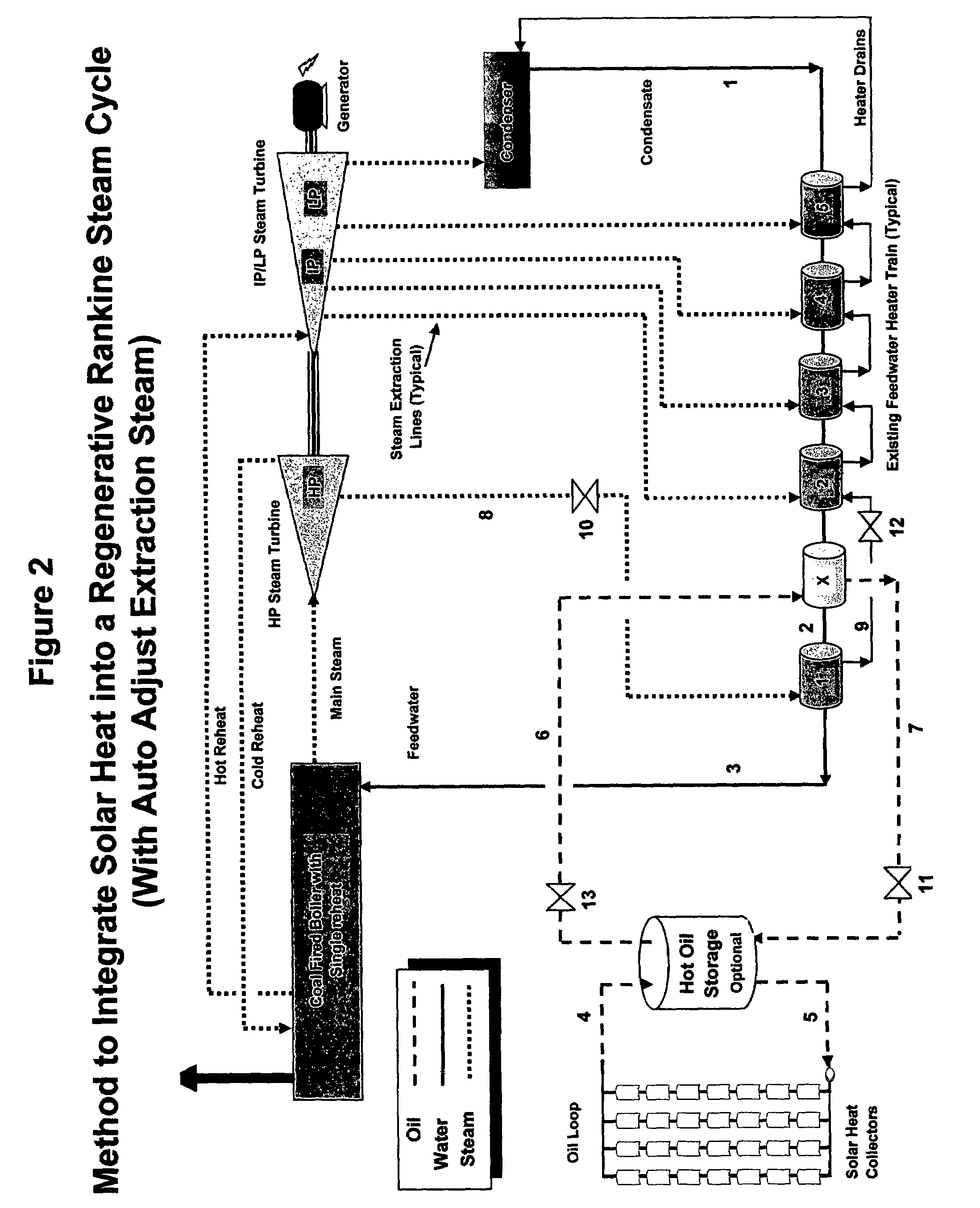

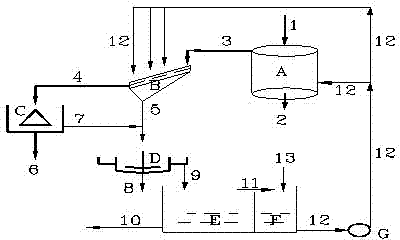

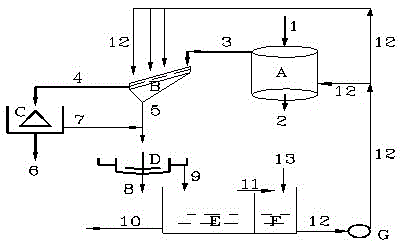

Method and system integrating solar heat into a regenerative rankine steam cycle

A method to integrate collected solar thermal energy into the feedwater system of a Rankine cycle power plant is disclosed. This novelty uses a closed loop, single phase fluid system to collect both the solar heat and to provide the heat input into the feedwater stream of a regenerative Rankine cycle. One embodiment of this method of integrating solar energy into a regenerative Rankine power plant cycle, such as a coal power plant, allows for automatic balancing of the steam extraction flows and does not change the temperature of the feedwater to the boiler. The concept, depending on the application, allows for the spare turbine capacity normally available in a coal plant to be used to produce incremental capacity and energy that is powered by solar thermal energy. By “piggybacking” on the available components and infrastructure of the host Rankine cycle power plant, considerable cost savings are achieved resulting in lower solar produced electricity costs.

Owner:MARKRON TECH

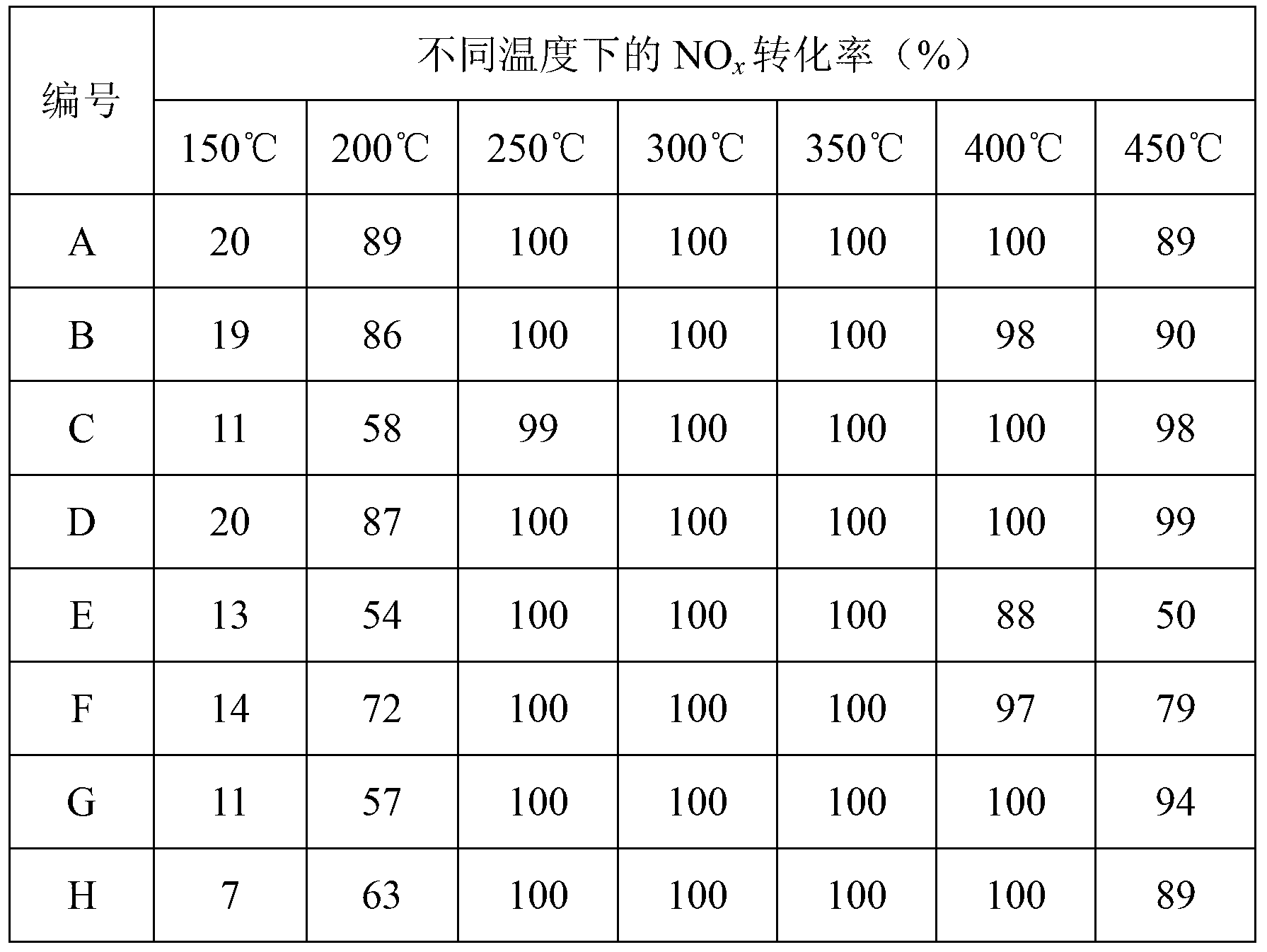

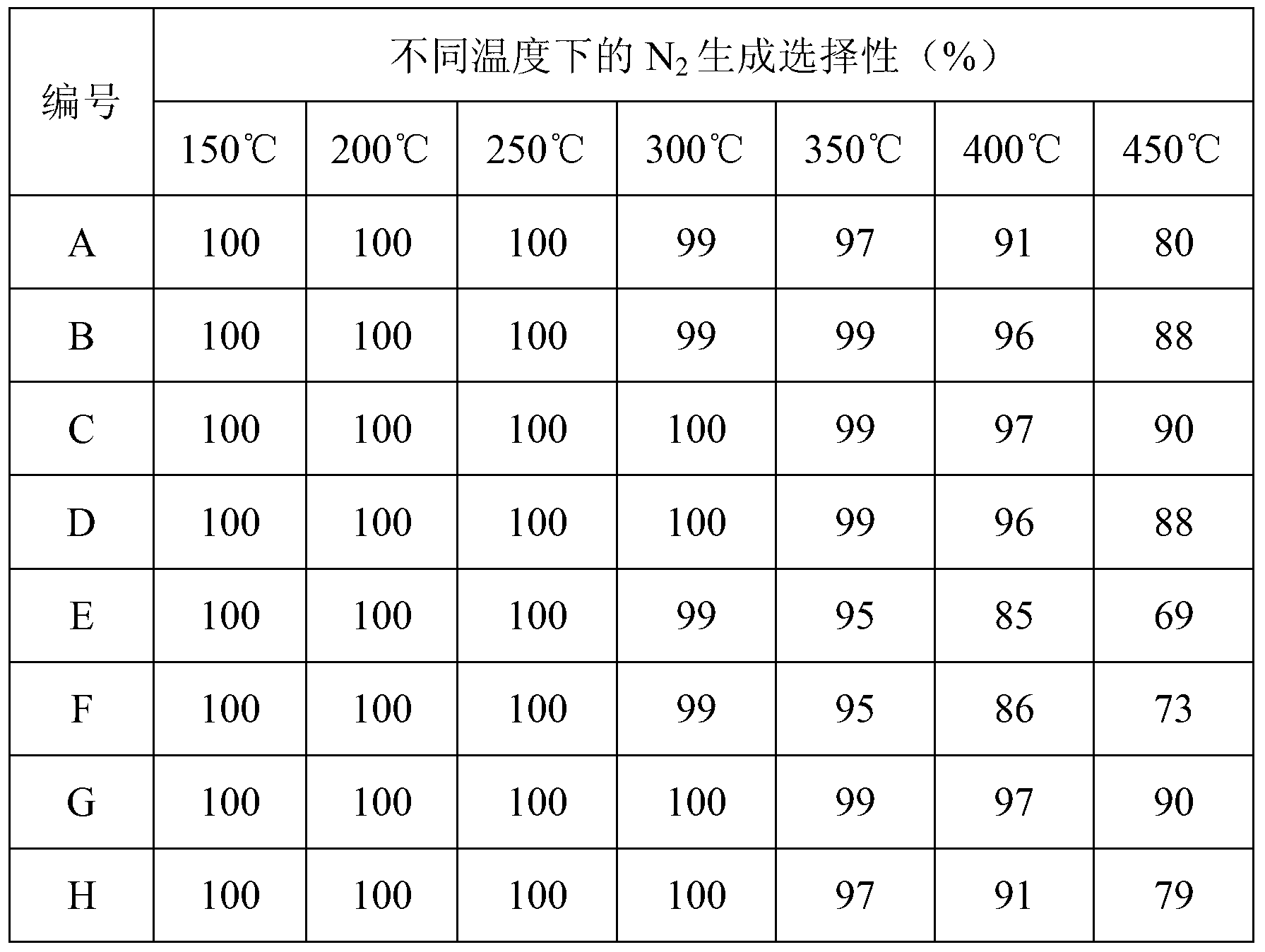

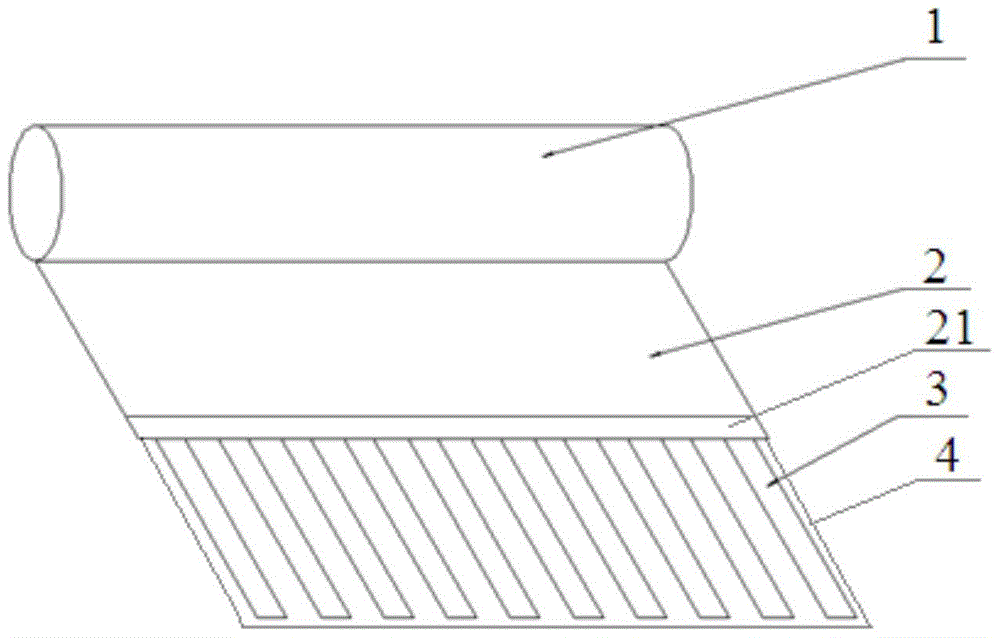

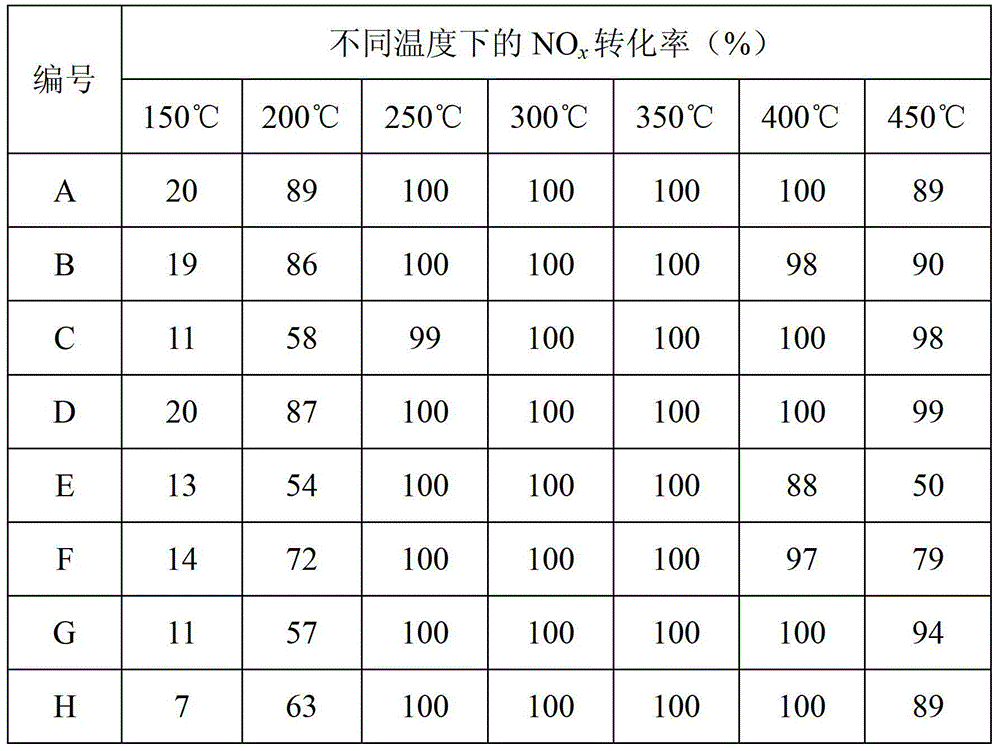

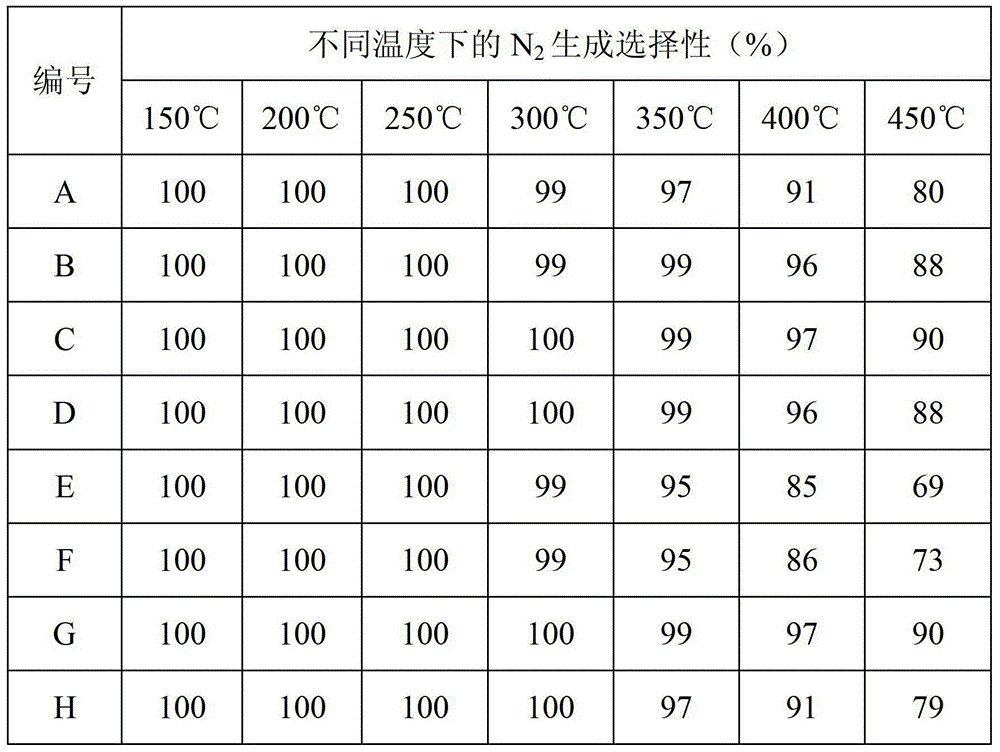

Zirconium-doped vanadium-based oxide catalyst, and preparation method and application thereof

ActiveCN103252232AWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoal plantNitrogen

The invention relates to a zirconium-doped vanadium-based oxide catalyst for selectively catalyzing and reducing the nitrogen oxide through ammonia, and a preparation method thereof. The catalyst is a metal oxide catalyst which is formed by loading zirconium and vanadium oxide onto the surface of titanium tungsten powder. Through the zirconium doping method, the catalytic properties such as high-temperature stability of the traditional vanadium-based catalyst and the N2 (nitrogen) generation selectivity can be greatly improved, the prepared zirconium-doped vanadium-based oxide catalyst is suitable for a nitrogen oxide catalytic purifying device adopting the diesel exhaust as a representative movable resource and the smoke of a coal plant as a representative fixed source.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Environmental functional material applied to electroplating wastewater treatment

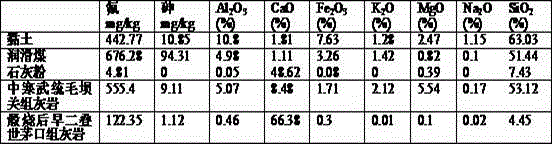

InactiveCN101648735ALarge floc particlesDense flocWater contaminantsWaste water treatment from metallurgical processSodium BentoniteTherapeutic effect

The invention discloses an environmental functional material applied to electroplating wastewater treatment; all components are as follows by mass percentage; kieselguhr, modified purified diatomite,bentonite, modified purified bentonite, attapulgite, modified purified attapulgite, kaoline and / or 20-80 percent of modified purified kaoline, 10-40 percent of humic acid and 10-40 percent of chitosan. The material has convenient usage, good treatment effect, and large and dense formed floccules, shortens settling time, and is easy to lead heavy metal ions, COD, ammonia-N, phosphorus, chromaticity and other indexes in wastewater to synchronously achieve discharge standard regulated nationally, the produced residue can recycle heavy metal, and secondary pollution is not easy to generate. Thematerial is suitable for treating wastewater in industries such as circuit boards, electro-plating, metal finishing, photographic film manufacturing, coal plants, municipal or industry waste incineration, battery production and the like.

Owner:NANJING NORMAL UNIVERSITY

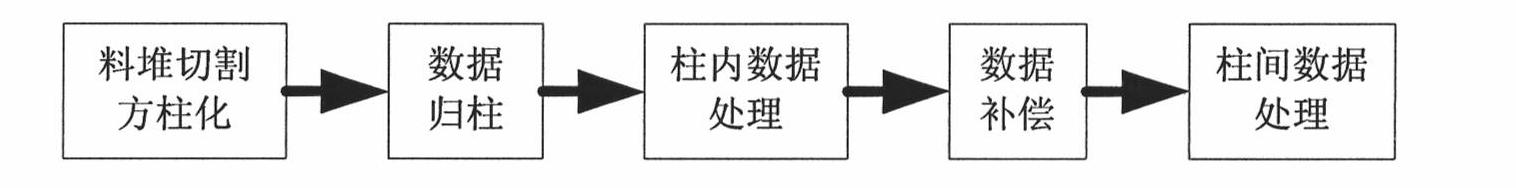

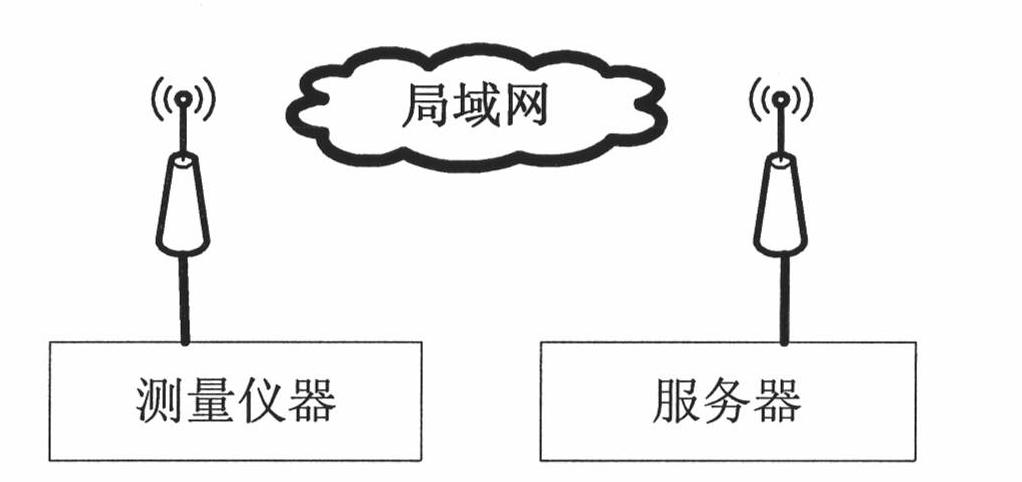

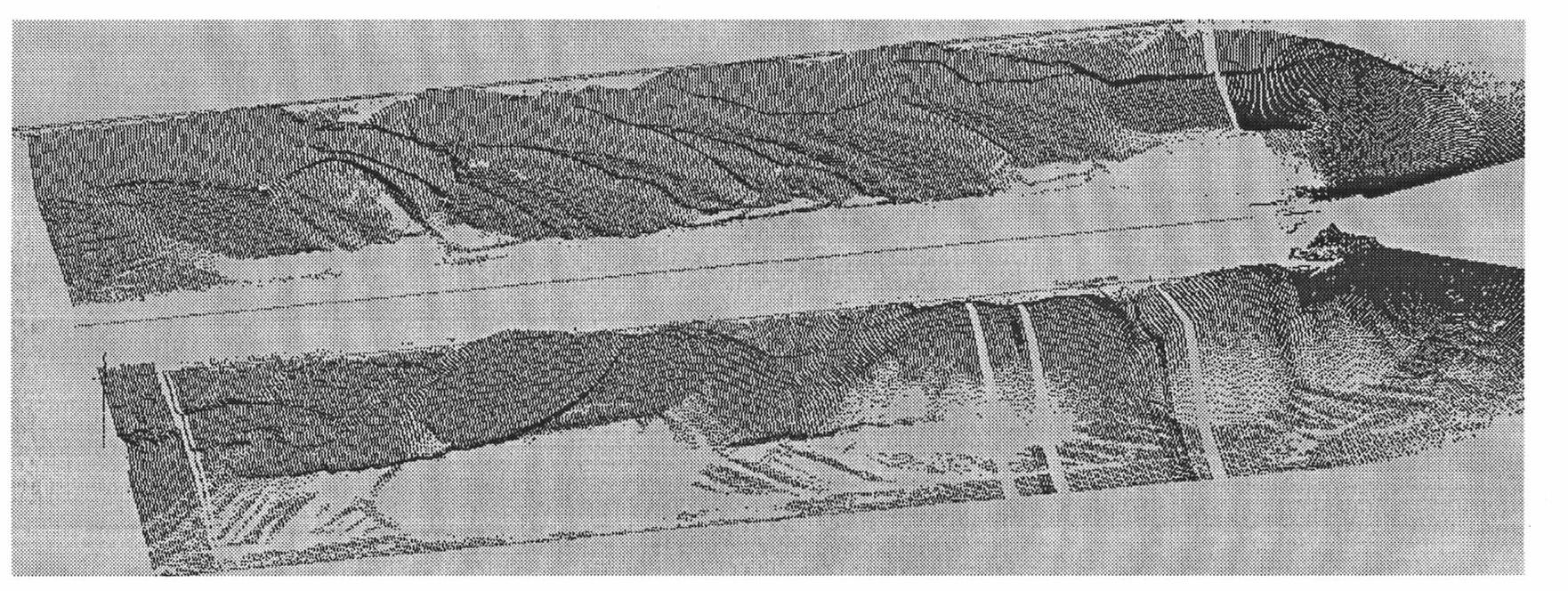

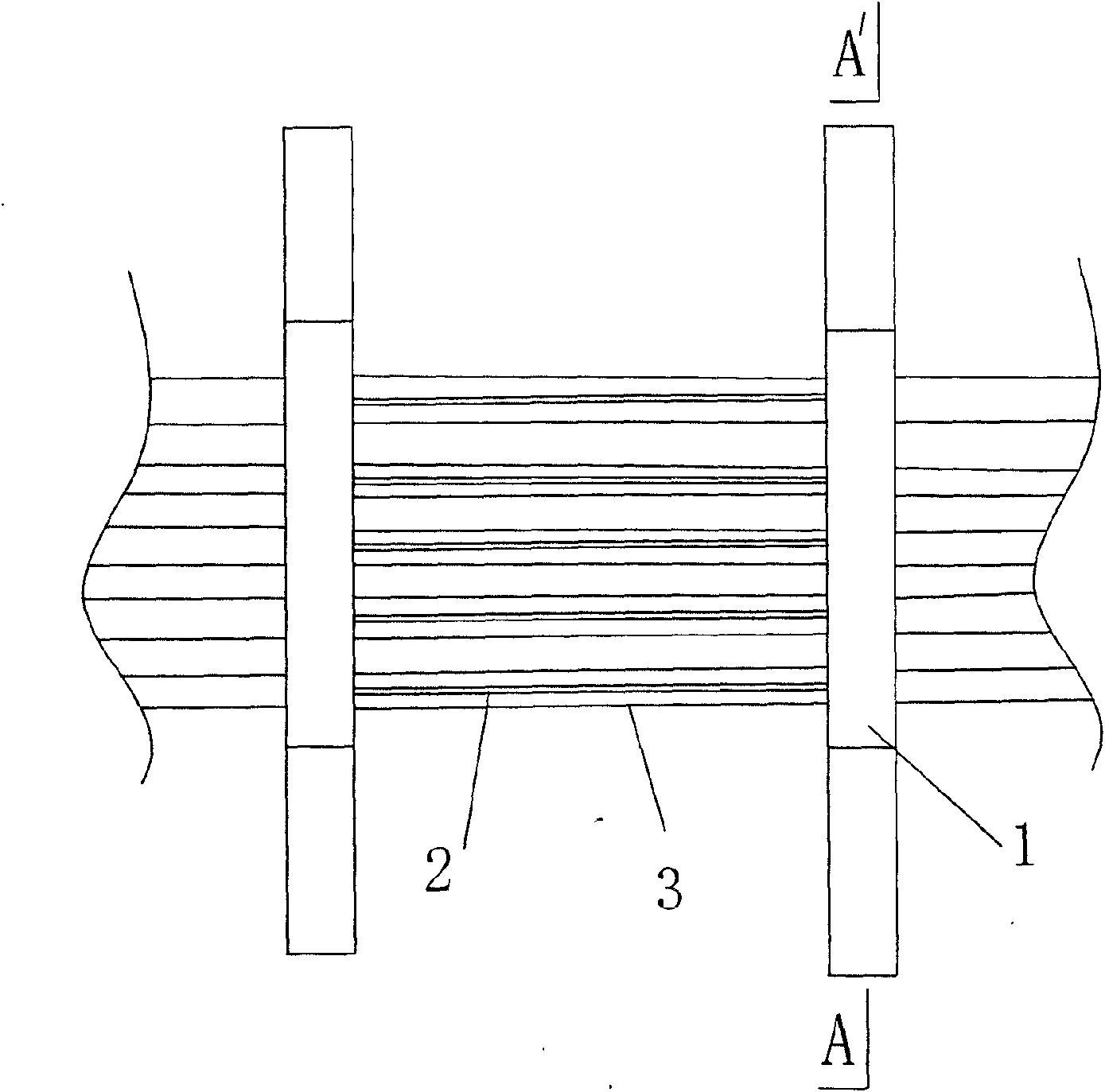

Computational method for modeling volume of material pile

The invention provides a computational method for modeling the volume of a material pile. In the method, a plurality of square columns are formed by longitudinal and transverse two-dimensional cutting of sampled data of the original profile of the material pile, column surface height data of each square column is obtain by filtering processing, the volume of each square column is computed, and the volumes of the square columns are added to obtain the total volume of the whole material pile. The method can be applied in the field of material pile volume measurement effectively, so that material pile profile sampled data obtained by the vertical scanning of the material pile by a measurement system is processed to obtain a continuous surface three-dimensional model of the material pile, and the volume of the material pile is computed at the same time. The processing process of the method comprises: cutting the material pile into square columns; distributing data into columns; processing data in columns; compensating for material pile data; processing data among columns; and the like. The three-dimensional model of the material pile can be displayed in several modes such as an original data mode, an after-modeling color mode, isohypse line color-based mode and the like. The method is applied in enterprises and public institutions such as power plants, coal plants and the like for realizing the accurate measurement and computation and visual display and management of the volume of the material pile.

Owner:CENT FOR SPACE SCI & APPLIED RES

Method for removing nitrogen oxide in sintering flue gas

InactiveCN101053749ALow costDispersed particle separationAir quality improvementNitric oxideChemistry

The invention discloses a method for desulfurizing nitric oxides in the sintering flue gas, comprising adding ammoniation to the sinter mixture and then sintering. The said ammoniation is distilled waste water or cyanogen and amino group salt of chemical plant such as carbamide, ammonium salt, ammonia and coal plant. The level of addition of said ammoniation is X=n*[(XNOx+XSO#-[2]*2) / m]. The method for desulfurizing nitric oxides in the sintering flue gas in the invention adds low-cost ammoniation to the sinter mixture, transmutes the NOx exhaust in sintering process to be N2 without harm to the environment, and also desulfurizes the SO2 producted in the sintering process at the same time. The method can desulfurize NOx at a lower cost, the desulfurizing ratio of saltpetre can reach to 66.7 percent, and the desulfurizing ratio of SO2 can reach to 80-95 percent.

Owner:武钢集团有限公司 +1

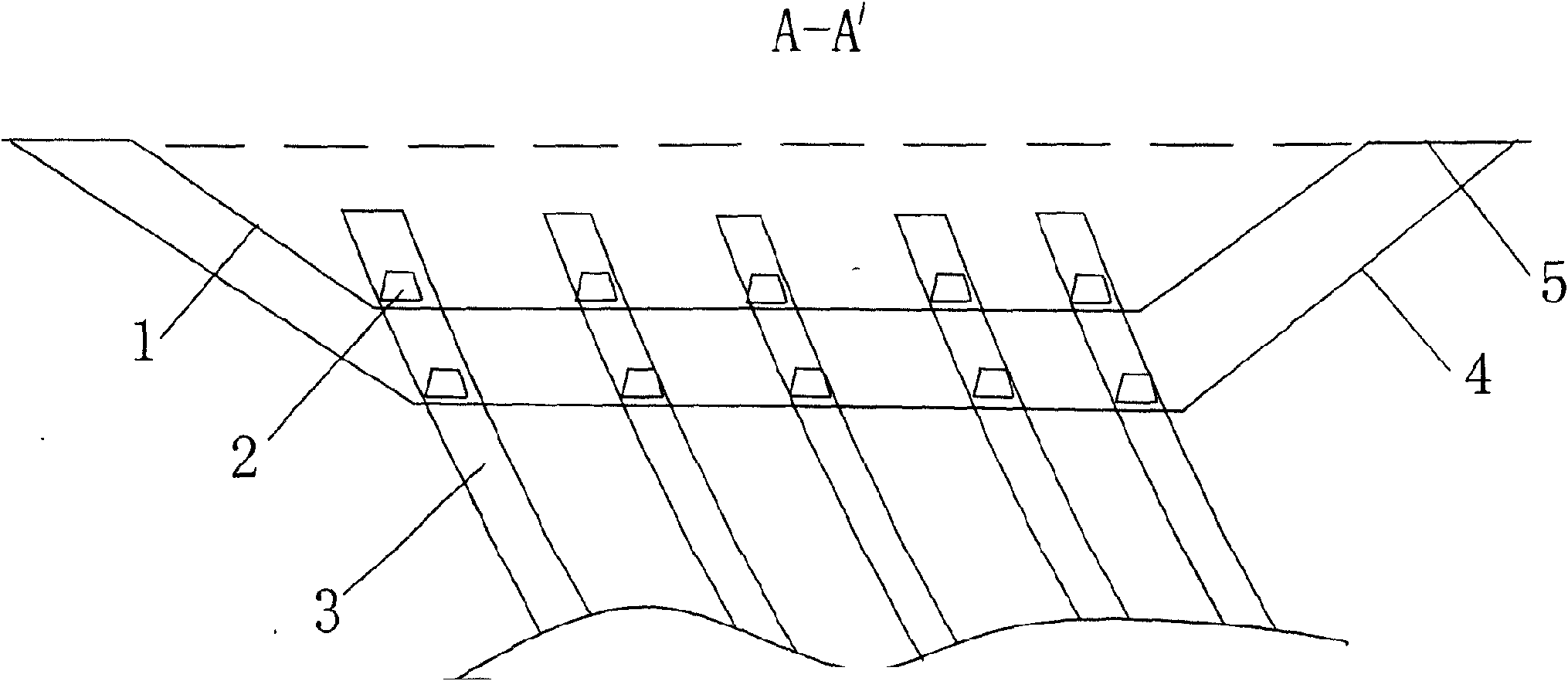

Opencast combined mining method of steeply inclined coal seam groups

InactiveCN101555796ALow costImprove resource recoveryUnderground miningSurface miningSocial benefitsOpen-pit mining

The invention provides an opencast and underground combined mining method of steeply inclined coal seam groups; the detailed implementation method comprises the following steps: opencast construction is carried out downwards in a certain angle along the inclined direction of the steeply inclined coal seam group, the construction is conducted to reach a certain distance deeper than that when the first coal seam appears, then horizontal construction is conducted until all of the steeply inclined coal seam groups are penetrated, and then the construction is continued back to the surface of the earth at a certain angle; at the location with a certain distance below the coal seam, another construction gallery is dug and penetrated through along the trend of the coal seams; transportation equipments are arranged in a laneway, the laneway is used for placing top coal or other coal mining methods are adopted, the coals mined are carried into the construction gallery by the laneway transportation equipment, and then are transported to a mine coal plant. The opencast and underground combined mining method of the steeply inclined coal seam groups solves a plurality of problems such as high mining cost and low resource recovery rate and the like in the opencast of the steeply inclined coal seam groups, simultaneously solves the problems such as low safety, high labor intensity, low efficiency and high cost and the like during the underground mining of the steeply inclined coal seam groups, causes the opencast mining to become underground mining and the underground mining to become opencast and ensures the complementation of the strengths and weaknesses, thus being a safe and highly efficient coal mining method of the steeply inclined coal seam groups and having good social benefit and economic benefit.

Owner:赵刚

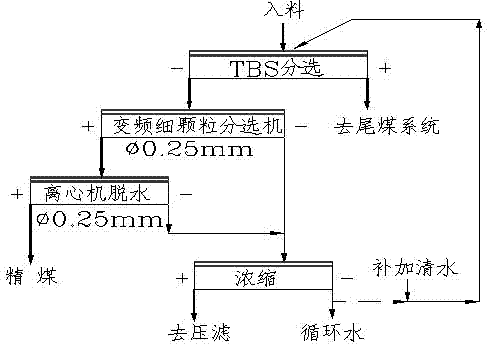

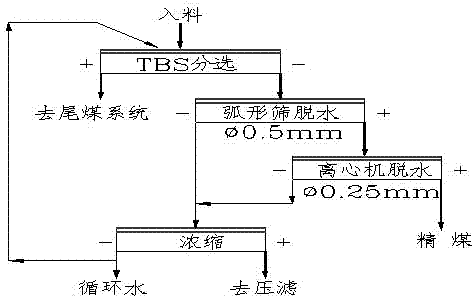

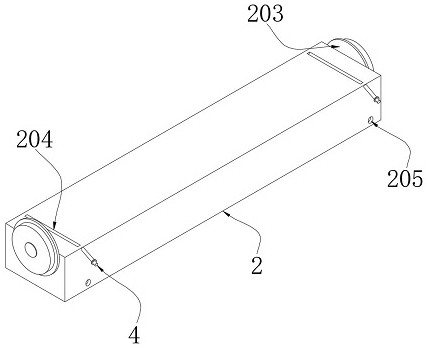

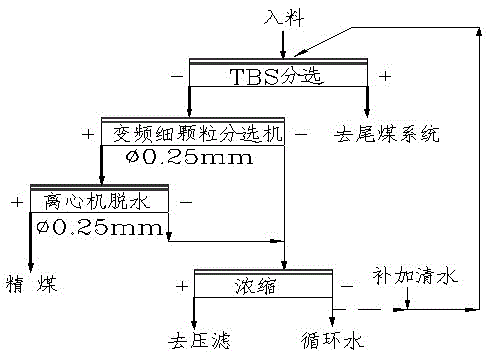

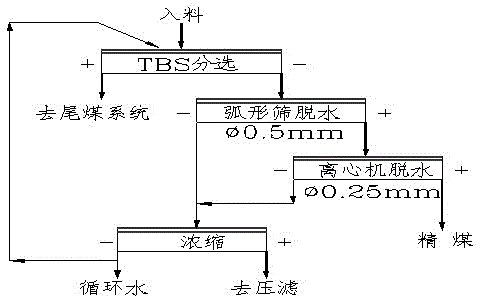

Coarse coal slime sorting equipment and technology of coarse coal slime sorting equipment

ActiveCN103495494AHigh recovery rateSolve the problem of high scoreWet separationThermodynamicsCoal plant

The invention relate to a sorting technology of coarse coal slime of a coal plant, in particular to coarse coal slime sorting equipment and a technology of the coarse coal slime sorting equipment. The coarse coal slime sorting equipment is characterized by comprising a TBS coal slime sorting machine which comprises a tank body, a feeding well, a turbulent flow plate, a density sensor, an actuator, a discharging valve and an overflow weir. Therefore, the coarse coal slime sorting equipment and the technology are reasonable in design and easy to achieve.

Owner:COAL IND JINAN DESIGN & RES

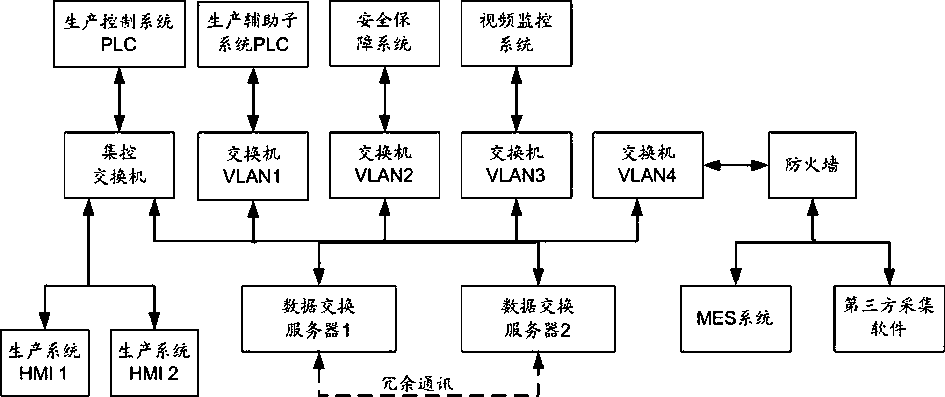

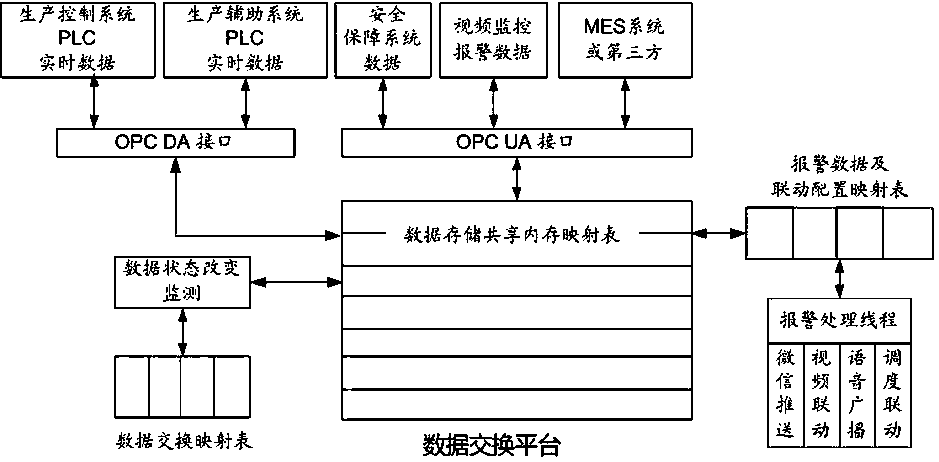

Intelligent coal preparation plant whole-network communication information system and data collecting and exchange method thereof

InactiveCN108572634ARealize data collectionReal-time data exchangeTotal factory controlProgramme total factory controlInformatizationVideo monitoring

The invention relates to an intelligent coal preparation plant whole-network communication information system, which comprises a whole plant production control system, a production assisting sub system, a safety guarantee system, a video monitoring system, a safety guarantee system, an upper-layer information management system and a data exchange platform, wherein the whole plant production control system, the production assisting sub system, the safety guarantee system, a video monitoring system, the safety guarantee system and the upper-layer information management system are connected to the data exchange platform through an Ethernet network; the data collection, storage and exchange of each system are completed on the data exchange platform; data with unified formats and specificationsis provided for the upper-layer information system. The intelligent coal preparation plant whole-network communication information system has the beneficial effects that various kinds of production and safety guarantee informatization system data in the coal preparation plant range can be stored and managed in a unified way; a solution of basic data collection is provided for coal plant MES system development and intelligentized building.

Owner:PINGDINGSHAN ZHONGXUAN AUTOMATIC CONTROL SYST

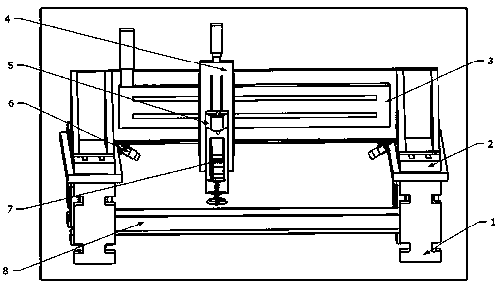

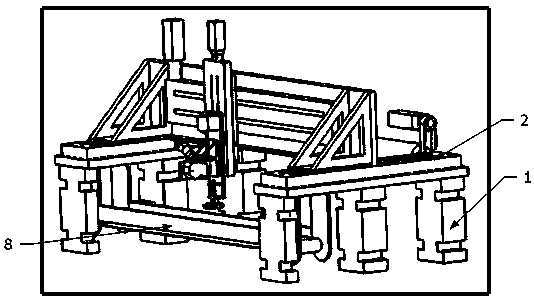

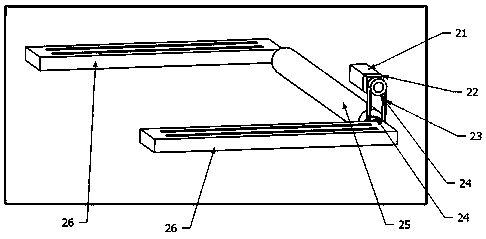

Automatic recognition and pickup mechanism for gangue on coal mine coarse and fine coal conveying belt

The invention relates to an automatic recognition and pickup mechanism for gangue on a coal mine coarse and fine coal conveying belt. The automatic recognition and pickup mechanism comprises an installing frame, an XYZ three-axis moving assembly, a tail end sucking assembly, a vision recognizing and distance measuring device and an impurity conveying assembly. Multiple sensors are utilized in thedevice for automatically recognizing the gangue on the conveying belt and measuring the position of the gangue; and a three-axis motion mechanism forming a cartesian coordinate system is utilized forsucking the gangue out. When the gangue and the center position of the gangue are obtained through the vision sensor, a three-axis motion system tracks the position through the interpolation motion, the distance sensor is used for measuring the height between the gangue and a suction cup, the suction cup rapidly sucks the gangue along with the movement in the Z direction, and then the gangue is placed on an impurity conveying belt to be conveyed into a gangue material barrel. The automatic recognition and pickup mechanism is simple in structure, high in recognition and motion precision, high in recognition and motion speed and suitable for picking up the gangue impurities on the coal plant coarse and fine coal conveying belt, the high-strength and high-danger labor work can be liberated, the production efficiency and the coal discharging quality are improved, and very large popularization space is achieved.

Owner:山西品东智能控制有限公司

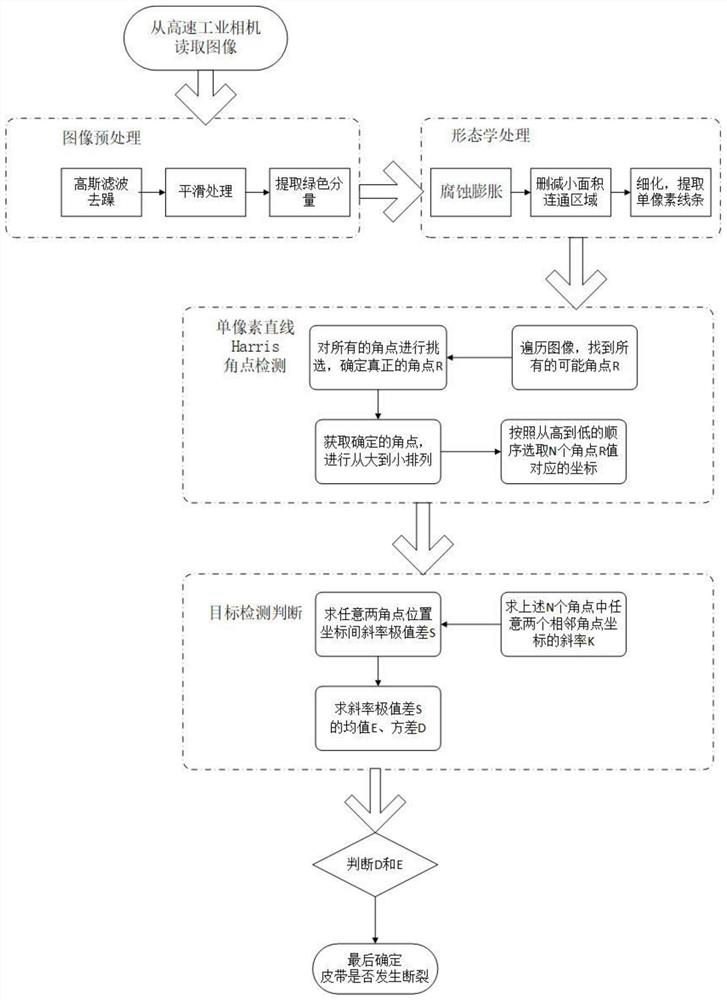

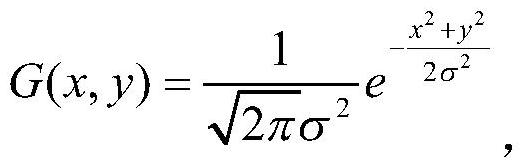

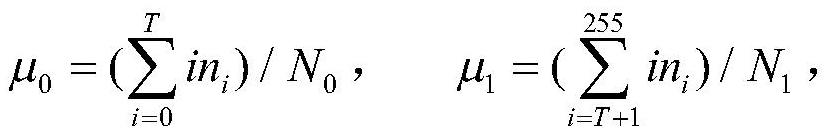

Intelligent detection method for conveyor belt damage conditions

ActiveCN111754466AEasy to implementThe detection result is highly accurateImage enhancementImage analysisCoal plantEngineering

The invention discloses an intelligent detection method for the damage condition of a belt of a conveyor, and mainly solves the problems that in the prior art, the tearing damage condition in the operation process of the belt conveyor cannot be detected in real time, and the false detection rate is high. The implementation scheme is as follows: 1) collecting an image of a to-be-detected belt; 2) sequentially carrying out cutting, denoising, normalization, expansion corrosion, convolution operation and smoothing processing on the image of the to-be-detected belt to obtain a new matrix M1; 3) calculating an angular point response function corresponding to each pixel by the new matrix M1, performing non-maximum suppression arrangement on the angular point response function, and solving a slope extreme value difference S; and 4) comparing the slope extreme value difference S with a given discrimination threshold k, if S is greater than k, the belt being torn, and if S is less than k, the belt being not torn. The method is high in detection speed and low in false detection rate, can detect the damage condition of the belt in real time, and can be used for detecting the damage conditionof the belt in the mechanical transmission process in mining industry, metallurgy and coal plants.

Owner:XIDIAN UNIV

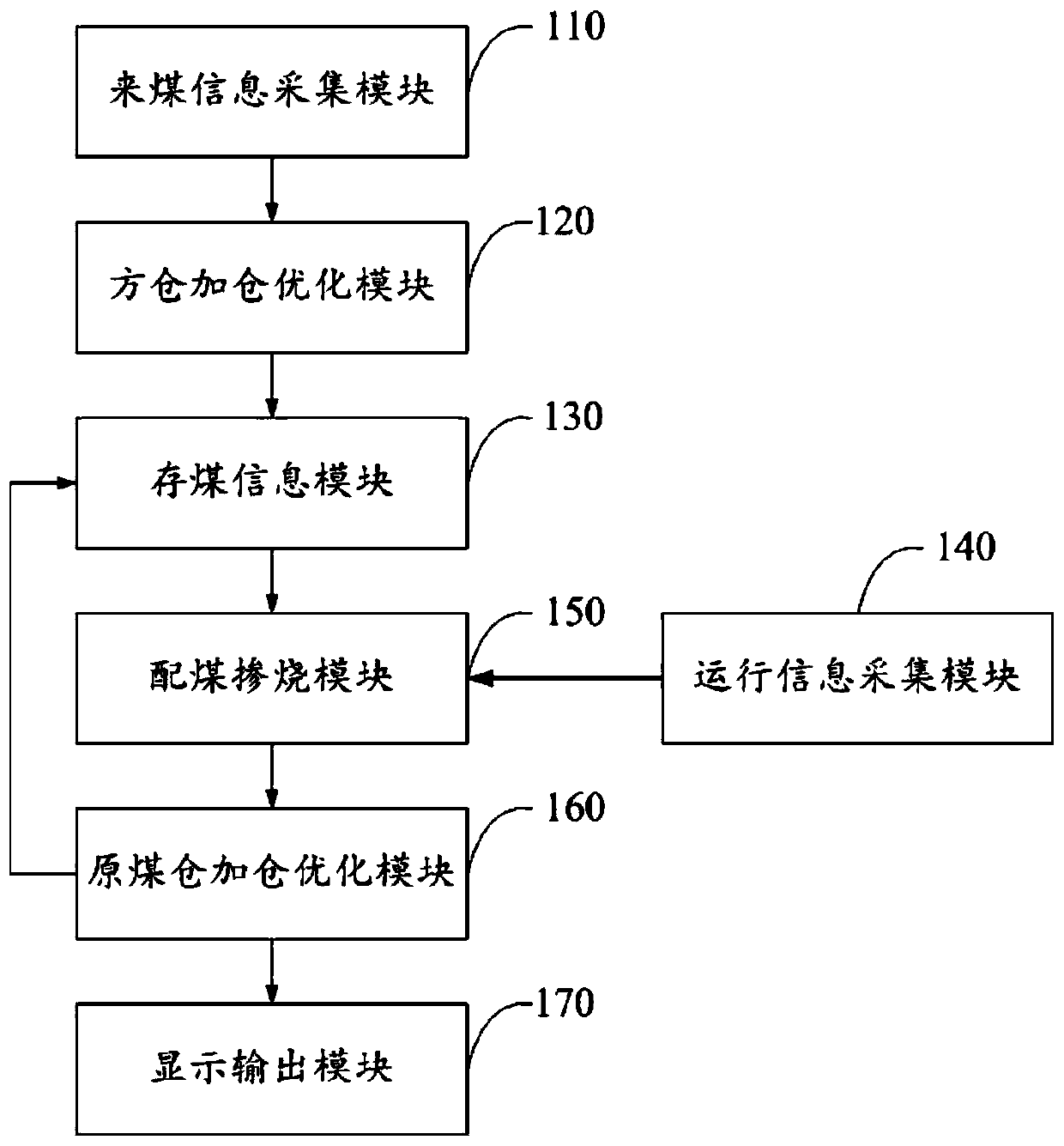

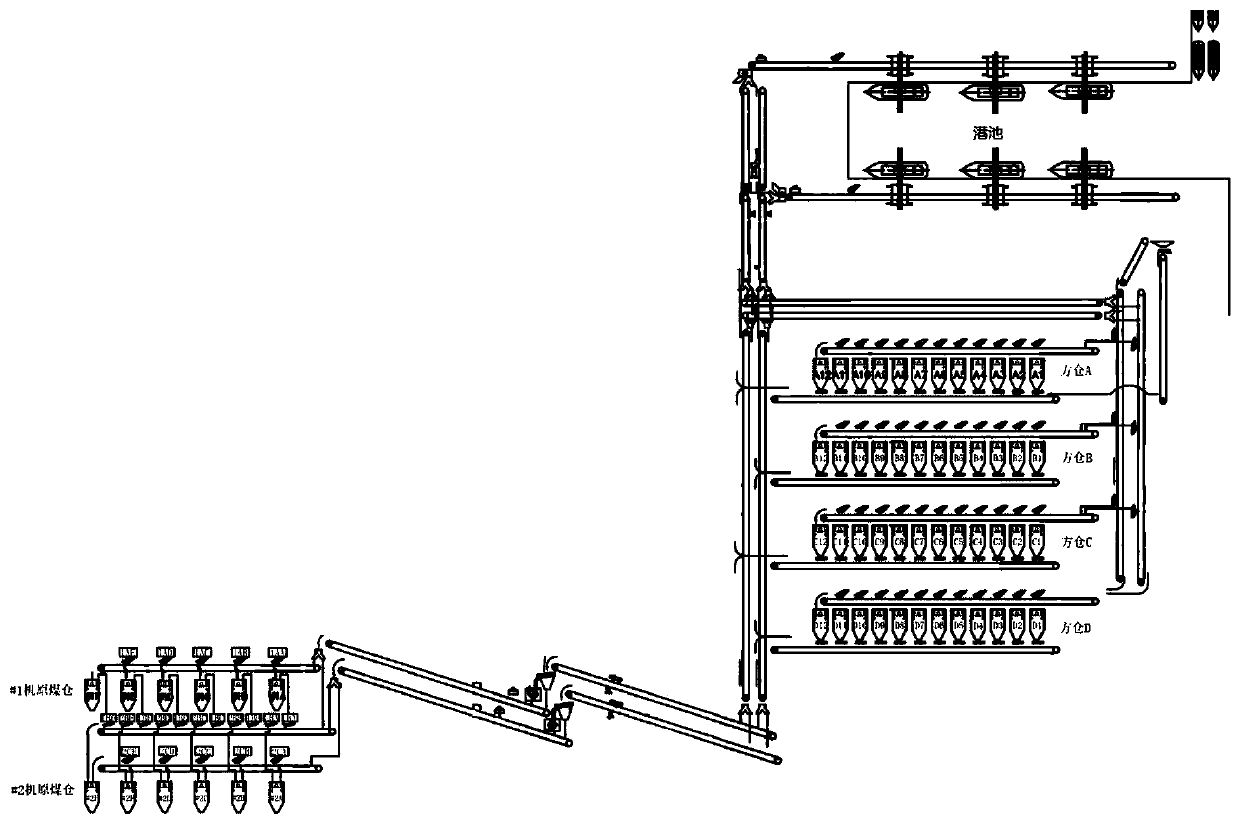

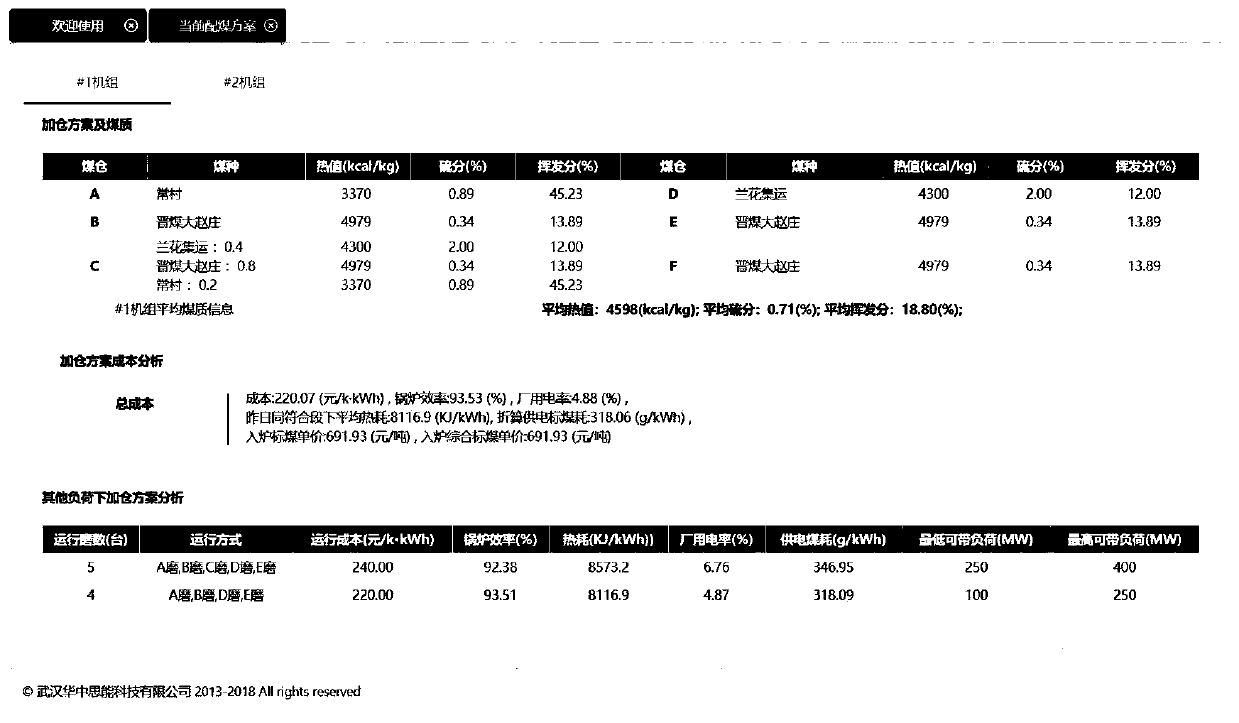

Coal dispatching system and method for cluster type coal plant

InactiveCN111506028ARealize reasonable schedulingImprove coal efficiencyTotal factory controlProgramme total factory controlCoal plantBunker

The invention provides a coal dispatching system and method for a cluster type coal plant. The system comprises an incoming coal information collection module which is used for collecting the incomingcoal information of the coal plant, a bunker adding optimization module which is used for generating a bunker adding strategy, a coal storage information module which is used for acquiring and counting the coal storage information of each bunker of the coal plant, an operation information acquisition module which is used for acquiring the operation information of a coal generator set, a coal blending combustion module which is used for generating a coal blending combustion strategy according to the unit operation information and the coal storage information, a raw coal bunker adding optimization module which is used for generating a final raw coal bunker adding strategy based on the coal blending combustion strategy and updating the coal storage information of each bunker, and a display output module which is used for displaying the coal storage information of each bunker, the bunker adding strategy information and the coal blending combustion strategy information. According to the technical schemes, the problems of low unit coal efficiency and high power supply coal consumption existing in existing coal dispatching of the cluster honeycomb type coal plant are solved, the coal efficiency of the generator set can be improved, the power supply coal consumption is reduced, and economic benefits are guaranteed.

Owner:HUANENG POWER INT INC +1

Briquette coal for reducing fluorine and arsenic pollution in stone coal combustion region

InactiveCN107177390AMaterials are readily availableLow priceSolid fuelsFuel additivesArsenic pollutionQuestionnaire analysis

The invention relates to briquette coal for reducing fluorine and arsenic pollution in a stone coal combustion region, and provides a manufacturing method of fluorine fixation and arsenic fixation briquette coal applicable to the stone coal combustion region. The briquette coal is prepared from the following ingredients: 1, charred amomum (or anthracite); 2, ordinary blocky stone coal; 3, fluorine fixation and arsenic fixation additives; 4, clay, wherein the additives are lime powder and powdery slimy stone coal. Through in-field evidence and scientific experiment, the condition that the indoor air pollution in the southern part of Shanxi is the real source of fluorine poisoning and arsenic poisoning is deducted. Through household survey and questionnaire analysis, the briquette coal proportion capable of meeting the people's living needs and reducing the coal consumption pollution is found. For the optimal proportion scheme, the fluorine and arsenic release factor is averagely and respectively reduced by 45 percent and 72 percent; the concentration of fluorine, sulfur dioxide and ammonia gas in the air is respectively reduced by 34.1 percent, 96.47 percent and 92.51 percent. The briquette coal is directly and successfully manufactured in a briquette coal plant; the materials are easily obtained; the cost is low; the briquette coal is easy to popularize. The briquette coal has good experiment effects in farmer homes and can be widely applied to residential stoves in the stone coal combustion region.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

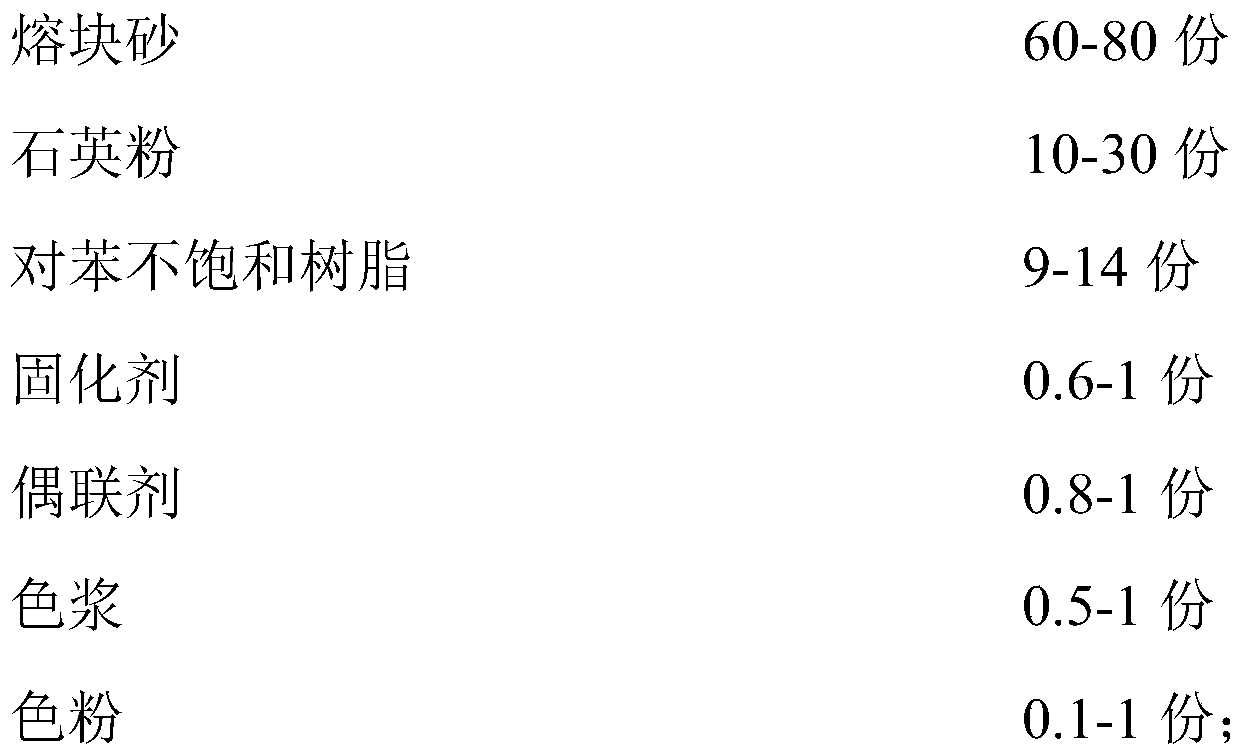

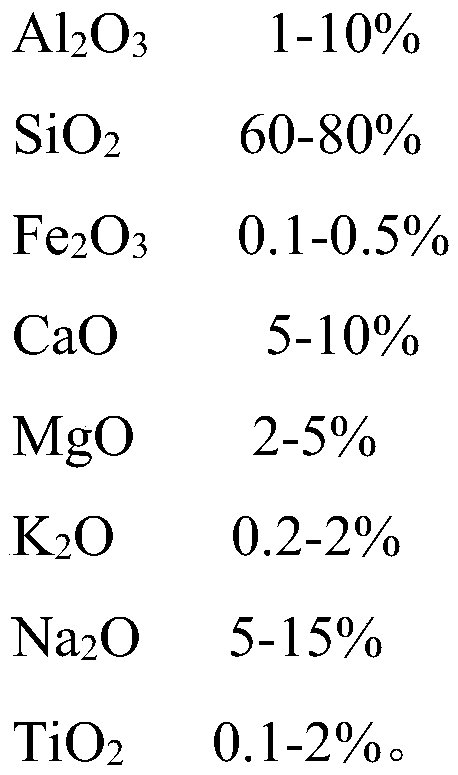

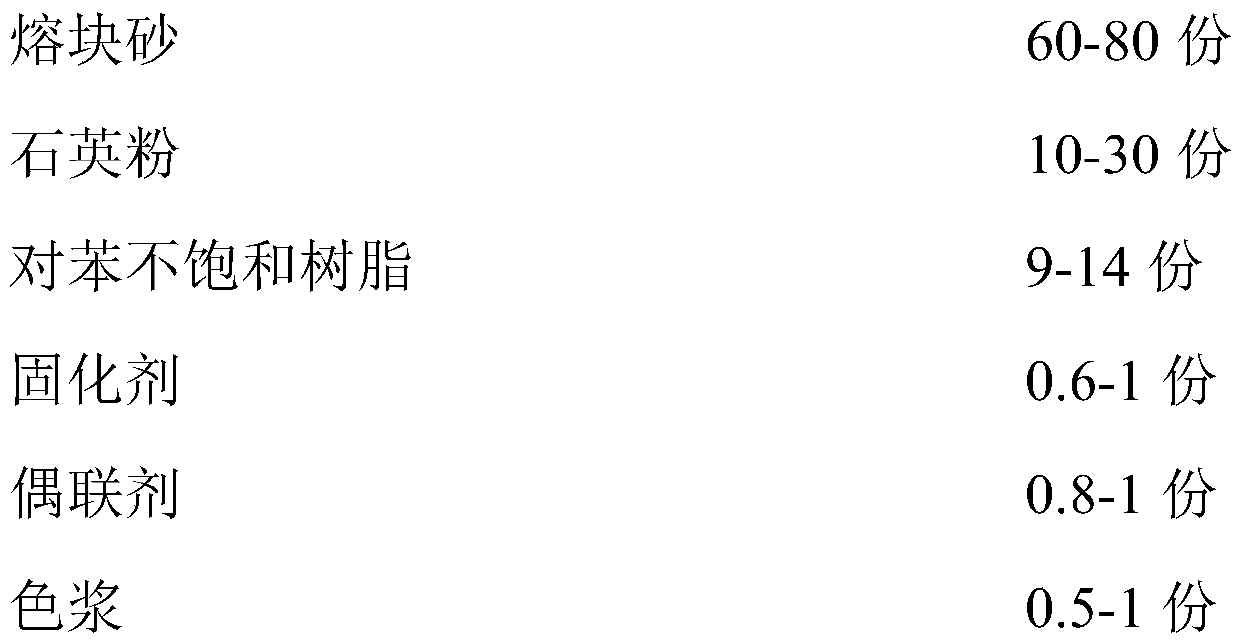

Environment-friendly, low-cost and high-strength artificial stone and method for preparing same

InactiveCN109734356ALess impuritiesUniform particle sizeGlass shaping apparatusIron plantInternational market

The invention relates to environment-friendly, low-cost and high-strength artificial stone and a method for preparing the same. The environment-friendly, low-cost and high-strength artificial stone comprises, by weight, 60-80 parts of fritted sand, 10-30 parts of quartz powder, 9-14 parts of terephthalic unsaturated resin, 0.6-1 part of curing agents, 0.8-1 part of coupling agents, 0.5-1 part of color paste and 0.1-1 part of toner. The environment-friendly, low-cost and high-strength artificial stone and the method have the advantages that mine solid waste materials or discarded materials canbe used as production raw materials, blast furnace gas and coke oven gas which are recycled and purified in steel and iron plants and coking coal plants in production procedures can be used as fuel inproduction procedures, accordingly, the production procedures are green and environmentally friendly, and waste can be recycled; the environment-friendly, low-cost and high-strength artificial stoneis high in strength, has natural streaks, is attractive, elegant, green and environmentally friendly and can be accepted by domestic and foreign clients, and accordingly the environment-friendly, low-cost and high-strength artificial stone and the method have broad prospects on domestic and international markets.

Owner:FOSHAN MONICA QUARTZ STONE CO LTD

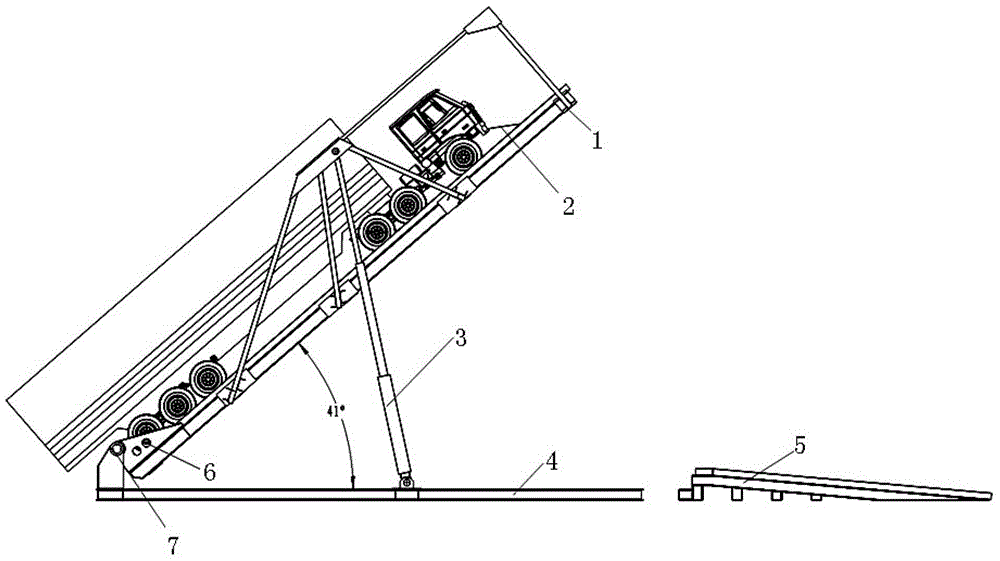

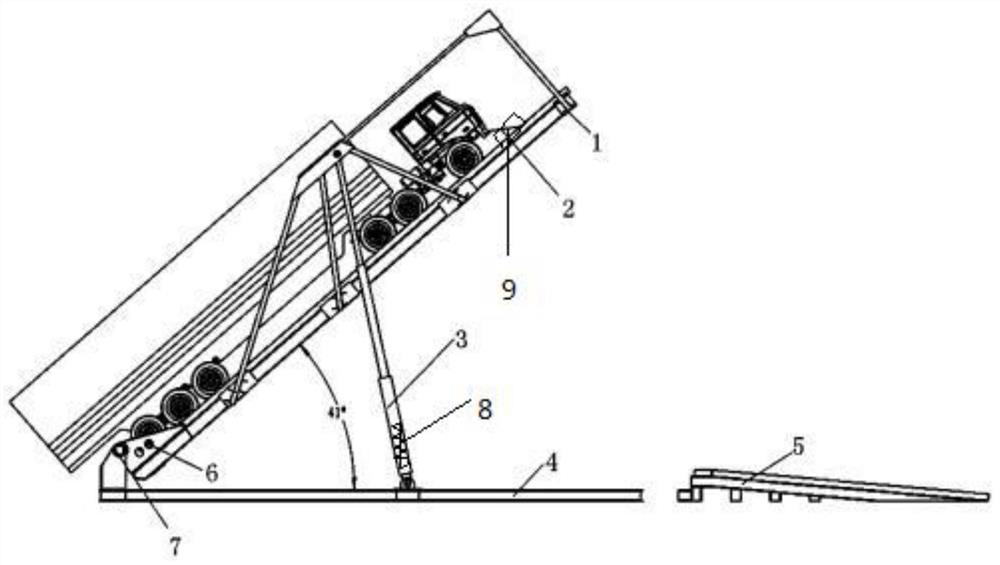

Flipping platform for entire vehicle unloading

InactiveCN103332638AReach the unloading functionLifting devicesHoisting equipmentsHydraulic cylinderCoal plant

The invention discloses a flipping platform for entire vehicle unloading. The flipping platform comprises a fixed rack device, wherein a moving rack device is arranged at the upper part of the fixed rack device, the moving rack device is hinged to the rear end of the fixed rack device, and a jacking hydraulic cylinder is arranged between the moving rack device and the fixed rack device. An entire vehicle limiting device is arranged at the rear part of the upper surface of the moving rack device, a protective steel wire rope is arranged at the front part of the upper surface of the moving rack device, a guide slope is arranged at the front part of the fixed rack device, and an included angle between the moving rack device and the fixed rack device is not smaller than 40 degrees when the moving rack device is lifted to the highest position. According to the lifting platform, an entire vehicle can be driven on the lifting platform and be automatically flipped, so as to reach the function of unloading; and the lifting platform is applicable to potato transportation unloading, coal plant transportation unloading, ore transportation unloading, sand and stone transportation unloading and the like and is particularly applicable to large-sized transport vehicles with the tonnage of over 80.

Owner:北京铁五院工程机械有限公司 +1

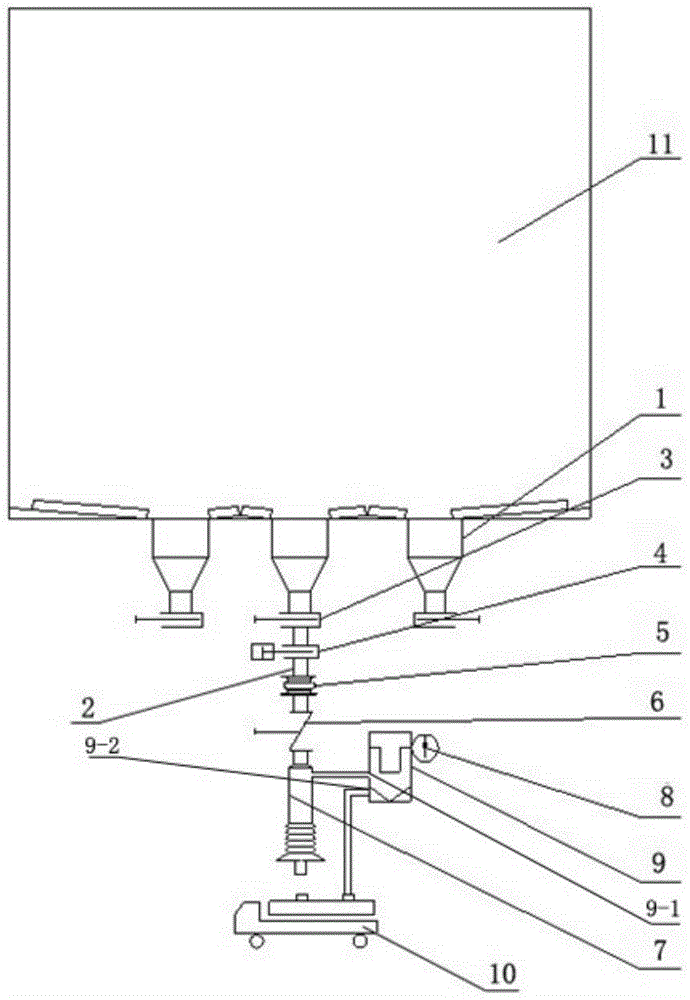

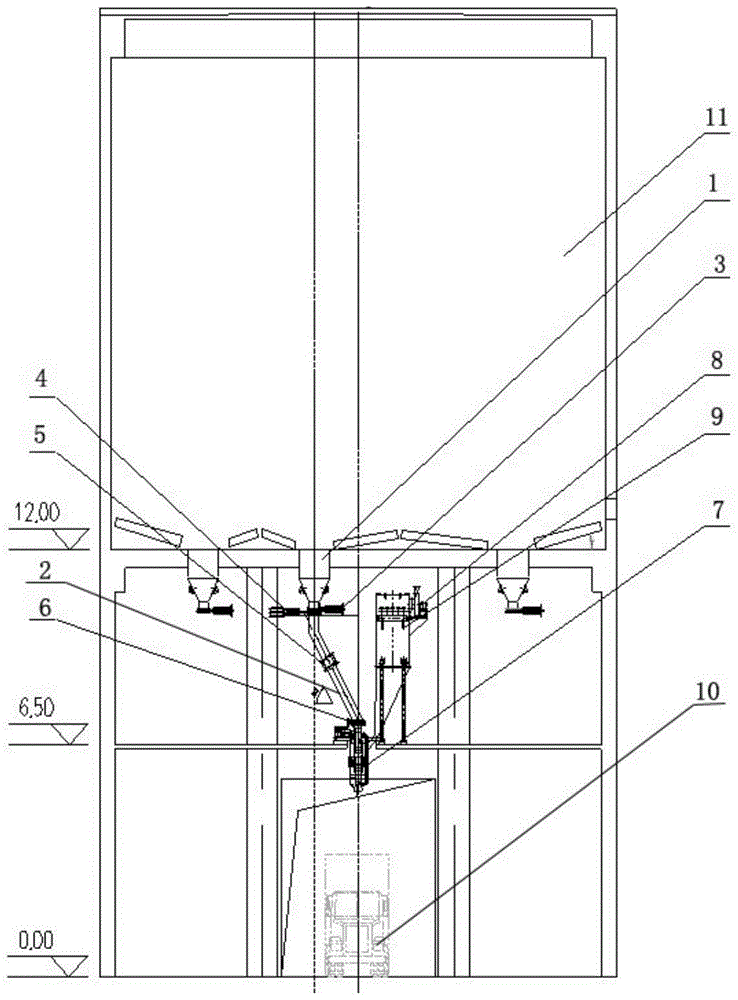

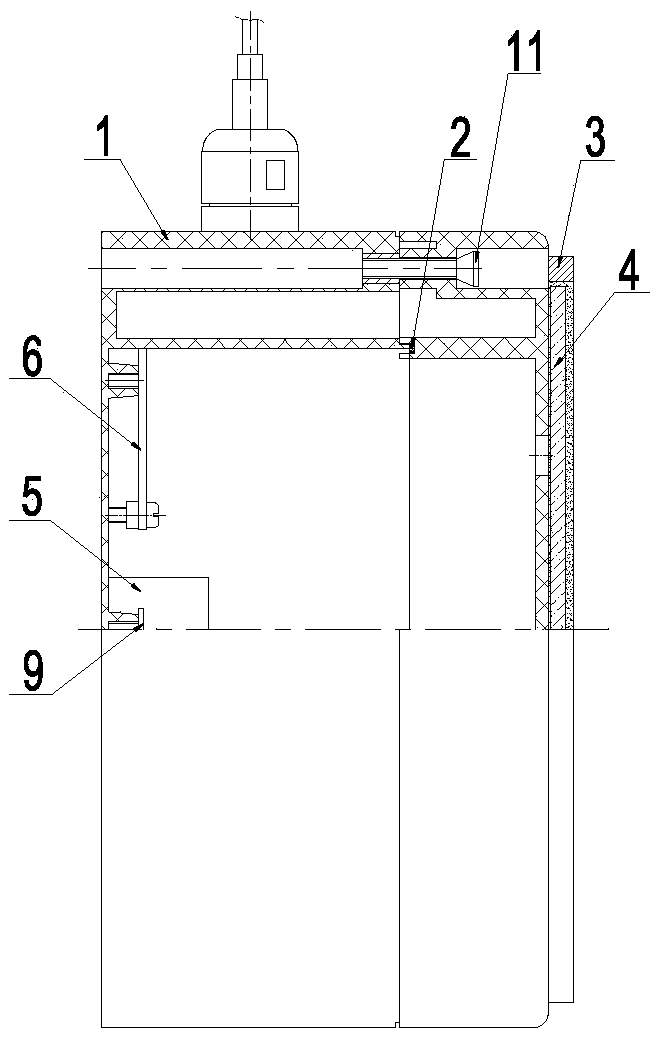

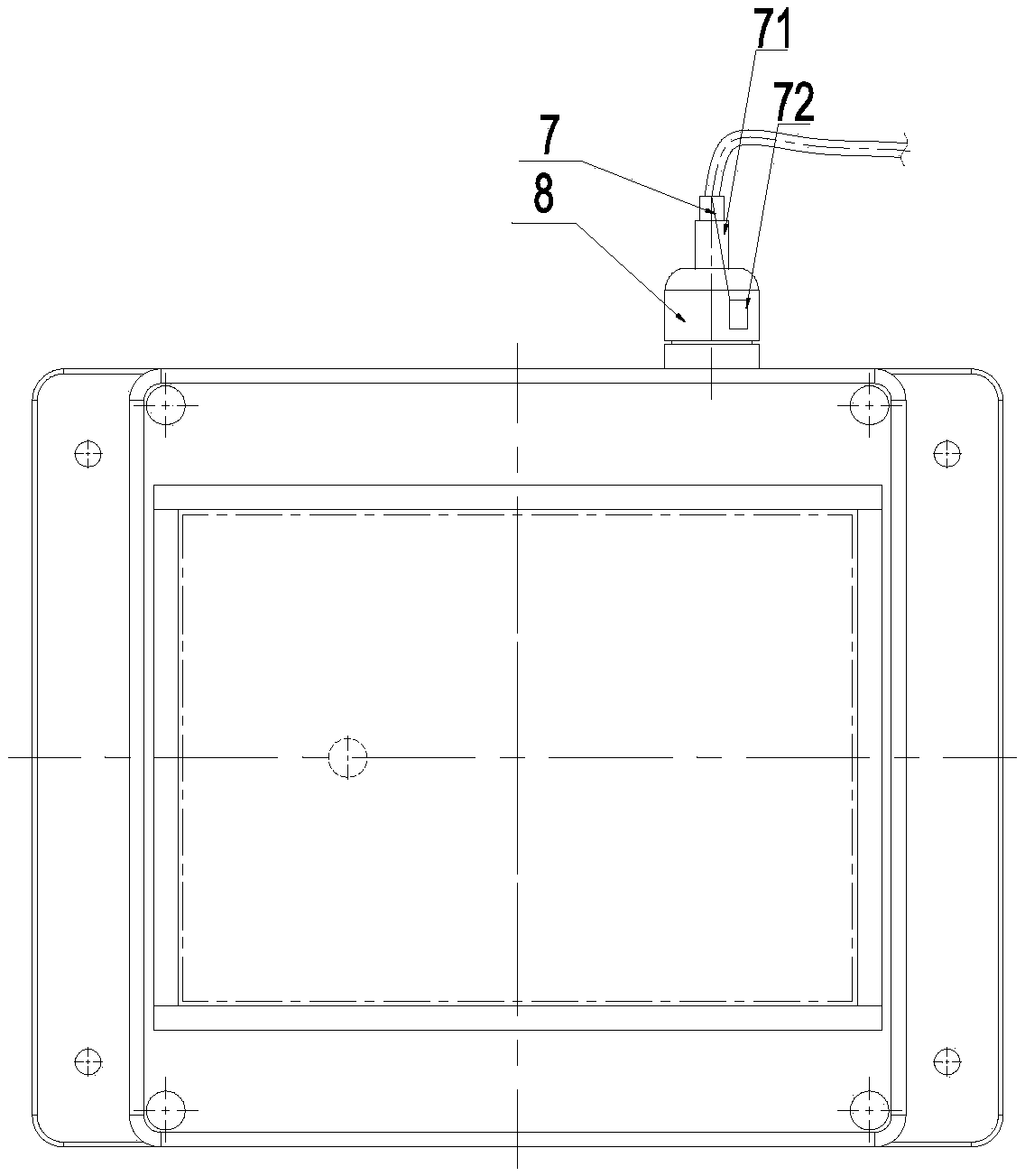

A dry ash loading device for coal-fired power plants

ActiveCN103466349BReduce flyingAvoid direct contactLarge containersLoading/unloadingBottom ashCoal plant

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

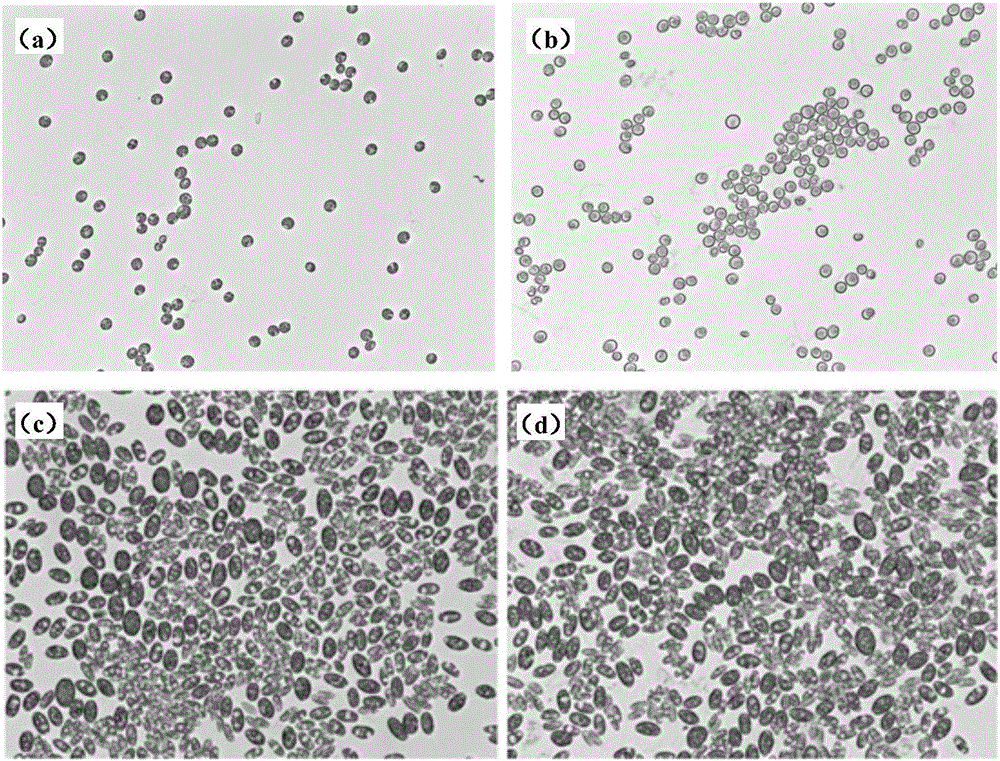

Method for flocculating microalgae by using flue gas and application thereof

InactiveCN106047712ACost-freeEliminate mutual repulsionUnicellular algaeMicroorganism based processesNutrient solutionHydrogen ion

The invention discloses a method for flocculating microalgae by using flue gas and application thereof, belonging to the technical field of biomass energy. The method comprises the following concrete steps: introducing flue gas containing sulfur dioxide into a nutrient solution where microalgae are cultured until microalga agglomeration algae is generated; carrying out standing; and removing supernatant so as to obtain flocculated microalgae; wherein the microalgae refer to fresh-water microalgae. According to the invention, flue gas from a coal-fired plant is continuously introduced into the microalga nutrient solution and sulfur dioxide hydrate in the flue gas interacts with extracellular polysaccharide organic matters secreted by the surfaces of microalgae, so the negatively-charged extracellular polysaccharide organic matters bond with the sulfur dioxide hydrate and free hydrogen ions produced thereof, surface expulsive force among cells is eliminated, and the balance state of microalgae in the nutrient solution is broken; thus, agglomeration and settlement of microalga cells are realized, and harvesting efficiency reaches 90% or above. The method is simple to operate and high in separation efficiency, has almost no cost and can be applied to separation of microalgae.

Owner:JINAN UNIVERSITY

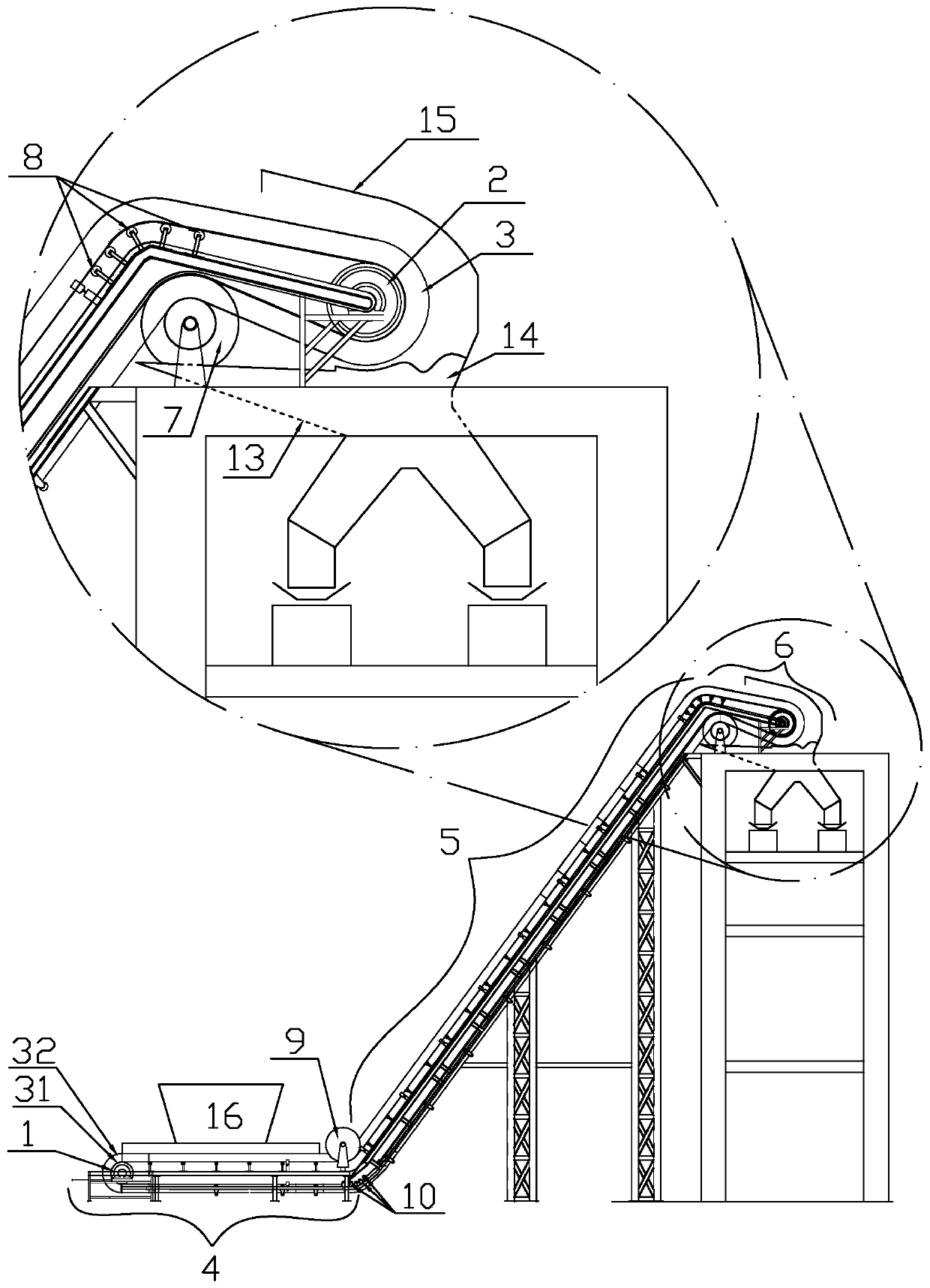

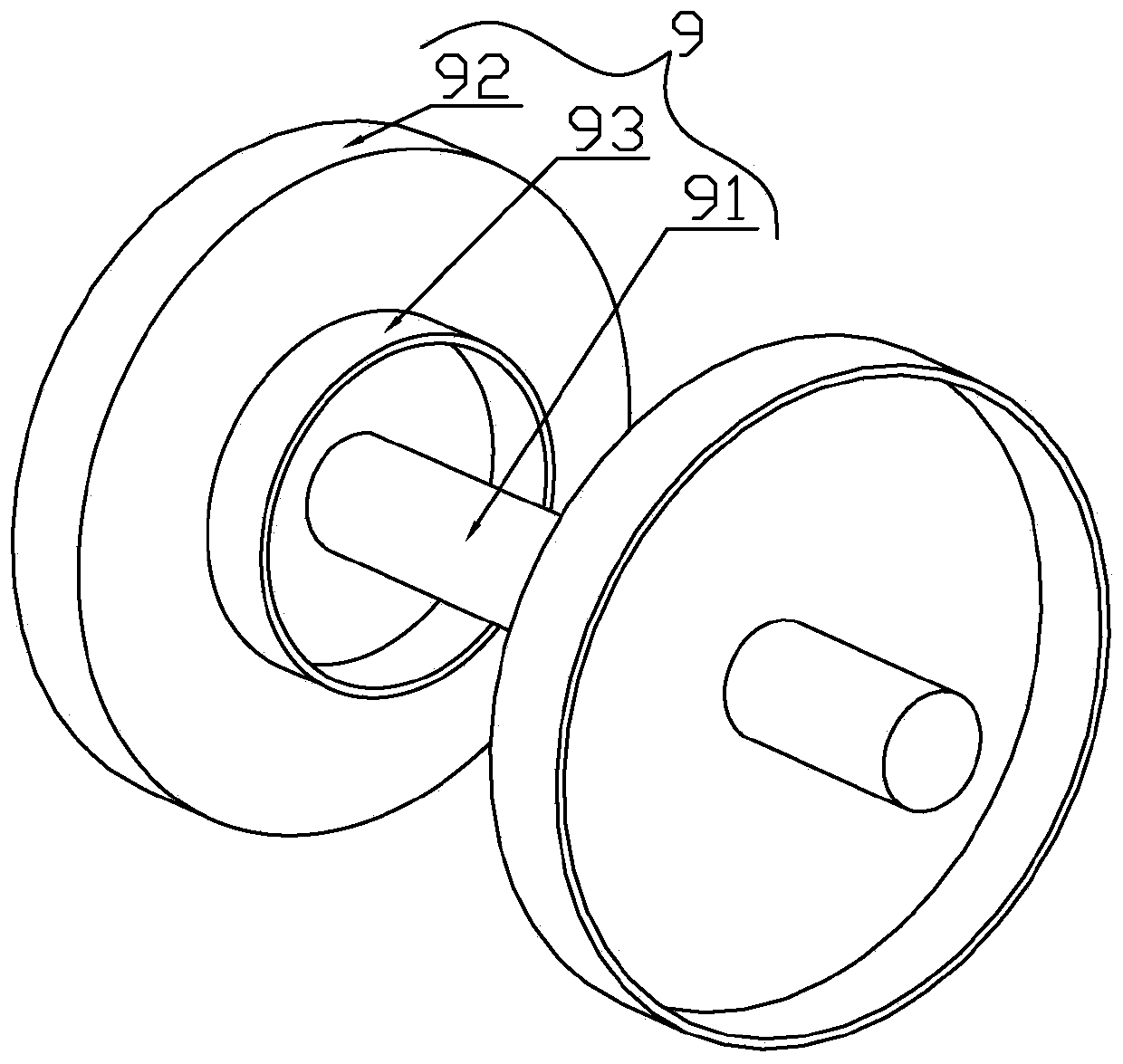

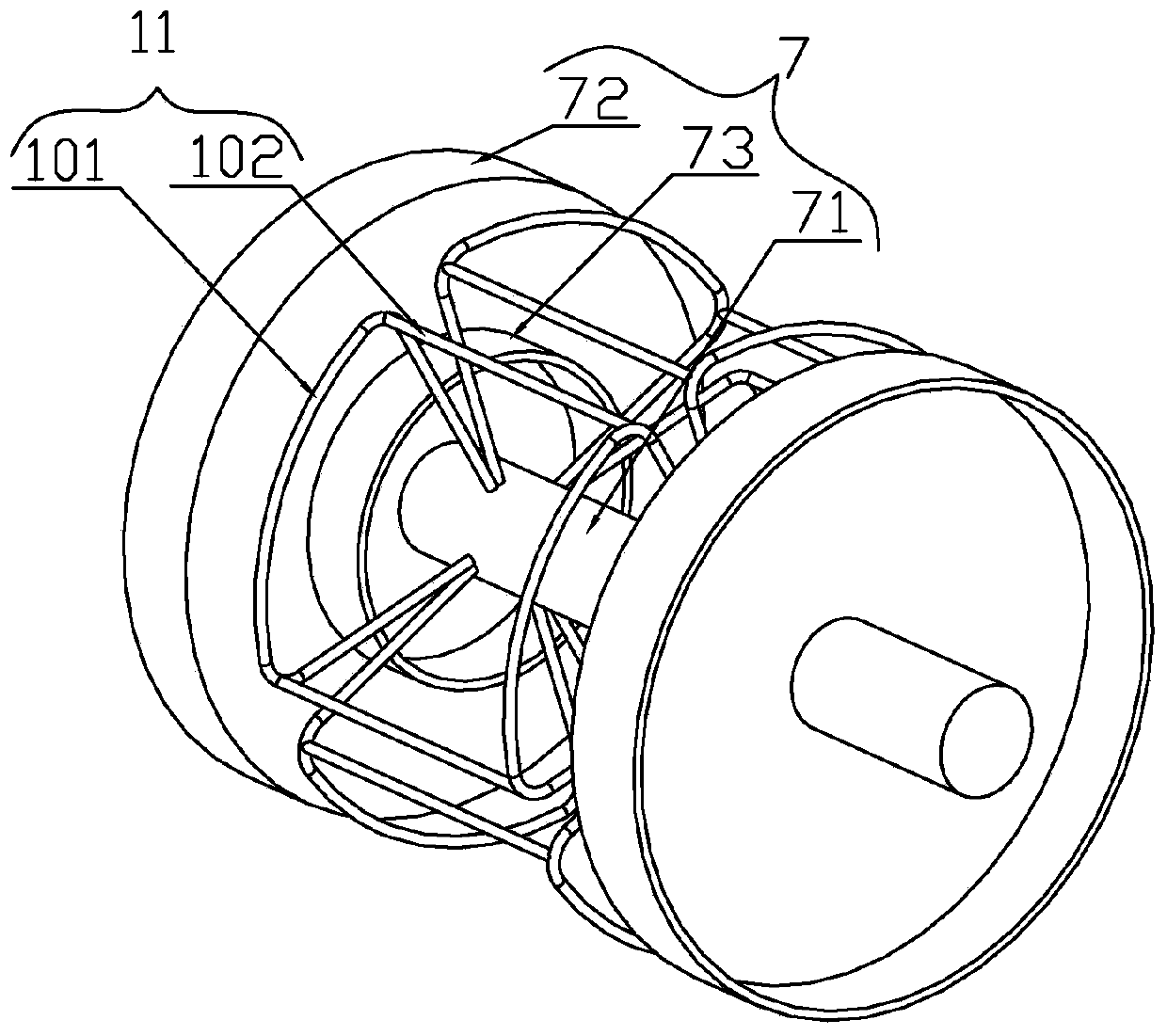

Large-inclination-angle belt conveyor

PendingCN110626710ASimple structureReduce on-site contaminationConveyorsCleaningCoal plantCoal particle

The invention relates to a large-inclination-angle belt conveyor. By using an existing large-inclination-angle belt conveyor, waste of coal resources and pollution to the field are likely to happen. The large-inclination-angle belt conveyor comprises a rack, a driving roller, a driven roller and a skirt belt. The rack comprises a horizontal feeding section, a middle inclined section and a discharging section. The driving roller is arranged at the head end of the horizontal feeding section through a shaft. The driven roller is arranged at the tail end of the discharging section through a shaft.The axial line height of the driving roller is lower than the axial line height of an upper corner pressing wheel. The tail end of the discharging section is inclined downwards. The discharging section is inclined downwards. When the skirt belt passes through the driving roller, corrugated ring edges are downward and fully expanded, so that coal powder or coal particles are more favorable for falling off. Most of the entrained coal powder or coal particles can fall into a matched downstream coal chute in time. The large-inclination-angle belt conveyor has the beneficial effects of being simple in structure, low in coal resource waste and small in on-site pollution and is widely applicable to coal enterprises such as large coal mines and coal plants.

Owner:兖矿能源集团股份有限公司 +1

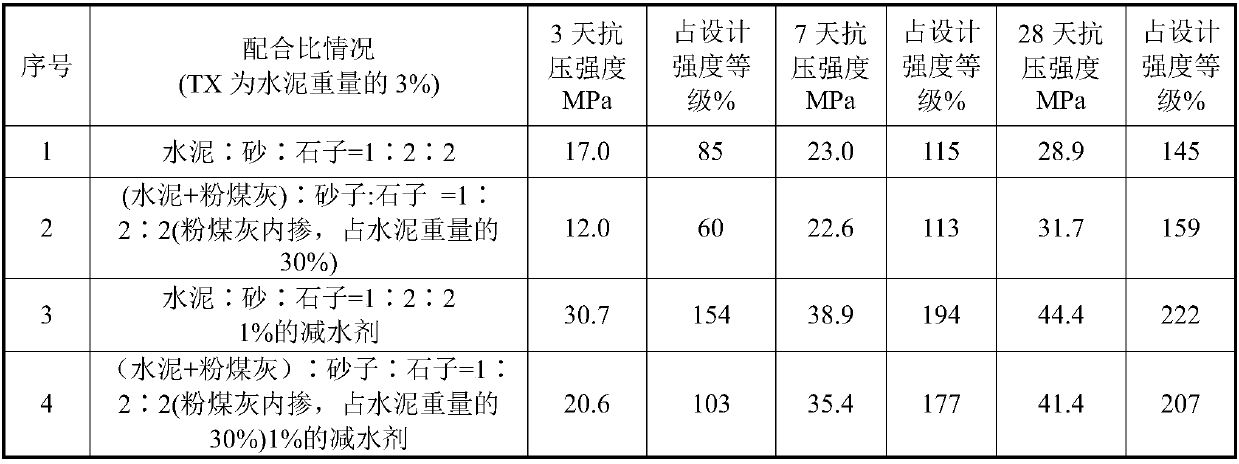

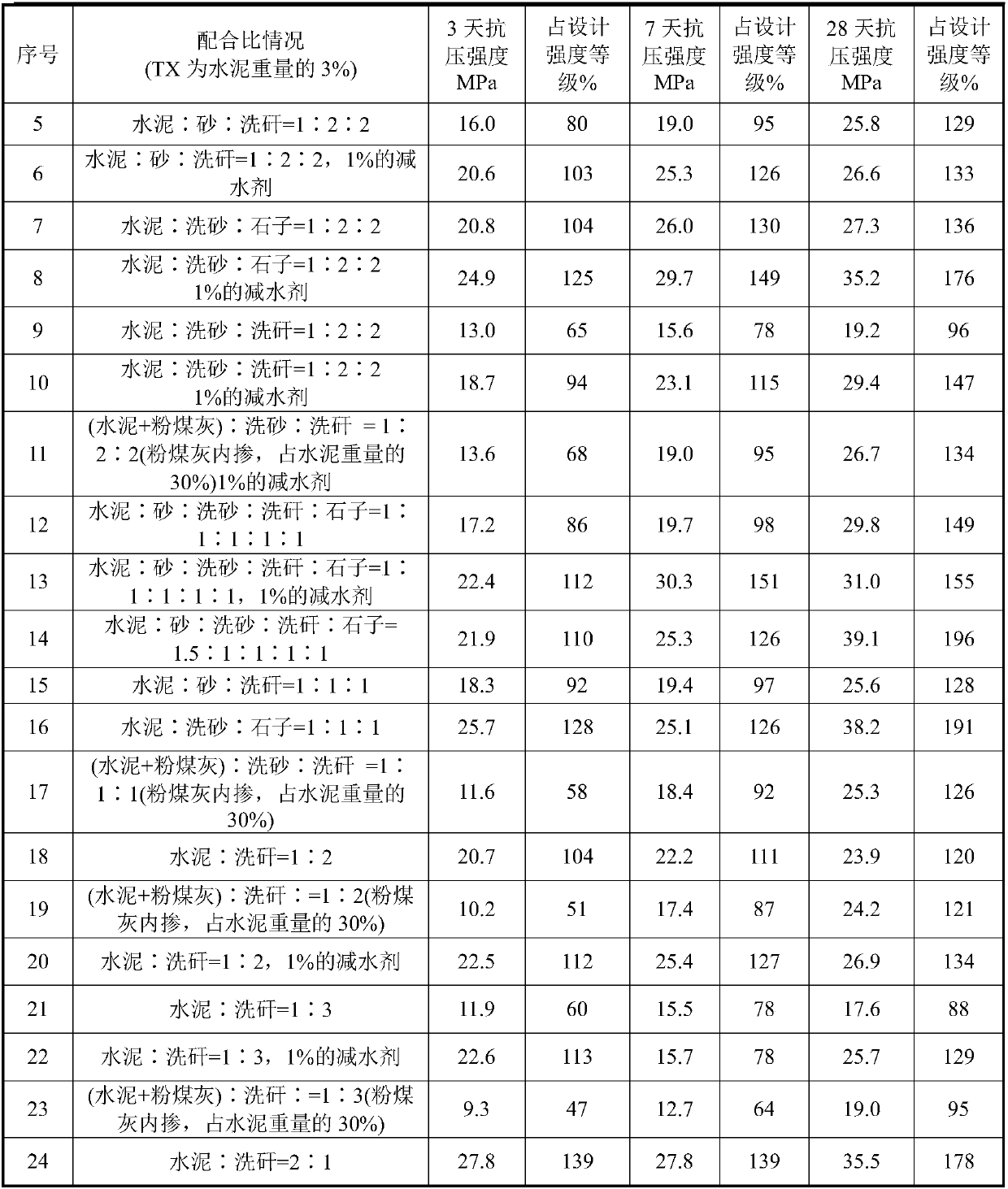

Shaft and drift injection concrete material with washery rejects and washed sand as aggregates

The invention discloses a shaft and drift injection concrete material with washery rejects and washed sand as aggregates, and belongs to concrete materials for shaft and drift supporting. The concretematerial takes cement, fly ash, the washery rejects and the washed sand in a washing and dressing coal plant of a coal mine as the aggregates, and takes an accelerator and a water-reducing agent as additives, wherein a ratio of a cementing material to the washed sand to the washery rejects is 1 to 2 to 2, and then 3 percent of the accelerator and 1 percent of the water-reducing agent are doped; the cementing material is prepared by mixing the cement with the fly ash; the fly ash is internally doped, accounts for 30 percent of weight of the cement, and reaches the intensity grade C20 of shaftand drift injection. The concrete material applied to coal shaft and drift supporting has the advantages that supporting cost is reduced, and mine benefits are increased; in addition, beneficial reuseof the washery rejects and the fly ash is realized; the concrete material is an important measure of reducing the pollution in the coal industry and practicing ecological civilization and green mining.

Owner:XINWEN MINING GROUP ZHAI TOWN COAL MINE +1

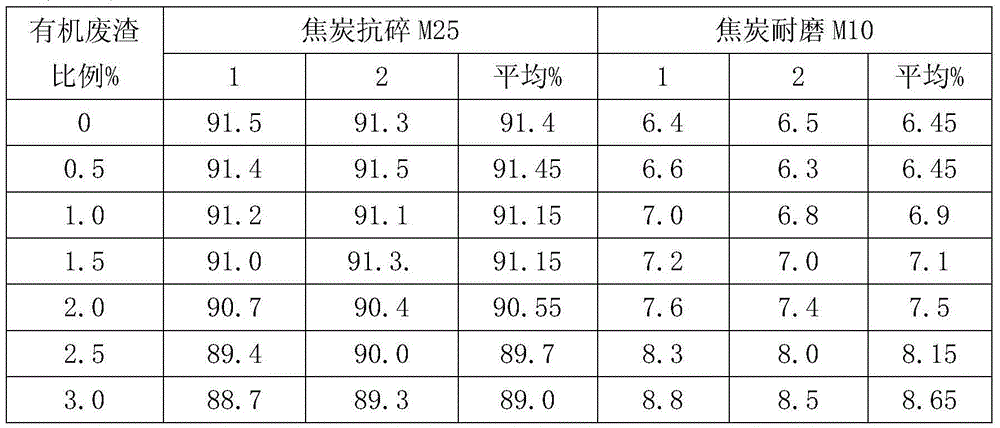

Method for treating organic waste residues in sorbic acid production

The invention belongs to the technical field of sorbic acid production and in particular relates to a method for treating organic waste residues in sorbic acid production. The method for treating organic waste residues in sorbic acid production comprises the following steps: transporting sorbic acid organic waste residues into a coal plant, uniformly adding the organic waste residues into lean coal during coal feeding in the coal plant, conveying the lean coal into a coal bunker, metering, mixing and grinding the lean coal with other coal kinds to obtain the mixed coal, and transporting the coal to a coal tower; and finally, feeding the mixed coal into a coke oven for coking. According to the treatment method, the coking cost is saved, and the environmental pollution is avoided.

Owner:JINNENG SCI & TECH

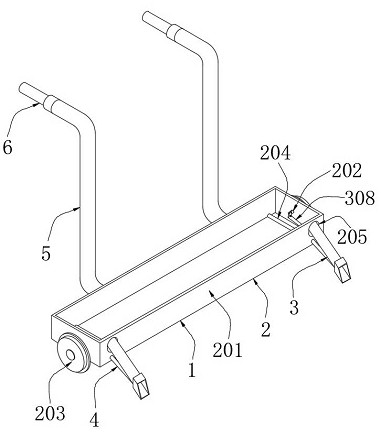

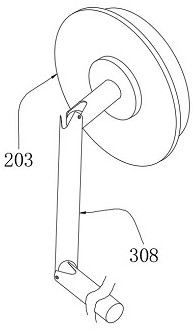

Embedded rail groove cleaning device for coal plant

PendingCN113802509AImplement the cleanup functionAvoid cloggingRailway cleaningCoal plantUniversal joint

The invention discloses an embedded rail groove cleaning device for a coal plant, and relates to the field of rail groove cleaning devices. The device comprises a device body, cleaning mechanisms and a holding rod part, a containing mechanism is arranged below the device body, one end of the containing mechanism is connected with the two cleaning mechanisms, each cleaning mechanism comprises a conveying shaft, and spiral blades are arranged on the outer wall of the conveying shaft. The rail groove cleaning function is achieved through a conveying barrel, a push shovel, a discharging port, the conveying shafts, the spiral blades and the like, in the constant-speed moving process of the device, a rail wheel drives the conveying shafts to rotate through a universal joint, the conveying shafts drive the spiral blades to rotate when rotating, and meanwhile conical thread heads at the tail ends of the conveying shafts rotate along with the conveying shafts; the fire coal entering the push shovel along with the pushing force is driven by the spiral blades to move to the top end of the conveying barrel from the contact position of the push shovel and the conveying barrel, and falls into the storage bin from the discharging port to be collected.

Owner:吕秋岩

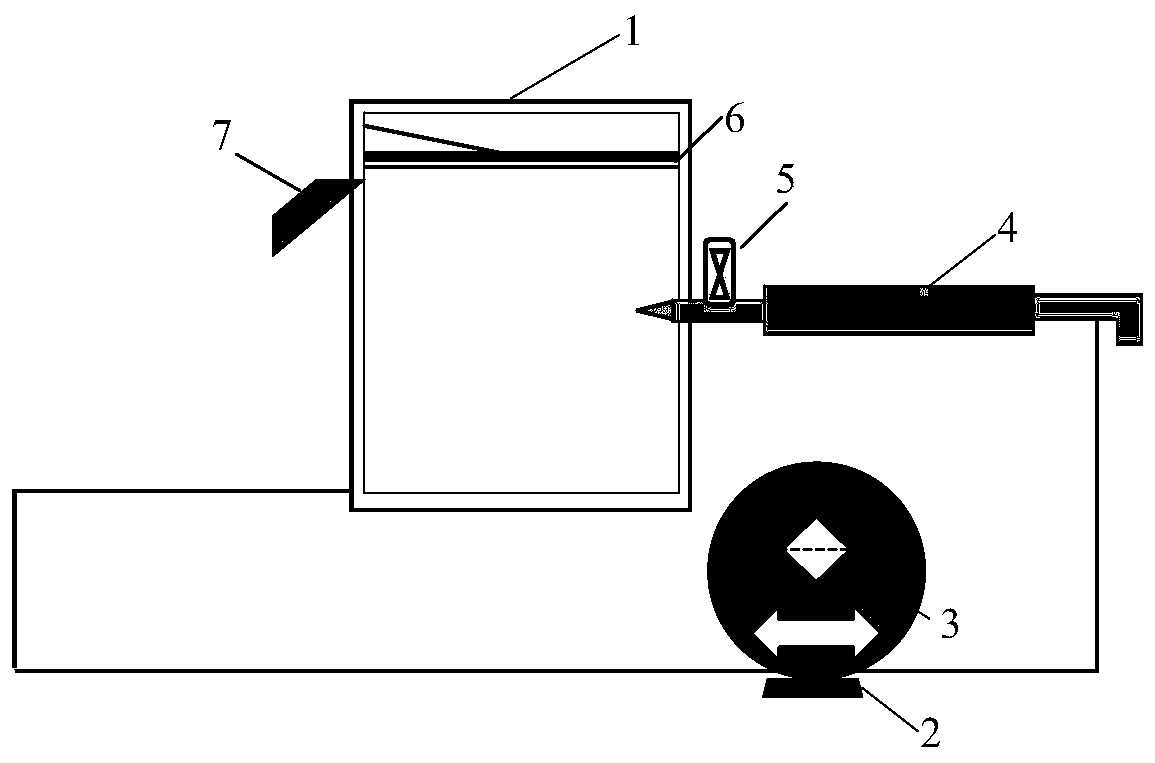

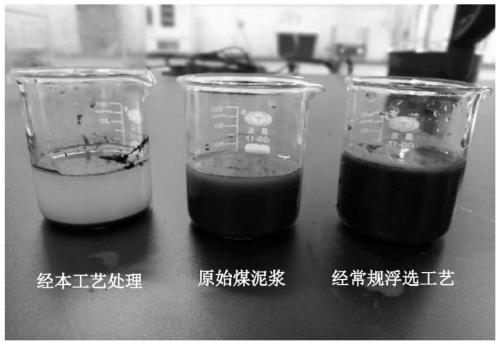

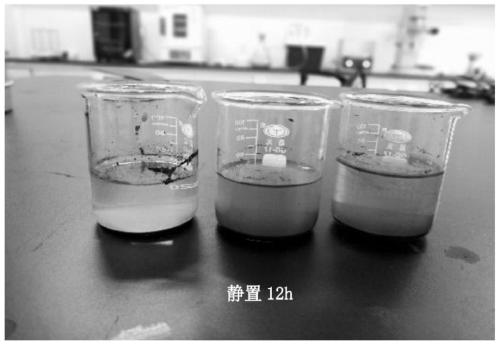

Simple device and method for physically separating coal slime of power coal plant

ActiveCN111468258AImprove surface hydrophobicityImprove hydrophobicityFlotationGrain treatmentsCoal plantSlurry

The invention discloses a simple device and method for physically separating coal slime of a power coal plant. The simple device comprises a slurry tank, a lower outlet of the slurry tank is connectedto a high-pressure pump through a high-pressure pump water inlet pipe, an outlet of the high-pressure pump is connected to a spray gun through a high-pressure pump water outlet pipe, a tip outlet ofthe spray gun is inserted into a middle inlet of the slurry tank, and a bubble scraper is arranged in the slurry tank. The device is simple in structure and convenient to operate, and coal and ganguein the coal slime can be separated just by physical means.

Owner:XI AN JIAOTONG UNIV

Fire detecting system sensor

PendingCN108844650AAccurate detectionTimely detectionThermometers using electric/magnetic elementsUsing electrical meansCoal plantMotherboard

The invention provides a fire detecting system sensor including a housing, an upper cover, a solar fixing panel, solar panels, a battery, a main board and a temperature sensor. The upper cover is fixedly mounted in the housing. The solar fixing panel is connected to one side of the housing. The solar panels are fixed on the solar fixing panel. The specification of the solar panels is 5V / 2W. The solar panels are connected in series. The solar fixing panel is connected fixed to one side of the housing through a Philip's head screw. The battery is fixedly connected to a battery fixing hoop whichis fixedly connected in the housing. The main board is fixedly mounted in the housing. The main board is a 2112226E type main board. The temperature sensor is connected to the top part of the housingthrough a waterproof connector which is a PA type waterproof connector. Therefore, coal layer temperature of an open pit coal mine and coal pile inside temperature of a coal plant, environment temperature and environment humidity can be detected timely and accurately and an effect of preventing coal layer spontaneous ignition is achieved.

Owner:XUZHOU JIANGMEI TECH

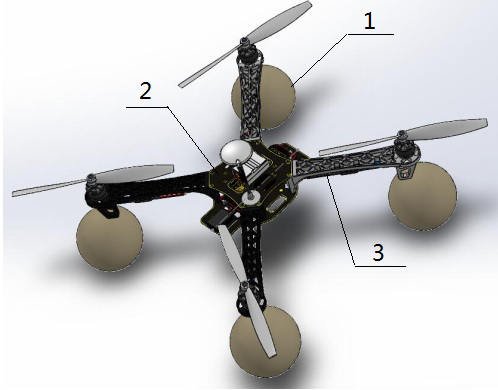

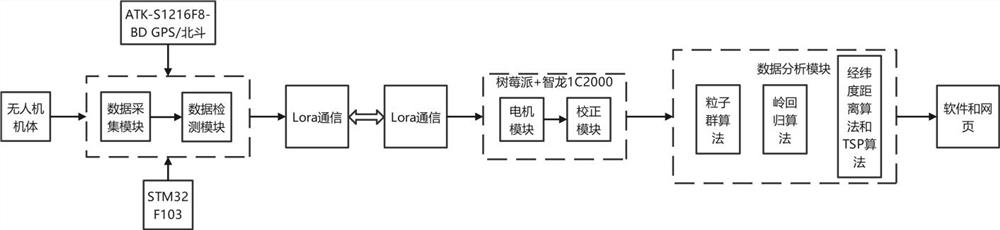

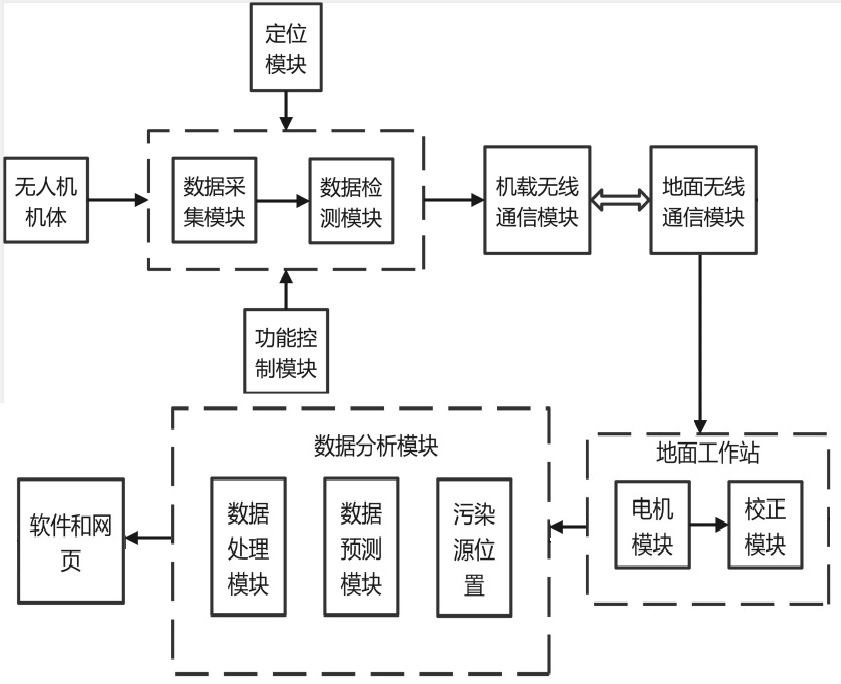

Unmanned aerial vehicle environment monitoring system and monitoring device thereof

PendingCN114877930AFacilitate emergency measuresPrevent proliferationGeneral water supply conservationTransmission systemsData acquisitionWorkstation

The invention provides an unmanned aerial vehicle environment monitoring system and a monitoring device thereof. The system comprises an unmanned aerial vehicle body 2, a data acquisition module, a positioning module, a data detection module, a function control module, an airborne wireless communication module, a ground wireless communication module, a ground workstation, a motor module, a data analysis module and a software module. The unmanned aerial vehicle is operated to slide on the water surface and fly at a specified position, then various pollutant concentrations at related positions are collected, and a wireless communication module is arranged on the unmanned aerial vehicle body, so that water quality and air conditions can be transmitted back in real time, and the collected information is displayed on software and a webpage terminal. The system is applied to emission monitoring of high-pollution enterprises, gas leakage monitoring of coal plants, environmental monitoring of scenic spots, monitoring of ecological environmental protection areas, monitoring of petroleum drain outlets and the like, and has wide application value.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

A boiler coal feeding device for improving coal combustion efficiency

ActiveCN104566435BBurn fullyHigh heat intensitySolid fuel combustionLump/pulverulent fuel feeder/distributionElectricityCoal plant

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

A zirconium-doped vanadium-based oxide catalyst, preparation method and use thereof

ActiveCN103252232BWide operating temperature windowExtended service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCoal plantNitrogen

The invention relates to a zirconium-doped vanadium-based oxide catalyst for selectively catalyzing and reducing the nitrogen oxide through ammonia, and a preparation method thereof. The catalyst is a metal oxide catalyst which is formed by loading zirconium and vanadium oxide onto the surface of titanium tungsten powder. Through the zirconium doping method, the catalytic properties such as high-temperature stability of the traditional vanadium-based catalyst and the N2 (nitrogen) generation selectivity can be greatly improved, the prepared zirconium-doped vanadium-based oxide catalyst is suitable for a nitrogen oxide catalytic purifying device adopting the diesel exhaust as a representative movable resource and the smoke of a coal plant as a representative fixed source.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

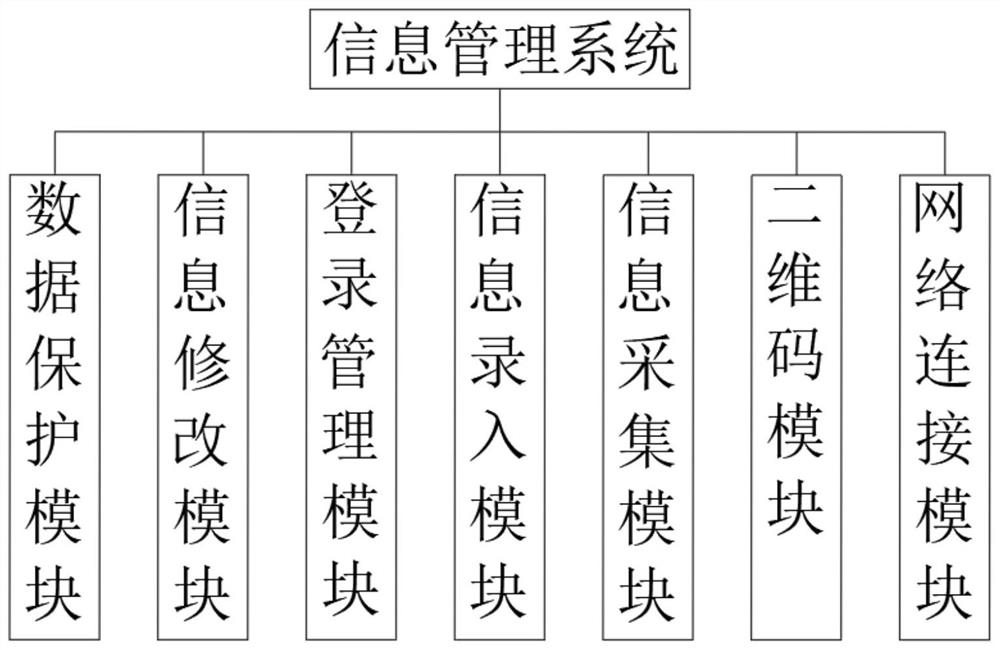

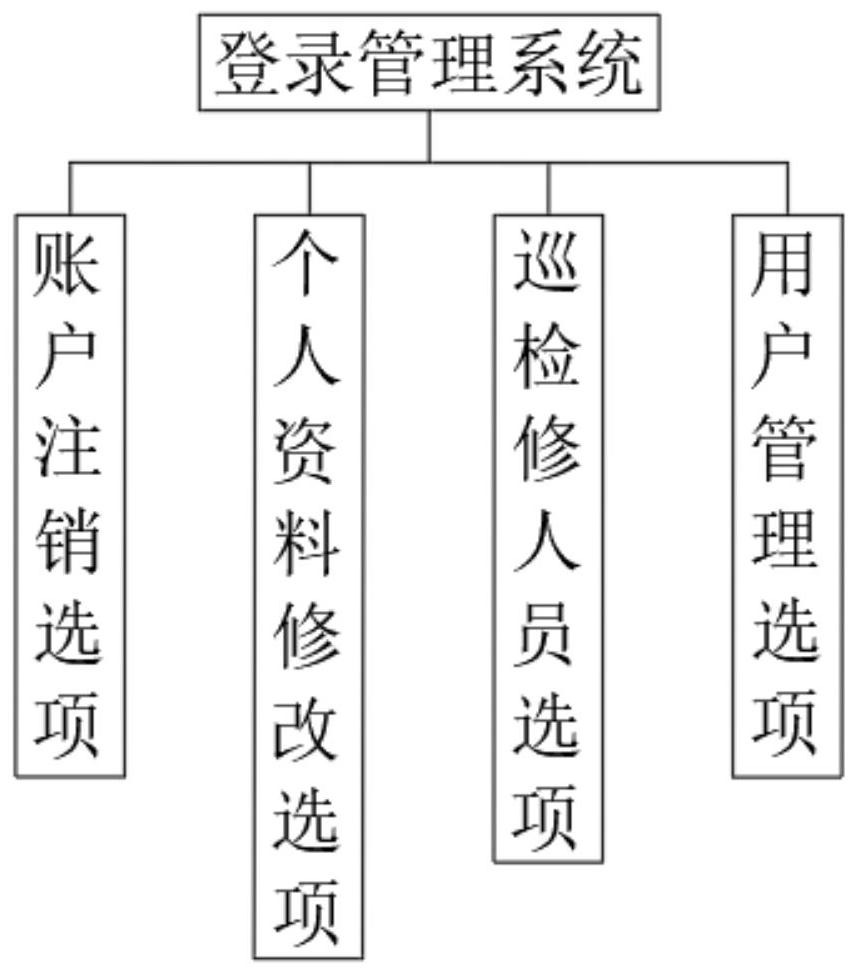

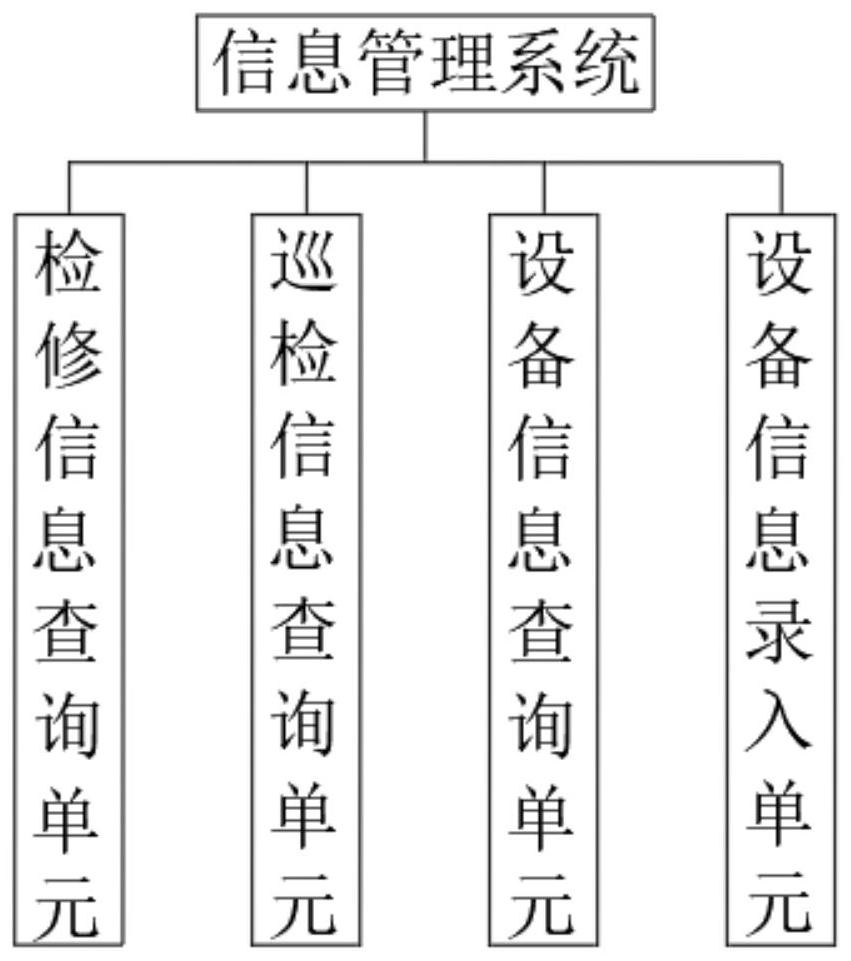

Information management system for coal plant electromechanical equipment management

PendingCN114298333AAvoid layoutSaving start-up fundsDatabase updatingData processing applicationsCode moduleCoal plant

The invention provides an information management system for coal plant electromechanical equipment management, and belongs to the technical field of coal mine equipment management. The information management system for coal plant electromechanical equipment management comprises a network connection module, a two-dimensional code module, an information acquisition module, an information input module, a login management module and an information modification module. The two-dimensional code module comprises two-dimensional code stickers used for being pasted on the end faces of all electromechanical devices, and an operator scans the two-dimensional code stickers corresponding to the electromechanical devices through a smart phone to inquire maintenance information of the electromechanical devices. The information acquisition module is used for acquiring basic information of the electromechanical equipment and inputting the basic information into the system, and then scanning a two-dimensional code sticker corresponding to the electromechanical equipment; the system has the advantages of saving invested funds, reducing the use cost, being convenient to update and maintain, simple to operate, having no error rate and improving the inspection and supervision efficiency.

Owner:HUAIBEI MINING IND

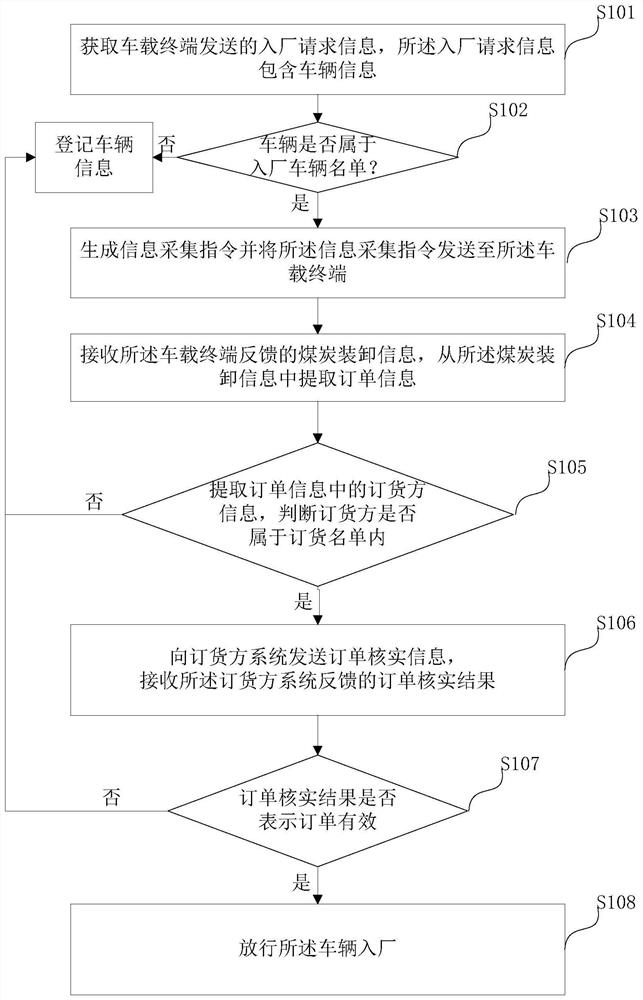

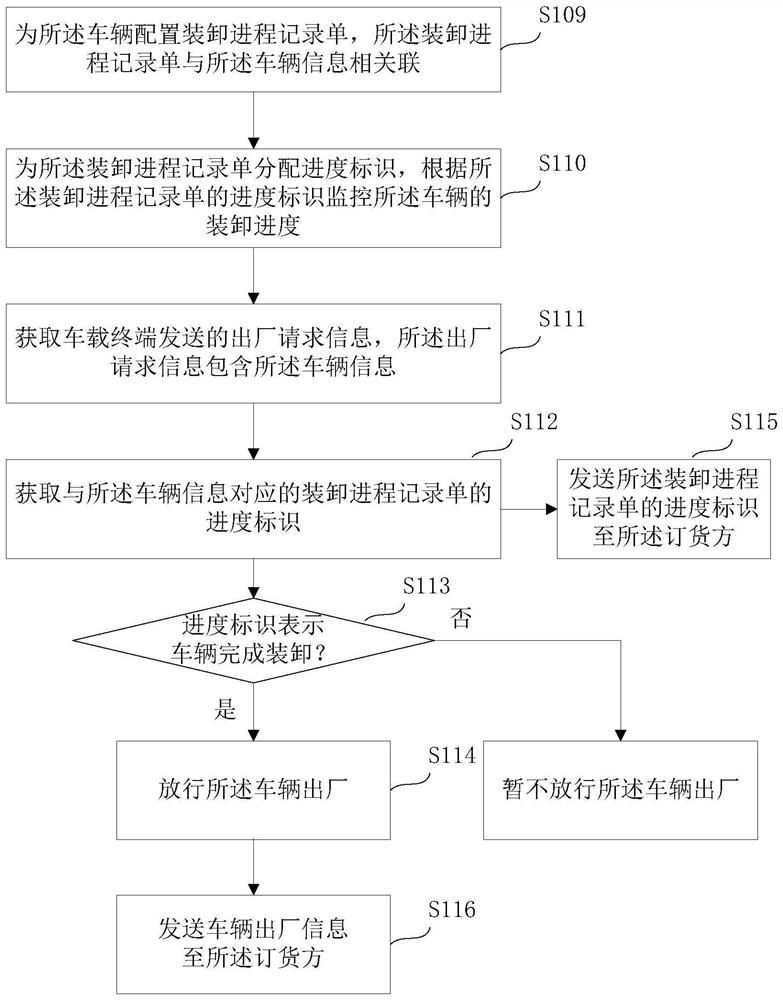

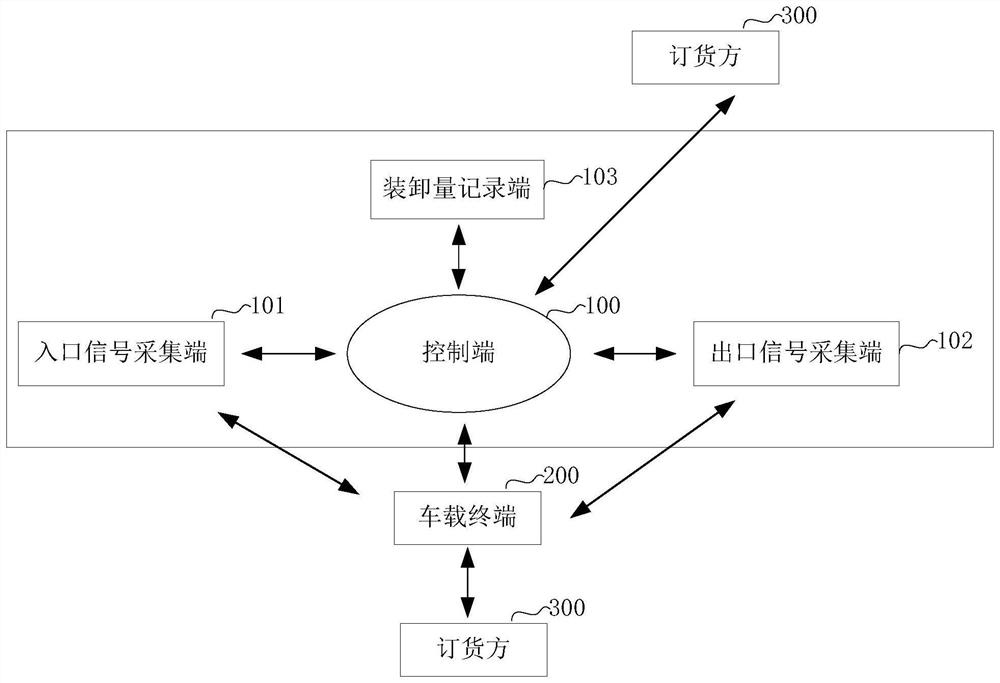

Method and system for collecting incoming information of coal transport vehicle

PendingCN114220072AHighly integratedRealize information exchangeCharacter and pattern recognitionLogisticsInformatizationInformation interoperability

The invention discloses a coal transport vehicle entry information acquisition method and system, and the method comprises the steps: obtaining entry request information sent by a vehicle-mounted terminal, and the entry request information comprises vehicle information; based on the vehicle information, determining whether the vehicle belongs to the incoming vehicle list, and sending an information acquisition instruction to the vehicle-mounted terminal when the vehicle belongs to the incoming measurement list; coal loading and unloading information fed back by the vehicle-mounted terminal is received, and order information is extracted from the coal loading and unloading information; ordering party information in the order information is extracted, whether an ordering party belongs to an ordering list or not is judged, and if the ordering party belongs to the ordering list, order verification information is sent to an ordering party system; and receiving an order verification result fed back by the ordering party system, and if the order verification result shows that the order is valid, releasing the vehicle to enter the factory. According to the scheme, information intercommunication among the coal plant system, the vehicle-mounted terminal and the ordering party is realized by taking the vehicle information of the coal transport vehicle as a link, and a high-integration-level informatization acquisition channel is realized by a simple network structure.

Owner:SHENHUA XINJIANG ENERGY

A kind of coarse coal slime separation equipment and its process

ActiveCN103495494BHigh recovery rateSolve the problem of high scoreWet separationCoal plantEngineering

The invention relate to a sorting technology of coarse coal slime of a coal plant, in particular to coarse coal slime sorting equipment and a technology of the coarse coal slime sorting equipment. The coarse coal slime sorting equipment is characterized by comprising a TBS coal slime sorting machine which comprises a tank body, a feeding well, a turbulent flow plate, a density sensor, an actuator, a discharging valve and an overflow weir. Therefore, the coarse coal slime sorting equipment and the technology are reasonable in design and easy to achieve.

Owner:COAL IND JINAN DESIGN & RES

Whole vehicle unloading turnover device

The invention discloses a whole vehicle unloading turnover device. The whole vehicle unloading turnover device comprises a fixed frame device, wherein a movable frame device is arranged at the upper part of the fixed frame device, the movable frame device is hinged to the rear end of the fixed frame device, a jacking hydraulic cylinder is arranged between the movable frame device and the fixed frame device, and a buffering device is arranged at the bottom of the hydraulic cylinder; a protective steel wire rope is arranged at the front part of the upper surface of the movable frame device; and a fixed frame is arranged at the bottom of the steel wire rope; the whole vehicle can be driven to the upper part to automatically turn over, the whole vehicle can be longitudinally turned over by 40 degrees or above, the unloading function is achieved, and the vehicle is suitable for potato transporting and unloading, coal plant transporting and unloading, ore transporting and unloading, sand and stone transporting and unloading and the like and particularly suitable for large transporting vehicles of 80 tons or above. The unloading period is shortened, the labor intensity of workers is relieved, potential safety hazards are eliminated, the personnel cost is greatly reduced, the maintenance cost is low, operation is easy and convenient, manual unloading is converted into automatic unloading, and application and popularization are facilitated.

Owner:湖北缘银建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com